A Review on Geothermal Energy and HPHT Packers for Geothermal Applications

Abstract

1. Introduction

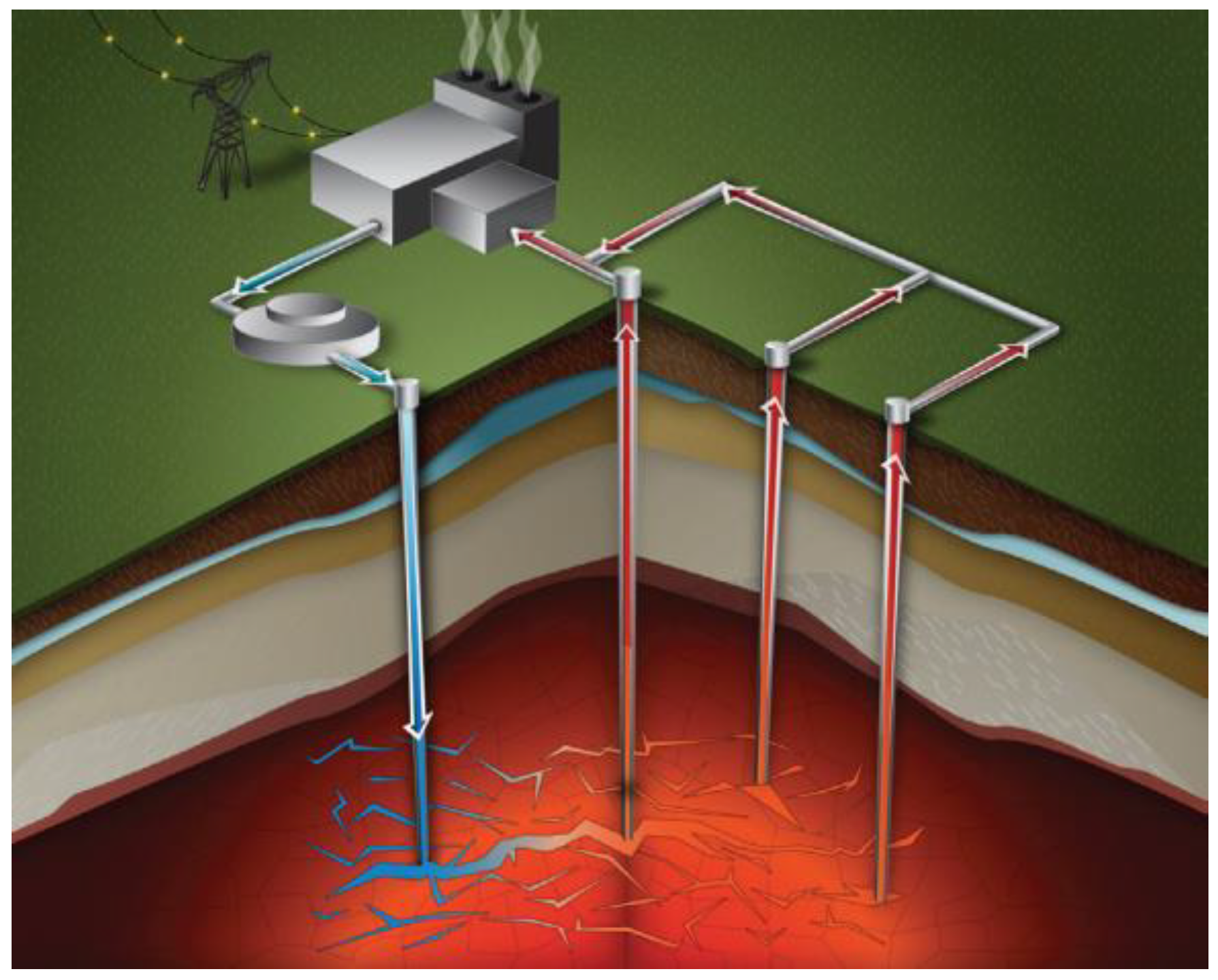

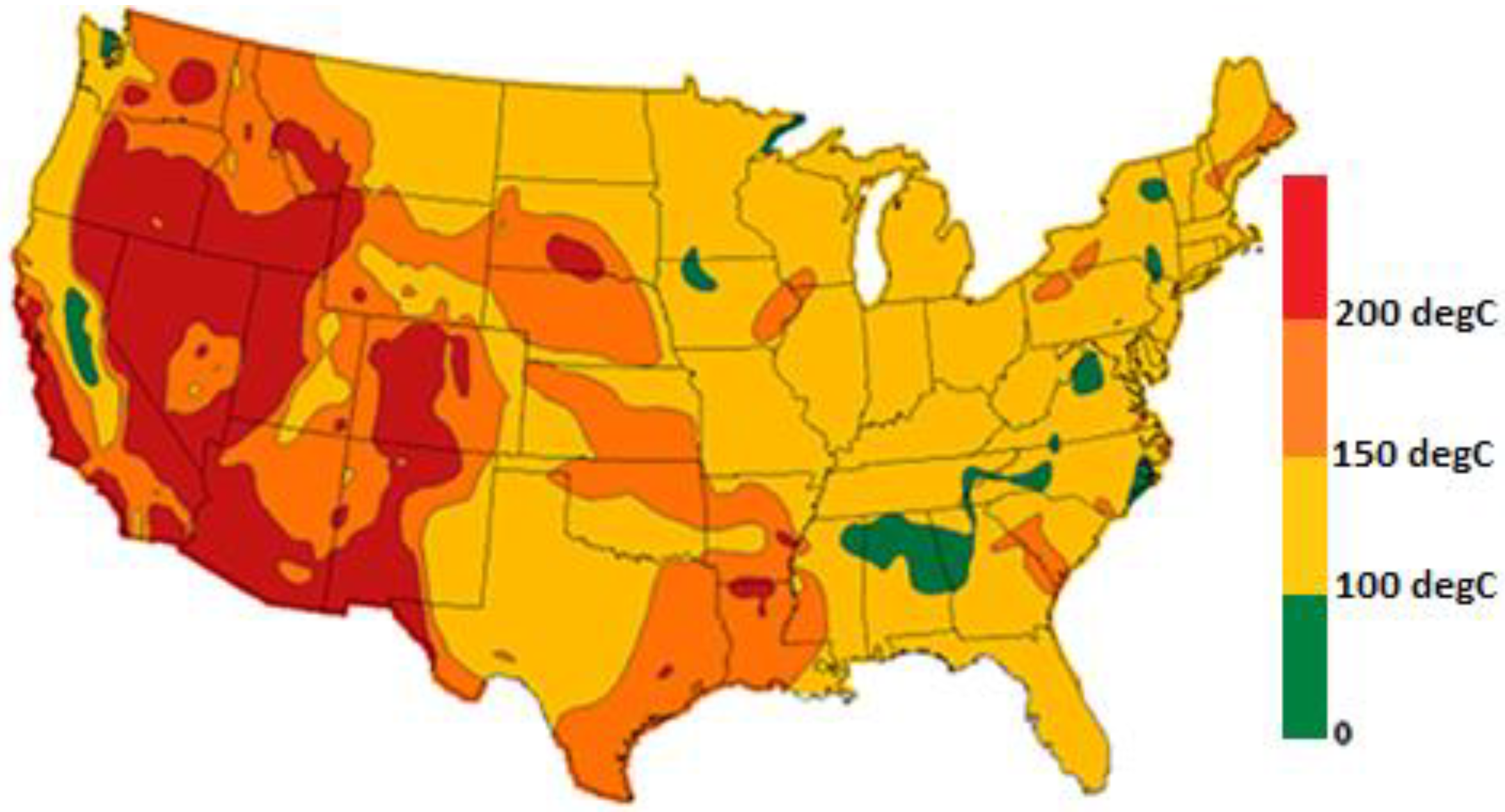

2. Geothermal Source Energy

3. Geothermal Systems

4. Uses of Geothermal Energy

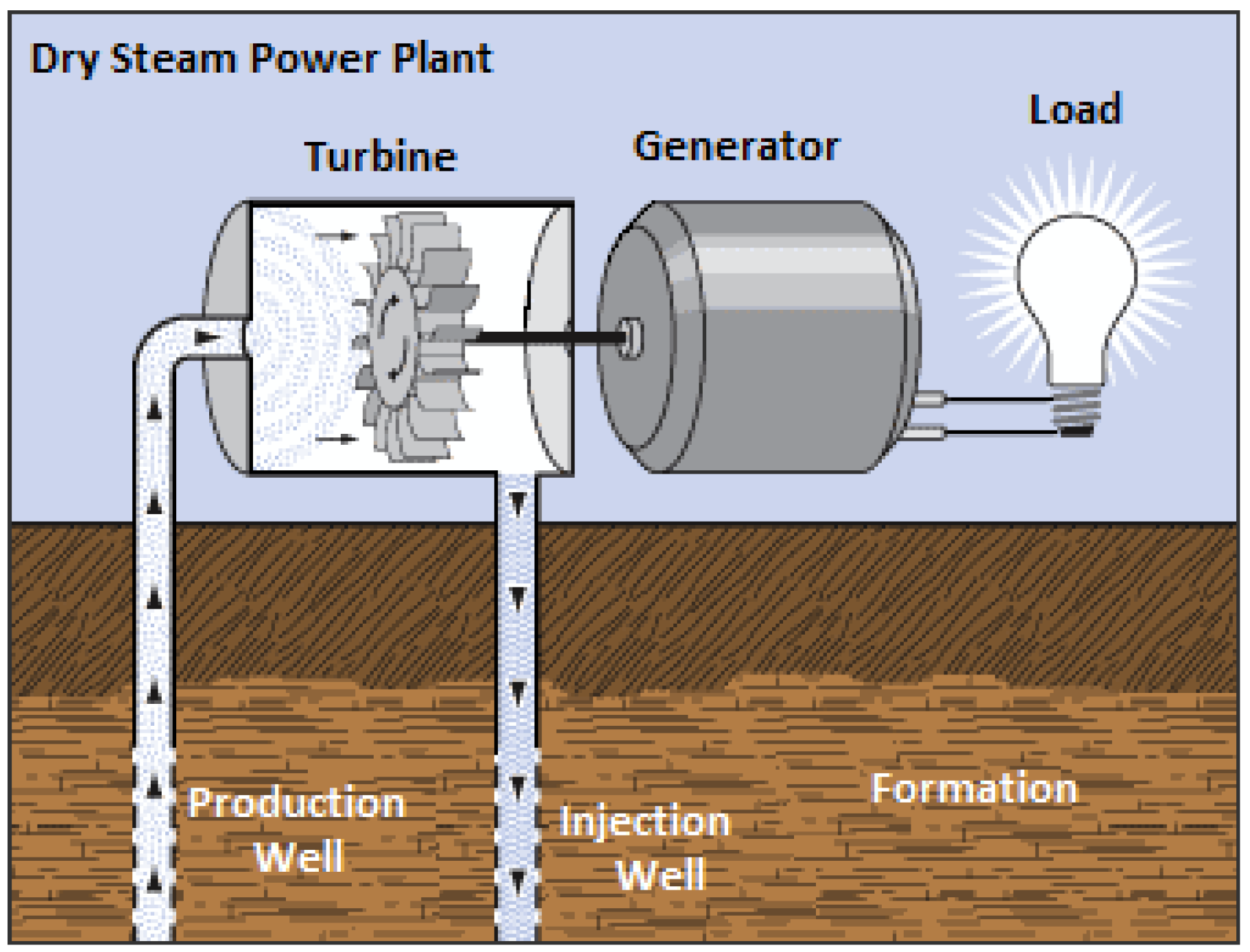

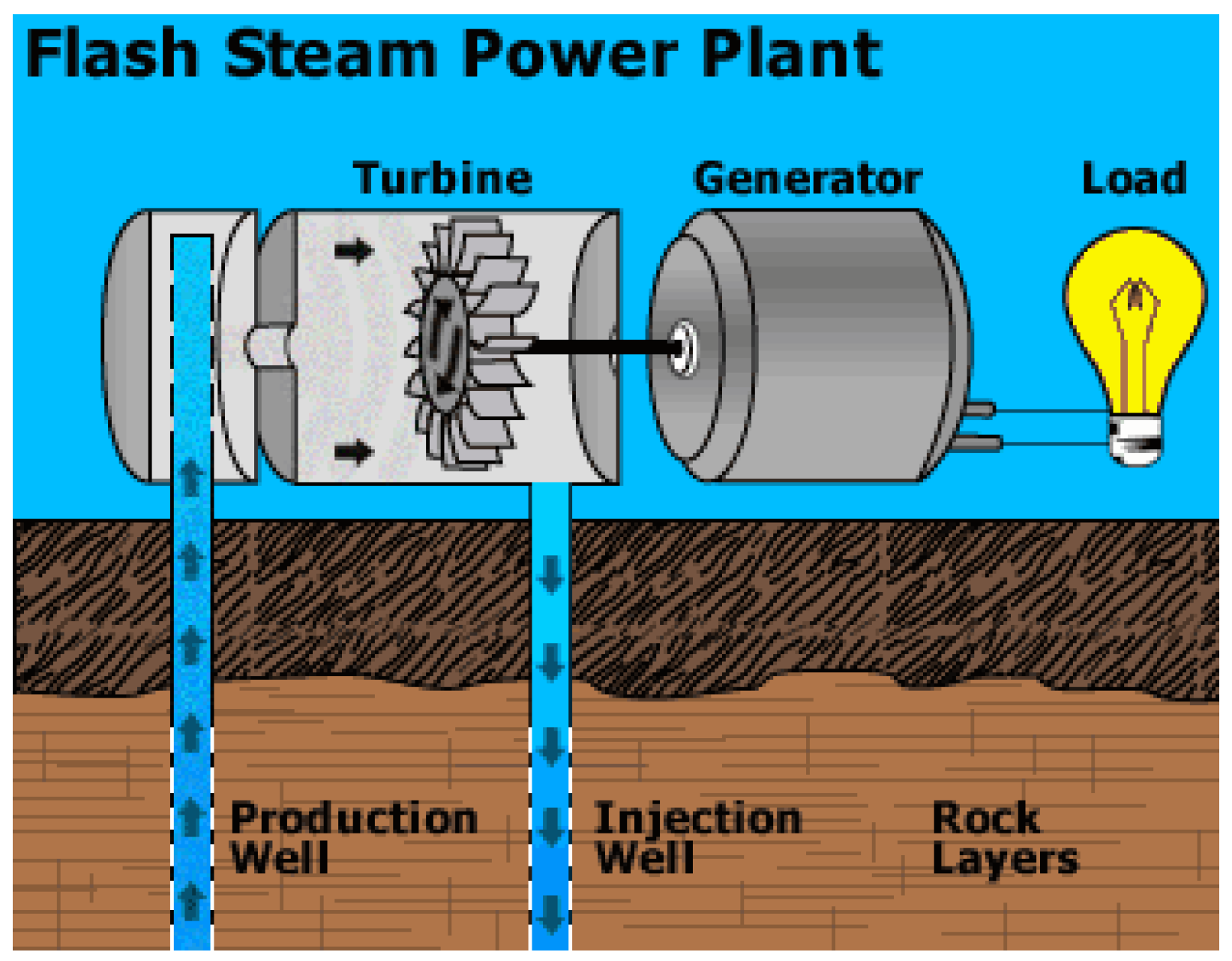

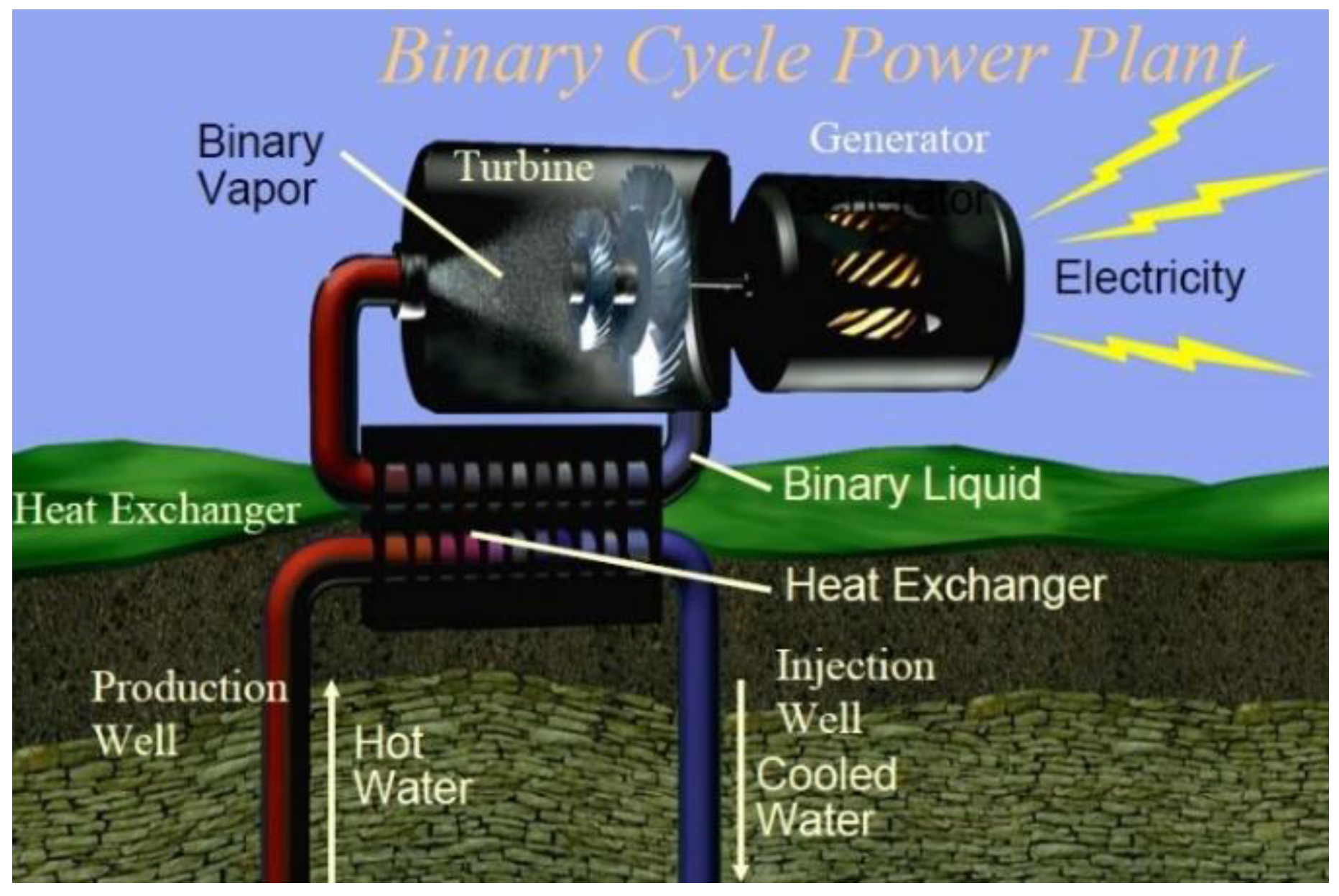

4.1. For Power Generation

4.2. Direct Use

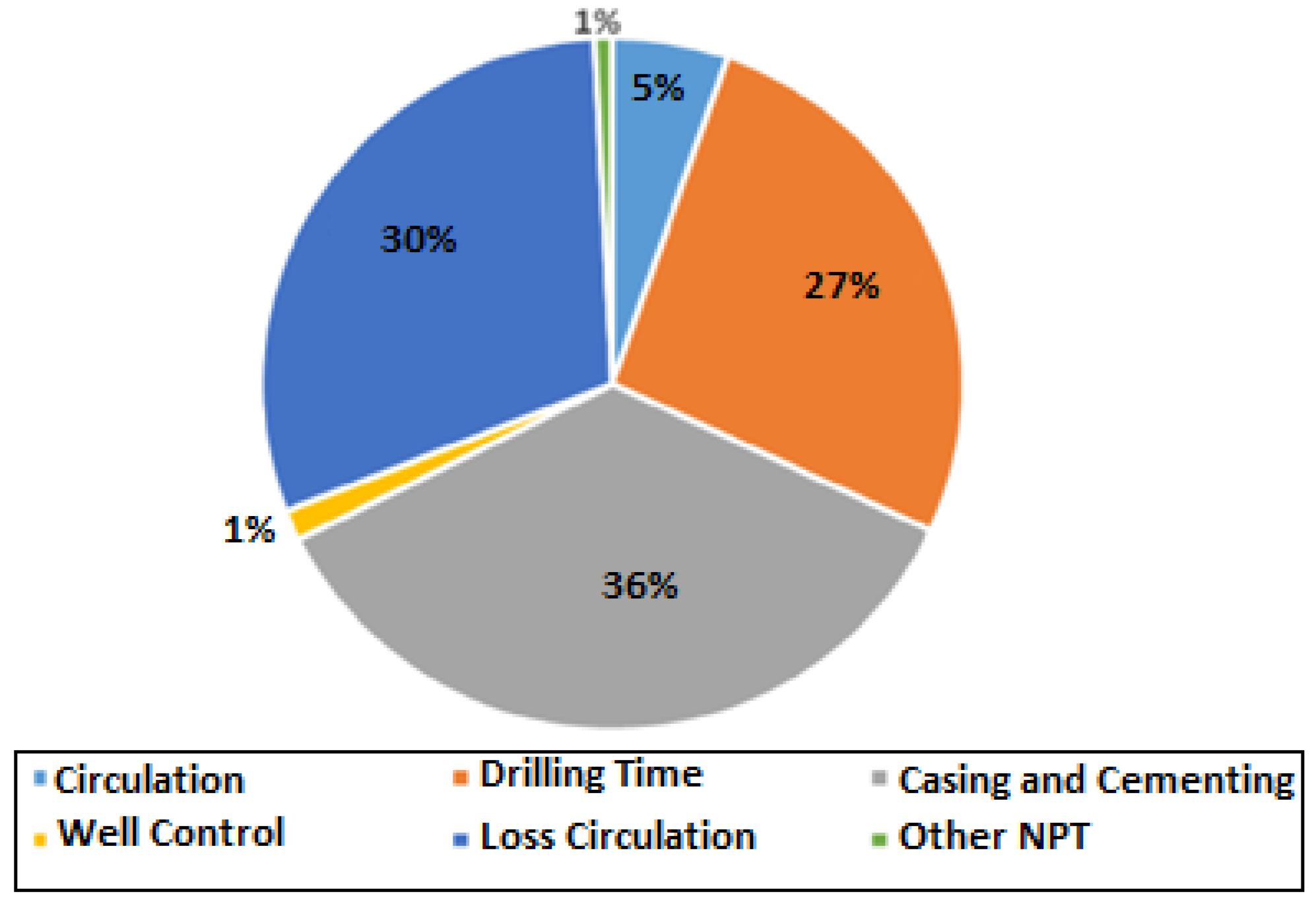

5. Drilling and Completion Challenges for Geothermal Well

5.1. Subsurface Environment

5.2. Corrosion and Scaling

5.3. Wellbore Instability

5.4. Circulation Loss

- Loss of fluid in the well can decrease the static head of the drilling fluid, which can result in a well control issue.

- If the drilling fluid fails to bring the cuttings to the surface, the cuttings can fall back to the bottom hole and stick to the BHA.

- Drilling fluid is expensive, it accounts for 25–40% of the drilling operations cost [49]. Excessive loss of drilling fluid can have a negative effect on the economics of the drilling operation.

5.5. Wellbore Cementing Challenges

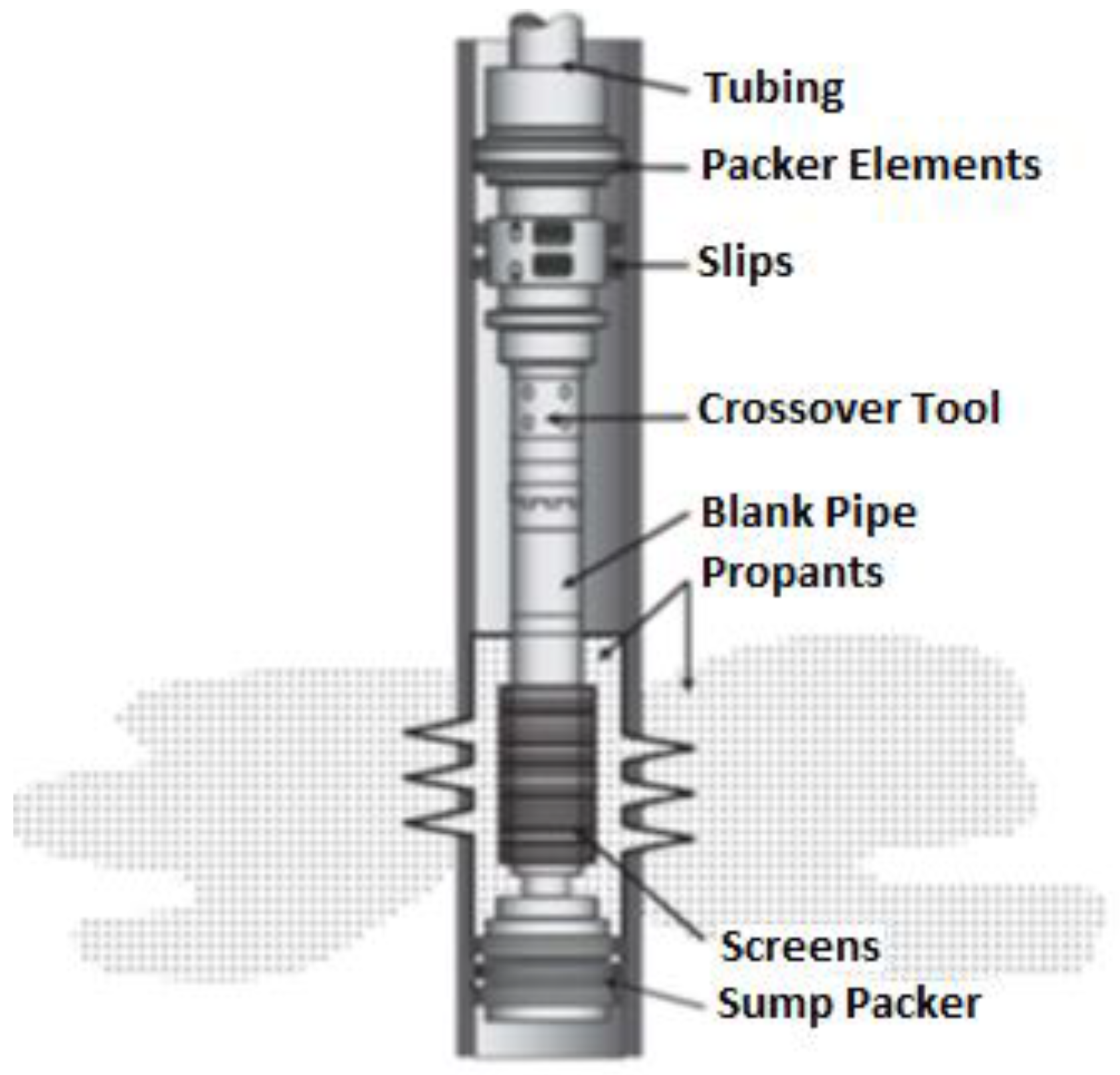

6. Downhole Tools for Geothermal Wells

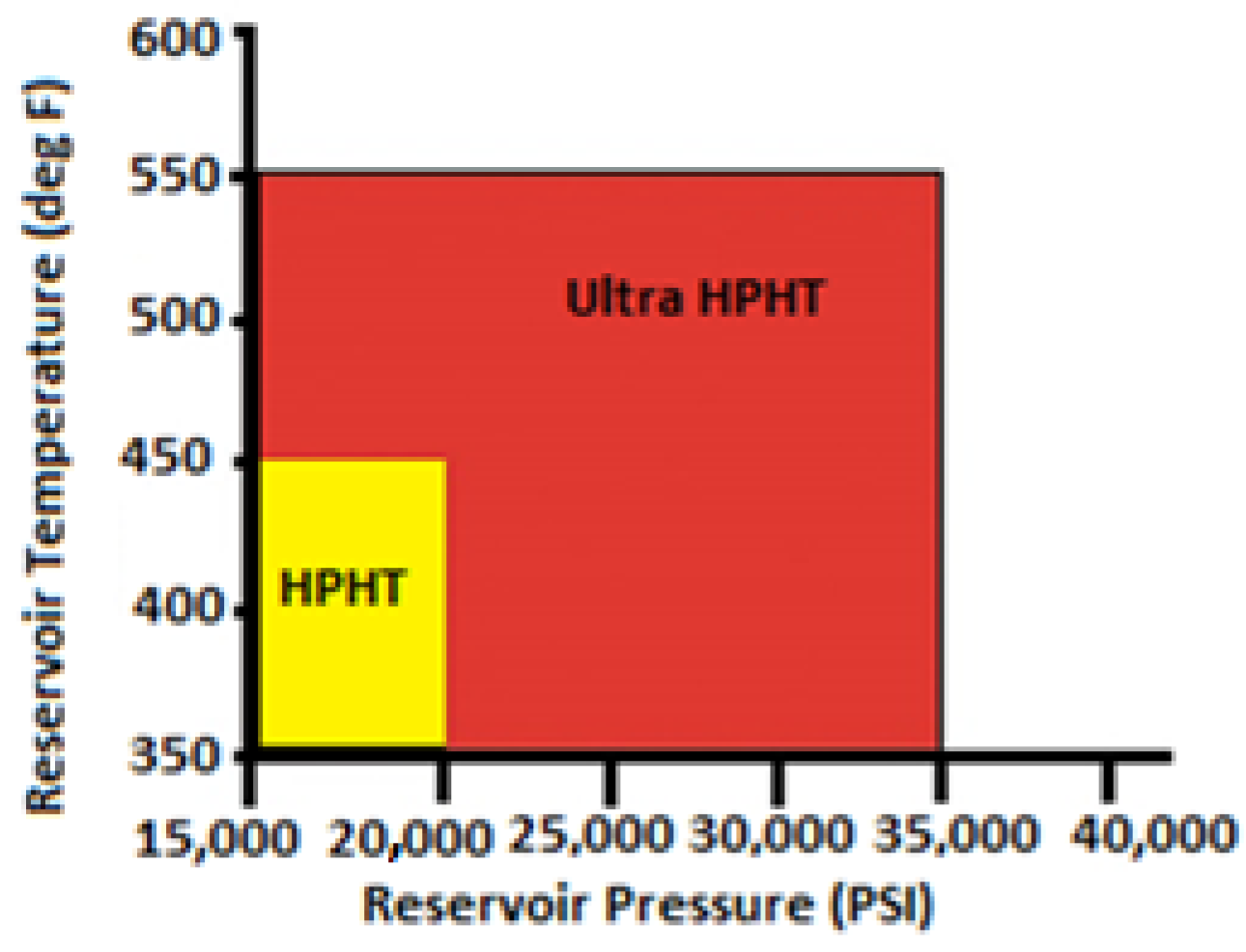

7. Relation of HPHT and Geothermal Well

8. Testing Standard for Packers

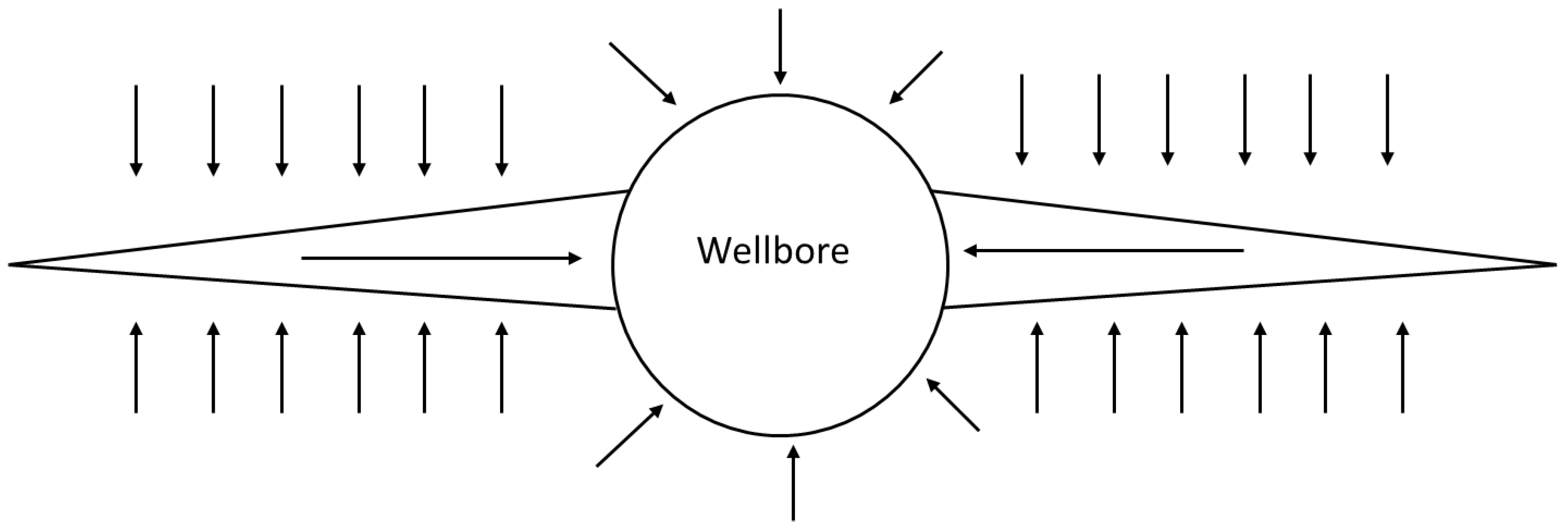

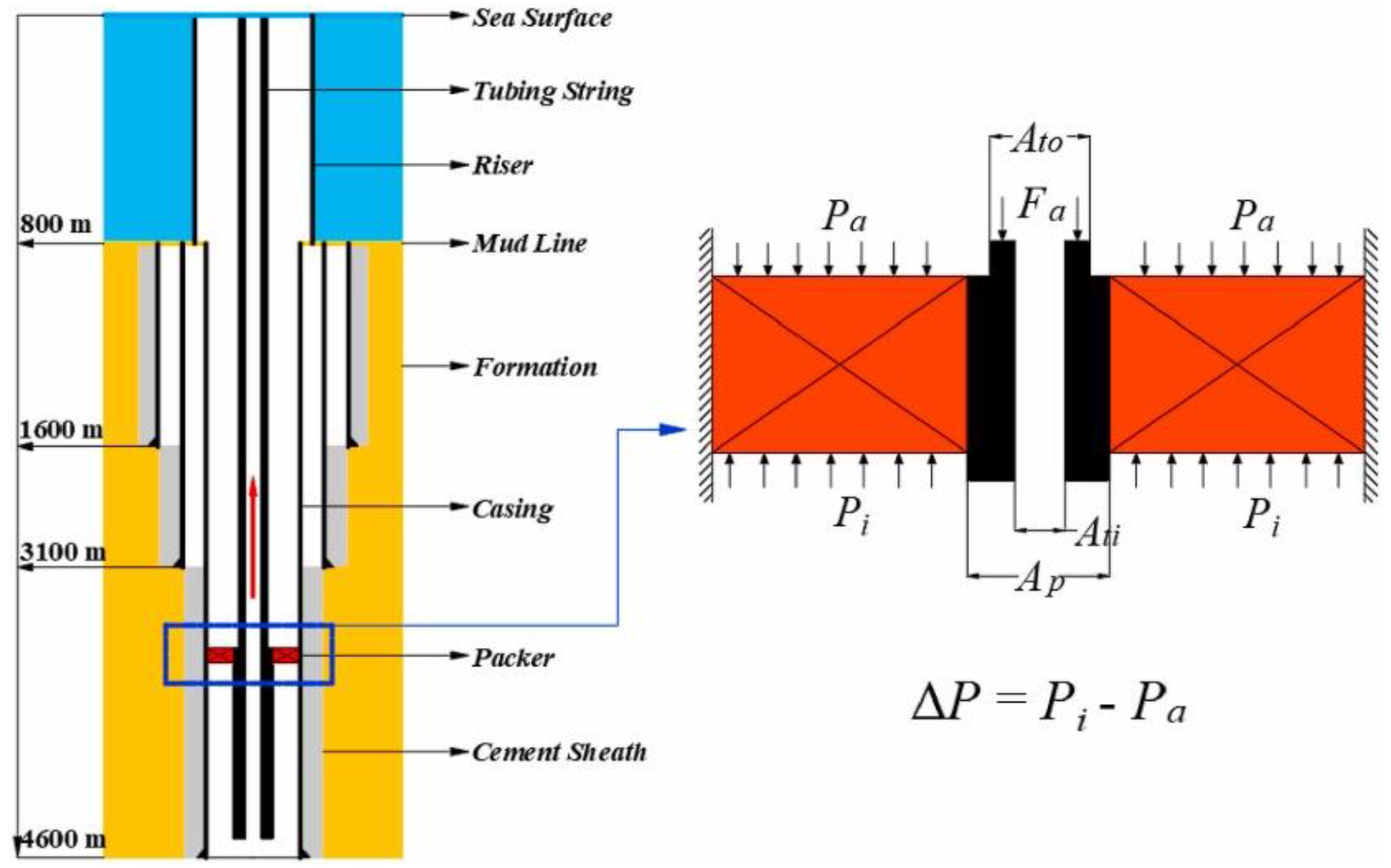

9. Forces Acting on the Packer in HPHT Condition

10. Challenges for Packers and Their Remedial Design

11. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dudley, B. BP Energy Outlook—2017 Edition; British Petroleum: London, UK, 2017. [Google Scholar]

- EIA. International Energy Outlook 2016; U.S. Energy Information Administration: Washington, DC, USA, 2016. [Google Scholar]

- WEC. World Energy Resources 2016; World Energy Council: London, UK, 2016. [Google Scholar]

- Lund, J.W. World Status of Geothermal Use Overview 1995–1999. In Proceedings of the World Geothermal Congress 2000, Kyushu-Tohoku, Japan, 28 May–10 June 2000. [Google Scholar]

- Sui, D.; Wiktorski, E.; Røksland, M.; Basmoen, T.A. Review and investigations on geothermal energy extraction from abandoned petroleum wells. J. Pet. Explor. Prod. Technol. 2018, 9, 1135–1147. [Google Scholar] [CrossRef]

- Budisulistyo, D.; Krumdieck, S. Thermodynamic and economic analysis for the pre-feasibility study of a binary geothermal power plant. Energy Convers. Manag. 2015, 103, 639–649. [Google Scholar] [CrossRef]

- Moya, D.; Aldás, C.; Kaparaju, P. Geothermal energy: Power plant technology and direct heat applications. Renew. Sustain. Energy Rev. 2018, 94, 889–901. [Google Scholar] [CrossRef]

- Shortall, R.; Davidsdottir, B.; Axelsson, G. Geothermal energy for sustainable development: A review of sustainability impacts and assessment frameworks. Renew. Sustain. Energy Rev. 2015, 44, 391–406. [Google Scholar] [CrossRef]

- DOE. A History of Geothermal Energy in America. 2022. Available online: https://www.energy.gov/eere/geothermal/history-geothermal-energy-america#:~:text=Archaeological%20evidence%20shows%20that%20the,as%20a%20source%20of%20healing (accessed on 14 July 2022).

- U.S. Energy Information Administration (EIA). Geothermal Explained: Geothermal Power Plants. 17 December 2021. Available online: https://www.eia.gov/energyexplained/geothermal/geothermal-power-plants.php (accessed on 14 July 2022).

- Finger, J.T.; Blankenship, D.A. Handbook of Best Practices for Geothermal Drilling; Sandia National Laboratory (SNL-NM): Albuquerque, NM, USA, 2012. [Google Scholar] [CrossRef]

- Walters, J.; Thorhallsson, S.; Wood, E. Zonal Isolation for Geothermal Wells; International Partnership for Geothermal Technology: Keflavik, Iceland, 2012. [Google Scholar]

- Pater, C.; Shaoul, J.R. Stimulation for geothermal wells in the Netherlands. Neth. J. Geosci. 2019, 98, e11. [Google Scholar] [CrossRef]

- Murphy, H.; Fehler, M. Hydraulic Fracturing of Jointed Formations. In Proceedings of the International Meeting on Petroleum Engineering, Beijing, China, 17 March 1986. [Google Scholar]

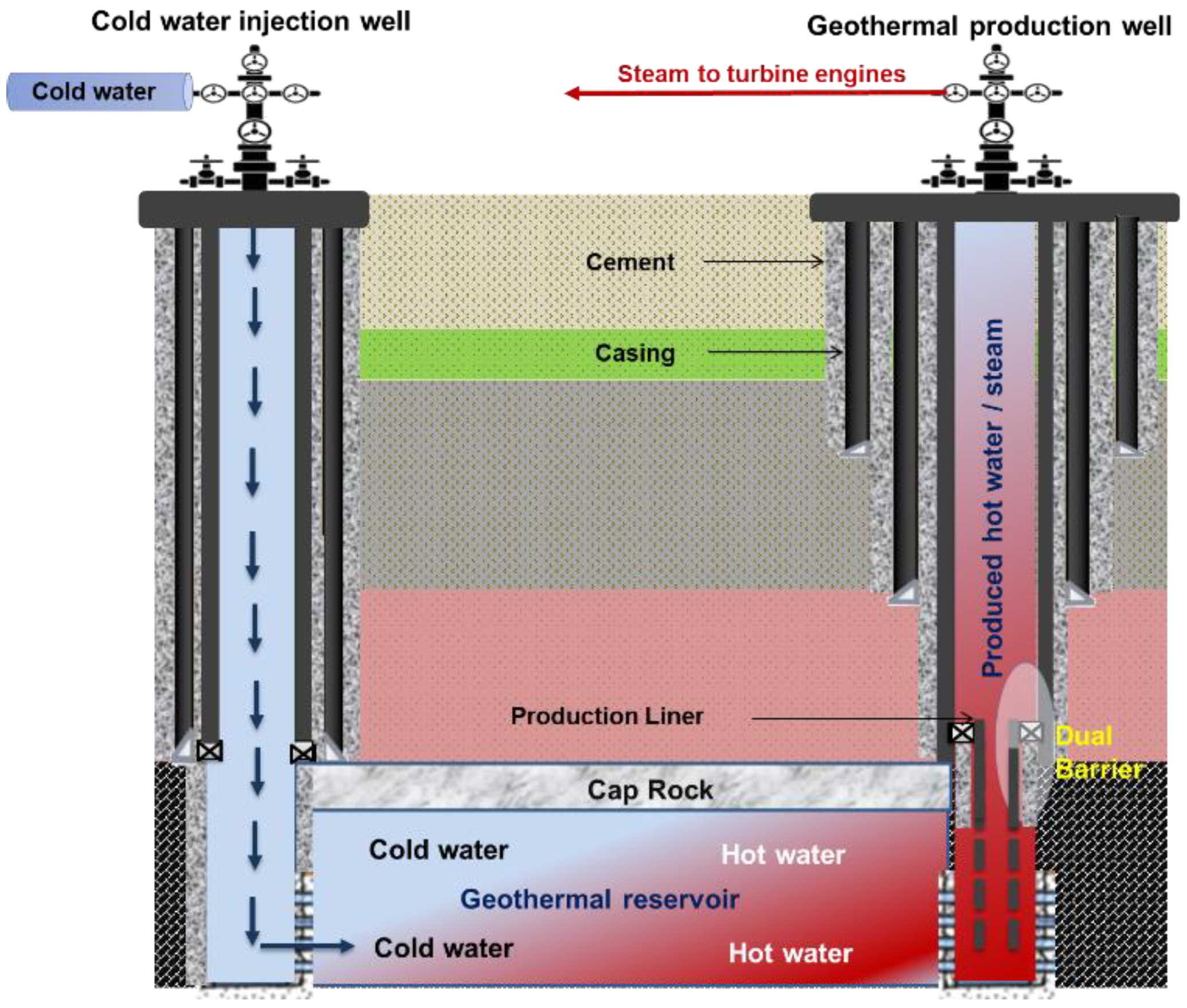

- Ahmed, S.; Patel, H.; Salehi, S.; Ahmed, R.; Teodoriu, C. Performance evaluation of liner dual barrier system in CO2-rich geothermal wells. Geothermics 2021, 95, 102121. [Google Scholar] [CrossRef]

- Karakuş, H. Helium and carbon isotope composition of gas discharges in the Simav Geothermal Field, Turkey: Implications for the heat source. Geothermics 2015, 57, 213–223. [Google Scholar] [CrossRef]

- Bragin, I.V.; Zippa, E.V.; Chelnokov, G.A.; Kharitonova, N.A. Kharitonova, Estimation of the Deep Geothermal Reservoir Temperature of the Thermal Waters of the Active Continental Margin (Okhotsk Sea Coast, Far East of Asia). Water 2021, 13, 1140. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, L.; Liu, X.; A, L.; Zhang, Y. Temperature effect on the transport of nitrate and ammonium ions in a loose-pore geothermal reservoir. J. Geochem. Explor. 2013, 124, 59–66. [Google Scholar] [CrossRef]

- Dincer, I.; Ezzat, M.F. Geothermal Energy Production. In Comprehensive Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 252–303. [Google Scholar]

- Shapely. Renewable Energy Overview. 2011. Available online: http://butane.chem.uiuc.edu/pshapley/Environmental/L8/index.html (accessed on 12 July 2022).

- Williams, C.F.; Reed, M.J.; Mariner, R.H. A Review of Methods Applied by the U.S.; U.S. Geological Survey: Reston, VA, USA, 2008. [Google Scholar]

- White, D.E.; Muffler, L.J.P.; Truesdell, A.H. Vapor-dominated hydrothermal systems compared with hot-water systems. Econ. Geol. 1971, 66, 75–97. [Google Scholar] [CrossRef]

- Truesdell, A.; White, D. Production of superheated steam from vapor-dominated geothermal reservoirs. Geothermics 1973, 2, 154–173. [Google Scholar] [CrossRef]

- Frederick, D.O.; Prestwood, D.C.; Roberts, K.; Vanston, J.H., Jr. Geopressured-Geothermal Commercialization: Four Mid-term Cameos; GRC Transactions: Davis, CA, USA, 1979; pp. 229–232. [Google Scholar]

- Chu, T.Y.; Dunn, J.C.; Finger, J.T.; Rundle, J.B.; Westrich, H.R. The Magma Energy Program, Geothermal Resources Council Bulletin; GRC Transactions: Davis, CA, USA, 1990; pp. 42–52. [Google Scholar]

- Duchane, D.; Brown, D. Hot Dry Rock (HDR) Geothermal Energy Research and Development at Fenton Hill, New Mexico; Oregon Institute of Technology: Klamath Falls, OR, USA, 2002; pp. 13–19. [Google Scholar]

- Allahvirdizadeh, P. A review on geothermal wells: Well integrity issues. J. Clean. Prod. 2020, 275, 124009. [Google Scholar] [CrossRef]

- DOE. A History of Geothermal Energy Research and Development in the United States 1976–2006; Department of Energy: Washington, DC, USA, 2010. [Google Scholar]

- Lavrov, A. Chapter 1—The Challenge of Lost Circulation. In Lost Circulation Mechanisms and Solutions; Elsevier Inc.: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Zoet, A. Geothermal 101: The Basics and Applications of Geothermal Energy; Dovetail Partners Inc.: Minneapolis, MN, USA, 2011. [Google Scholar]

- Hulen, J.; Wright, P. Geothermal Energy–Clean Sustainable Energy for the Benefit of Humanity and the Environment; Energy & Geoscience Institute, University of Utah: Salt Lake City, UT, USA, 2001. [Google Scholar]

- U.S. Energy Information Administration (EIA). Geothermal Explained. 17 December 2021. Available online: https://www.eia.gov/energyexplained/geothermal/ (accessed on 21 September 2022).

- Snow, K. Bontront’s Grade 12 Chemistry. 3 October 2011. Available online: http://jeanbont.pbworks.com/w/page-revisions/36105355/Group%201%20-%20Geothermal?show_all=1 (accessed on 8 April 2022).

- Huttrer, G.W.; Miletto, M. A Brief Introduction to Geothermal Energy and Its Utilization for Electric Power Generation; Organization of American States: Washington, DC, USA, 2008. [Google Scholar]

- U.S. Energy Information Administration (EIA). Geothermal Explained: Where Geothermal Energy Is Found. 19 November 2020. Available online: https://www.eia.gov/energyexplained/geothermal/where-geothermal-energy-is-found.php (accessed on 21 January 2022).

- Welltec. Well Sustained, 2022. Available online: https://welltec.com/geothermal-well-sustained/ (accessed on 18 July 2022).

- Orkustofnun. Economic Benefits of Using Geothermal Energy Instead of Oil for Space Heating In Iceland; Orkustofnun National Energy Authority: Reykjavík, Iceland, 2019. [Google Scholar]

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geothermics 2016, 60, 66–93. [Google Scholar] [CrossRef]

- DiPippo, R. Geothermal Power Generation (Development and Innovation); Woodhead: Deerfield, IL, USA, 2016. [Google Scholar]

- Reinsch, T.; Dobson, P.; Asanuma, H.; Huenges, E.; Poletto, F.; Sanjuan, B. Utilizing supercritical geothermal systems: A review of past ventures and ongoing research activities. Geotherm. Energy 2017, 5, 16. [Google Scholar] [CrossRef]

- Zhang, W.; Sun, Q.; Hao, S.; Geng, J.; Lv, C. Experimental study on the variation of physical and mechanical properties of rock after high temperature treatment. Appl. Therm. Eng. 2016, 98, 1297–1304. [Google Scholar] [CrossRef]

- Wittig, D.; Vollmar, D.; Wittig, V.; Bracke, R. Geothermal Drilling Best Practices: The Geothermal Translation of Conventional Drilling Recommendations-Main Potential Challenges; International Geothermal Association: Den Haag, The Netherlands, 2015. [Google Scholar]

- DeBerry, D.W.; Ellis, P.F.; Thomas, C.C. Materials Selection Guidelines for Geothermal Power Systems; DOE: Washington, DC, USA, 1978. [Google Scholar]

- Nogara, J.; Zarrouk, S.J. Corrosion in geothermal environment: Part 1: Fluids and their impact. Renew. Sustain. Energy Rev. 2018, 82, 1333–1346. [Google Scholar] [CrossRef]

- Diez, H.; Flores, M.; Ramírez, M.; Tovar, R.; Rosales, C.; Solano, F.; Sandova, F. Neutralization of Acid Fluids from Well H-43 (Superheated Steam). In Proceedings of the World Geothermal Congress, Melbourne, Australia, 19–25 April 2015. [Google Scholar]

- McLean, M.; Addis, M. Wellbore Stability Analysis: A Review of Current Methods of Analysis and Their Field Application. In Proceedings of the IADC/SPE Drilling Conference, Houston, TX, USA, 27 February 1990. [Google Scholar]

- Bugbee, J. Lost Circulation—A Major Problem in Exploration and Development. In Proceedings of the Spring Meeting of Southwestern District, Division of Production, State College, NM, USA, 2–3 January 1953. [Google Scholar]

- Nugroho, W.A.; Hermawan, S.; Lazuardi, B.H.; Mirza, R. Drilling Problems Mitigation in Geothermal Environment, Case Studies of Stuck Pipe and Lost Circulation. In Proceedings of the SPE/IATMI Asia Pacific Oil & Gas Conference and Exhibition, Jakarta, Indonesia, 17–19 October 2017. [Google Scholar]

- Lécolier, E.; Herzhaft, B.; Rousseau, L.; Néau, L.; Quillien, B.; Kieffer, J. Development of a Nanocomposite Gel for Lost Circulation Treatment. In Proceedings of the SPE European Formation Damage Conference, Sheveningen, The Netherlands, 25–27 May 2005. [Google Scholar]

- Kruszewski, M.; Ramirez, M.; Wittig, V.; Sanchez, M.; Bracke, R. Drilling and Well Completion Challenges in the Los; GRC Transactions: Ely, UK, 2018. [Google Scholar]

- Ghasemi, M.; Shadravan, A.; Alfi, M. Zonal Isolation in Geothermal Wells. In Proceedings of the Fortieth Workshop on Geothermal Reservoir Engineering, Stanford, CA, USA, 26–28 January 2015. [Google Scholar]

- Pierce, K.G.; Livesay, B.J.; Finger, J.T. Advanced Drilling Systems Study; DOE: Albuquerque, NM, USA, 1996. [Google Scholar] [CrossRef]

- Arbad, N.; Emadi, H.; Watson, M. A comprehensive review of geothermal cementing from well integrity perspective. J. Pet. Sci. Eng. 2022, 217, 110869. [Google Scholar] [CrossRef]

- Saito, S. MWD and Downhole Motor Performance in Very High Temperature Geothermal Wells in Kakkonda, Japan. In Proceedings of the World Geothermal Congress, Florence, Italy, 18–31 May 1995. [Google Scholar]

- Schlumberger. Rhino Integrated Borehole Enlargement System. 2021. Available online: https://www.slb.com/drilling/bottomhole-assemblies/reamers-and-stabilizers/rhino-integrated-borehole-enlargement-system#related-information (accessed on 13 September 2022).

- Liu, W.; Kai, G. Drilling Technical Difficulties and Solutions in Development of Hot Dry Rock Geothermal Energy. Adv. Pet. Explor. Dev. 2017, 13, 63–69. [Google Scholar]

- JRG Energy. High Temp Plugs and Wellhead Removal. 2022. Available online: https://www.jrgenergy.com/plugsandpackers (accessed on 13 September 2022).

- Li, Y.; She, C.; Liu, N.; Zhang, H.; Zhang, L.; Zhu, D. Completion difficulties of HTHP and high-flowrate sour gas wells in the Longwangmiao Fm gas reservoir, Sichuan Basin, and corresponding countermeasures. Nat. Gas Ind. B 2016, 3, 269–273. [Google Scholar] [CrossRef]

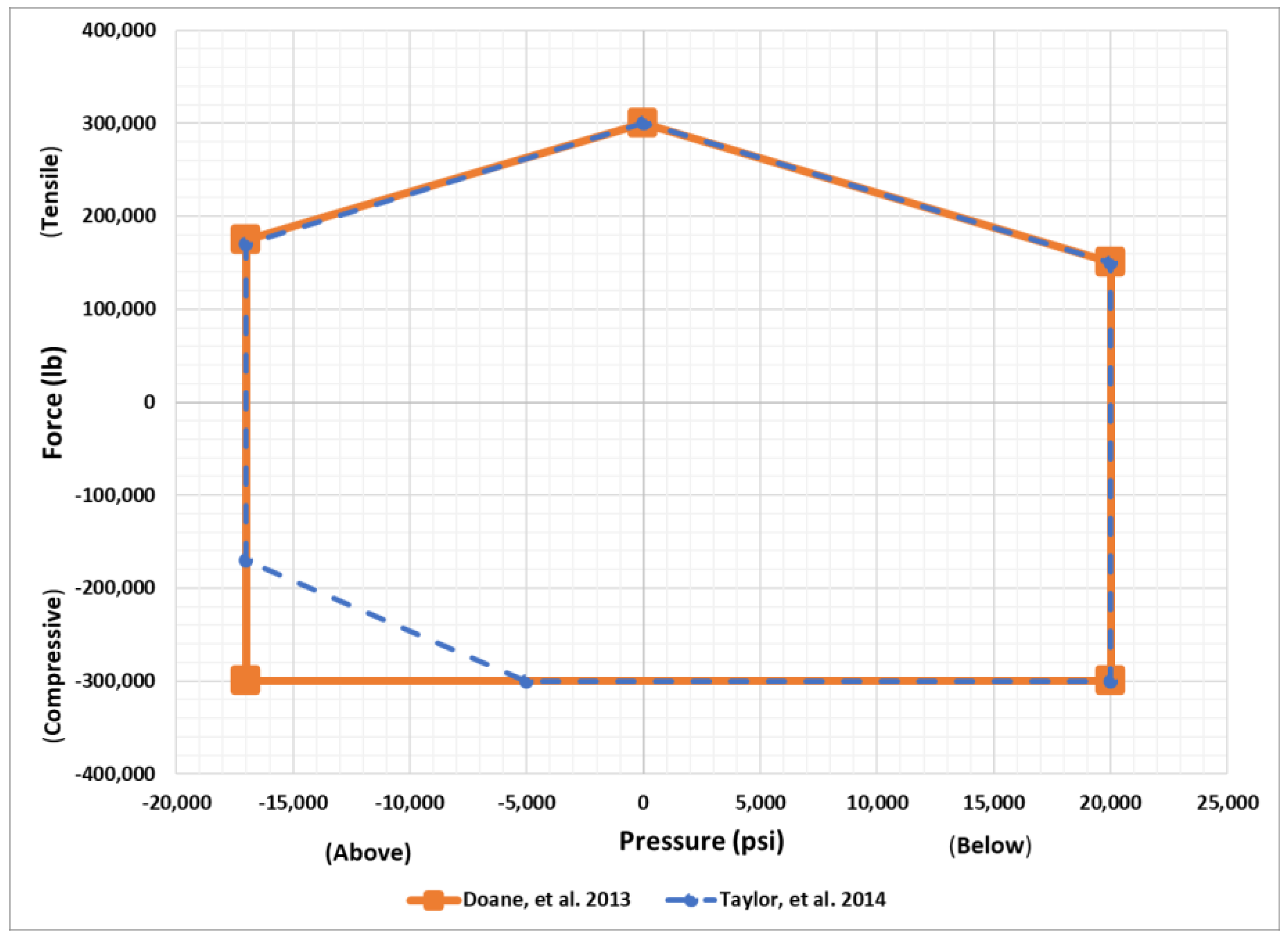

- Doane, J.; Deng, G.; Collins, S.; Anderson, G. Pushing the Boundary of Ultra-HPHT Completion Technology: The First 20,000 psi, 470 °F Permanent Production Packer for As-Rolled Casing. In Proceedings of the International Petroleum Technology Conference, Bejing, China, 26–28 March 2013. [Google Scholar]

- Doane, J.; Deng, G.; Collins, S. A Completion Technology Milestone-The First 25,000 psi 500 °F Packer Seal System. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- ISO 14310: 2008; Petroleum and Natural Gas Industries—Downhole Equipment—Packers and Bridge Plugs. ISO: Geneva, Switzerland, 2018.

- API Specification 11D1; Petroleum and Natural Gas Industries—Downhole Equipment—Packers and Bridge Plugs, First Edition. API: Washington, DC, USA, 2002.

- Hu, Z.; Yang, J.; Liu, S.; Li, W.; Li, S.; Tong, G. Prediction of sealed annular pressure between dual packers in HPHT deepwater wells. Arab. J. Geosci. 2018, 11, 489. [Google Scholar] [CrossRef]

- Sadana, A.; Kovalchuk, A.; Cook, C. Delayed Oil Swell Packer for Openhole Zonal Isolation of Long Laterals Wells. In Proceedings of the International Petroleum Technology Conference, Dhahran, Saudi Arabia, 13–15 January 2020. [Google Scholar] [CrossRef]

- Gao, B.; Wang, L.; Hu, T. Testing String Dynamics When Jarring Stuck Packer. In Proceedings of the 29th International Ocean and Polar Engineering Conference, Honolulu, HI, USA, 16–21 June 2019. [Google Scholar]

- Zhao, Y.; Li, H.; Xie, J.; Fan, L.; Jiao, S.; Hu, Y. Failure factors analysis and countermeasures of the casing-packer during well completion test. Technol. Superv. Petrol. Ind. 2016, 32, 52–56. (In Chinese) [Google Scholar]

- Li, C.; Guan, Z.; Zhang, B.; Wang, Q.; Xie, H.; Yan, Y.; Han, C. Failure and mitigation study of packer in the deepwater HTHP gas well considering the temperature-pressure effect during well completion test. Case Stud. Therm. Eng. 2021, 26, 101021. [Google Scholar] [CrossRef]

- Kang, Y.; Samuel, R.; Gonzales, A.; Liu, Z. Force Calculation with Oil Well Packer: A Revisit. In Proceedings of the InInternational Petroleum Technology Conference 2020, Dhahran, Saudi Arabia, 16 January 2020. [Google Scholar] [CrossRef]

- Hirasuna, A.; Friese, G.; Stephens, C. A Proven Elastomer Compound for Extremely Hostile Geothermal and Oilfield Environments. In Proceedings of the SIADC/SPE Drilling Conference, New Orleans, LA, USA, 20 February 1983. [Google Scholar]

- Dreesen, D.S.; Miller, J.R.; Halbardier, F.A.; Nicholson, R.W. Open hole Packer for High-Temperature Service in a 500 °F Precambrian Wellbore. SPE Prod. Eng. 1988, 3, 351–360. [Google Scholar] [CrossRef]

- Dreesen, D. Analytical and Experimental Evaluation of Expanded Metal Packers for Well Completion Service. In Proceedings of the SPE, Dallas, TX, USA, 6–9 October 1991. [Google Scholar]

- Polsky, Y.; Capuano, L.; Finger, J.; Huh, M.; Knudsen, S.; Mansure, A.C.; Raymond, D.; Swanson, R. Enhanced Geothermal Systems (EGS) Well Construction Technology Evaluation Report; Sandia National Laboratories: Albuquerque, NM, USA, 2008. [Google Scholar]

- Robb, T.E.; Valentine, E. New 9-?-in. HPHT Permanent Packer with New Back-Up System Provides North Sea Operator with Effective Solution for Damaged or Worn Casing. In Proceedings of the SPE Deep Gas Conference and Exhibition 2010, Manama, Bahrain, 24 January 2010. [Google Scholar] [CrossRef]

- Carroll, T. Successful selection of oil and gas seals. World Pumps 2016, 2016, 28–30. [Google Scholar] [CrossRef]

- Taylor, R.; Doane, J.; Anderson, G.; Deng, G.; Collins, S.; Ansohn, T. API 11D1/ISO 14310 Grade V0 Qualified Ultra-HPHT Permanent Production Packers. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2014. [Google Scholar]

- Suarez, A.V.; Young, C.; Urban, L.; Anderson, G.; Bisset, S. Ultra HP/HT Removable Production Packer for Deep Water Applications. In Proceedings of the Offshore Technology Conference 2017, Houston, TX, USA, 1–4 May 2017. [Google Scholar] [CrossRef]

- Patel, H.; Salehi, S.; Ahmed, R.; Teodoriu, C. Review of elastomer seal assemblies in oil & gas wells: Performance. J. Pet. Sci. Eng. 2019, 179, 1046–1062. [Google Scholar]

- Yu, C.; Xu, Z.; Shyu, G.-D.; Prieto, C. Development of Advanced Seal Material and Downhole Packer for High. In Proceedings of the Offshore Technology Conference 2017, Houston, TX, USA, 1–4 May 2017. [Google Scholar]

- Coronado, M.P.; Bjørkesett, H.; Jiral, D.G.; Førdedal, H. Advanced Openhole Completions Utilizing a Simplified Zone Isolation System. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September 2002. [Google Scholar]

- Deng, G.; Shyu, G.-D. An Innovative Approach to Optimizing Design of HP/HT Well Tubular Strings. In Proceedings of the SPE Annual Technical Conference and Exhibition (ATCE 2010), Florence, Itlay, 20–22 September 2010. [Google Scholar] [CrossRef]

- Mills, A.; Deng, G.; Wakefield, J.; Prieto, C. Extreme Expansion Openhole Packer with HP/HT Capabilities. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar] [CrossRef]

- Lan, W.-J.; Wang, H.-X.; Zhang, X.; Chen, S.-S. Sealing properties and structure optimization of packer rubber under high pressure and high temperature. Pet. Sci. 2019, 16, 632–644. [Google Scholar] [CrossRef]

- Plessing, H.; Arnskov, M.M. A Novel Well Annular Barrier Solution Alternative to Swellable Casing Packers. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 30 October–2 November 2011. [Google Scholar]

- Bårdsen, J.; Hazel, P.; Vasques, R.R.; Hjorteland, Ø.; Eikeskog, Ø. Improved Zonal Isolation in Open Hole Applications. In Proceedings of the SPE Bergen One Day Seminar, Bergen, Norway, 2 April 2014. [Google Scholar] [CrossRef]

- Bårdsen, J.; Dagestad, V.; Sliper, B.; Nilsen, L.H.; Eshraghi, D.; Lunkad, S. Novel Approach to Combat the B-annulus Pressure Build-up Challenge. In Proceedings of the International Petroleum Exhibition and Conference, Abu Dhabi, United Arab Emirates, 9–12 November 2015. [Google Scholar] [CrossRef]

- Bårdsen, J.; Dagestad, V. Evolution of a Well Annular Barrier for Mitigation of SCP. In Proceedings of the One Day Seminar, Bergen, Norway, 20 April 2016. [Google Scholar] [CrossRef]

- Welltec. Welltec Magma Packer. 21 April 2021. Available online: https://welltec.com/media/6541/welltec-a4-wmp-wab-for-geothermal-application.pdf?mode=pad&rnd=132651040510000000 (accessed on 19 July 2022).

- Roy, T.; Ben Naceur, K.; Singh, M.; Markel, D.; Harp, L.; Ardic, H.; Wilkinson, C.; Roy, I. Design of a 750 °F, 15 K packer for Enhanced Geothermal Systems, Supercritical CO2—Sequestration and SAGD: Energy Transition Through Technology Synthesis. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2022. [Google Scholar] [CrossRef]

- Packerplus. HPHT Solutions. 2022. Available online: https://packersplus.com/solution/hpht/ (accessed on 13 September 2022).

| Range | Temperature | Dominated Fluid | Application |

|---|---|---|---|

| High temperature | Above 150 °C | Vapor and liquid | Fuel and power generation |

| Medium temperature | Around 95 °C | Mostly liquid | Electricity production by utilizing binary plant |

| From 90 °C to 150 °C | Drying of timber, refrigeration, cooling, or heating of buildings | ||

| Low Temperature | From 90 °C to 30 °C | Liquid | Aquaculture, processing of food, and heating of the greenhouse |

| Below 30 °C | Warming of soil |

| USA States | Share Contributed by the State with Respect to the U.S. Geothermal Electricity Generation | Share of the Electricity Generated for the Given State |

|---|---|---|

| California | 70.5% | 6.1% |

| Nevada | 24.5% | 10.2% |

| Utah | 2.1% | 1.0% |

| Hawaii | 1.2% | 2.2% |

| Oregon | 0.9% | 0.2% |

| Idaho | 0.5% | 0.5% |

| New Mexico | 0.3% | 0.2% |

| Country (MWt/Population) | TJ/Year/Population |

|---|---|

| Iceland (6.26) | 82.04 |

| Sweden (0.57) | 5.30 |

| Finland (0.28) | 3.29 |

| Norway (0.25) | 1.61 |

| Switzerland (0.22) | - |

| Including Heat Pumps | |

|---|---|

| Country (MWt) | TJ/year |

| China (17,870) | 174,352 |

| USA (17,416) | 75,862 |

| Sweden (5600) | 51,920 |

| Turkey (2937) | 45,892 |

| Germany (2849) | - |

| Iceland (-) | 26,717 |

| Excluding Heat Pumps | |

| China (6089) | 74,041 |

| Turkey (2894) | 44,932 |

| Japan (2086) | 25,630 |

| Iceland (2035) | 26,700 |

| India (986) | - |

| Hungry (-) | 9573 |

| Grade | Liquid | Gas | Pressure | Loading (Axial and Tensile) | Temperature Cycle | Gas Tight |

|---|---|---|---|---|---|---|

| V6 * | ||||||

| V5 | ✓ | ✓ | ||||

| V4 | ✓ | ✓ | ✓ | |||

| V3 | ✓ | ✓ | ✓ | ✓ | ||

| V2 | ✓ | ✓ | ✓ | |||

| V1 | ✓ | ✓ | ✓ | ✓ | ||

| V0 | ✓ | ✓ | ✓ | ✓ | ✓ |

| Test | Description | Casing ID | Temp. Max/Min (°F) | Max Pressure Above/Below (psi) | ISO V0/V3 | Notes |

|---|---|---|---|---|---|---|

| A | Test the slip system to a maximum axial force of 900,000 lbs and retrieve | 8.875″ | Ambient | N/A | N/A | Pass. Slip system withstood 900 k lbs. of applied axial force. The slips successfully retrieved post-test |

| B | Validate to V0 at maximum casing ID and 17,500 psi | 8.875″ | 400/200 | 17,500/17,500 | V0 | Pass. The packer successfully met the design validation requirements of ISO14310 ANSI/API11D1 Grade V0 for 17.5 k psi differential performance from 200–400 °F |

| C | Validate to V0 acceptance criteria in minimum casing ID and 17,500 psi | 8.500″ | 400/200 | 17,500/17,500 | N/A (min ID) | Pass. The packer was successfully set at 200 °F, tested to 17.5 k psi differential per the rating envelope, gas-tight, no bubbles, and retrieved in minimum ID casing |

| D | Validate to V0 at maximum casing ID and 20,000 psi | 8.875″ | 450/200 | 20,000/20,000 | V0 | Pass. The packer successfully met the design validation requirements of ISO14310 ANSI/API11D1 Grade V0 for 20 k psi differential performance from 200–450 °F |

| Geotermal—All Metal | Geothermal—PTFE (Spring Energizad) | |||

|---|---|---|---|---|

| Welltec® WAB® | 812 Magma HT | 614 Magma | 812 Magma | 1214 Magma |

| Expansion Range (mm) | 8.50″ > 9.50″ (215.9 > 241.3 mm) | 6.25″ > 7.20″ (158.8 > 182.9 mm) | 8.50″ > 9.50″ (215.9 > 241.3 mm) | 12.25″ > 13.50″ (311.1 > 342.9 mm) |

| Minimum Running OD (mm) | 8.180″ (207.8 mm) | 5.900″ (150.0 mm) | 8.180″ (207.8 mm) | 11.380″ (289.1 mm) |

| Maximum Working Pressure psi (bar) | 6000 (414 bar) | 5000 psi (345 bar) | 10,000 psi (690 bar) | 6000 psi (414 bar) |

| Constant element ΔP across expansion range psi (bar) | 6000 (414 bar) | 5000 psi (345 bar) | 10,000 psi (690 bar) | 6000 psi (414 bar) |

| Standard element lengths ft (m) | Up to 6.4 ft (2 m) packer length can be customized | |||

| Temperature range °C (°F) | 300 °C (572 °F) | 260 °C (500 °F) | 260 °C (500 °F) | 260 °C (500 °F) |

| Base-pipe range (up to) | 7″ | 4 1/2″ | 7″ | 9 7/8″ |

| ID in (mm) | Full Bore (as per base-pipe) | |||

| Author | Packer/Sealing System | Element | Minimum Temperature (°F) | Maximum Temperature (°F) | Pressure (psi) | Tension/Compression (lbs) | Casing ID (Inches) | Challenges | Novelty/Solution |

|---|---|---|---|---|---|---|---|---|---|

| Dreeesen, et al. (1988) [70] | Open hole retrievable packers | Elastomer | 300 | 500 | 5450 | N/A | 9.2 (open hole) | Two parallel wells were to be connected through the fracturing in the impermeable layers. The conventional packers failed to perform the stimulation job | Elastomer and steel expansion element were integrated as a single packer and was able to connect the two wells through stimulation job |

| Robb and Valentine (2010) [73] | Permanent | AFLAS | 343 | 450 | 15,000 | 400,000/400,000 | 9.625 | Due to the worn-out casing in HPHT well the packer failed, and leakage happened | Developed a permanent packer design that was tested successfully in the worn-out casing |

| Doane, et al.(2012) [60] | Sealing system mounted on packer chassis | Perfluoro elastomer | 250 | 450 | 25,000 | 240,000/490,000 | 7.625 | The rubber element in the conventional packer becomes soft and extrudes over the backup ring in HPHT condition, which hinders the contact of the backup ring with the casing ID | The sealing system combined the design of ZXP and Premier packers |

| Doane, et al. (2013) [59] | Permanent | Perfluoro elastomer | 300 | 470 | 20,000 | 300,000/300,000 | 6.625 | Conventional packers have not shown good performance in the as-rolled casing | The packer consisted of three-piece element system that was coupled with the radially expandable seal setting. It was successfully tested in the as-rolled casing |

| Bårdsen, et al. (2014) [84] | Permanent | Elastomer | 20 | 90 | 5000 | 300,000/300,000 | Full bore | Effective annular isolation of the well | Full well bore metallic swellable packer with elastomer as a sealing element |

| Mills, et al. (2016) [81] | Hydraulically set short radius packer for open hole | Polymeric material | 200 | 350 | 13,000 | N/A | N/A | The backup ring in the short radius packer limits the extension of the elastomers | A nested backup ring was designed, which allowed the extension of 288% more than the conventional short radius packer |

| Suarez, et al. (2017) [76] | Retrievable | N/A | 200 | 450 | 20,000 | 900,000/900,000 | 8.875 | Use of retrieval packers in ultra-HPHT condition | Slip saver technology was deployed in the packer to release the trapped pressure in the packer element before the slips can be retrieved |

| Yu, et al. (2017) [78] | Model-D packer element systems | Porous Metallic structure | N/A | 450 | 6000 | 50,000 (setting force) | 6.25 | The rubber seal is degradable in an HPHT environment while the metal-to-metal seal is not favorable due to its low elasticity | Developed thermoplastic-Lattice metal composite seal |

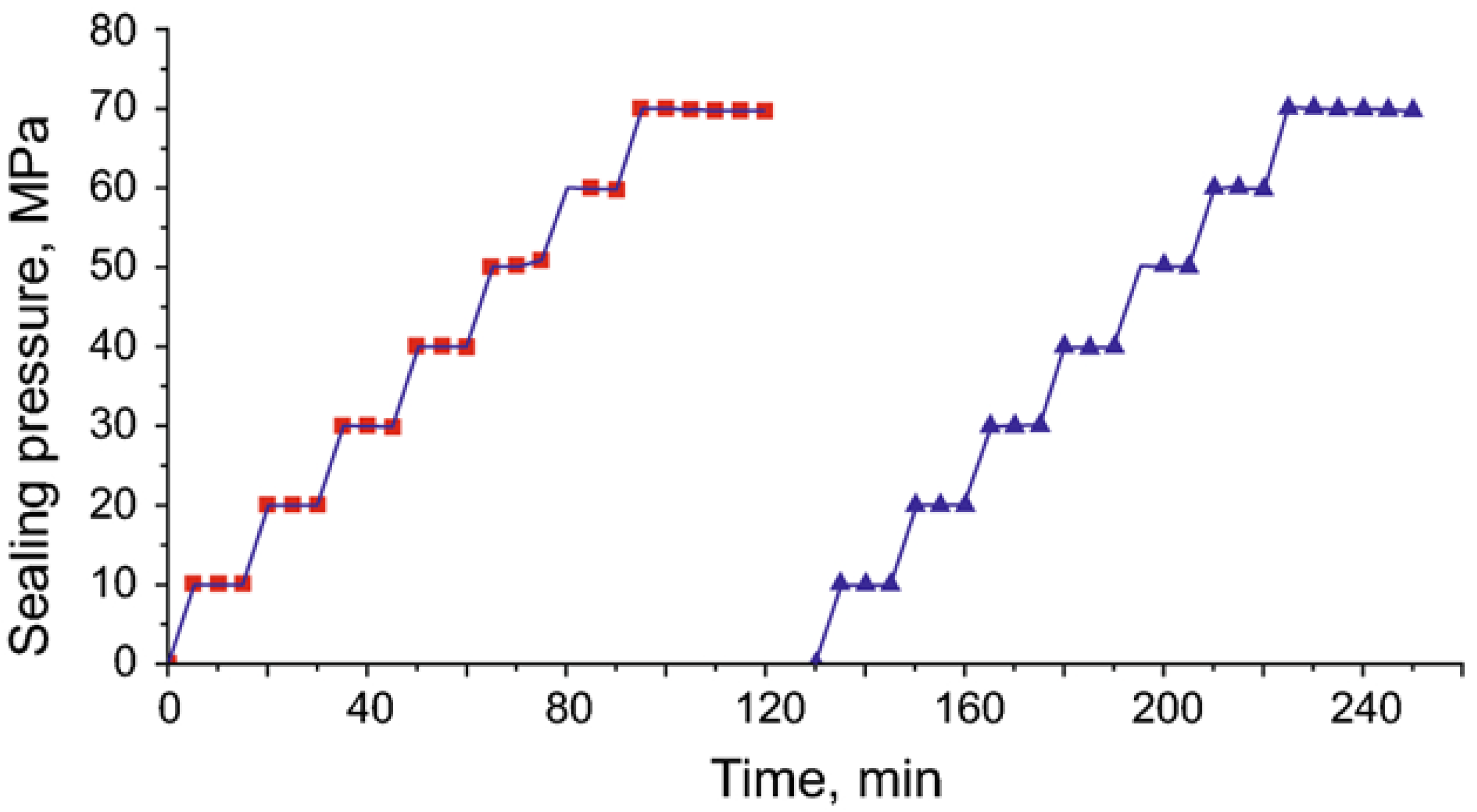

| Lan, et al. (2019) [82] | Sealing system | AFLAS and HNBR | N/A | 170 | 70 | N/A | 6 | Multistage fracturing in horizontal well | Single barrel rubber with expandable ring for multistage fracturing in horizontal well |

| Roy, et al. (2022) [88] | Sealing system and packer (Still in pilot phase) | Elastomer | N/A | >750 | 15,000 | N/A | N/A | The limitation of metal packers is that it does not provide good sealing when installed in rolled or corroded casing | Elastomer encapsulated in an insulated flexible gel that has a low thermal conductivity that acts as a protective layer. Then placed in flexible nano metallic Grain Body Engineered (GBE) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abid, K.; Sharma, A.; Ahmed, S.; Srivastava, S.; Toledo Velazco, A.; Teodoriu, C. A Review on Geothermal Energy and HPHT Packers for Geothermal Applications. Energies 2022, 15, 7357. https://doi.org/10.3390/en15197357

Abid K, Sharma A, Ahmed S, Srivastava S, Toledo Velazco A, Teodoriu C. A Review on Geothermal Energy and HPHT Packers for Geothermal Applications. Energies. 2022; 15(19):7357. https://doi.org/10.3390/en15197357

Chicago/Turabian StyleAbid, Khizar, Aditya Sharma, Shawgi Ahmed, Saket Srivastava, Alberto Toledo Velazco, and Catalin Teodoriu. 2022. "A Review on Geothermal Energy and HPHT Packers for Geothermal Applications" Energies 15, no. 19: 7357. https://doi.org/10.3390/en15197357

APA StyleAbid, K., Sharma, A., Ahmed, S., Srivastava, S., Toledo Velazco, A., & Teodoriu, C. (2022). A Review on Geothermal Energy and HPHT Packers for Geothermal Applications. Energies, 15(19), 7357. https://doi.org/10.3390/en15197357