Cascade-Free Modulated Predictive Direct Speed Control of PMSM Drives

Abstract

:1. Introduction

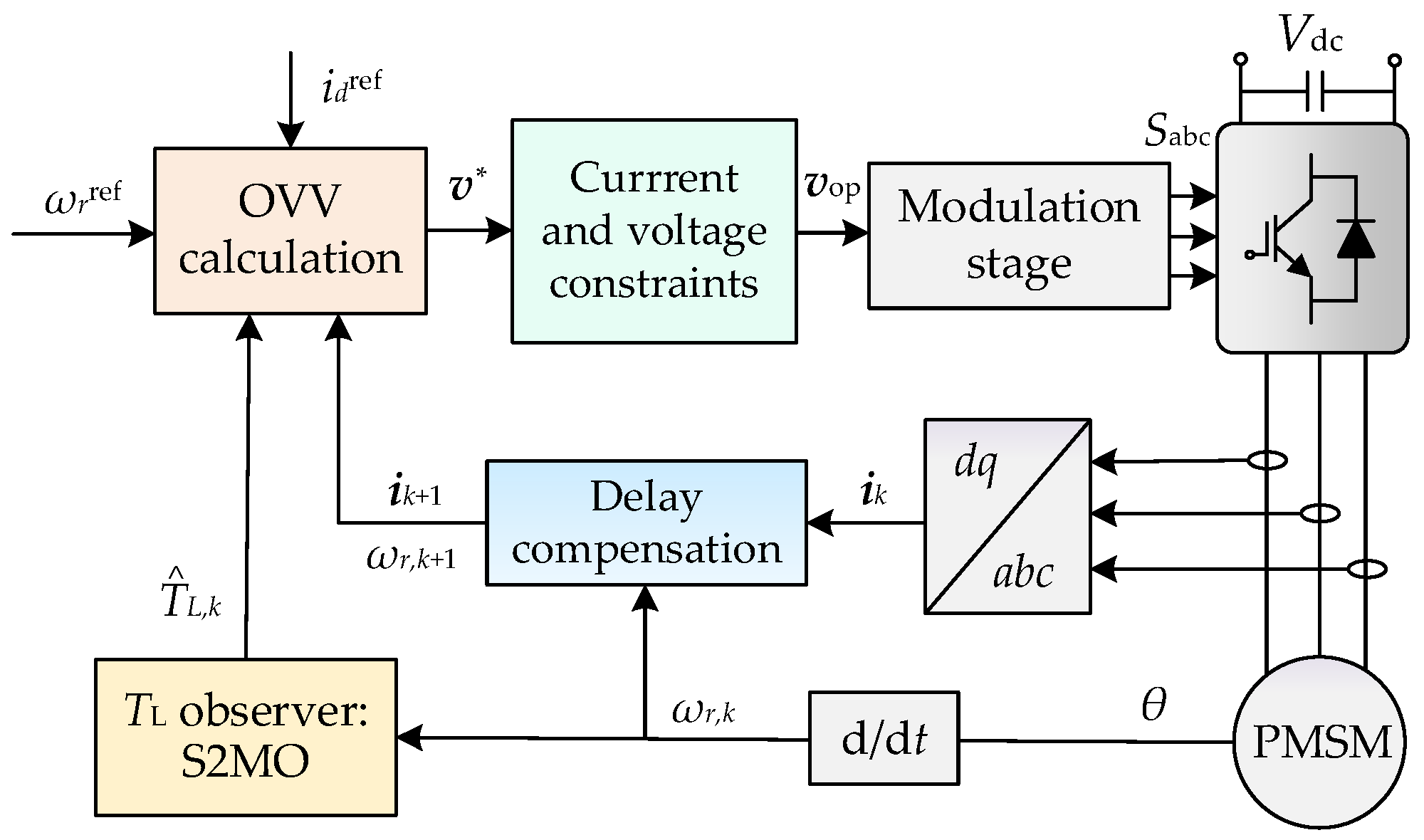

- (1)

- To complete the speed prediction, a second-order sliding mode observer (S2MO) is constructed, which can quickly and robustly estimate the load torque compared to existing observers.

- (2)

- A dual objective cost function with both speed and current tracking is designed, which reduces the stator current harmonics and torque ripples.

- (3)

- An analytical solution of the OVV with constraints is derived and synthesized by space vector modulation, resulting in a fixed switching frequency and further improving the steady-state performance.

2. Modeling of a PMSM Drive System

2.1. System Modeling

2.2. Delay Compensation

3. Proposed Modulated Predictive Direct Speed Control

3.1. Cost Function Design

3.2. Unconstrained OVV Derivation

3.3. Current Constraint Handling

3.4. Voltage Constraint Handling

3.5. Load Torque Observation

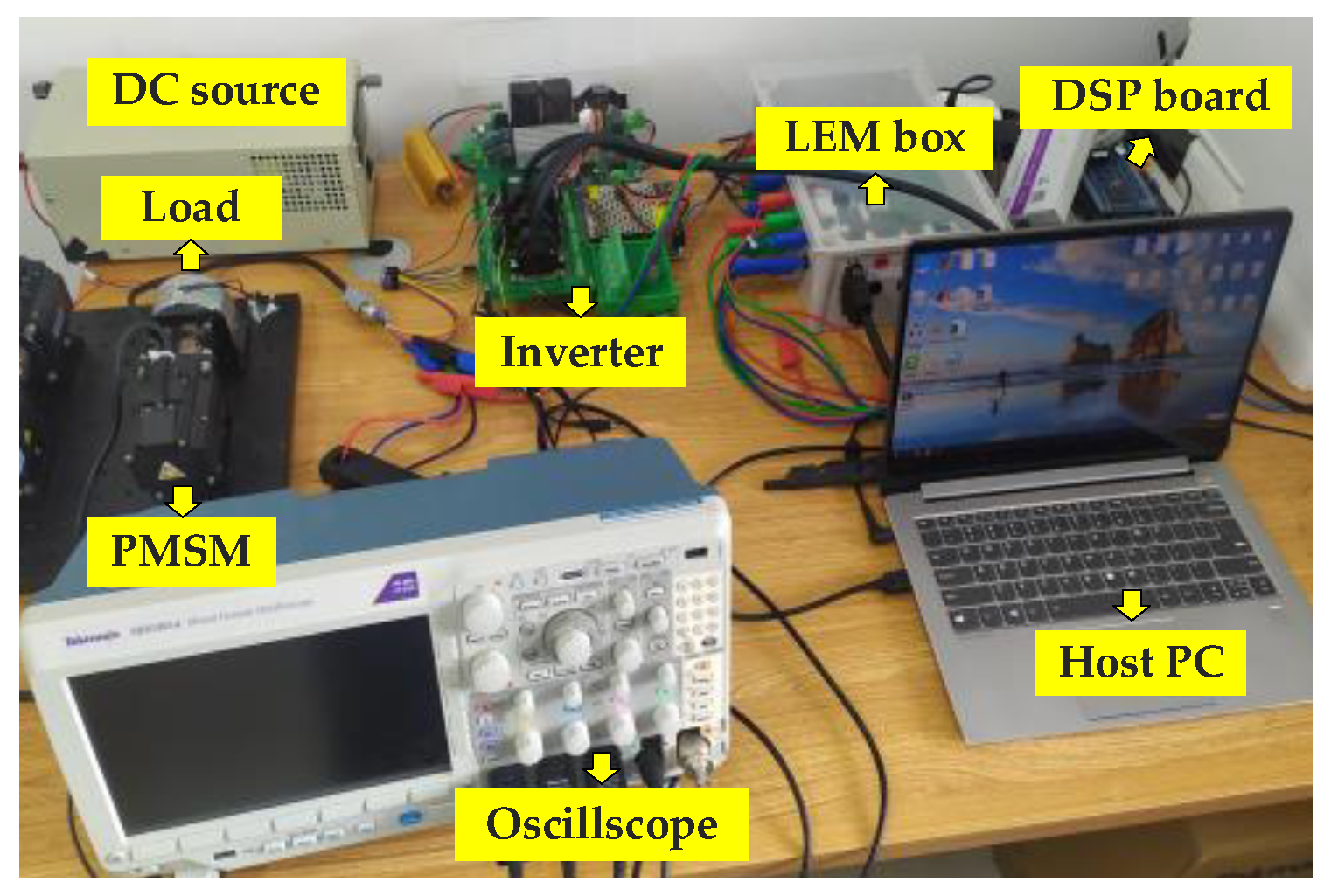

3.6. Experimental Setup

4. Experimental Results and Analysis

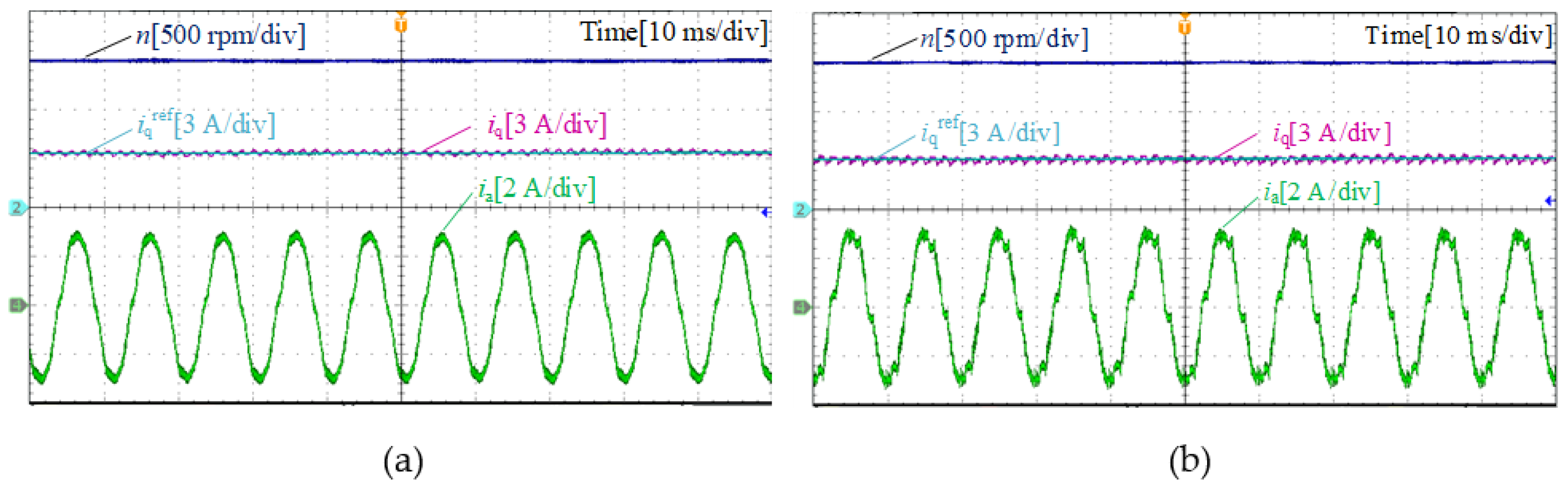

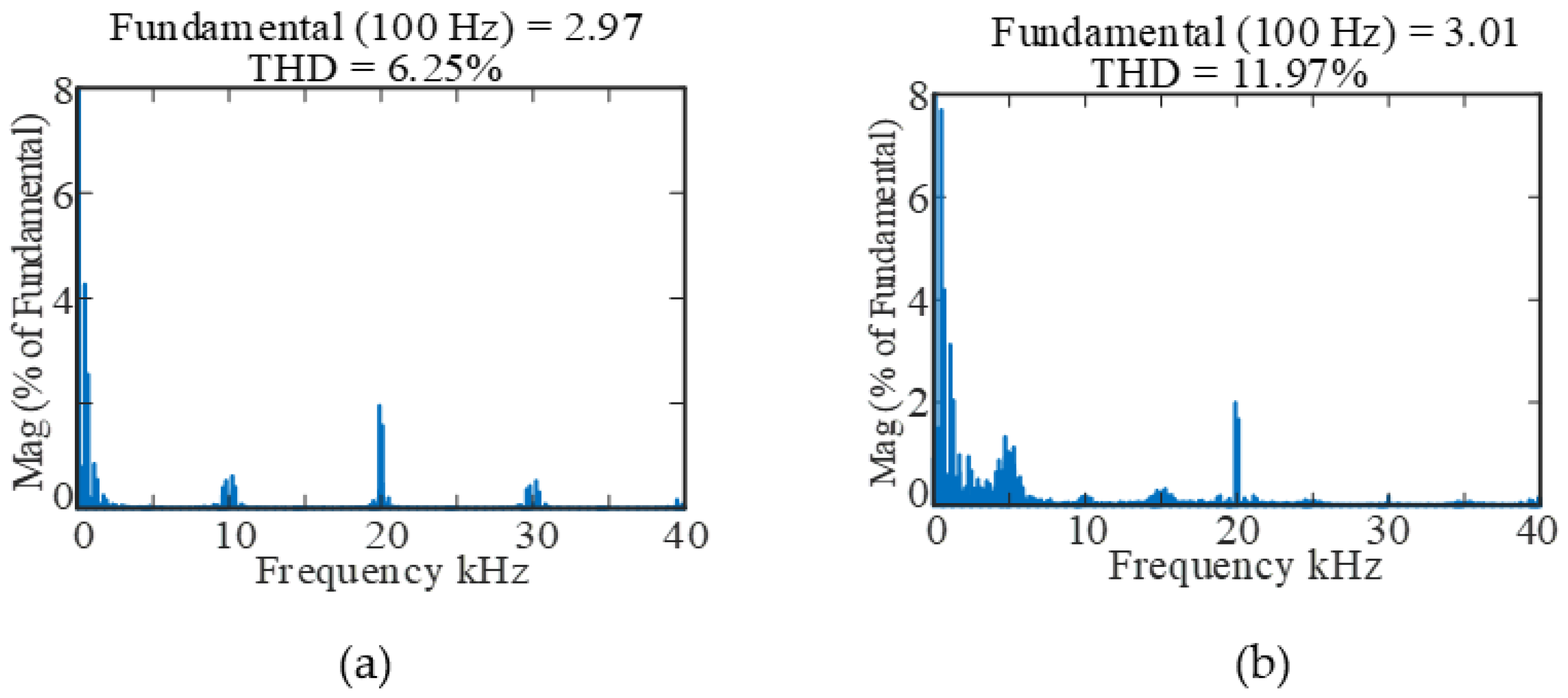

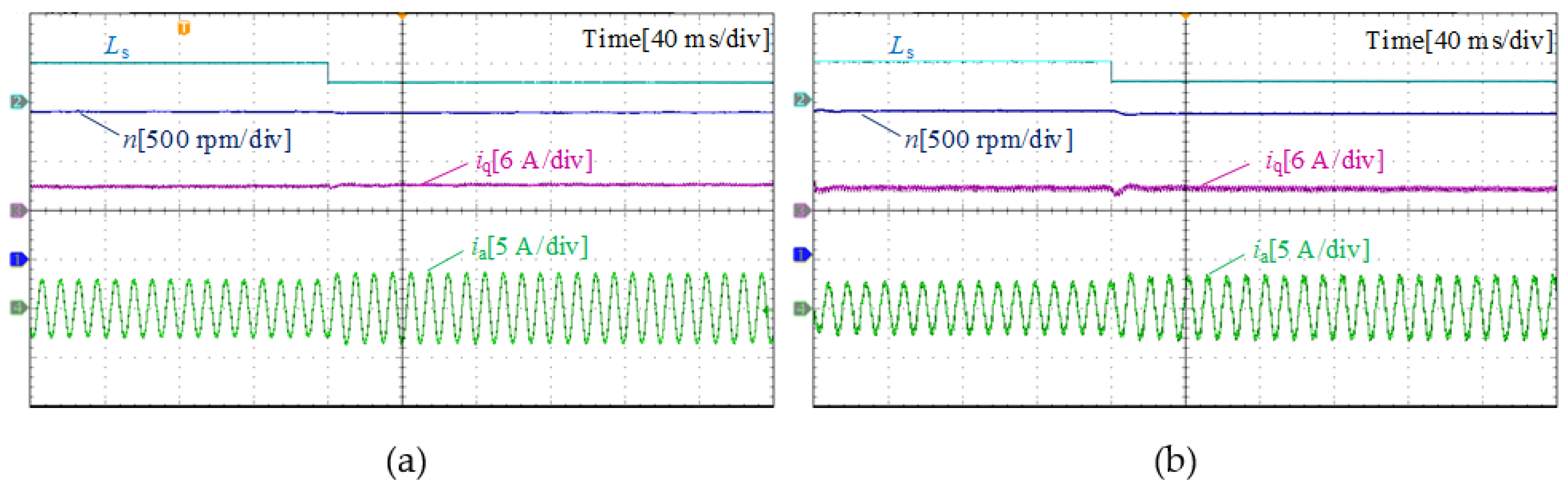

4.1. Steady-State Performance

4.2. Dynamic Performance

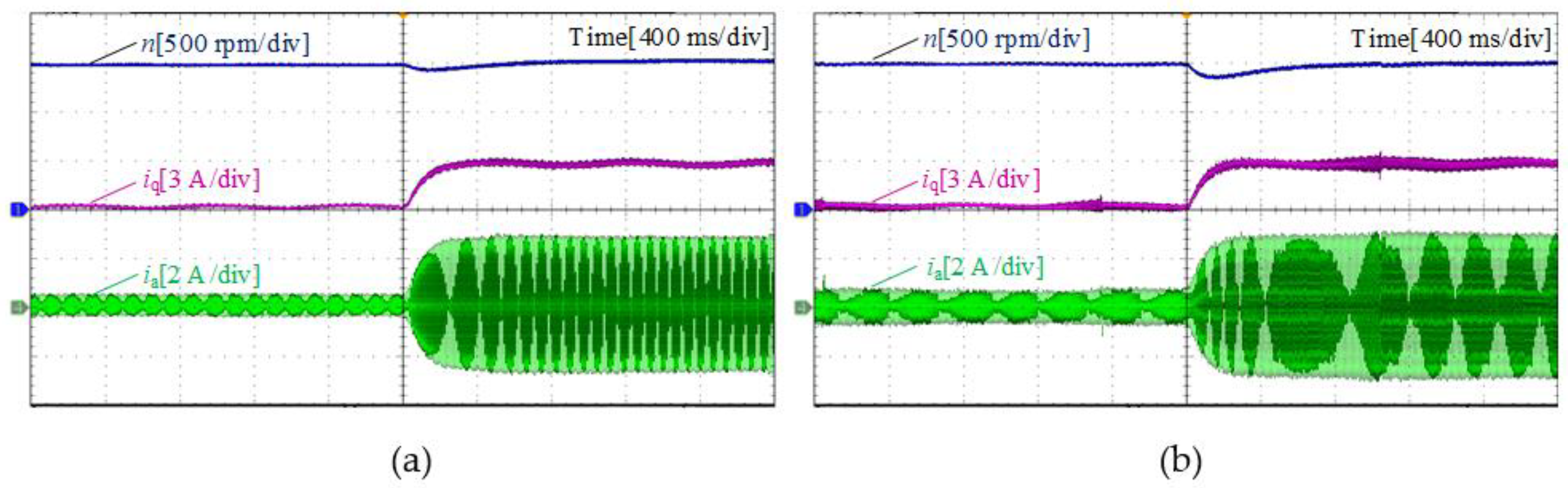

4.2.1. Load Torque Variations

4.2.2. Speed-Regulation Performance

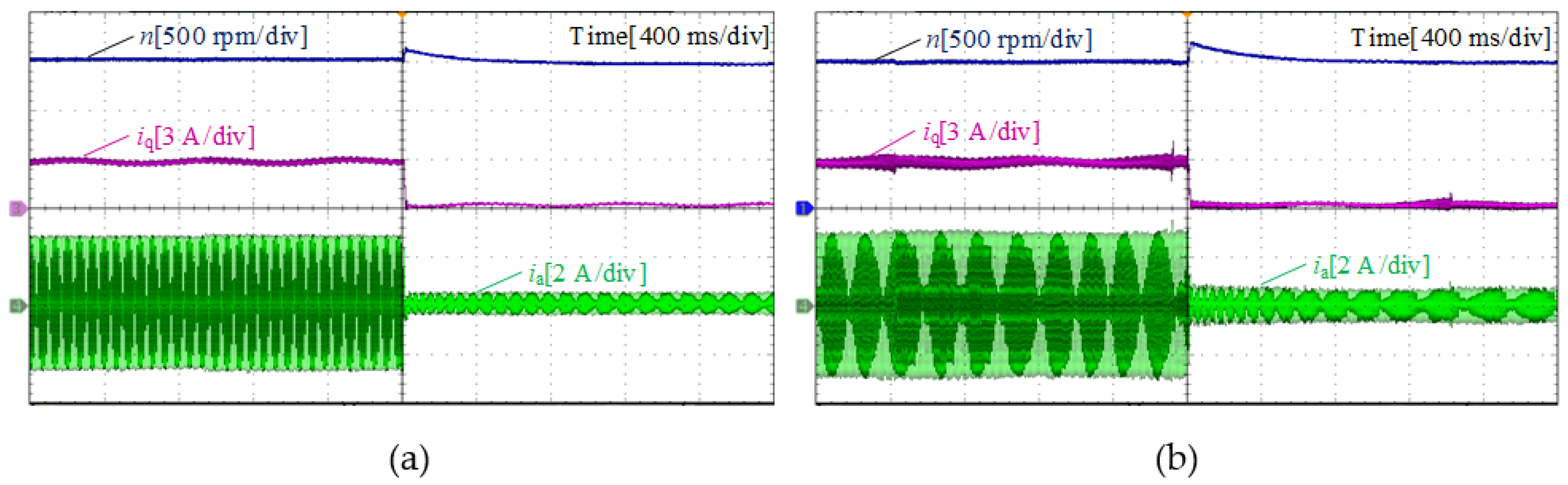

4.3. Robustness Evaluation

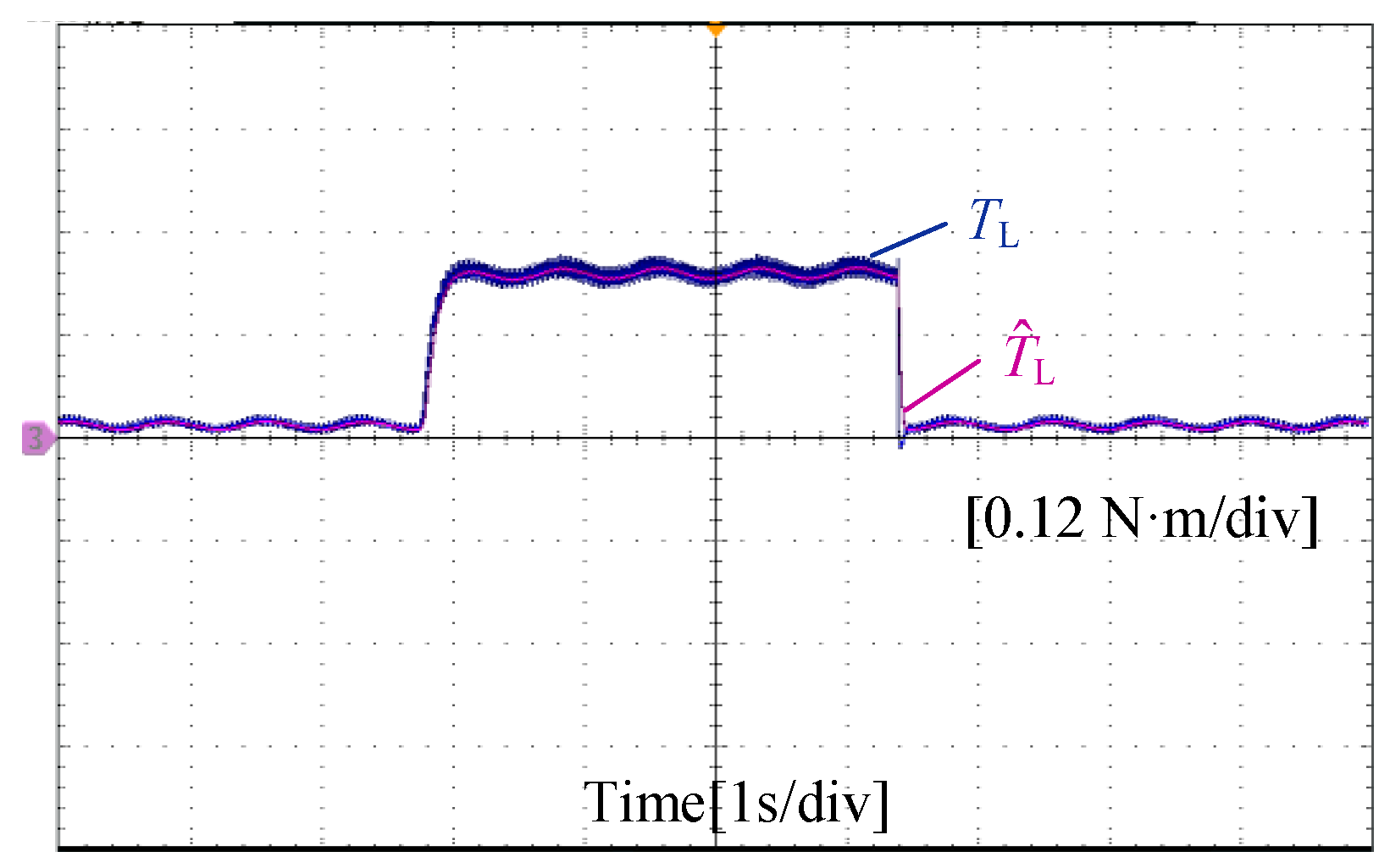

4.4. Load Torque Observation Evaluation

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Siami, M.; Khaburi, D.A.; Abbaszadeh, A.; Rodriguez, J. Robustness improvement of predictive current control using prediction error correction for permanent-magnet synchronous machines. IEEE Trans. Ind. Electron. 2016, 63, 3458–3466. [Google Scholar] [CrossRef]

- Zhang, Y.; Deng, F.; Hou, J.; Jiang, P.; Zhang, H.; Zhu, K.; Hu, Y.; Vazquez, S. Cascaded modular multilevel converter and cycloconverter based machine drive system. IEEE Trans. Ind. Electron. 2022. [Google Scholar] [CrossRef]

- Yang, M.; Lang, X.; Long, J.; Xu, D. Flux immunity robust predictive current control with incremental model and extended state observer for PMSM drive. IEEE Trans. Power Electron. 2017, 32, 9267–9279. [Google Scholar] [CrossRef]

- Belkhier, Y.; Achour, A.; Ullah, N.; Shaw, R.N.; Farooq, Z.; Ullah, A.; Alzaed, A.N. Intelligent energy-based modified super twisting algorithm and factional order PID control for performance improvement of PMSG dedicated to tidal power system. IEEE Access 2021, 9, 57414–57425. [Google Scholar] [CrossRef]

- Wang, Q.; Ding, Z.; Cheng, M.; Deng, F.; Buja, G. Direct power control of three-phase electric springs. IEEE Trans. Ind. Electron. 2021, 69, 13033–13044. [Google Scholar] [CrossRef]

- Gong, Z.; Li, J.; Dai, P.; Su, D.; Wu, X. Design and evaluation of a virtual vector based modulated model predictive control for the indirect matrix converters with improved performance. IEEE Trans. Ind. Electron. 2021, 69, 12019–12029. [Google Scholar] [CrossRef]

- Zheng, C.; Dragicevic, T.; Blaabjerg, F. Current-sensorless finite-set model predictive control for LC-filtered voltage source inverters. IEEE Trans. Power Electron. 2020, 35, 1086–1095. [Google Scholar] [CrossRef]

- Belkhier, Y.; Shaw, R.N.; Bures, M.; Islam, M.R.; Bajaj, M.; Albalawi, F.; Alqurashi, A.; Ghoneim, S.S.M. Robust interconnection and damping assignment energy-based control for a permanent magnet synchronous motor using high order sliding mode approach and nonlinear observer. Energy Rep. 2022, 8, 1731–1740. [Google Scholar] [CrossRef]

- Vazquez, S.; Rodriguez, J.; Rivera, M.; Franquelo, L.G.; Norambuena, M. Model predictive control for power converters and drives: Advances and trends. IEEE Trans. Ind. Electron. 2017, 64, 935–947. [Google Scholar] [CrossRef]

- Karamanakos, P.; Geyer, T. Guidelines for the design of finite control set model predictive controllers. IEEE Trans. Power Electron. 2020, 35, 7434–7450. [Google Scholar] [CrossRef]

- Xie, W.; Wang, X.; Wang, F.; Xu, W.; Kennel, R.M.; Gerling, D.; Lorenz, R.D. Finite-control-set model predictive torque control with a deadbeat solution for PMSM drives. IEEE Trans. Ind. Electron. 2015, 62, 5402–5410. [Google Scholar] [CrossRef]

- Xu, S.; Sun, Z.; Yao, C.; Zhang, H.; Hua, W.; Ma, G. Model predictive control with constant switching frequency for three-level t-type inverter-fed PMSM drives. IEEE Trans. Ind. Electron. 2022, 69, 8839–8850. [Google Scholar] [CrossRef]

- Zheng, C.; Dragicevic, T.; Blaabjerg, F. Model predictive control-based virtual inertia emulator for an islanded alternating current microgrid. IEEE Trans. Ind. Electron. 2021, 68, 7167–7177. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, B. Double Vectors Model predictive torque control without weighting factor based on voltage tracking error. IEEE Trans. Power Electron. 2018, 33, 2368–2380. [Google Scholar] [CrossRef]

- Chen, W.; Zeng, S.; Zhang, G.; Shi, T.; Xia, C. A modified double vectors model predictive torque control of permanent magnet synchronous motor. IEEE Trans. Power Electron. 2019, 34, 11419–11428. [Google Scholar] [CrossRef]

- Li, X.; Xue, Z.; Yan, X.; Zhang, L.; Ma, W.; Hua, W. Low-complexity multivector-based model predictive torque control for PMSM with voltage preselection. IEEE Trans. Power Electron. 2021, 36, 11726–11738. [Google Scholar] [CrossRef]

- Zheng, C.; Dragicevic, T.; Zhang, Z.; Rodriguez, J.; Blaabjerg, F. Model predictive control of LC-filtered voltage source inverters with optimal switching sequence. IEEE Trans. Power Electron. 2021, 36, 3422–3436. [Google Scholar] [CrossRef]

- Jiang, X.; Yang, Y.; Fan, M.; Ji, A.; Xiao, Y.; Zhang, X.; Zhang, W.; Garcia, C.; Vazquez, S.; Rodriguez, J. An improved implicit model predictive current control with continuous control set for PMSM drives. IEEE Trans. Transp. Electrif. 2022, 8, 2444–2455. [Google Scholar] [CrossRef]

- Garcia, C.; Rodriguez, J.; Silva, C.; Rojas, C.; Zanchetta, P.; Abu-Rub, H. Full predictive cascaded speed and current control of an induction machine. IEEE Trans. Energy Convers. 2016, 31, 1059–1067. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Model predictive direct speed control with finite control set of PMSM drive systems. IEEE Trans. Power Electron. 2013, 28, 1007–1015. [Google Scholar] [CrossRef]

- Formentini, A.; Trentin, A.; Marchesoni, M.; Zanchetta, P.; Wheeler, P. Speed finite control set model predictive control of a PMSM fed by matrix converter. IEEE Trans. Ind. Electron. 2015, 62, 6786–6796. [Google Scholar] [CrossRef]

- Han, Y.; Gong, C.; Yan, L.; Wen, H.; Wang, Y.; Shen, K. Multiobjective finite control set model predictive control using novel delay compensation technique for PMSM. IEEE Trans. Power Electron. 2020, 35, 11193–11204. [Google Scholar] [CrossRef]

- Kakosimos, P.; Abu-Rub, H. Predictive speed control with short prediction horizon for permanent magnet synchronous motor drives. IEEE Trans. Power Electron. 2018, 33, 2740–2750. [Google Scholar] [CrossRef]

- Zhang, X.; He, Y. Direct voltage-selection based model predictive direct speed control for PMSM drives without weighting factor. IEEE Trans. Power Electron. 2019, 34, 7838–7851. [Google Scholar] [CrossRef]

- Zheng, C.; Gong, Z.; Wu, X.; Dragicevic, T.; Rodriguez, J.; Blaabjerg, F. Finite-set quasi-sliding mode predictive control of LC-filtered voltage source inverters. IEEE Trans. Ind. Electron. 2022, 69, 11968–11978. [Google Scholar] [CrossRef]

- Yan, L.; Song, X. Design and implementation of luenberger model-based predictive torque control of induction machine for robustness improvement. IEEE Trans. Power Electron. 2020, 35, 2257–2262. [Google Scholar] [CrossRef]

- Zhao, L.; Huang, J.; Liu, H.; Li, B.; Kong, W. Second-order sliding-mode observer with online parameter identification for sensorless induction motor drives. IEEE Trans. Ind. Electron. 2014, 61, 5280–5289. [Google Scholar] [CrossRef]

- Sankaranarayanan, V.N.; Yadav, R.D.; Swayampakula, R.K.; Ganguly, S.; Roy, S. Robustifying payload carrying operations for quadrotors under time-varying state constraints and uncertainty. IEEE Robot. Autom. Lett. 2022, 7, 4885–4892. [Google Scholar] [CrossRef]

- Ganguly, S.; Sankaranarayanan, V.N.; Suraj, B.V.S.G.; Dev Yadav, R.; Roy, S. Efficient manoeuvring of quadrotor under constrained space and predefined accuracy. In Proceedings of the IEEE International Conference on Intelligent Robots and Systems, Prague, Czech Republic, 27 September–1 October 2021; pp. 6352–6357. [Google Scholar]

| Parameters | Symbols | Values |

|---|---|---|

| DC link voltage | Vdc | 36 V |

| Stator inductance | Ls | 0.85 mH |

| Stator resistance | Rs | 0.375 Ω |

| Rotor flux linkage | ψf | 0.01 Wb |

| Pole pairs | np | 4 |

| Inertia | J | 6 × 10−6 kg·m2 |

| Rated speed | nN | 2000 rpm |

| Rated torque | TN | 0.3 N·m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, C.; Yang, J.; Gong, Z.; Xiao, Z.; Dong, X. Cascade-Free Modulated Predictive Direct Speed Control of PMSM Drives. Energies 2022, 15, 7200. https://doi.org/10.3390/en15197200

Zheng C, Yang J, Gong Z, Xiao Z, Dong X. Cascade-Free Modulated Predictive Direct Speed Control of PMSM Drives. Energies. 2022; 15(19):7200. https://doi.org/10.3390/en15197200

Chicago/Turabian StyleZheng, Changming, Jiafeng Yang, Zheng Gong, Ziyu Xiao, and Xuanxuan Dong. 2022. "Cascade-Free Modulated Predictive Direct Speed Control of PMSM Drives" Energies 15, no. 19: 7200. https://doi.org/10.3390/en15197200

APA StyleZheng, C., Yang, J., Gong, Z., Xiao, Z., & Dong, X. (2022). Cascade-Free Modulated Predictive Direct Speed Control of PMSM Drives. Energies, 15(19), 7200. https://doi.org/10.3390/en15197200