Numerical Simulation of Bridging Ball Plugging Mechanism in Fractured-Vuggy Carbonate Reservoirs

Abstract

1. Introduction

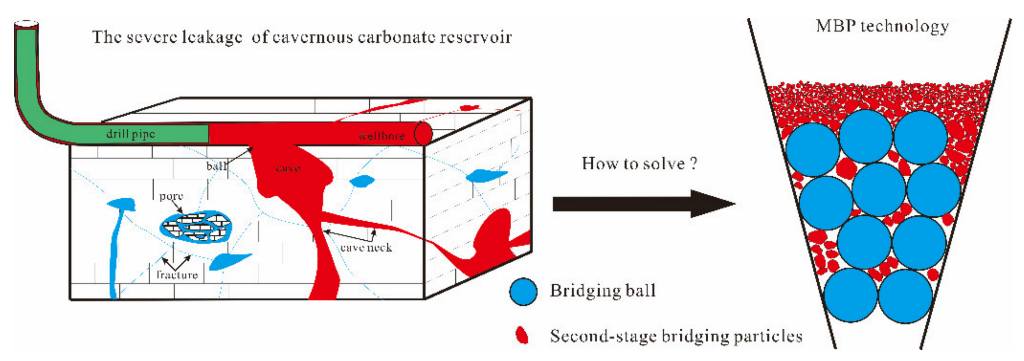

2. Background of MBP Technology

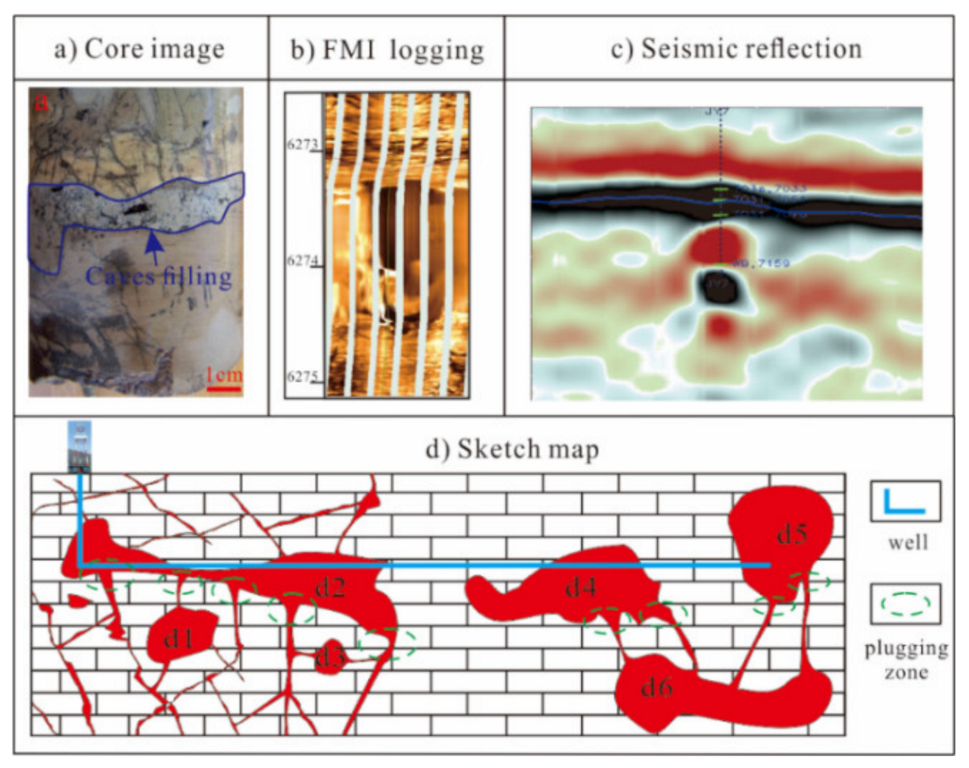

2.1. Geological and Leakage Characteristics of Reservoirs

2.2. MBP Technology Theory

3. Method

3.1. Contact Model

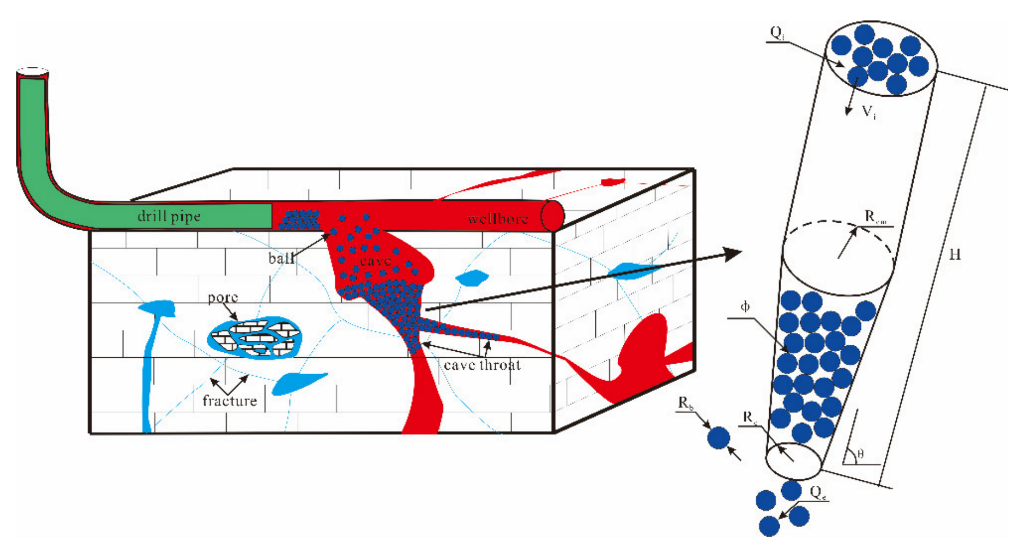

3.2. Geometry and Simulation Parameters

4. Results and Discussion

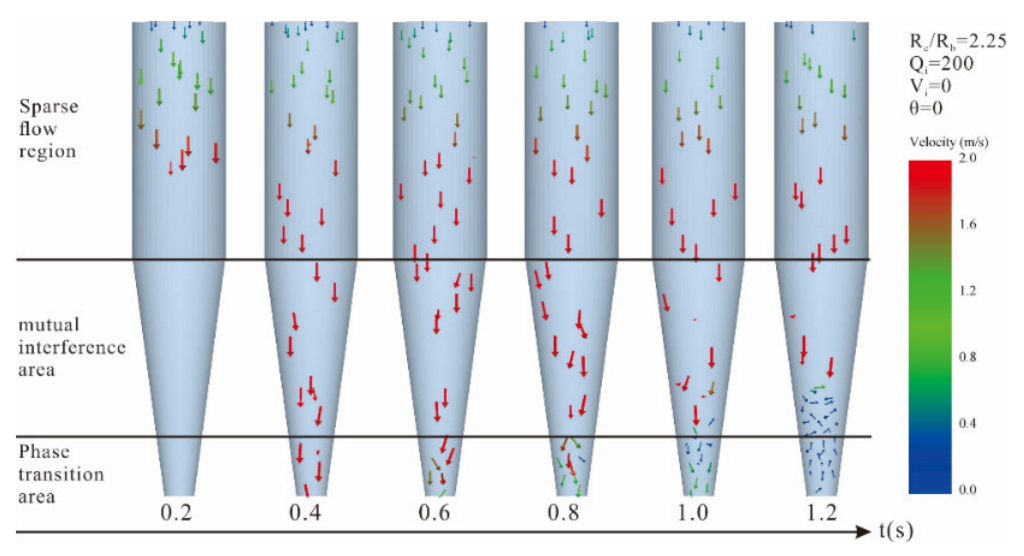

4.1. Flow Characteristics

4.2. Influence Factors of Ball Bridging

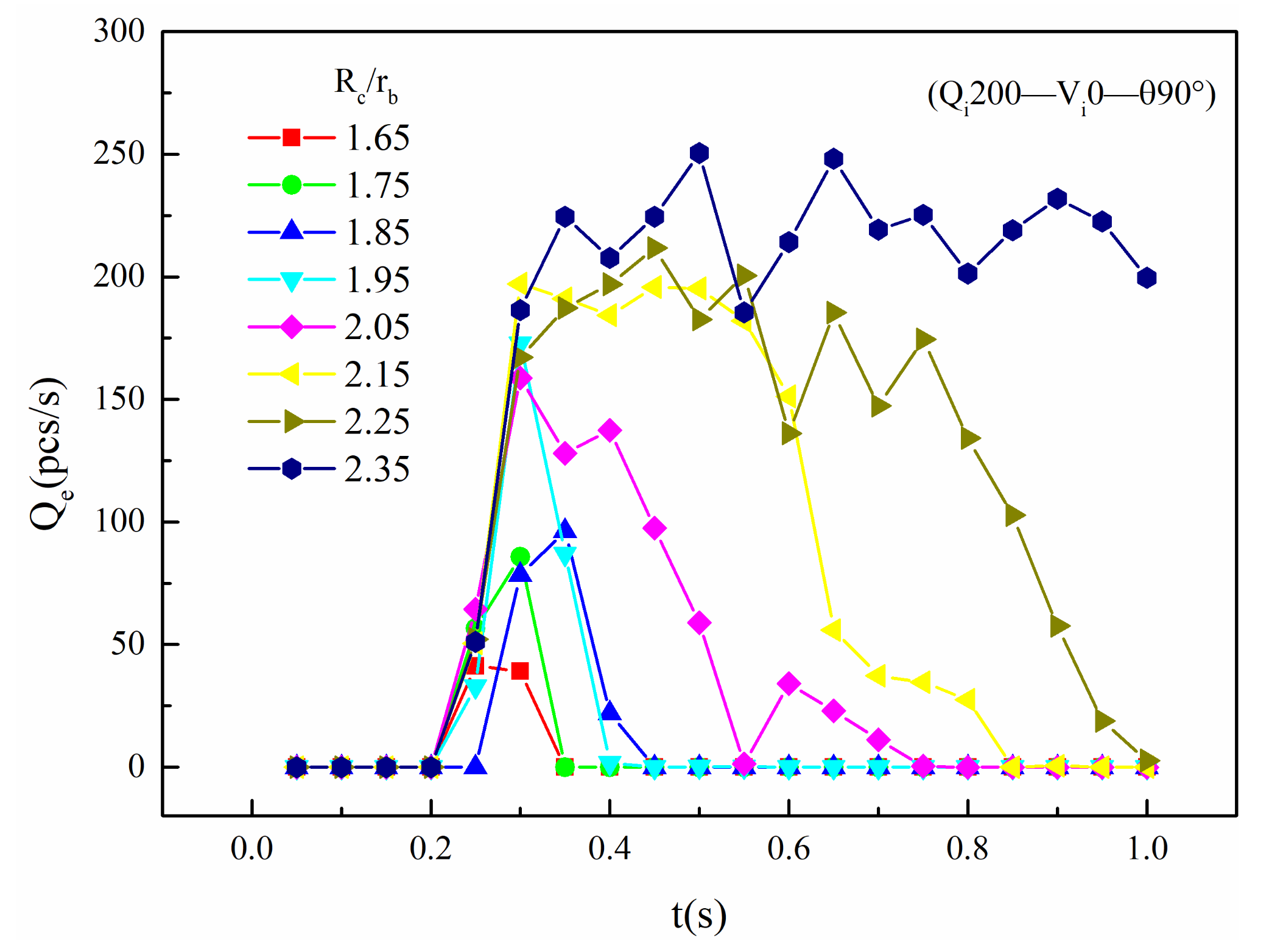

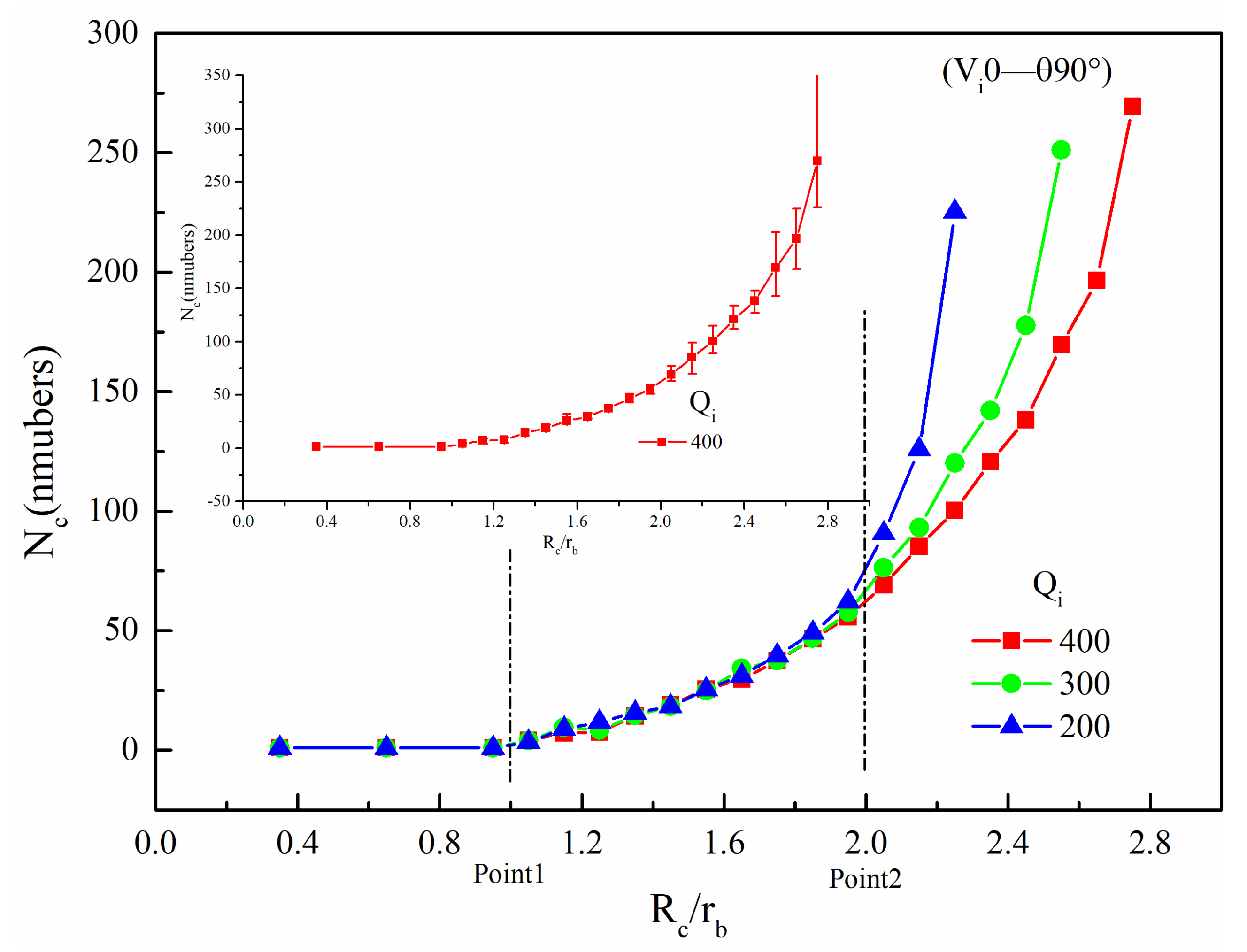

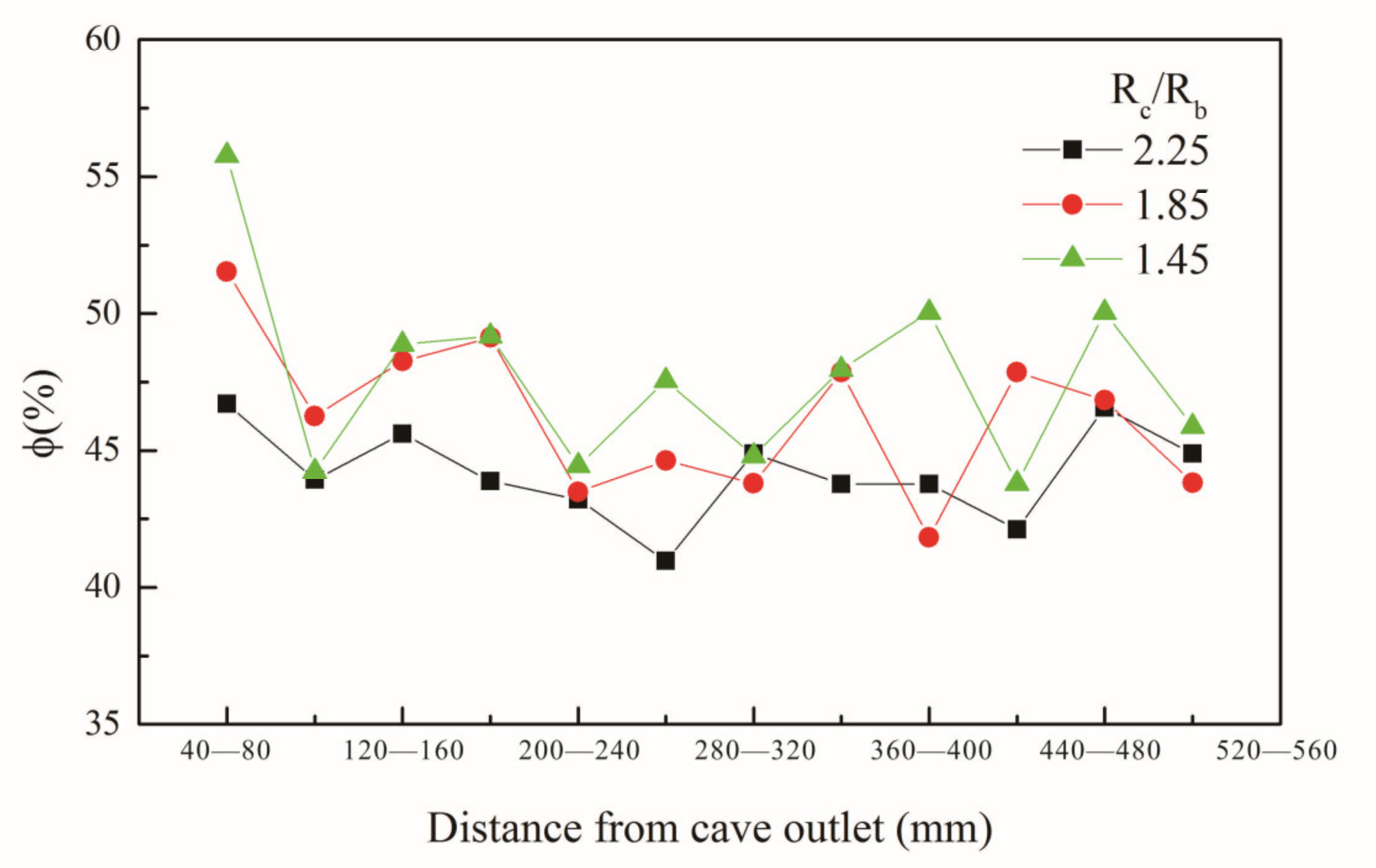

4.2.1. Effect of Rc/rb

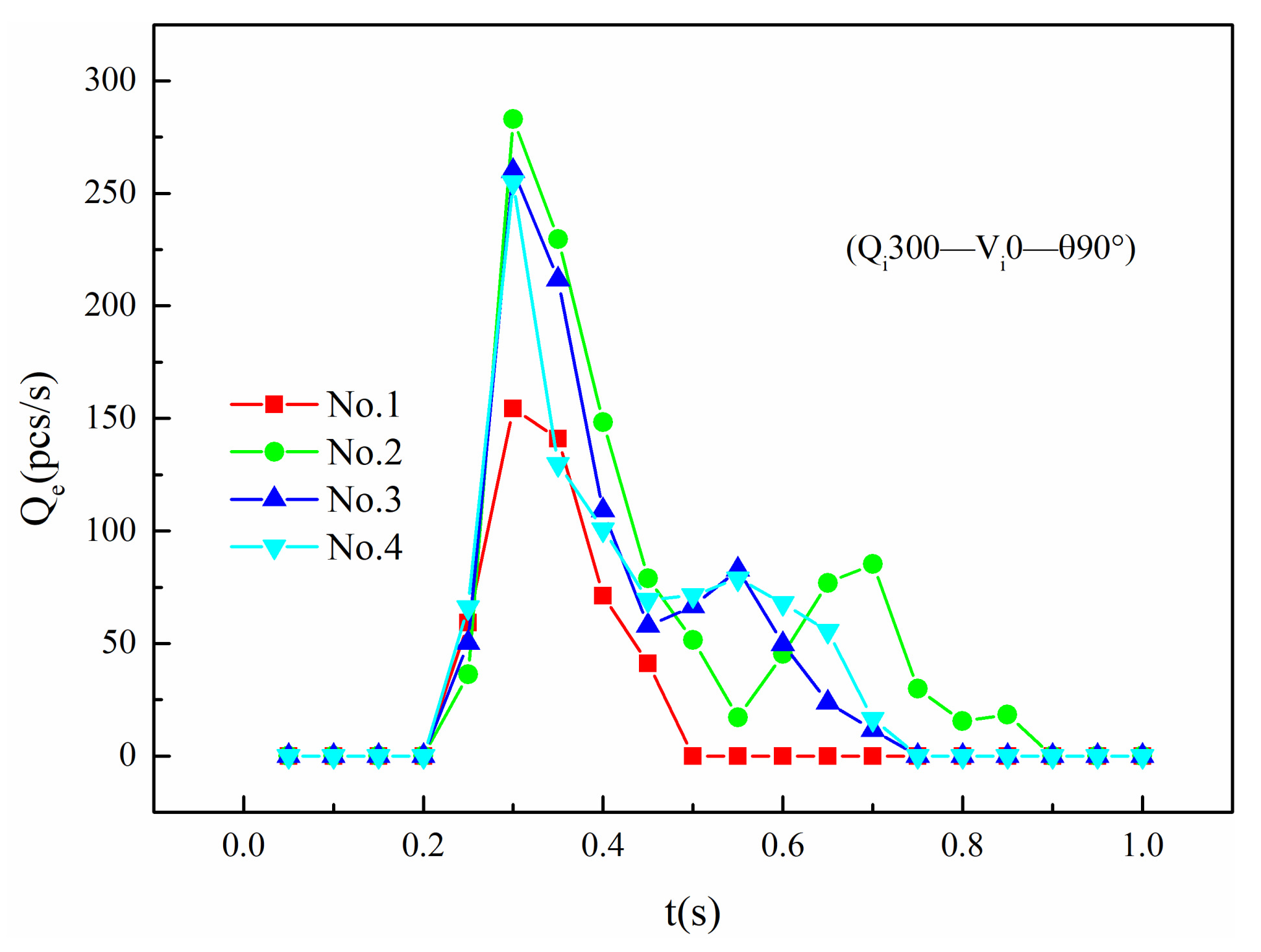

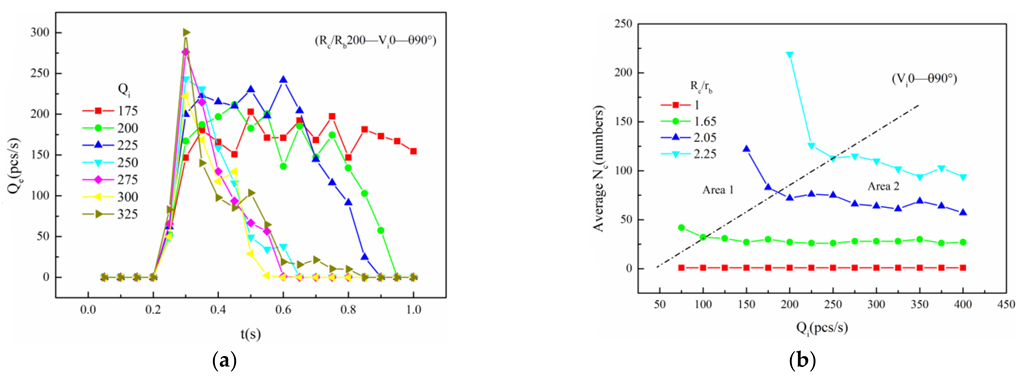

4.2.2. Effect of Qi

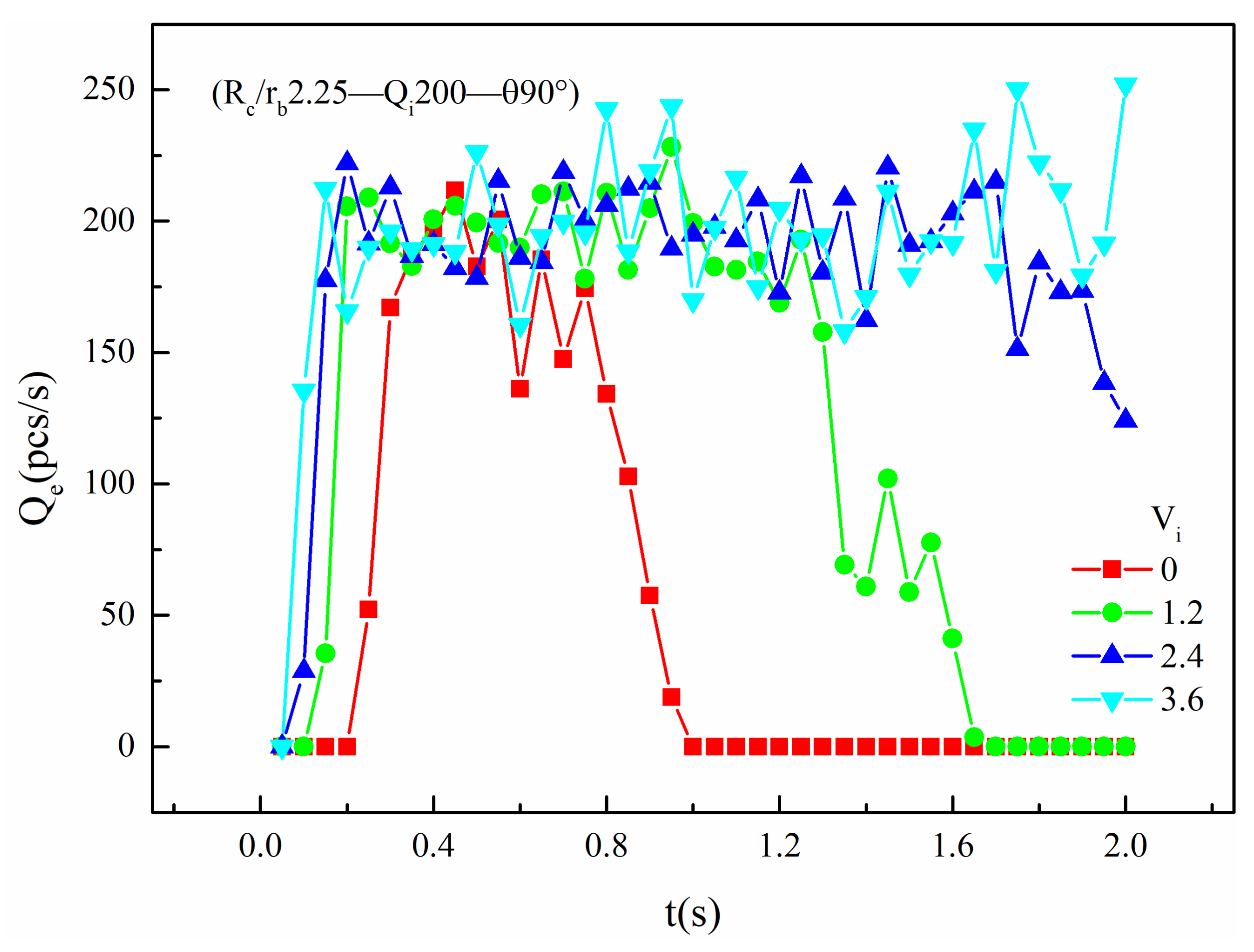

4.2.3. Effect of Vi

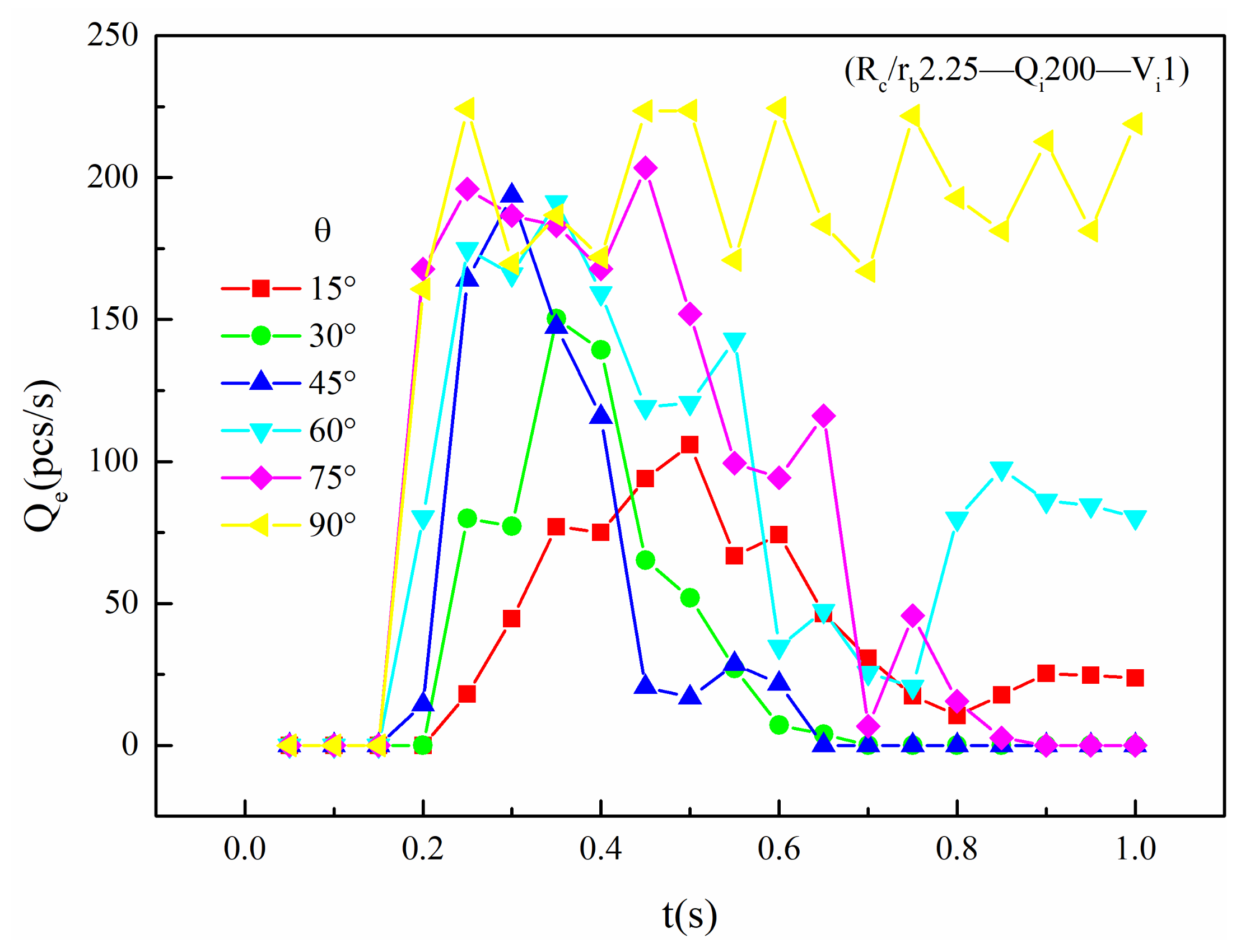

4.2.4. Effect of θ

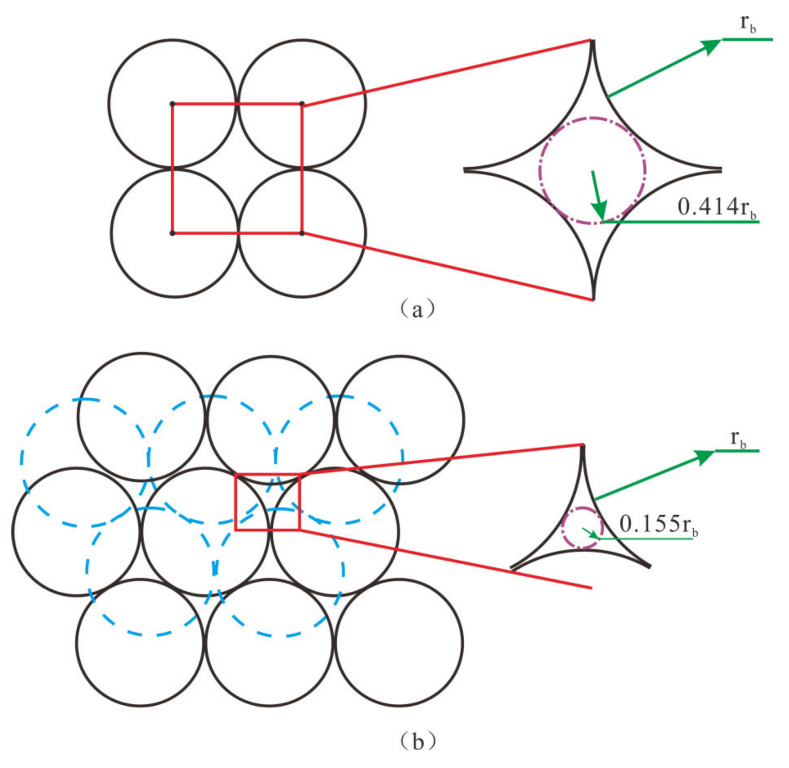

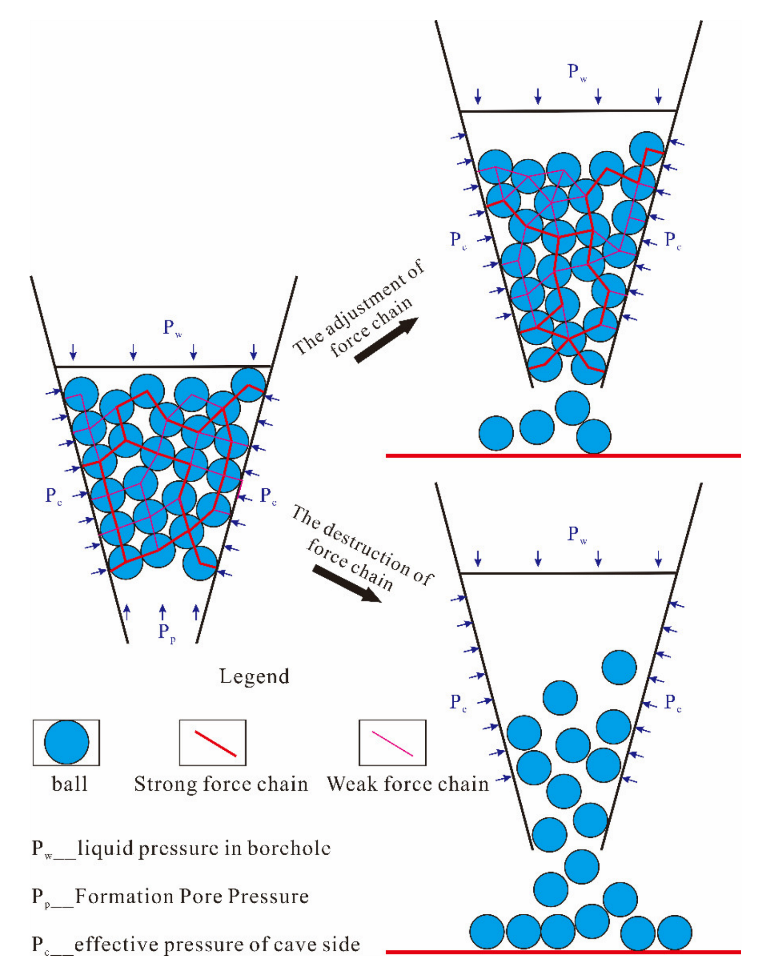

4.3. The Porous Medium Formed in the First-Stage Bridging

4.4. Discussion

- (1)

- Limited by the cave morphology of fracture-vugs in carbonate reservoirs, MBP technology is more likely to achieve effective plugging for caves with throats or high filling degrees near the wellbore. As for the lower cave and the upper throat type, the bridging ball cannot enter the cave neck at a large flow rate.

- (2)

- Limited by the borehole size, there is an upper limit on the diameter of the plug ball that coiled tubing can inject into the leaking zone. At the same time, there is an upper limit on the diameter of the cave neck that can be effectively plugged due to the limitation of initial flow Qi of the bridging ball. When the actual cave neck diameter exceeds this upper limit, MBP technology will fail.

- (3)

- All discussion in this research is based on the ideal situation. However, the cave pattern is difficult to describe by using several models, let alone by one ideal model. With the progress of seismic fine description technology, more accurate characterization of caves in carbonate reservoirs, or judging the types of caves by the experience of loss in the drilling process, will help to accurately formulate the plugging scheme and greatly improve the success rate of plugging technology.

- (4)

- MBP technology makes it possible to deal with the large loss in leakage pathways, but it is limited by the borehole size. The effective diameter of the bridging balls used in operations are limited by continuous oil piping, which means that the diameter of the cave neck that can be effectively plugged has an upper limit. Of course, MBP technology can be applied to plug while drilling. In plugging while drilling, MBP technology is limited by the size of the water eye of the drill bit. In order to avoid engineering risks, the size of the first-stage bridging particles should be less than 1/5 of the diameter of the water eye.

- (5)

- However, the bridging effect of multiscale mixing of bridging balls is better than single-scale bridging balls. Bridging balls with irregular surface morphology can bridge more easily, enabling the bridging structure to be more stable. In order to avoid particle settling and ensure migration in severe leakage and complex wellbore environments, a lighter and tougher material, with a density far smaller than 1.8 g/cm3, can be used to manufacture the bridging ball.

5. Conclusions

- (1)

- The prerequisite for the success of MBP is the presence of a constricted neck near the wellbore that connects with the drilled open caves in the process of well drilling loss. The first-stage bridging is the key to the success of MBP.

- (2)

- There are mainly five flow modes in different caves, and the formation of stable bridge goes through four stages: the sparse flow to the dense flow stage, the dense flow to the the jamming stage, the soft jamming flow to the deep jamming flow stage, and the readjustment stage.

- (3)

- The effect of the first-stage bridging takes into account the influence of the cave neck radius, the cave dip angle, the size and the velocity of the bridging ball, etc. (a) With the increase of Rc/rb, the Nc also increases. When Rc/rb > 2, the growth rate becomes faster. (b) With the increase of Rc/rb, the critical Qi also increases. After Rc/rb > 2, the critical Qi also increases rapidly. (c) The faster the velocity of the bridging ball, the larger the kinetic energy of the ball becomes, the higher the efficiency through the cave neck becomes, and the more difficult the bridging will be. (d) The cave dip angle mainly affects the manner of ball movement; it is easier to bridge between 75° and 90°, and the bridging is also the most stability.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zhong, Z.; Esteban, L.; Rezaee, R.; Josh, M.; Feng, R. The Pressure Dependence of the Archie Cementation Exponent for Samples from the Ordovician Goldwyer Shale Formation in Australia. SPE J. 2021, 26, 2849–2859. [Google Scholar] [CrossRef]

- Elkatatny, S.; Mahmoud, M.; Tariq, Z.; Abdulraheem, A. New insights into the prediction of heterogeneous carbonate reservoir permeability from well logs using artificial intelligence network. Neural Comput. Appl. 2017, 30, 2673–2683. [Google Scholar] [CrossRef]

- Van Oort, E.; Razavi, S.O. Wellbore strengthening and casing smear: The common underlying mechanism. In Proceedings of the IADC/SPE Drilling Conference and Exhibition, Fort Worth, TX, USA, 4–6 March 2014. [Google Scholar]

- Civan, F. Reservoir Formation Damage; Gulf Professional Publishing: Houston, TX, USA, 2015. [Google Scholar]

- Loloi, M.; Zaki, K.S.; Zhai, Z.; Abou-Sayed, A. Borehole Strengthening and Injector Plugging–The Common Geomechanics Thread. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 14–17 February 2010. [Google Scholar]

- Feng, Y.; Gray, K. Review of fundamental studies on lost circulation and wellbore strengthening. J. Pet. Sci. Eng. 2017, 152, 511–522. [Google Scholar] [CrossRef]

- Lee, L.; Magzoub, M.; Taleghani, A.D.; Salehi, S.; Li, G. Modelling of cohesive expandable LCMs for fractures with large apertures. Geothermics 2022, 104, 102–106. [Google Scholar] [CrossRef]

- Zhu, B.; Tang, H.; Yin, S.; Chen, G.; Zhao, F.; Li, L. Experimental and numerical investigations of particle plugging in fracture-vuggy reservoir: A case study. J. Pet. Sci. Eng. 2022, 208, 109610. [Google Scholar]

- Mindlin, R.D. Compliance of Elastic Bodies in Contact. J. Appl. Mech. 1949, 16, 259–268. [Google Scholar] [CrossRef]

- Yang, C.; Zhou, F.; Feng, W.; Tian, Z.; Yuan, L.; Gao, L. Plugging mechanism of fibers and particulates in hydraulic fracture. J. Pet. Sci. Eng. 2019, 176, 396–402. [Google Scholar] [CrossRef]

- Jiao, F. Practice and knowledge of volumetric development of deep fractured-vuggy carbonate reservoirs in Tarim Basin, NW China. Pet. Explor. Dev. 2019, 46, 576–582. [Google Scholar] [CrossRef]

- Liu, B.; Jin, Y.; Chen, M. Influence of vugs in fractured-vuggy carbonate reservoirs on hydraulic fracture propagation based on laboratory experiments. J. Struct. Geol. 2019, 124, 143–150. [Google Scholar] [CrossRef]

- Fang, J.; Jiao, B.; Zhao, G.; He, L.; Wu, Y.; Dai, C. Study on the channel flow control regulation of particle agents in fractured-vuggy carbonate reservoirs via CFD-DEM coupling method. J. Pet. Sci. Eng. 2019, 180, 495–503. [Google Scholar] [CrossRef]

- Li, S.; Kang, Y.; You, L.; Li, D.; Lian, Z. Experimental and numerical investigation of multiscale fracture deformation in fractured–vuggy carbonate reservoirs. Arab. J. Sci. Eng. 2014, 39, 4241–4249. [Google Scholar] [CrossRef]

- Sun, H.; Xu, S.; Pan, X.; Shi, L.; Geng, X.; Cai, Y. Investigating the jamming of particles in a three-dimensional fluid-driven flow via coupled CFD–DEM simulations. Int. J. Multiph. Flow 2019, 114, 140–153. [Google Scholar] [CrossRef]

- Abrams, A. Mud Design to Minimize Rock Impairment Due To Particle Invasion. J. Pet. Technol. 1976, 29, 586–592. [Google Scholar] [CrossRef]

- Hands, N.; Kowbel, K.; Maikranz, S.; Nouris, R. Drill-in fluid reduces formation damage, increases production rates. Oil Gas J. 1998, 96, 65–69. [Google Scholar]

- Dick, M.A.; Heinz, T.J.; Svoboda, C.F.; Aston, M. Optimizing the selection of bridging particles for reservoir drill-in fluids. In Proceedings of the SPE International Symposium on Formation Damage Control, Lafayette, LA, USA, 23–24 February 2000; pp. 1–8. [Google Scholar]

- Yuan, L.; Zhou, F.; Li, B.; Gao, J.; Yang, X.; Cheng, J.; Wang, J. Experimental study on the effect of fracture surface morphology on plugging efficiency during temporary plugging and diverting fracturing. J. Nat. Gas Sci. Eng. 2020, 81, 103–109. [Google Scholar] [CrossRef]

- Alberty, M.W.; Mclean, M.R. A physical model for stress cages. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004; pp. 26–29. [Google Scholar]

- Aston, M.S.; Alberty, M.W.; McLean, M.R.; De Jong, H.J.; Armagost, K. Drilling fluids for wellbore strengthening. In Proceedings of the IADC/SPE Drilling Conference, Dallas, TX, USA, 2–4 March 2004. [Google Scholar]

- Golshan, S.; Sotudeh-Gharebagh, R.; Zarghami, R.; Mostoufi, N.; Blais, B.; Kuipers, J. Review and implementation of CFD-DEM applied to chemical process systems. Chem. Eng. Sci. 2020, 221, 115646. [Google Scholar] [CrossRef]

- Dai, J.; Grace, J.R. Blockage of constrictions by particles in fluid–solid transport. Int. J. Multiph. Flow 2010, 36, 78–87. [Google Scholar] [CrossRef]

- Mondal, S.; Wu, C.H.; Sharma, M.M. Coupled CFD-DEM simulation of hydrodynamic bridging at constrictions. Int. J. Multiph. Flow 2016, 84, 245–263. [Google Scholar] [CrossRef]

- Xu, C.; You, Z.; Kang, Y.; You, L. Stochastic modelling of particulate suspension transport for formation damage prediction in fractured tight reservoir. Fuel 2018, 221, 476–490. [Google Scholar] [CrossRef]

- Li, J.; Qiu, Z.; Zhong, H.; Huang, W. Coupled CFD-DEM analysis of parameters on bridging in the fracture during lost circulation. J. Pet. Sci. Eng. 2020, 184, 106–131. [Google Scholar] [CrossRef]

- Xu, C.; Yang, X.; Liu, C.; Kang, Y.; Bai, Y.; You, Z. Dynamic fracture width prediction for lost circulation control and formation damage prevention in ultra-deep fractured tight reservoir. Fuel 2021, 307, 121770. [Google Scholar] [CrossRef]

- Zhong, Z.; Rezaee, R.; Esteban, L.; Josh, M.; Feng, R. Determination of Archie’s cementation exponent for shale reservoirs; an experimental approach. J. Pet. Sci. Eng. 2021, 201, 108527. [Google Scholar] [CrossRef]

- Zhong, Z.; Rezaee, R.; Josh, M.; Esteban, L.; Sarmadivaleh, M. The salinity dependence of electrical conductivity and Archie’s cementation exponent in shale formations. J. Pet. Sci. Eng. 2022, 208, 109324. [Google Scholar] [CrossRef]

- Feng, Y.; Gray, K.E. Modeling Lost Circulation Through Drilling-Induced Fractures. SPE J. 2017, 23, 205–223. [Google Scholar] [CrossRef]

- Feng, Y.; Li, G.; Meng, Y.F.; Guo, B.Y. A Novel Approach to Investigating Transport of Lost Circulation Materials in Rough Fracture. Energies 2019, 11, 2572. [Google Scholar] [CrossRef]

- Zhu, B.; Tang, H.; Wang, X.; Zhao, F.; Yuan, X. Coupled CFD-DEM simulation of granular LCM bridging in a fracture. Part. Sci. Technol. 2020, 38, 371–380. [Google Scholar] [CrossRef]

- Lei, S.; Sun, J.; Bai, Y.; BAI, Y.; Lyu, K.; Zhang, S.; Xu, C.; Cheng, R.; Liu, F. Formation mechanisms of fracture plugging zone and optimization of plugging particles. Pet. Explor. Dev. 2022, 49, 684–693. [Google Scholar] [CrossRef]

- Qiu, Z.; Liu, Y.; Zhou, B.; Bao, D.; Dou, T.; Xiao, C. Tight fracture-plugging mechanism and optimized design for plugging drilling fluid. Acta Pet. Sin. 2016, 37, 137. [Google Scholar]

- Tang, M.; Wang, C.; Yang, H.; Lu, J.; Yu, H. Experimental investigation on plugging performance of nanospheres in low-permeability reservoir with bottom water. Adv. Geo-Energy Res. 2022, 6, 95–105. [Google Scholar] [CrossRef]

- Zhang, L.; Zhou, F.; Mou, J.; Feng, W.; Li, Z.; Zhang, S. An integrated experimental method to investigate tool-less temporary-plugging multistage acid fracturing of horizontal well by using self-degradable diverters. SPE J. 2020, 25, 1204–1219. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Kloss, C.; Goniva, C.; Hager, A.; Amberger, S.; Pirker, S. Models, algorithms and validation for opensource DEM and CFD–DEM. Prog. Comput. Fluid Dyn. Int. J. 2012, 12, 140–152. [Google Scholar] [CrossRef]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

- Jiao, Y.; Torquato, S. Maximally random jammed packings of Platonic solids: Hyperuniform long-range correlations and isostaticity. Phys. Rev. E 2011, 84, 041309. [Google Scholar] [CrossRef] [PubMed]

- Weitz, D.A. Packing in the Spheres. Science 2004, 303, 968–969. [Google Scholar] [CrossRef]

- Pinson, D.; Zou, R.P.; Yu, A.; Zulli, P.; McCarthy, M.J. Coordination number of binary mixtures of spheres. J. Phys. D Appl. Phys. 1999, 31, 457–462. [Google Scholar] [CrossRef]

- Hoomans, B.P.B.; Kuipers, J.A.M.; Briels, W.J.; van Swaaij, W.P. Discrete particle simulation of bubble and slug formation in a two-dimensional gas-fluidised bed: A hard-sphere approach. Chem. Eng. Sci. 1996, 51, 99–118. [Google Scholar] [CrossRef]

- Sun, J.; Chen, H.; Duan, J.; Liu, Z.; Zhu, Q. Mechanical properties of the grooved-wheel drilling particles under multivariate interaction influenced based on 3D printing and EDEM simulation. Comput. Electron. Agric. 2020, 172, 105329. [Google Scholar] [CrossRef]

| Total Wells | Leaky Wells/Total Wells (%) | Min Leakage (m3) | Max Leakage (m3) | Return Loss Wells /Leaky Wells (%) | Drilling Open Caves in Single Wells /Leaky Wells (%) |

|---|---|---|---|---|---|

| 82 | 52.4 | 1.5 | 1338.0 | 53.4 | 62.8 |

| Parameters | Value (Varying Range) |

|---|---|

| Cave geometry parameters | |

| Dip angle θ (rad) | 90 (15~90) |

| Cave neck radius Rc (mm) | 38 (≥38) |

| Height H (mm) | 300 (300~900) |

| Cave maximum radius Rcm (mm) | 120 |

| ball properties | |

| Ball radius Rb (mm) | 8.44 (6.33~19) |

| Ball initial velocity Vi (m/s) | 0 (0~3.2) |

| Ball initial flow rate Qi (numbers per seconds) | 200 (100~400) |

| Ball density ρb (kg/m3) | 1800 |

| Shear Modulus (Pa) | 9.09 × 108 |

| Poisson ratio (–) | 0.25 |

| Cave properties | |

| Shear Modulus (Pa) | 1 × 1010 |

| Poisson ratio (–) | 0.25 |

| Interaction parameters | |

| Coefficient of restitution ebb = ebc (–) | 0.8 |

| Friction coefficient | |

| Sliding μs, bb = μs, bc (–) | 0.5 |

| rolling μr, bb = μr, bc (–) | 0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; You, L.; Zhu, B.; Tang, H.; Qu, H.; Feng, Y.; Zhong, Z. Numerical Simulation of Bridging Ball Plugging Mechanism in Fractured-Vuggy Carbonate Reservoirs. Energies 2022, 15, 7361. https://doi.org/10.3390/en15197361

Wang X, You L, Zhu B, Tang H, Qu H, Feng Y, Zhong Z. Numerical Simulation of Bridging Ball Plugging Mechanism in Fractured-Vuggy Carbonate Reservoirs. Energies. 2022; 15(19):7361. https://doi.org/10.3390/en15197361

Chicago/Turabian StyleWang, Xi, Lijun You, Baiyu Zhu, Hongming Tang, Haizhou Qu, Yutian Feng, and Zhiqi Zhong. 2022. "Numerical Simulation of Bridging Ball Plugging Mechanism in Fractured-Vuggy Carbonate Reservoirs" Energies 15, no. 19: 7361. https://doi.org/10.3390/en15197361

APA StyleWang, X., You, L., Zhu, B., Tang, H., Qu, H., Feng, Y., & Zhong, Z. (2022). Numerical Simulation of Bridging Ball Plugging Mechanism in Fractured-Vuggy Carbonate Reservoirs. Energies, 15(19), 7361. https://doi.org/10.3390/en15197361