Abstract

Renewable energy is predicted to play a crucial role in the energy sector as transitioning from fossil fuels to biofuels is key to achieving carbon neutrality. The comprehensive utilization of livestock manure and crop residues as a viable source of biofuels can play a significant role in Ghana’s future energy system. This current study aims to examine and predict the biofuel potential in Ghana from animal manure and crop residues. The biogas-biomethane potential of animal manure is determined using anaerobic digestion technology, whereas crop residues’ bioethanol potential is assessed using computational and analytical approaches. The findings demonstrate that animal manure biogas potential is 237.72 normal million cubic meters (NMm3). The highest manure-biogas potential per animal is from cattle (27.15 Nm3) and pigs (18.15 Nm3), while the least contribution is from chickens (1.80 Nm3). In addition, the annual bioethanol production is 3.74 gigaliters (GL), and residues from maize (0.88 GL), yams (0.82 GL), and plantains (0.47 GL) had the largest share per annum. By 2100, Ghana has the potential to produce 1288.56 NMm3 of manure-based biogas which can offset 13.88% of liquefied petroleum gas (LPG) consumption. The biogas potential positively correlates with the biomethane potential of 901.99 NMm3. Furthermore, 91.85% of the 14.76 GL of bioethanol will be from food crop residues. This study provides critical information to lawmakers and energy planners with strategies to achieve energy security and minimize the ecological footprint in an optimistic scenario.

1. Introduction

Anthropogenic global warming is directly linked to the use of fossil fuels. In the face of a growing global need for renewable energy, several countries still rely primarily on fossil fuels [1]. A paradigm shift away from fossil fuels and other nonrenewable energy sources is a critical strategy for achieving carbon neutrality [2]. As a result, energy managers and planners are scrambling to develop strategies for meeting rising energy needs while minimizing their negative influence on the environment. Using cutting-edge energy-saving techniques, including renewable energy resources and technologies, offers an excellent solution to these issues [3]. In the quest for renewable energy sources to decarbonize the global economy, biofuels provide the possibility for reduced greenhouse gas (GHG) emissions and energy security [4].

To attain energy security, Ghana has various renewable energy resources, including agricultural biomass [5], which can enhance economic development and reduce carbon emissions [6]. Crop residues can be converted into biofuels; however, the residues are often abandoned on farms or subjected to open field burning [7]. Similarly, various livestock wastes, including cattle, sheep, goats, pigs, and chickens, can be used to produce biofuels [8]. These can provide suitable biofuel substrates due to the vast amounts of manure they aggregate [9]. However, crop residues and livestock manure have not been comprehensively exploited and utilized as a viable source of biofuels while the country relies heavily on fossil fuels.

The over-dependence on fossil fuels in Ghana has persisted for decades. In 2014, 52.54% of Ghana’s energy was derived from fossil fuels [10]. Ghana uses high quantities of petroleum products, with gasoline and liquefied petroleum gas (LPG) among the top products imported and consumed. In 2020, the Ghanaian government recorded a 46.8% decrease in total petroleum products produced in the country. However, imports of petroleum products increased by 3.7%. Gasoline consumption rose by about 6.5% (1526.9 kilotons (kt)) and LPG consumption experienced a significant growth of 332.4 kt [11]. Biogas can be an alternative substitute to LPG which can be used in the cooking sector. The generation of biogas in Ghana can help to decrease the importation of petroleum products and increase biofuel generation. In addition, there has been a 48.3% gasoline price increase in Ghana since January 2022 [12], and high emissions of greenhouse gases (GHGs) are caused by gasoline use [13]. Bioethanol, on the other hand, can substitute for petrol or be blended with gasoline to reduce the high gasoline consumption. Given this information, promoting biofuels to substitute petroleum products will be beneficial.

As a potential replacement for fossil fuels, biofuels, including biogas, biomethane, and bioethanol, are popular options [14]. Many nations prioritize biofuel production with sustainability standards and criteria integrated into national regulatory frameworks [15], and the sustainability of biomass utilization is multifaceted [16]. Biofuels such as biogas production rely heavily on organic matter derived from farm animal waste as a raw material [17]. Carbon dioxide and methane are the two primary components of biogas. The anaerobic digestion (AD) of animal manure has a higher methane potential [18]. Likewise, incorporating bioenergy into Ghana’s energy mix could cut greenhouse gas emissions by approximately 6 Mt CO2e by 2030 [19].

Furthermore, forecasting has long played a crucial role in decision-making and planning [20]. The Sustainable Development Goals (SDG), as set forth by the United Nations and expanding the focus on renewable energy, implies biofuels will play a critical role in the future [21]. Given this, it is important to know how much agricultural biomass is being used as a feedstock for biofuel production and the potential for future production.

Some earlier studies have focused on the biofuel generation capacity of agricultural biomass. However, there are still knowledge gaps concerning animal manure-based biogas-methane and agricultural residue-based bioethanol potential in Ghana.

The bioethanol and biogas potential of West African agricultural residues was also assessed [22]. The study mainly focused on agro-residues, while there is a paucity of research on animal waste’s biofuel potential. In Ghana, previous studies focused on bioenergy technologies and the energy potential of agricultural biomass. According to Kemausour et al. [23], Ghana’s crop residues, animal manure, and other biomass sources can meet the country’s energy needs. However, the findings were based on a one-year dataset. The use of a one-year data set might not give a clear picture of the sustainability of Ghana’s biofuel sector. In the Lawra–Nandom district, Ayamga et al. [24] evaluated agricultural residues for second-generation bioethanol. However, the study was in only one district and could not cover all the 146 districts in Ghana. In addition, the bioethanol potential was assessed for only four crop residues specific to the northern sector; the study did not cover most of the residues generated in the southern part of Ghana.

In Sunyani, Präger et al. [25] assessed biomass resources excluding animal manure and identified the associated bioenergy potential. The research was limited to an administrative divisional level and not based on the national level. Furthermore, Azasi et al. [26] determined how different Ghanaian crop residues can contribute to the country’s specific heat and electricity needs without assessing the animal manure biofuel potential. Awafo and Agyeman [27] indicated that animal manure is among the most significant feedstocks for anaerobic digestion technology in Ghana. However, the authors did not quantify the manure and biogas generation potential from all the primary livestock raised in Ghana. Most studies on AD technology in Ghana are on crop residues as feedstock with little attention to animal manure. In addition, Ghana’s bioethanol potential of crop residues is not comprehensively explored, although gasoline consumption continues to increase. Some of these earlier studies did not highlight the future contribution of animal manure and crop residues to biofuel production. The prediction of the biofuels from animal and crop residues in Ghana and their role in supporting the country’s energy demand is worth researching. Specifically, Ghana is an agrarian economy and has vast biomass resources.

There are limitations and gaps in previous research in Ghana. Some previous studies only used a year’s data, whereas this research used a longitudinal research strategy for more accurate results and staving off uncertainties. In other research, although most households raise large quantities of livestock, additional emphasis was not placed on animal manure as a possible energy source to meet Ghana’s needs. Similarly, most research has not comprehensively examined the possibility of crop residue ethanol production. In contrast, this study aims to evaluate the biogas-biomethane potential of animal manure and the ethanol generation capacity of crop residues based on time series data. This study seeks to determine how much agricultural biomass (animal manure and crop residues) can be used as feedstock to produce biofuels to support Ghana’s energy mix as an energy security strategy.

Furthermore, the state of Ghana’s biogas system is examined. Subsequently, the study lays the foundation for forecasting biofuel production in Ghana to better support biomass-to-energy planning and decision-making processes. The valorization of agricultural biomass for biofuel generation on a multi-decadal scale is a strategic innovation pillar and crucial for the future of Ghana’s energy mix.

2. Materials and Methods

2.1. The Scope of the Research

The scope of the research includes the selection of significant livestock and crops in Ghana, followed by the potential generation of animal manure and crop residues. Subsequently, through anaerobic digestion (AD) technology, the theoretical biogas and biomethane potential of animal manure was determined. In addition, the bioethanol potential of crop residues was assessed. Based on the biomass (animal manure and crop residues) potential as well as the biofuel (biogas-biomethane and bioethanol) capacity, forecasts were done to ascertain their impact on Ghana’s energy system (Figure 1). Hence, the contribution of biofuels to petroleum products (LPG and gasoline) was examined.

Figure 1.

The research framework.

2.2. Biomass Generation Potential

Ghana is an agrarian economy characterized by both crop and livestock production. The livestock and agricultural production information from 2010 to 2020 was obtained from the Food and Agricultural Organization’s (FAO) database [28]. A total of 5 livestock and 13 leading food and cash crops were chosen for the study.

2.2.1. Available Animal Manure Estimation

The organic matter composition of livestock and poultry waste consists of manure. Ghana’s most common types of livestock are cattle, sheep, goats, pigs, and chickens [23]. Since ancient times, manure has been utilized as a fertilizer. If properly handled, it can be an asset, encouraging sustainable agriculture and enhancing crop productivity for smallholder farmers. Nevertheless, not all manure is used as fertilizer [29]. Manure has the potential to serve as the raw material for bioenergy production [17], and the amount of manure differs according to the type of animal, feeding method, body size, and breeding method [30]. This study focused on the sustainable generation of available manure for biofuel production. The number of animals, the average manure generation per animal, and the average recoverability fraction was used to determine the potential amount of manure produced by livestock [31], based on Equation (1).

is the available animal manure (ton/year); is the number of live animals (heads); is the dry matter production of livestock manure for cattle, goats, sheep, pigs, and chickens taken as 2.37 kg/head/day, 0.46 kg/head/day, 0.41 kg/head/day, 0.72 kg/head/day, and 0.07 kg/head/day, respectively. The dry matter production of livestock was from average estimations in published literature. In this regard, from Rosillo et al. [32], the values were 3.0 kg/head/day (cattle), 0.5 kg/head/day (goats and sheep), 0.6 kg/head/day (pigs), and 0.1 kg/head/day (chickens). From Simonyan and Fasina [33], the value of cattle dry matter content was 2.86 kg/head/day, goats (0.55 kg/head/day), (0.33 kg/head/day), pigs (0.66 kg/head/day), and chickens (0.04 kg/head/day). Similarly, from Oyedepo et al. [34] and Mohammed et al. [35], the values for cattle were 1.80 kg/head/day, goats and sheep (0.40 kg/head/day), pigs (0.8 kg/head/day), and chickens (0.06 kg/head/day). The 365 is the number of days in a year and is the recoverable fraction of the dry dung (Kg·Kg−1). The used for the study were 0.40 Kg·Kg−1 (cattle), 0.37 Kg·Kg−1 (goats), 0.32 Kg·Kg−1 (sheep), 0.90 Kg·Kg−1 (pigs), and 0.75Kg·Kg−1 (chickens). Estimations of the dry dung recoverable fraction were based on average calculations from earlier studies. From Tolessa et al. [31], the recoverable fraction value for cattle was 0.50 Kg·Kg−1, 0.33 Kg·Kg−1 (goats and sheep), 0.8 Kg·Kg−1 (pigs), and 0.50 Kg·Kg−1 (chicken); from Simonyan and Fasina, [33] the values obtained were 0.3 Kg·Kg−1 (cattle and sheep), 0.4 Kg·Kg−1 (goats), and 1.0 Kg·Kg−1 (pigs and chickens).

2.2.2. The Estimation of the Crop Residues’ Potential

This study focused on primary and secondary agricultural residues. Historically, crop residues were used for animal feed, cooking fuel, and landfills to prevent erosion and for fertilizer [36]. Due to various economic, social, and environmental constraints, not all crop residues generated may be accessible for collection and use [23]. Consequently, only a portion of residues can be used for biofuel production [37]. The recoverable fraction is a crucial component that could influence the annual crop residue supply [38]. Hence, the available potential was estimated based on Equation (2).

where (j) = Available crop residue potential of the jth state from nth number of crop residues, tonnes; = crop production of the ith crop, = residue to product ratio of the ith crop residue in jth state; and = Residue recoverable fraction of the ith crop residue in the jth state. The residues to product ratio and recoverable fraction were obtained from the published literature [23].

2.3. Biofuel Generation Potential

2.3.1. Assessment of the Biogas and Biomethane Potential of Animal Dung

Animal manure is rich in organic compounds and minerals such as carbon (C), nitrogen (N), hydrogen (H), oxygen (O), and sulfur (S) [39] that are suitable for biofuel production. Biomass power plants can utilize animal manure’s organic matter to generate energy [40]. In addition, biogas and biomethane can be generated from animal manure. Buswell’s method was used to calculate the manure biogas potential shown in Equations (3) and (4).

where represent the number of carbon (C), hydrogen (H), oxygen (O), and nitrogen (N) atoms, respectively. is the number of moles of water (H2O), is the number of moles of carbon dioxide (CO2), and is the number of moles of methane (CH4).

The estimations of were based on Equation (5) [41].

where K is the elemental composition of carbon (C), hydrogen (H), oxygen (O), and nitrogen (N) found in the ultimate analysis of animal manure [39,42]. M is the molar mass for C, H, O, and N obtained by Ayodele et al. [41]. were determined based on Equations (6)–(8).

The CO2 and CH4 densities were used to calculate the theoretical CO2 and CH4 potential for each kind of livestock manure as shown in Equations (9) and (10).

= the density of CO2 as 1.977 (kg/m3) and the density of CH4 as 0.717 (kg/m3) [41]. Biogas production from livestock manure was based on Equation (11).

is the overall volume of biogas in normal conditions (Nm3/t).

Practically, the biogas generated in an actual scenario is lower than the theoretical biogas potential. This is because approximately 10% of the biomass (animal manure) will fail to decompose in the digester. In addition, 5–10% of the organic matter synthesizes the cell tissue of organisms, which affects microbial breakdown [41]. The actual biogas () potential was evaluated using available animal manure; 85% of the biomass used for cell tissue synthesis [41] would be transformed into biogas, and the total volume of biogas was calculated as shown in Equation (12).

The amount of methane was analyzed using Equation (13).

where is the clean methane potential; is given between 60–70% and is regarded as the biomethane fraction of [43].

2.3.2. The Estimation of Bioethanol Potential from Crop Residues

The energy content of the biomass differs amongst plant species [44]. These residues are relatively affordable, naturally abundant, and non-competitive with the food and feed sectors [45]. Crop residues are identified as one of the most promising renewable resources for bioethanol production [45], which is a non-toxic, colorless, flammable, polar solvent, and the most effective alternative to gasoline [46]. The estimation of the bioethanol potential was based on the available crop residues generated, applied in Equation (14).

where is the bioethanol generation capacity in liters (l); = lower heating value (LHV) of the ith crop residue in the jth state (MJ/kg) obtained from published literature. The LHV for almost all the crop residues were obtained from NREL, [47] except for plantain residues [48]. is the available crop residue potential from the ith crop residue in the jth state; is the LHV of ethanol of 26.7 MJ/kg [49]; is the density of bioethanol taken as 0.79 kg/L [50], and ŋ is the thermodynamic conversion efficiency of bioethanol taken as 0.34 [26].

2.4. Biomass and Biofuels Forecast

The objective of forecasting was to enhance decision-making under uncertainty. Based on devoted advancements at the intersection of a variety of fields, the theory of forecasting looks mature today [20]. Accurate biofuel production projections can aid in the timely adjustment of agricultural product output. As a result, biofuel production projections can achieve a satisfactory result in a given period. Biofuel production projections are not only vital but also critical for the biofuel sector and agriculture’s development [51].

Using the 2010 data as the baseline, the biomass-biofuels production was projected from 2025 to 2100 at 5-year intervals. The biomass forecast was applied for the livestock manure and crop residues potential, and the biofuel potential was calculated for biogas, biomethane, and bioethanol. The forecast was applied based on Equations (15)–(17).

where is the quantity of biomass and bioenergy to be predicted, is the intercept of the y-axis, is the slope of the line, which is the change in the predicted value () over the dependent variable (, represent the average of the known value of while is the average of the known value.

3. Results and Discussions

3.1. Biomass Potential

3.1.1. Available Animal Manure Potential

The results highlight that 29.10 million tons (Mt) of manure were generated within the 11 years. The manure potential produced from 2010 to 2020 ranged from 1.96 Mt to 3.32 Mt. Chicken manure had the highest manure potential of 14.00 Mt, followed by cattle manure (6.55 Mt), goat manure (4.38 Mt), and sheep manure (2.36 Mt). In contrast, pig manure had the most negligible yield of 1.80 Mt (Table 1). Some similarities can be found between this study and Kemausour et al. [23], which found that cattle dung yielded the most manure. However, chicken manure yielded the least. The variation could be because this study used times series data (11 years), whereas earlier studies only focused on one-year data.

Table 1.

Available dry matter content of livestock manure in a million tons (Mt).

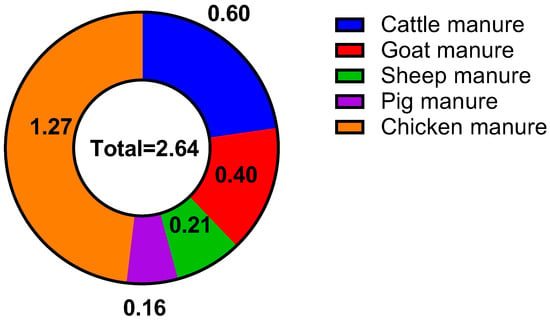

Furthermore, the annual manure potential was 2.64 Mt whereas, chicken manure had the highest potential of 1.27 Mt, followed by cattle, goat, sheep, and pig manure (Figure 2). The findings share similarities with Mohammed et al. [35], where animal manure production was higher for chicken manure, followed by cattle, goat, sheep, and pig manure.

Figure 2.

The annual share of animal manure (Mt).

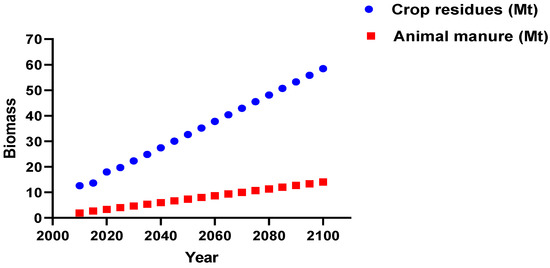

The forecast of the available manure yield indicates that Ghana has the potential to generate 3.99 Mt in 2025 and 14.04 Mt by 2100. The quantity of livestock manure will continue to experience an upward trend (Figure 3). The results reveal that there will be a variation in the contribution of the livestock manure. By 2100, the projection of the manure yield will be chicken (6.76 Mt), cattle (3.16 Mt), goat (2.12 Mt), sheep (1.14 Mt), and pig (0.87 Mt). Chicken and cattle manure will contribute to 70.65% of the total manure produced in the future, with a contribution of 48.12% and 22.52%, respectively. However, the other three livestock will contribute 29.35%. This implies that chicken and cattle manure have high potential for producing future animal wastes. The availability of animal manure could predict biogas production, and the possibility of producing biomethane from livestock manure appears promising [52]. The study highlights that for biofuel generation in Ghana, animal dung may be the best option [9].

Figure 3.

Biomass potential from the agriculture sector.

3.1.2. Available Agro-Waste Potential

The total residue generated within the 11 years was 159.98 Mt. In 2010, the crop residue generated was 12.62 Mt, which increased to 17.96 in 2020. Table 2 shows that the total crop residue potential for the different crops during the period was high for maize residues (40.06 Mt), yam residues (20.04 Mt), plantain residues (14.61 Mt), and cassava residues (11.77 Mt). Millet residues had the slightest total potential of 1.75 Mt.

Table 2.

Available crop residue potential in (Mt).

Similarly, the study exemplifies that Ghana has the potential of generating large quantities of animal manure and crop residues to meet future biofuel production. This is because livestock and crop production are the core components of Ghana’s agriculture sector; hence, the wastes generated can be sustainable.

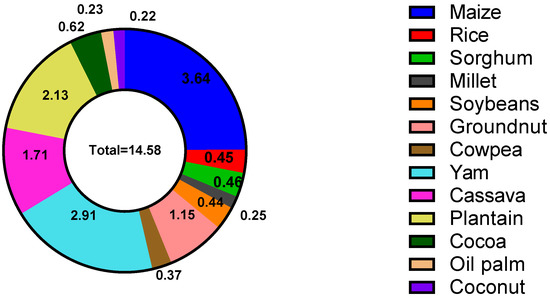

The average annual crop residue potential was 14.58 Mt. The maize, yam, plantain, and cassava residues had a yearly capacity of 3.64 Mt, 2.91 Mt, 2.13 Mt, and 1.71 Mt, respectively. In contrast, the least annual yield was from coconut residues (0.22 Mt) (Figure 4). The findings agree with a previous study where crop residues from yams, maize, and cassava were the most promising [23]. The results partly share similarities with Jekayinfa et al. [53], with the crops with prominent residue generation capacity being cassava, maize, and plantain. However, the number of residues can vary depending on the crop production in a specific area. In addition, food crop residues had a higher potential of 148.23 Mt, while cash crops had a lower residue potential of 11.75 Mt.

Figure 4.

The share of residues from the leading crops cultivated in Ghana (Mt).

Crop residue potential will increase from 19.70 Mt in 2025 to 58.41 Mt by 2100 (above in Figure 3). Maize, yam, and plantain will contribute to 59.69% of the total residues generated in the future, with the other residues contributing to 40.31%. The proportion of the food crop straws is estimated to be 92.65%, while cash crops will contribute 7.35%. The biomass potential from the agriculture sector will experience a higher crop residue potential. This implies that agro-waste will contribute the most, so future projects must focus on crop residues since biomass will play a prominent role in global energy by the year 2050. As a significant biomass and biofuel feedstock source, agricultural residues must be collected sustainably to meet bioenergy demand [54]. The findings show that Ghana has sufficient biofuel resources, which bodes well for the country’s future energy supply [35]. For every 1% increase in biomass use, GHG emissions are reduced by 0.89%, and promoting biofuels and the bioeconomy is one of the most successful measures for reducing carbon emissions [55].

3.2. Biofuel Potential in Ghana

3.2.1. Biogas-Biomethane Potential of Animal Manure

Ghana produced 174.70 NMm3 of biogas in 2010 and 301.08 NMm3 in 2020. The average annual biogas potential within the 11 years was 237.72 NMm3. For the specific livestock, chicken, cattle, goat, sheep, and pig manure had 1399.13 NMm3, 515.31 NMm3, 365.13 NMm3, 196.22 NMm3, and 139.14 NMm3, respectively (Table 3). The findings align with Mohammed et al. [35], where chicken manure had the highest energy content whilst pig manure had the least. This development indicates a positive correlation between the quantity of manure produced and its energy generation potential. Similarly, the high biogas-biomethane potential for chicken and cattle manure agrees with the findings of Awafo and Agyeman [27], who indicated that cattle and poultry raising is the most accessible feedstock for biogas generation. According to Alfa et al. [56], the biogas yield for chicken manure was higher than cow dung, which is highlighted in this study. Likewise, animal manure can produce a substantial amount of biomethane.

Table 3.

Biogas generation potential from livestock manure.

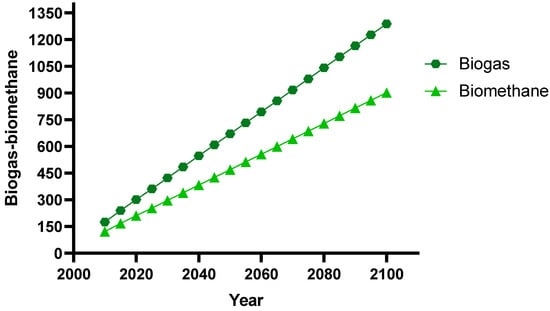

Biogas is mainly composed of methane (50–70%) and carbon dioxide (30–50%), with trace amounts of other gases being present [43]. Hence, the average annual biomethane potential was 166.40 NMm3. From 2010 to 2020, the biomethane potential experienced a higher yield from 122.29 NMm3 to 210.76 NMm3 (Table A1 in Appendix A). In response to the uncertainty of the future, forecasting can help minimize risks and maximize benefits [20]. The forecast results revealed that by 2100 Ghana has the potential to produce 1288.56 NMm3 (Figure 5). Chicken and cattle manure will contribute 73.21% of the total biogas generation potential, while the others will contribute 26.79%. However, the specific input of the various animal wastes is chicken manure (53.51%), cattle manure (19.71%), goat manure (13.96%), sheep manure (7.50%), and pig manure (5.32%). This implies that chicken manure will continue to generate the highest biogas potential. However, the results revealed that the annual livestock manure biogas potential per head for cattle, pig, goat, sheep, and chicken manure was 27.15 Nm3, 18.15 Nm3, 5.14 Nm3, 3.90 Nm3, and 1.80 Nm3, respectively. The high annual biogas generation potential for livestock is relatively close to Pollmann et al. [1], who stated that cow dung could produce roughly 30 Nm3. However, the fluctuation in biogas yield is attributable to the difference in manure dry matter generation per day.

Figure 5.

Biogas-biomethane potential from animal manure (NMm3).

A vast array of various organic substrates can be used for biogas production, and about 45% of the feedstock used in biogas generation is from animal dung. Cattle and pig dung are two of the most common animal types of waste utilized for biogas production [1]. This study demonstrates that animal manure is a promising renewable energy source that can be exploited effectively for biogas production. AD has the potential to play a crucial role in agricultural systems by adding value to animal manure and lowering its environmental presence, hence improving public health [57]. In addition, co-digestion could improve methane production, which can be carried out using inexpensive procedures [58] and a stable performance [59] to increase the methane output [60].

From 2010 to 2020, Ghana consumed about 178.4 to 332.4 kt of LPG [11], and by 2100 is expected to be 9285.41 NMm3. Although LPG consumption and biogas potential are projected to increase, the share of manure-based biogas concerning LPG consumption in Ghana is expected to be about 13.88%. The sustainability of the contribution of biogas can be associated with feedstock availability, climate change, the emergence of new forms of green energy, technological advancement, and other factors which could be examined in future research. Similarly, the inclusion of other forms of organic animal contents generated from abattoirs can be potential biomass sources for biogas production, as a biogas plant is a suitable approach. The slaughterhouse’s daily capacity of animals necessitates constant manure production, which is excellent for producing biogas and equivalent electricity [1].

Biogas potential for the various livestock manure positively correlated with the biomethane potential. The biomethane forecast in 2025 will be about 252.94 NMm3 which is expected to increase to 901.99 NMm3 by 2100. Furthermore, chicken and cattle dung produced the most significant methane outputs and agrees with Mohammed et al. [35]. The biomethane method produces high fuel due to its higher overall efficiency and lesser technological complexity [61]. Similarly, chicken manure will have a higher contribution, whereas the least yield will be from pig manure.

Natural gas substitution is possible with biomethane, and transportation fuel is the ultimate highest quality of the production process. The biomass AD technology has free input material flow, and the valuable products of biogas-methane and fertilizers are generated. The technology can readily produce biofuels for cooking, heating, or power [1].

Anaerobic digestion is a promising bioenergy method, however, 10–15% of the animal manure is not processed and can serve as organic fertilizer while the rest may be discarded. Given this, if the remaining slurry is not disposed of properly, it can cause environmental problems in society. Additionally, although livestock wastes are made up of a variety of organic contents, the study primarily focused on animal manure. Thus, future research may concentrate on other livestock solid wastes to provide a more comprehensive picture of the production of biofuel from animal wastes.

3.2.2. The Biogas Production System in Ghana

Biogas technology was first developed in Ghana in the late 1960s, providing cooking energy [62]. Ghana possesses the knowledge and skills necessary to handle biogas digesters on a small to medium scale, with the vast majority of plants in metropolitan areas concentrated in educational and health facilities [27]. Likewise, 89 and 31 biogas digesters were built in the Greater Accra region and Central region, respectively [63].

However, biogas technology has not progressed in Ghana as planned, and the total number of biogas plants in Ghana is not readily known. In 2017, an examination of 54 digesters revealed that the initial installation and maintenance costs appear to be expensive. In addition, some biogas digesters were abandoned for lack of cow dung and maintenance [63]. Critical impediments to bioenergy adoption in Ghana include technical expertise, research data, financial resources, appropriate regulatory framework, and political commitment [64]. Animal manure, crop residues, abattoir wastes, food-processing residues, municipal solid waste, and municipal sewage sludge are the most prevalent feedstocks readily available in Ghana for AD [27].

Biogas technology is adopted in Ghana for various reasons, such as bioelectricity generation, sanitation improvement, biofertilizer production, and the creation of jobs [63].

Recently, the Ghanaian government plans to build a prototype industrial biogas plant at the Kumasi Abattoir. Biogas will help with waste management and also help with green industrial growth and business promotion, with the potential of the combined waste components being 846 Nm3 per day [65]. Furthermore, in April 2022, the ‘Hybrid-PV-Biogas-Pyrolysis-Plant’ (400-kilowatt facility) was commissioned in the Ashanti region. It also aims to develop economic models for effectively replicating and disseminating this concept in 10 distinct regions of the country [66].

Given the challenges facing the biogas sector, Ghana should adopt a holistic approach to implementing an industrialized-scale biogas system. Inoperative plants must be revived to address the needs of the citizens. Biogas technology as renewable energy will achieve the primary objectives of several significant global conservation and socio-economic development projects [67].

3.2.3. Bioethanol Potential of Agro-Wastes

The total bioethanol potential of the crop residues for the 11 years was 41.12 gigaliters (GL), with an average annual potential of 3.74 GL. The top three residues with the highest total potential were maize residues with a capacity of 9.73 GL, yam residues (9.04 GL), and plantain residues (5.13 GL). Similarly, the annual contribution of the above-mentioned residues was 0.88 GL, 0.82 GL, and 0.47 GL, respectively (Table 4). According to Seglah et al. [68], the residues from yam and maize have a positive trend with energy potential. The high bioethanol potential of yam residues agrees with Thomsen et al. [22]. In addition, the larger the number and types of residues, the more enormous their biofuel potential is and vice versa. Other crops had a total bioethanol potential ranging from 4.63 GL for cassava residues to 0.70 GL (millet residues). Similarly, the annual bioethanol potential for the other crops was 0.42 GL (cassava residues) to 0.07 GL (coconut residues). However, oil palm residues had the lowest bioethanol potential of 0.65 GL for 11 years, and cassava and millet had an annual potential of 0.06 GL each.

Table 4.

Bioethanol production potential from crop residues (GL).

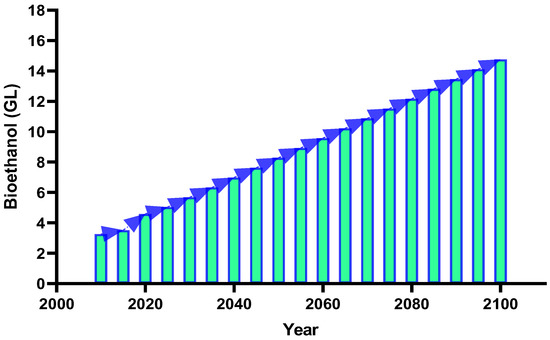

An increasing number of application fields rely significantly on forecasting [20], and this is where prediction comes into play. Figure 6 shows the projection of the bioethanol potential in 2025 to be 5.04 GL and 14.76 GL by 2100. Maize, yam, and plantain residues can generate 58.12% of the bioethanol, whiles the other 10 residues can contribute 41.88%. In addition, food crop residues have the potential to generate 91.85% of the future bioethanol, with cash crops contributing only 8.15%. From 2010 to 2020, actual gasoline consumption in Ghana ranged from 737.8 kt to 1607.70 kt [11]. Based on Ghana’s high bioethanol production in relative substantial quantities, bioethanol can be used as a replacement for petrol and blended with gasoline in any proportion [46].

Figure 6.

Bioethanol potential from crop residues.

Compared to unblended gasoline, bioethanol-blended gasoline’s smoke and flame properties are significantly different. As ethanol concentration increases, less apparent black smoke and orange flame are emitted. Additionally, it enables a vehicle’s engine to boost its compression ratio [69]. Furthermore, the high bioethanol production in the future can help minimize the high importation of gasoline into the country. Projections of bioethanol potential at the district level showed an increased positive trend [24]. Ethanol production is heavily influenced by residue quantity, so particle size and enzymatic digestion are critical considerations [70].

Biofuels are likely to experience a fast expansion in the 21st century, constituting a viable option. In the most optimistic scenario, Ghana can take advantage of the total energy demand in developing countries by meeting the biomass energy demand in developing countries [71]. However, the development of the biofuel sector would necessitate strong government backing [72]. For biofuel production to benefit society, political choices supporting adoption and implementation, financial support, and dissemination plans are required in Ghana. In this regard, lawmakers must also provide a legal framework to safeguard businesses and investors who are prepared to participate in biofuel initiatives [64].

The limitation of this study is that the findings do not specifically highlight the contribution of agricultural biomass (animal and crop wastes) at the regional level, although Ghana is made up of 16 administrative regions. This is due to the unavailability and difficulties in obtaining data at the administrative levels. Similarly, although the findings highlight the role of agriculture wastes in Ghana’s future energy mix, an economic feasibility assessment was not done to assess whether the project will be cost-effective. Given this information, future research could focus on the economic analysis of the project.

4. Conclusions

Alternatives to fossil fuels, such as biofuels, hold great promise to decarbonize the global economy by reducing greenhouse gas emissions and increasing energy security. The biofuel potential in Ghana was determined using the wastes of 5 livestock and 13 main crops. This study demonstrates that chicken and cattle produced 1.27 and 0.60 Mt manure annually. Similarly, residues from maize (3.64 Mt), yam (2.91 Mt), plantain (2.13 Mt), and cassava (1.71 Mt) had the highest yearly potential. The biogas and the biomethane potential of livestock manure were highly connected. The annual biogas and biomethane potential of animal manure were 237.72 NMm3 and 166.40 NMm3, respectively. In addition, crop residues had a yearly bioethanol potential of 3.74 GL.

Ghana’s sustainable supply of feedstock can meet the advanced biofuel demand. By 2100, Ghana has the potential to produce 1288.56 NMm3 of biogas, which can offset 13.88% of LPG consumption. Chicken and cattle manure will contribute 73.21% and 26.79% will be contributed from other livestock. Similarly, the biomethane potential in 2025 is expected to be 252.94 NMm3 and increase to 901.99 NMm3 by 2100. There is a need for a public-private transdisciplinary strategy to address the challenges faced by the biogas sector.

Furthermore, the bioethanol output is predicted to reach 5.04 GL in 2025 and 14.76 GL by 2100. The residues from maize, yam, and plantain can yield 58.12% of the bioethanol, while the remaining ten crops can produce 41.8%. Given Ghana’s large bioethanol production compared to its gasoline consumption, substantial quantities of bioethanol can be blended with gasoline. Biofuels could meet Ghana’s fossil fuel demand in a future scenario and eventually replace petrol as the nation’s primary fuel.

Future research could focus on biofuel generation from other organic animal waste contents in addition to other non-agricultural solid wastes to provide an extensive context of the future of Ghana’s biofuel industry. A future scenario of the economic and environmental impact analysis could be used to determine whether or not biofuel production is feasible.

Author Contributions

P.A.S. Conceptualization, Data curation, Methodology, Formal analysis, and Writing—original draft; Y.W. Supervision, Validation, and Writing—review and editing; H.W. Validation and Formal analysis; C.G. Validation and Writing—review and editing; Y.B. Conceptualization, Supervision, and Funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

The National Science Foundation of China (41771569) provided financial support for this research.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Biomethane generation potential from livestock manure.

Table A1.

Biomethane generation potential from livestock manure.

| Year | Cattle Dung (NMm3) | Goat Dung (NMm3) | Sheep Dung (NMm3) | Pig Dung (NMm3) | Chicken Dung (NMm3) |

|---|---|---|---|---|---|

| 2010 | 27.63 | 17.46 | 10.26 | 6.81 | 60.12 |

| 2011 | 28.47 | 18.48 | 10.61 | 7.21 | 66.19 |

| 2012 | 29.33 | 19.55 | 10.97 | 7.65 | 72.88 |

| 2013 | 30.22 | 20.69 | 11.35 | 8.10 | 80.24 |

| 2014 | 31.49 | 21.74 | 11.84 | 8.66 | 86.25 |

| 2015 | 32.96 | 22.85 | 12.35 | 9.27 | 90.14 |

| 2016 | 34.50 | 24.24 | 12.95 | 9.87 | 93.02 |

| 2017 | 36.13 | 25.72 | 13.62 | 10.36 | 94.88 |

| 2018 | 36.53 | 27.01 | 14.03 | 10.06 | 103.18 |

| 2019 | 36.93 | 28.36 | 14.48 | 9.76 | 112.31 |

| 2020 | 36.53 | 29.50 | 14.90 | 9.64 | 120.18 |

| Total | 360.71 | 255.59 | 137.35 | 97.40 | 979.39 |

References

- Pollmann, O.; Podruzsik, S.; Rensburg, L.V. Risks and Opportunities of Sustainable Biomass and Biogas Production for the African Market. In Human and Environmental Security in the Era of Global Risks; Springer: Cham, Switzerland, 2019; pp. 277–289. [Google Scholar]

- Koondhar, M.A.; Tan, Z.; Alam, G.M.; Khan, Z.A.; Wang, L.; Kong, R. Bioenergy consumption, carbon emissions, and agricultural bioeconomic growth: A systematic approach to carbon neutrality in China. J. Environ. Manag. 2021, 296, 113242. [Google Scholar] [CrossRef] [PubMed]

- Noorollahi, Y.; Kheirrouz, M.; Asl, H.F.; Yousefi, H.; Hajinezhad, A. Biogas production potential from livestock manure in Iran. Renew. Sustain. Energy Rev. 2015, 50, 748–754. [Google Scholar] [CrossRef]

- Kazamia, E.; Smith, A.G. Assessing the environmental sustainability of biofuels. Trends Plant Sci. 2014, 19, 615–618. [Google Scholar] [CrossRef] [Green Version]

- IRENA. Renewables Readiness Assessment: Ghana. 2020. Available online: https://www.irena.org/publications/2015/Nov/Renewables-Readiness-Assessment-Ghana (accessed on 27 January 2022).

- Morales-Polo, C.; Cledera-Castro, M.D.; Revuelta-Aramburu, M.; Hueso-Kortekaas, K. Bioconversion process of barley crop residues into biogas—Energetic-environmental potential in Spain. Agronomy 2021, 11, 640. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Bi, Y.; Zhou, K.; Wang, Y.; Wang, H.; Feng, X. Crop straw utilization and field burning in Northern region of Ghana. J. Clean. Prod. 2020, 261, 121191. [Google Scholar] [CrossRef]

- Arthur, R.; Baidoo, M.F.; Antwi, E. Biogas as a potential renewable energy source: A Ghanaian case study. Renew. Energy 2011, 36, 1510–1516. [Google Scholar] [CrossRef]

- Ossei-Bremang, R.N.; Kemausuor, F. A decision support system for the selection of sustainable biomass resources for bioenergy production. Environ. Syst. Decis. 2021, 41, 437–454. [Google Scholar] [CrossRef]

- Macrotrends. Ghana Fossil Fuel Consumption 1971–2022. 2022. Available online: https://www.macrotrends.net/countries/GHA/ghana/fossil-fuel-consumption (accessed on 20 June 2022).

- Energy Commission. Energy Outlook for Ghana. 2020. Available online: http://www.energycom.gov.gh/planning/data-center/energy-outlook-for-ghana (accessed on 13 June 2022).

- Statista. Weekly price of petrol in Ghana 2020–2022. 2022. Available online: https://www.statista.com/statistics/1200108/weekly-gasoline-prices-in-ghana/ (accessed on 20 June 2022).

- Ackah, I.; Frank, A.D.U. Modelling gasoline demand in Ghana: A structural time series analysis. Int. J. Energy Econ. Policy 2013, 4, 76–82. [Google Scholar]

- Kaup, F.; Selbmann, K. The seesaw of Germany’s biofuel policy e tracing the evolvement to its current state. Energy Policy 2013, 62, 513–521. [Google Scholar] [CrossRef]

- Webb, A.; Coates, D. Biofuels and Biodiversity. In Secretariat of the Convention on Biological Diversity. Montreal, Technical Series 2012. Available online: http://www.ourenergypolicy.org/wp-content/uploads/2012/10/cbd-ts-65-en.pdf (accessed on 7 July 2022).

- Thiffault, E.; Barrette, J.; Paré, D.; Titus, B.D.; Keys, K.; Morris, D.M.; Hope, G. Developing and validating indicators of site suitability for forest harvesting residue removal. Ecol. Indic. 2014, 43, 1–18. [Google Scholar] [CrossRef]

- Abdeshahian, P.; Lim, J.S.; Ho, W.S.; Hashim, H.; Lee, C.T. Potential of biogas production from farm animal waste in Malaysia. Renew. Sust. Energ. Rev. 2016, 60, 714–723. [Google Scholar] [CrossRef]

- Oladejo, O.S.; Dahunsi, S.O.; Adesulu-Dahunsi, A.T.; Ojo, S.O.; Lawal, A.I.; Idowu, E.O.; Olanipekun, A.A.; Ibikunle, R.A.; Osueke, C.O.; Ajayi, O.E.; et al. Energy generation from anaerobic co-digestion of food waste, cow dung and piggery dung. Bioresour. Technol. 2020, 313, 123694. [Google Scholar] [CrossRef] [PubMed]

- Kemausuor, F.; Nygaard, I.; Mackenzie, G. Prospects for bioenergy use in Ghana using Long-range Energy Alternatives Planning model. Energy 2015, 93, 672–682. [Google Scholar] [CrossRef] [Green Version]

- Petropoulos, F.; Apiletti, D.; Assimakopoulos, V.; Babai, M.Z.; Barrow, D.K.; Taieb, S.B.; Bergmeir, C.; Bessa, R.J.; Bijak, J.; Boylan, J.E.; et al. Forecasting: Theory and practice. Int. J. Forecast. 2022, 38, 705–871. [Google Scholar]

- Javed, S.A.; Zhu, B.; Liu, S. Forecast of biofuel production and consumption in top CO2 emitting countries using a novel grey model. J. Clean. Prod. 2020, 276, 123997. [Google Scholar] [CrossRef]

- Thomsen, S.T.; Kádár, Z.; Schmidt, J.E. Compositional analysis and projected biofuel potentials from common West African agricultural residues. Biomass Bioenergy 2014, 63, 210–217. [Google Scholar] [CrossRef]

- Kemausuor, F.; Kamp, A.; Thomsen, S.T.; Bensah, E.C.; Østergård, H. Assessment of biomass residue availability and bioenergy yields in Ghana. Resour. Conserv. Recycl. 2014, 86, 28–37. [Google Scholar] [CrossRef]

- Ayamga, E.A.; Kemausuor, F.; Addo, A. Technical analysis of crop residue biomass energy in an agricultural region of Ghana. Resour. Conserv. Recycl. 2015, 96, 51–60. [Google Scholar] [CrossRef]

- Präger, F.; Paczkowski, S.; Sailer, G.; Derkyi, N.S.A.; Pelz, S. Biomass sources for a sustainable energy supply in Ghana—A case study for Sunyani. Renew. Sustain. Energy Rev. 2019, 107, 413–424. [Google Scholar] [CrossRef]

- Azasi, V.D.; Offei, F.; Kemausuor, F.; Akpalu, L. Bioenergy from crop residues: A regional analysis for heat and electricity ap-plications in Ghana. Biomass Bioenergy 2020, 140, 105640. [Google Scholar] [CrossRef]

- Awafo, E.A.; Agyeman, V.K. Development of biogas resources and technologies in Ghana, a survey. Int. J. Energy Environ. 2020, 11, 167–178. [Google Scholar]

- FAOSTAT. Crops and Livestock Products. Food and Agriculture Organization of the United Nations. 2022. Available online: https://www.fao.org/faostat/en/#data (accessed on 10 May 2022).

- Ndambi, O.A.; Pelster, D.E.; Owino, J.O.; De Buisonje, F.; Vellinga, T. Manure management practices and policies in sub-Saharan Africa: Implications on manure quality as a fertilizer. Front. Sustain. Food Syst. 2019, 3, 29. [Google Scholar] [CrossRef] [Green Version]

- Avcioğlu, A.O.; Türker, U.F.U.K. Status and potential of biogas energy from animal wastes in Turkey. Renew. Sustain. Energy Rev. 2012, 16, 1557–1561. [Google Scholar] [CrossRef]

- Tolessa, A.; Zantsi, S.; Louw, T.M.; Greyling, J.C.; Goosen, N.J. Estimation of biomass feedstock availability for anaerobic digestion in smallholder farming systems in South Africa. Biomass Bioenergy 2020, 142, 105798. [Google Scholar] [CrossRef]

- Rosillo-Calle, F.; De Groot, P.; Hemstock, S.L.; Woods, J. (Eds.) The Biomass Assessment Handbook: Bioenergy for a Sustainable Environment; Earthscan: London, UK, 2008; Available online: https://cgspace.cgiar.org/bitstream/handle/10568/76863/epdf.pub_the-biomass-assessment-handbook-bioenergy-for-a-su.pdf?sequence=1 (accessed on 20 April 2022).

- Simonyan, K.J.; Fasina, O. Biomass resources and bioenergy potentials in Nigeria. Afr. J. Agric. Res. 2013, 8, 4975–4989. [Google Scholar]

- Oyedepo, S.O.; Dunmade, I.S.; Adekeye, T.; Attabo, A.A.; Olawole, O.C.; Babalola, P.O.; Oyebanji, J.A.; Udo, M.O.; Kilanko, O.; Leramo, R.O. Bioenergy technology development in Nigeria-pathway to sustainable energy development. Int. J. Environ. Sustain. Dev. 2019, 18, 175–205. [Google Scholar] [CrossRef]

- Mohammed, Y.S.; Mokhtar, A.S.; Bashir, N.; Saidur, R. An overview of agricultural biomass for decentralized rural energy in Ghana. Renew. Sustain. Energy Rev. 2013, 20, 15–25. [Google Scholar] [CrossRef]

- Ren, J.; Yu, P.; Xu, X. Straw utilization in China-status and recommendations. Sustainability 2019, 11, 1762. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Havrysh, V.; Klymchuk, O.; Nitsenko, V.; Balezentis, T.; Streimikiene, D. Utilization of crop residue for power generation: The case of Ukraine. Sustainability 2019, 11, 7004. [Google Scholar] [CrossRef] [Green Version]

- Kashif, M.; Awan, M.B.; Nawaz, S.; Amjad, M.; Talib, B.; Farooq, M.; Nizami, A.S.; Rehan, M. Untapped renewable energy potential of crop residues in Pakistan: Challenges and future directions. J. Environ. Manag. 2020, 256, 109924. [Google Scholar] [CrossRef]

- Alnhoud, O.T.; Al-Harahsheh, A.M.; Al-Harahsheh, M.S.; Irshaid, F.I. Animal solid waste as a potential renewable biomass energy source: A case study of Jordan. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Afazeli, H.; Jafari, A.; Rafiee, S.; Nosrati, M. An investigation of biogas production potential from livestock and slaughterhouse wastes. Renew. Sustain. Energy Rev. 2014, 34, 380–386. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- Wnetrzak, R.; Kwapinski, W.; Peters, K.; Sommer, S.G.; Jensen, L.S.; Leahy, J.J. The influence of the pig manure separation system on the energy production potentials. Bioresour. Technol. 2013, 136, 502–508. [Google Scholar] [CrossRef]

- Muzenda, E. Bio-methane Generation from Organic Waste: A. In Proceedings of the World Congress on Engineering and Computer Science (Vol. 2), WCECS 2014, San Francisco, CA, USA, 22–24 October 2014. [Google Scholar]

- Saleem, M. Possibility of utilizing agriculture biomass as a renewable and sustainable future energy source. Heliyon 2022, 8, e08905. [Google Scholar] [CrossRef]

- Deshavath, N.N.; Veeranki, V.D.; Goud, V.V. Lignocellulosic feedstocks for the production of bioethanol: Availability, struc-ture, and composition. In Sustainable Bioenergy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–19. [Google Scholar]

- Pandiyan, K.; Singh, A.; Singh, S.; Saxena, A.K.; Nain, L. Technological interventions for utilization of crop residues and weedy biomass for second generation bio-ethanol production. Renew. Energy 2019, 132, 723–741. [Google Scholar] [CrossRef]

- NREL. Assessment of Biomass Resources in Afghanistan. Technical Report. NREL/TP-6A20-49358. 2011. Available online: https://www.nrel.gov/docs/fy11osti/49358.pdf (accessed on 6 June 2022).

- Jekayinfa, S.O.; Scholz, V. Potential Availability of Energetically Usable Crop Residues in Nigeria. Energy Sources Part A Recovery Util. Environ. Eff. 2009, 31, 687–697. [Google Scholar] [CrossRef]

- Engineering ToolBox. Fuels—Higher and Lower Calorific Values. 2003. Available online: https://www.engineeringtoolbox.com/fuels-higher-calorific-values-d_169.html (accessed on 7 June 2022).

- Balat, M. Production of bioethanol from lignocellulosic materials via the biochemical pathway: A review. Energy Convers. Manag. 2011, 52, 858–875. [Google Scholar] [CrossRef]

- Yu, L.; Liang, S.; Chen, R.; Lai, K.K. Predicting monthly biofuel production using a hybrid ensemble forecasting methodology. Int. J. Forecast. 2022, 38, 3–20. [Google Scholar] [CrossRef]

- Melikoglu, M.; Menekse, Z.K. Forecasting Turkey’s cattle and sheep manure based biomethane potentials till 2026. Biomass bioenergy 2020, 132, 105440. [Google Scholar] [CrossRef]

- Jekayinfa, S.O.; Orisaleye, J.I.; Pecenka, R. An assessment of potential resources for biomass energy in Nigeria. Resources 2020, 9, 92. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F. Future role of bioenergy. In The Role of Bioenergy in the Bioeconomy; Academic Press: Cambridge, MA, USA, 2019; pp. 435–547. [Google Scholar]

- Baležentis, T.; Streimikiene, D.; Zhang, T.; Liobikiene, G. The role of bioenergy in greenhouse gas emission reduction in EU countries: An Environmental Kuznets Curve modelling. Resour. Conserv. Recycl. 2019, 142, 225–231. [Google Scholar] [CrossRef]

- Alfa, I.M.; Dahunsi, S.O.; Iorhemen, O.T.; Okafor, C.C.; Ajayi, S.A. Comparative evaluation of biogas production from Poultry droppings, Cow dung and Lemon grass. Bioresour. Technol. 2014, 157, 270–277. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roubík, H.; Mazancová, J.; Phung, L.D.; Dung, D.V. Quantification of biogas potential from livestock waste in Vietnam. Agron. Res. 2017, 15, 540–552. [Google Scholar]

- Morales-Polo, C.; Cledera-Castro, M.D.; Revuelta-Aramburu, M.; Hueso-Kortekaas, K. Enhancing energy recovery in form of biogas, from vegetable and fruit wholesale markets by-products and wastes, with pretreatments. Plants 2021, 10, 1298. [Google Scholar] [CrossRef]

- Mu, L.; Zhang, L.; Zhu, K.; Ma, J.; Ifran, M.; Li, A. Anaerobic co-digestion of sewage sludge, food waste and yard waste: Synergistic enhancement on process stability and biogas production. Sci. Total Environ. 2020, 704, 135429. [Google Scholar] [CrossRef]

- Chen, S.; Tao, Z.; Yao, F.; Wu, B.; He, L.; Hou, K.; Pi, Z.; Fu, J.; Yin, H.; Huang, Q.; et al. Enhanced anaerobic co-digestion of waste activated sludge and food waste by sulfidated microscale zerovalent iron: Insights in direct interspecies electron transfer mechanism. Bioresour. Technol. 2020, 316, 123901. [Google Scholar] [CrossRef]

- Eisentraut, A. Sustainable Production of Second-Generation Biofuels: Potential and Perspectives in Major Economies and Developing Countries, IEA Energy Papers, No. 2010/01; OECD Publishing: Paris, France, 2010. [Google Scholar] [CrossRef]

- Bensah, E.C.; Brew-Hamond, A. Biogas technology dissemination in Ghana: History, current status, future prospects, and policy significance. Int. J. Energy Environ. 2010, 1, 277–294. [Google Scholar]

- Osei-Marfo, M.; Awuah, E.; de Vries, N.K. Biogas technology diffusion and shortfalls in the central and greater Accra regions of Ghana. Water Pract. Technol. 2018, 13, 932–946. [Google Scholar] [CrossRef]

- Wiredu, J.; Yang, Q.; Sampene, A.K.; Shams, F.K.; Nishimwe, A.; Agyeman, F.O.; Awuah, A. Key Barriers for Bioenergy Projects Implementation: A fresh insight from Ghana. Int. J. Sci. Manag. Res. 2022, 5, 237–256. [Google Scholar] [CrossRef]

- Awafo, E.A.; Amenorfe, J. Techno-economic studies of an industrial biogas plant to be implemented at Kumasi Abattoir in Ghana. Sci. Afr. 2021, 11, e00712. [Google Scholar] [CrossRef]

- Joy Online. Government Commissions €6.2m Waste-to-Energy Conversion Plant at Gyankobaa. 2022. Available online: https://www.myjoyonline.com/government-commissions-e6-2m-waste-to-energy-conversion-plant-at-gyankobaa/ (accessed on 10 June 2022).

- Agyenim, F.B.; Dzamboe, P.D.; Mohammed, M.; Bawakyillenuo, S.; Okrofu, R.; Decker, E.; Agyemang, V.K.; Nyarko, E.H. Powering communities using hybrid solar–biogas in Ghana, a feasibility study. Environ. Technol. Innov. 2020, 19, 100837. [Google Scholar] [CrossRef]

- Seglah, P.A.; Wang, Y.; Wang, H.; Neglo, K.A.W.; Gao, C.; Bi, Y. Energy Potential and Sustainability of Straw Resources in Three Regions of Ghana. Sustainability 2022, 14, 1434. [Google Scholar] [CrossRef]

- Sun, Y.; Cheng, J. Hydrolysis of lignocellulosic materials for ethanol production: A review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Ezealigo, U.S.; Ezealigo, B.N.; Kemausuor, F.; Achenie, L.E.K.; Onwualu, A.P. Biomass Valorization to Bioenergy: Assessment of Biomass Residues’ Availability and Bioenergy Potential in Nigeria. Sustainability 2021, 13, 13806. [Google Scholar] [CrossRef]

- Demirbas, A. Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers. Manag. 2008, 49, 2106–2116. [Google Scholar] [CrossRef]

- Alizadeh, R.; Lund, P.D.; Soltanisehat, L. Outlook on biofuels in future studies: A systematic literature review. Renew. Sustain. Energy Rev. 2020, 134, 110326. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).