1. Introduction

Global biomass harvested worldwide mostly ends up in the livestock subsystem as feed or bedding material (almost 60%) [

1]. Reducing greenhouse gas (GHG) emissions is currently one of the biggest challenges for the livestock industry in terms of climate change. Using the life-cycle approach, it has been estimated that livestock accounts for approx. 14.5% to 16.5% of the world’s anthropogenic GHG emissions, with dairy production accounting for about 20% of this value [

2,

3,

4]. The problem is, however, quite complicated because it requires the simultaneous provision of sufficient food for more and more people in the world, and on the other hand, not so much as not increasing, but even reducing the environmental burden associated with food production [

5].

Dairy farms are a major contributor to the total life cycle greenhouse gas emissions of milk and other dairy products. About 70–85% of the GHG emissions occurred in the processes preceding the milk leaving the farm, i.e., cradle-to-farm gate emissions [

6,

7]. This means that already proper management inside the dairy farm can significantly reduce greenhouse gas emissions.

Methane is a gas whose emissions from animals are mainly related to enteric fermentation and the storage of manure without adequate protection, is a gas that contributes 25–28 times more to global warming than carbon dioxide (CO

2) [

8,

9,

10]. Nitrous oxide (N

2O), resulting from the improper storage of manure and the use of various types of fertilizers, it is a compound whose negative impact on climate change is 265–298 times higher than CO

2 [

5,

8,

9,

10]. Carbon dioxide equivalent is the standard unit used to calculate the global warming potential [

11]. It is estimated that the mere use of manure for fertilization to obtain animal feed and leaving the manure on pastures contributes to the production of N

2O in such an amount that it can account for about half of the total global imissions. [

3]. Reducing direct nitrous oxide emissions during storage may result in more significant nitrate leaching and ammonia volatilization during field use.

The overall impact of changing the feed source on the total greenhouse gas emissions of a farm is not clear-cut. For example, elements of undigested feed may generate emissions at a later stage (e.g., during storage [

12,

13]), or planting a given type of feed may reduce GHG from agriculture by sequestering CO

2 in agricultural soils [

6,

14]. Changes in soil carbon content and their impact on GHG emissions (and carbon footprint) are currently not sufficiently defined, mainly due to the lack of a uniform methodology and the high complexity of the various cultivation processes [

2].

While the impact of feed or appropriate cultivation emissions is complex, and the effect on the carbon and economic footprint is difficult to predict, even averaged calculations for proper manure management show much better results. There are indications in the literature [

15] that emissions of gases from animal production, such as CH

4, N

2O and NH

3, come largely from the storage of manure, which is a common practice in livestock farms. In addition, such storage of manure not only has a negative impact on the environment, but also leads to a loss of manure quality as a source of nutrients. Such a situation causes a decrease in the value of manure as a soil enrichment substance, which is also associated with a decrease in its price [

16].

In this article, on the basis of a farm in Poland (similar to others in east Europe, above 61% [

17]), the differences in the emission of CH

4, N

2O in the traditional manner of its storage and using it immediately as a substrate for biogas production are presented.

In the 2015/2016 agricultural season, approximately 674 thous. farmers used natural fertilizers, of which 662 thous. used manure, and 116 thous. slurry. This corresponds to the proportion of solid and liquid livestock keeping systems in which constants predominate [

18]. This means that the emissions of CH

4 alone from manure heaps could be over 0.5 million Mg per year.

The origination mechanism is related to the usual practices for forming solid manure piles. Most often, this fertilizer is spread, and then piles are formed. Commonly, their compressing is not performed—as is the case, for example, when forming piles of chopped fresh maize for silage. As a consequence, the oxygen present in the manure is used by the microorganisms to decompose the organic matter and generate heat [

19]. The possible temperature inside such a prism is even 40–60 °C, which can be reached in several dozen hours. During the period, the oxygen contained inside the heap is used up, which creates conditions for the anaerobic decomposition of organic matter. During this process, bacteria emit energy no longer in the form of heat (as is the case with aerobic decomposition), but in the form of a chemical—methane. Such conditions are characteristic of those prevailing in typical biogas reactors [

20]. On the other hand, nitrous oxide increases especially when no methane formation is observed (possibly its level is very low). It is formed as a result of changes (nitrification and denitrification) of nitrogen present in manure. This mainly concerns organic forms (e.g., protein) and, to a much lesser extent, inorganic forms (e.g., NH

3 and NH

4+), from which, with the participation of oxygen, nitrites and then nitrates are formed. In contrast, denitrification takes place anaerobic conditions where nitrates are converted to N

2O and N

2 [

21]. The pH significantly influences on the balance between ammonium and ammonia, with the level of ammonia increases as the pH increases.

The share of manure in GHG depends mainly on the chemical composition of the manure (and therefore primarily on the feed) and on the storage conditions. One of the main factors predicting of CH

4 emissions from manure is volatile solids content [

22], and in the case of the N

2O emissions is nitrogen content of excreta [

5]. If manure were to be used as a substrate or co-substrate in anaerobic digestion processes, the higher content of organic matter (OM) in its composition results in higher biogas production. In anaerobic digestion processes, the substrate is transformed into CH

4, which can be used as a renewable energy source [

23,

24].

Poland is currently one of the largest producers of manure in the EU. As demonstrated by Kozłowski [

25], in Poland, over 112 million Mg of manure is produced annually, and only less than 1% is used to produce biogas. This is a surprisingly small amount, as the digestate is quite often used in crops, mainly due to its rich elemental composition, i.e., nitrogen, potassium and phosphorus [

26,

27]. It has been proven in many cultivation studies that the addition of digestate to the soil has a positive effect on the quality of crops [

26,

28,

29,

30,

31,

32]. Apart from providing plants with nutrients, it has been noticed that the use of digestate inhibits the growth of harmful insects and plant pathogens (i.e., bacteria and fungi) [

33]. The effect of using digestates in crops is their greater resistance to various diseases, which was found on the basis of many years of research with the participation of farmers [

26,

34]. Alternatively, the digestate could also be used as solid biofuels, e.g., as pellets. Then its calorific value is similar to that of biofuels made from sawdust [

35].

The paper presents how the emission of methane and nitrous oxide will change if, instead of its traditional storage for several months, solid manure is immediately used for energy purposes in a biogas plant. Energy and economic calculations were made for a real farm with dairy cattle breeding. Two basic scenarios were developed without a biogas plant and with a biogas plant using solid manure (and manure with addition of straw) as a substrate for anaerobic digestion processes. This approach is recommended in the Strategic Plan for Poland—common agricultural policy (CAP) reform [

36] and is consistent with the EU climate change mitigation framework, which includes, inter alia, the carbon dioxide emissions trading system.

For the calculation of gaseous emissions, research data were used to determine the average emission of methane and nitrous oxide from 1 Mg of stored manure and the laboratory studies on the biogas efficiency on manure from dairy cows collected from a farm which is a case study.

2. Materials and Methods

The energy and economic calculations presented in the paper were based on data from an average farm with dairy cows in Poland. It was chosen because of the characteristic size for which until now it seemed unreasonable to use methane fermentation to recover energy (heat and electricity) and the potential ecological benefits in the form of a significant reduction in CO2 equivalent production.

The presented case study concerns one of the Experimental Farms of the Poznań University of Life Sciences (Poland)—in Brody. On the area of approx. 900 ha, there is approx. 500 ha of commercial area and approx. 400 ha of forage area, as well as 600 cattle and 900 sheep. The breeds are adapted to the difficult environment (wet and periodically flooded areas). Despite such unfavorable conditions, manure is still piled up here due to the lack of appropriate investments. The estimated calculations presented in the paper can be used to plan appropriate solutions for this and similar farms in Central and Eastern Europe.

The basic cattle feeding system is the feed in the barn. Overall, GHG emissions are higher from the manure into the barn feed subsystem compared to the grazing feed subsystem [

37]. Within the feed subsystem, cattle are kept indoors and eat mainly preserved grass silage. The manure produced by the cattle in the barn feed subsystem and other waste is stored and mechanically returned to the soil when field conditions are right in spring and early summer.

Greenhouse gas emissions from the dairy farming system can be distinguished between those that arise within the physical boundaries of the dairy farm (GHG emissions on the farm) and those that arise before the dairy farm section (indirect GHG emissions). The main sources of greenhouse gas emissions on the farm are cultivated soil, enteric fermentation, manure management, and energy consumption [

38,

39].

This work focuses on manure management, so far not treated as a source of heat, electricity, and income related to the reduction of carbon dioxide equivalent emissions.

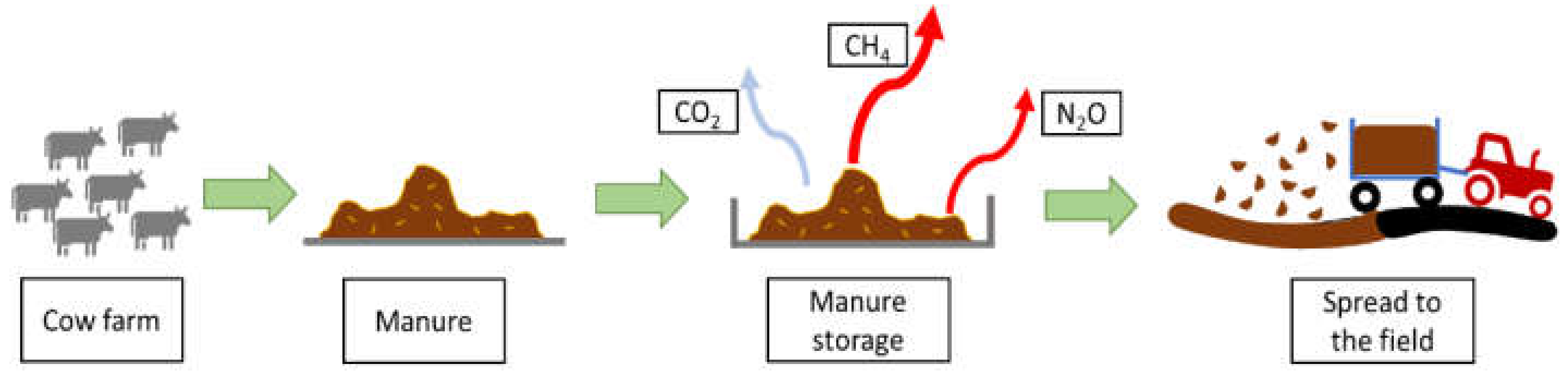

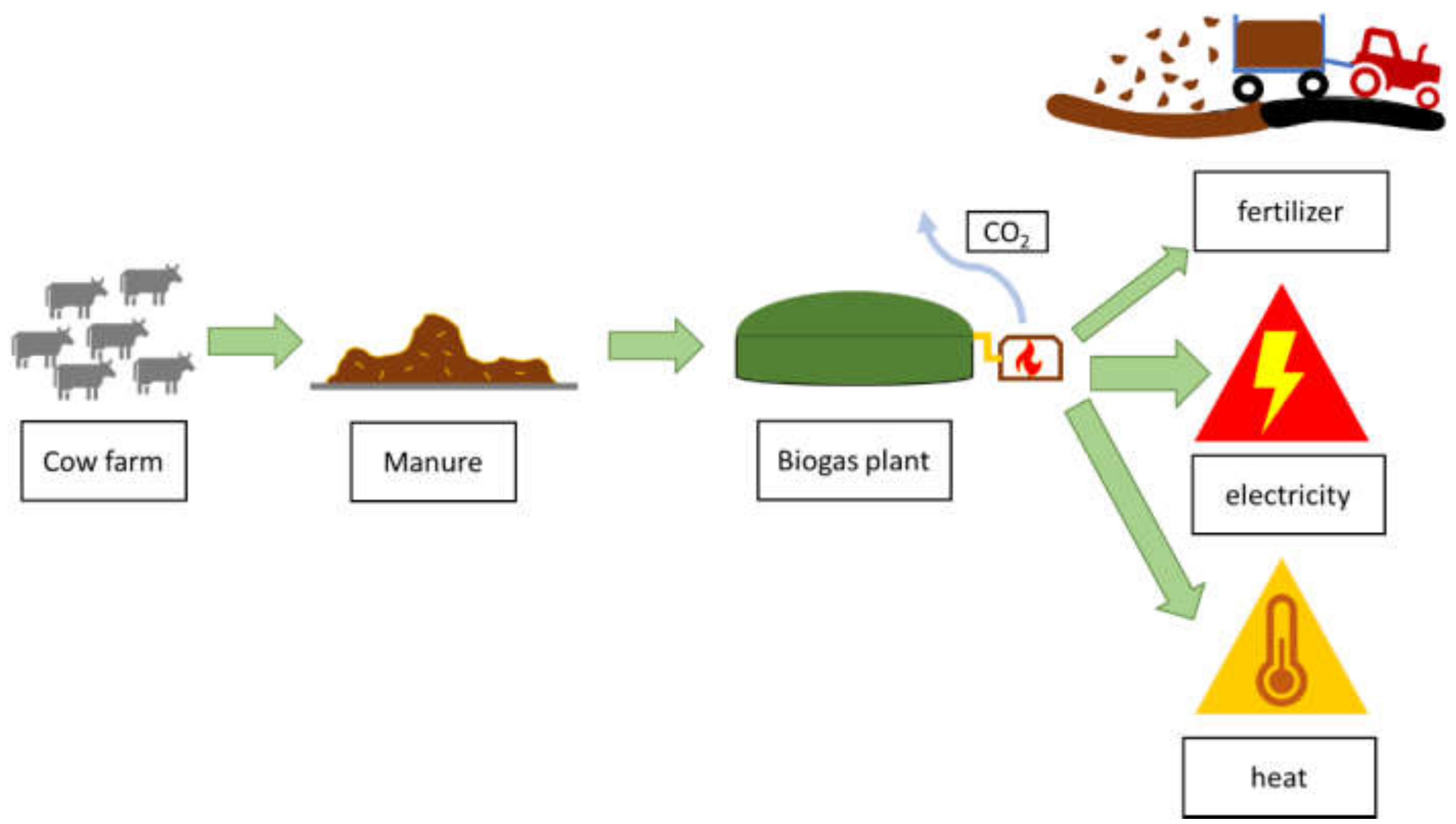

Two scenarios were considered:

I—storage the manure on the stockpile, and then scattering them on the field (high GHG emissions),

Figure 1.

II—anaerobic digestion of solid manure, the field spreading of digestate (almost no GHG emissions, large revenues from electricity, heat and, savings from charges for CO

2 equivalent emissions),

Figure 2.

2.1. Estimation of CH4 Emissions from Manure Management

The Tier 2 methodology was used to establish domestic CH

4 emission factors for cattle [

41]:

where:

EF—emission factor,

VS—average daily volatile excreted solids,

D/Y—the number of days taken for the calculation during the year,

BO—maximum CH4 production capacity for manure produced by animal,

CF—conversion factor from kg to m3,

MCF—methane conversion factors for each manure management system for cool climate [

42],

MS—a fraction of livestock category manure.

For cattle, volatile solids (VS) and maximum CH

4 producing capacity (B

O) were estimated based on equations in 2019 and 2006 IPCC [

41,

42] and Poland’s national inventory report 2021 [

10].

Above mentioned parameters and emission factors used for the calculation of CH

4 emissions from manure management for livestock are shown in

Table 1.

Methane conversion factor (MFC)—2%, for solid systems was taken from Table 10.17 of the IPCC 2006 Guidelines for cool climate ≤10 °C [

41]. Due to calculations only for dairy cattle solid manure, MS—a fraction of livestock category manure was 100%.

Methane combusted in biogas plants, including agricultural biogas plants, is classified as eco-energy. The separation of methane emissions from anaerobic digesters based, in particular on animal faeces, is under investigation [

10]. The IPCC 2006 guidelines contain an ambiguous methodology for anaerobic digesters where the MCF for anaerobic digesters is not specified and ranges from 0 to 100%.

2.2. Estimation of Direct N2O Emissions from Manure Management

Direct nitrous oxide emissions from manure management were estimated based on recommended IPCC methodology [

41] using the same MS data as for CH

4 emissions:

where:

N2OD(mm)—direct N2O emissions from manure management in the country (kg N2O/animal/year),

Nex—annual average N excretion per head of livestock,

MS—fraction of total annual nitrogen excretion for dairy cow managed in solid manure management system,

EF3—emission factor for direct N2O emissions from solid manure management system,

CFN—conversion of (N2O−N) (mm) emissions to N2O (mm) emissions, 44/28

The parameters for Nex cattle were based on the IPCC methodology [

41], but for calculation, data from national studies were taken, such as the crude protein content in the diet was adopted according to national research [

43,

44].

Above mentioned parameters and emission factors used for calculation of N

2O emissions from manure management for livestock are shown in

Table 2.

Based on default animal mass, Nex values for cattle category, were chosen—70.26 kg N/animal [

41]. The fraction of N consumption which is retained by the animal (Nretention) was taken according to the IPCC guidelines [

41], for dairy cows, it is 0.2. Due to calculations only for dairy cattle solid manure MS—a fraction of livestock category manure was 100%.

2.3. Calcultion of CO2 Equivalents and Carbon Emissions Allowances Prices

Emissions of each gas (CH

4 and N

2O) were converted to CO

2eq emissions based on the global warming potential (GWP) conversion factor of 25 for CH

4 and 298 for N

2O [

8,

9,

10].

EU Carbon Permits increased EUR 26.72 or 81.66% since the beginning of 2021, according to trading on a contract for difference (CFD) that tracks the benchmark market for this commodity [

45]. Trading Economics Carbon Emissions Allowances Prices are sourced from the European Union Emissions Trading System (EU ETS), the world’s largest cap and trade greenhouse gas emissions market [

45]. Allowances for carbon emissions are first allocated considering EU directives for the maximum amount of greenhouse gases that can be emitted. Allowances for carbon emissions are then auctioned and traded. On 14 October, the EUA was EUR 61.41 [

45,

46] for 1 Mg CO

2eq.

2.4. Price for Energy in FIT (Feed-in-Tariff System) and for Heat

Aid schemes for small RES energy producers for the resale of unused electricity at a fixed price or the right to subsidize the electricity market price under so-called FIT system will function for at least the next 5 years. This means the guaranteed price for the energy produced is approx. EUR 160 per 1 MWh [

47]. It is almost 3 times more than 1 MWh currently costs on the market (average EUR 56 in Q2) [

47].

Average sales prices of heat generated in regional generation units oscillated around EUR 10 per 1 GW [

48].

2.5. Biogas Production Efficiency from Substrates

The analysis of the efficiency of biogas production from solid manure was performed at the Ecotechnologies Laboratory of the University of Life Sciences in Poznań (PULS), the largest Polish biogas laboratory. The research methodology was based on the German standards DIN 38414/S8 [

49] and VDI 4630 [

50], which are currently the most frequently used laboratory procedure in Europe. Our Ecotechnologies Laboratory was the first in Poland to receive a certificate confirming the qualitative proficiency in biogas testing. Such an award is given, only after a series of tests, by the German organization Verband Deutscher Landwirtschaftlicher Untersuchungs- und Forschungsanstalten (VDLUFA [

51]) and the Kuratorium für Technik und Bauwesen in der Landwirtschaft e.V. (KTBL [

52]).

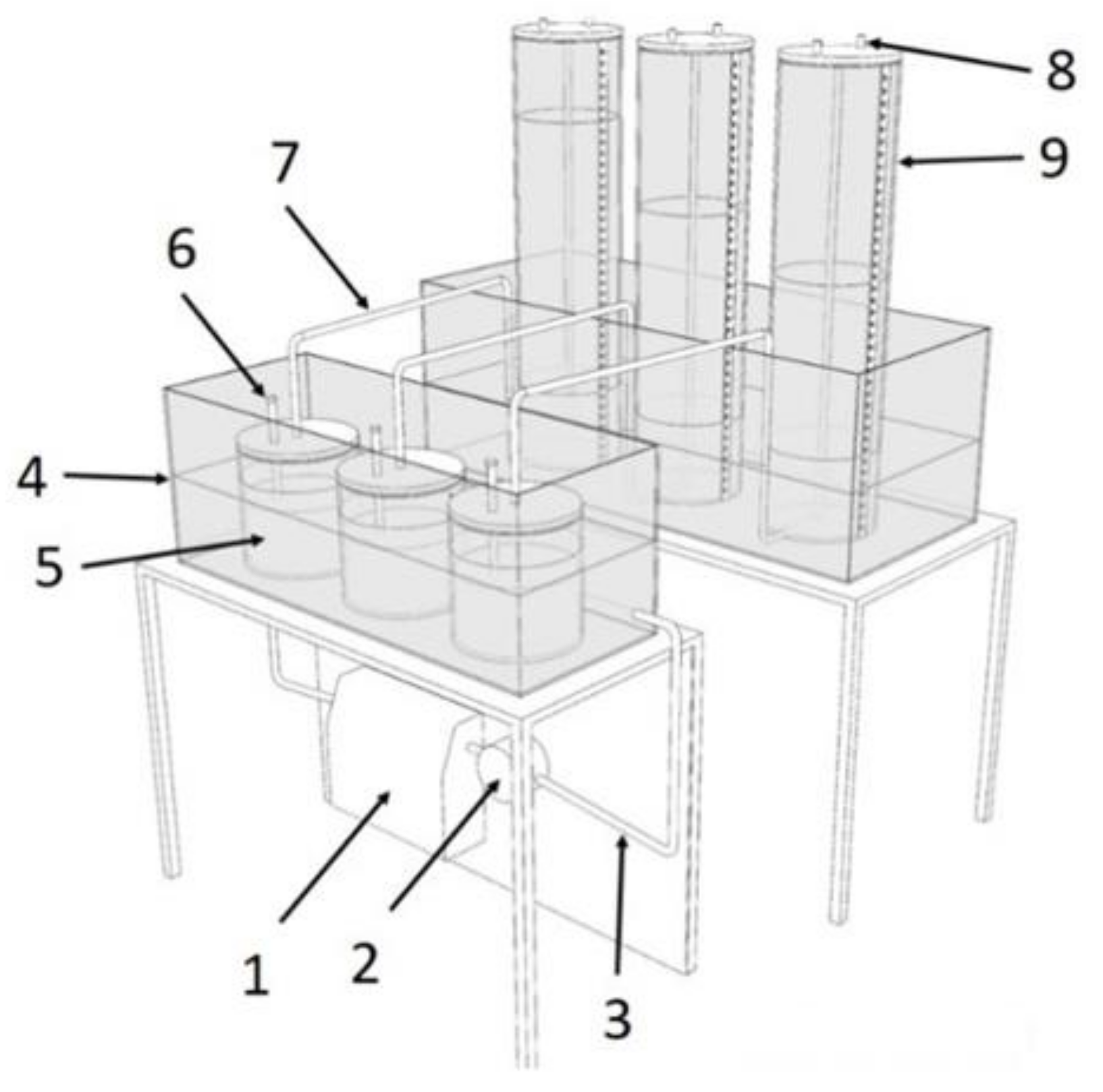

The experiment of manure samples anaerobic digestion has proceeded in a special 3-chambers biofermentor. The simple version of the fermenter’s 3-chambers section is shown in

Figure 3.

The fermentation process occurs in glass reactors (capacity 2 dm

3), well-closed with a can system. The reactors are kept at a stable temperature (39 °C) by placing them inside an aquarium with warm water. The samples (about 50 g of organic dry matter) are placed in the reactors (always in triplicate) and then filled with the inoculum of fermentation microorganisms. Control samples, for comparison, are filled only with the inoculum (3 replicates). The bacterial inoculum comes from the liquid part of the digestate taken from a typical, well-functioning biogas plant. The analyzed substrates were put inside each reactor with the weight-related to VS content and then mixed with inoculum standardized with DIN [

49] and (VDI) norms [

50]. Reactors were flushed with nitrogen gas to remove air and immediately create anaerobic conditions (oxygen is an inhibitor for methanogenic bacteria).

The biogas production measurements were taken every 24 h with accuracy of 0.01 dm

3 by connecting gas reservoirs (9) (

Figure 3) through sampling valve (8) with gas analyzer Geotech GA5000. This analyzer possesses quality certifications such as ATEX II 2G Ex ib IIA T1 Gb (Ta = −10 °C to +50 °C), IECEx, CSA, and calibration certificate UKAS ISO 17025. The measurement ranches for the Geotech analyzer are: O

2 0–25%; CO

2 0–100%; CH

4 0–100%; NH

3 0–1000 ppm and H

2S 0–10,000 ppm. GA5000 was usually calibrated once a week using calibration gases (from the Air Product company) in the concentrations: 65% CH

4, 35% CO

2 (in one mixture); 500 ppm H

2S, 100 ppm NH

3 and O

2 using synthetic air.

The generated results for each material are reduced by the production from control samples, and then converted into the production of biogas and methane from 1 Mg of fresh mass (FM) and converted to dry mass (TS) and organic mass (VS) of the analysed sample. Final data on methane production efficiency from the substrates analyzed in laboratory tests, sent from the Ecotechnologies Laboratory to contractors, are expressed in CH4 m3 with 1 Mg FM. This approach enables further energy calculations for the planned investment or operation of a biogas plant.

2.6. Energetic and Economic Calculations

Based on data obtained from a similar working biogas plan in an experimental university farm (25 km west of Poznan) “Przybroda” the following energy calculations were made. The installation working in Przybroda (Dynamic Biogas Technology) (

Figure 4) mainly uses: bio-waste (including food waste and agri-food industry waste) as the main substrates [

54]. However, it should be noted that apart from the cost of the substrates, all other operating data will be almost identical for the presented case study in Brody (the same fermentation technology and the same installation power).

Production of the electric energy (Ee) by cogeneration—combined heat and power (CHP) unit from methane produced yearly from manure was calculated as follow:

where:

VCH4—volume of methane produced from digested manure (m3);

WCH4—energetic value of 1 cubic meter of methane;

ƞe—electric efficiency of CHP unit.

Production of the thermal energy (Et) by CHP unit from methane produced yearly from manure was calculated as follow:

where:

VCH4—volume of methane produced from digested substrates (m3);

WCH4—energetic value of 1 cubic meter of methane;

ƞt—thermal efficiency of CHP unit.

The calculation of the electric power of a biogas plant (Pe) is based on the amount of electricity produced throughout the year in relation to the operation of the cogeneration unit, in accordance with the formula:

where:

For thermal power (Pt), a similar equation was used:

where:

The analyzed parameters and coefficients used for energy calculations are summarized in

Table 3.

It should be emphasized that currently operating biogas plants show the actual working time in the range 7100–8500 h/year. Here, the value is close to the maximum—in the order of 8200 h/year. Such high reliability is due to technological changes introduced over several decades. In the case study, it would also be possible to use the value of 8400 h/year, which corresponds to the Biogas Dynamic technology [

54]. However, it was decided to choose values that take into account more frequent operational problems and interruptions in biogas production so that the example could be reproduced in most modern technologies available on the market.

Since the most frequently used unit by enterprises and people to determine the amount of heat is GJ, the value in these units can be presented using a standard conversion factor—1 MWh equals 3.6 GJ.

4. Discussion

In the presented work, an analysis was performed that shows that reducing the emission of carbon dioxide equivalent brings significant benefits in the economic and ecological balance. Reducing emissions from manure (through methane digestion) is an approach that is frequently analyzed today. The present publication, however, presents a new aspect, which is the introduction to the economic balance of investments in biogas plants, the savings resulting from the lack of fees for N2O and CH4 emissions from improper manure management.

According to 9 studies discussed in Grossi [

5] (

Table 11), the mitigation effects refer to the percentage change from “standard practice”, the greatest potential is solid-liquid separation followed by solids fermentation in a biogas plant. It can be particularly effective when combined with synergistic actions such as: shortening the storage time and frequent manure removal.

However, the increased productivity listed in the table may not be such a favorable solution. While the total number of dairy cattle might not increase, but only milk production per cow, gas emissions may increase due to higher feed consumption of cows, which in turn results in higher intestinal methane (CH

4) emissions [

6]. Although some studies emphasize that especially animal faeces should be subjected to anaerobic digestion, these this type of waste characterized by a low biogas productivity [

55,

56]. This was also the case in similar study [

54], because the entire manure production could cover not even 50% of the estimated capacity. Therefore, additional substrates are sometimes required for use [

57,

58]. The wheat straw was used in this study due to its ease of harvesting and high biogas efficiency. Many researchers emphasized the high energy value of various types of straw as a substrate for anaerobic digestion, such as corn straw [

59,

60] or cereal straw [

54,

61]. Importantly, straw as a material for energy purposes does not cause a conflict between food production and biofuel (biomethane) [

62]. In contrast with maize silage (which is often used as a substrate for biogas plants in place of forage), straw is only a by-waste. The above-described approach was applied to the analysis performed in this work. Reducing carbon dioxide equivalent emissions has been shown to bring additional significant economic and environmental benefits.

Of course, the entire balance sheet should include the costs associated, inter alia, land purchase and administration fees. On the other hand, the profits should consider the savings resulting from the reduced transmission fee for electricity and heat, charge for ordered power, lower fertilization costs (digestate is a more valuable product than manure).

In the analysis presented in the paper, current prices were taken into account, including the costs of energy and heat consumed as well as the costs of CO

2eq emissions. However, as indicated by market analyses, a significant increase in the above-mentioned costs should be expected in the coming year, which would additionally significantly accelerate the return on investment in biogas plants. The use of a local installation for production as a RES to a large extent makes it independent of the wave of the energy crisis that is currently taking place across the continent. Europe’s leading benchmark reports that prices have risen from EUR 16 MWh in early January to EUR 98 by late September, a six-fold hike in less than one year [

63]. The willingness of East Asian countries to pay more for fuel has exacerbated the trend.

Very high volatility and subsequent records of CO

2eq emission allowances prices are already a constant trend for the allowances market this year. In January this year, allowances were valued at around EUR 31, while in April, they approached EUR 49. These are increases at the level of approx. 60%. Noteworthy is the extremely high price volatility that has been maintained since February, which on average amounted to approx. EUR 6 per month (EUR 6.36 in April) [

64]. This shows that price stability in the allowances market is unlikely to happen in the near future. In line with Trading Economics ‘global macro models and analysts’ expectations, by the end of this quarter, the EU’s carbon allowances will amount to EUR 64.75. The published predictions indicate mean values at the level of EUR 73.63 [

45]. This situation means that the return on investment in biogas plants will be even faster, so the solution will be financially more favorable by up to 20% from the next year (EUR 61.45 to EUR 73.63).

Apart from the benefits of the energetic, economic and environmental points mentioned by many scientists [

65,

66,

67], the use of manure as a substrate for biogas plants has another important aspect. During anaerobic digestion, a significant proportion of the antibiotics present in manure is broken down [

68]. A consequence of the direct use of manure, which currently contains significant amounts of antibiotics used in animal production, results in the uncontrolled release of drugs into the environment via animal (and human) faeces. This phenomenon is the main cause of the emergence of “super worms”—resistant to all known antibiotics [

54].

Unfortunately, due to a considerable dependence and on many factors (air humidity and temperature and its variability, wind speed, formation of the surface crust, length and method of storage) [

69], there are no unambiguous data in the literature about the emission of methane, e.g., from 1 m

3 or 1 Mg of cow manure.

The analysis presented in the paper is based on the use of the international IPCC methodology [

41] and the indicators adopted therein. Only a few places use national data.

However, national and regional sources can be found that rely on slightly different data that significantly increase the benefits of using a biogas plant for manure processing.

Single information can be found in the literature review by Chianese et al. [

70], who determined the average annual emissions from solid manure in heaps for methane at 2.3 kg CH

4/m

3, and for N

2O equal to 0.1 kg N

2O/m

3. These values are estimated 4 times higher than in this study, i.e., the annual methane production would amount to approx. 12 Mg per year. However, as shown by other sources, the aforementioned value is burdened with a very substantial error, e.g., in different regions, the same breed of cows differed by 300% [

70]. In turn, the values given in other literature are, for example, emission of manure is 20% of biogas efficiency, i.e., as much as 15 m

3 CH

4/Mg of manure [

71]. The adoption of such values would mean an almost 6 times higher result than the previously quoted one and several times higher than this work, with one reservation—it was not stated whether this only applies to the solid fraction. Such imprecision is common, which complicates a meaningful comparison very much. Grossi et al. [

5] points that manure (liquid and solid fractions) may be responsible for 8% of methane emissions and 7% of N

2O.

By Moral et al. [

72] the cumulative CH

4–C emission was determined as approx. 0.54 kg C/Mg in relation to the starting weight of the initial manure fresh mass, approx. 0.6% of the total C in the pile at the beginning of manure storage, which corresponds to the results of this study—0.6% of the starting carbon content would account for approx. 2.8 Mg of CH

4 emitted annually, and the study determined this value at approx. 3.4 Mg/year.

On the other hand, generally, the estimation of Chadwick [

73] is that total losses of CH

4–C ranged from 0.4% to 9.7%, which is in line with the results of this work. However, most of his results (from three conventionally stored periods) were within limits of 1.8% to 4.4% of the initial carbon content of cattle manure. Chadwick [

73] noted that covering and thickening the piles is not as important as might be expected and works primarily in the initial phase. Alternatively, frequent rotation of the pile should be introduced to reduce methane emissions. This action introduces oxygen into the manure and reduces the compaction (“loosens the pile”), allowing better air flow inside the manure. Such a solution may result in the loss of methane at the level of approx. 0.5% of the original carbon content in the manure [

74,

75].

5. Conclusions

As a result of the conducted research, it can be concluded that:

1. The solution variant assuming the use of solid manure as a substrate for a biogas plant equipped with a cogeneration system is definitely more advantageous in economic and ecological terms.

2. The payback period assumed for the presented biogas installation does not exceed 5 years, and with the current trend of increasing energy prices, it can be estimated that it will shorten to even 4 years.

3. To properly determine the economic balance, it would be necessary to conduct energy and economic analyses for additional waste streams (dairy waste, agri-food industry waste, etc.) that could increase the biogas plant’s power, thus its efficiency.

4. The use of solid manure as a source of chemical energy (biogas) enables the reduction of carbon dioxide equivalent emissions by up to 100 Mg per year.

5. The use of a renewable energy source such as biogas can be an essential aspect when determining the LCA or carbon footprint for farm dairy products.