Prognosis and Health Management (PHM) of Solid-State Batteries: Perspectives, Challenges, and Opportunities

Abstract

:1. Introduction

2. Solid-State Batteries

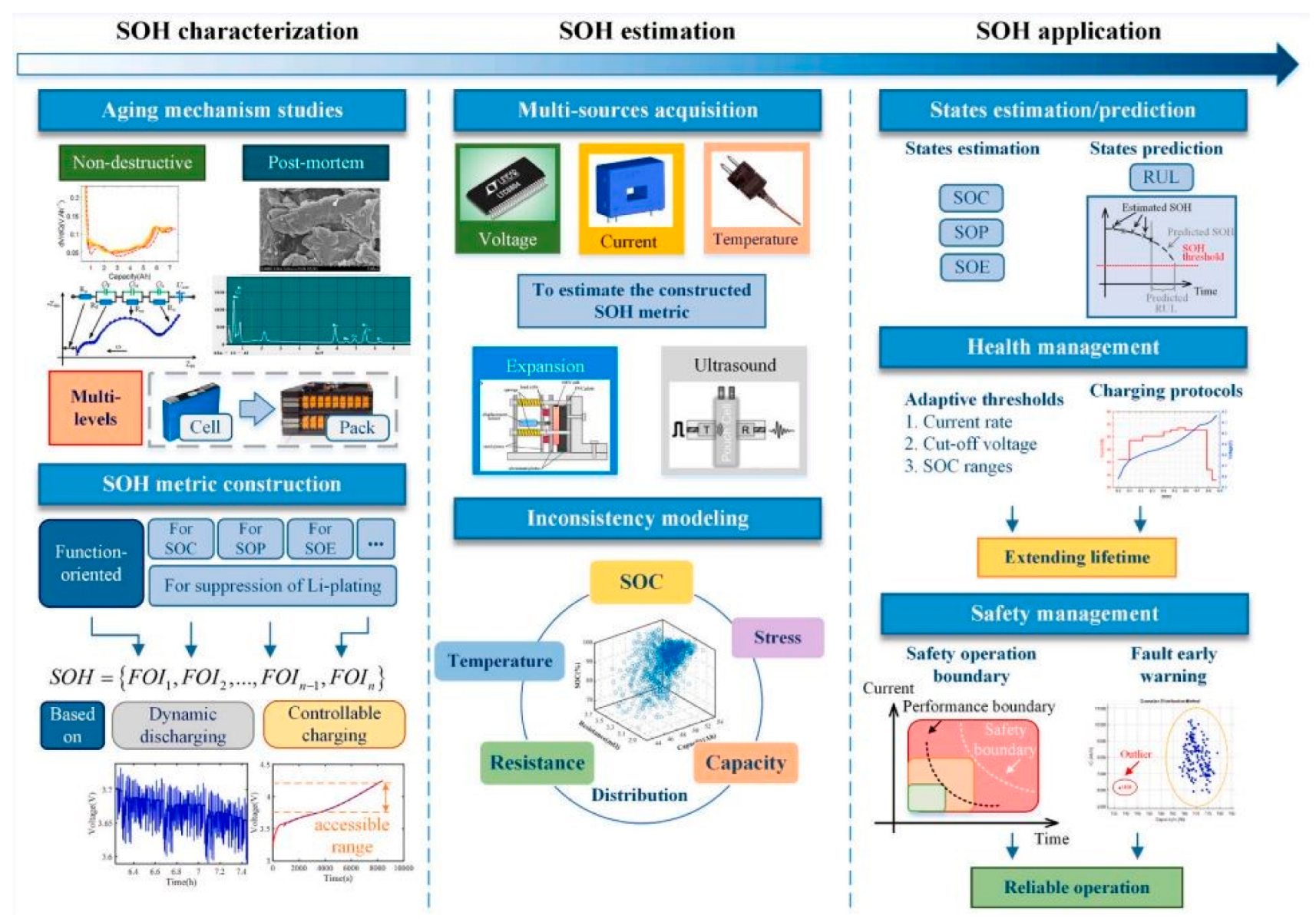

2.1. Health Status Assessment of SSBs

- SOH characterization

- 2.

- SOH estimation

- 3.

- SOH application

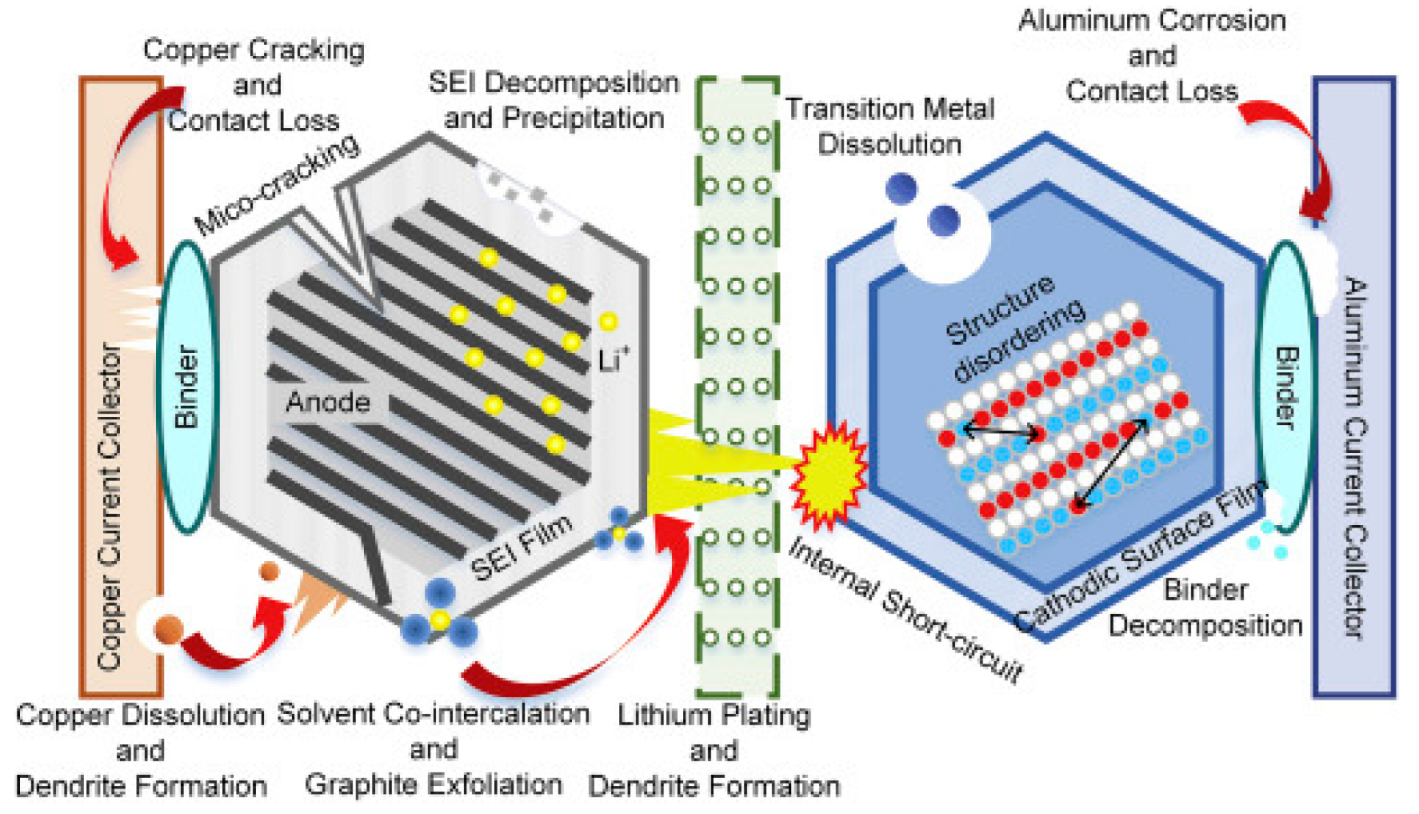

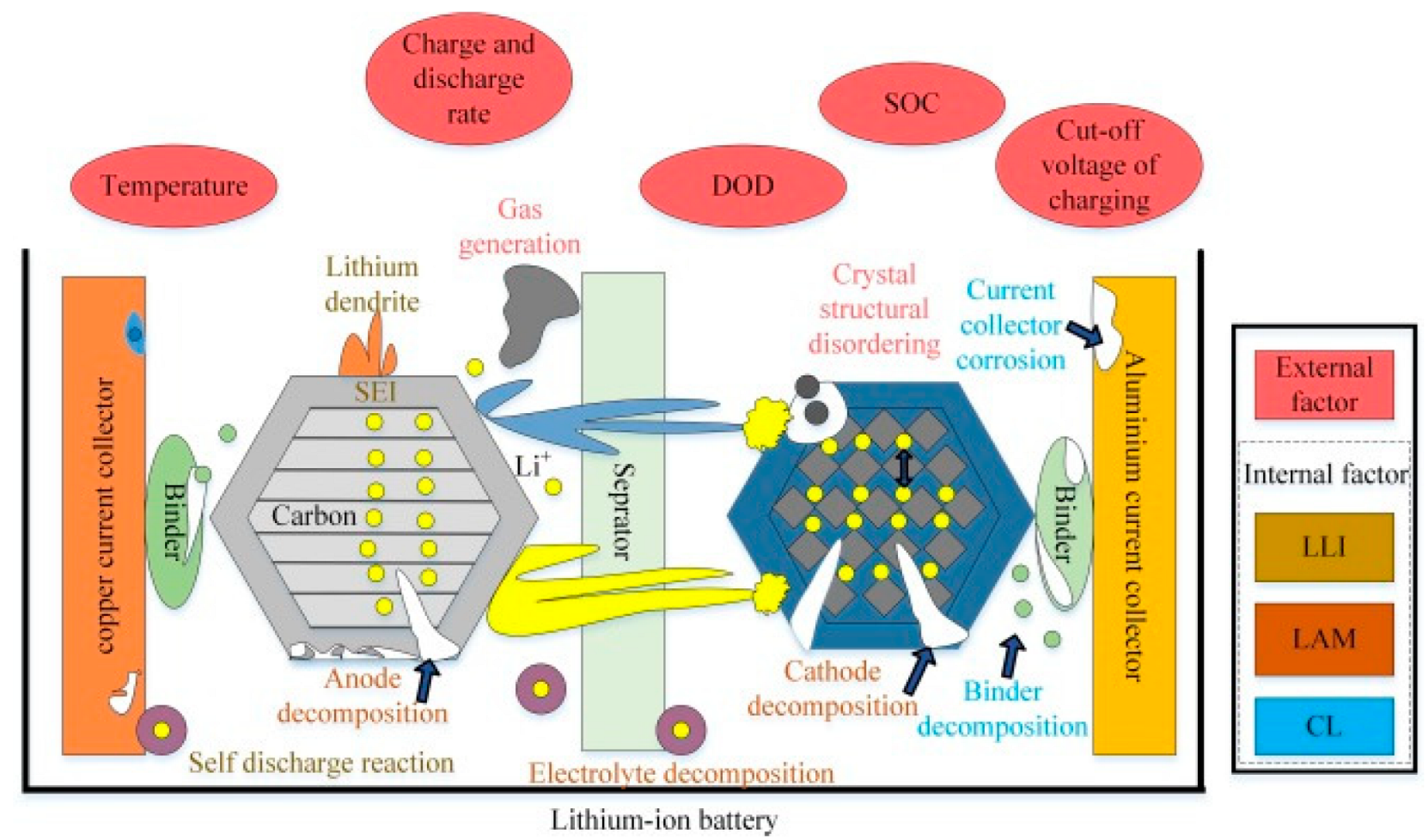

2.2. Battery Aging and Aging Characteristics

3. Prognostics and Health Management (PHM)

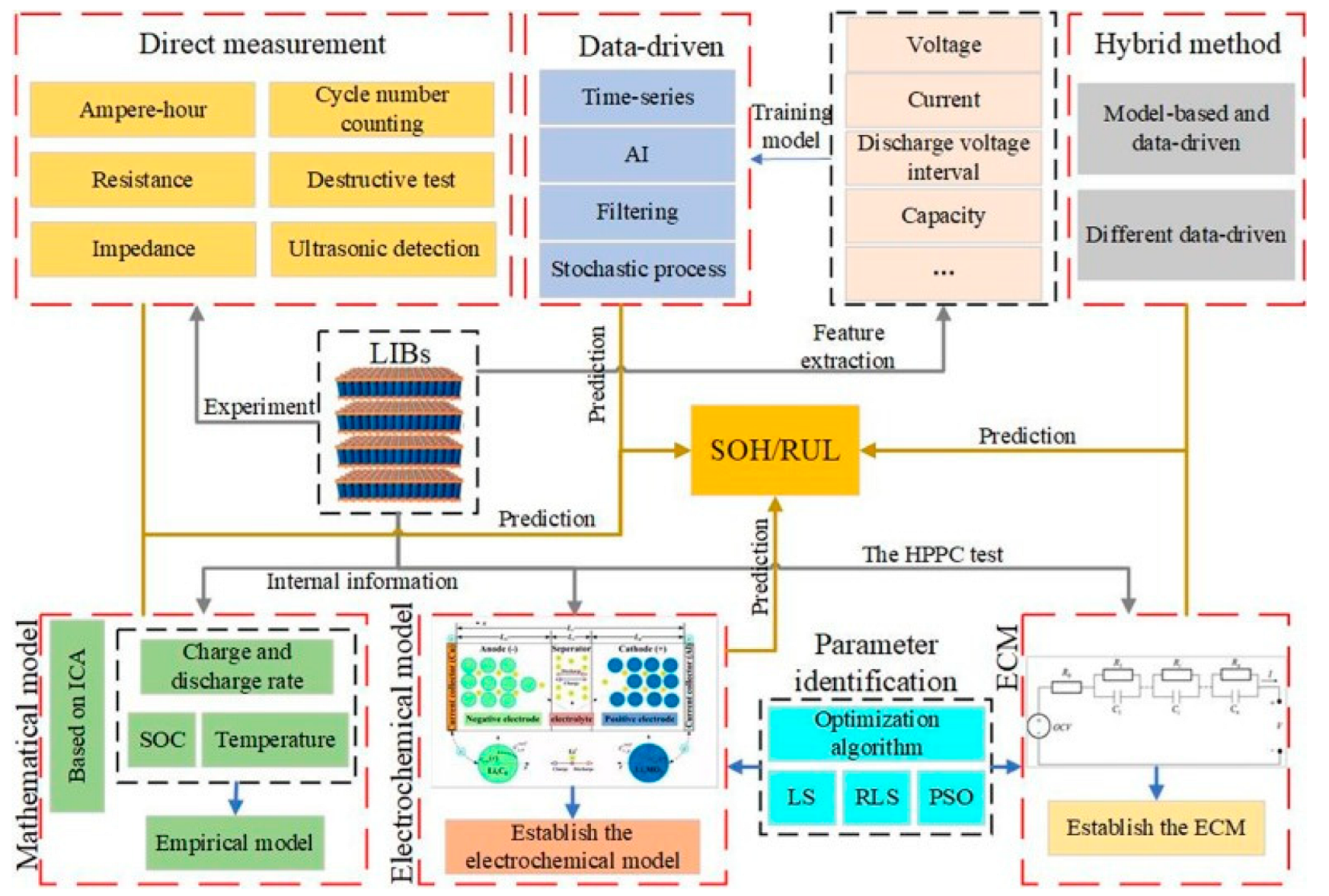

3.1. Model-Based (Physics-Based) Approaches

3.1.1. Electrochemical (Mechanistic) Models

3.1.2. Equivalent Circuit Models

3.1.3. Empirical Models

3.1.4. Fused Models

3.1.5. Comparison of Physics-Based Approaches

3.2. Data-Driven Approaches

3.2.1. Artificial Neural Network (ANN)

3.2.2. Kernel Ridge Regression (KRR)

3.2.3. Data-Driven Prognosis (DDP)

3.2.4. Support Vector Machine (SVM)

3.2.5. k-Nearest Neighbor (kNN)

3.2.6. Random Forest (RF)

3.2.7. Bayesian Method (BM)

3.3. Application of ML-Based Data-Driven Techniques in Solid-State Batteries Research

3.3.1. Anode Materials

3.3.2. Cathode Materials

3.3.3. Electrolyte Materials

3.3.4. Comparison of Data-Driven Approaches

3.4. Hybrid Approaches

4. Challenges, Perspectives, and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- EDTA. Electric Drive Transportation Association (EDTA); EDTA: Washington, DC, USA, 2021. [Google Scholar]

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Source 2013, 226, 272–288. [Google Scholar] [CrossRef]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Source 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Li, L.; Chen, X.; Yuan, Q.; Wang, T.; Ji, H.; Papović, S.; Raleva, K.; Pan, F.; Yang, T.; Li, J. Effects of minor mechanical deformation on the lifetime and performance of commercial 21700 lithium-ion battery. J. Electrochem. Soc. 2022, 169, 060544. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, S.; He, X.; Wang, C.; Zhao, D. A multi-factor evaluation method for the thermal runaway risk of lithium-ion batteries. J. Energy Storage 2022, 45, 103767. [Google Scholar] [CrossRef]

- Held, M.; Tuchschmid, M.; Zennegg, M.; Figi, R.; Schreiner, C.; Mellert, L.D.; Welte, U.; Kompatscher, M.; Hermann, M.; Nachef, L. Thermal runaway and fire of electric vehicle lithium-ion battery and contamination of infrastructure facility. Renew. Sustain. Energy Rev. 2022, 165, 112474. [Google Scholar] [CrossRef]

- Schnell, J.; Günther, T.; Knoche, T.; Vieider, C.; Köhler, L.; Just, A.; Keller, M.; Passerini, S.; Reinhart, G. All-solid-state lithium-ion and lithium metal batteries—Paving the way to large-scale production. J. Power Source 2018, 382, 160–175. [Google Scholar] [CrossRef]

- Takada, K. Progress in solid electrolytes toward realizing solid-state lithium batteries. J. Power Source 2018, 394, 74–85. [Google Scholar] [CrossRef]

- Michael, G.; Pecht, M.K. Prognostics and Health Management of Electronics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018. [Google Scholar]

- Meng, H.; Li, Y.F. A review on prognostics and health management (PHM) methods of lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 116, 109405. [Google Scholar] [CrossRef]

- Shin, I.; Lee, J.; Lee, J.Y.; Jung, K.; Kwon, D.; Youn, B.D.; Jang, H.S.; Choi, J.H. A framework for prognostics and health management applications toward smart manufacturing systems. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 535–554. [Google Scholar] [CrossRef]

- Baur, M.; Albertelli, P.; Monno, M. A review of prognostics and health management of machine tools. Int. J. Adv. Manuf. Technol. 2020, 107, 2843–2863. [Google Scholar] [CrossRef]

- Sunil, K.; Pradhan, B.C. Battery management strategies: An essential review for battery state of health monitoring techniques. J. Energy Storage 2022, 51, 104427. [Google Scholar]

- Zio, E. Prognostics and health management (PHM): Where are we and where do we (need to) go in theory and practice. Reliab. Eng. Syst. Saf. 2022, 218, 108119. [Google Scholar] [CrossRef]

- Palacín, M.R. Recent advances in rechargeable battery materials: A chemist’s perspective. Chem. Soc. Rev. 2009, 38, 2565–2575. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Li, S.E.; Jia, Z.; Egardt, B. Enhanced sample entropy-based health management of li-ion battery for electrified vehicles. Energy 2014, 64, 953–960. [Google Scholar] [CrossRef]

- Feng, X.; Li, J.; Ouyang, M.; Lu, L.; Li, J.; He, X. Using probability density function to evaluate the state of health of lithium-ion batteries. J. Power Source 2013, 232, 209–218. [Google Scholar] [CrossRef]

- Zheng, Y.; Han, X.; Lu, L.; Li, J.; Ouyang, M. Lithium ion battery pack power fade fault identification based on shannon entropy in electric vehicles. J. Power Source 2013, 223, 136–146. [Google Scholar] [CrossRef]

- Guan, P.; Liu, L.; Lin, X. Simulation and experiment on solid electrolyte interphase (SEI) morphology evolution and lithium-ion diffusion. J. Electrochem. Soc. 2015, 162, A1798–A1808. [Google Scholar] [CrossRef]

- Han, X.; Ouyang, M.; Lu, L.; Li, J.; Zheng, Y.; Li, Z. Comparative study of commercial lithium ion battery cycle life in electrical vehicle: Aging mechanism identification. J. Power Source 2014, 251, 38–54. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, C.; Guo, Z. Simulation of crack behavior of secondary particles in Li-ion battery electrodes during lithiation/de-lithiation cycles. Int. J. Mech. Sci. 2019, 155, 4802. [Google Scholar] [CrossRef]

- Schmidt, A.P.; Bitzer, M.; Imre, Á.W.; Guzzella, L. Model-based distinction and quantification of capacity loss and rate capability fade in Li-ion batteries. J. Power Source 2010, 195, 7634–7638. [Google Scholar] [CrossRef]

- Ramadesigan, V.; Chen, K.; Burns, N.A.; Boovaragavan, V.; Braatz, R.D.; Subramanian, V.R. Parameter estimation and capacity fade analysis of lithium-ion batteries using reformulated models. J. Electrochem. Soc. 2011, 158, A1048. [Google Scholar] [CrossRef]

- Fu, R.; Choe, S.-Y.; Agubra, V.; Fergus, J. Modeling of degradation effects considering side reactions for a pouch type Li-ion polymer battery with carbon anode. J. Power Source 2014, 261, 120–135. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Source 2011, 196, 6007–6014. [Google Scholar] [CrossRef]

- Watrin, N.; Blunier, B.; Miraoui, A. Review of adaptive systems for lithium batteries State-of-Charge and State-of-Health estimation. In Proceedings of the 2012 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 18–20 June 2012. [Google Scholar]

- Barré, A.; Deguilhem, B.; Grolleau, S.; Gérard, M.; Suard, F.; Riu, D. A review on lithium-ion battery ageing mechanisms and estimations for automotive applications. J. Power Source 2013, 241, 680–689. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

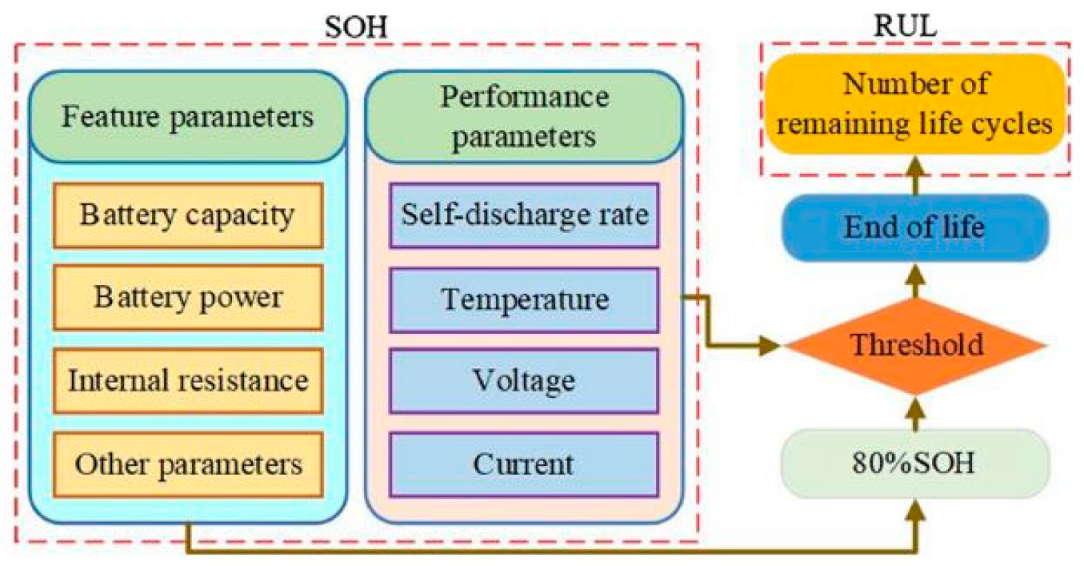

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A review of the state of health for lithium-ion batteries: Research status and suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

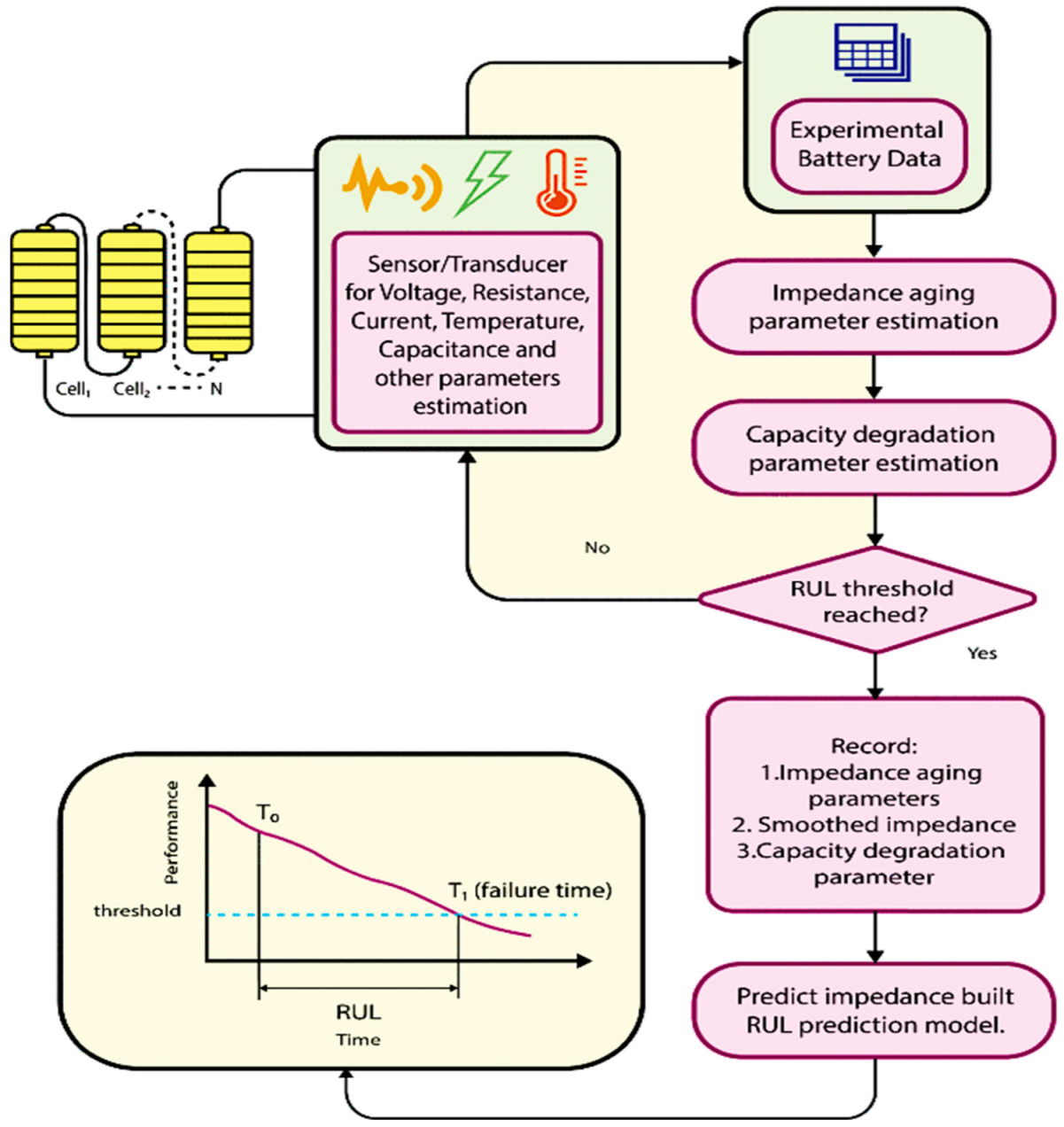

- Hasib, S.A.; Islam, S.; Chakrabortty, R.K.; Ryan, M.J.; Saha, D.K.; Ahamed, M.H.; Moyeen, S.I.; Das, S.K.; Ali, M.F.; Islam, M.R.; et al. Comprehensive review of available battery datasets, RUL prediction approaches, and advanced battery management. IEEE Access 2021, 9, 86166–86193. [Google Scholar] [CrossRef]

- Ge, M.-F.; Liu, Y.; Jiang, X.; Liu, J. A review on state of health estimations and remaining useful life prognostics of lithium-ion batteries. Measurement 2021, 174, 109057. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Cuma, M.U.; Koroglu, T. A comprehensive review on estimation strategies used in hybrid and battery electric vehicles. Renew. Sustain. Energy Rev. 2015, 42, 517–531. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Source 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Lipu, M.H.; Hannan, M.; Hussain, A.; Hoque, M.; Ker, P.J.; Saad, M.; Ayob, A. A review of state of health and remaining useful life estimation methods for lithium-ion battery in electric vehicles: Challenges and recommendations. J. Clean. Prod. 2018, 205, 115–133. [Google Scholar] [CrossRef]

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State estimation for advanced battery management: Key challenges and future trends. Renew. Sustain. Energy Rev. 2019, 114, 109334. [Google Scholar] [CrossRef]

- Huang, L.; Ling, C. Practicing deep learning in materials science: An evaluation for predicting the formation energies. J. Appl. Phys. 2020, 128, 124901. [Google Scholar] [CrossRef]

- Ungurean, L.; Cârstoiu, G.; Micea, M.V.; Groza, V. Battery state of health estimation: A structured review of models, methods and commercial devices. Int. J. Energy Res. 2017, 41, 151–181. [Google Scholar] [CrossRef]

- Sarmah, S.B.; Kalita, P.; Garg, A.; Niu, X.D.; Zhang, X.W.; Peng, X.; Bhattacharjee, D. A Review of State of Health Estimation of Energy Storage Systems: Challenges and Possible Solutions for Futuristic Applications of Li-Ion Battery Packs in Electric Vehicles. J. Electrochem. Energy Convers. Storage 2019, 16, 040801. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Jiang, J.; Zhang, W.; Zhang, L.; Wang, Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. J. Clean. Prod. 2021, 314, 128015. [Google Scholar] [CrossRef]

- Hu, X.; Xu, L.; Lin, X.; Pecht, M. Battery lifetime prognostics. Joule 2020, 4, 310–346. [Google Scholar] [CrossRef]

- Fabre, S.D.; Guy-Bouyssou, D.; Bouillon, P.; Cras, F.L.; Delacourt, C. Charge/discharge simulation of an all-solid-state thin-film battery using a one-dimensional model. J. Electrochem. Soc. 2011, 159, A104–A115. [Google Scholar] [CrossRef]

- Remmlinger, J.; Buchholz, M.; Meiler, M.; Bernreuter, P.; Dietmayer, K. State-of health monitoring of lithium-ion batteries in electric vehicles by on-board internal resistance estimation. J. Power Source 2011, 196, 5357–5363. [Google Scholar] [CrossRef]

- Wang, P.; Wang, L.W.; Wang, S.; Fan, L.; Wang, T. Influence of temperature on discharge capacity of 18650 ternary lithium batteries. Technol. Mark. 2018, 25, 10–14. [Google Scholar]

- Ma, Z.; Jiang, J.; Zhang, W.; Wang, Z.; Zheng, L.; Shi, W. Path dependence study on thermal aging of lithium ion power batteries. J. Electr. Eng. 2014, 29, 221–227. [Google Scholar]

- Gao, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Ma, Z.; Jiang, Y. Lithium ion battery aging mechanisms and life model under different charging stresses. J. Power Source 2017, 356, 103–114. [Google Scholar] [CrossRef]

- Maher, K.; Yazami, R. Effect of overcharge on entropy and enthalpy of lithium-ion batteries. Electrochim. Acta 2013, 101, 71–78. [Google Scholar] [CrossRef]

- Meng, X.; Liu, L.; Hui, H.; Feng, X.; Chen, G. Effect of discharge depth on battery life. Automot. Sci. Technol. 2016, 3, 47–51. [Google Scholar]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; van den Bossche, P.; Coosemans, T.; et al. Lithium iron phosphate based battery-assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Notten, P.H.; Danilov, D.L. Battery modeling: A versatile tool to design advanced battery management systems. Adv. Chem. Eng. Sci. 2014, 4, 62–72. [Google Scholar] [CrossRef]

- Jiang, J.; Gao, Y.; Zhang, C.; Zhang, W.; Jiang, Y. Lifetime rapid evaluation method for lithium-ion battery with Li (NiMnCo)O-2 cathode. J. Electrochem. Soc. 2019, 166, A1070–A1081. [Google Scholar] [CrossRef]

- Castro, L.; Dedryvère, R.; Ledeuil, J.B.; Bréger, J.; Tessier, C.; Gonbeau, D. Aging mechanisms of LiFePO4//graphite cells studied by XPS: Redox reaction and electrode/electrolyte interfaces. J. Electrochem. Soc. 2012, 159, A357–A363. [Google Scholar] [CrossRef]

- Liu, W.G.; Zhou, B.; Wang, X.D.; Gao, J.K.; Liu, X.J. Study on attenuation of circulating capacity of 18650 lithium ion batteries. Power Technol. 2012, 36, 306–309. [Google Scholar]

- Kim, J.H.; Woo, S.C.; Park, M.S.; Kim, K.J.; Yim, T.; Kim, J.S.; Kim, Y.J. Capacity fading mechanism of LiFePO4-based lithium secondary battery for stationary energy storage. J. Power Source 2013, 229, 190–197. [Google Scholar] [CrossRef]

- Kassem, M.; Bernard, J.; Revel, R.; Pelissier, S.; Duclaud, F.; Delacourt, C. Calendar aging of a graphite/LiFePo4 cell. J. Power Source 2012, 208, 296–305. [Google Scholar] [CrossRef]

- Li, X.; Zhang, H.; Zhang, J.P.; Li, J. Analysis of factors influencing the cycle life of lithium ion batteries. Power Technol. 2015, 39, 2772–2774. [Google Scholar]

- Pastor-Fernández, C.; Uddin, K.; Chouchelamane, G.H.; Widanage, W.D.; Marco, J. A comparison between electrochemical impedance spectroscopy and incremental capacity-differential voltage as li-ion diagnostic techniques to identify and quantify the effects of degradation modes within battery management systems. J. Power Source 2017, 360, 301–318. [Google Scholar] [CrossRef]

- Yang, B.J.; Dai, H.F. Quantification method of lithium ion battery aging mode based on ac impedance spectrum. J. Wuhan Univ. Nat. Sci. Ed. 2019, 52, 635–641. [Google Scholar]

- Miguel, E.; Plett, G.L.; Trimboli, M.S.; Oca, L.; Iraola, U.; Bekaert, E. Review of computational parameter estimation methods for electrochemical models. J. Energy Storage 2021, 44, 103388. [Google Scholar] [CrossRef]

- Tian, H.K.; Qi, Y. Simulation of the effect of contact area loss in all-solid-state Li-ion batteries. J. Electrochem. Soc. 2017, 164, E3512–E3521. [Google Scholar] [CrossRef]

- Danilov, D.; Niessen, R.A.H.; Notten, P.H.L. Modeling all-solid-state Li-ion batteries. J. Electrochem. Soc. 2011, 158, A215. [Google Scholar] [CrossRef]

- Kim, Y.; Lin, X.; Abbasalinejad, A.; Kim, S.U.; Chung, S.H. On state estimation of all solid-state batteries. Electrochim. Acta 2019, 317, 663–672. [Google Scholar] [CrossRef]

- Shao, Y.Q.; Liu, H.L.; Shao, X.D.; Sang, L.; Chen, Z.T. An all coupled electrochemical-mechanical model for all-solid-state Li-ion batteries considering the effect of contact area loss and compressive pressure. Energy 2022, 239, 121929. [Google Scholar] [CrossRef]

- Fathiannasab, H.; Zhu, L.; Chen, Z. Chemo-mechanical modeling of stress evolution in all-solid-state lithium-ion batteries using synchrotron transmission X-ray microscopy tomography. J. Power Source 2021, 483, 229028. [Google Scholar] [CrossRef]

- Ansah, S.; Shin, N.; Lee, J.S.; Cho, H.H. A comprehensive parametric study for solid-state lithium-ion battery through finite element simulation. Electron. Mater. Lett. 2021, 17, 532–542. [Google Scholar] [CrossRef]

- Grazioli, D.; Verners, O.; Zadin, V.; Brandell, D.; Simone, A. Electrochemical-mechanical modeling of solid polymer electrolytes: Impact of mechanical stresses on Li-ion battery performance. Electrochim. Acta 2019, 296, 1122–1141. [Google Scholar] [CrossRef]

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling of galvanostatic charge and discharge of the lithium polymer insertion cell. J. Electrochem. Soc. 1993, 140, 1526–1533. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.B.; Jaegermann, W.; Hausbrand, R.; Xu, B.X. Interface equilibrium modeling of all-solid-state lithium-ion thin film batteries. J. Power Source 2020, 454, 227892. [Google Scholar] [CrossRef]

- Safari, M.; Delacourt, C. Mathematical modeling of lithium iron phosphate electrode: Galvanostatic charge/discharge and path dependence. J. Electrochem. Soc. 2011, 158, A63. [Google Scholar] [CrossRef]

- Bucci, G.; Swamy, T.; Chiang, Y.M.; Carter, W.C. Modeling of internal mechanical failure of all-solid-state batteries during electrochemical cycling, and implications for battery design. J. Mater. Chem. 2017, 5, 19422–19430. [Google Scholar] [CrossRef]

- Kodama, M.; Horikawa, N.; Ohashi, A.; Hirai, S. Coupled nonlinear stress and electric field numerical simulation for all-solid-state lithium-ion batteries. J. Power Sources Adv. 2021, 8, 100049. [Google Scholar] [CrossRef]

- Kazemi, N.; Danilov, D.L.; Haverkate, L.; Dudney, N.J.; Unnikrishnan, S.; Notten, P.H. Modeling of all-solid-state thin-film Li-ion batteries: Accuracy improvement. Solid State Ion. 2019, 334, 111–116. [Google Scholar] [CrossRef]

- West, W.C.; Hood, Z.D.; Adhikari, S.P.; Liang, C.; Lachgar, A.; Motoyama, M.; Iriyama, Y. Reduction of charge-transfer resistance at the solid electrolyte—Electrode interface by pulsed laser deposition of films from a crystalline Li2PO2N source. J. Power Source 2016, 312, 116–122. [Google Scholar] [CrossRef]

- Takada, K.; Ohta, N.; Zhang, L.; Fukuda, K.; Sakaguchi, I.; Ma, R.; Osada, M.; Sasaki, T. Interfacial modification for high-power solid-state lithium batteries. Solid State Ion. 2008, 179, 1333–1337. [Google Scholar] [CrossRef]

- Nagao, M.; Hayashi, A.; Tatsumisago, M. High-capacity Li2S–nanocarbon composite electrode for all-solid-state rechargeable lithium batteries. J. Mater. Chem. 2012, 22, 10015–10020. [Google Scholar] [CrossRef]

- Nishio, Y.; Kitaura, H.; Hayashi, A.; Tatsumisago, M. All-solid-state lithium secondary batteries using nanocomposites of NiS electrode/Li2S–P2S5 electrolyte prepared via mechanochemical reaction. J. Power Source 2009, 189, 629–632. [Google Scholar] [CrossRef]

- Song, X.; Lu, Y.; Wang, F.; Zhao, X.; Chen, H. A coupled electro-chemo-mechanical model for all-solid-state thin film Li-ion batteries: The effects of bending on battery performances. J. Power Source 2020, 452, 227803. [Google Scholar] [CrossRef]

- Becker-Steinberger, K.; Funken, S.; Landstorfer, M.; Urban, K. A mathematical model for all solid-state lithium-ion batteries. ECS Trans. 2019, 25, 285–296. [Google Scholar] [CrossRef]

- Deng, Z.; Chen, C.; Li, X.-G.; Ong, S.P. An electrostatic spectral neighbor analysis potential for lithium nitride. npj Comput. Mater. 2019, 5, 75. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Fan, J. Evaluation of lithium-ion battery equivalent circuit models for state of charge estimation by an experimental approach. Energy 2011, 4, 582–598. [Google Scholar] [CrossRef]

- Rajabloo, B.; Jokar, A.; Wakem, W.; Désilets, M.; Brisard, G. Lithium iron phosphate electrode semi-empirical performance mode. J. Appl. Electrochem. 2018, 48, 663–674. [Google Scholar] [CrossRef]

- Jeon, D.H.; Baek, S.M. Thermal modeling of cylindrical lithium ion battery during discharge cycle. Energy Convers. Manag. 2011, 52, 2973–2981. [Google Scholar] [CrossRef]

- Rasmussen, C.E. Gaussian Processes in Machine Learning. In Advanced Lectures on Machine Learning: ML Summer Schools 2003; Lectures Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Cho, S.; Jeong, H.; Han, C.; Jin, S.; Lim, J.H.; Oh, J. State-of charge estimation for lithium-ion batteries under various operating condition using an equivalent circuit model. Comput. Chem. Eng. 2012, 41, 1–9. [Google Scholar] [CrossRef]

- Zhu, W.H.; Zhu, Y.; Tatarchuk, B.J. A simplified equivalent circuit model for simulation of Pb-acid batteries at load for energy storage application. Energy Convers. Manag. 2011, 52, 2794–2799. [Google Scholar] [CrossRef]

- Snoek, J.; Larochelle, H.; Adams, R.P. Practical bayesian optimization of machine learning algorithms. arXiv 2012, arXiv:1206.2944. [Google Scholar]

- Ling, C. A review of the recent progress in battery informatics. npj Comput. Mater. 2022, 8, 33. [Google Scholar] [CrossRef]

- Eremin, R.A.; Zolotarev, P.N.; Ivanshina, O.Y.; Bobrikov, I.A. Li(Ni,Co,Al)O2 cathode delithiation: A combination of topological analysis, density functional theory, neutron diffraction, and machine learning techniques. J. Phys. Chem. C 2017, 121, 8293–28305. [Google Scholar] [CrossRef]

- Natarajan, A.R.; Ven, A.V.D. Machine-learning the configurational energy of multicomponent crystalline solids. npj Comput. Mater. 2018, 4, 56. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K.; Poll, S.; Christophersen, J. Prognostics methods for battery health monitoring using a bayesian framework. IEEE Trans-Actions Instrum. Meas. 2009, 58, 291–297. [Google Scholar] [CrossRef]

- Wright, R.B.; Motloch, C.G.; Belt, J.R.; Christophersen, J.P.; Ho, C.D.; Richardson, R.A.; Bloom, I.; Jones, S.A.; Battaglia, V.S.; Henriksen, G.L.; et al. Calendar and cycle-life studies of advanced technology development program gen-eration 1 lithium-ion batteries. J. Power Source 2002, 110, 445–470. [Google Scholar] [CrossRef]

- Christophersen, J.P.; Bloom, I.; Thomas, E.V.; Gering, K.L.; Henriksen, G.L.; Battaglia, V.S.; Howell, D. Advanced Technology Development Program for Lithium-Ion Batteries: Gen 2 Performance Evaluation Final Report; U.S. Department of Energy: Washington, DC, USA, 2006.

- Ramadass, P.; Haran, B.; White, R.; Popov, B.N. Mathematical model-ing of the capacity fade of Li-ion cells. J. Power Source 2003, 123, 230–240. [Google Scholar] [CrossRef]

- Ning, G.; White, R.E.; Popov, B.N. A generalized cycle life model of rechargeable Li-ion batteries. Electrochim. Acta 2006, 51, 2012–2022. [Google Scholar] [CrossRef]

- Verbrugge, M.; Tate, E. Adaptive state of charge algorithm for nickel metal hydride batteries hysteresis phenomena. J. Power Source 2004, 126, 236–249. [Google Scholar] [CrossRef]

- Verbrugge, M.; Koch, B. Generalized recursive algorithm for adaptive multiparameter regression application to lead acid, nickel metal hydride, and lithium-ion batteries. J. Electrochem. Soc. 2006, 153, A187–A201. [Google Scholar] [CrossRef]

- Liu, C.; Liu, L. Optimal design of li-ion batteries through multi-physics modeling and multi-objective optimization. J. Electrochem. Soc. 2017, 164, E3254–E3264. [Google Scholar] [CrossRef]

- Xing, Y.; Ma, E.W.; Tsui, K.L.; Pecht, M. An ensemble model for predict-ing the remaining useful performance of lithium-ion batteries. Microelectron. Reliab. 2013, 53, 811–820. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, L.; Su, X.; Ma, P. Prognostics of lithium-ion batteries based on flexible support vector regression. In Proceedings of the Prognostics & System Health Management Conference, Zhangjiajie, China, 24–27 August 2014; Volume 7, pp. 6492–6508. [Google Scholar]

- Rezvani, M.; AbuAli, M.; Lee, S.; Lee, J.; Ni, J. A comparative analysis of techniques for electric vehicle battery prognostics and health manage-ment (PHM). SAE Pap. 2011, 191, 1–9. [Google Scholar]

- Prada, E.; Di Domenico, D.; Creff, Y.; Bernard, J.; Sauvant-Moynot, V.; Huet, F. Simplified electrochemical and thermal model of LiFePO4-graphite Li-ion batteries for fast charge application. J. Electrochem. Soc. 2012, 159, A1508–A1519. [Google Scholar] [CrossRef]

- Markou, M.; Singh, S. Novelty detection: A review—Part 1: Statistical approaches. Signal Process. 2003, 83, 2481–2497. [Google Scholar] [CrossRef]

- Zeng, S.; Zhao, Y.; Li, G.; Wang, R.; Wang, X.; Ni, J. Atom table convolutional neural networks for an accurate prediction of compounds properties. npj Comput. Mater. 2019, 5, 84. [Google Scholar] [CrossRef]

- Xie, T.; Grossman, J.C. Crystal graph convolutional neural networks for an accurate and interpretable prediction of material properties. Phys. Rev. Lett. 2018, 120, 145301. [Google Scholar] [CrossRef]

- Li, F.; Cheng, X.; Lu, L.-L.; Yin, Y.-C.; Luo, J.-D.; Lu, G.; Meng, Y.-F.; Mo, H.; Tian, T.; Yang, J.-T.; et al. Stable all-solid-state lithium metal batteries enabled by machine learning simulation designed halide electrolytes. Nano Lett. 2022, 22, 2461–2469. [Google Scholar] [CrossRef]

- Ahmad, Z.; Xie, T.; Maheshwari, C.; Grossman, J.C.; Viswanathan, V. Machine learning enabled computational screening of inorganic solid electrolytes for suppression of dendrite formation in lithium metal anodes. ACS Cent. Sci. 2018, 4, 996–1006. [Google Scholar] [CrossRef]

- Liu, H.; Ma, S.; Wu, J.; Wang, Y.; Wang, X. Recent advances in screening lithium solid-state electrolytes through machine learning. Front. Energy Res. 2021, 9, 639741. [Google Scholar] [CrossRef]

- Dudani, S.A. The distance-weighted k-nearest-neighbor rule. IEEE Trans. Syst. Man Cybern. 1976, SMC-6, 325–327. [Google Scholar] [CrossRef]

- Svetnik, V.; Liaw, A.; Tong, C.; Culberson, J.C.; Sheridan, R.P.; Feuston, B.P. Random forest: A classification and regression tool for compound classification and QSAR modeling. J. Chem. Inf. Comput. Sci. 2003, 43, 1947–1958. [Google Scholar] [CrossRef]

- Hastie, T.; Tibshirani, R.; Friedman, J.H.; Friedman, J.H. The Elements of Statistical Learning: Data Mining, Inference, and Prediction, 2nd ed.; Springer Series in Statistics; Springer: New York, NY, USA, 2009. [Google Scholar]

- Chandra, A.; Kar, O.; Wu, K.-C.; Hall, M.; Gillette, J. Prognosis of anterior cruciate ligament reconstruction: A data-driven approach. Proc. R. Soc. A Math. Phys. Eng. Sci. 2015, 471, 20140526. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Kouhestani, H.S.; Chandra, A. Data-driven prognosis of the failure of lithium-ion batteries. ECS Meet. Abstr. 2021, 2021, 1864. [Google Scholar] [CrossRef]

- Suykens, J.A.K.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Eckhoff, M.; Lausch, K.N.; Blöchl, P.E.; Behler, J. Predicting oxidation and spin states by high-dimensional neural networks: Applications to lithium manganese oxide spinels. J. Chem. Phys. 2020, 153, 164107. [Google Scholar] [CrossRef]

- Eckhoff, M.; Schönewald, F.; Risch, M.; Volkert, C.A.; Blöchl, P.E.; Behler, J. Closing the gap between theory and experiment for lithium manganese oxide spinels using a high-dimensional neural network potential. Phys. Rev. B 2020, 102, 174102. [Google Scholar] [CrossRef]

- Bartel, C.J.; Trewartha, A.; Wang, Q.; Dunn, A.; Jain, A.; Ceder, G. A critical examination of compound stability predictions from machine-learned formation energies. npj Comput. Mater. 2020, 6, 97. [Google Scholar] [CrossRef]

- Artrith, N.; Urban, A.; Ceder, G. Constructing first-principles phase diagrams of amorphous lixsi using machine-learning-assisted sampling with an evolutionary algorithm. J. Chem. Phys. 2018, 148, 241711. [Google Scholar] [CrossRef]

- Onat, B.; Cubuk, E.D.; Malone, B.D.; Kaxiras, E. Implanted neural network potentials: Application to Li-Si alloys. Phys. Rev. B 2018, 97, 094106. [Google Scholar] [CrossRef]

- Yoo, D.; Lee, K.; Jeong, W.; Lee, D.; Watanabe, S.; Han, S. Atomic energy mapping of neural network potential. Phys. Rev. Mater. 2019, 3, 093802. [Google Scholar] [CrossRef]

- Zuo, Y.; Chen, C.; Li, X.-G.; Deng, Z.; Chen, Y.; Behler, J.; Csányi, G.; Shapeev, A.V.; Thompson, A.P.; Wood, M.A.; et al. Performance and cost assessment of machine learning interatomic potentials. J. Phys. Chem. A 2020, 124, 731–745. [Google Scholar] [CrossRef] [PubMed]

- LaCivita, V.; Artrith, N.; Ceder, G. Structural and compositional factors that control the li-ion conductivity in LiPON electrolytes. Chem. Mater. 2018, 30, 7077–7090. [Google Scholar] [CrossRef]

- Li, W.; Ando, Y.; Minamitani, E.; Watanabe, S. Study of li atom diffusion in amorphous Li3PO4 with neural network potential. J. Chem. Phys. 2017, 147, 214106. [Google Scholar] [CrossRef]

- Miwa, K.; Ohno, H. Interatomic potential construction with self-learning and adaptive database. Phys. Rev. Mater. 2017, 1, 053801. [Google Scholar] [CrossRef]

- Miwa, K.; Asahi, R. Molecular dynamics simulations with machine learning potential for Nb-doped lithium garnet-type oxide Li7−xLa3(Zr2−xNbx)O12. Phys. Rev. Mater. 2018, 2, 105404. [Google Scholar] [CrossRef]

- Wang, C.; Aoyagi, K.; Aykol, M.; Mueller, T. Ionic conduction through reaction products at the electrolyte–electrode interface in all-solid-state Li+ batteries. ACS Appl. Mater. Interfaces 2020, 12, 55510–55519. [Google Scholar] [CrossRef]

- Fujimura, K.; Seko, A.; Koyama, Y.; Kuwabara, A.; Kishida, I.; Shitara, K.; Fisher, C.A.J.; Moriwake, H.; Tanaka, I. Accelerated materials design of lithium superionic conductors based on first-principles calculations and machine learning algorithms. Adv. Energy Mater. 2013, 3, 980–985. [Google Scholar] [CrossRef]

- Sendek, A.D.; Cheon, G.; Pasta, M.; Reed, E.J. Quantifying the search for solid li-ion electrolyte materials by anion: A data-driven perspective. J. Phys. Chem. C 2020, 124, 8067–8079. [Google Scholar] [CrossRef]

- Xie, W.; Liu, X.; He, R.; Li, Y.; Gao, X.; Li, X.; Peng, Z.; Feng, S.; Feng, X.; Yang, S. Challenges and opportunities toward fast-charging of lithium-ion batteries. J. Energy Storage 2020, 32, 101837. [Google Scholar] [CrossRef]

- Wu, B.; Widanage, W.D.; Yang, S.; Liu, X. Battery digital twins: Perspectives on the fusion of models, data and artificial intelligence for smart battery management systems. Energy AI 2020, 1, 100016. [Google Scholar] [CrossRef]

- Lyu, Z.; Gao, R. A model-based and data-driven joint method for state-of-health estimation of lithium-ion battery in electric vehicles. Int. J. Energy Res. 2019, 43, 7956–7969. [Google Scholar] [CrossRef]

- Lin, M.; Zeng, X.; Wu, J. State of health estimation of lithium-ion battery based on an adaptive tunable hybrid radial basis function network. J. Power Source 2021, 504, 230063. [Google Scholar] [CrossRef]

| Categories | Technique |

|---|---|

| Model-based and Physics-based method | Equivalent circuit model [85] |

| Electrochemical model [61,62,77] | |

| Electrochemical-mechanical model [63,64,68,70] | |

| Mathematical model [65,72,78] | |

| Data-driven method | ANN [104,105,106,107,114,115] |

| kNN [108] | |

| DDP [111,112] | |

| SVM [113] | |

| RF [109] | |

| PF [87] | |

| BM [86,90] | |

| Hybrid method | Series [129,130] |

| Parallel [131] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadegh Kouhestani, H.; Yi, X.; Qi, G.; Liu, X.; Wang, R.; Gao, Y.; Yu, X.; Liu, L. Prognosis and Health Management (PHM) of Solid-State Batteries: Perspectives, Challenges, and Opportunities. Energies 2022, 15, 6599. https://doi.org/10.3390/en15186599

Sadegh Kouhestani H, Yi X, Qi G, Liu X, Wang R, Gao Y, Yu X, Liu L. Prognosis and Health Management (PHM) of Solid-State Batteries: Perspectives, Challenges, and Opportunities. Energies. 2022; 15(18):6599. https://doi.org/10.3390/en15186599

Chicago/Turabian StyleSadegh Kouhestani, Hamed, Xiaoping Yi, Guoqing Qi, Xunliang Liu, Ruimin Wang, Yang Gao, Xiao Yu, and Lin Liu. 2022. "Prognosis and Health Management (PHM) of Solid-State Batteries: Perspectives, Challenges, and Opportunities" Energies 15, no. 18: 6599. https://doi.org/10.3390/en15186599

APA StyleSadegh Kouhestani, H., Yi, X., Qi, G., Liu, X., Wang, R., Gao, Y., Yu, X., & Liu, L. (2022). Prognosis and Health Management (PHM) of Solid-State Batteries: Perspectives, Challenges, and Opportunities. Energies, 15(18), 6599. https://doi.org/10.3390/en15186599