Investigation of Performance and Emission Characteristics of CI Engine Using Diesel and Waste Cooking Oil Blends

Abstract

:1. Introduction

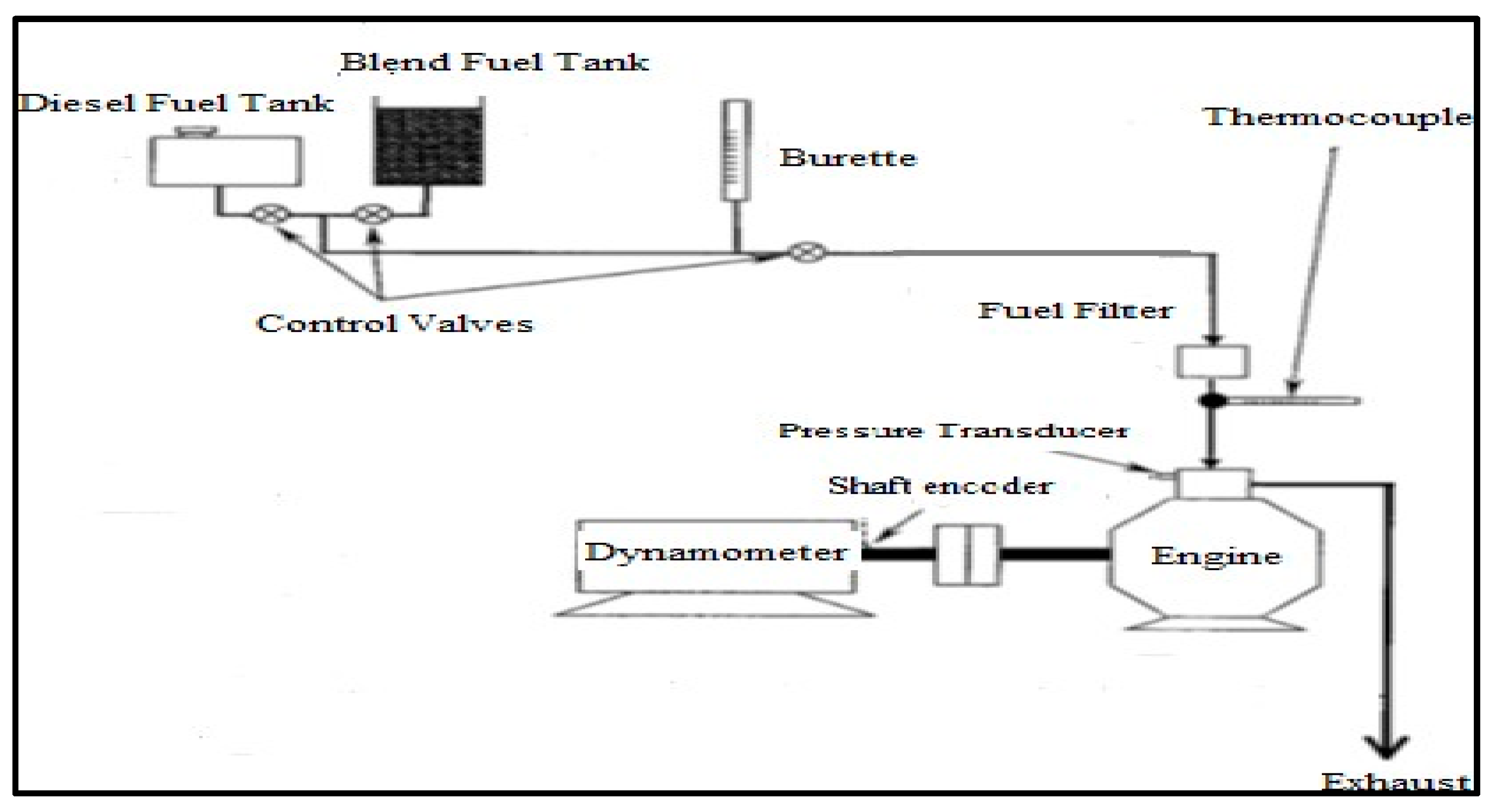

2. Materials and Methods

Engine Test Bed

3. Results and Discussion

3.1. Engine Performance

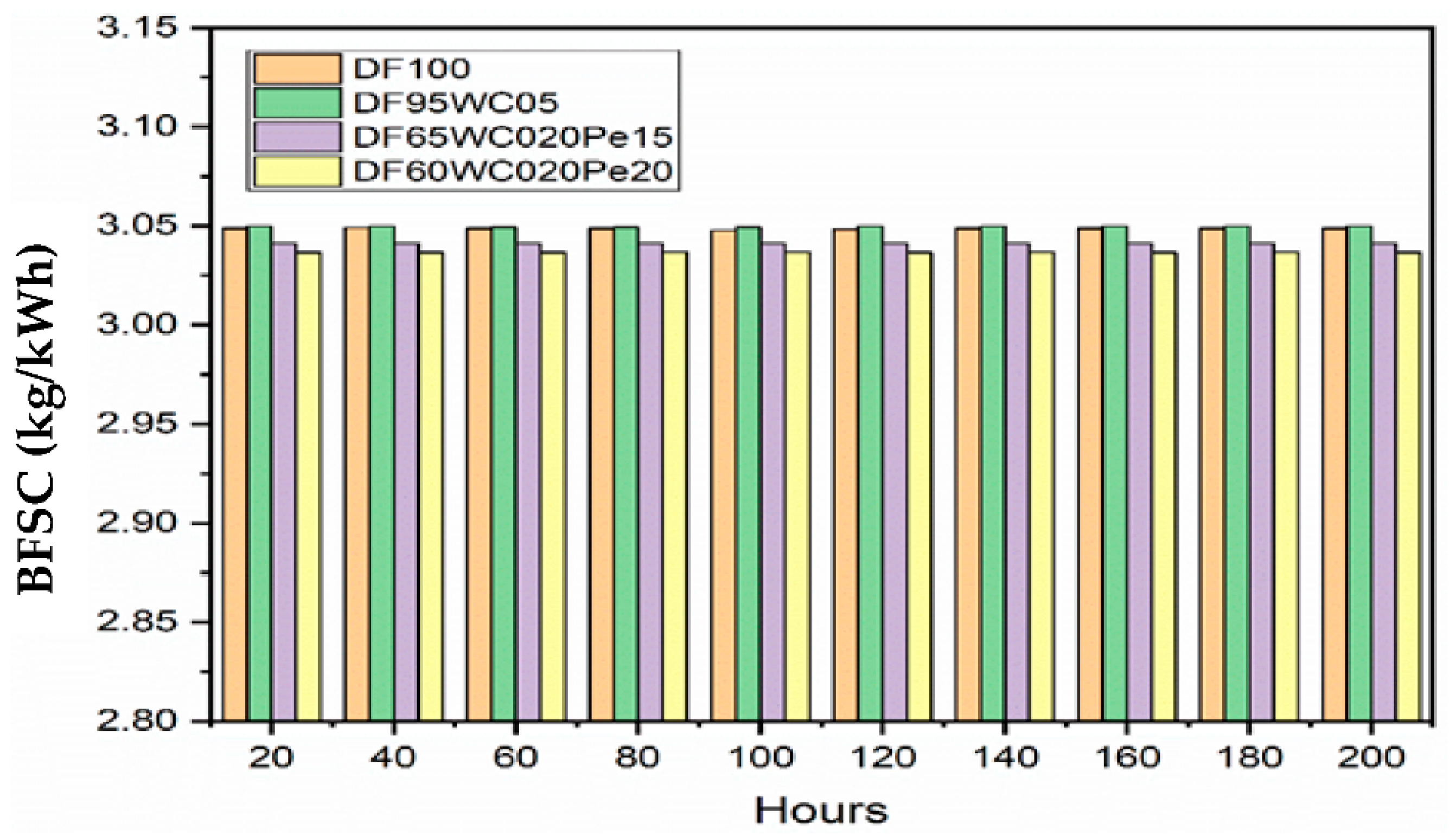

3.1.1. Brake Specific Fuel Consumption (BSFC)

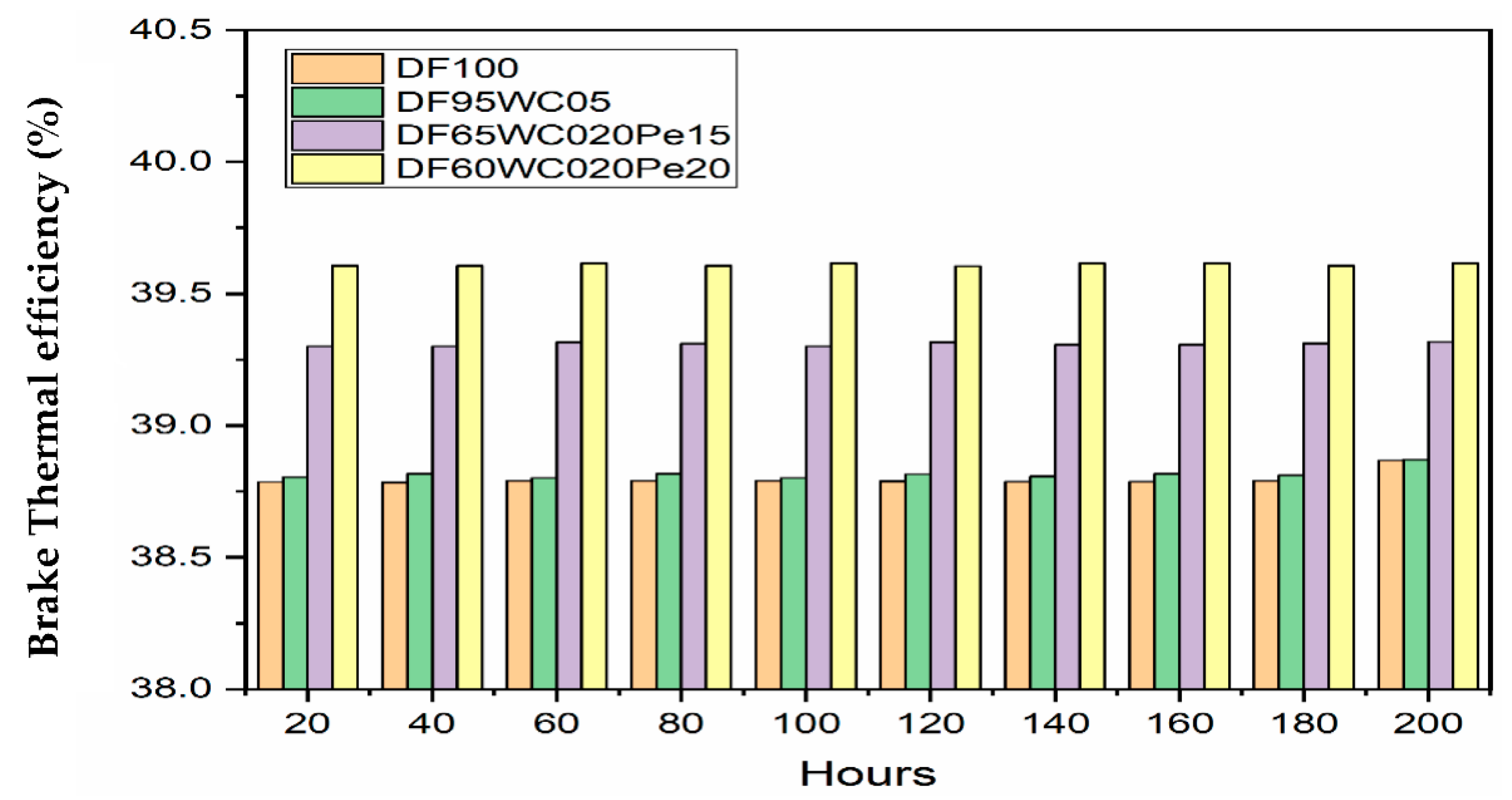

3.1.2. Brake Thermal Efficiency

3.2. Engine Emissions

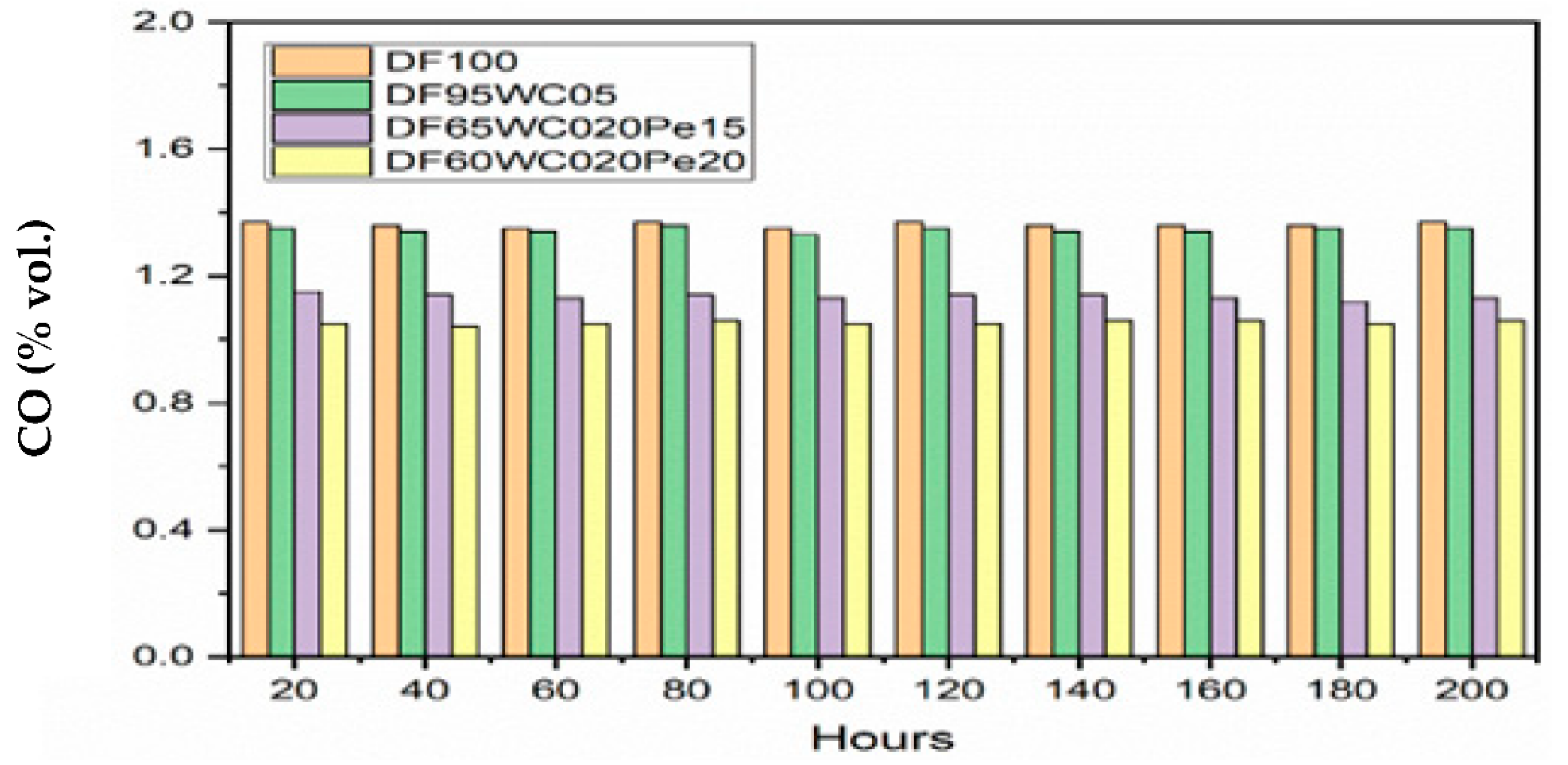

3.2.1. Carbon Monoxide (CO)

3.2.2. Carbon Dioxide (CO2)

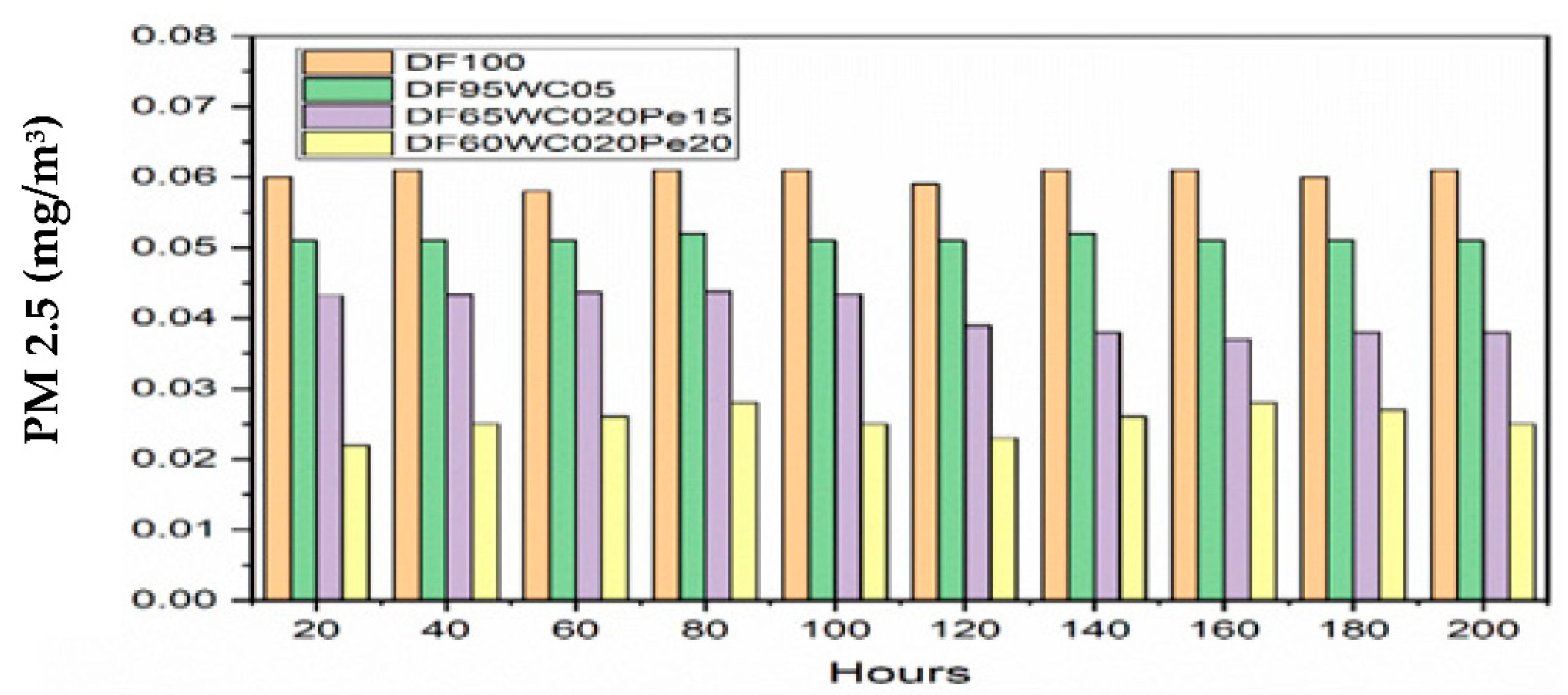

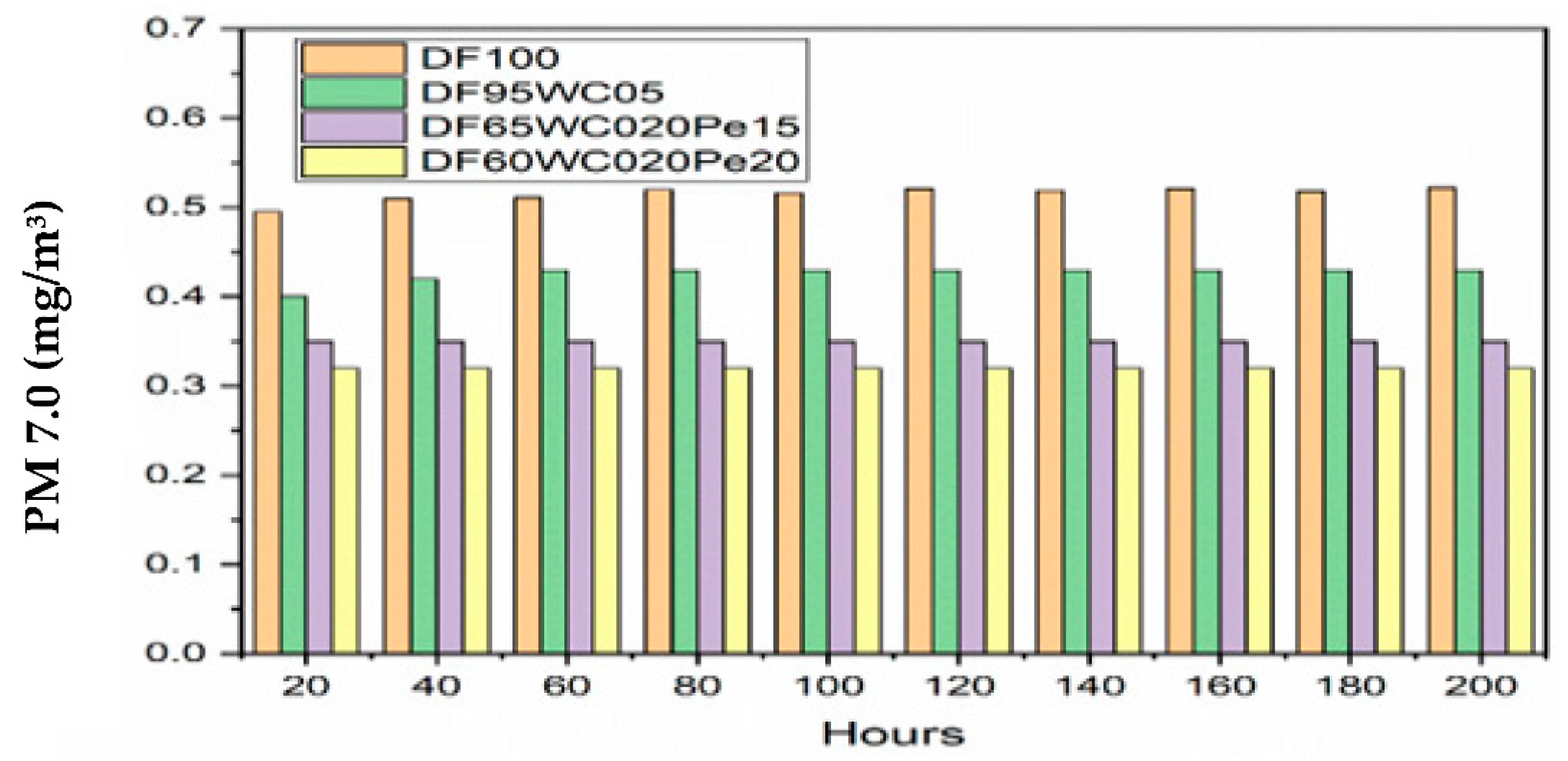

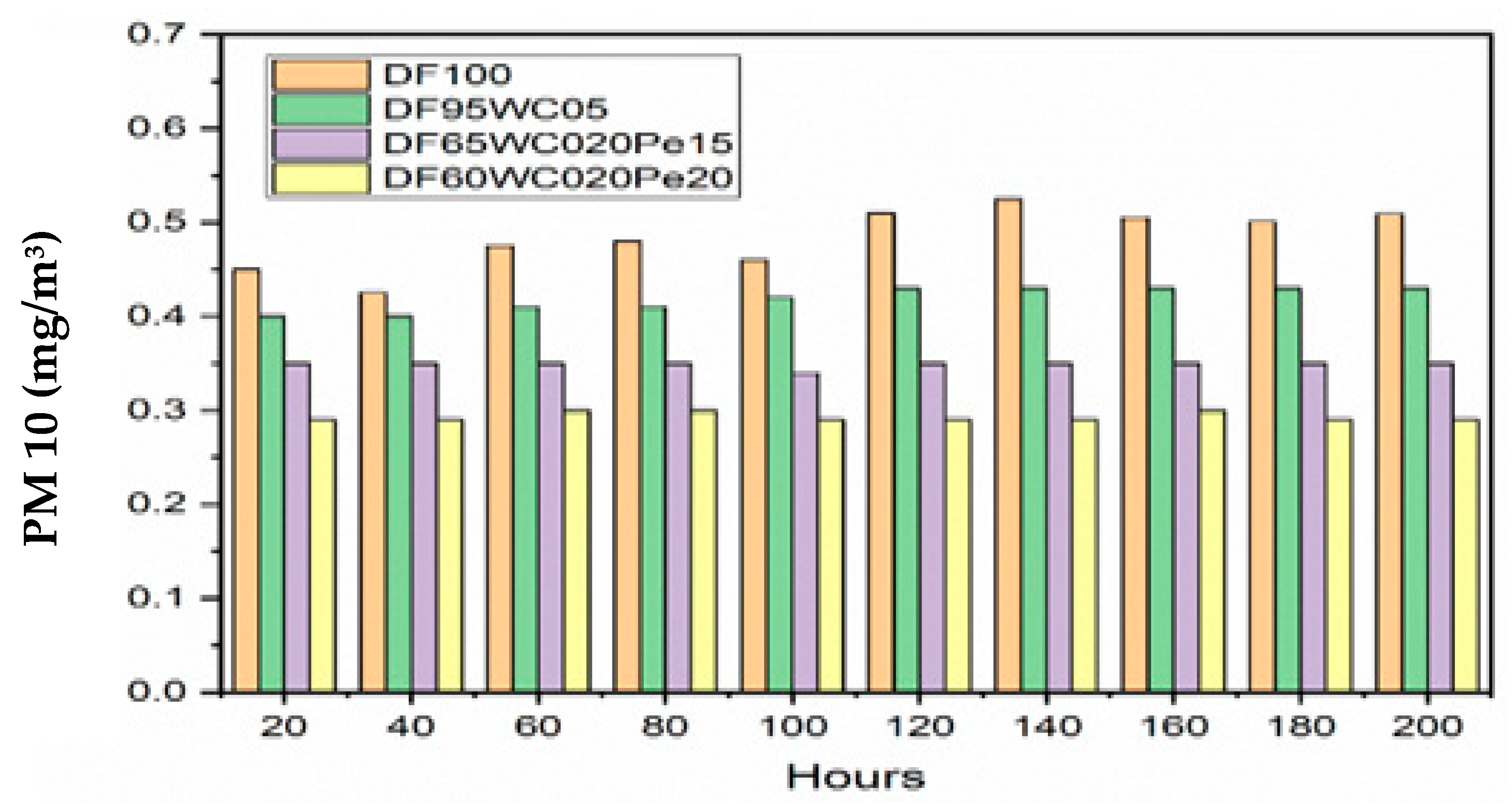

3.2.3. Particulate Matter (PM)

3.3. Statistical Analysis

SM Method

4. Conclusions

- The experimental results showed that BSFC of the DF95-WCO5 blend improved 0.32%. However, with the addition of n-Pentanol as a ternary blend DF65-WCO20-Pe15 and DF60-WCO20-Pe20 increased by 0.49% and 0.68%, compared to diesel fuel, respectively.

- The experimental data showed that Brake thermal efficiency for DF95-WCO5 improved by 38.7%, while the BTEs for ternary blends were DF65-WCO20-Pe15 (39.2%) and DF60-WCO20-Pe20 (39.6%), respectively.

- CO measurements were DF65-WCO20-Pe15 (0.15%), and DF60-WCO20-Pe20 (0.14%), showing a decrease compared to diesel under the same engine operating conditions. However, the binary blend DF95WCO5 (0.18%) increased CO, compared to diesel, due to incomplete burning of fuel.

- Finally, the results showed that CO2 in the case of DF95-WCO5 (0.48%) improved, as compared to diesel fuel. However, the figures were DF65-WCO20-Pe15 (0.511%), and DF60-WCO20-Pe20 (0.518%), compared to diesel fuel.

- PM at the exhaust tended to decrease using WCO compared to petrol-diesel, due to the presence of oxygen content in the oil, probably to let the soot form. Sll test fuel blends produced Particulate matter due to improper combustion of fuel. However, with the addition of n-pentanol in the test fuels there was a decrease in concentration of particulate matter.

5. Future Scope

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| BSFC | Brake Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| CI | Compression ignition |

| DF | Diesel fuel |

| D95-WCO5 | 95%vol. diesel, WCO5%vol. waste cooking oil |

| D65-WCO20-Pe15 | 65%vol. diesel, 20%vol. waste cooking oil, and 15%vol. n-pentanol |

| D60-WCO20-Pe20 | 60%vol. diesel, 20%vol. waste cooking oil and 20%voil. n-pentanol |

| DI | Direct Injection |

| IC | Internal combustion |

| PM | Particulate Matter |

| RMSE | Root Mean Square Error |

| RMS | Root Mean Square |

| SI | Spark ignition |

| SM’s Method | Sanaullah Mastoi’s Method |

| WCO | Waste Cooking Oil |

References

- Debbarma, S.; Misra, R.D.; Das, B. Performance of graphene-added palm biodiesel in a diesel engine. Clean Technol. Environ. Policy 2020, 22, 523–534. [Google Scholar] [CrossRef]

- Dabi, M.; Saha, U.K. Application potential of vegetable oils as alternative to diesel fuels in compression ignition engines: A review. J. Energy Inst. 2019, 92, 1710–1726. [Google Scholar] [CrossRef]

- Capuano, D.; Costa, M.; Di Fraia, S.; Massarotti, N.; Vanoli, L. Direct use of waste vegetable oil in internal combustion engines. Renew. Sustain. Energy Rev. 2017, 69, 759–770. [Google Scholar] [CrossRef]

- Yesilyurt, M.K. The effects of the fuel injection pressure on the performance and emission characteristics of a diesel engine fuelled with waste cooking oil biodiesel-diesel blends. Renew. Energy 2018, 132, 649–666. [Google Scholar] [CrossRef]

- Food and Agricultural Organization of the United Nations. Oilseeds and Oils and Meals—Monthly Price updates Report; Food and Agricultural Organization of the United Nations: Rome, Italy, 2018. [Google Scholar]

- Charpe, T.W.; Rathod, V.K. Biodiesel production using waste frying oil. Waste Manag. 2011, 31, 85–90. [Google Scholar] [CrossRef]

- Majhi, S.; Ray, S. A study on production of biodiesel using a novel solid oxide catalyst derived from waste. Environ. Sci. Pollut. Res. 2015, 23, 9251–9259. [Google Scholar] [CrossRef]

- Can, Ö. Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Convers. Manag. 2014, 87, 676–686. [Google Scholar] [CrossRef]

- Murugesan, A.; Umarani, C.; Subramanian, R.; Nedunchezhian, N. Bio-diesel as an alternative fuel for diesel engines—A review. Renew. Sustain. Energy Rev. 2009, 13, 653–662. [Google Scholar] [CrossRef]

- Prabu, S.S.; Asokan, M.A.; Roy, R.; Francis, S.; Sreelekh, M.K. Performance, combustion and emission character-istics of diesel engine fueled with waste cooking oil bio-diesel or diesel blends with additives. Energy 2017, 122, 638–648. [Google Scholar] [CrossRef]

- Dey, P.; Ray, S. Valorization of waste vegetable oil (WVO) for utilization as diesel blends in CI engine—Performance and emission studies. Energy Sources Part A Recover. Util. Environ. Eff. 2019, 1–14. [Google Scholar] [CrossRef]

- Murugesan, A.; Umarani, C.; Chinnusamy, T.; Krishnan, M.; Subramanian, R.; Neduzchezhain, N. Production and analysis of bio-diesel from non-edible oils—A review. Renew. Sustain. Energy Rev. 2009, 13, 825–834. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Use of vegetable oils as IC engine fuels—A review. Renew. Energy 2004, 29, 727–742. [Google Scholar] [CrossRef]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Thiyagarajan, S.; Geo, V.E.; Leenus, J.M.; Nagalingam, B. Experimental investigation to reduce CO2 emission in a single cylinder CI engine using low carbon fuel blend with Karanja oil methyl ester and amine injection in the exhaust manifold. Int. J. Glob. Warm. 2017, 13, 278–295. [Google Scholar] [CrossRef]

- Martin, M.L.J.; Geo, V.E.; Nagalingam, B. Effect of fuel inlet temperature on cottonseed oil–diesel mixture composition and performance in a DI diesel engine. J. Energy Inst. 2017, 90, 563–573. [Google Scholar] [CrossRef]

- Vallinayagam, R.; Vedharaj, S.; Yang, W.; Lee, P.; Chua, K.J.; Chou, S. Combustion performance and emission characteristics study of pine oil in a diesel engine. Energy 2013, 57, 344–351. [Google Scholar] [CrossRef]

- Varuvel, E.G.; Mrad, N.; Tazerout, M.; Aloui, F. Experimental analysis of biofuel as an alternative fuel for diesel engines. Appl. Energy 2012, 94, 224–231. [Google Scholar] [CrossRef]

- Misra, R.; Murthy, M. Straight vegetable oils usage in a compression ignition engine—A review. Renew. Sustain. Energy Rev. 2010, 14, 3005–3013. [Google Scholar] [CrossRef]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Diaz-Felix, W.; Riley, M.R.; Zimmt, W.; Kazz, M. Pretreatment of yellow grease for efficient production of fatty acid methyl esters. Biomass Bioenergy 2009, 33, 558–563. [Google Scholar] [CrossRef]

- Hribernik, A.; Kegl, B. Performance and Exhaust Emissions of an Indirect-Injection (IDI) Diesel Engine When Using Waste Cooking Oil as Fuel. Energy Fuels 2009, 23, 1754–1758. [Google Scholar] [CrossRef]

- Murayama, T.; Fujiwara, Y.; Nato, T. Evaluating waste vegetable oils as a diesel fuel. Proc. Inst. Mech. Eng. Part D: J Automob. Eng. 2000, 214, 141–148. [Google Scholar] [CrossRef]

- Kalam, M.; Masjuki, H.; Jayed, M.; Liaquat, A. Emission and performance characteristics of an indirect ignition diesel engine fuelled with waste cooking oil. Energy 2011, 36, 397–402. [Google Scholar] [CrossRef]

- Pugazhvadivu, M.; Jeyachandran, K. Investigations on the performance and exhaust emissions of a diesel engine using preheated waste frying oil as fuel. Renew. Energy 2005, 30, 2189–2202. [Google Scholar] [CrossRef]

- Senthil Kumar, M.; Jaikumar, M. A comprehensive study on performance, emission and combustion behavior of a com-pression ignition engine fuelled with WCO (waste cooking oil) emulsion as fuel. J. Energy Inst. 2014, 87, 263–271. [Google Scholar] [CrossRef]

- Atmanlı, A.; Yüksel, B.; Ileri, E. Experimental investigation of the effect of diesel–cotton oil–n-butanol ternary blends on phase stability, engine performance and exhaust emission parameters in a diesel engine. Fuel 2013, 109, 503–511. [Google Scholar] [CrossRef]

- Sharon, H.; Ram, P.J.S.; Fernando, K.J.; Murali, S.; Muthusamy, R. Fueling a stationary direct injection diesel engine with diesel-used palm oil–butanol blends—An experimental study. Energy Convers. Manag. 2013, 73, 95–105. [Google Scholar] [CrossRef]

- Lujaji, F.; Kristóf, L.; Bereczky, A.; Mbarawa, M. Experimental investigation of fuel properties, engine performance, combustion and emissions of blends containing croton oil, butanol, and diesel on a CI engine. Fuel 2011, 90, 505–510. [Google Scholar] [CrossRef]

- Atmanli, A.; İleri, E.; Yüksel, B. Experimental investigation of engine performance and exhaust emissions of a diesel engine fueled with diesel–n-butanol–vegetable oil blends. Energy Convers Manag. 2014, 81, 312–321. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yüksel, B. Effects of higher ratios of n-butanol addition to diesel–vegetable oil blends on performance and exhaust emissions of a diesel engine. J. Energy Inst. 2015, 88, 209–220. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.; Nada, S.A. Improvement of CI engine combustion and performance running on ternary blends of higher alcohol (Pentanol and Octanol)/hydrous ethanol/diesel. Fuel 2019, 251, 10–22. [Google Scholar] [CrossRef]

- Atmanli, A.; Ileri, E.; Yuksel, B.; Yilmaz, N. Extensive analyses of diesel–vegetable oil– n -butanol ternary blends in a diesel engine. Appl. Energy 2015, 145, 155–162. [Google Scholar] [CrossRef]

- Atmanli, A. Effects of a cetane improver on fuel properties and engine characteristics of a diesel engine fueled with the blends of diesel, hazelnut oil and higher carbon alcohol. Fuel 2016, 172, 209–217. [Google Scholar] [CrossRef]

- Atmanli, A. Comparative analyses of diesel–waste oil biodiesel and propanol, n-butanol or 1-pentanol blends in a diesel engine. Fuel 2016, 176, 209–215. [Google Scholar] [CrossRef]

- Krishnamoorthy, V.; Dhanasekaran, R.; Rana, D.; Saravanan, S.; Kumar, B.R. A comparative assessment of ternary blends of three bio-alcohols with waste cooking oil and diesel for optimum emissions and performance in a CI engine using response surface methodology. Energy Convers. Manag. 2018, 156, 337–357. [Google Scholar] [CrossRef]

- Imdadul, H.; Masjuki, H.; Kalam, M.; Zulkifli, N.; Alabdulkarem, A.; Rashed, M.; Teoh, Y.; How, H. Higher alcohol–biodiesel–diesel blends: An approach for improving the performance, emission, and combustion of a light-duty diesel engine. Energy Convers. Manag. 2016, 111, 174–185. [Google Scholar] [CrossRef]

- Atmanlı, A.; Yüksel, B.; Ileri, E.; Karaoglan, A.D. Response surface methodology based optimization of diesel–n-butanol –cotton oil ternary blend ratios to improve engine performance and exhaust emission characteristics. Energy Convers. Manag. 2015, 90, 383–394. [Google Scholar] [CrossRef]

- Rakopoulos, D.; Rakopoulos, C.; Giakoumis, E.; Dimaratos, A.; Kyritsis, D. Effects of butanol–diesel fuel blends on the performance and emissions of a high-speed DI diesel engine. Energy Convers. Manag. 2010, 51, 1989–1997. [Google Scholar] [CrossRef]

- Campos-Fernández, J.; Arnal, J.M.; Gómez, J.; Dorado, M.P. A comparison of performance of higher alcohols/diesel fuel blends in a diesel engine. Appl. Energy 2012, 95, 267–275. [Google Scholar] [CrossRef]

- Elumalai, P.V.; Parthasarathy, M.; Hariharan, V.; Jayakar, J.; Iqbal, S.M. Evaluation of water emulsion in biodiesel for engine performance and emission characteristics. J. Therm. Anal. 2021, 147, 4285–4301. [Google Scholar] [CrossRef]

- Lalvani, J.I.J.; Kirubhakaran, L.; Parthasarathy, M.; Sabarish, R.; Annamalai, K. Performance characteristics and emission analysis of a single cylinder diesel engine operated on blends of diesel and waste cooking oil. In Proceedings of the International Conference on IEEE Energy Efficient Technologies for Sustainability (ICEETS), Nagercoil, India, 10–12 April 2013. [Google Scholar]

- Wei, L.; Cheung, C.S.; Huang, Z. Effect of n-pentanol addition on the combustion, performance and emission characteristics of a direct-injection diesel engine. Energy 2021, 70 (Suppl. 01), 172–180. [Google Scholar] [CrossRef]

- Zhu, L.; Xiao, Y.; Cheung, C.; Guan, C.; Huang, Z. Combustion, gaseous and particulate emission of a diesel engine fueled with n-pentanol (C5 alcohol) blended with waste cooking oil biodiesel. Appl. Therm. Eng. 2016, 102, 73–79. [Google Scholar] [CrossRef]

- Mastoi, S.; Ganie, A.H.; Saeed, A.M.; Ali, U.; Rajput, U.A.; Othman, W.A.M. Numerical solution for two-dimensional partial differential equations using SM’s method. Open Phys. 2022, 20, 142–154. [Google Scholar] [CrossRef]

- Mastoi, S.; Kalhoro, N.B.; Mugheri, A.B.; Rajput, S.A.; Othman, W.A.M.; Nallasamy, K. A Simple Introduction to the SM’s Method. Sciencetech 2022, 3, 5–6. [Google Scholar] [CrossRef]

| Properties | Diesel Fuel | WCO | n-Pentanol |

|---|---|---|---|

| Viscosity 40 °C Cst | 2.28 | 52 | 2.89 |

| Density g/mL | 835 | 900 | 814.4 |

| Flash point °C | 78 | 271 | 49 |

| Oxygen (wt %) | 0 | 20 | 8.47 |

| Calorific valve MJ/Kg | 42.5 | 37.68 | 34.75 |

| Cetane number | 50 | 54 | 20 |

| Properties | D100 | D95-WCO5 | D65-WCO15-Pe15 | D60-WCO20-Pe20 | Test Method |

|---|---|---|---|---|---|

| Calorific valve MJ/Kg | 42.5 | 39 | 40 | 41.5 | ASTM D-240 |

| Viscosity 40 °C Cst | 2.28 | 2.34 | 1.95 | 1.14 | ASTM D-88 |

| Density g/mL | 0.85 | 0.89 | 0.84 | 0.83 | ASTM D-854 |

| Flash point °C | 78 | 85 | 94 | 98 | ASTM D-92 |

| Cetane number | 50 | 53 | 55.5 | 56 | ASTM D-4737 |

| Model | Single-Cylinder, Horizontal, Water Cooled Four Stroke Pre-Combustion Chamber |

|---|---|

| Bore | 75 mm |

| Stroke | 80 mm |

| Output (12 h rating) | 4.4 kW/2600 r/min |

| Displacement | 0.353 L |

| Compression ratio | 21–23 |

| Means effective pressure | 576 kPa |

| Piston mean speed | 6.93 m/s |

| Specific fuel consumption | 278.8 g/kW h |

| Specific oil consumption | 4.08 g/kW h |

| Cooling water consumption | 1360 g/kW h |

| Injection pressure | 14.2 + 0.5 MPa |

| Valves clearance | Inlet valve 0.15–0.25 mm |

| Maximum engine power | 7.7 kW |

| Maximum engine torque | 80 Nm |

| Dynamometer | Air Cooled Eddy-Current Electro Brake Dynamometer Maximum Absorbing Horse Power: 10 P.S. Torque Indicator: Load Cell |

|---|---|

| Flow meter for cooling water | Float type area flow meter |

| Accessories | Cooling water supply valve, electricity switch, electric live outlet for meters |

| Fuel consumption meter | Skewer type 3-burettes of 5, 10, 20 cc |

| Exhaust gas temperature sensor and indictor | K-type thermocouple transducer |

| Lubricant temperature sensor and indictor | Iron-constantan thermocouple detector Lube oil temperature digital indicator (0–400 °C) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Solangi, F.A.; Memon, L.A.; Samo, S.R.; Luhur, M.R.; Bhutto, A.A.; Ansari, A.M. Investigation of Performance and Emission Characteristics of CI Engine Using Diesel and Waste Cooking Oil Blends. Energies 2022, 15, 7211. https://doi.org/10.3390/en15197211

Solangi FA, Memon LA, Samo SR, Luhur MR, Bhutto AA, Ansari AM. Investigation of Performance and Emission Characteristics of CI Engine Using Diesel and Waste Cooking Oil Blends. Energies. 2022; 15(19):7211. https://doi.org/10.3390/en15197211

Chicago/Turabian StyleSolangi, Faheem Ahmed, Liaquat Ali Memon, Saleem Raza Samo, Muhammad Ramzan Luhur, Aqeel Ahmed Bhutto, and Ali Murtaza Ansari. 2022. "Investigation of Performance and Emission Characteristics of CI Engine Using Diesel and Waste Cooking Oil Blends" Energies 15, no. 19: 7211. https://doi.org/10.3390/en15197211

APA StyleSolangi, F. A., Memon, L. A., Samo, S. R., Luhur, M. R., Bhutto, A. A., & Ansari, A. M. (2022). Investigation of Performance and Emission Characteristics of CI Engine Using Diesel and Waste Cooking Oil Blends. Energies, 15(19), 7211. https://doi.org/10.3390/en15197211