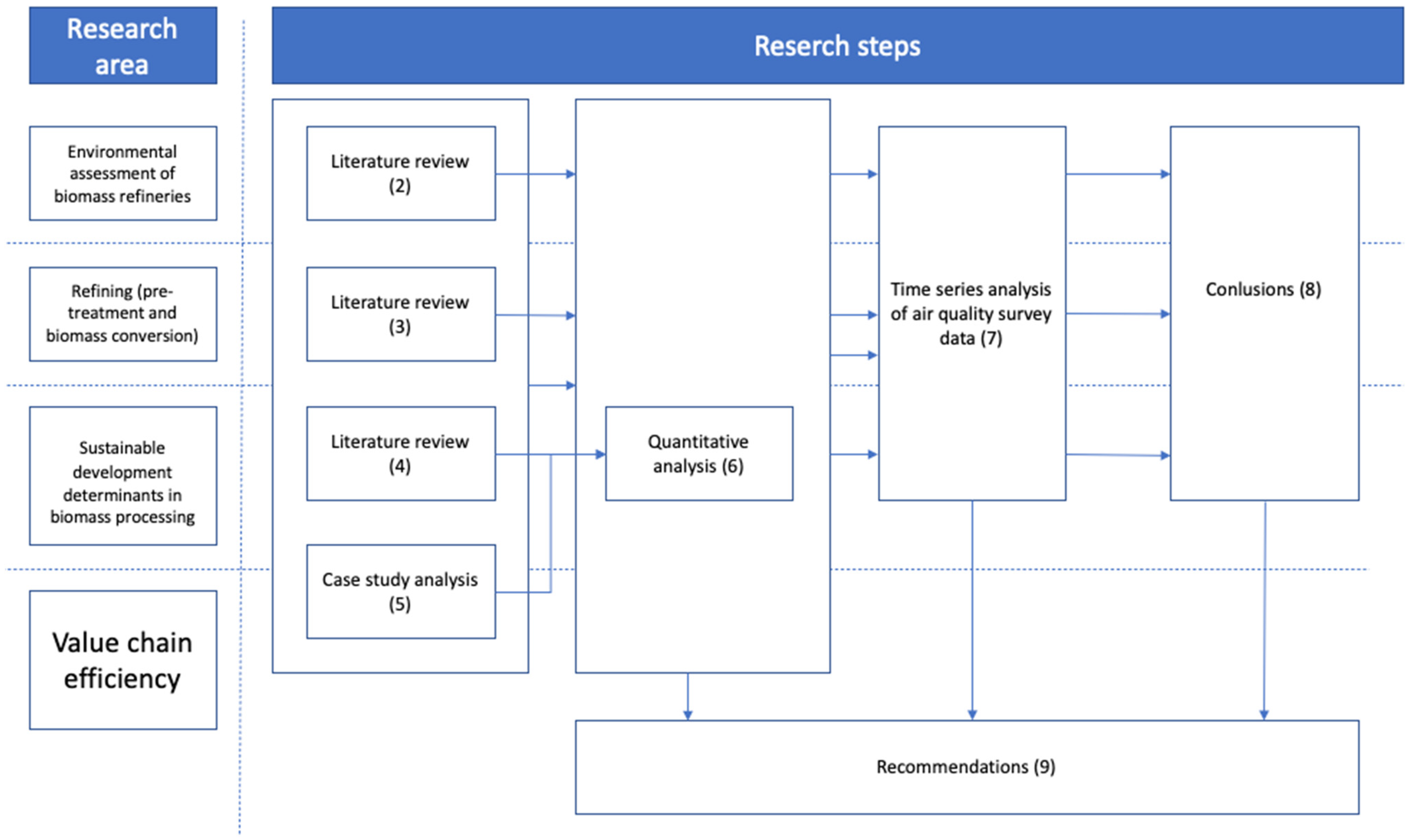

Efficiency of Shaping the Value Chain in the Area of the Use of Raw Materials in Agro-Biorefinery in Sustainable Development

Abstract

1. Introduction

- Refineries from whole crops—the substrate is the whole plant, e.g., oil refinery, in which oilseeds (rapeseed, sunflower, soybeans) are used;

- ‘green’ refineries with inedible ‘green’ parts of plants or whole energy crops (e.g., wet biomass, green grass, alfalfa, clover, unripe grain, unsuitable for agriculture, and food industry plants or their parts);

- Lignocellulosic refineries, based on lignocellulosic biomass (e.g., straw, forestry waste, wood, paper);

- Two-platform refineries (producing syngas and sugars in one product in the first technology platform with simultaneous fuel production in the second platform), based on renewable raw materials (waste from agriculture, forestry, food industry, biodegradable municipal waste).

- Biomass from crop production.

- Biodegradable waste products of plant or animal origin.

- Dedicated plants grown for energy purposes.

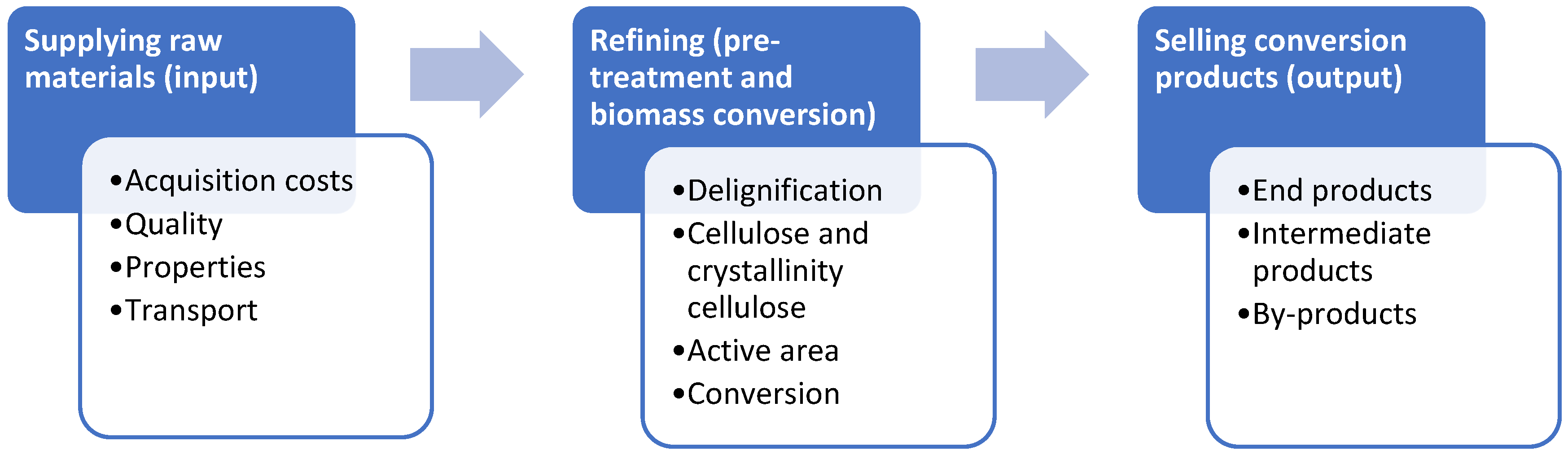

2. Analysis of the Processes That Make up Value Chains in an Agricultural Biorefinery

2.1. Supplying Raw Materials (Input)

2.2. Refining (Pre-Treatment and Biomass Conversion)

2.3. Selling Conversion Products (Output)

3. Sustainable Development Determinants in Biomass Processing

4. Resource Assessment (Waste Valorization)

5. Social Significance of Agro-Biorefinery Development

6. Environmental Assessment of Biomass Refineries

- Waste management.

- Use of targeted biomass.

- Use of surplus biomass.

- Reduction of greenhouse gas emissions.

- Reduction of acidifying impurities.

- Use of products resulting from biorefining.

- CLM method—a method of intermediate points, in which the following indicators are used: depletion of abiotic resources (ADP), global warming potential (GWP), reduction of stratospheric ozone resources (ODP), soil toxicity potential, soil acidification (AP), eutrophication potential, and resource perceptibility potential (OTV).

- Umberto program—allows for analyzing the energy and materials flow in companies, production installations, or facilities, calculating operating costs and lifecycle, choosing an ecologically optimal version of the product, etc.

- SimaPro program—uses the eco-indicator method for assessing the damage caused to the environment by the adverse impact of a process or product.

7. Value Chain Efficiency

7.1. Logistic Efficiency of Biomass

- Staryfy(d. s)—the cost of transport according to the basic tariff for a given vehicle s and distance d.

- ks/km—rate in PLN/km for vehicle s.

- upowr—negotiated discount of the return fee.

- Ks post—additional fee for parking after exceeding 4 h of driving (we assume that it will be added for each subsequent 250 km of the route).

- Ks difficulties—additional fee for difficulties specific to a given route (driving through large cities, poor road conditions).

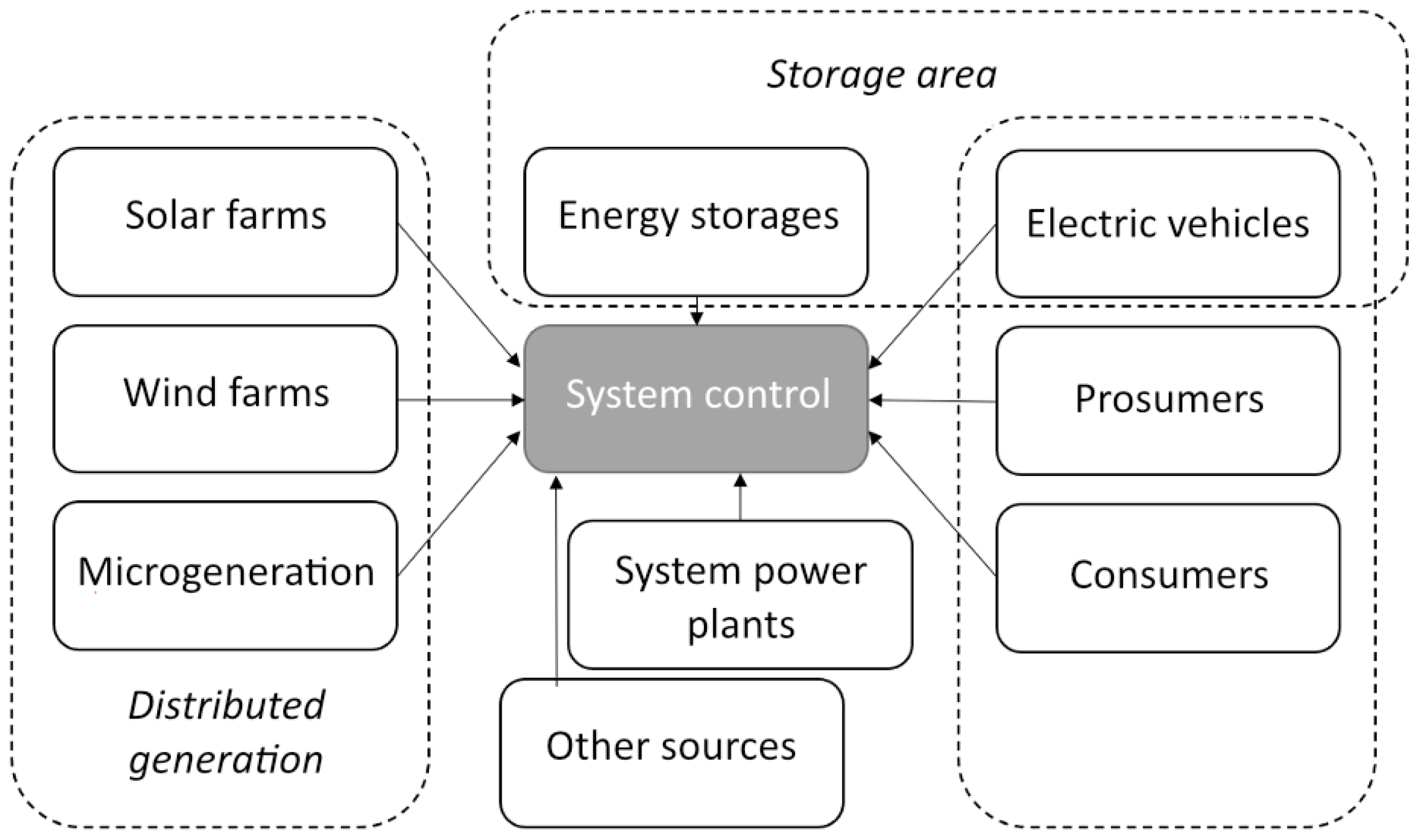

7.2. Biomass Energy Efficiency

7.3. Environmental Efficiency

7.4. Economic Efficiency of Biorefineries

8. Conclusions

- The processing of biomass in agro-biorefineries achieves environmental, social, and economic objectives;

- A rational supply chain makes it possible to exploit the potential of biomass and adapt transport to the type of biomass, cargo volume, cargo weight, distance, and travel costs. It also has a positive effect on reducing CO2 emissions during transport;

- A favorable amount of energy produced from biomass can be obtained, as exemplified by the studies of Witaszek, Pilarska, and Pilarski [42] that included the pre-treatment analyses. By selecting the biomass share appropriately, a much higher profitability of the treatment used can be achieved;

- Based on an environmental performance analysis, the optimal biorefinery technology can be selected, mainly being regionally diverse, taking into account the sustainable availability of raw materials, and the environmental impacts identification. The environmental impact of a biorefining investment can also be estimated, including the level of reductions in emissions of methane, carbon dioxide, nitrogen oxides, sulfur oxides, and dust;

- Studies have shown that, for example, the annual revenue from biogas production in a biogas plant with a capacity of 0.5 MW and production of approx. 4000 MWh may amount to almost PLN 3 million (EUR 0.6 million).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RM | Road map |

| FIT455 | Program EU “Fit for Fifthy Five” |

| GreenDeal | Program EU for Climate Saving |

| RES | Renewable Energy Sources |

| LCA | Life Cycle Assessment |

| ADP | Depletion of abiotic resources |

| GWP | Global warming potential |

| AP | Soil acidification |

| LCC | Lifecycle cost calculation |

| eLCC | Environmental lifecycle cost calculation |

| sLCC | Social lifecycle cost calculation |

| ODP | Stratospheric ozone resources |

| OTV | Resource perceptibility potential |

References

- Koszel, M.; Bartkowiak, P. Taksonomiczna miara zrównoważonego rozwoju obszarów metropolitalnych w Polsce. Zesz. Nauk. Uniw. Ekon. Krakowie 2018, 3, 83–100. [Google Scholar] [CrossRef]

- Bartkowiak, P.; Rutkowski, I.P.; Bartkowiak, A. A model approach to the maturity and the level of risk in the product innovation process. Stud. Pr. WNEiZ 2019, 55, 129–142. [Google Scholar] [CrossRef]

- Bartkowiak, A.; Bartkowiak, P. The Determinants of Sustainable Development of Agriculture Sector in Poland. Transform. Bus. Econ. 2012, 11, 298–314. [Google Scholar]

- Kleinand, R.M.; Taylor, T.L.; Kingstone, A. Against a role for attentional disengagement in the gap effect: A friendly amendment to Tam and Stelmach (1993). Percept. Psychophys. 1995, 57, 573–577. [Google Scholar] [CrossRef]

- Kaszyński, P.; Komorowska, A.; Zamasz, K.; Kinelski, G.; Kamiński, J. Capacity Market and (the Lack of) New Investments: Evidence from Poland. Energies 2021, 14, 7843. [Google Scholar] [CrossRef]

- Jasiński, J.; Kozakiewicz, M.; Sołtysik, M. The Effectiveness of Energy Cooperatives Operating on the Capacity Market. Energies 2021, 14, 3226. [Google Scholar] [CrossRef]

- Bartkowiak, A.; Bartkowiak, P. Technical and Technological Progress in the Context of Sustainable Development of Agriculture in Poland. Procedia Eng. 2017, 182, 66–75. [Google Scholar] [CrossRef]

- Wałowski, G. Development of Biogas and Biorafinery Systems in Polish Rural Communities. J. Water Land Dev. 2021, 49, 156–168. [Google Scholar]

- Krzakiewicz, K.; Bartkowiak, P. Imitation as a Competitive Strategy. In Proceedings of the International Scientific Conference Hradec Economic Days, Hradec Králové, Czech Republic, 25–26 March 2021; Volume 11. [Google Scholar]

- Bartkowiak, A. Metody i instalacje do produkcji energii elektrycznej i ciepła w rafinerii biomasy. In Produkcja Biogazu w Rafinerii Biomasy z Uwzględnieniem Aspektów Eksploatacji Biogazowi; Wydawnictwo ITP: Poznań, Poland, 2020. [Google Scholar]

- Celiktas, M.S.; Alptekin, F.M. Biorefinery Concept: Current Status and Future Prospects. Int. Conf. Eng. Technol. 2017, 7, 9. [Google Scholar]

- Oleśkowicz-PoPiel, P.; Jankowska, E. Application of Fermentation Processes in Biorefineries. Przemysl Chem. 2014, 93, 351–354. [Google Scholar]

- Bałdowski, M.; Będkowski-Kozioł, M.; Bruszewski, M.; Grzejdziak, Ł.; Hawranek, P.; Jankowski, Ł.; Karpiński, M.; Kinelski, G.; Kosiński, E.; Kowalczyk, J. Prawo Energetyczne. Ustawa o Odnawialnych Źródłach Energii. Ustawa o Rynku Mocy. Ustawa o Inwestycjach w Zakresie Elektrowni Wiatrowych: Komentarz; Wydawnictwo C.H.Beck Sp. z o.o.: Warsaw, Poland, 2020. [Google Scholar]

- Soeters, J. Michael Porter. In Management and Military Studies; Routledge: London, UK, 2020. [Google Scholar]

- Weil, K.E. PORTER, Competitive advantage, creating and sustaining superior performance. Rev. Adm. Empres. 1985, 25, 82–84. [Google Scholar] [CrossRef]

- Stonehouse, G.; Snowdon, B. Competitive Advantage Revisited: Michael Porter on Strategy and Competitiveness. J. Manag. Inq. 2007, 16, 256–273. [Google Scholar] [CrossRef]

- Krzakiewicz, K.; Cyfert, S. Dynamic capabilities in strategic choice processes within organisations. Management 2017, 21, 7–19. [Google Scholar] [CrossRef]

- Dyduch, W.; Chudziński, P.; Cyfert, S.; Zastempowski, M. Dynamic capabilities, value creation and value capture: Evidence from SMEs under COVID-19 lockdown in Poland. PLoS ONE 2021, 16, e0252423. [Google Scholar] [CrossRef]

- Borowiecki, R.; Siuta-Tokarska, B. Challanges Facing Polish SMES in the Face of Globalization Processes. Folia Oeconomica Stetin. 2011, 9, 52–71. [Google Scholar] [CrossRef]

- Rzepka, A.; Borowiecki, R.; Miskiewicz, R.; Olesinski, Z. Changes in Management During Transformation of Power Industry. Eur. Res. Stud. J. 2021, XXIV, 1149–1162. [Google Scholar] [CrossRef]

- Gorynia, M. Competition and globalisation in economic sciences. Selected aspects. Econ. Bus. Rev. 2019, 5, 118–133. [Google Scholar] [CrossRef]

- Mroczek-Dąbrowska, K.; Gorynia, M. Understanding transaction costs in the mesoeconomic perspective. Argum. Oeconomica 2019, 1, 337–360. [Google Scholar] [CrossRef]

- McGee, J.; Sammut, T. Wiley Encyclopedia of Management: Strategic Management; Wiley: Hoboken, NJ, USA, 2015; Volume 12. [Google Scholar]

- Parajuli, R.; Dalgaard, T.; Jørgensen, U.; Adamsen, A.P.S.; Knudsen, M.T.; Birkved, M.; Gylling, M.; Schjørring, J.K. Biorefining in the Prevailing Energy and Materials Crisis: A Review of Sustainable Pathways for Biorefinery Value Chains and Sustainability Assessment Methodologies. Renew. Sustain. Energy Rev. 2015, 43, 244–263. [Google Scholar] [CrossRef]

- Owczuk, M.; Rogulska, M.; Bogumil, D.; Biernat, K. Development Prospects of Biorefinery Technologies. Chemik 2015, 69, 11. [Google Scholar]

- Harasym, J. Biorafinerie—Rozwój Konceptu. Przegląd Zbożowo-Młynarski 2015, 2, 2–4. [Google Scholar]

- Biernat, K.; Samson-Bręk, I.; Chłopek, Z.; Owczuk, M.; Matuszewska, A. Assessment of the Environmental Impact of Using Methane Fuels to Supply Internal Combustion Engines. Energies 2021, 14, 3356. [Google Scholar] [CrossRef]

- Dahmen, N.; Lewandowski, I.; Zibek, S.; Weidtmann, A. Integrated lignocellulosic value chains in a growing bioeconomy: Status quo and perspectives. GCB Bioenergy 2018, 11, 107–117. [Google Scholar] [CrossRef]

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; Da Silva, S.S. The path forward for lignocellulose biorefineries: Bottlenecks, solutions, and perspective on commercialization. Bioresour. Technol. 2018, 264, 370–381. [Google Scholar] [CrossRef] [PubMed]

- Zarębski, P. Uwarunkowania przestrzenne lokalizacji biogazowni w Polsce. Roczniki 2014, 16. [Google Scholar] [CrossRef]

- Myczko, A. Budowa i Eksploatacja Biogazowni Rolniczych; ITP: Warsaw, Poland, 2011. [Google Scholar]

- Mitterleitner, H.; Schilcher, A.; Demmel, M. Konzepte Zur Reduzierung Der Kosten Beim Transport von Nachwachsenden Rohstoffen Für Biogasanlagen; NawaRo-Transport; LFL: Munchen, Germany, 2007. [Google Scholar]

- Wyszomierski, R.; Bórawski, P.; Jankowski, K.; Zalewski, K. Przestrzenne zróżnicowanie produkcji biomasy w Polsce. Roczniki 2017, 2017. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Olkiewicz, A.; Wolniak, R.; Wyszomirski, A. Effects of Pro-Ecological Investments on an Example of the Heating Industry—Case Study. Energies 2021, 14, 5959. [Google Scholar] [CrossRef]

- Duda-Kękuś, A. Transport biomasy w logistyce dostaw paliw dla elektrowni systemowych realizujących program zielonej energetyki. Logistyka 2021, 2, 107–118. [Google Scholar]

- Kowalczyk-Juśko, A.; Maj, G.; Piekarski, W.; Ignaciuk, H. Gospodarka surowcowa wybranej biogazowni rolniczej. Logistyka 2014, 6, 156–161. [Google Scholar]

- Kowalczyk, J.; Ochwat, R. Agroenergia—Biogazownie Rolnicze i Małe Elektrownie Wodne. Available online: https://ekodotacje.ios.edu.pl/agroenergia/ (accessed on 23 May 2022).

- Sadurski, D. ENEA Zamowienia-Niepubliczne. Available online: https://www.enea.pl/bip/zamowienia/platforma-zakupowa (accessed on 23 May 2022).

- Wilk, M.; Krzywonos, M. Distillery Wastewater Decolorization by Lactobacillus Plantarum MiLAB393. Arch. Environ. Prot. 2020, 46, 76–84. [Google Scholar] [CrossRef]

- Wilk, M.; Krzywonos, M.; Seruga, P. Microbiological Colourants Removal from Sugar Beet Molasses Vinasse—The Effects of Process Parameters and Vinasse Dilution. Econ. Environ. Stud. 2017, 17, 335–345. [Google Scholar] [CrossRef]

- Seruga, P.; Krzywonos, M.; Wilk, M. Thermophilic Co-Digestion of the Organic Fraction of Municipal Solid Wastes—The Influence of Food Industry Wastes Addition on Biogas Production in Full-Scale Operation. Molecules 2018, 23, 3146. [Google Scholar] [CrossRef] [PubMed]

- Witaszek, K.; Polarska, A.A.; Pilarski, K. Wybrane metody obróbki surowców roślinnych stosowanych do produkcji biogazu. Ekon. Środowisko Stud. Mater. 2015, 2, 130–144. [Google Scholar]

- Wilk, M.; Krzywonos, M.; Borowiak, D.; Seruga, P. Decolourization of Sugar Beet Molasses Vinasse by Lactic Acid Bacteria—The Effect of Yeast Extract Dosage. Pol. J. Environ. Stud. 2018, 28, 385–392. [Google Scholar] [CrossRef]

- Seruga, P.; Krzywonos, M.; Wilk, M. Treatment of By-Products Generated from Anaerobic Digestion of Municipal Solid Waste. Waste Biomass-Valoriz. 2019, 11, 4933–4940. [Google Scholar] [CrossRef]

- Ekman, A.; Wallbergb, O.; Joelsson, E.; Börjesson, P. Possibilities for sustainable biorefineries based on agricultural residues—A case study of potential straw-based ethanol production in Sweden. Appl. Energy 2013, 102, 299–308. [Google Scholar] [CrossRef]

- Ahlgren, S.; Björklund, A.; Ekman, A.; Karlsson, H.; Berlin, J.; Börjesson, P.; Ekvall, T.; Finnveden, G.; Janssen, M.; Strid, I. LCA of Biorefineries—Identification of Key Issues and Methodological Recommendations; The Swedish Knowledge Centre for Renewable Transportation Fuels: Göteborg, Sweden, 2013. [Google Scholar]

- Mroziński, A. (Ed.) Inżynieria Rozdrabniania Biomasy. In Wydawnictwo Współfinansowanie ze Środków Funduszy Norweskich Oraz Środków Krajowych; Grafpol: Bydgoszcz, Poland, 2016. [Google Scholar]

- Gadsbøll, R.; Clausen, L.; Thomsen, T.P.; Ahrenfeldt, J.; Henriksen, U.B. Flexible TwoStage biomass gasifier designs for polygeneration operation. Energy 2019, 166, 939–950. [Google Scholar] [CrossRef]

- Hildreth, W.; Fierstein, J.; Calvert, A.T. McGee Till—oldest glacial deposit in the Sierra Nevada, California—And Quaternary evolution of the rangefront escarpment. Quat. Sci. Rev. 2018, 198, 242–265. [Google Scholar] [CrossRef]

- Archer, S.A.; Steinberger-Wilckens, R. Systematic analysis of biomass derived fuels for fuel cells. Int. J. Hydrog. Energy 2018, 43, 23178–23192. [Google Scholar] [CrossRef]

- Li, S.; Song, X. Study on the preparation and production factors of a direct lignocellulose biomass fuel cell. J. Electroanal. Chem. 2018, 810, 55–61. [Google Scholar] [CrossRef]

- Firmansyah, H.; Tan, Y.; Yan, J. Power and methanol production from biomass combined with solar and wind energy: Analysis and comparison. Energy Procedia 2018, 145, 576–581. [Google Scholar] [CrossRef]

- Pellegrini, L.A.; De Guido, G.; Langé, S. Biogas to liquefied biomethane via cryogenic upgrading technologies. Renew. Energy 2018, 124, 75–83. [Google Scholar] [CrossRef]

- Butlewski, K. Biofuel Production Level and the Development of Biofuel Technologies in the World. In Proceedings of the 1st Sustainable Solutions for Growth (SSG) 2018 Conference, Wrocław, Poland, 17–18 September 2018. [Google Scholar]

- Butlewski, K. Metody Uzdatniania biogazu z uwzględnieniem możliwości integracji termicznej z procesem fermentacji biomasy. Probl. Inżynierii Rolniczej 2016, 92, 67–83. [Google Scholar]

- Butlewski, K. Current Status and Prospects for Biofuel Production in Poland. In Proceedings of the European Biomass Conference and Exhibition, Copenhagen, Denmark, 14–18 May 2018; Volume 2018. [Google Scholar]

- Scarlat, N.; Dallemand, J.-F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Bartkowiak, P.; Bartkowiak, A. Contextual nature of sustainable development in the activity of an enterprise, on the example of a municipal enterprise. J. Water Land Dev. 2021, X–XII, 279–284. [Google Scholar] [CrossRef]

- Mucha-Kuś, K.; Sołtysik, M.; Zamasz, K. Rola koopetycji w klastrach energii. In Zeszyty Naukowe Wydziału Elektrotechniki i Automatyki Politechniki Gdańskiej; Gdańsk University of Technology: Gdańsk, Poland, 2017. [Google Scholar]

- Mucha-Kuś, K.; Sołtysik, M.; Zamasz, K.; Szczepańska-Woszczyna, K. Coopetitive Nature of Energy Communities—The Energy Transition Context. Energies 2021, 14, 931. [Google Scholar] [CrossRef]

- Jasiński, J.; Kozakiewicz, M.; Sołtysik, M. Determinants of Energy Cooperatives’ Development in Rural Areas—Evidence from Poland. Energies 2021, 14, 319. [Google Scholar] [CrossRef]

- Knezevic, B.; Falat, M.; Mestrovic, I.S. Differences between X and Y Generation in Attitudes towards Online Book Purchasing. J. Logist. Inform. Serv. Sci. 2020, 7, 1–6. [Google Scholar] [CrossRef]

- Vlahovic, N.; Knezevic, B.; Batalic, P. Implementing Delivery Drones in Logistics Business Process: Case of Pharmaceutical Industry. Int. J. Econ. Manag. Eng. 2016, 3, 4026–4031. [Google Scholar]

- Gontard, N.; Sonesson, U.; Birkved, M.; Majone, M.; Bolzonella, D.; Celli, A.; Angellier-Coussy, H.; Jang, G.-W.; Verniquet, A.; Broeze, J.; et al. A research challenge vision regarding management of agricultural waste in a circular bio-based economy. Crit. Rev. Environ. Sci. Technol. 2018, 48, 614–654. [Google Scholar] [CrossRef]

- Arancon, R.A.D.; Lin, C.S.K.; Chan, K.M.; Kwan, T.H.; Luque, R. Advances on waste valorization: New horizons for a more sustainable society. Energy Sci. Eng. 2013, 1, 53–71. [Google Scholar] [CrossRef]

- Krajowy Ośrodek Wsparcia Rolnictwa. Available online: https://www.kowr.gov.pl/ (accessed on 23 May 2022).

- Rogulska, M.; Grzybek, A.; Szlachta, J.; Tys, J.; Krasuska, E.; Biernat, K.; Bajdor, K. Powiązanie rolnictwa i energetyki w kontekście realizacji celów gospodarki niskoemisyjnej w Polsce. Pol. J. Agron. 2011, 7, 92–101. [Google Scholar]

- EurObserv’ER. Measures the Progress Made by Renewable Energies European Union; The state of renewable energies in Europe edition 2019 19th Report; EurObserv’ER: Paris, France, 2019. [Google Scholar]

- Szczepańska-Woszczyna, K. Strategy, Corporate Culture, Structure and Operational Processes as the Context for the Innovativeness of an Organization. Found. Manag. 2018, 10, 33–44. [Google Scholar] [CrossRef]

- Szczepańska-Woszczyna, K. Innovation processes in the social space of the organization. Reg. Form. Dev. Stud. 2021, 14, 220–229. [Google Scholar] [CrossRef]

- Hys, K.; Szczepanska-Woszczyna, K.; Czart, P. Analysis of Family Engagement in the Evaluation of Organisational Effectiveness in Family Businesses. Eur. Res. Stud. J. 2020, XXIII, 962–972. [Google Scholar] [CrossRef]

- Zavadsky, J.; Zavadska, Z.; Szczepanska-Woszczyna, K. Quantification of the Process Improvement Exigency Related to Industry 4.0. Eur. Res. Stud. J. 2021, XXIV, 65–86. [Google Scholar] [CrossRef]

- Szczepańska-Woszczyna, K.; Dacko-Pikiewicz, Z. Managerial Competencies and Innovations in the Company—The Case Of Enterprises in Poland. Business Manag. Educ. 2014, 12, 266–282. [Google Scholar] [CrossRef]

- Kurowska-Pysz, J.; Szczepańska-Woszczyna, K. The Analysis of the Determinants of Sustainable Cross-Border Cooperation and Recommendations on Its Harmonization. Sustainability 2017, 9, 2226. [Google Scholar] [CrossRef]

- Petkovic, G.; Knezevic, B.; Pindzo, R.; Goran, P.; Blaženka, K.; Renata, P. Social initiatives in trade and tourism: The cases of Serbia and Croatia. Èkon. Preduzeca 2017, 65, 229–243. [Google Scholar] [CrossRef]

- Sosa Meštrović, I.; Knežević, B.; Falat, M. What Influences Decision Making in Online Purchasing of Books in Generation X and Y? SSRN Electron. J. 2019, 5, 367–375. [Google Scholar] [CrossRef]

- Lindorfer, J.; Lettner, M.; Hesser, F.; Fazeni, K.; Rosenfeld, D.; Annevelink, B.; Mandl, M. Technical, Economic and Environmental Assessment of Biorefinery Concepts; IEA Bioenergy: Paris, France, 2019. [Google Scholar]

- Lesiuk, A.; Oleszczuk, P.; Kuśmierz, M. Zastosowanie techniki LCA w ekologicznej ocenie produktów, technologii i gospodarce odpadami. In Ryczkowski, Adsorbenty i katalizatory, Wybrane technologie a środowisko; Ryczkowski, J., Ed.; Uniwersytet Rzeszowski: Rzeszów, Poland, 2012; Volume 1, pp. 453–466. [Google Scholar]

- Wrana, K.; Szulc, T.; Budziński, M.; Raczek, M. Non-spatial factors of development of Functional Urban Areas—Case study of selected FUAs of Silesian Voivodeship. Stud. Reg. 2017, 47, 51–69. [Google Scholar] [CrossRef]

- Budzinski, M.; Cavalett, O.; Nitzsche, R.; Strømman, A.H. Assessment of lignocellulosic biorefineries in Germany using a hybrid LCA multi-objective optimization model. J. Ind. Ecol. 2019, 23, 1172–1185. [Google Scholar] [CrossRef]

- Wróblewski, L. Where there is a will, there is a way: Some remarks on institutional distance in the Polish-German borderland. Pogran. Pol. Borderl. Stud. 2021, 9, 39–62. [Google Scholar] [CrossRef]

- Wróblewski, L. The Use of the Taxonomic Measure in Assessing the Intensity of Border Regions Interaction. Pogran. Pol. Borderl. Stud. 2021, 9, 91–104. [Google Scholar] [CrossRef]

- Wróblewski, L.; Grzesiak, M. The Impact of Social Media on the Brand Capital of Famous People. Sustainability 2020, 12, 6414. [Google Scholar] [CrossRef]

- Lisiński, M.; Šaruckij, M. Principles of the Application of Strategic Planning Methods. J. Bus. Econ. Manag. 2006, 7, 37–43. [Google Scholar] [CrossRef][Green Version]

- Lisiński, M.; Sroka, W.; Brzeziński, P.; Jabłoński, A.; Stuglik, J. Application of Modern Management Concepts by Polish Companies—Analysis of Research Results. Organizacija 2012, 45, 41–49. [Google Scholar] [CrossRef]

- Lis, M. Improving the Availability of University Offerings for the Business Sector Based on Blended Learning Tools. Cult. Manag. Sci. Educ. 2021, 5, 93–103. [Google Scholar] [CrossRef]

- Lis, M. Circle Patterns and Critical Ising Models. Commun. Math. Phys. 2019, 370, 507–530. [Google Scholar] [CrossRef]

- Sulewski, P.; Wąs, A. Index-Based Insurance of Gross Margin in Agriculture—Key Challenges. Probl. Agric. Econ. 2018, 355, 3–27. [Google Scholar] [CrossRef]

- Sulewski, P.; Majewski, E.; Wąs, A. The Importance of Agriculture in the Renewable Energy Production in Poland and the EU. Probl. Agric. Econ. 2017, 350, 50–74. [Google Scholar] [CrossRef]

- Wąs, A.; Sulewski, P.; Majewski, E. Methodical and Practical Aspects of The Parity Income in the Polish Agriculture. Probl. Agric. Econ. 2019, 2, 3–27. [Google Scholar] [CrossRef]

- Sulewski, P.; Wąs, A.; Kobus, P.; Pogodzińska, K.; Szymańska, M.; Sosulski, T. Farmers’ Attitudes towards Risk—An Empirical Study from Poland. Agronomy 2020, 10, 1555. [Google Scholar] [CrossRef]

- Kołodziej, B.; Matyka, M. Odnawialne Źródła Energii. Rolnicze Surowce Energetyczne, 1st ed.; Kołodziej, B., Matyka, M., Eds.; PWRiL: Poznań, Poland, 2012. [Google Scholar]

- Samson-Bręk, I.; Smerkowska, B.; Filip, A. Environmental Aspects in the Life Cycle of Liquid Biofuels with Biocomponents, Taking into Account the Storage Process. In Storage Stability of Fuels; IntechOpen: London, UK, 2015. [Google Scholar]

- Smolarek, T. Kalkulator biogazowy jako użyteczne narzędzie do obliczeń wskaźników pracy biogazowi. Eliksir 2016, 1, 52–55. [Google Scholar]

- Koszty Biogazowni. 2021. Available online: https://www.odnawialne-firmy.pl/wiadomosci/pokaz/108,koszty-biogazowni (accessed on 23 May 2022).

- Curkowski, A.; Mroczkowski, P.; Oniszk-Popławska, A.; Wiśniewski, G. Biogaz Rolniczy—Produkcja i Wykorzystanie; Mazowiecka Agencja Energetyczna Sp. z o.o.: Warszawa, Poland, 2009. [Google Scholar]

- Curkowski, A.; Oniszk-Popławska, A.; Mroczkowski, P.; Zowsik, M.; Wiśniewski, G. Przewodnik Dla Inwestorów Zainteresowanych Budową Biogazowni Rolniczych, 1st ed.; Instytut Energetyki Odnawialnej: Warszawa, Poland, 2011. [Google Scholar]

- Mikos, P. Tygidnik Rolniczy. 2020. Available online: https://www.Tygodnik-Rolniczy.Pl/Articles/Pieniadze-i-Prawo/Jakie-Gospodarstwa-Moga-Postawic-Biogazownie-i-Ile-Kosztuje/ (accessed on 23 May 2022).

| Index | Statistical Code/Field | Description |

|---|---|---|

| sAll | Averaging period | The basic data averaging period at a measurement site. The results of measurements are averaged in the form of annual series in accordance with that period. |

| All | Average | The average annual concentration. |

| SO2 | L 350 (S1) | The number of hours in a calendar year when the average 1 h concentration exceeded 350 µg/m3 (rounded to an integer). |

| SO2 | L 125 (S24) | The number of hours in a calendar year when the average 24-h concentration exceeded 125 µg/m3 (rounded to an integer). |

| NO2 | L 200 (S1) | The number of hours in a calendar year when the average 24-h concentration exceeded 200 µg/m3 (rounded to an integer). |

| NO2 | 19th max. (S1) | The 19th maximum value in an annual series of results—1 h averages, in [µg/m3]. |

| PM10 | L 50 (S24) | The number of hours in a calendar year when the average 24-h concentration exceeded 50 µg/m3 (rounded to an integer). |

| PM10 | Max. (S24) | The maximum average 24 h concentration in a year. |

| Distance above Threshold 2 | Cargo Volume 15 m3 Load Weight 7 t * | Cargo Volume 15 m3 Load Weight 14 t * | Cargo Volume 80 m3 Load Weight 24 t ** | Cargo Volume 80 m3 Load Weight 38 t ** | ||||

|---|---|---|---|---|---|---|---|---|

| Rate over Threshold 2 (1.9 pln/km) | Increase % | Rate over Threshold 2 (0.68 pln/km) | Increase % | Rate over Threshold 2 (3.3 pln/km) | Increase % | Rate above Threshold 2 (1.13 pln/km) | Increase % | |

| 5 | 64.50 | 17 | 58.40 | 6 | 716.50 | 2 | 705.65 | 1 |

| 10 | 74.00 | 35 | 61.80 | 12 | 733.00 | 5 | 711.30 | 2 |

| 20 | 93.00 | 69 | 68.60 | 25 | 766.00 | 9 | 722.60 | 3 |

| 40 | 131.00 | 138 | 82.20 | 49 | 832.00 | 19 | 745.20 | 6 |

| 60 | 169.00 | 207 | 95.80 | 74 | 898.00 | 28 | 767.80 | 10 |

| 80 | 207.00 | 276 | 109.40 | 99 | 964.00 | 38 | 790.40 | 13 |

| 100 | 245.00 | 345 | 123.00 | 124 | 1030.00 | 47 | 813.00 | 16 |

| 120 | 283.00 | 415 | 136.60 | 148 | 1096.00 | 57 | 835.60 | 19 |

| 140 | 321.00 | 484 | 150.20 | 173 | 1162.00 | 66 | 858.20 | 23 |

| 160 | 359.00 | 553 | 163.80 | 198 | 1228.00 | 75 | 880.80 | 26 |

| 180 | 397.00 | 622 | 177.40 | 223 | 1294.00 | 85 | 903.40 | 29 |

| 200 | 435.00 | 691 | 191.00 | 247 | 1360.00 | 94 | 926.00 | 32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bartkowiak, A.; Bartkowiak, P.; Kinelski, G. Efficiency of Shaping the Value Chain in the Area of the Use of Raw Materials in Agro-Biorefinery in Sustainable Development. Energies 2022, 15, 6260. https://doi.org/10.3390/en15176260

Bartkowiak A, Bartkowiak P, Kinelski G. Efficiency of Shaping the Value Chain in the Area of the Use of Raw Materials in Agro-Biorefinery in Sustainable Development. Energies. 2022; 15(17):6260. https://doi.org/10.3390/en15176260

Chicago/Turabian StyleBartkowiak, Anna, Piotr Bartkowiak, and Grzegorz Kinelski. 2022. "Efficiency of Shaping the Value Chain in the Area of the Use of Raw Materials in Agro-Biorefinery in Sustainable Development" Energies 15, no. 17: 6260. https://doi.org/10.3390/en15176260

APA StyleBartkowiak, A., Bartkowiak, P., & Kinelski, G. (2022). Efficiency of Shaping the Value Chain in the Area of the Use of Raw Materials in Agro-Biorefinery in Sustainable Development. Energies, 15(17), 6260. https://doi.org/10.3390/en15176260