Laboratory Evaluation of the Plugging Performance of an Inorganic Profile Control Agent for Thermal Oil Recovery

Abstract

:1. Introduction

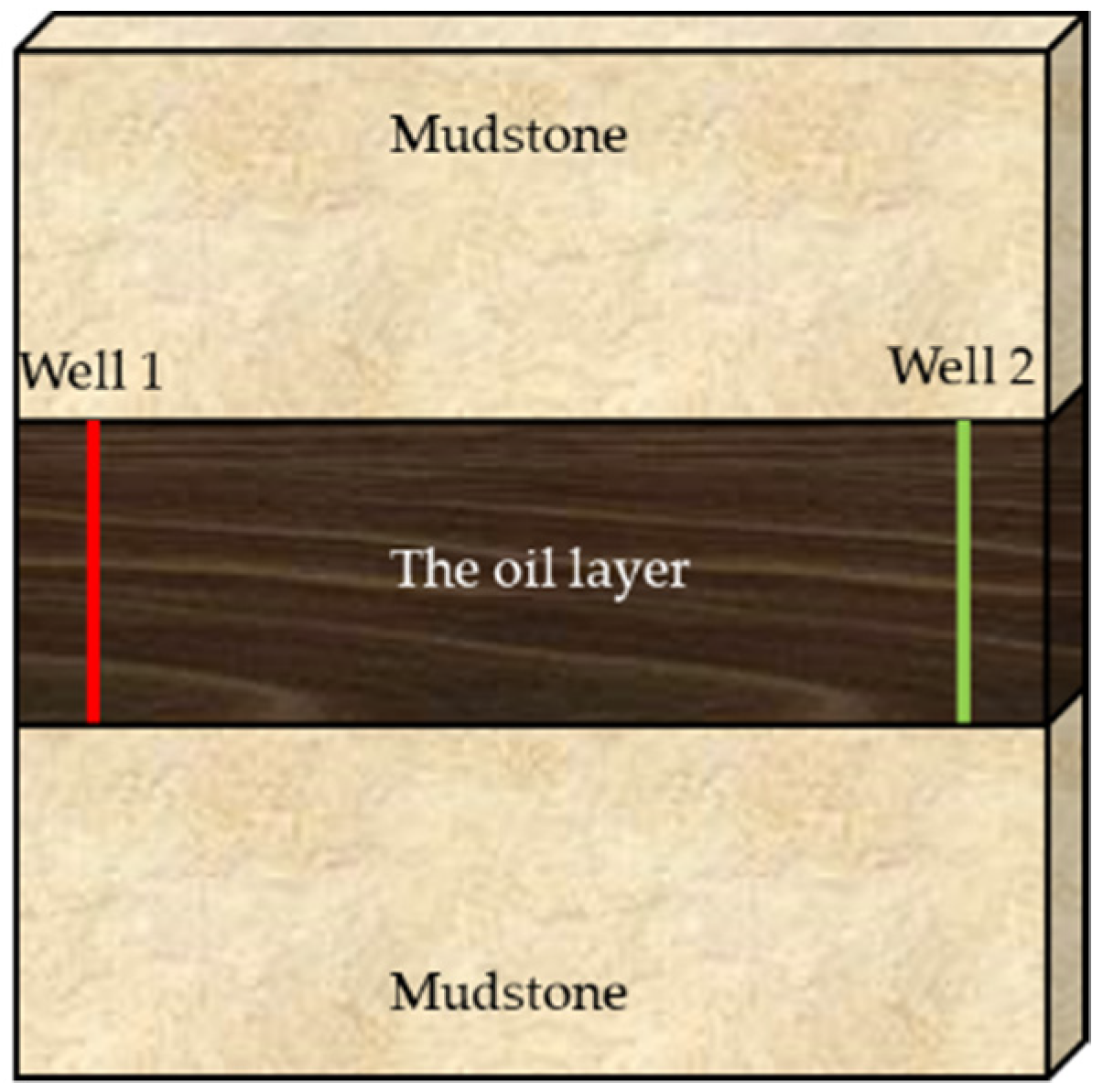

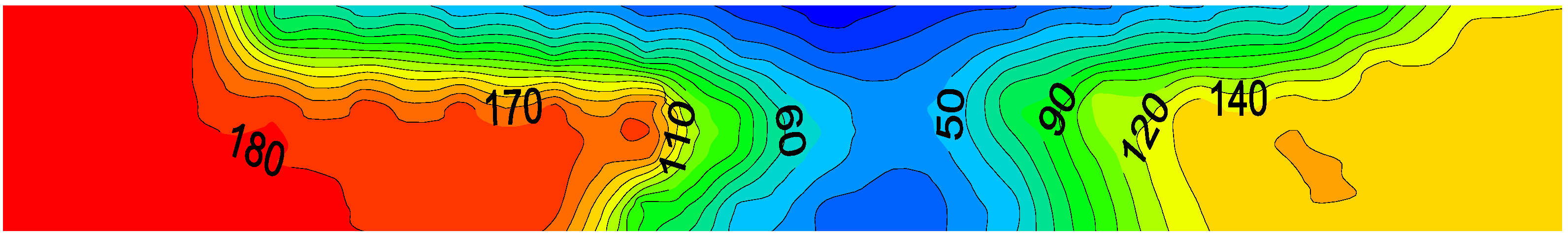

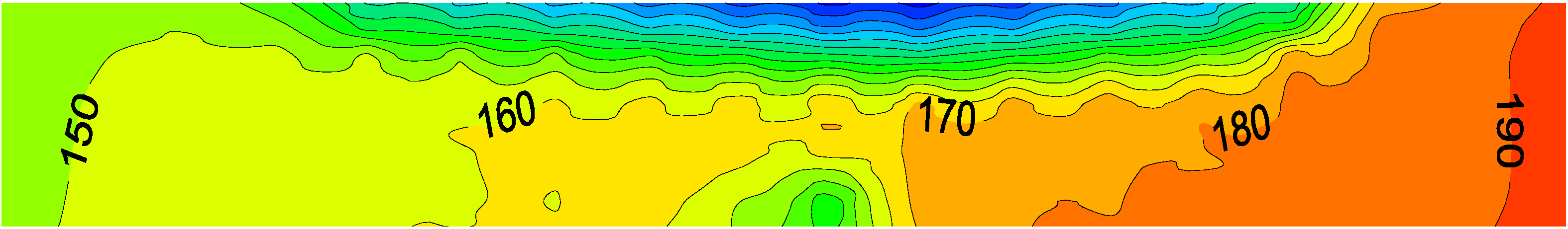

2. Characteristics of Steam Channeling between Two Wells

3. Experimental Section

3.1. Material

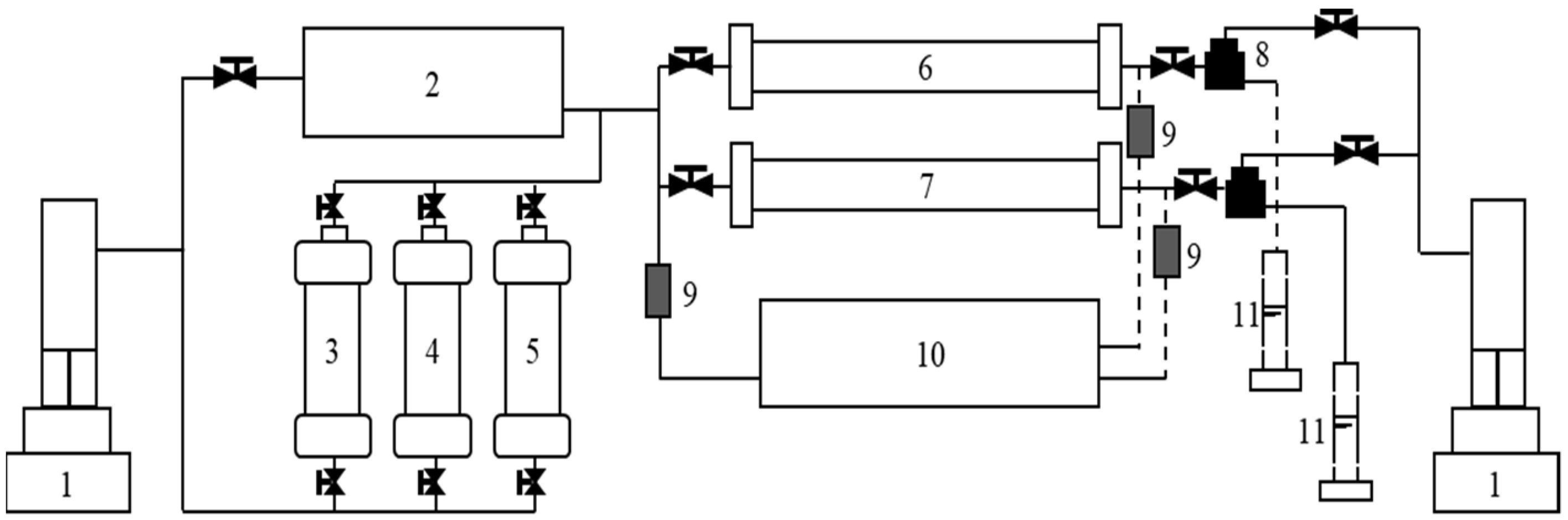

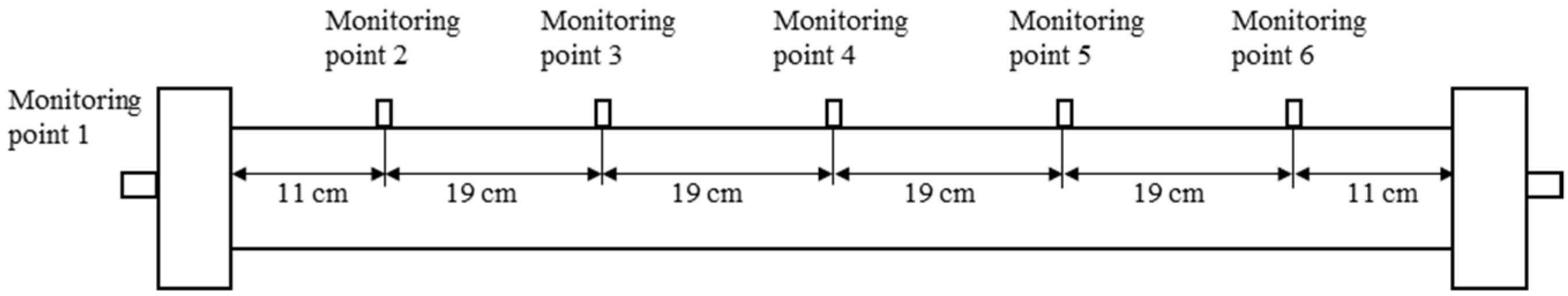

3.2. Experimental Setup

3.3. Experimental Procedure

- Suspension stability and consolidation strength test

- Plugging experiment

- Oil displacement experiment

4. Experiment Results

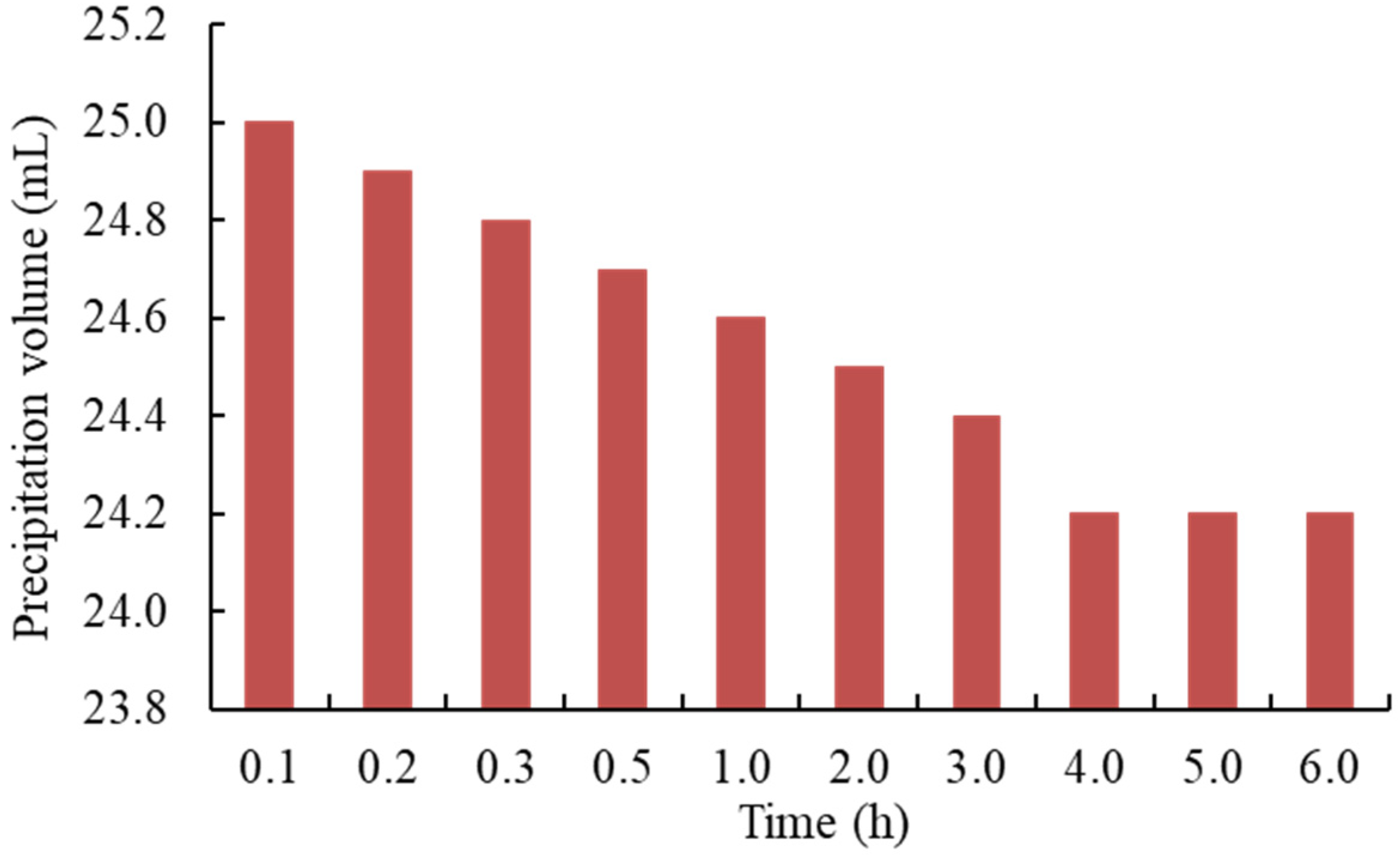

4.1. Stability Evaluation

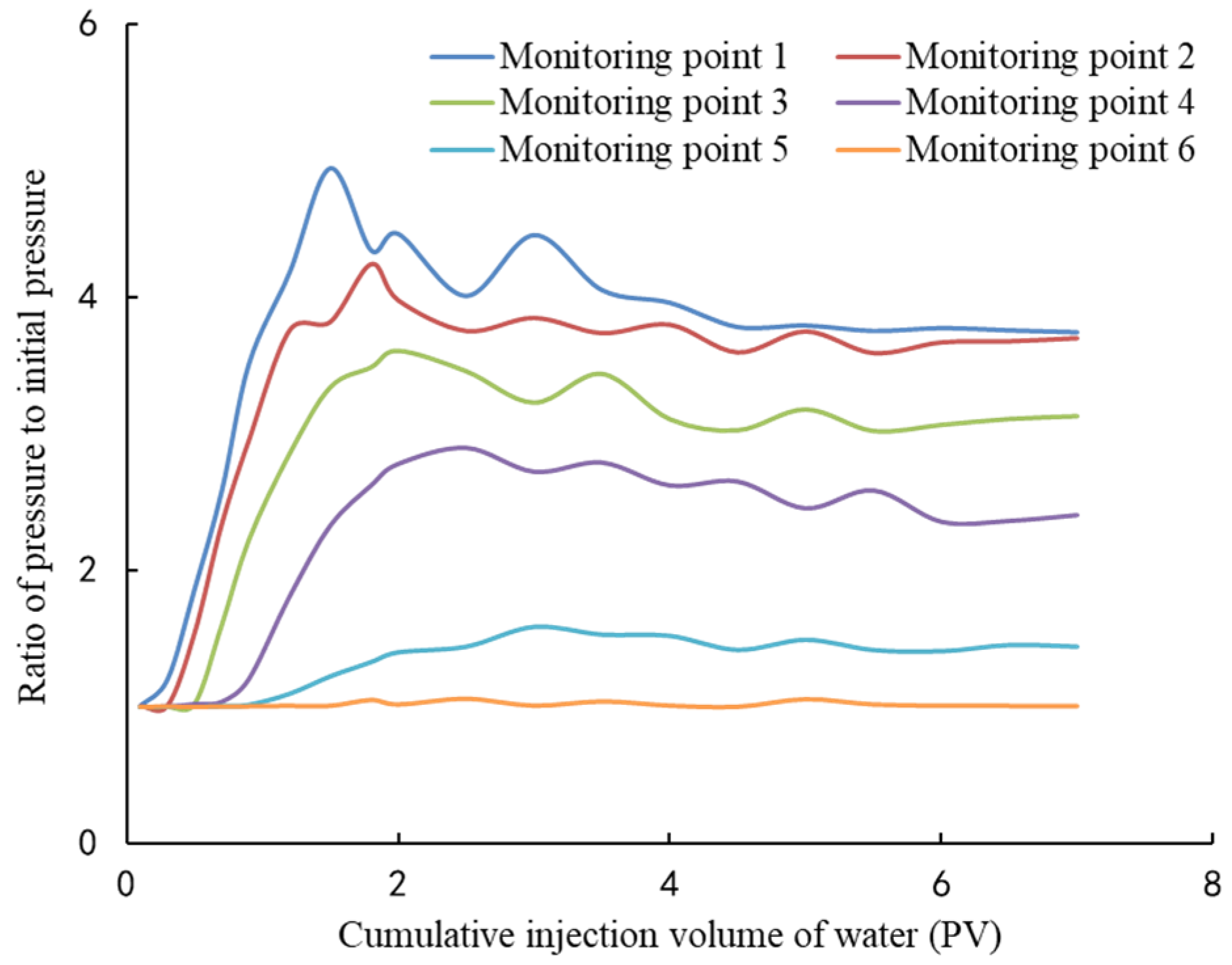

4.2. Plugging Evaluation

4.3. Selective Plugging in Porous Media

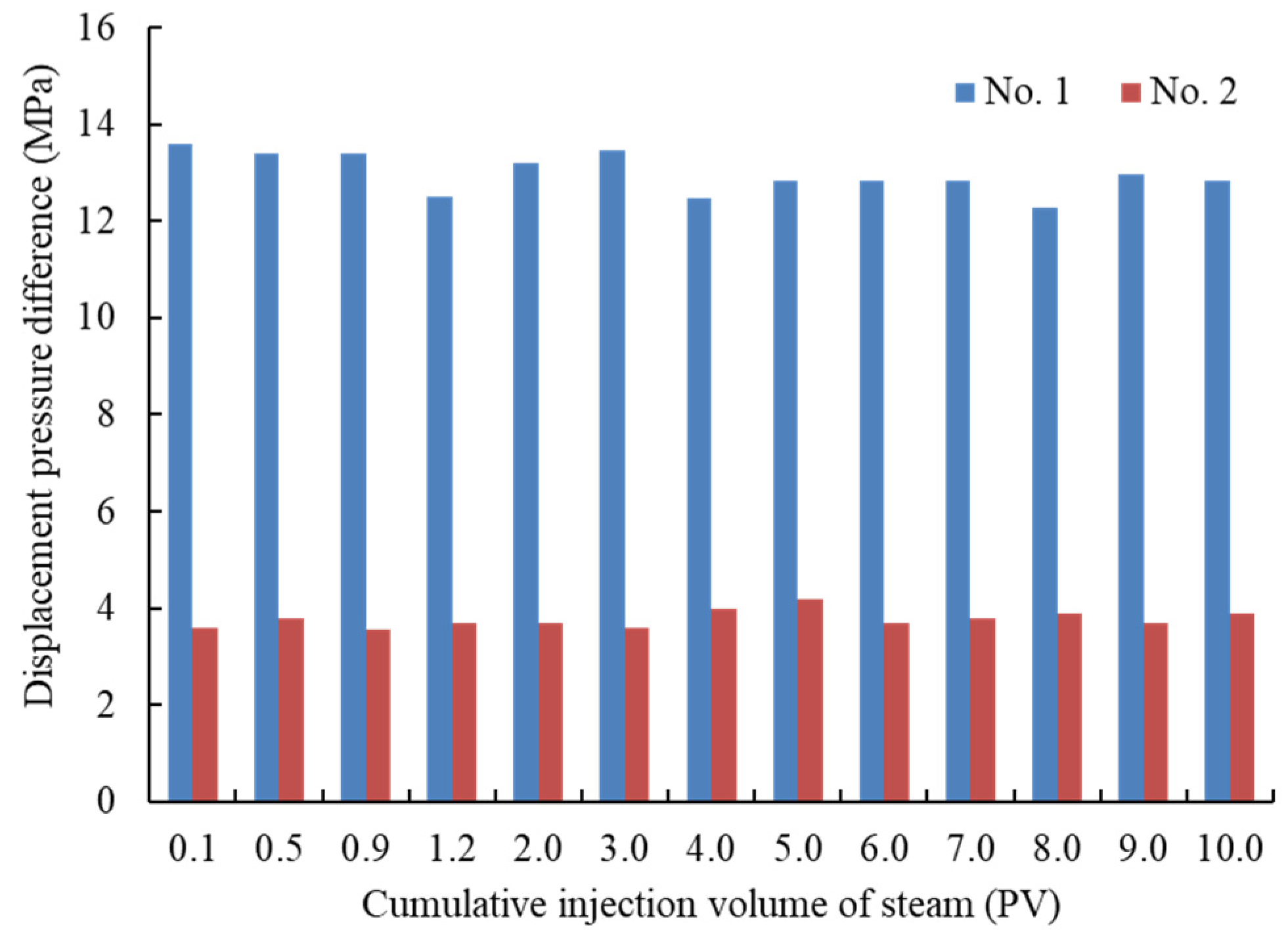

4.4. The Displacement Effect

5. Conclusions

- (1)

- The inorganic particle plugging agent made from the fly ash had a good suspension stability and consolidation strength. The water extraction rate was 3.2%, the consolidation time was 12 h, and the consolidation strength was rigid. It met the requirements for plugging large pores.

- (2)

- The inorganic particle plugging agent made from the fly ash had a good injection performance and plugging effect. The plugging depth was longer in the high-permeability formation, the plugging rate was greater than 99%, and the scour resistance was strong. It had the characteristic of “plugging larger pores but not plugging small” and showed little damage to the low permeability formation.

- (3)

- The inorganic particle plugging agent made from the fly ash could effectively plug the steam breakthrough channels, which could improve the steam injection profile and the thermal recovery of the heavy oil reservoir.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Im, S.I.; Shin, S.; Park, J.W.; Yoon, H.J.; Go, K.S.; Nho, N.S.; Lee, K.B. Selective separation of solvent from deasphalted oil using CO2 for heavy oil upgrading process based on solvent deasphalting. Chem. Eng. J. 2018, 331, 389–394. [Google Scholar] [CrossRef]

- Dong, X.; Liu, H.; Chen, Z.; Wu, K.; Lu, N.; Zhang, Q. Enhanced oil recovery techniques for heavy oil and oilsands reservoirs after steam injection. Appl. Energy 2019, 239, 1190–1211. [Google Scholar] [CrossRef]

- Guo, K.; Li, H.; Yu, Z. In-situ heavy and extra-heavy oil recovery: A review. Fuel 2016, 185, 886–902. [Google Scholar] [CrossRef]

- Zhao, S.; Pu, W.-F.; Su, L.; Shang, C.; Song, Y.; Li, W.; Het, H.-Z.; Liu, Y.-G.; Liu, Z.-Z. Properties, combustion behavior, and kinetic triplets of coke produced by low-temperature oxidation and pyrolysis: Implications for heavy oil in-situ combustion. Pet. Sci. 2021, 18, 1483–1491. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zheng, A.; Sun, X.; Dong, X.; Li, D.; Zhang, Q. Experimental investigation on improving steam sweep efficiency by novel particles in heavy oil reservoirs. J. Pet. Sci. Eng. 2020, 193, 107429. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, W.; Zhang, X.; Long, G.; Fan, J.; Chen, H.; Deng, L. A novel fractal solution for permeability and Kozeny-Carman constant of fibrous porous media made up of solid particles and porous fibers. Powder Technol. 2019, 349, 92–98. [Google Scholar] [CrossRef]

- Liang, M.; Fu, C.; Xiao, B.; Luo, L.; Wang, Z. A fractal study for the effective electrolyte diffusion through charged porous media. Int. J. Heat Mass Transf. 2019, 137, 365–371. [Google Scholar] [CrossRef]

- Li, X.; Yue, X.; Yue, T.; Yan, R.; Olaleye, O.E.; Shao, M. Novel chemical flood combination of CSA particles and strong emulsifying surfactant in heterogeneous reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126838. [Google Scholar] [CrossRef]

- Hu, L.Z.; Sun, L.; Zhao, J.Z.; Wei, P.; Pu, W.F. Influence of formation heterogeneity on foam flooding performance using 2D and 3D models: An experimental study. Pet. Sci. 2020, 17, 734–748. [Google Scholar] [CrossRef] [Green Version]

- Liu, D.; Shi, X.; Zhong, X.; Zhao, H.; Pei, C.; Zhu, T.; Zhang, F.; Shao, M.; Huo, G. Properties and plugging behaviors of smectite-superfine cement dispersion using as water shutoff in heavy oil reservoir. Appl. Clay Sci. 2017, 147, 160–167. [Google Scholar] [CrossRef]

- AlSofi, A.M.; Blunt, M.J. Polymer flooding design and optimization under economic uncertainty. J. Pet. Sci. Eng. 2014, 124, 46–59. [Google Scholar] [CrossRef]

- Eftekhari, A.A.; Krastev, R.; Farajzadeh, R. Foam stabilized by fly-ash nanoparticles for enhancing oil recovery. In Proceedings of the SPE Kuwait Oil and Gas Show and Conference, Mishref, Kuwait, 11–14 October 2015. SPE-175382-MS. [Google Scholar] [CrossRef]

- Seright, R.; Brattekas, B. Water shutoff and conformance improvement: An introduction. Pet. Sci. 2021, 18, 450–478. [Google Scholar] [CrossRef]

- Zhao, G.; Dai, C.; Chen, A.; Yan, Z.; Zhao, M. Experimental study and application of gels formed by nonionic polyacrylamide and phenolic resin for in-depth profile control. J. Pet. Sci. Eng. 2015, 135, 552–560. [Google Scholar] [CrossRef]

- Assi, L.N.; Deaver, E.; Elbatanouny, M.K.; Ziehl, P. Investigation of early compressive strength of fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 807–815. [Google Scholar] [CrossRef] [Green Version]

- Naghizadeh, A.; Ekolu, S.O. Method for comprehensive mix design of fly ash geopolymer mortars. Constr. Build. Mater. 2019, 202, 704–717. [Google Scholar] [CrossRef]

- You, Q.; Wang, H.; Dai, C.L.; Liu, Y.; Fang, J.; Zhao, G.; Zhao, M.; Wang, K. Case study on in-depth blocking for thermal recovery by steam stimulation in heavy oil reservoirs. SPE 2015, 174596, 360–376. [Google Scholar] [CrossRef]

- Akbari, S.; Taghavi, S.M. Fluid experiments on the dump bailing method in the plug and abandonment of oil and gas wells. J. Pet. Sci. Eng. 2021, 205, 108920. [Google Scholar] [CrossRef]

- Raffa, P.; Broekhuis, A.A.; Picchioni, F. Polymeric surfactants for enhanced oil recovery: A review. J. Pet. Sci. Eng. 2016, 145, 723–733. [Google Scholar] [CrossRef] [Green Version]

- Grant Norton, M.; Provis, J.L. 1000 at 1000: Geopolymer technology—The Current State of the Art. J. Mater. Sci. 2020, 55, 13487–13489. [Google Scholar] [CrossRef]

- Yao, X.; Yang, T.; Zhang, Z. Fly ash-based geopolymers: Effect of slag addition on efflorescence. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2016, 31, 689–694. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; Van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Pan, J.; Deng, W.; Wang, Z. Studies and application of slag-blocking agent for steam-injection reservoir. SPE 2006, 104426, 1036–1041. [Google Scholar] [CrossRef]

| SiO2(%) | Al2O3(%) | Fe2O3(%) | CaO(%) | MgO(%) | K2O(%) | Na2O(%) |

|---|---|---|---|---|---|---|

| 55.63 | 18.38 | 6.75 | 4.93 | 1.72 | 2.49 | 1.09 |

| Model Number | Diameter (cm) | Length (cm) | Pore Volume (mL) | Porosity (%) | Permeability (D) |

|---|---|---|---|---|---|

| 1 | 3.8 | 100 | 302 | 27.32 | 1.15 |

| 2 | 3.8 | 100 | 359 | 32.46 | 7.23 |

| 3 | 3.8 | 100 | 316 | 28.54 | 0.99 |

| 4 | 3.8 | 100 | 373 | 33.67 | 7.68 |

| 5 | 3.8 | 100 | 298 | 26.85 | 1.09 |

| 6 | 3.8 | 100 | 355 | 31.98 | 7.16 |

| Number | Time (h) | Appearance |

|---|---|---|

| 1 | 3 | Suspension, and high fluidity |

| 2 | 6 | Comparatively high fluidity, and beginning of consolidation |

| 3 | 8 | Medium fluidity, and unstable form |

| 4 | 10 | Stable form, and relatively high strength |

| 5 | 11 | Stable form, and high strength |

| 6 | 12 | Rigid strength, and the glass rod cannot enter |

| 7 | 13 | Rigid strength, and the glass rod cannot enter |

| Model Number | Fractional Flow Rate (%) | Pre-Plug Recovery Factor (%) | Fractional Flow Rate after Plugging (%) | Recovery Factor after Plugging (%) | Enhanced Oil Recovery (%) |

|---|---|---|---|---|---|

| 5 | 25.00 | 31.28 | 48.00 | 55.62 | 24.34 |

| 6 | 75.00 | 60.33 | 52.00 | 64.78 | 4.45 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, K.; Liu, Y.; Qi, Z.; Tian, J.; Luo, T.; Hu, S.; Li, J. Laboratory Evaluation of the Plugging Performance of an Inorganic Profile Control Agent for Thermal Oil Recovery. Energies 2022, 15, 5452. https://doi.org/10.3390/en15155452

Cheng K, Liu Y, Qi Z, Tian J, Luo T, Hu S, Li J. Laboratory Evaluation of the Plugging Performance of an Inorganic Profile Control Agent for Thermal Oil Recovery. Energies. 2022; 15(15):5452. https://doi.org/10.3390/en15155452

Chicago/Turabian StyleCheng, Keyang, Yongjian Liu, Zhilin Qi, Jie Tian, Taotao Luo, Shaobin Hu, and Jun Li. 2022. "Laboratory Evaluation of the Plugging Performance of an Inorganic Profile Control Agent for Thermal Oil Recovery" Energies 15, no. 15: 5452. https://doi.org/10.3390/en15155452

APA StyleCheng, K., Liu, Y., Qi, Z., Tian, J., Luo, T., Hu, S., & Li, J. (2022). Laboratory Evaluation of the Plugging Performance of an Inorganic Profile Control Agent for Thermal Oil Recovery. Energies, 15(15), 5452. https://doi.org/10.3390/en15155452