A New Robust Direct Torque Control Based on a Genetic Algorithm for a Doubly-Fed Induction Motor: Experimental Validation

Abstract

:1. Introduction

2. α, β Model of a DFIM

- Stator voltage components:

- Rotor voltage components:

- Stator flux components:

- Rotor flux components:

- Mechanical subsystem:

3. Direct Torque Control

3.1. Control Scheme

3.2. Block of Signal Estimation

3.3. Hysteresis Regulators

3.4. Inverters Switching Table

4. PID Optimization by GA

4.1. GA Parameters and Operators

4.1.1. Chromosome Coding

4.1.2. Assignment of the First Population

4.1.3. Learning of the Regulator Gains by the GA

4.1.4. Fitness

4.1.5. Initialization of Populations

4.1.6. Selection Operator

4.1.7. Crossover Operator

4.1.8. Mutation Operator

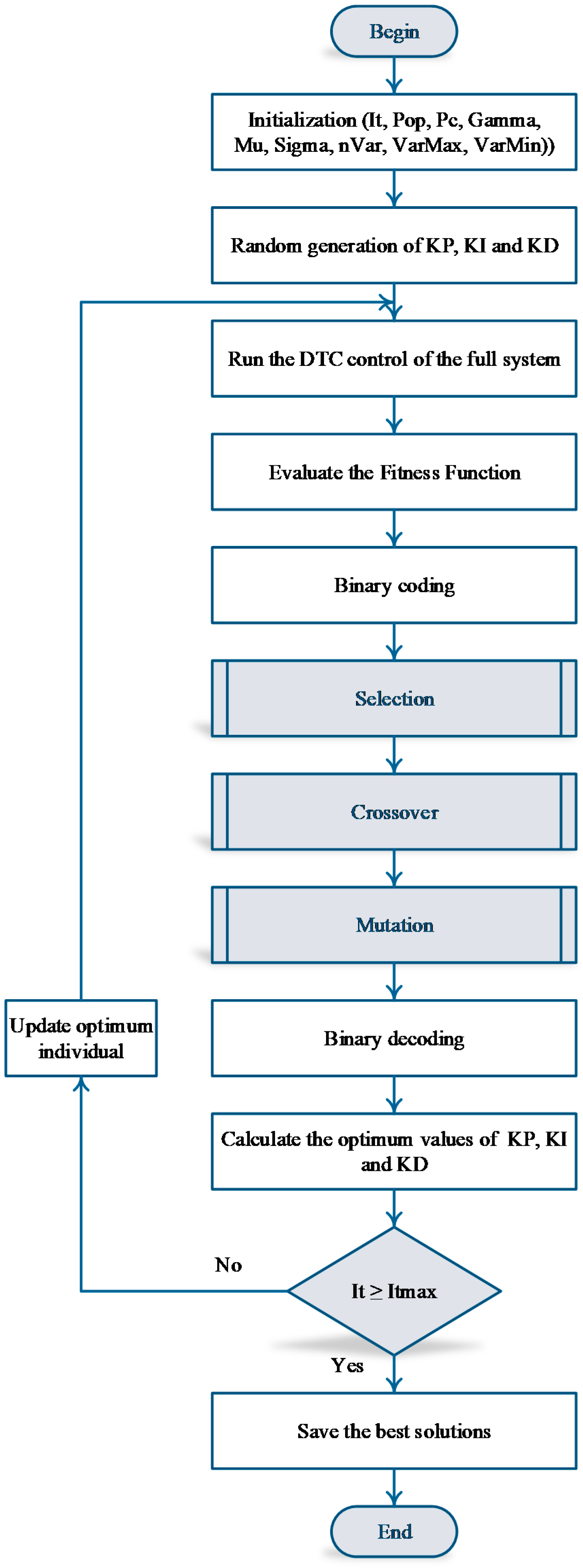

| Algorithm 1. Genetic Algorithm |

| Begin Step 1. Initialize the algorithm parameters (It, Pop, Pc, gamma, mu, sigma, nVar, VarMax, VarMin). Step 2. Randomly generate the regulator gains. Step 3. Apply the DTC control. Step 4. Evaluate the fitness function instantaneously. Step 5. Apply binary coding. Step 6. Move to the selection operation. Step 7. Move to the crossover operation. Step 8. Move to the mutation operation. Step 9. Apply binary decoding. Step 10. Update the optimal individual and repeat Step 3 until the maximum number of iterations is fulfilled. Step 11. Save the optimal solutions. End |

5. Simulation Procedure and Interpretation

5.1. Simulation Procedure

- A speed step of 157 rad/s is applied from 0.7 s to 2.35 s, and then the setpoint begins to decrease in the form of an affine function of negative slope down to −157 rad/s, which presents the opposite direction of rotation. This speed remains constant up to 4.65 s, and then the motor is stopped.

- During the speed variation, a load torque is applied to the system, which starts with a nominal load torque step of 10 Nm at 1.1–2.1 s, and then the motor remains idle until the instant 3.05–4.25 s, when a negative load torque is applied, which follows the direction of machine rotation.

- Sampling frequency: fs =10 kHz.

- Hysteresis bands widths: ΔTem = ±0.01 Nm, ΔΨs = ΔΨr = ±0.001 Nm.

5.2. Discussion and Comparison

6. Practical Validation and Interpretation

6.1. Practical Validation

- First of all, the control system is designed using the Simulink modeling program.

- It is necessary to simulate the system in order to generate several control results, in order to know the control validity.

- Generation of the .sdf file using the RTI interface.

- When the global model is run in real time, the DS1104 R&D board is used through the ControlDesk environment with a processor (MPC8240) operating at a clock frequency equal to 250 MHz. An image of the experimental setup and a diagram showing the link between the DS1104 R&D Board and the DFIM are shown in Figure 19 and Figure 20, respectively. In order to perform the experimental test, the control board and the RTW tool are used together.

6.2. Results and Interpretation

- -

- Allows an optimal reference monitoring profile.

- -

- Adaptation with a sudden change in front of a system’s internal and external disturbances.

- -

- Rapid optimization of the gains of a regulator such as the PID

- -

- Can be used as an estimator of parameters sensitive to physical variations.

- -

- Convergence of solutions towards local solutions.

- -

- Estimates of the parameters of the genetic algorithm, such as the population size and the number of iterations; requires more than two weeks to have a reduced execution time with optimal gains.

7. Conclusions

- Reducing the speed overshoot, with and without load torque.

- Reducing the disturbance rejection time by 81.07%.

- Minimizing the ripples of the stator and rotor fluxes, as well as torque ripples, with improvements of 29.71%, 24.32%, and 16.16%, respectively.

- Acceptable enhancements in the current THDs, by 60.17% and 47.82%, respectively.

- The practical validation findings obtained using ControlDesk confirmed the simulated results obtained via MATLAB/Simulink.

- Validation of ANN–DTC for DFIMs using a dSPACE board.

- Elaboration of the review of the techniques applied to DFIMs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Symbols | Values (Unit) |

|---|---|

| 1.5 Kw | |

| 400 v | |

| 130 v | |

| 2 | |

| 50 Hz | |

| 1.75 Ω | |

| 1.68 Ω | |

| 0.295 H | |

| 0.104 H | |

| 0.165 H | |

| 0.0027 kg·m2/s | |

| 0.01 kg·m2 |

| Descriptions | Types/Values |

|---|---|

| Population Size | 20 |

| Maximum Iterations | 50 |

| Crossover Probability | 0.9 |

| Mutation Probability | 0.001 |

| Beta | 1 |

| Sigma | 0.1 |

| Gamma | 0.1 |

| Coding | Binary |

| Selection | Uniform |

| Crossover | Roulette Wheel Selection |

| Mutation | Uniform |

| Parameters | Description |

|---|---|

| Vsα, Vsβ, Vrα, and Vrβ | (α, β) Components of Stator and Rotor Voltages |

| Udcs and Udcr | Stator and Rotor Direct Voltages |

| Isα, Isβ, Irα, and Irβ | (α, β) Components of Stator and Rotor Currents |

| Ψsα, Ψsβ, Ψrα, and Ψrβ | (α, β) Components of Stator and Rotor Fluxes |

| Rs, Rr | Resistances of Stator and Rotor Windings |

| Ls, Lr | Inductances of Stator and Rotor Windings |

| Lm | Magnetizing Inductance |

| p | Pole Pairs |

| ωr | Angular Rotor Speed |

| ωs | Angular Stator Frequency |

| Ω | Rotational Speed |

| Tem | Developed Torque |

| Tr | EncounteredTorque |

| f | Friction |

| J | Motor Inertia |

| Abbreviations | Wording |

|---|---|

| DFIM | Doubly-Fed Induction Motor |

| IM | Induction Machine |

| DC | Direct Current |

| THD | Total Harmonic Distortion |

| DTC | Direct Torque Control |

| GA | Genetic Algorithm |

| GA-DTC | Genetic Algorithm–Direct Torque Control |

| CLFT | Closed-Loop Function Transfer |

| PID | Proportional–Integral–Derivative |

| DTFC | Direct Torque Fuzzy Control |

| DTNC | Direct Torque Neural Control |

| DTNFC | Direct Neural Fuzzy Torque Control |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| RTI | Real-Time Interface |

| R&D | Research and Development |

| RTW | Real-Time Workbench |

| CP | Control Panel |

| PWM | Pulse-Width Modulation |

References

- Mahfoud, S.; Derouich, A.; Iqbal, A.; El Ouanjli, N. ANT-colony optimization-direct torque control for a doubly fed induction motor: An experimental validation. Energy Rep. 2022, 8, 81–98. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N.; Mohammed, T.; Hanafi, A. Field Oriented Control of Doubly Fed Induction Motor using Speed Sliding Mode Controller. In E3S Web of Conferences, Proceedings of the 3rd International Conference of Computer Science and Renewable Energies, Agadir, Morocco, 22–24 December 2020.; EDP Sciences: Les Ulis, France, 1920; Volume 220, p. 01061. [Google Scholar]

- Mossa, M.A.; Abdelhamid, M.K.; Hassan, A.A.; Bianchi, N. Improving the Dynamic Performance of a Variable Speed DFIG for Energy Conversion Purposes Using an Effective Control System. Processes 2022, 10, 456. [Google Scholar] [CrossRef]

- Mossa, M.A.; Al-Sumaiti, A.S.; Do, T.D.; Diab, A.A.Z. Cost-Effective Predictive Flux Control for a Sensorless Doubly Fed Induction Generator. IEEE Access 2019, 7, 172606–172627. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N.; Quynh, N.V.; Mossa, M.A. A New Hybrid Ant Colony Optimization Based PID of the Direct Torque Control for a Doubly Fed Induction Motor. World Electr. Veh. J. 2022, 13, 78. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; EL Ouanjli, N.; EL Mahfoud, M.; Taoussi, M. A New Strategy-Based PID Controller Optimized by Genetic Algorithm for DTC of the Doubly Fed Induction Motor. Systems 2021, 9, 37. [Google Scholar] [CrossRef]

- El Ouanjli, N.; Derouich, A.; El Ghzizal, A.; Chebabhi, A.; Taoussi, M. A comparative study between FOC and DTC control of the Doubly Fed Induction Motor (DFIM). In Proceedings of the 2017 International Conference on Electrical and Information Technologies (ICEIT), Rabat, Morocco, 15–18 November 2017; IEEE: Piscataway, NJ, USA, 1963; pp. 1–6. [Google Scholar]

- Mossa, M.A.; Bolognani, S. Effective sensorless model predictive direct torque control for a doubly fed induction machine. In Proceedings of the 2017 IEEE Nineteenth International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 19–21 December 2017; pp. 1201–1207. [Google Scholar]

- Mossa, M.A.; Mohamed, Y.S. Novel Scheme for Improving the Performance of a Wind Driven Doubly Fed Induction Generator during Grid Fault. Wind Eng. 2012, 36, 305–334. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; Ouanjli, N.E.; Taoussi, M.; Mahfoud, M.E. Improved DTC of the PID Controller by Using Genetic Algorithm of a Doubly Fed Induction Motor. In Digital Technologies and Applications, Proceedings of the Lecture Notes in Networks and Systems, Fez, Morocco, 28–30 January 2022; Motahhir, S., Bossoufi, B., Eds.; Springer: Cham, Switzerland, 2022; Volume 211, pp. 1687–1698. [Google Scholar]

- Hassan, A.; Mohamed, Y.S.; El-Sawy, A.; Mossa, M.A. Control of a Wind Driven DFIG Connected to the Grid Based on Field Orientation. Wind Eng. 2011, 35, 127–143. [Google Scholar] [CrossRef]

- Mossa, M.A.; Echeikh, H.; Iqbal, A. Enhanced control technique for a sensor-less wind driven doubly fed induction generator for energy conversion purpose. Energy Rep. 2021, 7, 5815–5833. [Google Scholar] [CrossRef]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N.; El Mahfoud, M. Enhancement of the Direct Torque Control by using Artificial Neuron Network for a Doubly Fed Induction Motor. Intell. Syst. Appl. 2022, 13, 200060. [Google Scholar] [CrossRef]

- Blaschke, F. The principle of field oriented as applied to the new transvector closed-Iloop control system for rotating machines. Siemens Rev. 1972, 139, 217–220. [Google Scholar]

- Mossa, M.A. Field Orientation Control of a Wind Driven DFIG Connected to the Grid. Wseas Trans. Power Syst. 2012, 4, 182–197. [Google Scholar]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N.; El Idrissi, A.; El Mahfoud, M. Optimized PID Controller by Ant Colony Optimization of DTC for Doubly Fed Induction Motor. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer: Cham, Switzerland; pp. 767–778. [Google Scholar]

- Mossa, M.A.; Bolognani, S. Predictive Power Control for a Linearized Doubly Fed Induction Generator Model. In Proceedings of the 2019 21st International Middle East Power Systems Conference (MEPCON), Cairo, Egypt, 17–19 December 2019; pp. 250–257. [Google Scholar]

- Mahfoud, S.; Derouich, A.; El Ouanjli, N. Performance Improvement of DTC for Doubly Fed Induction Motor by Using Artificial Neuron Network. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer: Cham, Switzerland, 2022; pp. 32–42. [Google Scholar]

- Hamidia, F.; Abbadi, A.; Skender, M.R. Pumping FOC-DFIM System Supplied with PVG and Based on FLC Type-2. In Advances in Green Energies and Materials Technology; Springer: Singapore, 2021; pp. 87–93. [Google Scholar]

- Takahashi, I.; Ohmori, Y. High-performance direct torque control of an induction motor. IEEE Trans. Ind. Appl. 1989, 25, 257–264. [Google Scholar] [CrossRef]

- Takahashi, I.; Noguchi, T. Take a look back upon the past decade of direct torque control [of induction motors]. In Proceedings of the IECON’97 23rd International Conference on Industrial Electronics, Control, and Instrumentation, New Orleans, LA, USA, 14 November 1997; Volume 2, pp. 546–551. [Google Scholar]

- Das, K.R.; Das, D.; Das, J. Optimal tuning of PID controller using GWO algorithm for speed control in DC motor. In Proceedings of the 2015 International Conference on Soft Computing Techniques and Implementations (ICSCTI), Faridabad, India, 8–10 October 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 108–112. [Google Scholar]

- Madadi, A.; Motlagh, M.M. Optimal control of DC motor using grey wolf optimizer algorithm. Tech. J. Eng. Appl. Sci. 2014, 4, 373–379. [Google Scholar]

- Kanojiya, R.G.; Meshram, P.M. Optimal tuning of PI controller for speed control of DC motor drive using particle swarm optimization. In Proceedings of the 2012 International Conference on Advances in Power Conversion and Energy Technologies (APCET), Mylavaram, Andhra Pradesh, India, 2–4 August 2012; IEEE: Piscataway, NJ, USA; pp. 1–6. [Google Scholar]

- Ayala, H.V.H.; dos Santos Coelho, L. Tuning of PID controller based on a multiobjective genetic algorithm applied to a robotic manipulator. Expert Syst. Appl. 2012, 39, 8968–8974. [Google Scholar] [CrossRef]

- Krohling, R.A.; Rey, J.P. Design of optimal disturbance rejection PID controllers using genetic algorithms. IEEE Trans. Evol. Comput. 2001, 5, 78–82. [Google Scholar] [CrossRef]

- Nagaraj, B.; Murugananth, N.A. Comparative study of PID controller tuning using GA, EP, PSO and ACO. In Proceedings of the 2010 International Conference on Communication Control And Computing Technologies, Nagercoil, India, 7–9 October 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 305–313. [Google Scholar]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT press: Cambridge, MA, USA, 1992; p. 211. [Google Scholar]

- Goldberg, D.E. Sizing populations for serial and parallel genetic algorithms. In Proceedings of the 3rd international conference on genetic algorithms, George Mason University, Fairfax, VA, USA, 4–7 June 1989; pp. 70–79. [Google Scholar]

- Reeves, C.R. Using Genetic Algorithms with Small Populations. In Proceedings of the ICGA, Champaign, IL, USA, 17–21 June 1993; Volume 590, p. 92. [Google Scholar]

- El Mahfoud, M.; Bossoufi, B.; El Ouanjli, N.; Mahfoud, S.; Taoussi, M. Three speed controllers of direct torque control for a doubly fed induction motor drive–A comparison. Electrica 2021, 21, 129–142. [Google Scholar] [CrossRef]

- El Ouanjli, N.; Mahfoud, S.; Bhaskar, M.S.; El Daoudi, S.; Derouich, A.; El Mahfoud, M. A new intelligent adaptation mechanism of MRAS based on a genetic algorithm applied to speed sensorless direct torque control for induction motor. Int. J. Dyn. Control. 2022, 1–16. [Google Scholar] [CrossRef]

- Meena, D.C.; Devanshu, A. Genetic algorithm tuned PID controller for process control. In Proceedings of the 2017 International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19–20 January 2017; pp. 1–6. [Google Scholar]

- Amirjanov, A. The parameters setting of a changing range genetic algorithm. Nat. Comput. 2015, 14, 331–338. [Google Scholar] [CrossRef]

- Mohammed, E.M.; Badre, B.; Najib, E.O.; Abdelilah, H.; Houda, E.A.; Btissam, M.; Said, M. Predictive Torque and Direct Torque Controls for Doubly Fed Induction Motor: A Comparative Study. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer: Cham, Switzerland, 2022; pp. 825–835. [Google Scholar]

- El Mahfoud, M.; Bossoufi, B.; El Ouanjli, N.; Said, M.; Taoussi, M. Improved direct torque control of doubly fed induction motor using space vector modulation. Int. J. Intell. Eng. Syst 2021, 14, 177–188. [Google Scholar] [CrossRef]

- Chlaihawi, A.A. Genetic algorithm error criteria as applied to PID controller DC-DC buck converter parameters: An investigation. In IOP Conference Series: Materials Science and Engineering, Proceedings of the 3rd International Conference on Engineering Sciences, Kerbala, Iraq, 4–6 November 2019; IOP Publishing: Bristol, UK, 2020; Volume 671, p. 012032. [Google Scholar] [CrossRef]

- Grefenstette, J.J. Optimization of control parameters for genetic algorithms. IEEE Trans. Syst. Man Cybern. 1986, 16, 122–128. [Google Scholar] [CrossRef]

- El Mahfoud, M.; Bossoufi, B.; El Ouanjli, N.; Mahfoud, S.; Yessef, M.; Taoussi, M. Speed Sensorless Direct Torque Control of Doubly Fed Induction Motor Using Model Reference Adaptive System. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer: Cham, Switzerland, 2022; pp. 1821–1830. [Google Scholar]

- Bharadwaj, C.S.; Babu, T.S.; Rajasekar, N. Tuning PID Controller for Inverted Pendulum Using Genetic Algorithm. In Advances in Systems, Control and Automation; Springer: Singapore, 2018; pp. 395–404. [Google Scholar]

- El Idrissi, A.; Derouich, A.; Mahfoud, S. Fault Diagnosis of the Bearing Outer Ring of an Induction Motor Under DTC Control by Using Hilbert Filter. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer: Cham, Switzerland, 2022; pp. 802–812. [Google Scholar]

- Robertson, G.G. Population size in classifier systems. In Machine Learning Proceedings1988; Morgan Kaufmann: Burlington, MA, USA, 1988; pp. 142–152. [Google Scholar]

- Abderazak, S.; Farid, N. Comparative study between Sliding mode controller and Fuzzy Sliding mode controller in a speed control for doubly fed induction motor. In Proceedings of the 2016 4th International Conference on Control Engineering & Information Technology (CEIT), Hammamet, Tunisia, 16–18 December 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar]

- El Ouanjli, N.; Mahfoud, S.; Derouich, A.; El Daoudi, S.; El Mahfoud, M. Speed Sensorless Fuzzy Direct Torque Control of Induction Motor Based MRAS Method. In Proceedings of the International Conference on Digital Technologies and Applications, Fez, Morocco, 28–30 January 2022; Springer: Cham, Switzerland, 2022; pp. 779–790. [Google Scholar]

| Sector Si | |||||||

|---|---|---|---|---|---|---|---|

| S1(Sa Sb Sc) | S2(Sa Sb Sc) | S3(Sa Sb Sc) | S4(Sa Sb Sc) | S5(Sa Sb Sc) | S6(Sa Sb Sc) | ||

| 1 | 1 | v2(110) | v3(010) | v4(011) | v5(001) | v6(101) | v1(100) |

| 0 | v7(111) | v0(000) | v7(111) | v0(000) | v7(111) | v0(000) | |

| −1 | v6(101) | v1(100) | v2(110) | v3(010) | v4(011) | v5(001) | |

| 0 | 1 | v3(010) | v4(011) | v5(001) | v6(101) | v1(100) | v2(110) |

| 0 | v0(000) | v7(111) | v0(000) | v7(111) | v0(000) | v7(111) | |

| −1 | v5(001) | v6(101) | v1(100) | v2(110) | v3(010) | v4(011) | |

| PID Parameters | KP | KI | KD |

|---|---|---|---|

| Maximum Value | 100 | 1 | 1 |

| Minimum Value | 0 | −1 | −1 |

| Controller Parameters | Classic DTC | GA–DTC |

|---|---|---|

| KP | 0.776 | 72.8895 |

| KI | 28.74 | 0.0729 |

| KD | 0 | 0.5262 |

| Performances | Characteristics | DTC | GA–DTC | Improvements (%) |

|---|---|---|---|---|

| Response Time (ms) | 61.1 | 49.7 | 18.66 | |

| Overshoot (rad/s) | 60.14 | 0 | 100 | |

| Rejection Time (ms) | 84 | 15.9 | 81.07 | |

| Undershoot (rad/s) | 9.826 | 4.73 | 51.86 | |

| Ripples (Nm) | 2.445 | 2.05 | 16.16 | |

| Ripples (wb) | 0.06123 | 0.04304 | 29.71 | |

| Ripples (wb) | 0.0118 | 0.00893 | 24.32 | |

| THD (%) | 10.47 | 4.17 | 60.17 | |

| THD (%) | 7.57 | 3.95 | 47.82 |

| Publication | Approaches | Response Time (s) | Torque Ripples (Nm) | Robustness |

|---|---|---|---|---|

| [6] | Field-Oriented Control | 0.56 | 2.5 | Not Robust |

| [40] | Sliding Mode Control | 0.19 | 2.4 | Not Robust |

| Studied in This Work | Classical DTC | 0.0507 | 2.445 | Robust |

| [41] | FL–DTC | 0.28 | 1.14 | Robust |

| Proposed Technique | GA–DTC | 0.0497 | 2.05 | Robust |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahfoud, S.; Derouich, A.; El Ouanjli, N.; Mossa, M.A.; Bhaskar, M.S.; Lan, N.K.; Quynh, N.V. A New Robust Direct Torque Control Based on a Genetic Algorithm for a Doubly-Fed Induction Motor: Experimental Validation. Energies 2022, 15, 5384. https://doi.org/10.3390/en15155384

Mahfoud S, Derouich A, El Ouanjli N, Mossa MA, Bhaskar MS, Lan NK, Quynh NV. A New Robust Direct Torque Control Based on a Genetic Algorithm for a Doubly-Fed Induction Motor: Experimental Validation. Energies. 2022; 15(15):5384. https://doi.org/10.3390/en15155384

Chicago/Turabian StyleMahfoud, Said, Aziz Derouich, Najib El Ouanjli, Mahmoud A. Mossa, Mahajan Sagar Bhaskar, Ngo Kim Lan, and Nguyen Vu Quynh. 2022. "A New Robust Direct Torque Control Based on a Genetic Algorithm for a Doubly-Fed Induction Motor: Experimental Validation" Energies 15, no. 15: 5384. https://doi.org/10.3390/en15155384

APA StyleMahfoud, S., Derouich, A., El Ouanjli, N., Mossa, M. A., Bhaskar, M. S., Lan, N. K., & Quynh, N. V. (2022). A New Robust Direct Torque Control Based on a Genetic Algorithm for a Doubly-Fed Induction Motor: Experimental Validation. Energies, 15(15), 5384. https://doi.org/10.3390/en15155384