Sizing of an Island Standalone Hybrid System Considering Economic and Environmental Parameters: A Case Study

Abstract

:1. Introduction

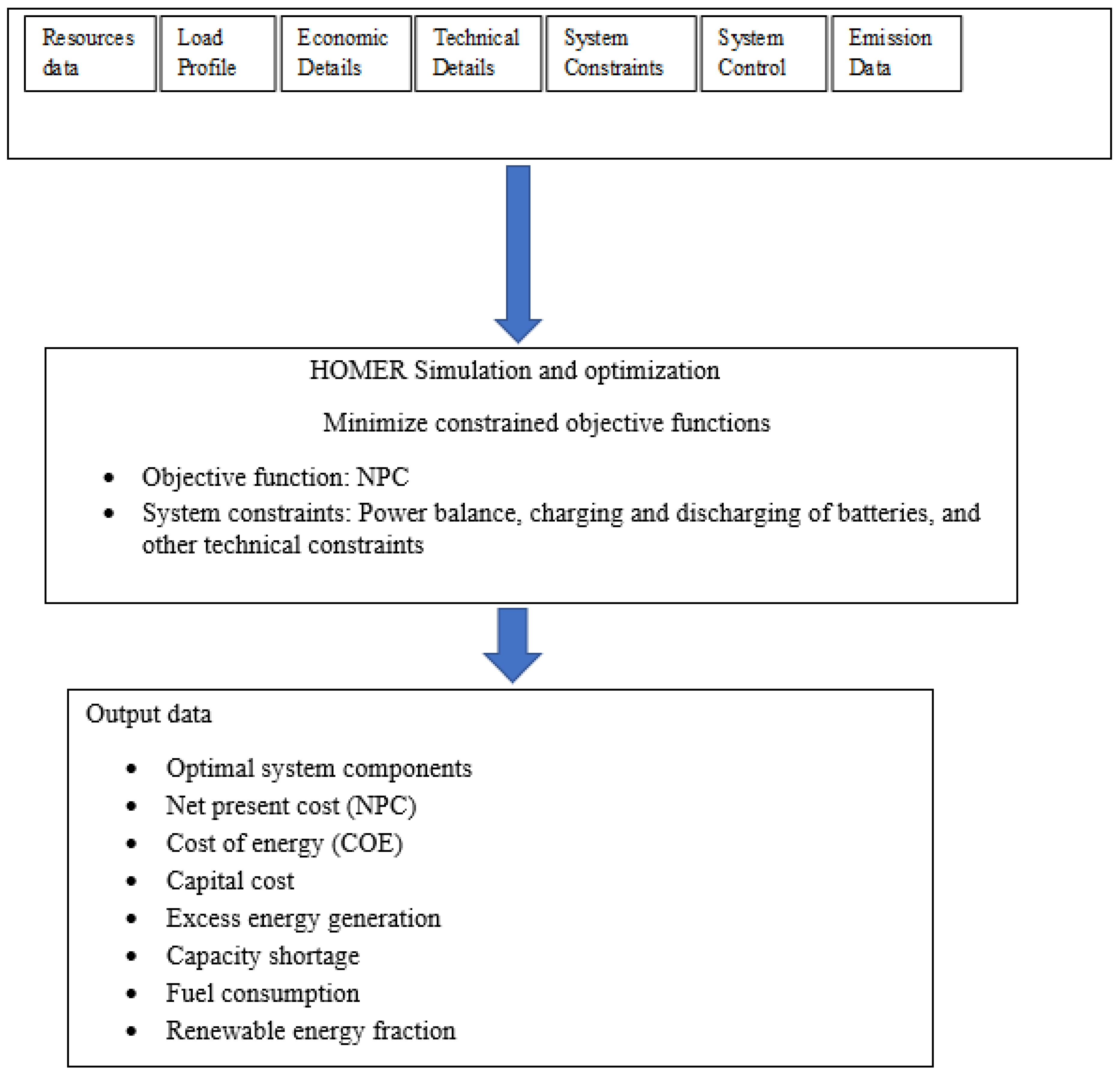

2. Energy Condition of Bangladesh

3. Methodology

3.1. Site Location and Present Electricity Conditions

3.2. Load Design

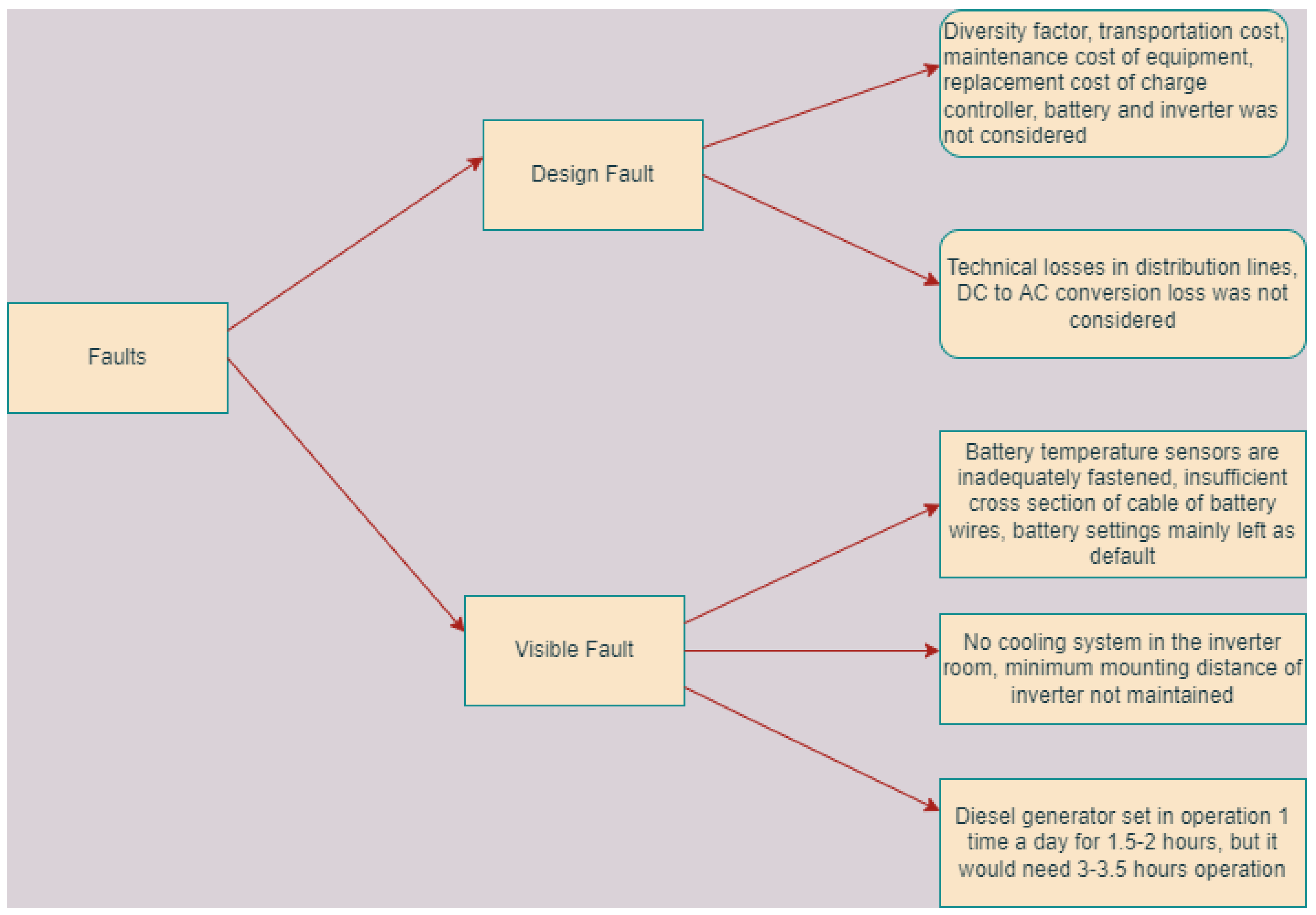

3.3. Existing Electricity Condition

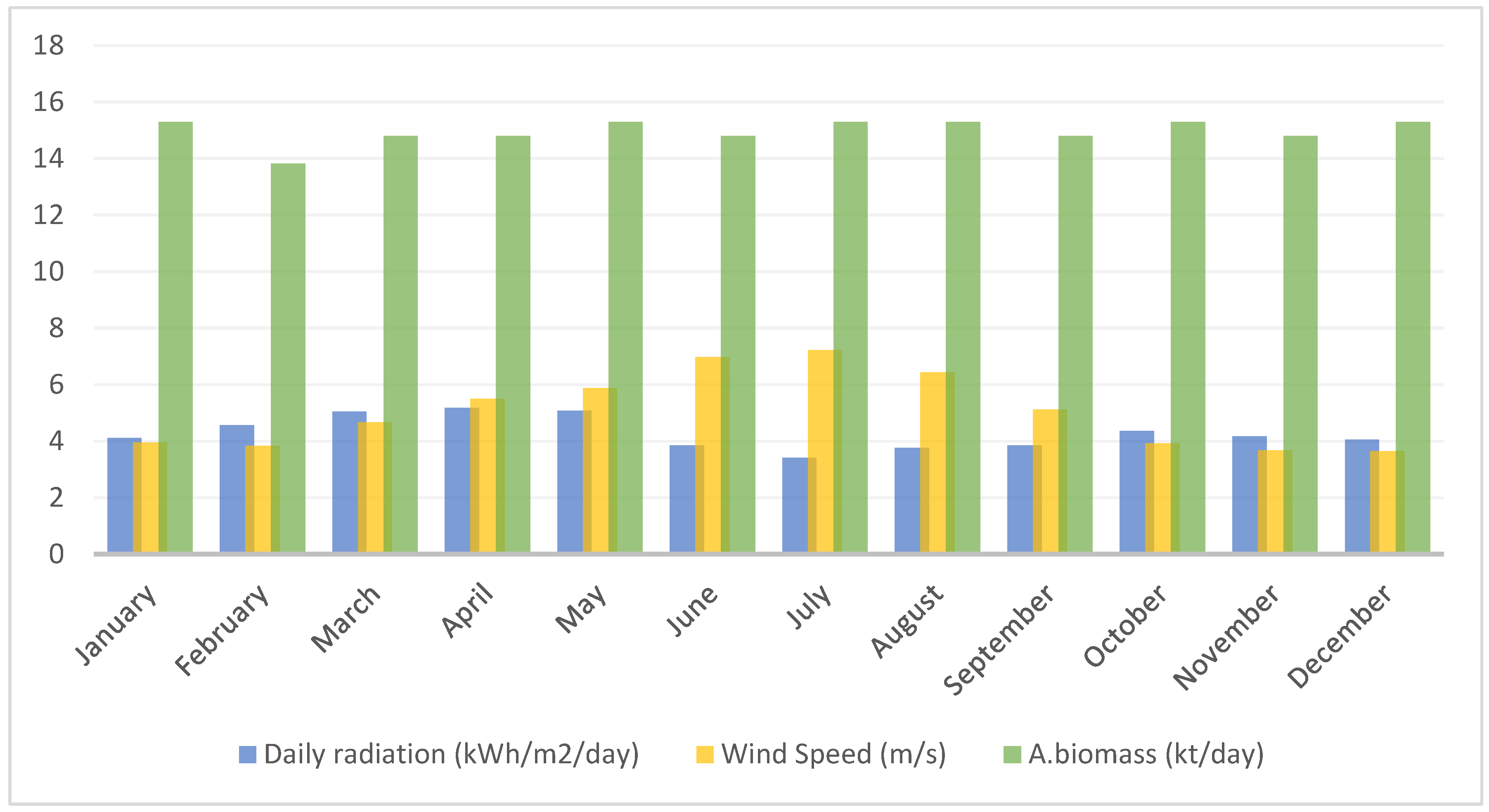

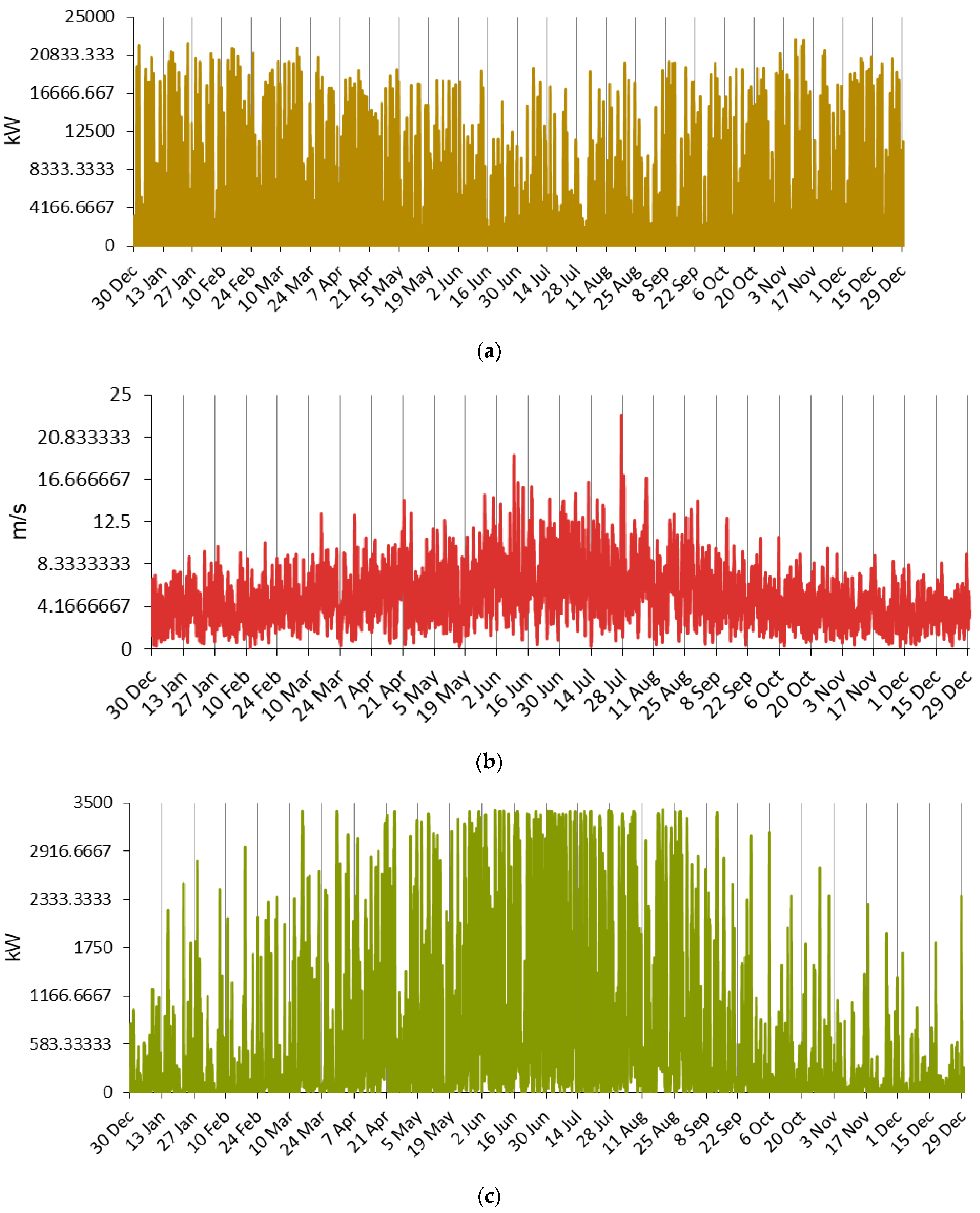

3.4. Solar Resource

3.5. Wind Resource

3.6. Biogas Resource

3.7. Modeling of the System

3.7.1. Diesel Generator (DG)

3.7.2. Inverter

3.7.3. Lithium-Ion Battery

3.7.4. PV Module

3.7.5. Wind Turbine

3.7.6. Dispatch Strategy

3.7.7. Economic Analysis

3.7.8. Environmental Analysis

3.8. Hybrid MCDM

4. Results and Discussion

4.1. Definition of Optimization Patterns

4.2. Optimized Result

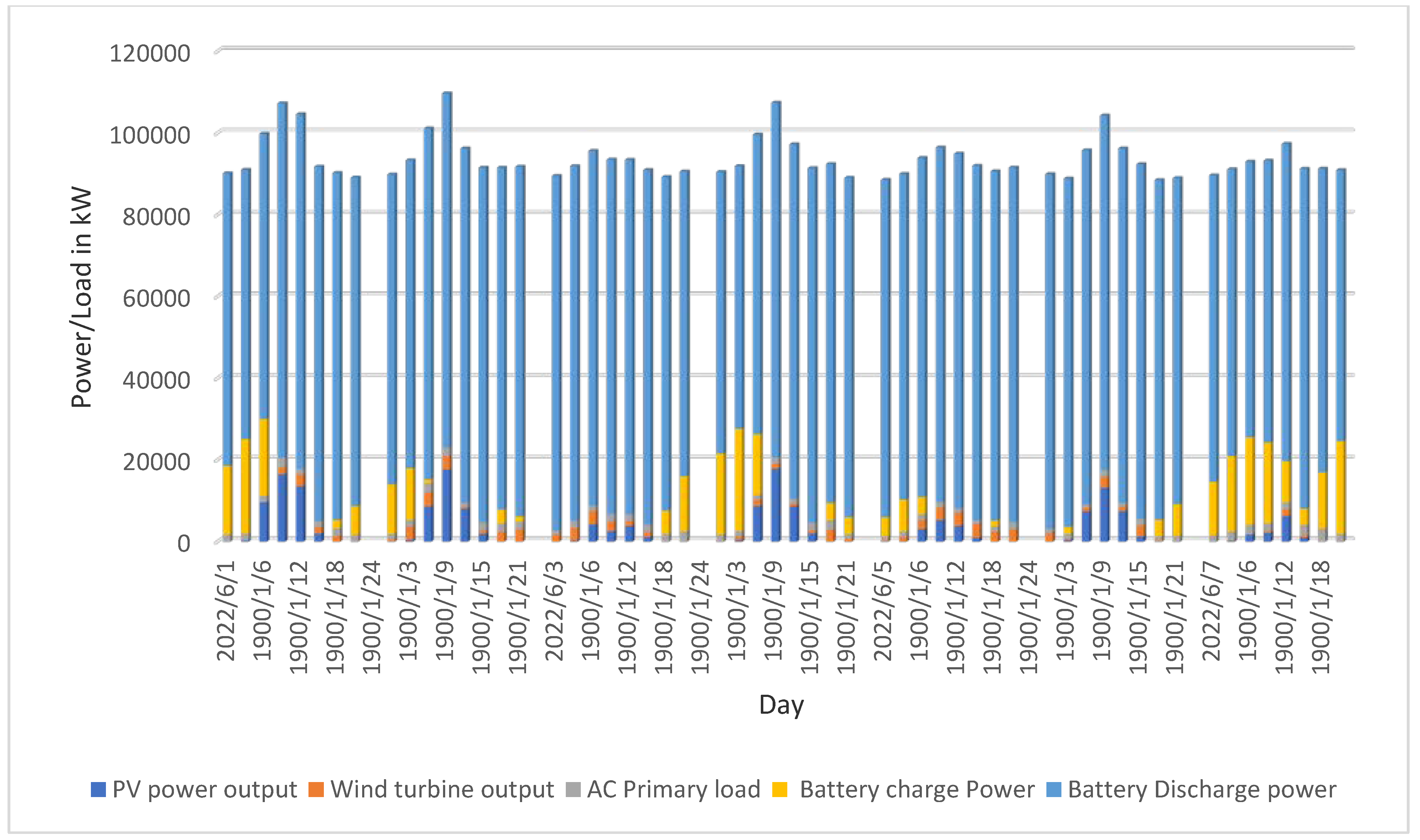

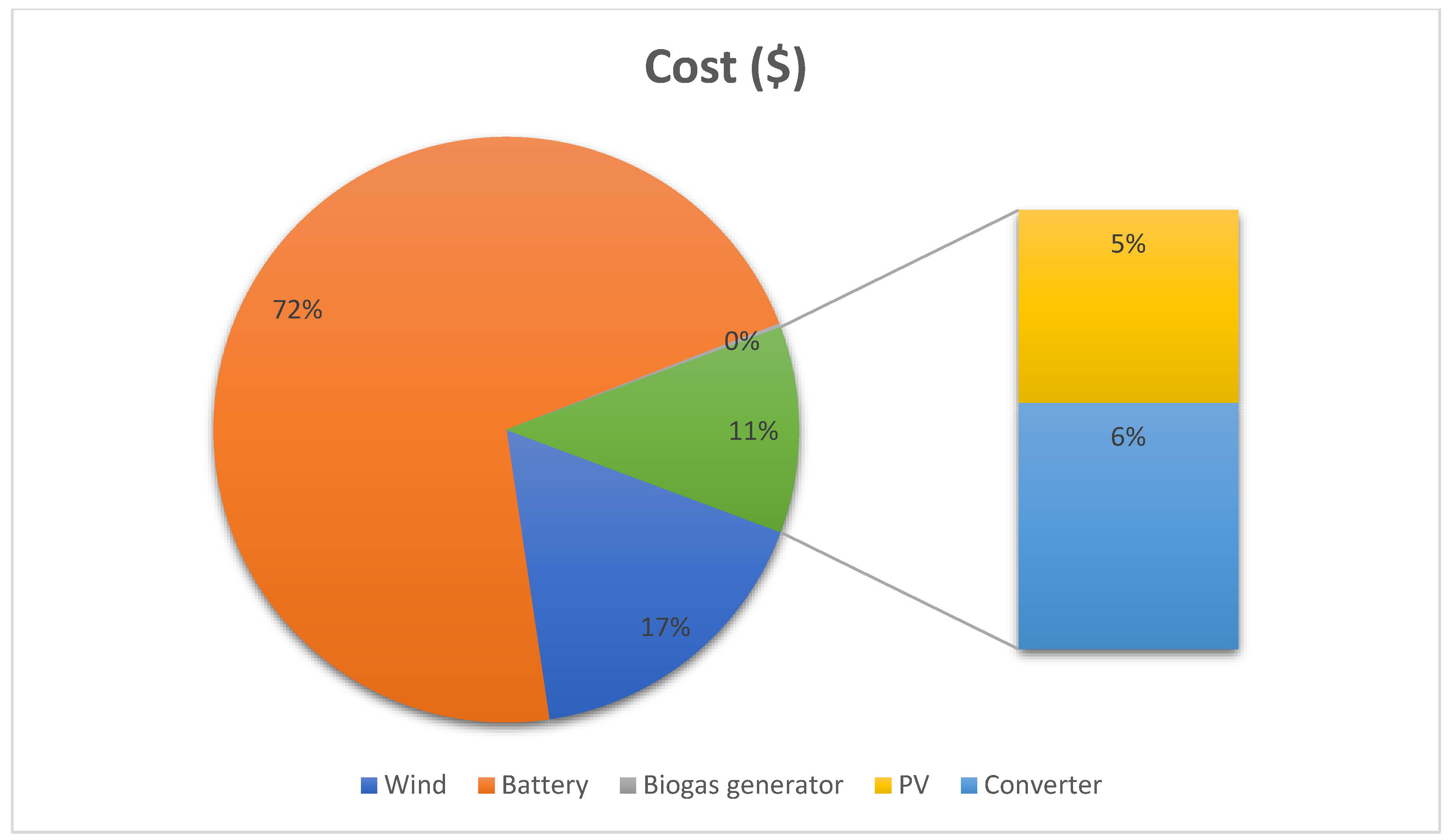

4.3. Evaluation of the Best Hybrid Scenario's Performance

4.4. Sensitivity Analysis

4.5. Social Benefits

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

References

- Castán Broto, V.; Kirshner, J. Energy Access Is Needed to Maintain Health during Pandemics. Nat. Energy 2020, 5, 419–421. [Google Scholar] [CrossRef]

- Li, J.; Liu, P.; Li, Z. Optimal Design of a Hybrid Renewable Energy System with Grid Connection and Comparison of Techno-Economic Performances with an off-Grid System: A Case Study of West China. Comput. Chem. Eng. 2022, 159, 107657. [Google Scholar] [CrossRef]

- Miskat, M.I.; Rashedi, A. Exergy Efficiency and Enviroeconomic Analysis of Solar Photovoltaic Power in Nepal. Energy Technol. 2021, 9, 100093. [Google Scholar] [CrossRef]

- Akram, F.; Asghar, F.; Majeed, M.A.; Amjad, W.; Manzoor, M.O.; Munir, A. Techno-Economic Optimization Analysis of Stand-Alone Renewable Energy System for Remote Areas. Sustain. Energy Technol. Assess. 2020, 38, 100673. [Google Scholar] [CrossRef]

- Khan, M.J.; Yadav, A.K.; Mathew, L. Techno Economic Feasibility Analysis of Different Combinations of PV-Wind-Diesel-Battery Hybrid System for Telecommunication Applications in Different Cities of Punjab, India. Renew. Sustain. Energy Rev. 2017, 76, 577–607. [Google Scholar] [CrossRef]

- Das, B.K.; Hasan, M. Optimal Sizing of a Stand-Alone Hybrid System for Electric and Thermal Loads Using Excess Energy and Waste Heat. Energy 2021, 214, 119036. [Google Scholar] [CrossRef]

- Khirennas, A.; Kaabeche, A.; Talha, A.; Bakelli, Y. A New Optimal Sizing Methodology of Storage-Less PV System for Retrofitting Existing Diesel-Based Power Generation System within Mini-Grids. Energy Convers. Manag. 2021, 250, 114854. [Google Scholar] [CrossRef]

- Makhdoomi, S.; Askarzadeh, A. Impact of Solar Tracker and Energy Storage System on Sizing of Hybrid Energy Systems: A Comparison between Diesel/PV/PHS and Diesel/PV/FC. Energy 2021, 231, 120920. [Google Scholar] [CrossRef]

- Elkadeem, M.R.; Wang, S.; Azmy, A.M.; Atiya, E.G.; Ullah, Z.; Sharshir, S.W. A Systematic Decision-Making Approach for Planning and Assessment of Hybrid Renewable Energy-Based Microgrid with Techno-Economic Optimization: A Case Study on an Urban Community in Egypt. Sustain. Cities Soc. 2020, 54, 102013. [Google Scholar] [CrossRef]

- Das, H.S.; Tan, C.W.; Yatim, A.H.M.; Lau, K.Y. Feasibility Analysis of Hybrid Photovoltaic/Battery/Fuel Cell Energy System for an Indigenous Residence in East Malaysia. Renew. Sustain. Energy Rev. 2017, 76, 1332–1347. [Google Scholar] [CrossRef]

- Salameh, T.; Ghenai, C.; Merabet, A.; Alkasrawi, M. Techno-Economical Optimization of an Integrated Stand-Alone Hybrid Solar PV Tracking and Diesel Generator Power System in Khorfakkan, United Arab Emirates. Energy 2020, 190, 116475. [Google Scholar] [CrossRef]

- Azerefegn, T.M.; Bhandari, R.; Ramayya, A.V. Techno-Economic Analysis of Grid-Integrated PV/Wind Systems for Electricity Reliability Enhancement in Ethiopian Industrial Park. Sustain. Cities Soc. 2020, 53, 101915. [Google Scholar] [CrossRef]

- Das, B.K.; Tushar, M.S.H.K.; Zaman, F. Techno-Economic Feasibility and Size Optimisation of an off-Grid Hybrid System for Supplying Electricity and Thermal Loads. Energy 2021, 215, 119141. [Google Scholar] [CrossRef]

- Konneh, K.V.; Masrur, H.; Konneh, D.A.; Senjyu, T. Independent or Complementary Power System Configuration: A Decision Making Approach for Sustainable Electrification of an Urban Environment in Sierra Leone. Energy 2022, 239, 122310. [Google Scholar] [CrossRef]

- Guerello, A.; Page, S.; Holburn, G.; Balzarova, M. Energy for Off-Grid Homes: Reducing Costs through Joint Hybrid System and Energy Efficiency Optimization. Energy Build. 2020, 207, 109478. [Google Scholar] [CrossRef]

- Rajbongshi, R.; Borgohain, D.; Mahapatra, S. Optimization of PV-Biomass-Diesel and Grid Base Hybrid Energy Systems for Rural Electrification by Using HOMER. Energy 2017, 126, 461–474. [Google Scholar] [CrossRef]

- Halabi, L.M.; Mekhilef, S.; Olatomiwa, L.; Hazelton, J. Performance Analysis of Hybrid PV/Diesel/Battery System Using HOMER: A Case Study Sabah, Malaysia. Energy Convers. Manag. 2017, 144, 322–339. [Google Scholar] [CrossRef]

- Konneh, K.V.; Masrur, H.; Othman, M.L.; Senjyu, T. Performance Assessment of a Hybrid Complementary Power System for Sustainable Electrification: A Case Study. Sustain. Cities Soc. 2022, 76, 103412. [Google Scholar] [CrossRef]

- Abnavi, M.D.; Mohammadshafie, N.; Rosen, M.A.; Dabbaghian, A.; Fazelpour, F. Techno-Economic Feasibility Analysis of Stand-Alone Hybrid Wind/Photovoltaic/Diesel/Battery System for the Electrification of Remote Rural Areas: Case Study Persian Gulf Coast-Iran. Environ. Prog. Sustain. Energy 2019, 38, 13172. [Google Scholar] [CrossRef]

- Sanni, S.O.; Oricha, J.Y.; Oyewole, T.O.; Bawonda, F.I. Analysis of Backup Power Supply for Unreliable Grid Using Hybrid Solar PV/Diesel/Biogas System. Energy 2021, 227, 120506. [Google Scholar] [CrossRef]

- 5% People Now Have Access to Electricity. Available online: https://www.tbsnews.net/bangladesh/935-people-now-have-access-electricity-100153 (accessed on 25 December 2021).

- Bangladesh Energy Situation-Energypedia. Available online: https://energypedia.info/wiki/Bangladesh_Energy_Situation#Natural_Gas (accessed on 26 December 2021).

- Abdulrazak, L.F.; Islam, A.; Hossain, M.B. Towards Energy Sustainability: Bangladesh Perspectives. Energy Strategy Rev. 2021, 38, 100738. [Google Scholar] [CrossRef]

- Shahriar Ahmed Chowdhury, National Solar Energy Action Plan, 2021–2041. Available online: https://climateportal.ccdbbd.org/wp-content/uploads/2021/03/National-Solar-Energy-Roadmap.pdf (accessed on 28 May 2022).

- Halder, P.K.; Paul, N.; Joardder, M.U.H.; Sarker, M. Energy Scarcity and Potential of Renewable Energy in Bangladesh. Renew. Sustain. Energy Rev. 2015, 51, 1636–1649. [Google Scholar] [CrossRef]

- Infrastructure Development Company Limited (IDCOL). Available online: https://www.idcol.org/ (accessed on 26 December 2021).

- Chowdhury, S.A. Feasibility and Integration of Wind Energy into Solar Mini-Grid at Monpura Island. 2018. Available online: https://www.undp.org/sites/g/files/zskgke326/files/migration/bd/2018.11.11---SREPGen-Final-Report-on-Wind-Energy-Integration-in-SMG.pdf (accessed on 28 May 2022).

- Aziz, S.; Chowdhury, S.A. Performance Evaluation of Solar Mini-Grids in Bangladesh: A Two-Stage Data Envelopment Analysis. Clean. Environ. Syst. 2021, 2, 100003. [Google Scholar] [CrossRef]

- Lozano, L.; Querikiol, E.M.; Abundo, M.L.S.; Bellotindos, L.M. Techno-Economic Analysis of a Cost-Effective Power Generation System for off-Grid Island Communities: A Case Study of Gilutongan Island, Cordova, Cebu, Philippines. Renew. Energy 2019, 140, 905–911. [Google Scholar] [CrossRef]

- NASA POWER. Prediction Of Worldwide Energy Resources. Available online: https://power.larc.nasa.gov/ (accessed on 26 December 2021).

- Bhatt, A.; Sharma, M.P.; Saini, R.P. Feasibility and Sensitivity Analysis of an Off-Grid Micro Hydro-Photovoltaic-Biomass and Biogas-Diesel-Battery Hybrid Energy System for a Remote Area in Uttarakhand State, India. Renew. Sustain. Energy Rev. 2016, 61, 53–69. [Google Scholar] [CrossRef]

- Das, B.K.; Hoque, N.; Mandal, S.; Pal, T.K.; Raihan, M.A. A Techno-Economic Feasibility of a Stand-Alone Hybrid Power Generation for Remote Area Application in Bangladesh. Energy 2017, 134, 775–788. [Google Scholar] [CrossRef]

- Das, B.K.; Hassan, R.; Tushar, M.S.H.K.; Zaman, F.; Hasan, M.; Das, P. Techno-Economic and Environmental Assessment of a Hybrid Renewable Energy System Using Multi-Objective Genetic Algorithm: A Case Study for Remote Island in Bangladesh. Energy Convers. Manag. 2021, 230, 113823. [Google Scholar] [CrossRef]

- Das, B.K.; Alotaibi, M.A.; Das, P.; Islam, M.S.; Das, S.K.; Hossain, M.A. Feasibility and Techno-Economic Analysis of Stand-Alone and Grid-Connected PV/Wind/Diesel/Batt Hybrid Energy System: A Case Study. Energy Strategy Rev. 2021, 37, 100673. [Google Scholar] [CrossRef]

- Das, B.K.; Al-Abdeli, Y.M.; Kothapalli, G. Integrating renewables into stand-alone hybrid sys-tems meeting electric, heating, and cooling loads: A case study. Renew. Energy 2021, 180, 1222–1236. [Google Scholar] [CrossRef]

- Muhsen, D.H.; Khatib, T.; Abdulabbas, T.E. Sizing of a Standalone Photovoltaic Water Pumping System Using Hybrid Multi-Criteria Decision Making Methods. Sol. Energy 2018, 159, 1003–1015. [Google Scholar] [CrossRef]

- Chauhan, A.; Khan, M.T.; Srivastava, A.; Tripathi, A.; Hussain, S.M.S.; Ustun, T.S. Techno-Economic Assessment and Environmental Analysis of an Optimal Hybrid System under Novel Demand Response Scheme for a Remote Region of India. Energy Rep. 2022, 8, 284–291. [Google Scholar] [CrossRef]

- El-Sattar, H.A.; Kamel, S.; Sultan, H.M.; Zawbaa, H.M.; Jurado, F. Optimal Design of Photovoltaic, Biomass, Fuel Cell, Hydrogen Tank Units and Electrolyzer Hybrid System for a Remote Area in Egypt. Energy Rep. 2022, 8, 9506–9527. [Google Scholar] [CrossRef]

- Vakili, S.; Schönborn, A.; Ölçer, A.I. Techno-Economic Feasibility of Photovoltaic, Wind and Hybrid Electrification Systems for Stand-Alone and Grid-Connected Shipyard Electrification in Italy. J. Clean. Prod. 2022, 366, 132945. [Google Scholar] [CrossRef]

- Al-Badi, A.; al Wahaibi, A.; Ahshan, R.; Malik, A. Techno-Economic Feasibility of a Solar-Wind-Fuel Cell Energy System in Duqm, Oman. Energy 2022, 15, 5379. [Google Scholar] [CrossRef]

- Miao, C.; Teng, K.; Wang, Y.; Jiang, L. Technoeconomic Analysis on a Hybrid Power System for the Uk Household Using Renewable Energy: A Case Study. Energy 2020, 13, 3231. [Google Scholar] [CrossRef]

- Akarsu, B.; Serdar Genç, M. Optimization of Electricity and Hydrogen Production with Hybrid Renewable Energy Systems. Fuel 2022, 324, 124465. [Google Scholar] [CrossRef]

- SDG Tracker. Available online: https://www.sdg.gov.bd/#1 (accessed on 6 August 2022).

- Hassan, R.; Das, B.K.; Hasan, M. Integrated Off-Grid Hybrid Renewable Energy System Optimization Based on Economic, Environmental, and Social Indicators for Sustainable Development. Energy 2022, 250, 123823. [Google Scholar] [CrossRef]

- Dvořák, P.; Martinát, S.; van der Horst, D.; Frantál, B.; Turečková, K. Renewable Energy Investment and Job Creation; a Cross-Sectoral Assessment for the Czech Republic with Reference to EU Benchmarks. Renew. Sustain. Energy Rev. 2017, 69, 360–368. [Google Scholar] [CrossRef]

- Cai, W.; Mu, Y.; Wang, C.; Chen, J. Distributional Employment Impacts of Renewable and New Energy-A Case Study of China. Renew. Sustain. Energy Rev. 2014, 39, 1155–1163. [Google Scholar] [CrossRef]

- Nasirov, S.; Girard, A.; Peña, C.; Salazar, F.; Simon, F. Expansion of Renewable Energy in Chile: Analysis of the Effects on Employment. Energy 2021, 226, 120410. [Google Scholar] [CrossRef]

- A National Jobs Strategy for Bangladesh Technical Report Ministry of Labour and Employment. 2019. Available online: https://dife.portal.gov.bd/sites/default/files/files/dife.portal.gov.bd/page/a51db80d_ca8e_4cae_9579_5f6f089d5754/2021-09-15-05-58-20b6eeb7481056b939b691d2d26a401a.pdf (accessed on 28 May 2022).

- Chowdhury, H.; Chowdhury, T.; Rashedi, A.; Banik, S.C.; Khanam, T.; Saidur, R.; Sait, S.M.; Rosen, M.A. Energy and Exergy Assessment with Updated Reistad Estimates: A Case Study in the Transportation Sector of Bangladesh. Energy Sci. Eng. 2021, 9, 1349–1358. [Google Scholar] [CrossRef]

- Rashedi, A.; Sridhar, I.; Tseng, K.J. Life Cycle Assessment of 50 MW Wind Firms and Strategies for Impact Reduction. Renew. Sustain. Energy Rev. 2013, 21, 89–101. [Google Scholar] [CrossRef]

- Rashedi, A.; Sridhar, I.; Tseng, K.J. Multi-Objective Material Selection for Wind Turbine Blade and Tower: Ashby’s Approach. Mater. Des. 2012, 37, 521–532. [Google Scholar] [CrossRef]

| Project Location | Capacity (kW) | Project Status |

|---|---|---|

| Enam Nahar, Sandwip, Chittagong | 100 | Operational |

| Kutubdia, Cox’s Bazar | 100 | Operational |

| Bagha, Rajshahi | 141 | Operational |

| Paratoli, Raipura, Narshingdi | 141 | Operational |

| Narayanpur, Nageshwari, Kurigram | 158 | Operational |

| Godagari, Rajshahi | 149 | Operational |

| Monpura, Bhola | 177 | Operational |

| Nooner Tek, Sonargao, Narayangonj | 168 | Under construction |

| Rupsha Char, Sadar, Sirajganj | 130 | Under construction |

| Chilmari, Daulatpur, Kushtia | 188 | Under construction |

| Munmiar Char, Islampur, Jamalpur | 162 | Under construction |

| Baghutia char, Doulatpur, Manikganj | 228 | Under construction |

| Nijhum island, Hatiya, Noakhali | 200 | Under construction |

| North Channel Union, Sadar, Faridpur | 162 | Under construction |

| Char Kajal, Patuakhali | 100 | Under construction |

| Char Biswas, Patuakhali | 100 | Under construction |

| Ghaschapru, Belkuchi, Sirajganj | 218.4 | Under construction |

| Poschim Shalipur, Char Bhadrashan, Faridpur | 156 | Under construction |

| Instruments | Specification |

|---|---|

| Solar Panels | 672 panels, each of 250 watt |

| Battery | 216 sets (2 V, 1540 A) |

| Generator | 60 kW |

| MPPT Charger | 4 sets (48 V, 2.5 kW) |

| Inverters | (i) Bi-directional (12 sets, each of 6 kW), |

| (ii) Grid-tied (7 sets, 20 kW) | |

| Connecting meters | 661 sets |

| Cattles | Number of Cattles | Dung Availability (kg/cattle/day) [31] | Total Dung (kg/day) | Available Dung (Assuming 70% Conversion Efficiency) | Total Gas Yield (m3) | Energy Yield (kWh/day) |

|---|---|---|---|---|---|---|

| Cows | 21,000 | 10 | 210,000 | 147,000 | 5292 | 7693 |

| Buffalos | 10,500 | 15 | 157,500 | 110,250 | 3969 | 5769.81 |

| Goats | 13,100 | 1 | 13,100 | 9170 | 330.12 | 479.90 |

| Sheep | 5000 | 1.6 | 8000 | 5600 | 201.6 | 293.07 |

| Chickens | 50,900 | 0.045 | 2290.5 | 1603.35 | 57.72 | 83.90 |

| Ducks | 11,000 | 0.045 | 495.0 | 346.5 | 12.47 | 18.12 |

| Pigeons | 2500 | 0.045 | 112.5 | 78.75 | 2.835 | 4.12 |

| Total | 9865.745 | 14,341.92 |

| System | Configuration | PV (kW) | Generator (kW) | Wind (kW) | Battery (No) | Converter (kW) |

|---|---|---|---|---|---|---|

| Proposed | PV/Wind | 15,000 | - | 8475 | 130,136 | 8170 |

| PV/Wind/Diesel | 15,000 | 100 | 8498 | 130,821 | 6850 | |

| PV/Biogas | 23,000 | 500 | - | 172,221 | 6337 | |

| PV/Biogas/Wind | 22,756 | 500 | 3400 | 114,280 | 6834 | |

| Wind/Biogas | - | 2200 | 45,861 | 191,510 | 7902 | |

| Existing | PV/Diesel | 23,000 | 100 | - | 175,253 | 7754 |

| System | Configuration | COE (USD/kWh) | NPC (USD) | O&M Cost (USD) | Initial Cost (USD) | Unmet Load (%) | Excess Electricity (%) | CO2 (kg/year) |

|---|---|---|---|---|---|---|---|---|

| Proposed | PV/Wind | 0.8259 | 190 M | 42.53 M | 99.6 M | 0.056 | 40.2 | - |

| PV/Diesel/Wind | 0.8218 | 189 M | 42.35 M | 99 M | 0.0513 | 40.3 | 755 | |

| PV/Biogas | 0.7296 | 168 M | 26.14 | 84.7 M | 0.05 | 36.1 | 6.24 | |

| PV/Biogas/Wind | 0.691 | 141 M | 26.82 M | 74.4 M | 0.07 | 45 | 4.43 | |

| Wind/Biogas | 2.19 | 504 M | 148.56 | 272 M | 0.0496 | 71.3 | 228 | |

| Existing | PV/Diesel | 0.7481 | 172 M | 26.93 M | 86.8 M | 0.06 | 36.1 | 683 |

| Standard deviation = 0.5338 | Standard deviation = 124.7953 | Standard deviation = 43.6608 | Standard deviation = 68.7832 |

| Alternative | Weighted Normalized Decision Matrix | Ranking | |||||

|---|---|---|---|---|---|---|---|

| Case 1 | 0.2148 | 0.05673 | 0 | 0.0386 | 0.3956 | 0.9111 | 3 |

| Case 2 | 0.2148 | 0.0549 | 0.096 | 0.1032 | 0.3842 | 0.7882 | 4 |

| Case 3 | 0.19332 | 0.04941 | 7.91 × 10−4 | 0.0161 | 0.4174 | 0.9628 | 2 |

| Case 4 | 0.179 | 0.04209 | 5.61 × 10−4 | 0.0561 | 0.4328 | 0.9987 | 1 |

| Case 5 | 0.58712 | 0.15006 | 0.028 | 0.4230 | 0.068 | 0.1384 | 5 |

| Alternative | Weighted Normalized Decision Matrix | Ranking | |||||

|---|---|---|---|---|---|---|---|

| Case 1 | 0.096 | 0.0961 | 0 | 0.0295 | 0.4310 | 0.9359 | 3 |

| Case 2 | 0.096 | 0.093 | 0.3648 | 0.3657 | 0.2316 | 0.3877 | 5 |

| Case 3 | 0.0864 | 0.0837 | 3.0058 × 10−3 | 0.0143 | 0.4369 | 0.9683 | 2 |

| Case 4 | 0.080 | 0.0713 | 2.1318 × 10−3 | 2.1318 × 10−3 | 0.4452 | 0.9952 | 1 |

| Case 5 | 0.2624 | 0.2542 | 0.1064 | 0.2793 | 0.2584 | 0.4805 | 4 |

| System | Location | COE (USD/kWh) | Reference |

|---|---|---|---|

| PV/Diesel Generator/Grid | India | 0.127 | [37] |

| PV/Biomass Gasifier/Electrolyzer/Hydrogen Tank units/Fuel Cell | Egypt | 0.2106 | [38] |

| PV/Wind/Grid/Diesel generator | Italy | 0.109 | [39] |

| PV/Wind/Fuel cell | Oman | 0.196 | [40] |

| Wind/Biogas genset/Battery | United Kingdom | 0.588 | [41] |

| PV/Wind/Diesel generator/Battery/Hydrogen Storage | Kayseri | 0.376 | [42] |

| Energy Technology | Job Creation Factor (Jobs/MW) |

|---|---|

| PV | 2.70 |

| Wind turbine | 1.10 |

| Biogas generator | 0.19 jobs/GWh/yr |

| Battery | 0.01 jobs/MWh |

| Micro-hydro turbine | 1.50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chowdhury, T.; Hasan, S.; Chowdhury, H.; Hasnat, A.; Rashedi, A.; Asyraf, M.R.M.; Hassan, M.Z.; Sait, S.M. Sizing of an Island Standalone Hybrid System Considering Economic and Environmental Parameters: A Case Study. Energies 2022, 15, 5940. https://doi.org/10.3390/en15165940

Chowdhury T, Hasan S, Chowdhury H, Hasnat A, Rashedi A, Asyraf MRM, Hassan MZ, Sait SM. Sizing of an Island Standalone Hybrid System Considering Economic and Environmental Parameters: A Case Study. Energies. 2022; 15(16):5940. https://doi.org/10.3390/en15165940

Chicago/Turabian StyleChowdhury, Tamal, Samiul Hasan, Hemal Chowdhury, Abul Hasnat, Ahmad Rashedi, M. R. M. Asyraf, Mohamad Zaki Hassan, and Sadiq M. Sait. 2022. "Sizing of an Island Standalone Hybrid System Considering Economic and Environmental Parameters: A Case Study" Energies 15, no. 16: 5940. https://doi.org/10.3390/en15165940

APA StyleChowdhury, T., Hasan, S., Chowdhury, H., Hasnat, A., Rashedi, A., Asyraf, M. R. M., Hassan, M. Z., & Sait, S. M. (2022). Sizing of an Island Standalone Hybrid System Considering Economic and Environmental Parameters: A Case Study. Energies, 15(16), 5940. https://doi.org/10.3390/en15165940