1. Introduction

The two-stage inverter is composed of a front-end dc-dc converter and a downstream single-phase inverter, which is widely used for the power supply with a wide input voltage range [

1,

2,

3,

4]. The instantaneous output power of the single-phase inverter fluctuates at twice the output frequency (2

fo), resulting in the second harmonic current (SHC) in the inductance branch of the front-end dc-dc converter [

5,

6]. The SHC will increase the current stress and power losses of the power switches and the magnetic components, decrease the energy conversion efficiency, and shorten the lifespan of the dc source such as fuel cells and batteries [

7,

8,

9]. Thus, it is necessary to reduce the SHC in the dc-dc converter.

The SHC reduction approaches can be classified into two categories. The first approach is to provide the additional hardware circuit for the two-stage inverter. In [

10], an improved circuit consists of an isolated dc/dc converter and interconnection inverter, which achieves the dc active filter function and reduces the ripple current to approximately 20% of that of the conventional circuit. An active low-frequency ripple control device based on the virtual capacitor concept is proposed [

11], and the low-frequency ripple current caused by the single-phase inverter can be compensated by introducing a current integrator. Moreover, an SHC compensator (SHCC) is adopted to buffer the ripple power in a single-phase power factor correction converter and a single-phase inverter [

12,

13], and the SHCC is connected to the dc bus and the port current is required to follow the SHC [

12]. A virtual impedance is introduced to be in parallel with the port of the SHCC for compensating the SHC, and the virtual impedance is realized by feeding forward the SHCC port voltage [

13]. The suppression of the SHC in the frontend dc-dc converter with dc transformer resonant converter is investigated [

14], and the preregulator or postregulator is necessary to regulate the output voltage. In summary, an additional hardware circuit is essential for SHC reduction in the above approaches [

10,

11,

12,

13,

14], and it is evident that the extra circuit increases the complexity, volume, and cost of the overall inverter.

The second approach is to reduce the SHC by the appropriate control scheme for the front-end dc-dc converter. In [

15,

16], the secondary component in the input current of the single-phase inverter is extracted and fed to the voltage regulator to compensate for the current fluctuation, which can suppress the SHC in the front-end dc-dc converter, whereas the accurate dc bus capacitance is necessary and the dynamic performance in the voltage control mode is relatively general. In [

17], the second harmonic component in the inductor current is calculated with the small signal model, then a compensation controller is designed based on the calculation results, which can compensate the second harmonic in the two-stage inverter, however, the calculation is very complex and dependent on the accuracy of the model. In [

18], a load current feedforward method for the dual active bridge dc-dc converter is proposed to increase the output impedance at 2

fo and reduce the SHC, but it is not appropriate for other dc-dc converter structures. In [

19], by adding the inductor current feedback to the back of the current regulator through a bandpass filter (BPF), the presented BPF inserted inductor current feedback method can increase the output impedance of the dc-dc converter, thereby suppressing the SHC. However, the virtual impedance will decrease with the increase in the loop gain, which limits the reduction ability of the SHC. In [

20], the introduction of the inner current loop on the basis of the voltage control mode can suppress the current pulsation in the dc-dc converter, whereas the low crossover frequency of the outer voltage loop will affect the dynamic performance of the inverter. In [

21], a resonant controller is inserted between the voltage regulator and the current regulator in the forward path, which can reduce the second harmonic component, but the resonant controller limits the loop gain and the dynamic performance. In [

22], the notch-filter-inserted load current feedforward scheme (NF-LCFFS) with the virtual parallel impedance is proposed, which can suppress the SHC by the inner inductor current loop and improve the dynamic response of the front-end dc-dc converter by the load current feed-forward path. Based on the NF-LCFFS, the notch-filter-inserted current reference plus load current feedforward scheme (NF-CR+LCFFS) is also proposed in [

22], which can further increase the output impedance of the dc-dc converter at 2

fo and reduce the SHC. Meanwhile, the crossover frequency of the voltage outer loop in the NF-CR+LCFFS can be increased to improve the dynamic performance.

To further reduce the SHC as well as improve the dynamic performance in the two-stage inverter without adding any extra circuit, this paper proposes a new inductor current feedback path scheme (NICFPS) for the front-end dc-dc converter. By virtue of the virtual resistance and the BPF, this scheme introduces a new feedback path for the inductor current, and the feed point is in the front of the voltage regulator. In this way, the output impedance of the front-end dc-dc converter at 2fo can be increased obviously, so the SHC can be reduced effectively. Meanwhile, the dynamic response of the front-end dc-dc converter can also be improved by increasing the crossover frequency of the outer voltage loop. Moreover, the simulation and experimental results verify the effectiveness of the proposed scheme.

This paper is organized as follows. The SHC mechanism of a two-stage inverter with buck dc-dc converter is studied in

Section 2.

Section 3 presents the virtual resistance-based NICFPS and its implementation approach.

Section 4 designs the key parameters in the feedback function for the proposed NICFPS, and gives a performance comparison of the output impedance with different control schemes. Based on a 10 kW two-stage inverter, the proposed NICFPS is verified by simulation and experiment in

Section 5 and

Section 6. Finally,

Section 7 concludes this paper.

2. SHC Mechanism of Two-Stage Inverter

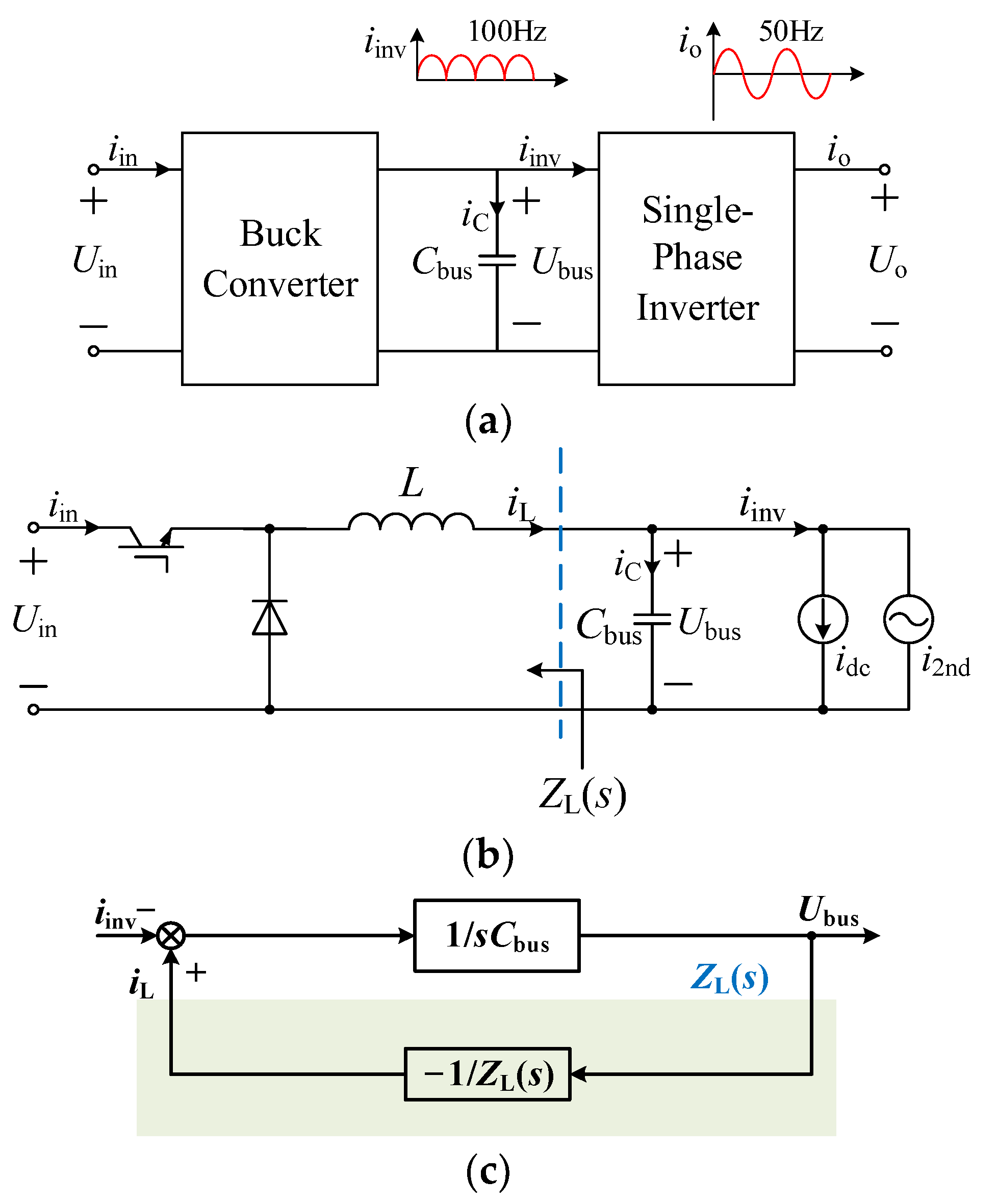

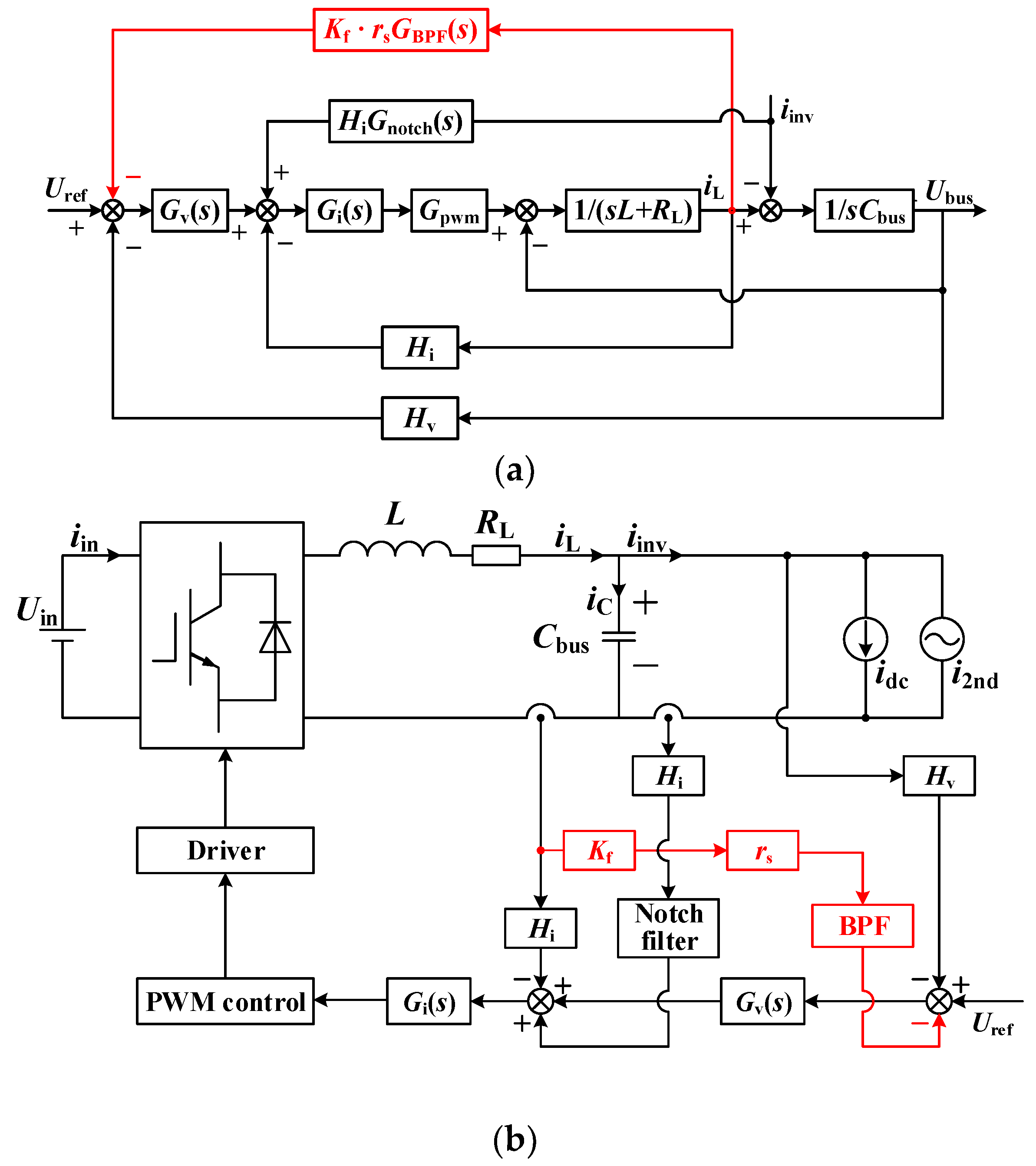

Figure 1a gives the configuration of the two-stage inverter studied in this paper, where the front-end dc-dc converter is a buck converter and the downstream inverter is a single-phase inverter.

Figure 1b shows the equivalent schematic diagram. In

Figure 1,

Uin and

iin are the input voltage and input current of the converter, respectively;

Cbus and

Ubus are the capacitor and voltage of the intermediate dc bus, respectively;

io and

Uo are the output current and output voltage of the inverter, respectively;

iC is the capacitor current;

iinv is the input current of the inverter;

L is the inductor;

iL is the inductor current.

The instantaneous output power of the single-phase inverter pulsates at twice the output frequency, and the input current of the inverter can be expressed as [

22]

where

Um and

im are the amplitudes of the output voltage and the output current, respectively;

φ is the load impedance angle;

ωo is the angular frequency;

ωo = 2π

fo, and

fo is the frequency of the output voltage.

It can be seen from Equation (1) and

Figure 1b that

iinv is composed of two parts, one is the dc component

idc, and the other is the SHC component

i2nd, which is provided by the intermediate bus capacitor branch and inductor branch. Hence, the SHC proportion in the front-end buck converter is determined by the inductor branch impedance

ZL(

s) of the buck converter and the impedance of

Cbus at 2

fo. Moreover,

Cbus is always designed large enough to achieve a very low dc-link voltage ripple, and the SHC in

iin is mainly caused by the inductor branch [

22,

23]. Thus, the SHC suppression in

iL can effectively reduce the input power fluctuation and the SHC on the input side.

4. Parameter Design and Performance Analysis

The main parameters in the feedback function, including the current and voltage regulator parameters, equivalent gain Kf, the virtual resistance rs, and the bandwidth fb of the BPF, will be designed in this section.

The parameters of the inverter prototype are shown in

Table 1, which are used for the theoretical analysis, simulation, and experimental verification in this paper.

4.1. BPF Parameter Design

It can be seen from

Figure 5a that the inner current loop gain

Ti_NICFPS can be expressed as

The crossover frequency

fci of the inner current loop is usually selected to be 1/5 to 1/10 of the switching frequency to guarantee excellent tracking ability [

22]. Hence, when 1/10 is selected, we have

fci = 1 kHz.

According to Equations (4) and (5), the transfer function of the current regulator at

fci can be derived as

where

Kpi and

fLi are the proportional gain and corner frequency of the current regulator, respectively.

When fLi = 5 Hz, it is evident that fci is much larger than fLi. Hence, according to Equation (9), we have Gi(j2πfci) ≈ Kpi.

The magnitude of the inner current loop has a unity gain at

fci. According to Equation (8), (10) can be obtained.

Then from Equation (10),

Kpi can be derived as

From Equations (5) and (11), the current regulator is obtained as

For the outer voltage loop, the higher crossover frequency means better dynamic performance. Moreover, the effect of the BPF in the voltage loop is similar to that of the notch filter in the forward path in [

22], so the crossover frequency

fcv of the voltage loop should be less than the center frequency of the BPF. To improve the dynamic response while reducing the influence of the BPF on the stability margin,

fcv = 50 Hz is determined.

Based on

Figure 5a, the outer voltage loop gain

Tv_NICFPS can be expressed as Equation (13). The magnitude of the outer voltage loop has a gain unity at

fcv, then Equation (14) is obtained.

According to Equation (14), the proportional gain

Kpv of the voltage regulator can be derived as

From Equations (5) and (15), the voltage regulator is derived as

Based on Equations (7), (12) and (16), the equivalent gain Kf in the feedback function can be obtained.

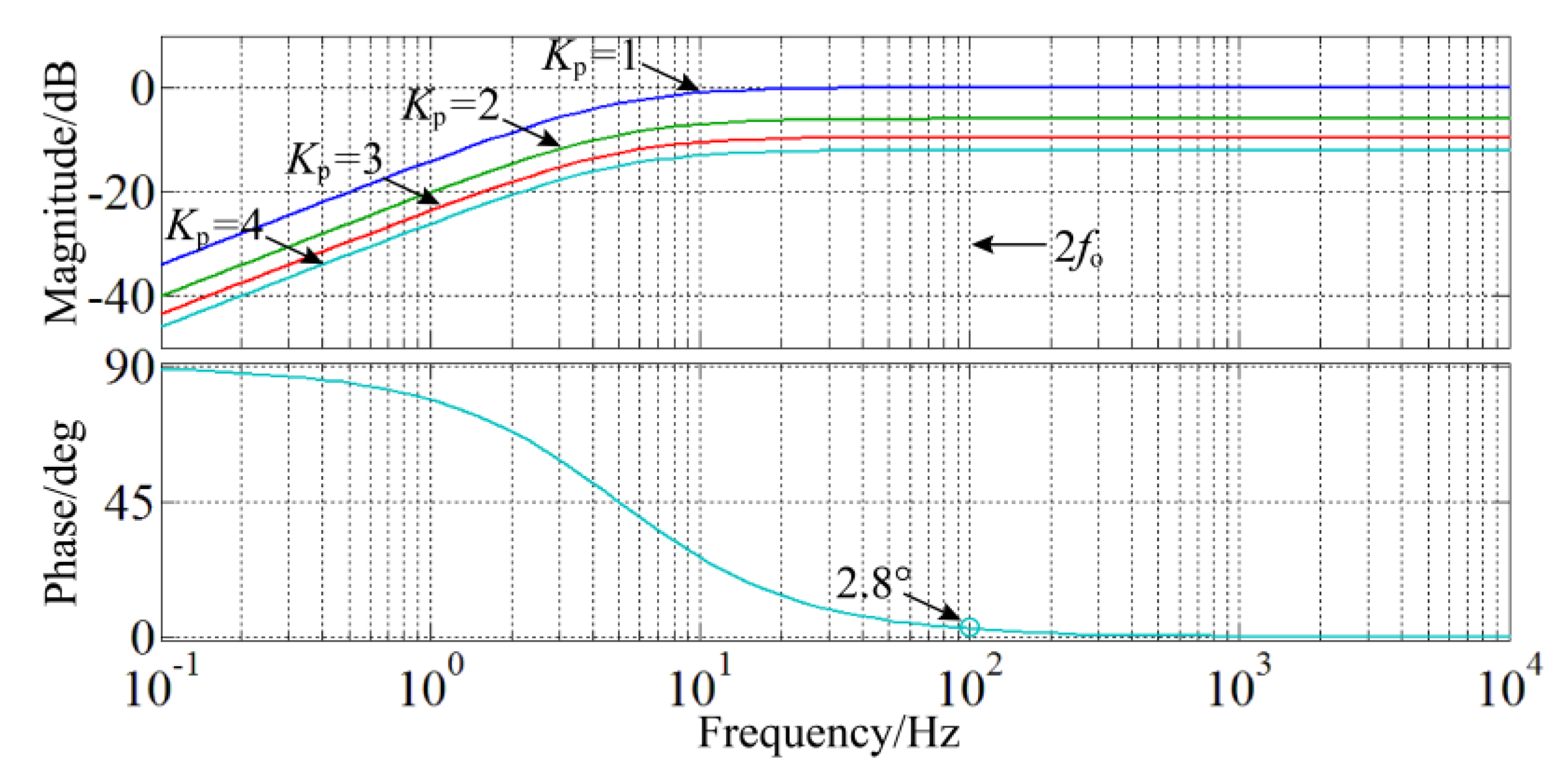

4.2. Determination of Virtual Resistor Value

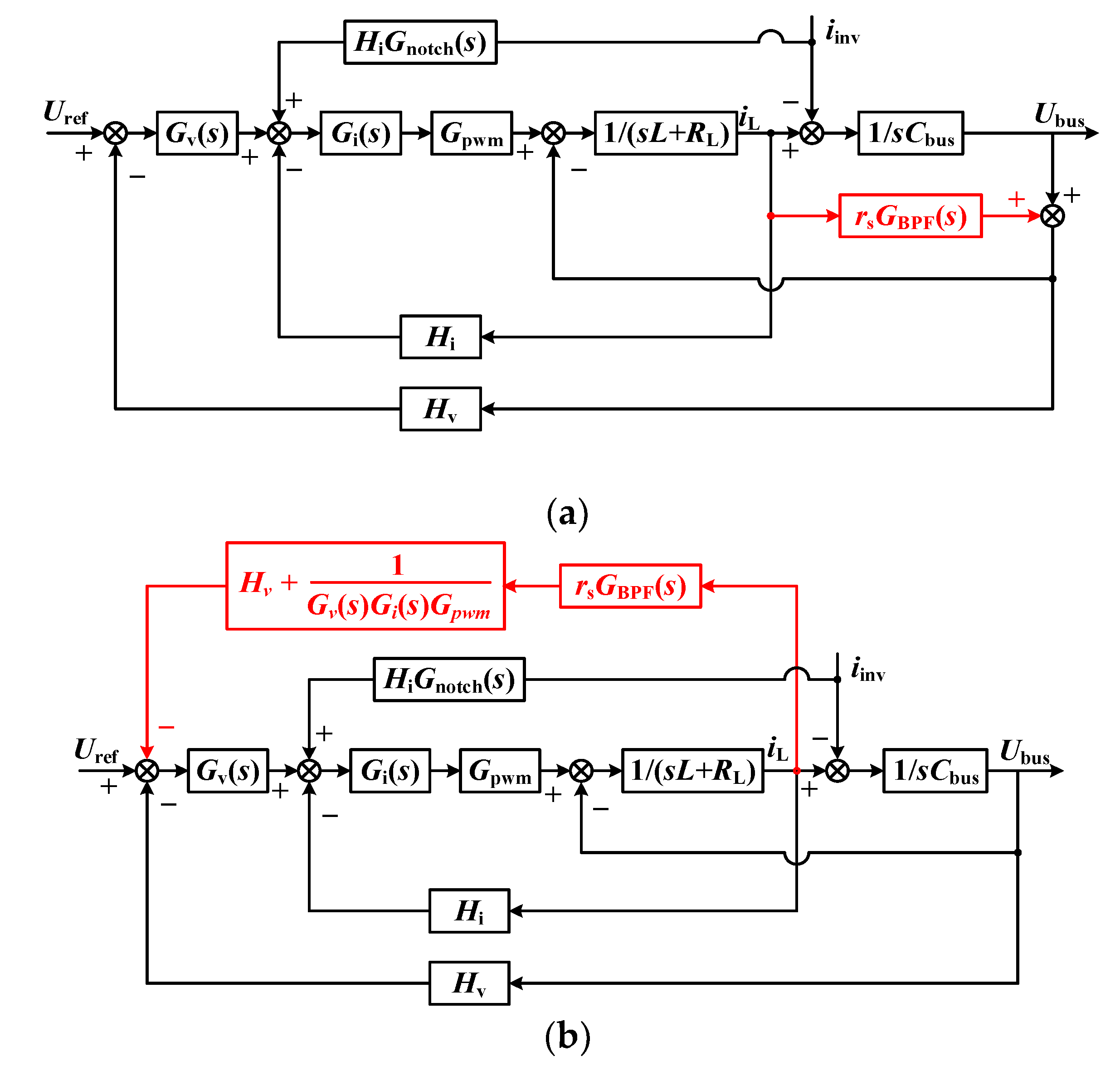

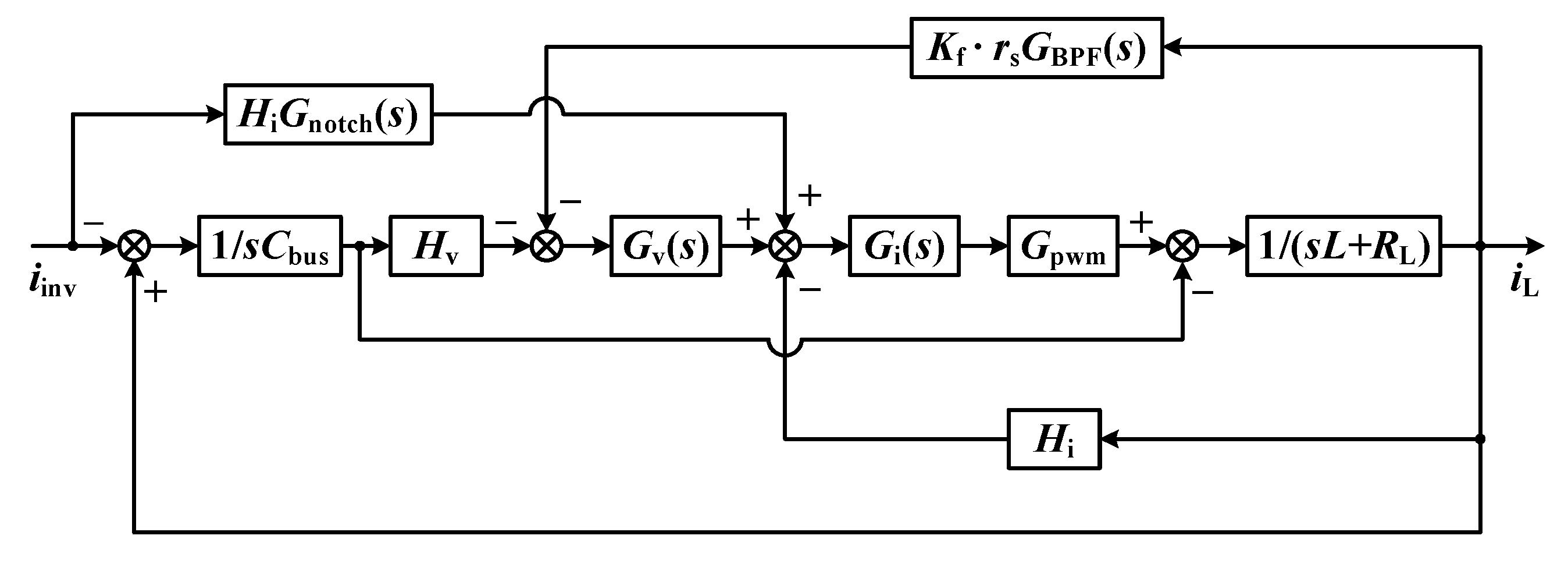

The SHC suppression ratio is used to determine the minimum value of the virtual resistor. By setting the reference voltage to zero, the control block diagram in

Figure 5a can be equivalently transformed into that in

Figure 6.

Based on

Figure 6, the transfer function

Gii(s) from

iinv to

iL can be derived as Equation (17). The corner frequency

fLv of the voltage regulator is much lower than 2

fo, hence when

fLv = 5 Hz, we have

Gv(

j2

π·2

fo) ≈

Kpv. For the reason that 2

fo is the center frequency of both the BPF and the notch filter, the magnitude of

GBPF(

s) is around 1 at 2

fo, and the magnitude of

Gnotch(

s) is nearly 0 at 2

fo.

Defining |

Gii(

j2π·2

fo)| as the SHC suppression ratio and

α as the SHC suppression requirement, then Equation (18) can be obtained from Equation (17). In general, α is required to be less than 5%, i.e.,

α ≤ 5% [

19]. When α is set to 5%, by substituting Equations (11) and (15) into (18), it can be deduced that the requirement of virtual resistance is

rs ≥ 15.5 Ω.

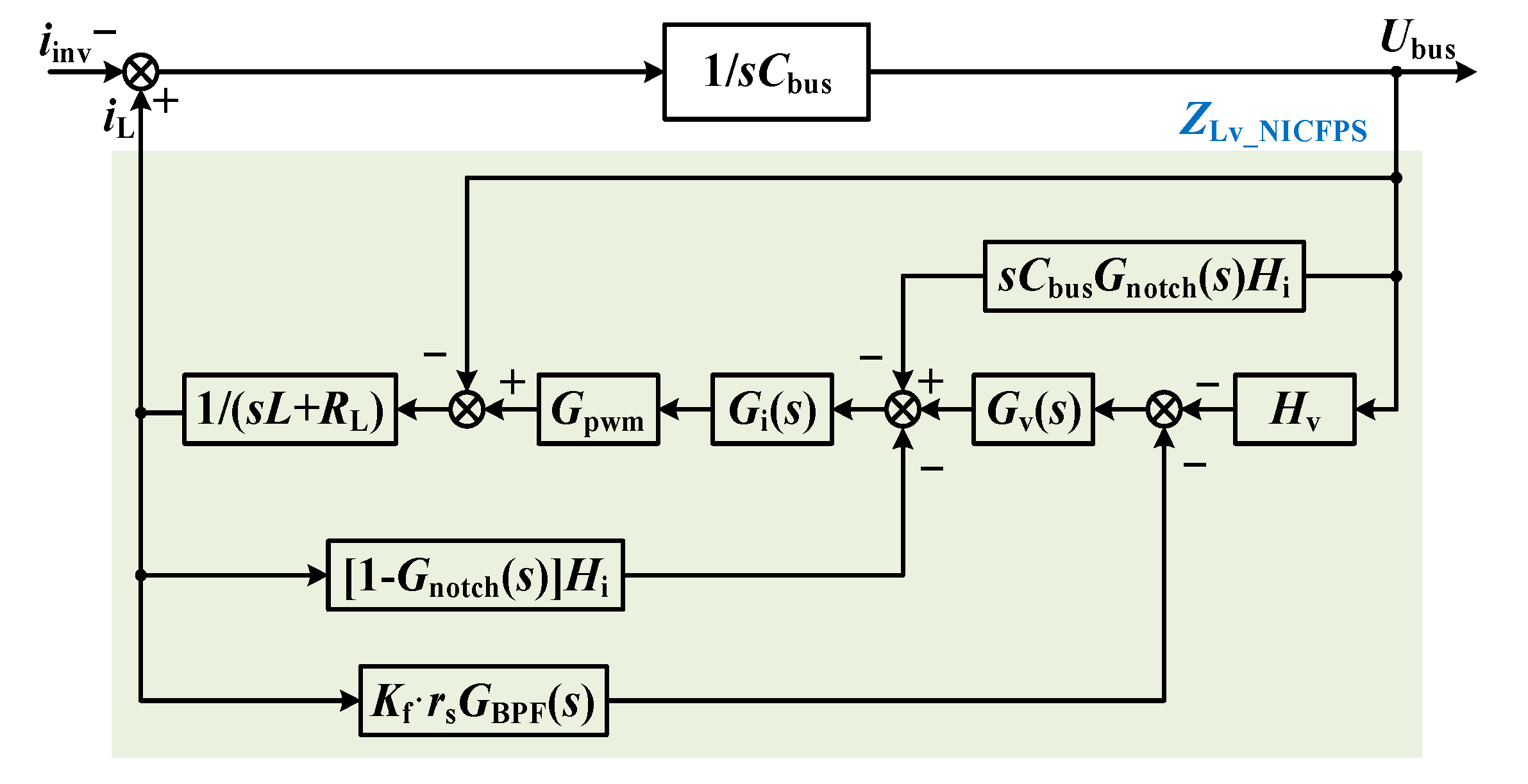

To obtain the inductor branch impedance

ZLv_NICFPS(s),

Uref in

Figure 5a is set to 0, then the block diagram in

Figure 5a can be transformed into that shown in

Figure 7. Based on

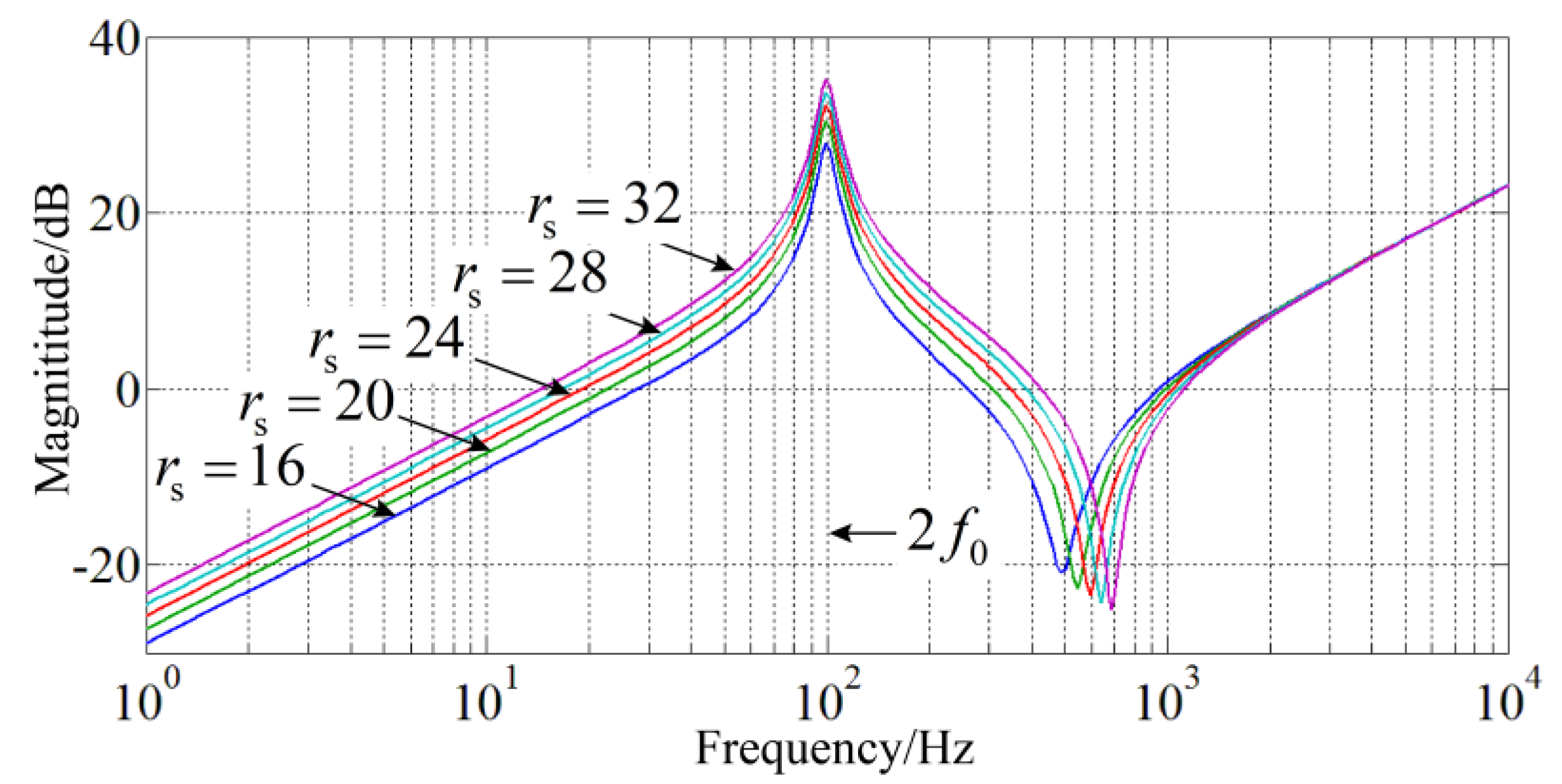

Figure 7, the inductor branch impedance can be obtained as Equations (19) and (20). When

α ≤ 5% and

rs ≥ 15.5 Ω, the magnitude plots of

ZLv_NICFPS(s) with different

rs are shown in

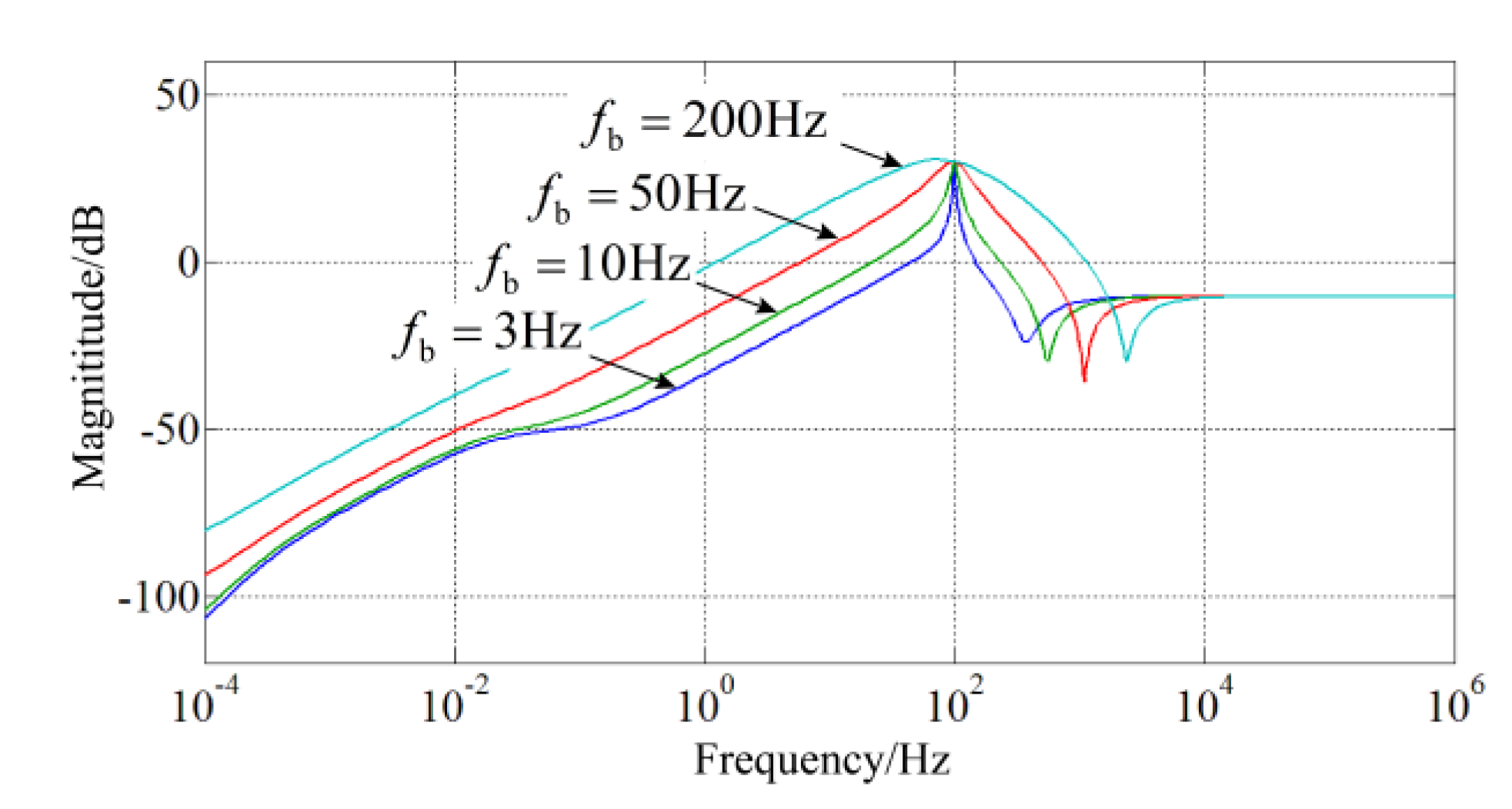

Figure 8.

As can be seen from

Figure 8,

ZLv_NICFPS(s) will increase with the increase in

rs in the wide frequency range near 2

fo, which shows that the SHC suppression capability will improve, but the dynamic performance will deteriorate. The reason is that the actual BPF is not ideal,

rs will affect the inductor branch impedance not only at 2

fo but also at frequencies except for 2

fo. In view of both the SHC and the dynamic performance,

rs = 20 Ω is determined.

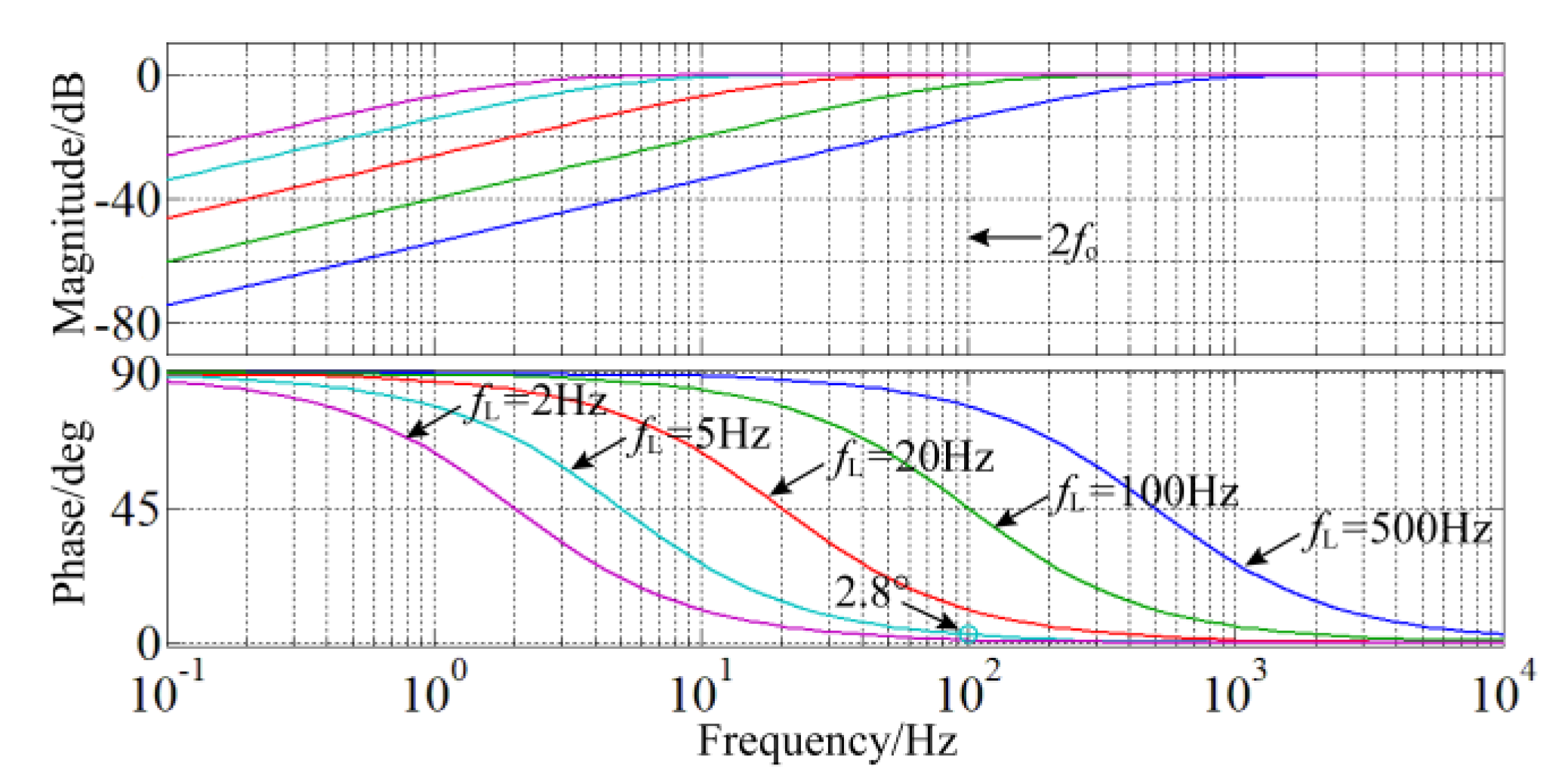

4.3. Design of Bandwidth for BPF

Figure 9 shows the magnitude plots of the

ZLv_NICFPS(

s) with different BPF bandwidth fb. It is obvious that, as

fb increases,

ZLv_NICFPS(

s) grows larger at low frequency, decreasing the dynamic response. Thus,

fb should not be too large in view of the dynamic performance. Meanwhile, when

fb is too small, such as the value lower than 10 Hz, the magnitude change of

ZLv_NICFPS(

s) at low frequency is not quite obvious. Moreover,

fb should be greater than the fluctuation range of 2

fo [

15,

18]. Thus, in /the inverter illustrated in

Table 1,

fb in the feedback function is designed as 10 Hz.

4.4. Output Impedance Comparison

The magnitude of the output impedance can be used to evaluate the performance of SHC reduction and dynamic response during the load transient. The higher magnitude of the output impedance at 2fo means the better ability for SHC reduction, and the lower magnitude at frequencies except for 2fo means the lower bus voltage overshoot and undershoot during the load transient.

In the existing typical control schemes, the NF-LCFFS and NF-CR+LCFFS in [

22] have a relatively high performance of SHC reduction and dynamic response. Hence, to evaluate the performance of the proposed NICFPS, this section compares the output impedance among the proposed NICFPS and the two abovementioned schemes, in which scheme I and scheme II indicate the NF-LCFFS and NF-CR+LCFFS, respectively.

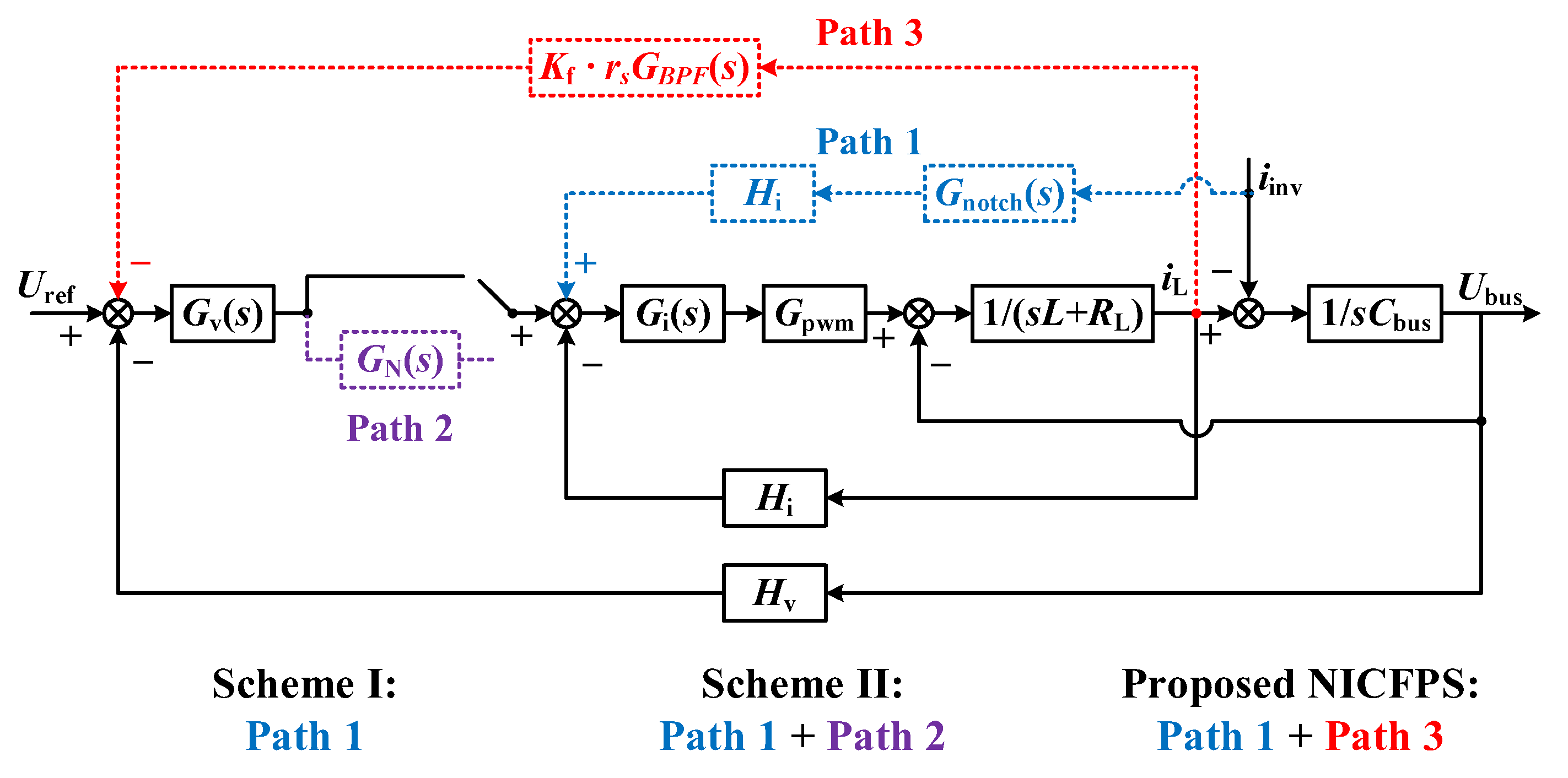

The block diagram of the three schemes is shown in

Figure 10. Compared with scheme II, the proposed NICFPS requires the additional parameter design for

rs,

fb, and

Kf, however, the parameters can be easily determined only by the simple calculation and output impedance comparison as described in

Section 4.

In the three schemes, the parameters of the current regulator and crossover frequency of the inner current loop are the same. In order to reduce the SHC effectively, the crossover frequency of the outer voltage loop is selected as 10 Hz in scheme I, and 50 Hz in both scheme II and the proposed NICFPS.

Based on

Figure 10 in this paper and Equations (21) and (23) in the Reference [

22], inductor branch impedance at 2

fo for schemes I and II can be derived as

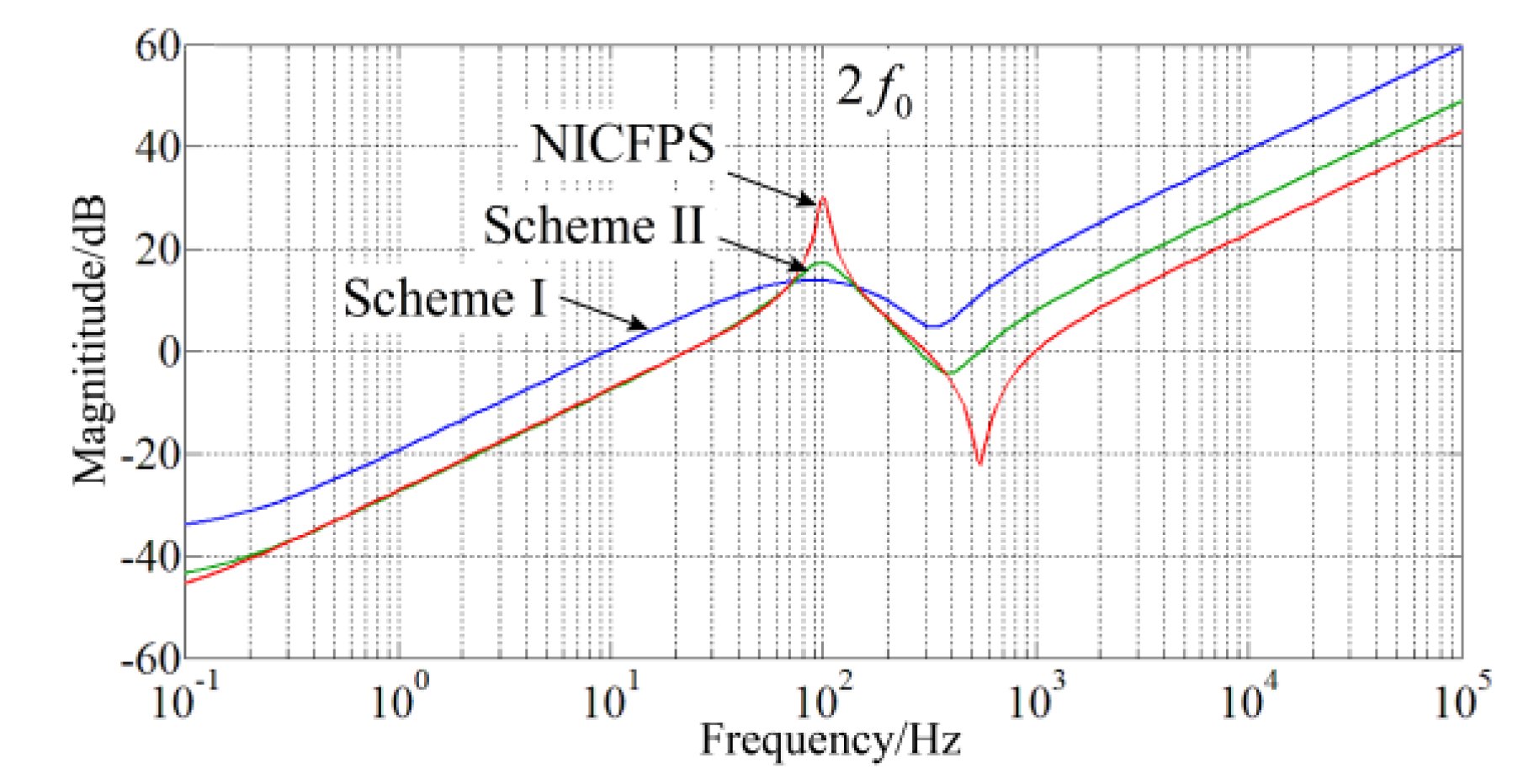

According to Equations (20)–(22), the magnitude plots of the inductor branch impedance of the buck converter with the three schemes are shown in

Figure 11. It can be seen from

Figure 11 that, at frequencies except for 2

fo, the proposed NICFPS and scheme II have lower output impedance, which means better dynamic performance. Moreover, the proposed NICFPS has the highest output impedance at 2

fo, which indicates the best SHC suppression ability among the three schemes.

5. Simulation Results

To verify the effectiveness of the proposed NICFPS, the simulation results of about a 10 kW two-stage inverter with the parameters in

Table 1 are provided. The simulation model is built by MATLAB software, and based on that, the proposed NICFPS and the two typical schemes are tested.

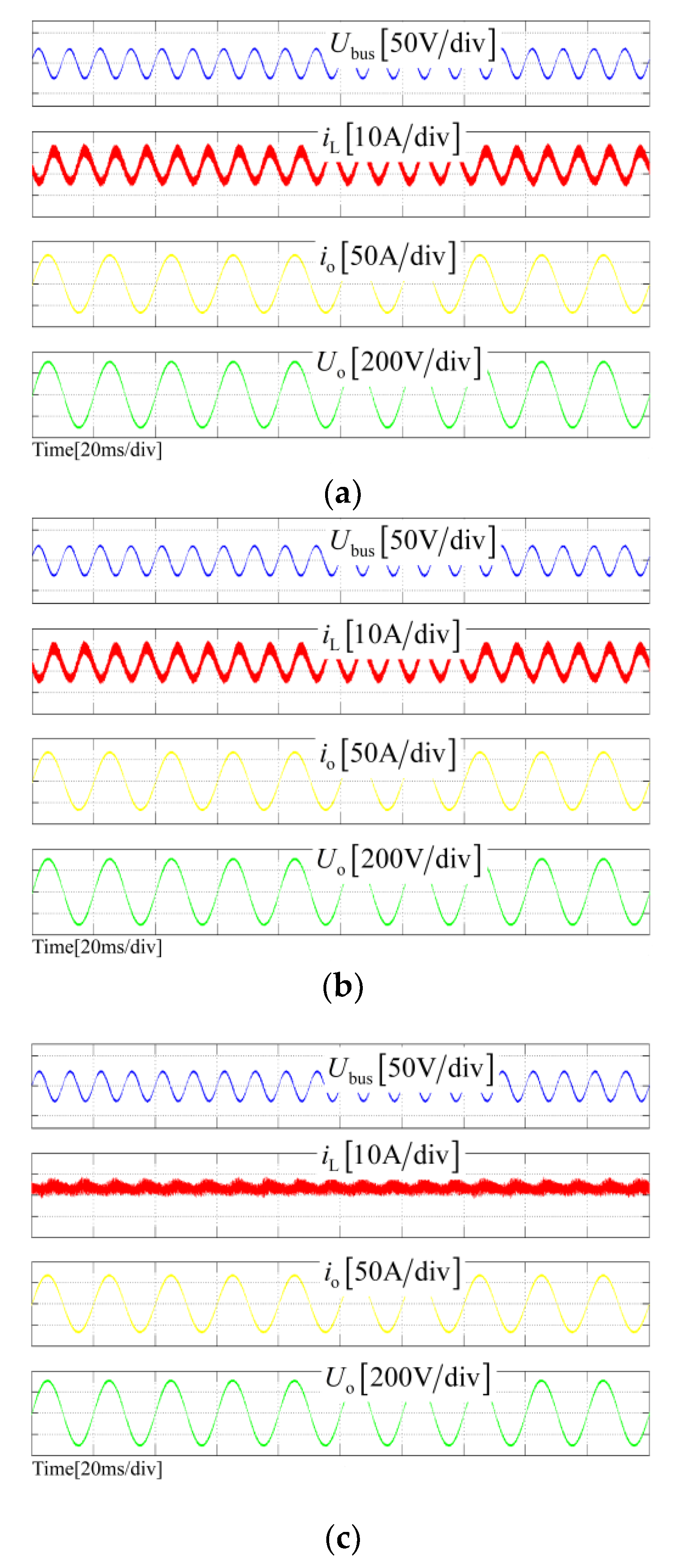

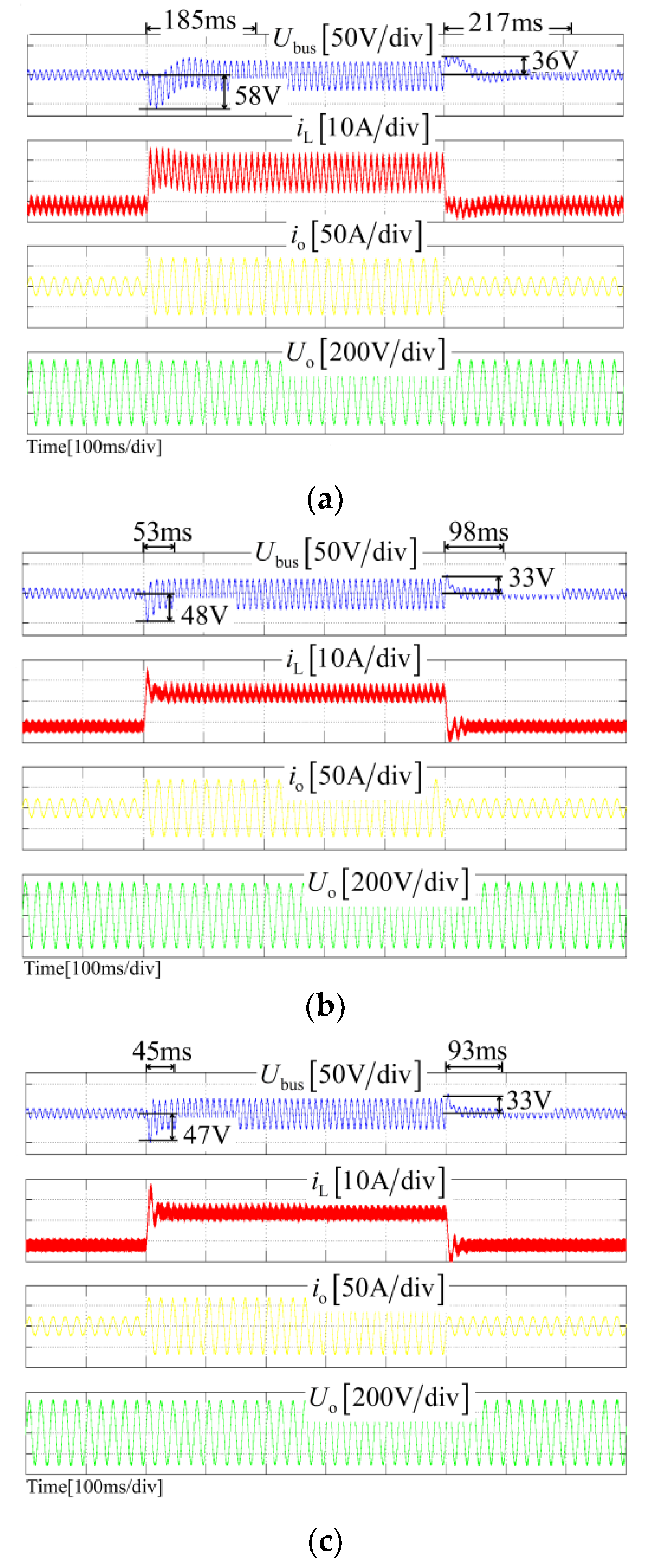

Figure 12 shows the steady-state simulation results of the three schemes with the 10 kW output power. As seen, the SHC proportion in

iL is around 4.3% in the NICFPS, while 32.6% in scheme I and 10% in scheme II. It is obvious that the proposed NICFPS has the best ability to suppress the SHC, and the reason is that the scheme has the highest output impedance at 2

fo, which can be seen in

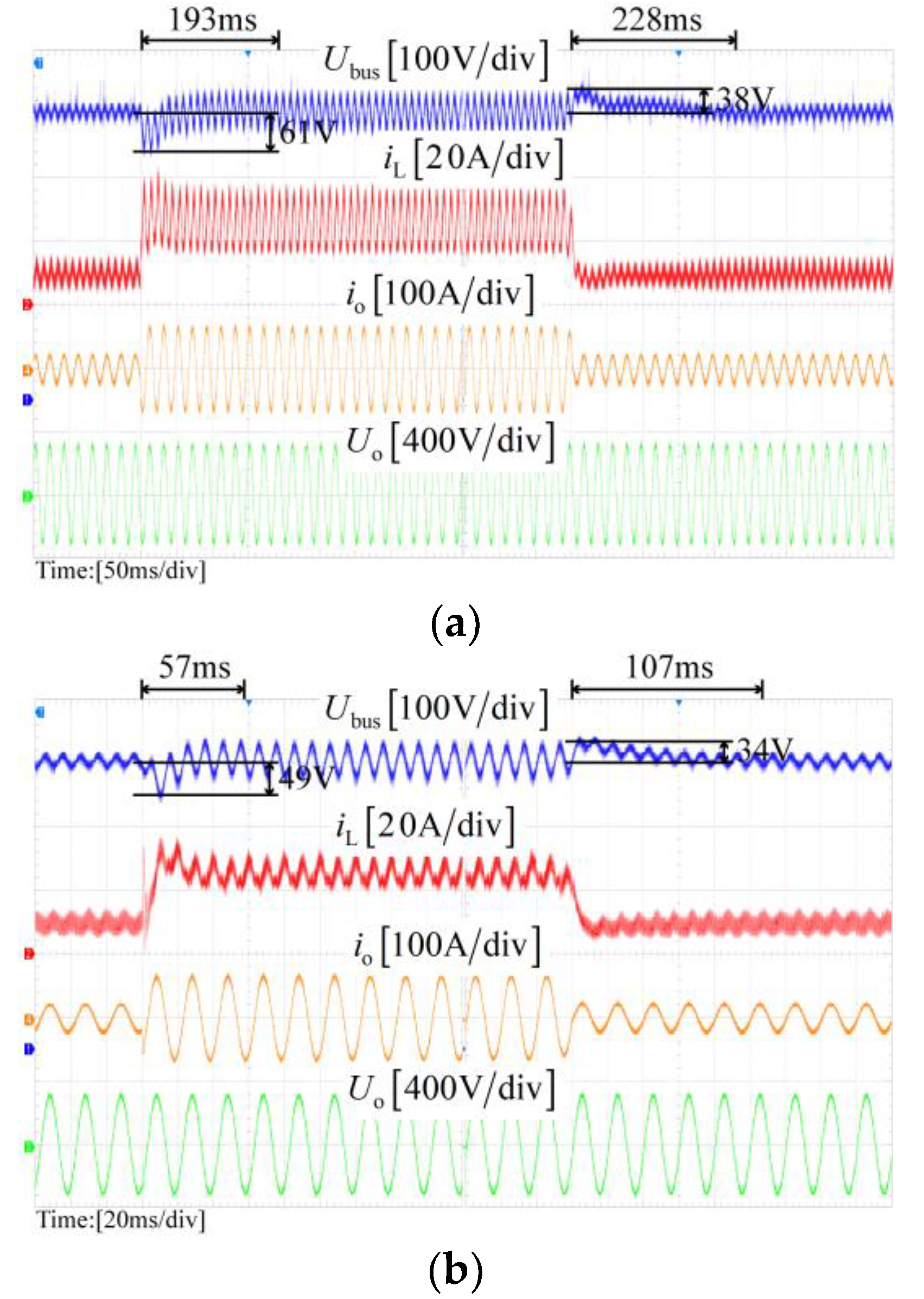

Figure 11.

Figure 13 shows the dynamic simulation results of the three schemes, and the load of the inverter changes between 33% and 100% full load. As seen, in the proposed NICFPS and scheme II, the undershoots of

Ubus are both close to 50 V and the settling times are both about 50 ms when the load steps up, the overshoots of

Ubus are both 33 V, and the settling times are both nearly 100 ms when the load steps down. However, in the scheme I, the settling time is about 200 ms, and the undershoot and overshoot are 58 V and 36 V, respectively. It can be seen from

Figure 13 that scheme I has the evident overshoot and undershoot during the load transient, and the proposed NICFPS and scheme II have better dynamic performance. This is because scheme I has the highest output impedance almost at all frequencies, but the proposed NICFPS and scheme II can reduce the output impedance at the frequencies except for 2

fo, and the characteristic comparison of the output impedance among the three schemes can be seen from

Figure 11.

Based on

Figure 12 and

Figure 13,

Table 2 gives the simulation results of the three control schemes in terms of the SHC proportion and voltage fluctuation during load transient. The results in

Table 2 show that the proposed NICFPS has both the best ability to suppress SHC and good dynamic performance. Moreover, the simulation results are in accordance with the theoretical analysis in

Section 4.

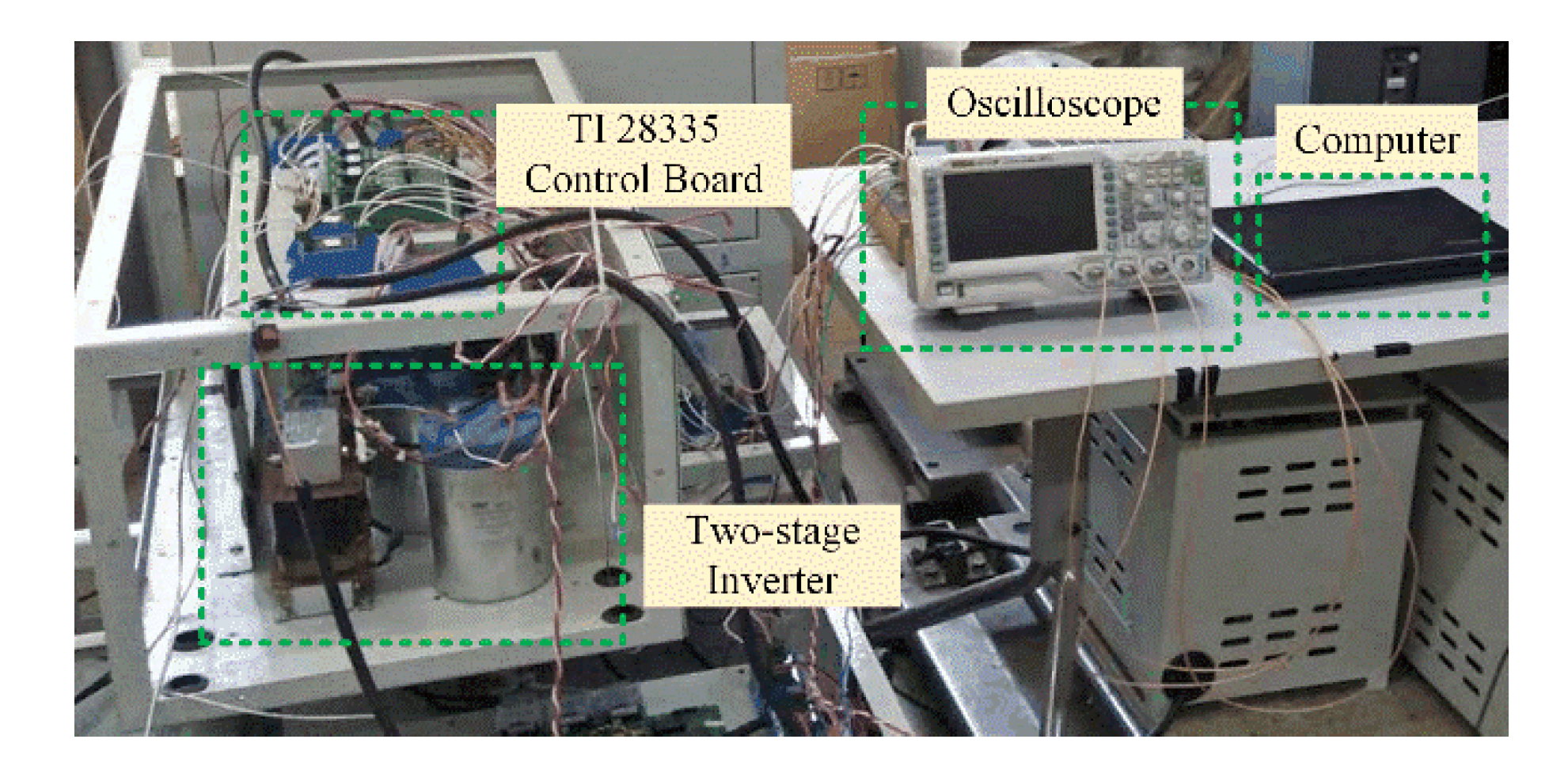

6. Experimental Results

To further verify the aforementioned theoretical analysis and simulation results, a 10 kW prototype is developed and tested with the three control schemes, namely, scheme I (NF-LCFFS), scheme II (NF-CR+LCFFS), and the proposed NICFPS. The experimental platform is shown in

Figure 14, which mainly consists of a two-stage inverter, a control board, an oscilloscope, and a debugging computer. The two-stage inverter is composed of a front-end buck converter and a downstream single-phase inverter. The microprocessor of the inverter is TMS320F28335 from TI company. The parameters of the prototype are listed in

Table 1.

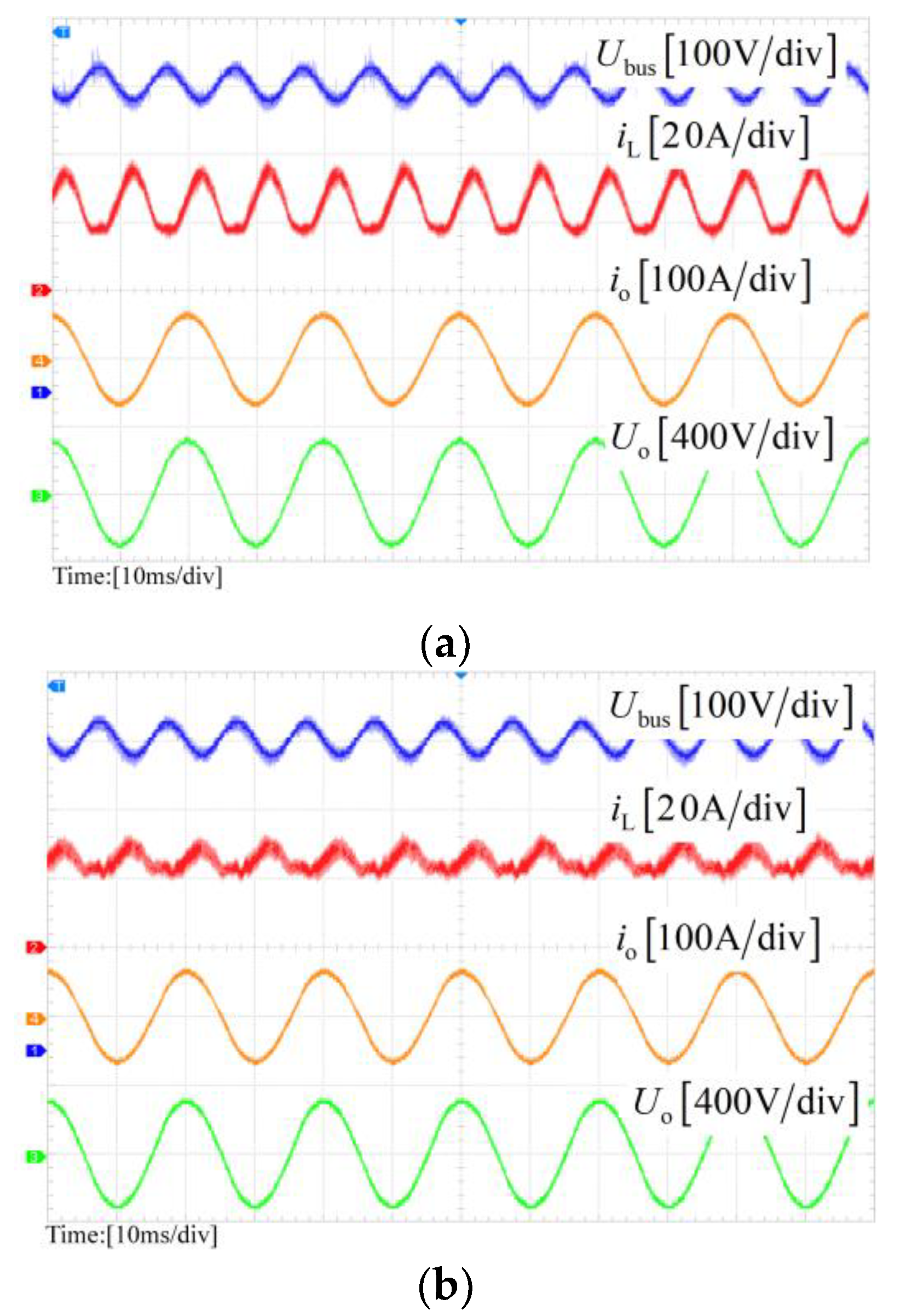

Figure 15 shows the steady-state experimental results of the three schemes with 10 kW ac output power. It can be seen from

Figure 15 that the SHC proportion in the proposed NICFPS is about 4.7%, while in scheme I it is 33.2% and in scheme II it is 11.1%. Thus, it is clear that the proposed NICFPS has the best effect on the SHC reduction because the highest output impedance at 2

fo can be obtained for the scheme as shown in

Figure 11.

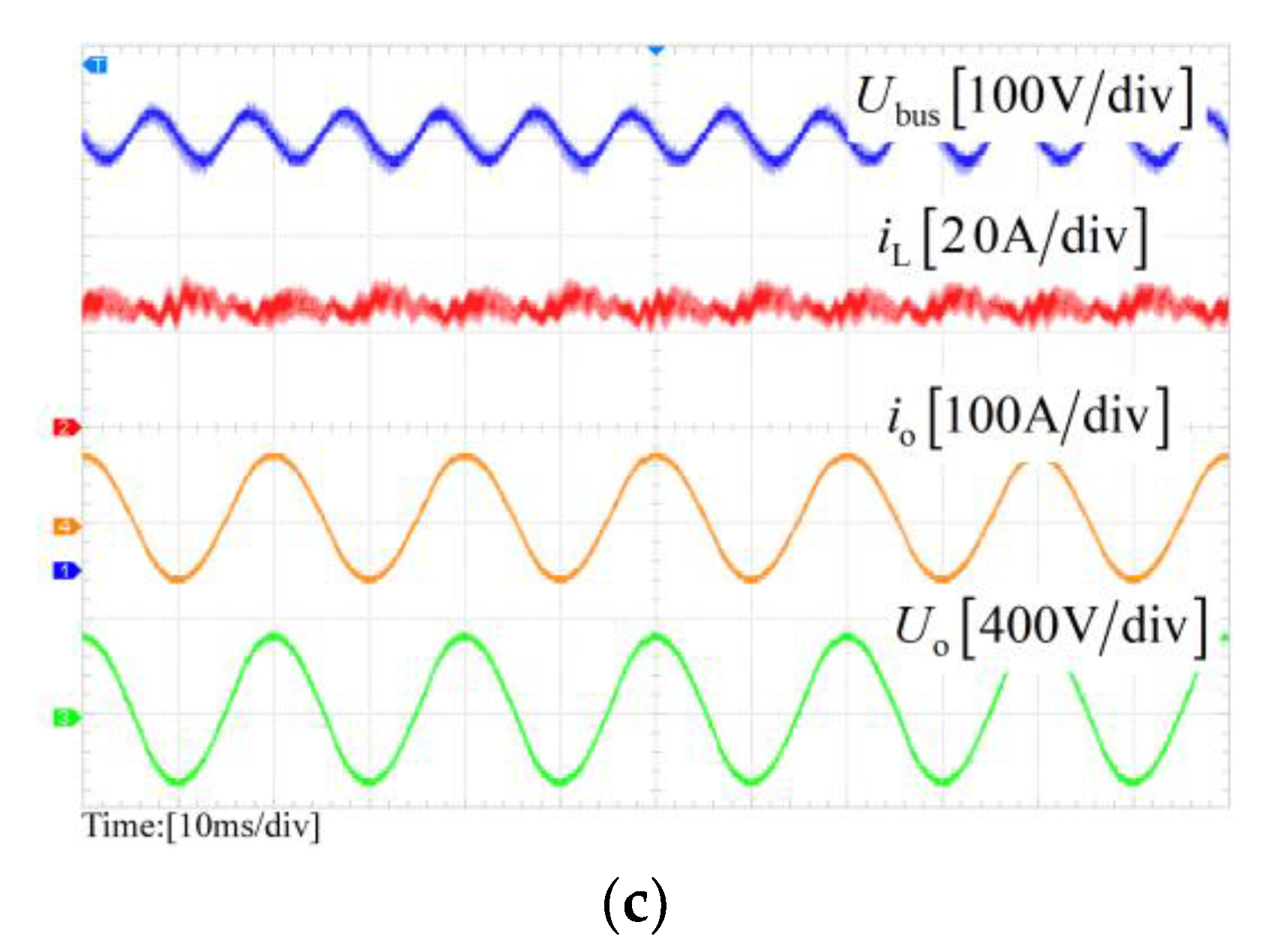

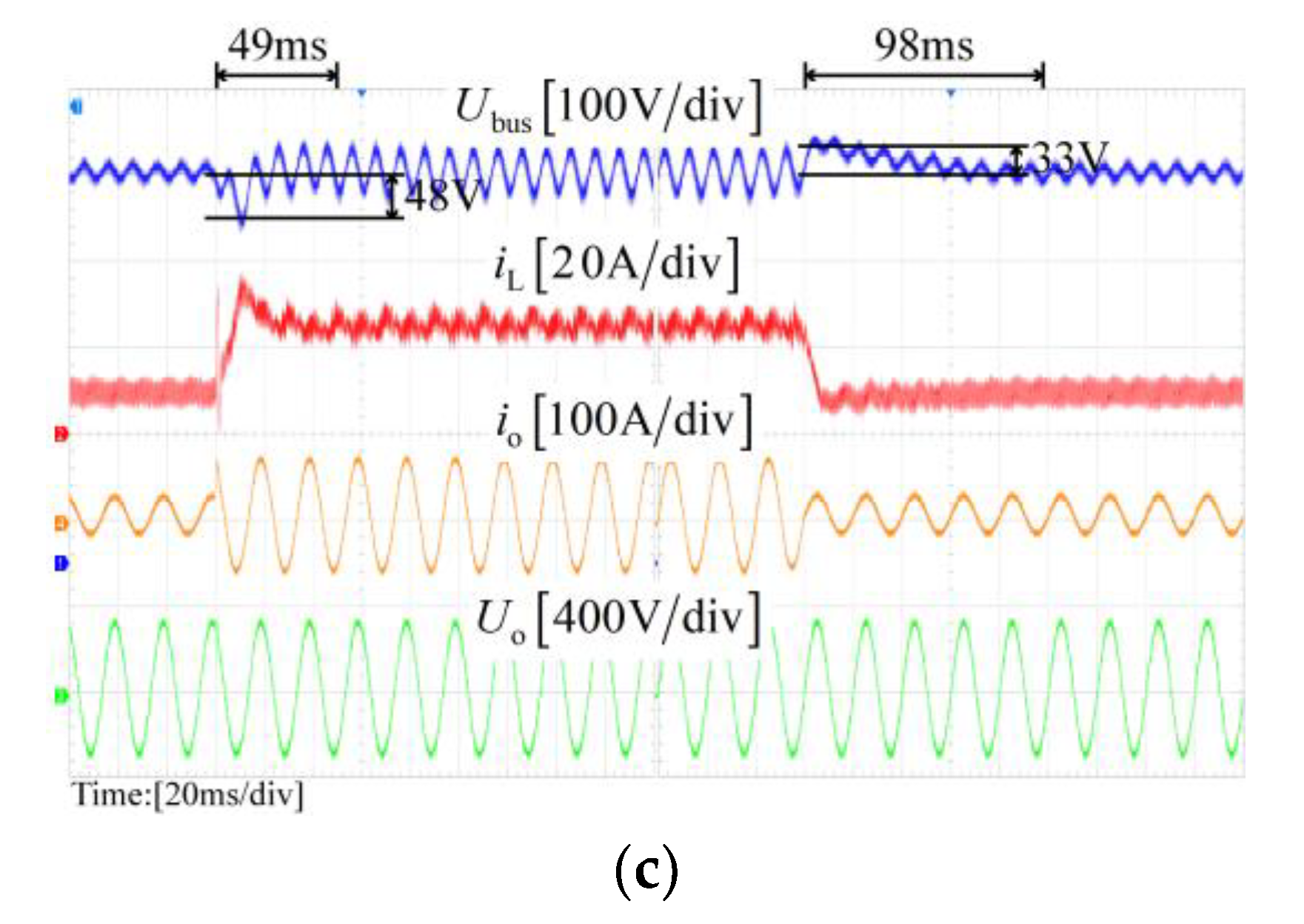

Figure 16 shows the dynamic experimental results of the three schemes, and the ac load of the inverter changes between 33% and 100% full load. In the proposed NICFPS and scheme II, the undershoots of

Ubus are both close to 50 V and the settling times are both about 50 ms when the load steps up, the overshoots of

Ubus are both 33 V, and the settling times are both nearly 100 ms when the load steps down. However, in scheme I, the settling time is even close to 230 ms, and the undershoot and overshoot are 61 V and 38 V, respectively. It is obvious that the NICFPS and scheme II have better dynamic performance. The reason is that the proposed NICFPS and scheme II can reduce the output impedance at the frequencies except for 2

fo, which can be seen in

Figure 11.

Table 3 summarizes the experimental results comparison of the three control schemes in terms of the SHC proportion and the bus voltage fluctuation when the output power step changes between a 33% and 100% rated load. As seen, the proposed NICFPS has the best ability to suppress the SHC since it has the highest magnitude of the output impedance at 2

fo. Meanwhile, due to the lower output impedance at the frequencies except for 2

fo, the proposed NICFPS and scheme II have better dynamic performance than scheme I.

In brief, among the three control schemes, the proposed NICFPS has the best SHC reduction ability and dynamic performance. Furthermore, comparing the SHC proportion, overshoot, and undershoot in

Table 3 with those in

Table 2, it can be seen that the experimental results are well in agreement with the simulation results in

Section 5 and the theoretical analysis in

Section 4.