Strain-Sensing Mechanism and Axial Stress Response Characterization of Bolt Based on Fiber Bragg Grating Sensing

Abstract

:1. Introduction

2. Bolt Force Characterization Method in Surface-Bonded FBG

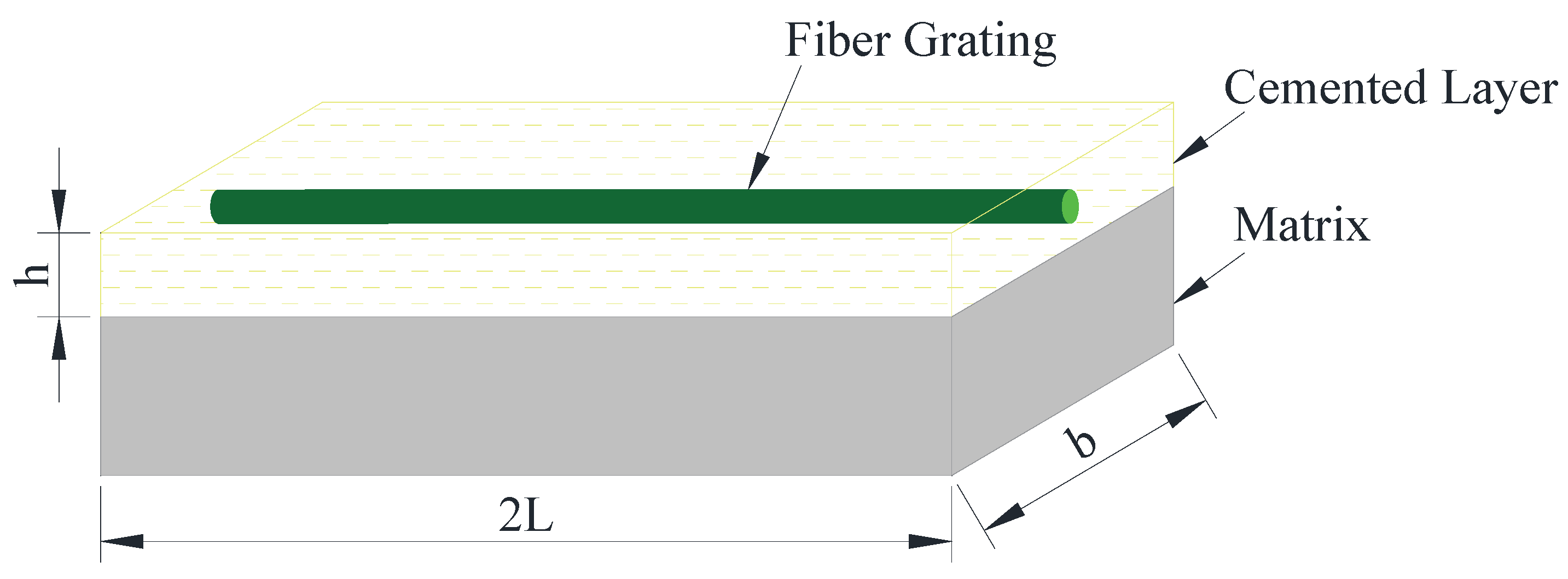

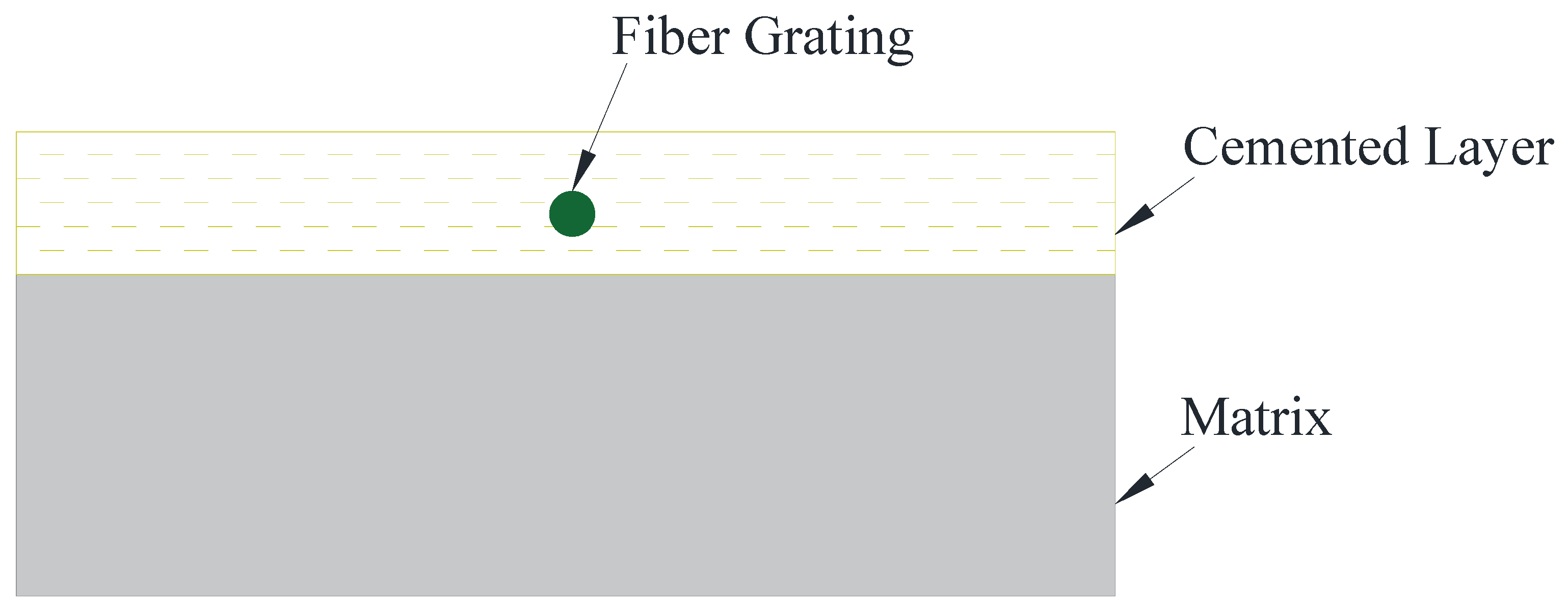

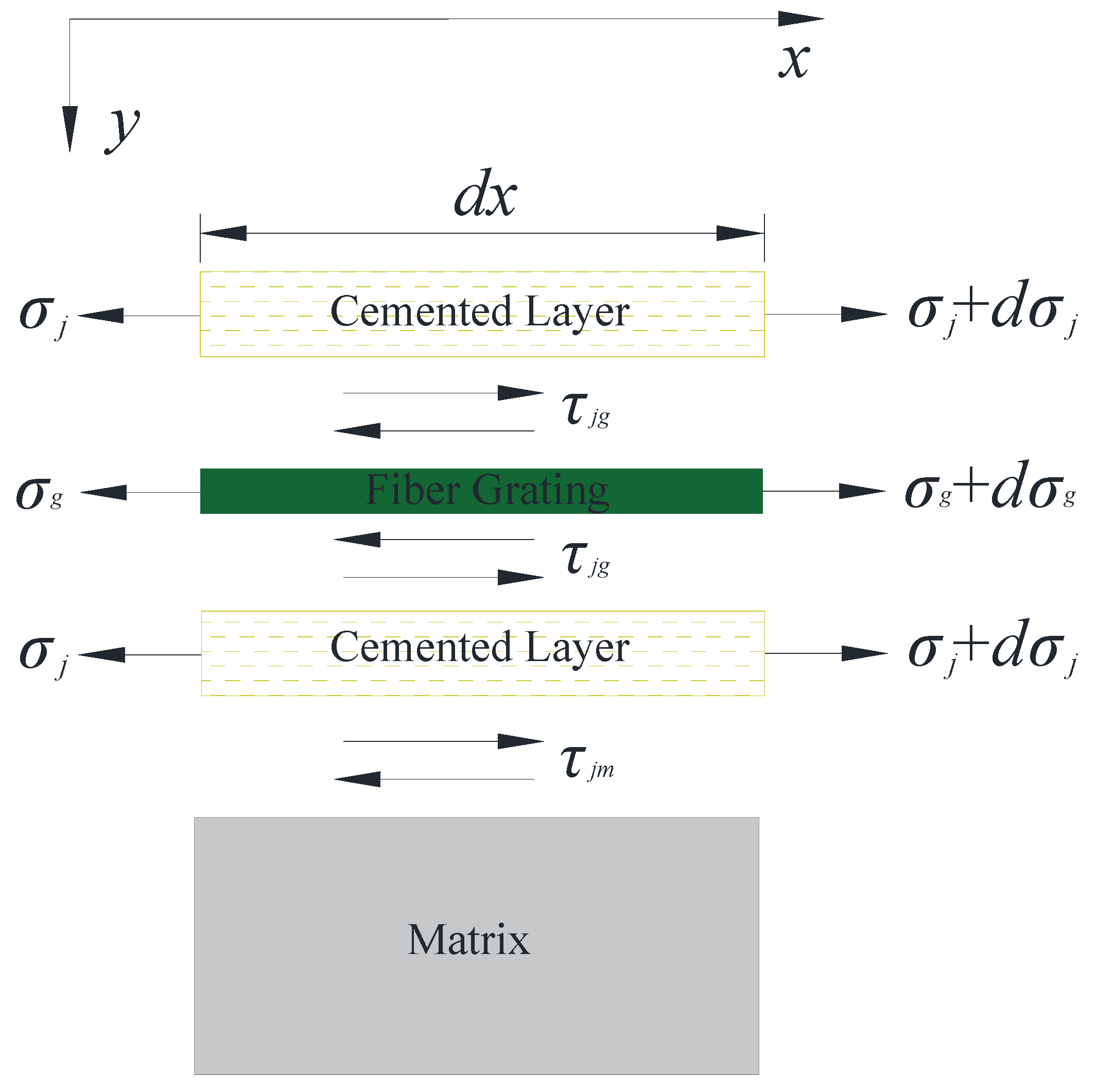

2.1. Analysis of Strain Transmission between Bolt and FBG

2.2. FBG Characterization Model of Bolt Axial Force

3. Bolt Optical Fiber Testing System and Pull-Out Test Scheme

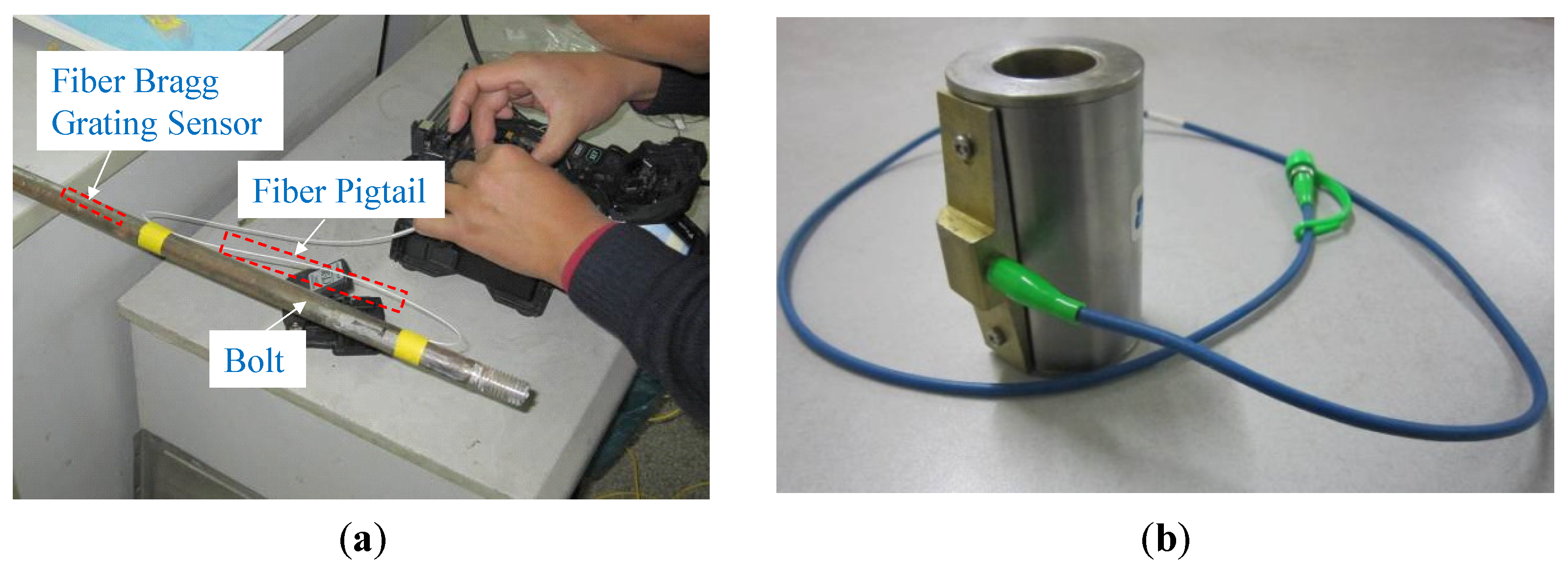

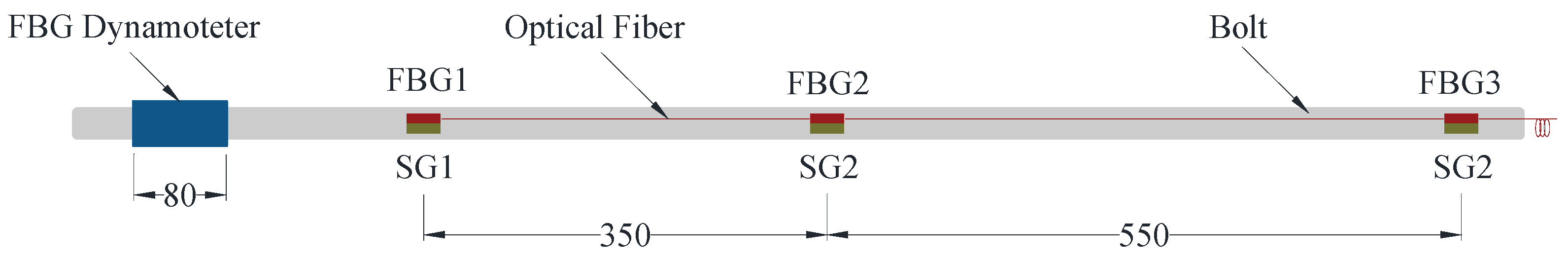

3.1. Design of Surface-Bonded FBG Force-Measuring Bolt

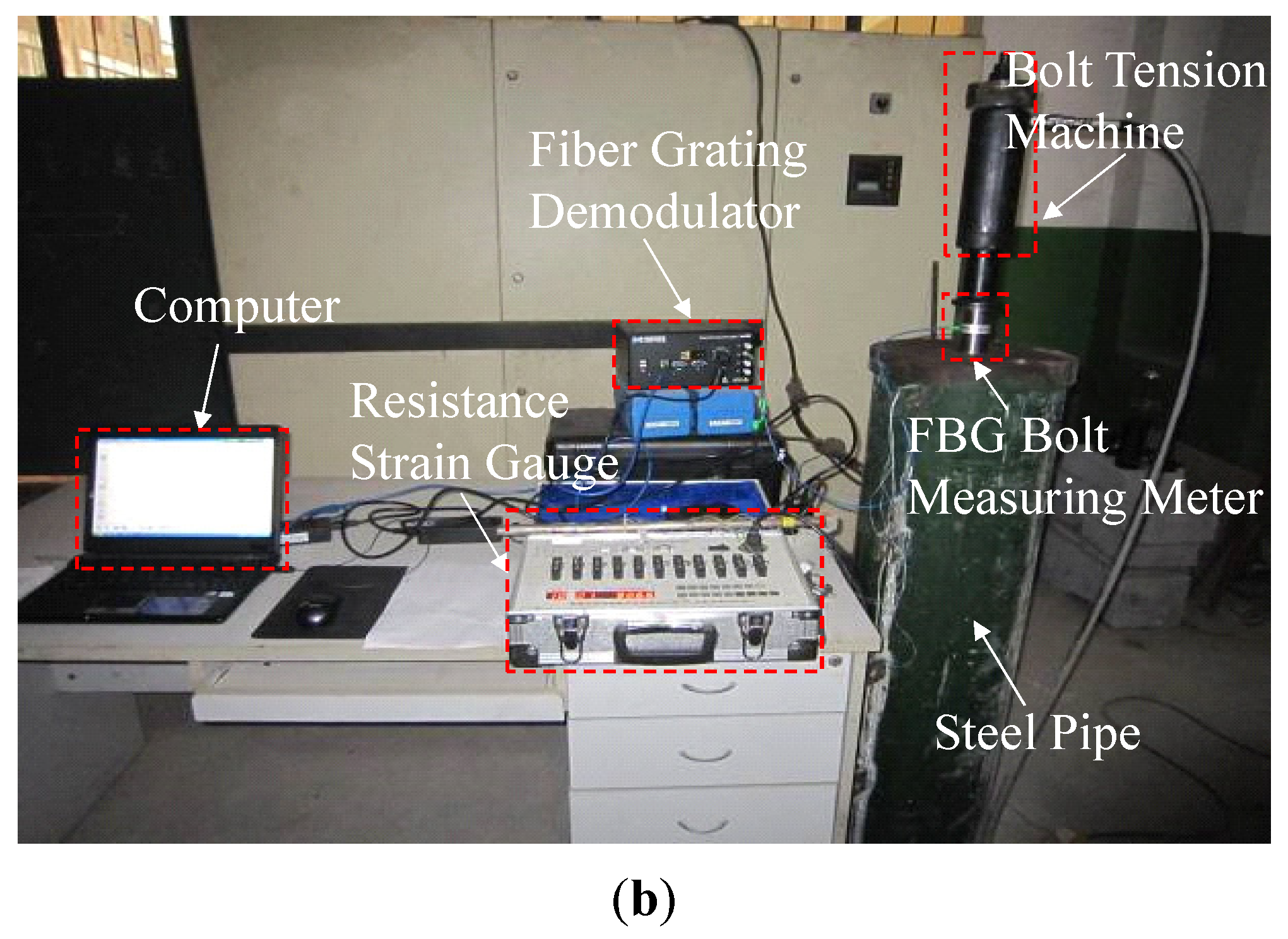

3.2. Testing Setup

3.3. Loading Protocol

4. Analysis of Test Results

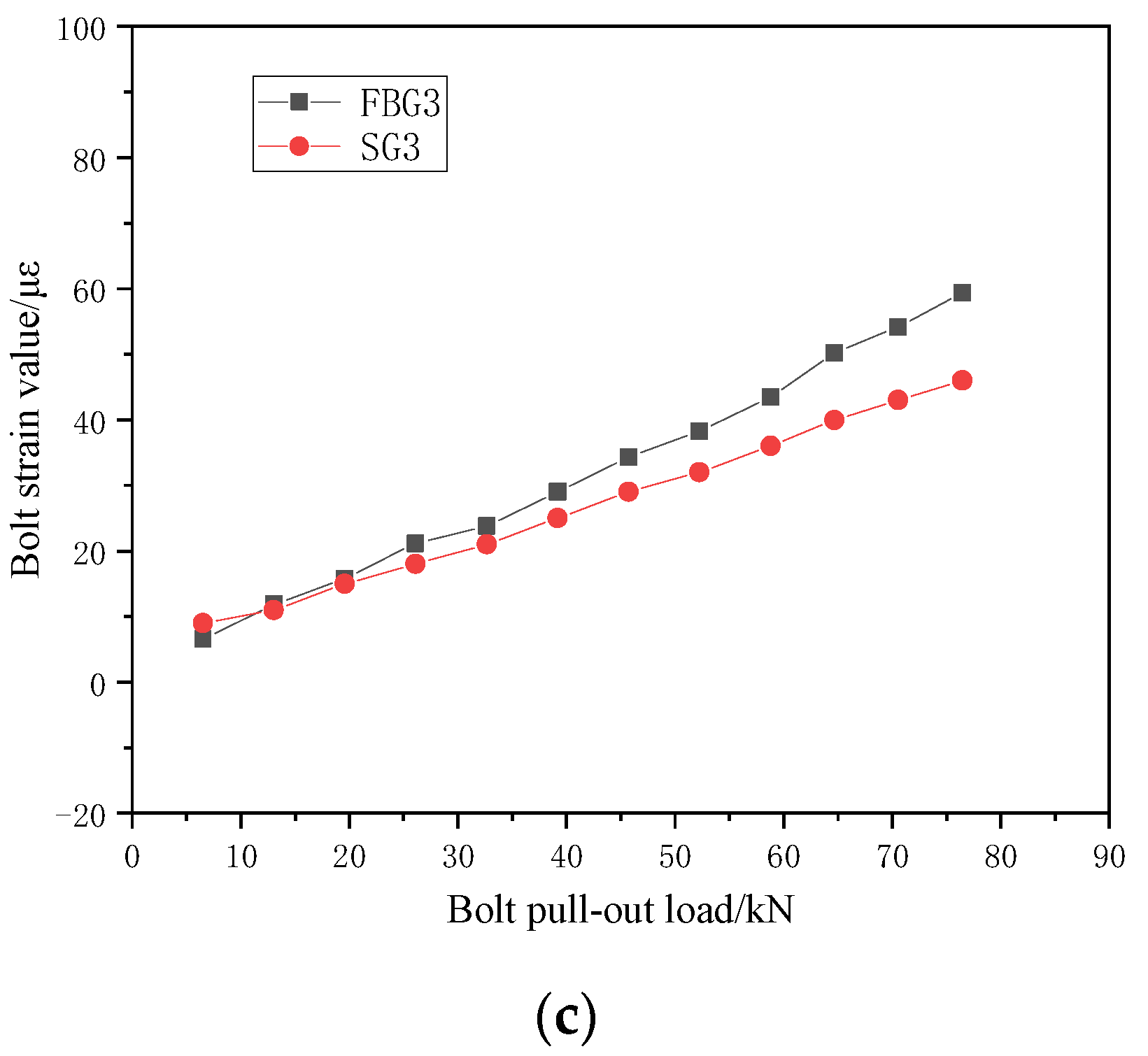

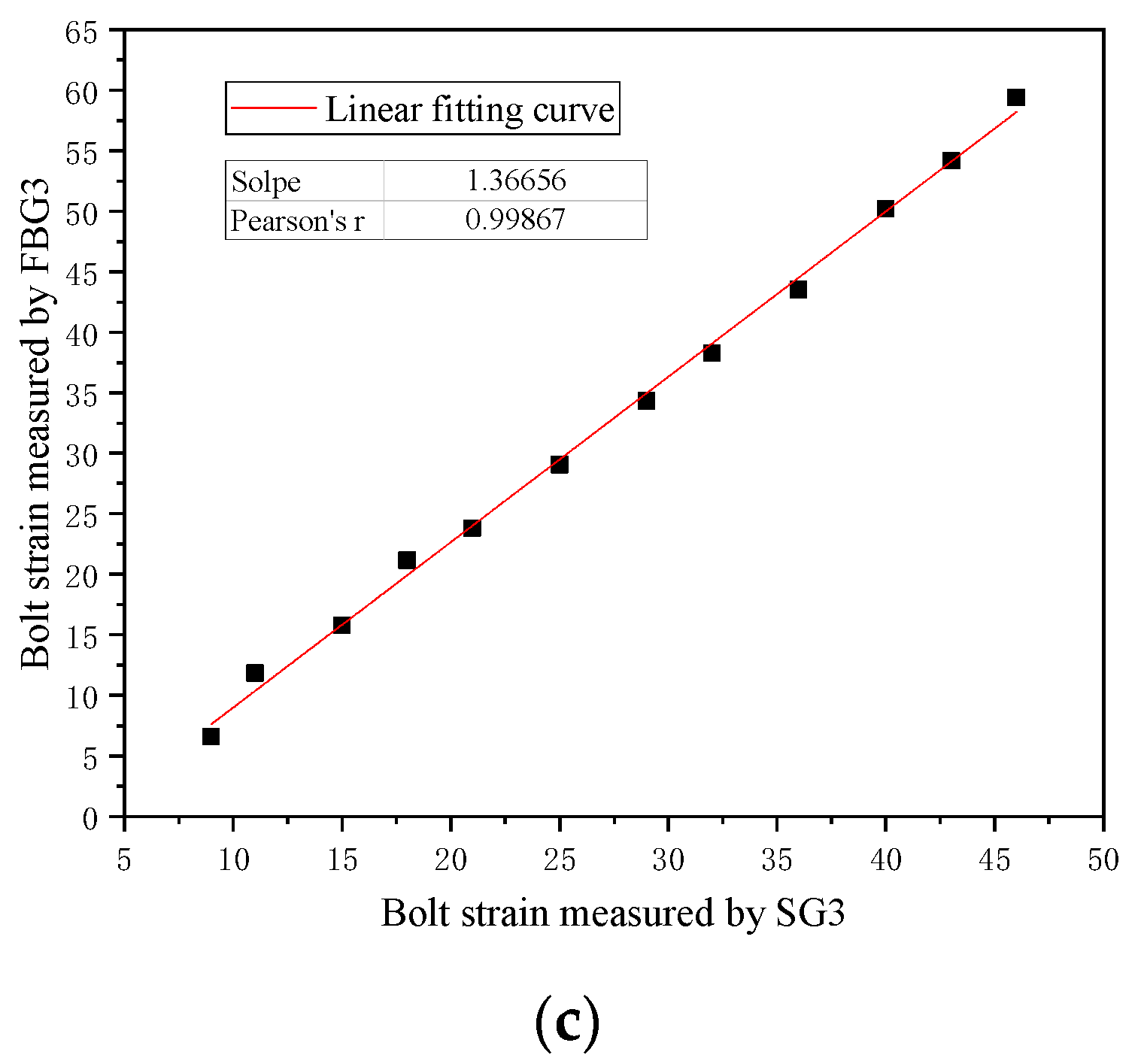

4.1. Calculation of Strain Transfer Coefficient between Bolt and FBG

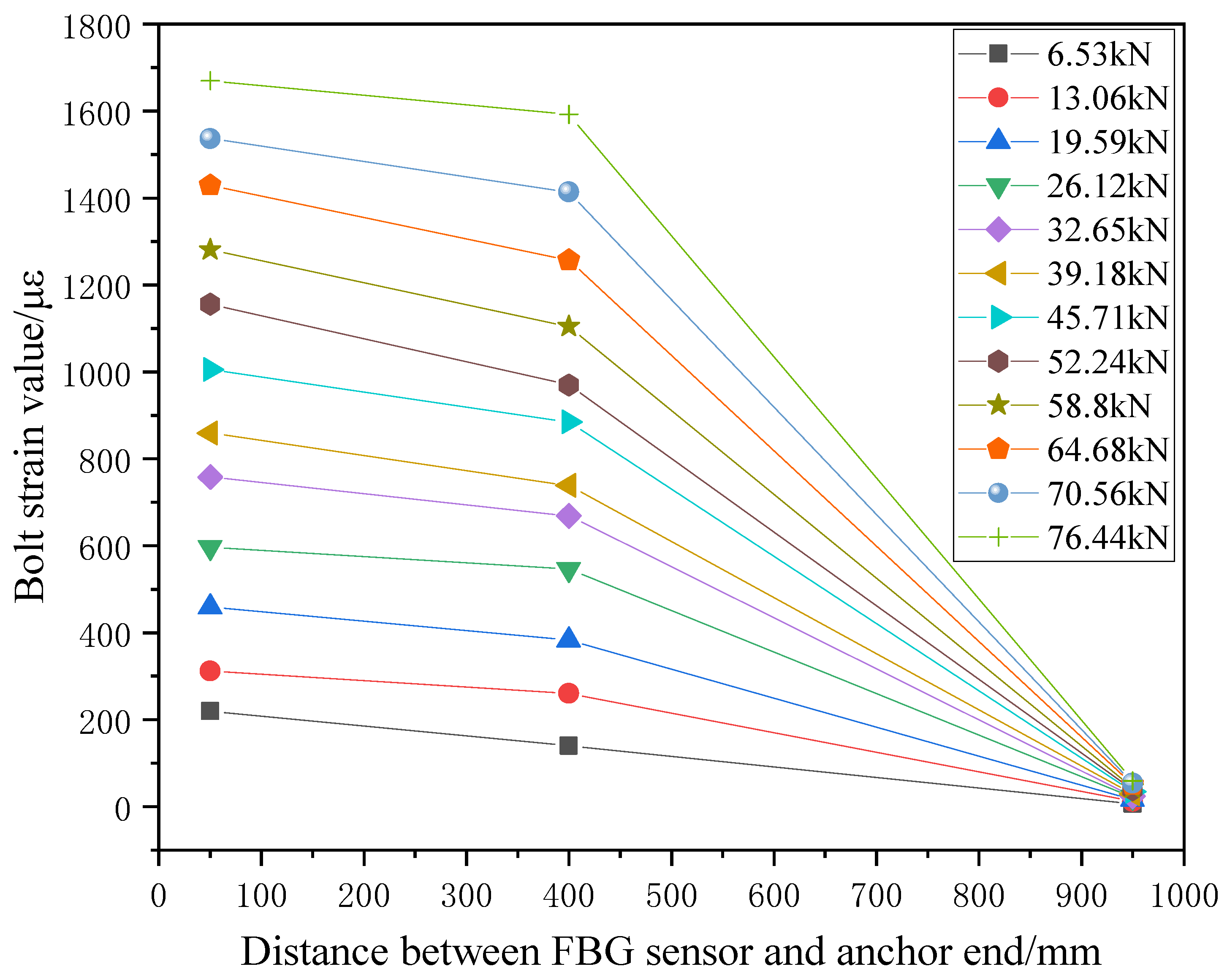

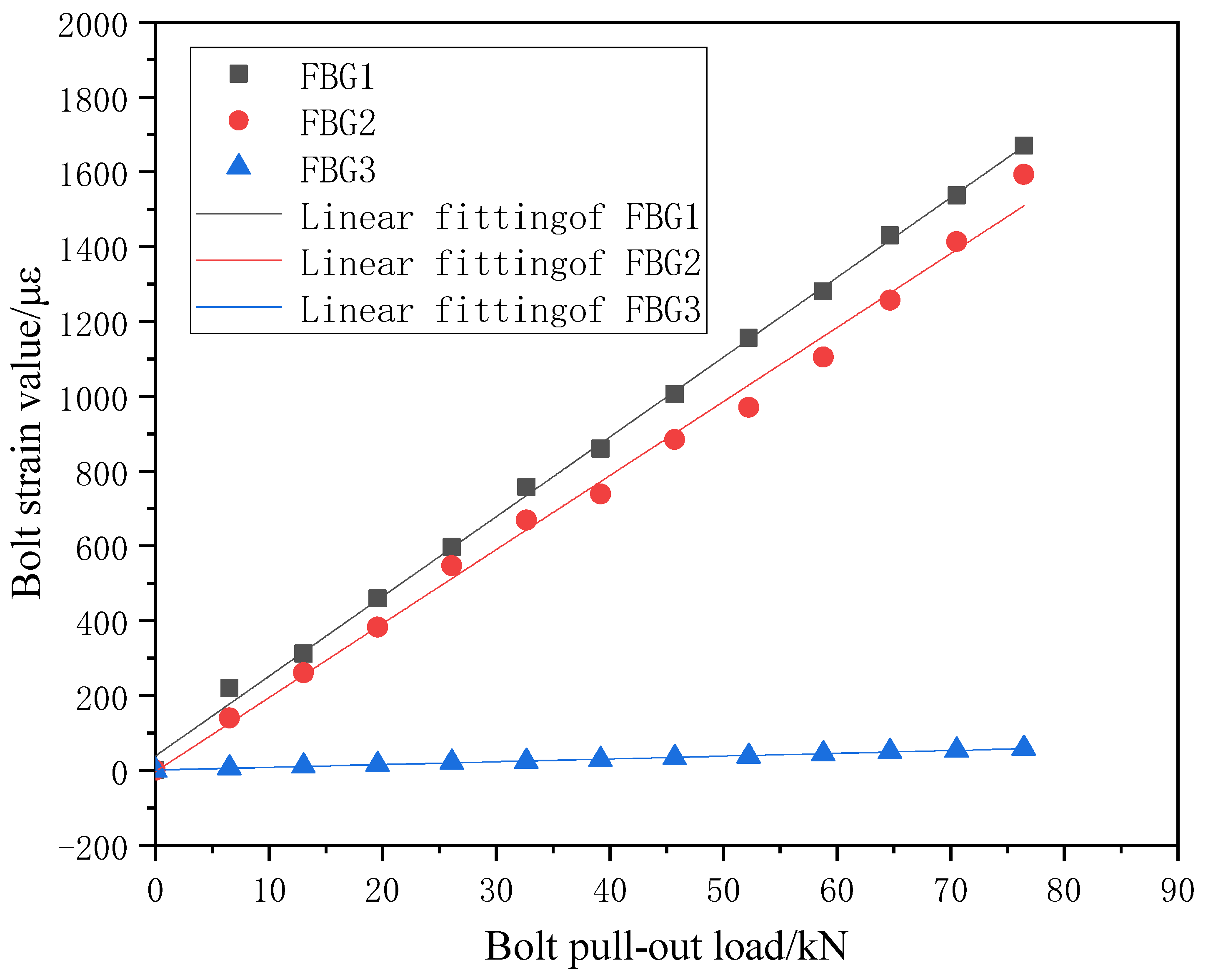

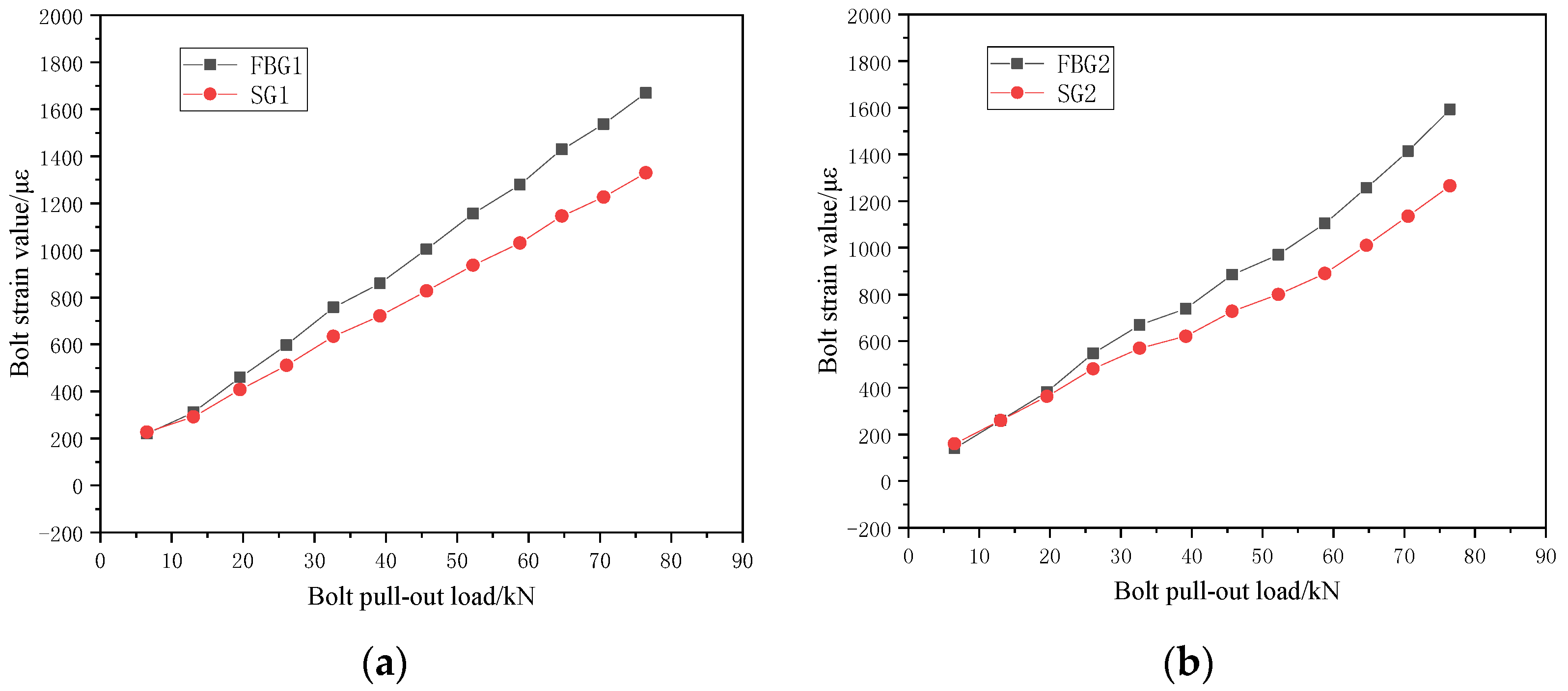

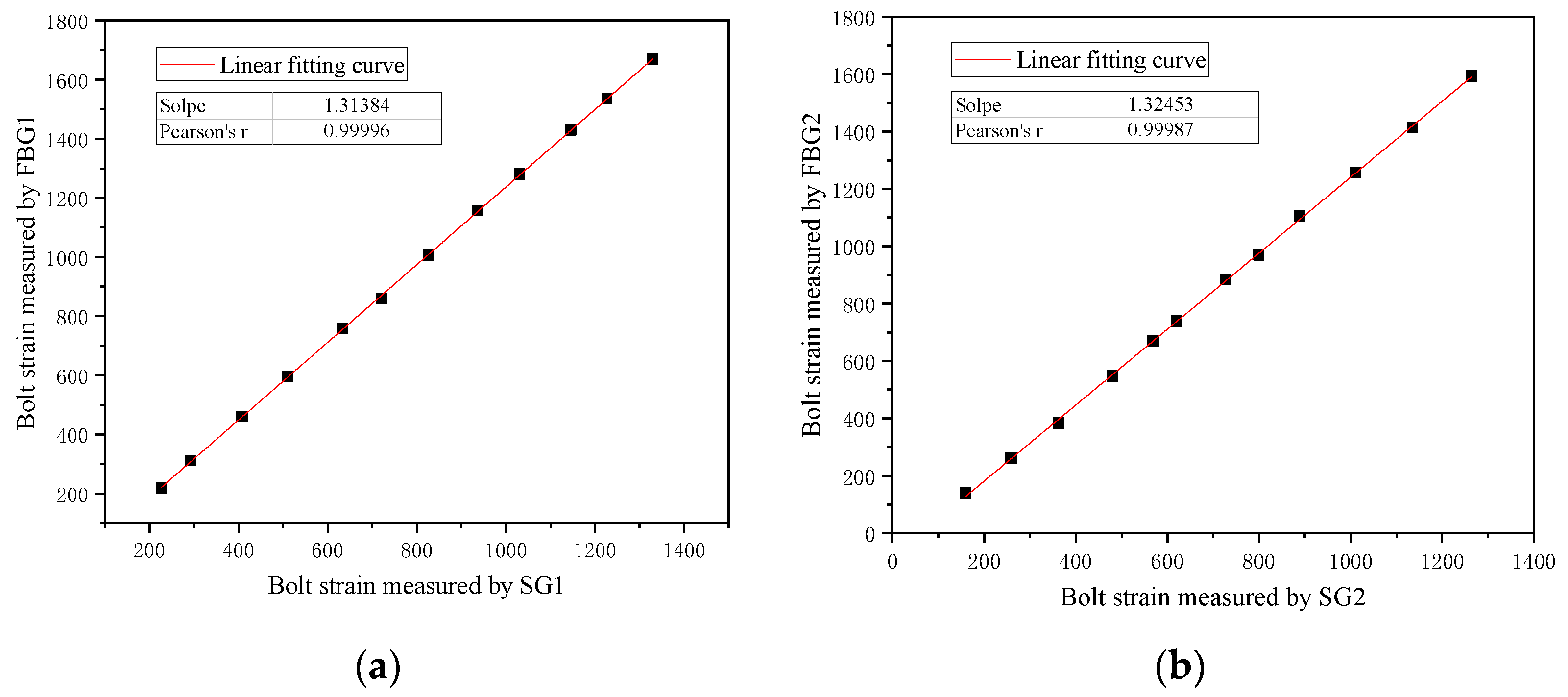

4.2. Analysis of FBG Monitoring Results of Bolt Interface Strain

4.3. Analysis of Axial Force Distribution of Bolt

5. Conclusions

- (1)

- The strain transmission mechanism of surface-bonded FBG was analyzed, the strain transmission relationship of FBG considering the transmission effect of the cemented layer was established, the strain transmission coefficient between the bolt and surface-bonded FBG was calculated, and the characterization model of the bolt axial force of FBG was derived. Indeed, the bolt pull-out test results verified that the characterization equation can be applied to understanding the bolt axial force evolution.

- (2)

- The strain values on the bolt body at different positions varied. The strain value at the bolt’s anchor end was the largest, and the strain value gradually decreased along the length. The strain at any position of the bolt increased linearly with the increase in the load.

- (3)

- The strain values measured by the FBG sensor and strain gauge were consistent with the changing trend of the loading, which verified that the FBG can be applied to the bolt’s strain value measurement. The test value of FBG and strain gauge increased linearly in a non-positive proportion with the continuous loading at the end of the bolt, and the test difference gradually increased. It is necessary to consider the influence of the thickness and width of the cemented layer on the test results.

- (4)

- The bolt’s axial force gradually increased with the increase in the pull-out load. In addition, the axial force of the end bolt was the same as the pull-out force, the bolt gradually broke away from the friction-binding force of the rock mass, and the bolt tended to a slip failure when the load increased to a certain value. Based on the fitting of the FBG monitoring value of the bolt axial force, the bolt axial force under any load conditions follows an exponential pattern.

- (5)

- Optical fiber sensing technology provides high-precision strain sensing ability, which can realize the sensing of the microstrain and axial force of the bolt. Furthermore, considering that light as a fiber transmission signal is safer than electrical signal transmissions in coal mining, it has become a technology with great application potential in mining engineering. The test results of this paper have a significant engineering application value for the evaluation of the surrounding rock stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, P.; Zhang, N.; Kan, J.; Xie, Z.; Wei, Q.; Yao, W. Fiber Bragg Grating Monitoring of Full-bolt Axial Force of the Bolt in the Deep Strong Mining Roadway. Sensors 2020, 20, 4242. [Google Scholar] [CrossRef] [PubMed]

- Smith, J.A.; Ramandi, H.L.; Zhang, C.; Timms, W. Analysis of the influence of groundwater and the stress regime on bolt behaviour in underground coal mines. Int. J. Coal Sci. Technol. 2019, 6, 286–300. [Google Scholar] [CrossRef]

- Cruz, D.; Vlachopoulos, N. The geo-mechanical response of axially loaded rock bolts using fiber optic technology. In Proceedings of the XV Colombian Geotechnical Congress & the 2nd International Specialized Conference of Soft Rocks, Cartagena, Colombia, 6–7 October 2016; International Society of Rock Mechanics: Lisbon, Portugal, 2016. [Google Scholar]

- Zuo, J.; Wang, J.; Jiang, Y. Macro/meso failure behavior of surrounding rock in deep roadway and its control technology. Int. J. Coal Sci. Technol. 2019, 6, 301–319. [Google Scholar] [CrossRef]

- Kang, H.P. Support technologies for deep and complex roadways in underground coal mines: A review. Int. J. Coal Sci. Technol. 2014, 1, 261–277. [Google Scholar] [CrossRef]

- Guo, X.; Wang, B.; Ma, Z.; Wang, Z. Testing Mechanical Properties of Rock Bolt under Different Supports Using Fiber Bragg Grating Technology. Sensors 2019, 19, 4098. [Google Scholar] [CrossRef]

- Dongping, D.; Liang, L.; Liansheng, G. Experimental study on stress wave method for detecting anchorage quality of anchor cable. J. Cent. South Univ. 2016, 47, 2768–2775. [Google Scholar]

- Zhang, Y.; An, L.; Yu, G. Numerical Simulation and infrared radiation detection experiment for acting area of bolt supporting. Jouranl China Univ. Min. Technol. 2006, 35, 545–548. [Google Scholar]

- Nicholson, L. Analysis and Interpretation of in Situ Rock Bolt Pull Tests in Hard Rock Mines. Master’s Thesis, University of Toronto, Toronto, ON, Canada, 2016. [Google Scholar]

- Deng, L.; Zhang, C.; Zhou, L.; Cui, G.; Lyu, H.; Tang, Y.; Zhou, H. Experimental study on shear mechanical properties of bolt-resin interfaces under constant normal stiffness. Chin. J. Rock Mech. Eng. 2020, 39, 2254–2263. [Google Scholar]

- Hill, K.O.; Fujii, Y.; Johnson, D.C.; Kawasaki, B.S. Photosensitivity in optical fiber wave guide: Application to reflection fiber fabrication. Appl. Phys. Lett. 1978, 32, 647–649. [Google Scholar] [CrossRef]

- Prohaska, J.D.; Snitze, E.; Chen, B.; Maher, M.; Nawy, E.G.; Morey, W.W. Fiber optic Bragg grating strain sensor in large scale concrete structures. In Proceedings of the Fiber Optic Smart Structures and Skins V, Boston, MA, USA, 8–11 September 1992; SPIE: Bellingham, DC, USA, 1992; Volume 1798, pp. 286–294. [Google Scholar]

- Zhang, D.D.; Ma, C.Y.; Duan, Y.Y.; Du, W.G.; Liu, J.X. Wavelength Characteristic Analysis of a FBG Array Embedded in Quaternary Unconsolidated Strata during a Deep Borehole Installation. J. Sens. 2021, 2021, 1207374. [Google Scholar] [CrossRef]

- Zhang, D.D.; Chen, Q.; Wang, Z.S.; Yang, J.F.; Chai, J. Optical fiber frequency shift characterization of overburden deformation in short-distance coal seam mining. Geofluids 2021, 2021, 1751256. [Google Scholar] [CrossRef]

- Forbes, B.; Vlachopoulos, N.; Mark, S. Diederichs and Jonathan Aubertin. Augmenting the in-situ rock bolt pull test with distributed optical fiber strain sensing. Int. J. Rock Mech. Min. Sci. 2020, 126, 1–12. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fiber materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Nanni, A.; Yang, C.C.; Pan, K.; Wang, J.S.; Michael, R.R. Fiber-optic Sensor for Concrete strain/stress measurement. ACI Mater. J. 1991, 88, 257–264. [Google Scholar]

- Farhad, A.; Yuan, L. Mechanics of bond and interface shear transfer in optical fiber sensors. J. Eng. Mech. 1998, 124, 385–394. [Google Scholar]

- Lau, K.-T.; Yuan, L.; Zhou, L.-M.; Wu, J.; Woo, C.-H. Strain monitoring in FRP laminates and concreste beams using FBG sensors. Compos. Struct. 2001, 51, 9–20. [Google Scholar] [CrossRef]

- Li, D.; Li, H. Strain transferring analysis of embedded fiber bragg grating sensors. Chin. J. Theor. Appl. Mech. 2005, 37, 436–441. [Google Scholar]

- Zhang, D.D.; Chai, J.; Li, Y.; Sun, Y.Y. Strain Transfer Function of Embedded Fiber Bragg Grating Sensors for Unconsolidated Layer Settlement Deformation Detector and its Application. Chin. J. Rock Mech. Eng. 2015, 34, 3289–3297. [Google Scholar]

- Li, W.; Zhang, M.; Bai, X.; Kou, H. Experimental Research on Anchorage Performance of GFRP and Steel Anti-floating Anchors. Chin. J. Undergr. Space Eng. 2015, 11, 108–114. [Google Scholar]

- Liang, M.; Fang, X.; Chen, N.; Ma, M.; Li, X. Strain sensing mechanism of surface bonded fiber Bragg grating bolt and its application. J. China Univ. Min. Technol. 2018, 47, 1243–1251. [Google Scholar]

- Li, G.; Dai, J.; Jian, N.; Ni, C.; Yin, J.; Yu, L. Bond behavior between concrete frame beam and large-diameter glass fiber reinforced polymer anchor rod with built-in fiber Bragg grating sensor. Chin. J. Rock Mech. Eng. 2013, 7, 1449–1457. [Google Scholar]

- Vlachopoulos, N.; Cruz, D.; Forbes, B. Utilizing a novel fiber optic technology to capture the axial responses of fully grouted rock bolts. J. Rock Mech. Geotech. Eng. 2018, 10, 222–235. [Google Scholar] [CrossRef]

- Thenevin, I.; Blanco-Martín, L.; Hadj-Hassen, F.; Schleifer, J.; Lubosik, Z.; Wrana, A. Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar] [CrossRef]

- Hyett, A.J.; Bawden, W.F.; Reichert, R.D. The effect of rock mass confinement on the bond strength of fully grouted cable bolts. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 503–524. [Google Scholar] [CrossRef]

- Chapeleau, X.; Bassil, A. A General Solution to Determine Strain Profile in the Core of Distributed Fiber Optic Sensors under Any Arbitrary Strain Fields. Sensors 2021, 21, 5423. [Google Scholar] [CrossRef] [PubMed]

- Forbes, B.; Vlachopoulos, N.; Hyett, A.J.; Diederichs, M.S. A new optical sensing technique for monitoring shear of rock bolts. Tunn. Undergr. Space Technol. 2017, 66, 34–46. [Google Scholar] [CrossRef]

- Oktavianus, Y.; Chang, H.; Goldsworthy, H.M.; Gad, E.F. Component model for pull-out behavior of headed anchored blind bolt within concrete filled circular hollow section. Eng. Struct. 2017, 148, 210–224. [Google Scholar] [CrossRef]

| Parameter | Numerical Value | Parameter | Numerical Value |

|---|---|---|---|

| Elastic modulus of optical fiber Eg | 7.2 × 104 MPa | Fiber shear modulus Gn | 25 MPa |

| Fiber core radius rg | 62.5 μm | Coating length of cemented layer 2L | 40 mm |

| Coating width of cemented layer b | 5 mm | Shear modulus of bolt matrix Gm | 6.8 × 104 MPa |

| Coating thickness of cemented layer | 1 mm | Strain transfer coefficient α | 1.32 |

| Load/kN | Parameter A | Parameter R | Parameter P |

|---|---|---|---|

| 6.53 | −1.38403 | 0.00253 | 15.8301 |

| 13.06 | −2.15701 | 0.00248 | 23.4722 |

| 19.59 | −0.4902 | 0.00422 | 27.91978 |

| 26.12 | −1.37855 | 0.00341 | 36.32265 |

| 32.65 | −2.49628 | 0.00294 | 42.23259 |

| 39.18 | −1.99645 | 0.00332 | 48.40325 |

| 45.71 | −4.91951 | 0.00257 | 58.53292 |

| 52.24 | −3.56005 | 0.00299 | 62.75264 |

| 58.8 | −2.83122 | 0.00332 | 68.78824 |

| 64.68 | −1.12299 | 0.00434 | 71.73917 |

| 70.56 | −0.34911 | 0.00564 | 76.91032 |

| 76.44 | −1.38403 | 0.00253 | 15.8301 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, G.; Zhang, D.; Duan, Y.; Zhang, G.; Chai, J. Strain-Sensing Mechanism and Axial Stress Response Characterization of Bolt Based on Fiber Bragg Grating Sensing. Energies 2022, 15, 6384. https://doi.org/10.3390/en15176384

Guo G, Zhang D, Duan Y, Zhang G, Chai J. Strain-Sensing Mechanism and Axial Stress Response Characterization of Bolt Based on Fiber Bragg Grating Sensing. Energies. 2022; 15(17):6384. https://doi.org/10.3390/en15176384

Chicago/Turabian StyleGuo, Gaochuan, Dingding Zhang, Yanyan Duan, Guihua Zhang, and Jing Chai. 2022. "Strain-Sensing Mechanism and Axial Stress Response Characterization of Bolt Based on Fiber Bragg Grating Sensing" Energies 15, no. 17: 6384. https://doi.org/10.3390/en15176384

APA StyleGuo, G., Zhang, D., Duan, Y., Zhang, G., & Chai, J. (2022). Strain-Sensing Mechanism and Axial Stress Response Characterization of Bolt Based on Fiber Bragg Grating Sensing. Energies, 15(17), 6384. https://doi.org/10.3390/en15176384