Optimization of Load Sharing in Compressor Station Based on Improved Salp Swarm Algorithm

Abstract

:1. Introduction

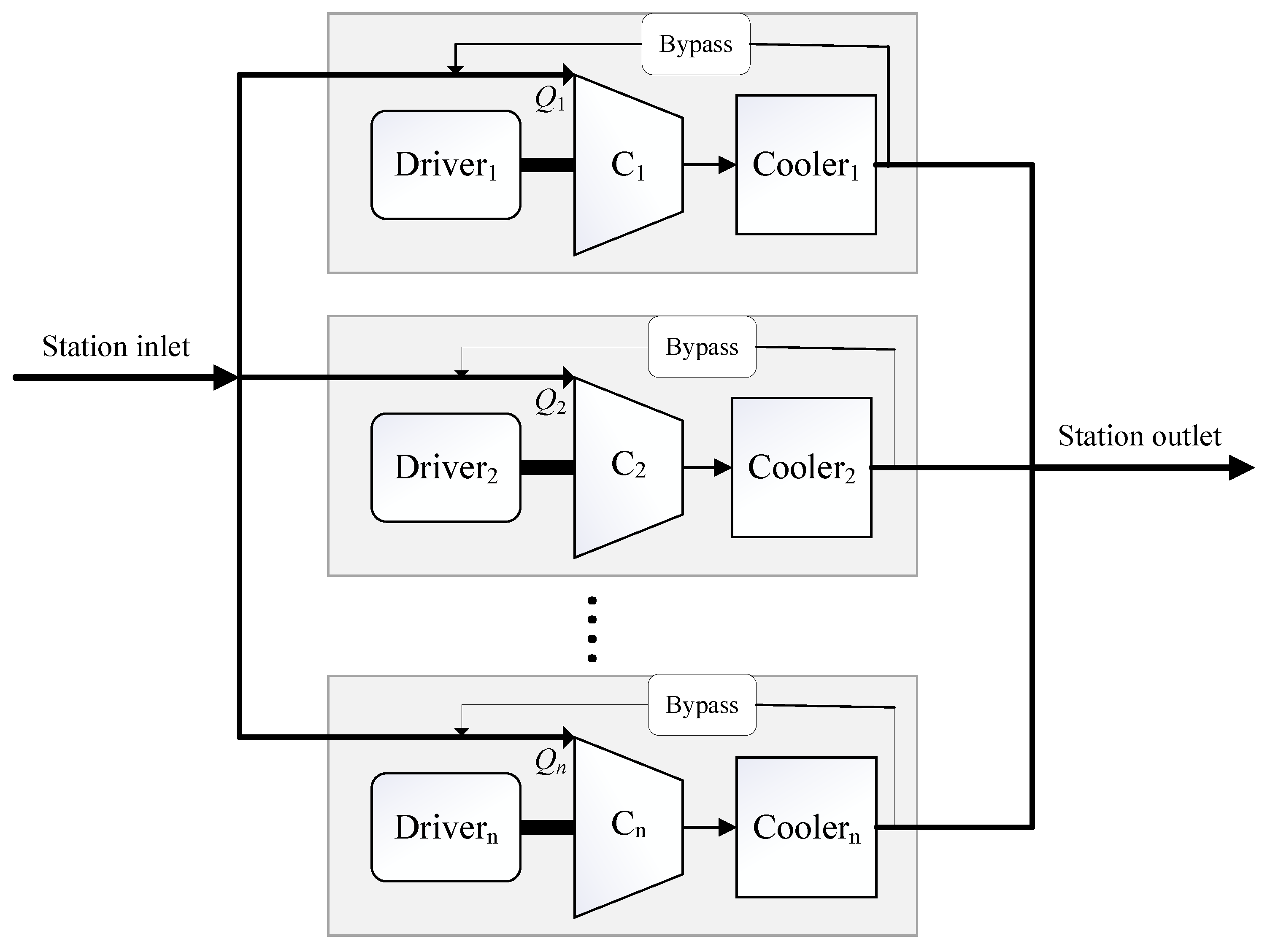

2. Model

2.1. Object Function

2.2. Constraints

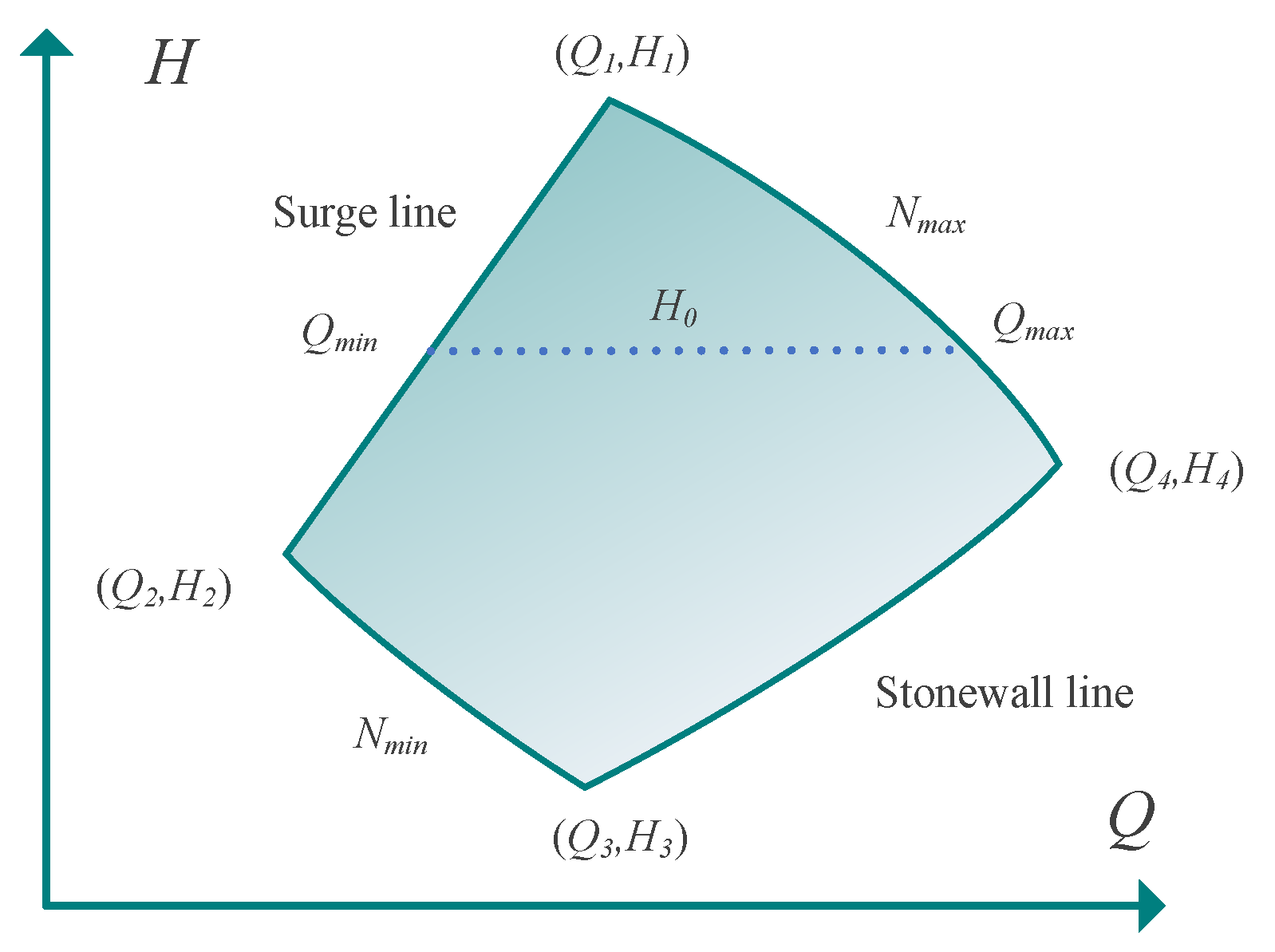

2.2.1. Compressor Unit Limitations

2.2.2. Load Balance Constrainst

2.3. Question Summary

3. Solution Approach

3.1. Model Preprocessing

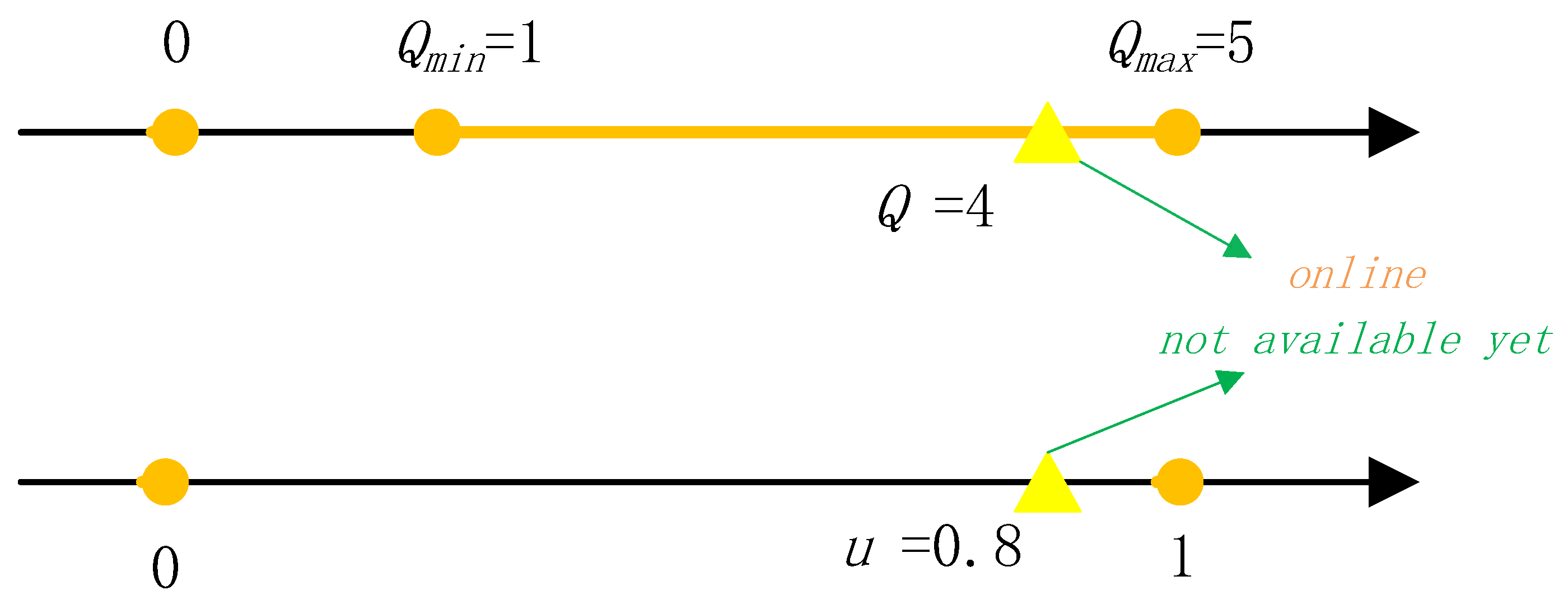

3.1.1. Binary and Semi-Continuous Variables

3.1.2. Flow Balance Constraint

3.2. Salp Swarm Algorithm

| Algorithm 1 SSA. |

|

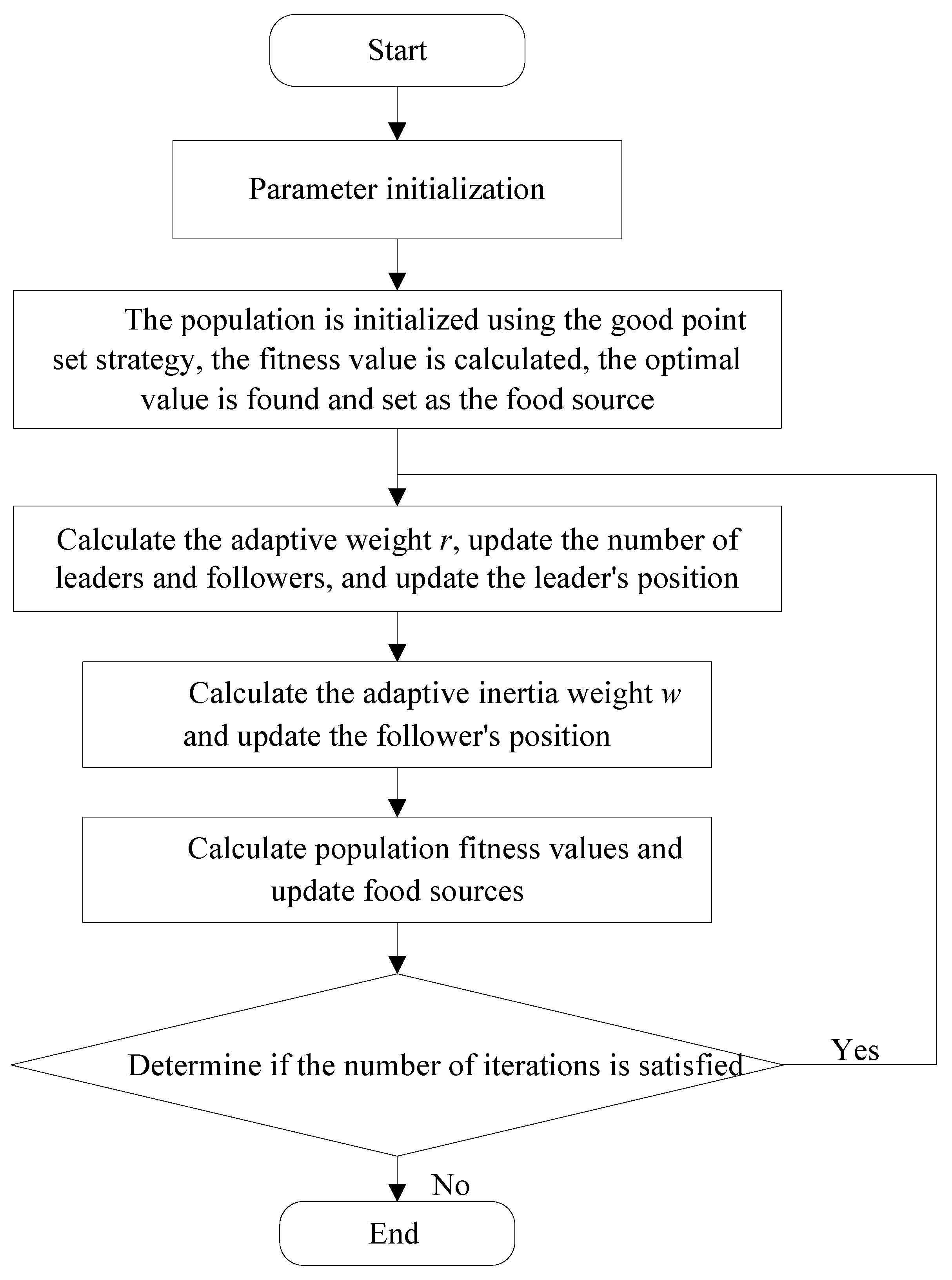

3.3. Improved Salp Swarm Algorithm

3.3.1. Good Point Set

3.3.2. Adaptive Population Division

3.3.3. Adaptive Inertia Weight

| Algorithm 2 GASSA. |

|

4. Simulations and Comparisons

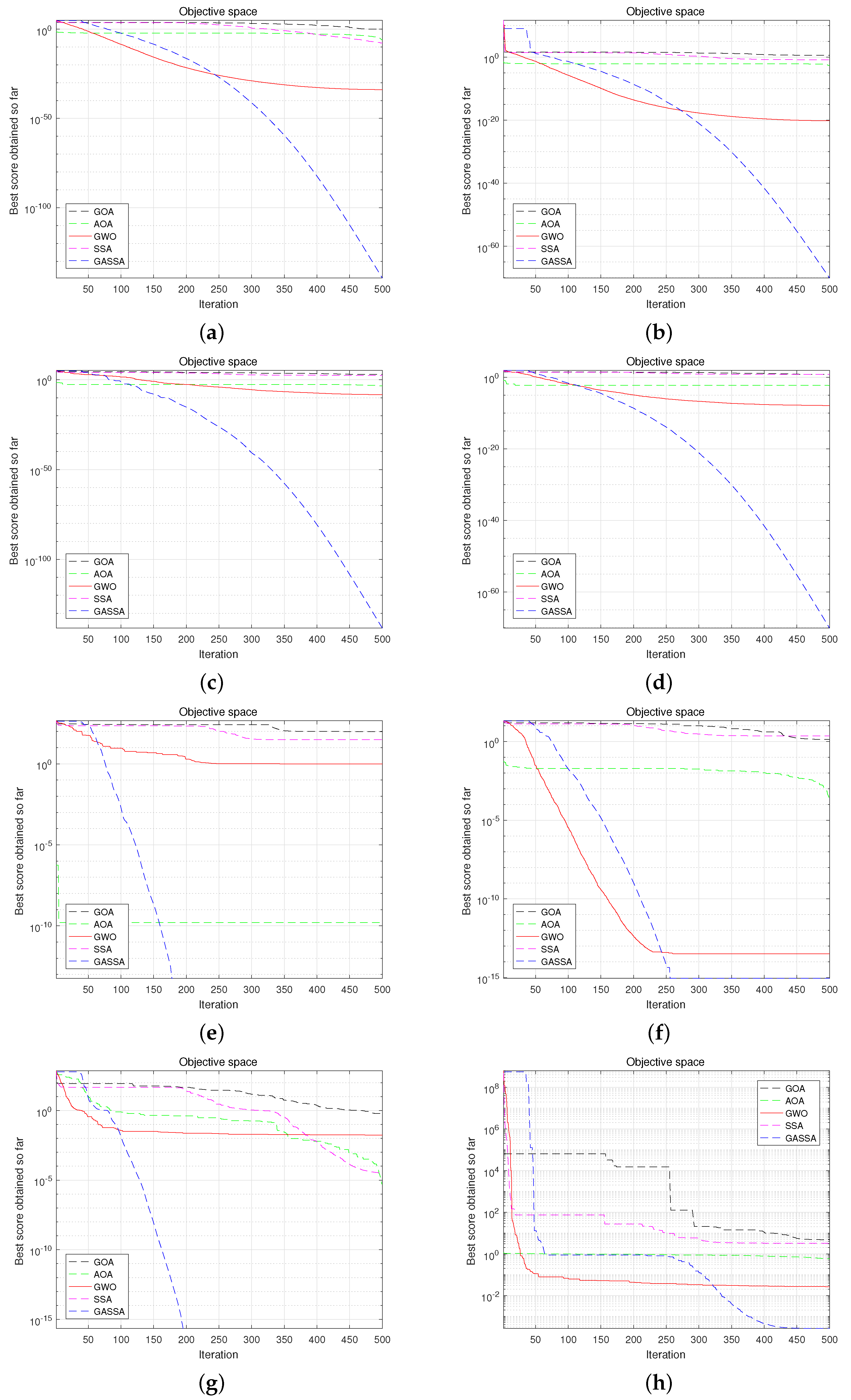

4.1. Evaluation of ISSA on Benchmark Functions

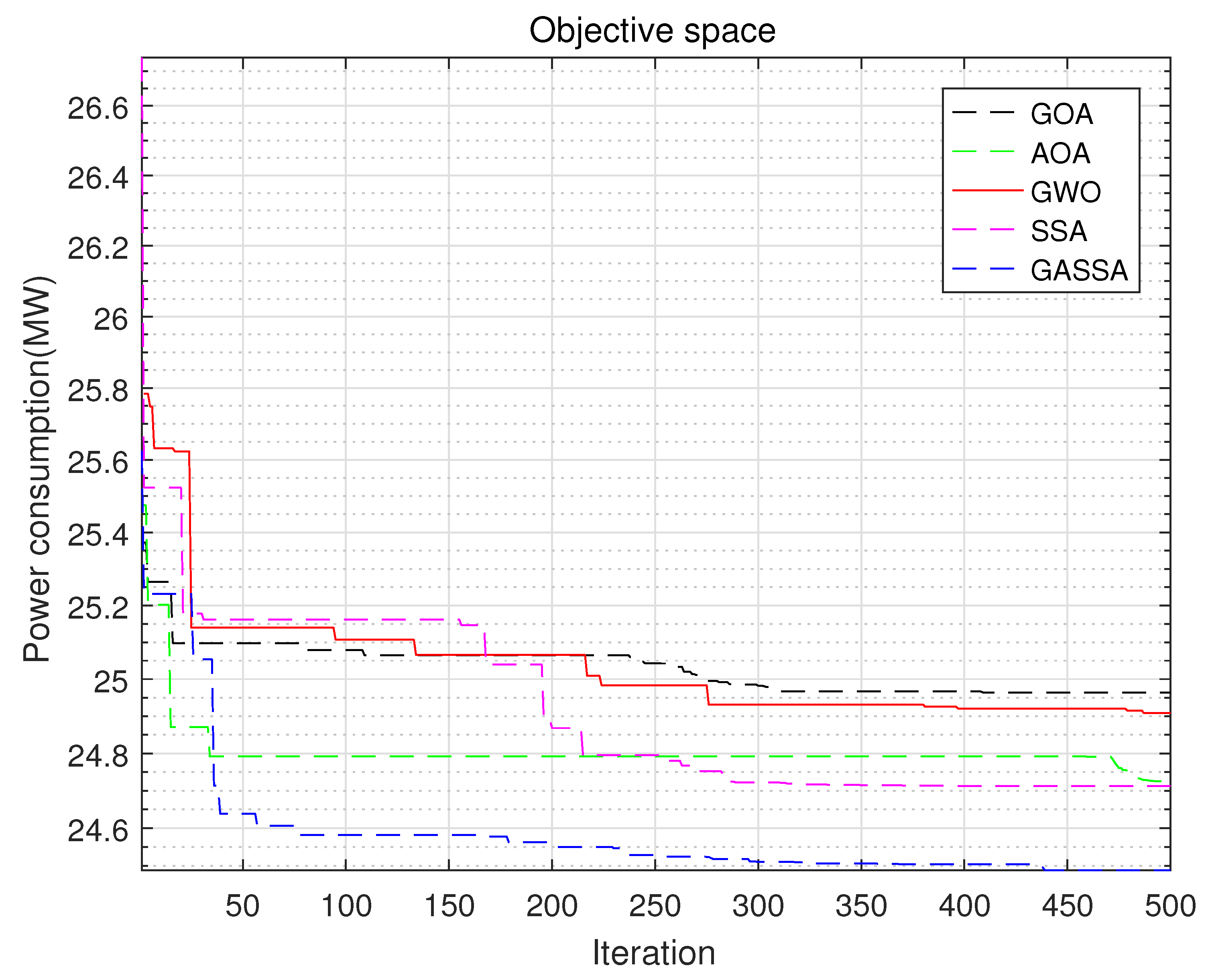

4.2. Evaluation of ISSA on Load-Sharing Optimization

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lu, S.; Fang, M.; Wang, Q.; Huang, L.; Sun, W.; Zhang, Y.; Li, Q.; Zhang, X. Public Acceptance Investigation for 2 Million Tons/Year Flue Gas CO2 Capture, Transportation and Oil Displacement Storage Project. Int. J. Greenh. Gas Control. 2021, 111, 103442. [Google Scholar] [CrossRef]

- Arya, A.K.; Honwad, S. Modeling, Simulation, and Optimization of a High-Pressure Cross-Country Natural Gas Pipeline: Application of an Ant Colony Optimization Technique. J. Pipeline Syst. Eng. Pract. 2016, 7, 04015008. [Google Scholar] [CrossRef]

- Wang, B.; Liang, Y.; Yuan, M. Water Transport System Optimisation in Oilfields: Environmental and Economic Benefits. J. Clean. Prod. 2019, 237, 117768. [Google Scholar] [CrossRef]

- Sadeghi, Z.; Horry, H.R.; Khazaee, S. An Economic Evaluation of Iranian Natural Gas Export to Europe through Proposed Pipelines. Energy Strategy Rev. 2017, 18, 1–17. [Google Scholar] [CrossRef]

- Vahdati, N.; Wang, X.; Shiryayev, O.; Rostron, P.; Yap, F.F. External Corrosion Detection of Oil Pipelines Using Fiber Optics. Sensors 2020, 20, 684. [Google Scholar] [CrossRef] [Green Version]

- Lu, H.; Ma, X.; Azimi, M. US Natural Gas Consumption Prediction Using an Improved Kernel-Based Nonlinear Extension of the Arps Decline Model. Energy 2020, 194, 116905. [Google Scholar] [CrossRef]

- Bagheri, M.; Sari, A. Study of Natural Gas Emission from a Hole on Underground Pipelines Using Optimal Design-Based CFD Simulations: Developing Comprehensive Soil Classified Leakage Models. J. Nat. Gas Sci. Eng. 2022, 102, 104583. [Google Scholar] [CrossRef]

- Su, Z.; Liu, E.; Xu, Y.; Xie, P.; Shang, C.; Zhu, Q. Flow Field and Noise Characteristics of Manifold in Natural Gas Transportation Station. Oil Gas Sci. Technol.—Revue d’IFP Energies Nouv. 2019, 74, 70. [Google Scholar]

- Liu, K.; Biegler, L.T.; Zhang, B.; Chen, Q. Dynamic Optimization of Natural Gas Pipeline Networks with Demand and Composition Uncertainty. Chem. Eng. Sci. 2020, 215, 115449. [Google Scholar] [CrossRef]

- Liu, E.; Lv, L.; Ma, Q.; Kuang, J.; Zhang, L. Steady-State Optimization Operation of the West–East Gas Pipeline. Adv. Mech. Eng. 2019, 11, 1687814018821746. [Google Scholar] [CrossRef] [Green Version]

- Kumar, S.; Cortinovis, A. Load Sharing Optimization for Parallel and Serial Compressor Stations. In Proceedings of the 2017 IEEE Conference on Control Technology and Applications (CCTA), Maui, HI, USA, 27–30 August 2017; pp. 499–504. [Google Scholar]

- Deng, T. Minimization of Power Usage in a Compressor Station with Multiple Compressors. J. Energy Eng. 2016, 142, 04015048. [Google Scholar] [CrossRef]

- Wu, S.; Ríos-Mercado, R.Z.; Boyd, E.A.; Scott, L.R. Model Relaxations for the Fuel Cost Minimization of Steady-State Gas Pipeline Networks. Math. Comput. Model. 2000, 31, 197–220. [Google Scholar] [CrossRef]

- Milosavljevic, P.; Marchetti, A.G.; Cortinovis, A.; Faulwasser, T.; Mercangöz, M.; Bonvin, D. Real-Time Optimization of Load Sharing for Gas Compressors in the Presence of Uncertainty. Appl. Energy 2020, 272, 114883. [Google Scholar] [CrossRef]

- Cortinovis, A.; Mercangöz, M.; Zovadelli, M.; Pareschi, D.; De Marco, A.; Bittanti, S. Online Performance Tracking and Load Sharing Optimization for Parallel Operation of Gas Compressors. Comput. Chem. Eng. 2016, 88, 145–156. [Google Scholar] [CrossRef]

- Zapukhliak, V.; Poberezhny, L.; Maruschak, P.; Grudz, V., Jr.; Stasiuk, R.; Brezinová, J.; Guzanová, A. Mathematical Modeling of Unsteady Gas Transmission System Operating Conditions under Insufficient Loading. Energies 2019, 12, 1325. [Google Scholar] [CrossRef] [Green Version]

- Liu, E.; Lv, L.; Yi, Y.; Xie, P. Research on the Steady Operation Optimization Model of Natural Gas Pipeline Considering the Combined Operation of Air Coolers and Compressors. IEEE Access 2019, 7, 83251–83265. [Google Scholar] [CrossRef]

- Rodrigues, L.R. A Hybrid Multi-Population Metaheuristic Applied to Load-Sharing Optimization of Gas Compressor Stations. Computers Electr. Eng. 2022, 97, 107632. [Google Scholar] [CrossRef]

- Li, X.; Cui, T.; Huang, K.; Ma, X. Optimization of Load Sharing for Parallel Compressors Using a Novel Hybrid Intelligent Algorithm. Energy Sci. Eng. 2021, 9, 330–342. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A Bio-Inspired Optimizer for Engineering Design Problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Pavan Kumar Neeli, V.S.R.; Salma, U. Automatic Generation Control for Autonomous Hybrid Power System Using Single and Multi-objective Salp Swarm Algorithm. In Proceedings of the Intelligent Computing, Information and Control Systems, Madurai, India, 15–17 May 2019; Springer: Cham, Switzerland, 2020; pp. 624–636. [Google Scholar]

- Yang, B.; Zhong, L.; Zhang, X.; Shu, H.; Yu, T.; Li, H.; Jiang, L.; Sun, L. Novel Bio-Inspired Memetic Salp Swarm Algorithm and Application to MPPT for PV Systems Considering Partial Shading Condition. J. Clean. Prod. 2019, 215, 1203–1222. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Luo, X. Parameter Estimation for Soil Water Retention Curve Using the Salp Swarm Algorithm. Water 2018, 10, 815. [Google Scholar] [CrossRef] [Green Version]

- Mahmoudimehr, J.; Sanaye, S. Minimization of Fuel Consumption of Natural Gas Compressor Stations with Similar and Dissimilar Turbo-Compressor Units. J. Energy Eng. 2014, 140, 04013001. [Google Scholar] [CrossRef] [Green Version]

- Liu, E.; Li, C.; Yang, Y. Optimal Energy Consumption Analysis of Natural Gas Pipeline. Sci. World J. 2014, 2014, e506138. [Google Scholar] [CrossRef] [PubMed]

- Borraz-Sánchez, C.; Haugland, D. Minimizing Fuel Cost in Gas Transmission Networks by Dynamic Programming and Adaptive Discretization. Comput. Ind. Eng. 2011, 61, 364–372. [Google Scholar] [CrossRef]

- Paparella, F.; Domínguez, L.; Cortinovis, A.; Mercangöz, M.; Pareschi, D.; Bittanti, S. Load Sharing Optimization of Parallel Compressors. In Proceedings of the 2013 European Control Conference (ECC), Zurich, Switzerland, 17–19 July 2013; pp. 4059–4064. [Google Scholar]

- Borraz-Sánchez, C.; Ríos-Mercado, R.Z. Improving the Operation of Pipeline Systems on Cyclic Structures by Tabu Search. Comput. Chem. Eng. 2009, 33, 58–64. [Google Scholar] [CrossRef]

- Chen, Q.; Shen, Z.; Chen, Z. A Penalty Function Semi-Continuous Thresholding Methods for Constraints of Hashing Problems. J. Vis. Commun. Image Represent. 2022, 87, 103552. [Google Scholar] [CrossRef]

- Toragay, O.; Silva, D.F.; Vinel, A.; Shamsaei, N. Exact Global Optimization of Frame Structures for Additive Manufacturing. Struct. Multidiscip. Optim. 2022, 65, 97. [Google Scholar] [CrossRef]

- Ni, S.; Chen, W.; Ju, H.; Chen, T. Coordinated Trajectory Planning of a Dual-Arm Space Robot with Multiple Avoidance Constraints. Acta Astronaut. 2022, 195, 379–391. [Google Scholar] [CrossRef]

- Arora, S.; Singh, S. Butterfly Optimization Algorithm: A Novel Approach for Global Optimization. Soft Comput. 2019, 23, 715–734. [Google Scholar] [CrossRef]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef] [Green Version]

- Saremi, S.; Mirjalili, S.; Lewis, A. Grasshopper Optimisation Algorithm: Theory and Application. Adv. Eng. Softw. 2017, 105, 30–47. [Google Scholar] [CrossRef] [Green Version]

- Abualigah, L.; Diabat, A.; Mirjalili, S.; Abd Elaziz, M.; Gandomi, A.H. The Arithmetic Optimization Algorithm. Comput. Methods Appl. Mech. Eng. 2021, 376, 113609. [Google Scholar] [CrossRef]

| Funtion | Dim | Domain | Optimum Value |

|---|---|---|---|

| 30 | [−100,100] | 0 | |

| 30 | [−10,10] | 0 | |

| 30 | [−100,100] | 0 | |

| 30 | [−100,100] | 0 | |

| 30 | [−5.12,5.12] | 0 | |

| 30 | [−32,32] | 0 | |

| 30 | [−600,600] | 0 | |

| 30 | [−50,50] | 0 |

| Funtion | Criteria | GOA | AOA | GWO | SSA | GASSA |

|---|---|---|---|---|---|---|

| Best Worst Mean Std | 6.3653 0.3697 1.8666 1.306 | 2.61E-06 3.48E-08 1.33E-06 5.76E-07 | 1.81E-34 6.71E-37 3.01E-35 5.00E-35 | 2.28E-08 8.81E-09 1.62E-08 3.88E-09 | 6.95E-140 2.37E-140 4.81E-140 1.28E-140 | |

| Best Worst Mean Std | 7.8752 0.5053 2.9865 1.6878 | 0.0037 9.29E-13 4.54E-04 8.75E-04 | 8.05E-21 8.01E-22 4.02E-21 1.94E-21 | 2.7071 0.0024 0.6907 0.7423 | 1.14E-70 7.40E-71 9.17E-71 1.10E-71 | |

| Best Worst Mean Std | 2.22E+03 477.663 1.08E+03 579.2324 | 0.0015 1.42E-05 3.47E-04 3.15E-04 | 7.26E-09 3.56E-12 9.72E-10 1.63E-09 | 874.2436 75.0897 339.2362 210.5062 | 1.73E-138 7.45E-140 7.73E-139 5.77E-139 | |

| Best Worst Mean Std | 12.7393 3.8623 7.8885 2.6074 | 0.0355 5.31E-04 0.0092 0.0086 | 3.52E-08 5.03E-10 7.49E-09 8.37E-09 | 10.2434 0.9004 5.4139 2.7326 | 1.24E-70 7.44E-71 9.38E-71 1.20E-71 | |

| Best Worst Mean Std | 108.56 36.8248 65.2024 22.2072 | 1.26E-06 0 3.95E-07 4.48E-07 | 7.867 0 1.6685 2.7474 | 71.6369 17.9093 40.6606 13.4296 | 0 0 0 0 | |

| Best Worst Mean Std | 4.3593 1.9727 2.968 0.7744 | 4.05E-04 3.63E-06 2.39E-04 1.04E-04 | 5.06E-14 2.93E-14 3.78E-14 4.72E-15 | 3.28E+00 3.48E-05 1.8597 0.6383 | 8.88E-16 8.88E-16 8.88E-16 0 | |

| Best Worst Mean Std | 0.7141 0.2833 0.5249 0.1303 | 0.0197 3.45E-06 6.64E-04 0.0036 | 0.0338 0 0.0071 0.0102 | 0.032 1.92E-06 0.0103 0.0099 | 0 0 0 0 | |

| Best Worst Mean Std | 11.5914 2.7514 5.8342 2.9491 | 0.6629 0.5459 0.6058 0.0289 | 0.0458 0.0058 0.0196 0.0109 | 10.1161 1.2637 4.6115 1.8673 | 0.0252 1.2706e-05 0.0042 0.0071 |

| Function | GOA | AOA | GWO | SSA | GASSA |

|---|---|---|---|---|---|

| 269.278 | 0.7114 | 1.0598 | 0.6286 | 0.7394 | |

| 250.785 | 0.7466 | 1.0821 | 0.6239 | 0.7458 | |

| 261.153 | 2.1571 | 2.4746 | 2.0541 | 2.2215 | |

| 243.992 | 0.8495 | 1.1084 | 0.6534 | 0.7567 | |

| 212.327 | 0.7871 | 1.1723 | 0.6936 | 1.5918 | |

| 235.341 | 0.8496 | 1.2113 | 0.7198 | 1.6647 | |

| 240.101 | 0.9282 | 1.3054 | 0.8385 | 1.8246 | |

| 259.278 | 1.4948 | 1.8724 | 1.3668 | 3.1296 |

| Parameters | Value |

|---|---|

| Suction pressure () | 3.3 |

| Suction temperature () | 293.15 |

| Gas constant () | 518.75 |

| Total volume flow rate () | 15 |

| Compressor ratio | 1.5 |

| Parameter | A-Type | B-Type | C-Type | D-Type |

|---|---|---|---|---|

| 0.835 | 0.918 | 0.572 | 0.547 | |

| 1.01E-05 | 1.30E-05 | 6.9E-06 | 2.62E-05 | |

| 6.29E-08 | 3.87E-08 | 9.93E-08 | 5.18E-08 | |

| 0.226 | 0.226 | 0.834 | −0.0177 | |

| 0.000644 | 0.000644 | 0.000417 | 0.00099 | |

| 5.09E08 | 5.09E-08 | 1.00E-07 | 2.56E-08 | |

| 0.00215 | 0.00198 | 0.0034 | 0.001923 | |

| 0.515 | 0.515 | 0.488 | 2.72 | |

| −1564 | −1564 | −1481 | −2174 | |

| 0.607 | 0.636 | 0.528 | 0.405 | |

| 877 | 751 | 921 | 1252 | |

| −700,000 | −614,000 | −650,000 | −844,000 | |

| 3965 | 3965 | 3120 | 3380 | |

| 6405 | 6405 | 5040 | 5460 |

| Power Consumption (MW) | GOA | AOA | GWO | SSA | GASSA |

|---|---|---|---|---|---|

| Best | 24.5371 | 24.5132 | 24.5192 | 24.5069 | 24.4878 |

| Worst | 25.1881 | 25.1184 | 25.1748 | 25.0106 | 24.782 |

| Mean | 24.8105 | 24.8043 | 24.7988 | 24.6998 | 24.6022 |

| Std | 0.1822 | 0.1561 | 0.1446 | 0.1322 | 0.0668 |

| Algorithm | NO.1 | NO.2 | NO.3 | NO.4 | NO.5 | NO.6 |

|---|---|---|---|---|---|---|

| GOA | 3.6630 | 3.4148 | 3.7158 | 4.2065 | 0 | 0 |

| AOA | 3.9099 | 3.8071 | 3.7392 | 3.5437 | 0 | 0 |

| GWO | 3.7975 | 3.3440 | 4.0933 | 0 | 0 | 3.7652 |

| SSA | 3.5098 | 0 | 4.0020 | 3.9907 | 0 | 3.4975 |

| GASSA | 3.8135 | 3.7715 | 3.8502 | 0 | 0 | 3.5647 |

| Computation Time | GOA | AOA | GWO | SSA | GASSA |

|---|---|---|---|---|---|

| Average value | 43.6421 | 0.6173 | 0.5883 | 0.6038 | 0.6209 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, L.; Zhang, Q.; Wu, Y. Optimization of Load Sharing in Compressor Station Based on Improved Salp Swarm Algorithm. Energies 2022, 15, 5720. https://doi.org/10.3390/en15155720

Zhang J, Li L, Zhang Q, Wu Y. Optimization of Load Sharing in Compressor Station Based on Improved Salp Swarm Algorithm. Energies. 2022; 15(15):5720. https://doi.org/10.3390/en15155720

Chicago/Turabian StyleZhang, Jiawei, Lin Li, Qizhi Zhang, and Yanbin Wu. 2022. "Optimization of Load Sharing in Compressor Station Based on Improved Salp Swarm Algorithm" Energies 15, no. 15: 5720. https://doi.org/10.3390/en15155720

APA StyleZhang, J., Li, L., Zhang, Q., & Wu, Y. (2022). Optimization of Load Sharing in Compressor Station Based on Improved Salp Swarm Algorithm. Energies, 15(15), 5720. https://doi.org/10.3390/en15155720