Toward Circular Supply Chains for Flat Glass: Challenges of Transforming to More Energy-Efficient Solutions

Abstract

1. Introduction

2. Literature Review

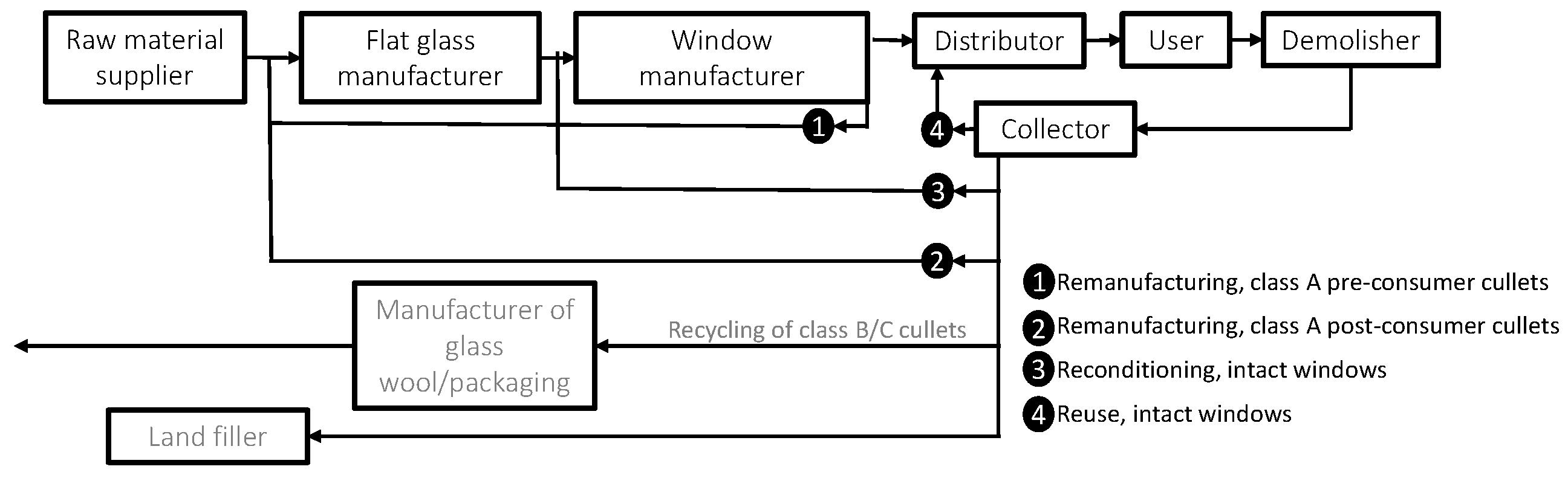

2.1. Different CLSC Types

2.2. Challenges Regarding Material Characteristics and Quality

- High contamination risk for flat glass manufacturers;

- Windows are not designed for recycling—challenging to safely disassemble glass;

- Lack of flat glass material knowledge;

- Difficult to safely identify, mark, and sort different glass qualities.

2.3. Challenges Regarding Inefficient Logistics Systems

- Lack of logistics and recycling knowledge;

- Lack of storage space for windows to enable consolidation;

- Lack of storage space for cullets to enable consolidation;

- Complex international transports are required.

2.4. Challenges Regarding Demand and Supply

- Lack of supply of class A cullets.

2.5. Challenges Regarding Means of Control and Costs

- Low compliance with the new EU legislation;

- Lack of cost knowledge and business cases.

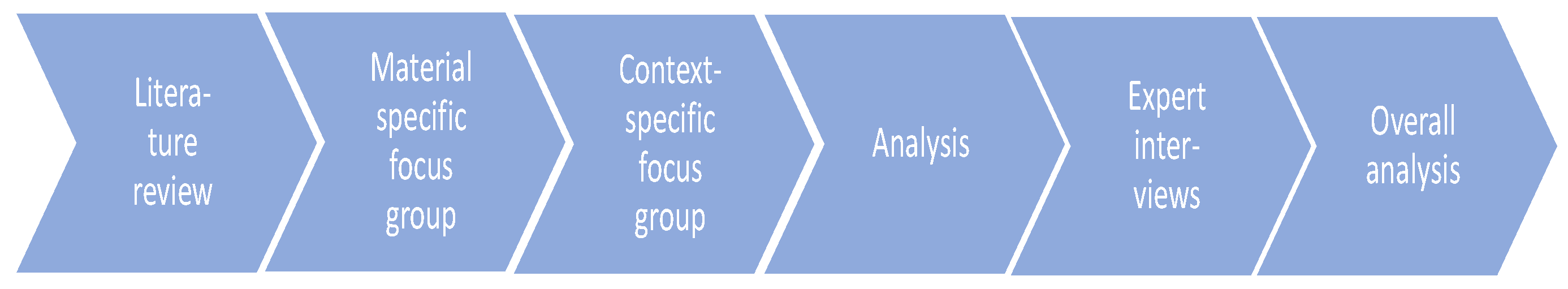

3. Methods

4. Empirical Findings

4.1. Glass Stakeholders’ Focus Group

4.2. Construction Stakeholders’ Focus Group

4.3. Expert Interviews

5. Results and Discussion

5.1. CLSC Types, Actors Involved and Energy Efficiency Potential

5.2. CLSC Challenges for Flat Glass

5.3. Challenges in Applying Different Types of CLSC for Flat Glass

6. Conclusions, Contributions, Limitations, and Further Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Majiwala, H.; Kant, R. A state-of-art review of circular economy in the supply chain management: Scientometric mapping. Manag. Environ. Qual. 2022, 33, 1226–1248. [Google Scholar] [CrossRef]

- Bhatia, M.S.; Jakhar, S.K.; Mangla, S.K.; Gangwani, K.K. Critical factors to environment management in a closed loop supply chain. J. Clean. Prod. 2020, 255, 120239. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.; Haughton, M.; Khosrojerdi, A. Closed-loop supply chain network design under disruption risks: A robust approach with real world application. Comput. Ind. Eng. 2018, 116, 178–191. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability and energy-efficient supply chain management: A Review of Research Trends and Proposed guidelines. Energies 2018, 11, 275. [Google Scholar] [CrossRef]

- Shimada, T.; van Wassenhove, L.N. Closed-Loop supply chain activities in Japanese home appliance/personal computer manufacturers: A case study. Int. J. Prod. Econ. 2019, 212, 259–265. [Google Scholar] [CrossRef]

- Guide, V.D.R.; van Wassenhove, L.N. The evolution of closed-loop supply chain research. Oper. Res. 2009, 57, 10–18. [Google Scholar] [CrossRef]

- Aguiar, M.F.; Mesa, J.A.; Jugend, D.; Pinheiro, M.A.P.; Fiorini, P.D.C. Circular product design: Strategies, challenges and relationships with new product development. Manag. Environ. Qual. 2022, 33, 300–329. [Google Scholar] [CrossRef]

- Jia, F.; Yin, S.; Chen, L.; Chen, X. The circular economy in the textile and apparel industry: A systematic literature review. J. Clean. Prod. 2020, 59, 120728. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Z.; Wang, Y. A review of the criteria and methods of reverse logistics supplier selection. Processes 2020, 8, 705. [Google Scholar] [CrossRef]

- Shaharudin, M.R.; Govindan, K.; Zailani, S.; Tan, K.C.; Iranmanesh, M. Product return management: Linking product returns, closed-loop supply chain activities and the effectiveness of the reverse supply chains. J. Clean. Prod. 2017, 149, 1144–1156. [Google Scholar] [CrossRef]

- Marchi, B.; Zanoni, S. Supply chain management for improved energy efficiency: Review and opportunities. Energies 2017, 10, 1618. [Google Scholar] [CrossRef]

- MahmoumGonbadi, A.; Genovese, A.; Sgalambro, A. Closed-loop supply chain design for the transition towards a circular economy: A systematic literature review of methods, applications and current gaps. J. Clean. Prod. 2021, 323, 129101. [Google Scholar] [CrossRef]

- Carter, C.R.; Hatton, M.R.; Wu, C.; Chen, X. Sustainable supply chain management: Continuing evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2020, 50, 122–146. [Google Scholar] [CrossRef]

- Coenen, J.; van der Heijden, R.E.C.M.; van Riel, A.C.R. Understanding approaches to complexity and uncertainty in closed-loop supply chain management: Past findings and future directions. J. Clean. Prod. 2018, 201, 1–13. [Google Scholar] [CrossRef]

- Bryman, A.; Bell, E. Business Research Methods; Oxford University Press: New York, NY, USA, 2015. [Google Scholar]

- Abbey, J.D.; Guide, V.D.R., Jr. Closed-loop supply chains: A strategic overview. In Sustainable Supply Chains; Bouchery, Y., Corbett, C.J., Fransoo, J.C., Tan, T., Eds.; Springer: Berlin, Germany, 2017; pp. 375–393. [Google Scholar]

- Kazemi, N.; Modak, N.M.; Govindan, K. A review of reverse logistics and closed loop supply chain management studies published in IJPR: A bibliometric and content analysis. Int. J. Prod. Res. 2018, 57, 4937–4960. [Google Scholar] [CrossRef]

- Market value of Flat Glass Worldwide in 2020 and 2021, with a Forecast for 2030. Available online: www.statista.com/statistics/1132697/flat-glass-market-value-worldwide/ (accessed on 19 March 2022).

- Hartwell, R.; Macmillan, S.; Overend, M. Circular economy of façades: Real-world challenges and opportunities. Resour. Conserv. Recycl. 2021, 175, 105827. [Google Scholar] [CrossRef]

- DeBrincat, G.; Babic, E. Re-Thinking the Life Cycle of Architectural Glass. 2018. Available online: https://www.arup.com/perspectives/publications/research/section/re-thinking-the-life-cycle-of-architectural-glass (accessed on 22 November 2021).

- Widing, A.; Sonnentail, C.; Storm, O.; Berglund, H.O.; Löfås, P.; Colm, T.; Kordestani, A.; Bokström, A.; Sjösten, O. RE:Source—Ökad Cirkulär Användning av Planglas; RISE Sweden: Gothenburg, Sweden, 2021. (In Swedish) [Google Scholar]

- Rose, A.; Sack, N.; Nothacker, K.; Gassman, A. Recycling of Flat Glass in the Building Industry–Analysis of the Current Situation and Derivation of Recommendations for Action; Ift Rosenheim: Rosenheim, Germany, 2019; Available online: https://www.irbnet.de/daten/kbf/kbf_e_F_3202.pdf (accessed on 19 March 2021).

- He, M.; Lin, T.; Wu, X.; Luo, J.; Peng, Y. A systematic literature review of reverse logistics of end-of-life vehicles: Bibliometric analysis and research trend. Energies 2020, 13, 5586. [Google Scholar] [CrossRef]

- Govindan, K.; Soleimani, H. A review of reverse logistics and closed-loop supply chains: A journal of cleaner production focus. J. Clean. Prod. 2017, 142, 371–384. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Towards a Circular Economy: Business Rationale for an Accelerated Transition; Ellen MacArthur Foundation: Cowes, UK, 2015. [Google Scholar]

- Nußholz, J.L.K.; Nygaard-Rasmussen, F.; Whalen, K.; Plepys, A. Material reuse in buildings: Implications of a circular business model for sustainable value creation. J. Clean. Prod. 2020, 245, 118546. [Google Scholar] [CrossRef]

- Young-woo, K.; Tai-Woo, C.; Jinwoo, P. Gen2 RFID-based system framework for resource circulation in closed-loop supply chains. Sustainability 2017, 9, 1995. [Google Scholar]

- Berlin, D.; Feldmann, A.; Nuur, C. Supply network collaborations in a circular economy: A case study of Swedish steel recycling. Resour. Conserv. Recycl. 2022, 179, 106112. [Google Scholar] [CrossRef]

- Hazen, B.T.; Russo, I.; Confente, I.; Pellathy, D. Supply chain management for circular economy: Conceptual framework and research agenda. Int. J. Logist. Manag. 2021, 32, 510–537. [Google Scholar] [CrossRef]

- McKinnon, A.; Cullinane, S.; Whiteing, A.; Browne, M. Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page: London, UK, 2015. [Google Scholar]

- Alphonsa, J.K.; Surendra, K.S. Theory of planned behavior in predicting the construction of eco-friendly houses. Manag. Environ. Qual. 2022, 33, 938–954. [Google Scholar]

- Gonzalez, A.; Sendra, C.; Herena, A.; Rosquillas, M.; Vaz, D. Methodology to assess the circularity in building construction and refurbishment activities. Resour. Conserv. Recycl. Adv. 2021, 12, 200051. [Google Scholar] [CrossRef]

- Lindblad, F.; Bolmsvik, Å.; Pettersson, J.; Wiberg, S. Efficiencies in the on-site material handling process by using radio frequency identification in the wood building construction industry. Int. J. Innov. Manag. Tech. 2018, 9, 252–259. [Google Scholar] [CrossRef]

- Sadeghi, M.; Mahmoudi, A.; Deng, X.; Luo, X. Prioritizing requirements for implementing blockchain technology in the construction supply chain based on circular economy: Fuzzy ordinal priority approach. Int. J. Environ. Sci. Technol. 2022, 2022, 1–22. [Google Scholar] [CrossRef]

- Wikner, J. On decoupling points and decoupling zones. Prod. Manuf. Res. 2014, 2, 167–215. [Google Scholar] [CrossRef]

- Aldoukhi, M.; Gupta, S.M. A robust multiple objectives model to design a network of a closed loop supply chain. J. Bus. Manag. 2021, 23, 31–41. [Google Scholar]

- Wang, Y.; Hazen, B.T.; Mollenkopf, D.A. Consumer value considerations and adoption of remanufactured products in closed-loop supply chains. Ind. Manag. Data Syst. 2018, 118, 480–498. [Google Scholar] [CrossRef]

- Jiao, Z.; Li, Z.; Ran, L.; Zhang, W. Data-driven approaches to integrated closed-loop sustainable supply chain design under multi-uncertainties. J. Clean. Prod. 2018, 185, 105–127. [Google Scholar] [CrossRef]

- Chileshe, N.; Rameezdeen, R.; Hosseini, M.R.; Lehmann, S. Barriers to implementing reverse logistics in South Australian construction organizations. Supply Chain Manag. 2015, 20, 179–204. [Google Scholar] [CrossRef]

| Type of Organization | Participant/Job Title | |

|---|---|---|

| Material-specific/Glass stakeholders’ focus group | Research institute | Flat glass project leader (RIPL) |

| University | Professor in glass design (UPGD) | |

| Context-specific/Construction stakeholders’ focus group | Construction company 1 | Project leader (CC1PL) Project responsible (CC1PR) |

| Construction company 2 | CEO (CC2CEO) | |

| Property company 1 | Project responsible/owner (PC1PR) | |

| Property company 2 | Project leader renovation (PC2PL) Property management responsible (PC2MR) | |

| Architectural company | CEO/architect (ACCEO) | |

| Municipality business development department | Business developer (MBD) Head of market and business development (MBH) | |

| Expert interviews | Municipality-owned waste management company | Business developer circular economy (WMCBD) |

| Glass material/recycling consulting firm | Owner/consultant (RCC) | |

| Window glass industry organization | CEO/glass expert (IOCEO) |

| Challenge Area | Flat Glass-Specific Challenges | Sources (Literature/Empiry) | In CLSC | ||

|---|---|---|---|---|---|

| Material characteristics and quality | High contamination risk for flat glass manufacturers | Flat glass literature/glass stakeholders focus group, expert interviews | 1 | 2 | |

| Windows are not designed for recycling—challenging to safely disassemble glass | Flat glass literature/construction stakeholders focus group | 2 | |||

| Lack of flat glass material knowledge | Flat glass literature/construction stakeholders focus group | 1 | 2 | ||

| Difficult to safely identify, mark, and sort different glass qualities | Flat glass literature/glass stakeholders focus group, construction stakeholders focus group | 1 | 2 | ||

| Inefficient logistics systems | Lack of space for sorting on already-crowded demolition sites | Construction stakeholders focus group | 2 | ||

| Labor-intense sorting gets de-prioritized | Construction stakeholders focus group | 2 | |||

| Lack of logistics and recycling knowledge | General literature/construction stakeholders focus group, expert interviews | 2 | |||

| Lack of adapted large-scale containers | Construction stakeholders focus group | 2 | |||

| Lack of storage space for windows to enable consolidation | Flat glass literature/construction stakeholders focus group | 4 | |||

| Lack of storage space for cullets to enable consolidation | Flat glass literature | 2 | |||

| Complex international transports are required | General literature/expert interviews | 1 | 2 | ||

| A general lack of professionalized, large-scale actors/collectors | Construction stakeholders focus group | 2 | |||

| Demand and supply | Lack of knowledge about customer behavior and demand | Construction stakeholders focus group | 2 | ||

| Lack of marketplaces/unavailable information flows | Construction stakeholders focus group | 2 | |||

| Lack of supply of class A cullets | Flat glass literature/construction stakeholders focus group | 1 | 2 | ||

| Means of control and cost | No leading actor for promoting CLSC | Expert interviews | 2 | ||

| Low compliance with the new EU legislation | Flat glass literature/expert interviews | 2 | |||

| Lack of cost knowledge and business cases | Flat glass literature/construction stakeholders focus group, expert interviews | 2 | |||

| Lack of business models | Construction stakeholders focus group | 2 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forslund, H.; Björklund, M. Toward Circular Supply Chains for Flat Glass: Challenges of Transforming to More Energy-Efficient Solutions. Energies 2022, 15, 7282. https://doi.org/10.3390/en15197282

Forslund H, Björklund M. Toward Circular Supply Chains for Flat Glass: Challenges of Transforming to More Energy-Efficient Solutions. Energies. 2022; 15(19):7282. https://doi.org/10.3390/en15197282

Chicago/Turabian StyleForslund, Helena, and Maria Björklund. 2022. "Toward Circular Supply Chains for Flat Glass: Challenges of Transforming to More Energy-Efficient Solutions" Energies 15, no. 19: 7282. https://doi.org/10.3390/en15197282

APA StyleForslund, H., & Björklund, M. (2022). Toward Circular Supply Chains for Flat Glass: Challenges of Transforming to More Energy-Efficient Solutions. Energies, 15(19), 7282. https://doi.org/10.3390/en15197282