Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany

Abstract

:1. Introduction

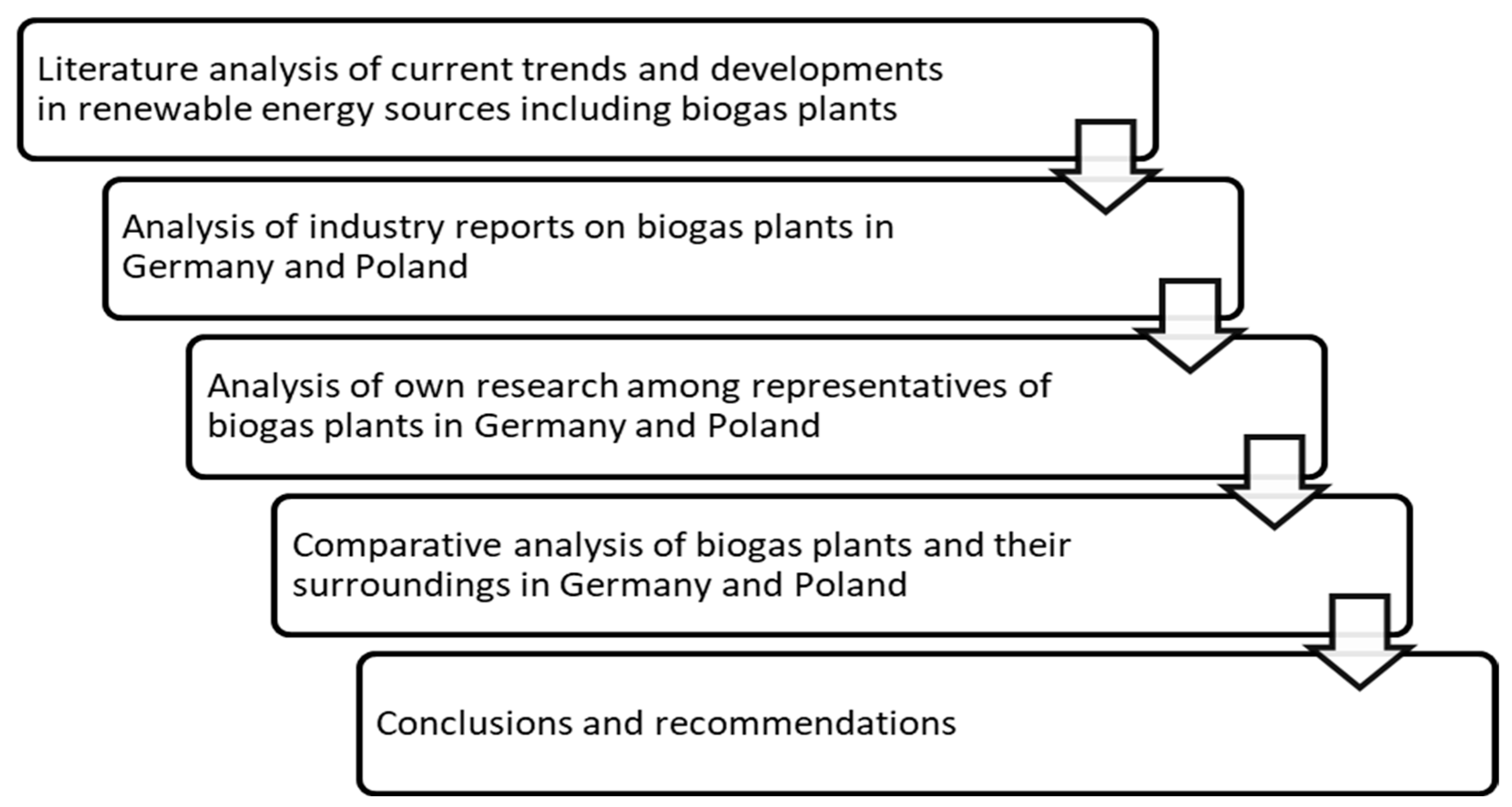

2. Materials and Methods

- -

- Desk research—a literature review was conducted on reports and scientific publications from digital libraries. The desk research results were used to prepare a global overview of the energy situation, particularly the characteristics of biogas plants in Poland and Germany. The desk research results were also used to prepare a CAWI survey to collect information from representatives of biogas plants in Germany and Poland.

- -

- Computer-Assisted Web Interview (CAWI) technique—the authors used this method to collect information from representatives about biogas plants in Poland and Germany, especially their strengths and weaknesses, opportunities and threats. Data were collected in two rounds. The first round of the survey included mainly closed questions. Mainly, a five-point scale was used. In the second round, 10 interviews were conducted with representatives of biogas plants—five from each country. In the interviews, the questions were open-ended.

- -

- Biogas plant development plans or lack thereof;

- -

- Problems faced by biogas plants in the broad area;

- -

- Planned changes in the area of substrates used;

- -

- The extent to which the biogas plant uses liquid manure;

- -

- The area of livestock farmers’ problems that affect the restriction of animal husbandry;

- -

- An assessment of the cost-effectiveness of starting up a biogas plant under current economic conditions;

- -

- Evaluation of the technology used in the biogas plant under study;

- -

- Institutional support for biogas plant development;

- -

- Substrate costs.

- -

- Deductive (fragmentary), growing out of the thesis formula based on synthetic results, allowing the search for causes and effects to identify them in detail;

- -

- Inductive (synthesis), allowing for the exploration of individual threads and their subsequent generalisation in the form of conclusions and evaluations.

3. Results

3.1. Biogas and Its Formation

- -

- Agricultural biogas plant;

- -

- Landfill biogas plant;

- -

- Biogas plant at the sewage treatment plant.

- 80–165—maize with 32% dry matter;

- 85–115—whole cereal plants harvested at the stage of milk maturity of the grain;

- 60–100—field grown grasses, clover with grasses;

- 40–90—lichen from grassland;

- 50–85—cereal grains [58].

3.2. Biogasification in Poland

3.3. Biogasification in Germany

- 97%—whole-crop maize silage;

- 50%—cereal grains, mainly wheat and triticale;

- 49%—whole-crop silage;

- 35%—grass silage;

- 8%—green fodder from grass;

- 3%—maize grain;

- 1%—other raw materials, i.e., sunflower silage, beet, hay, straw, distillery stock, potatoes [13].

4. Discussion

- (a)

- 82% of biogas plant managers are interested in expanding their plants;

- (b)

- 62% of respondents indicate current and future problems with substrate acquisition;

- (c)

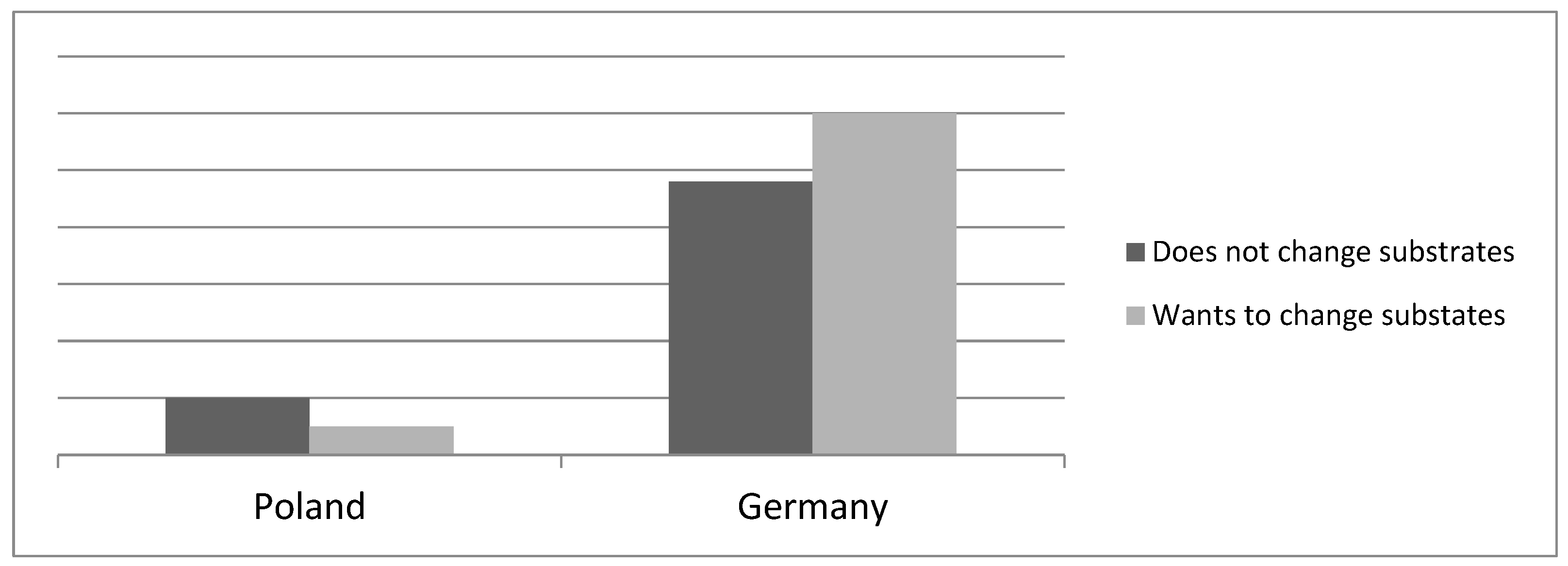

- 47% of respondents do not plan to change substrates, while 26% want to make changes in this area and look for new development directions;

- (d)

- 96% use liquid manure and want to follow this path;

- (e)

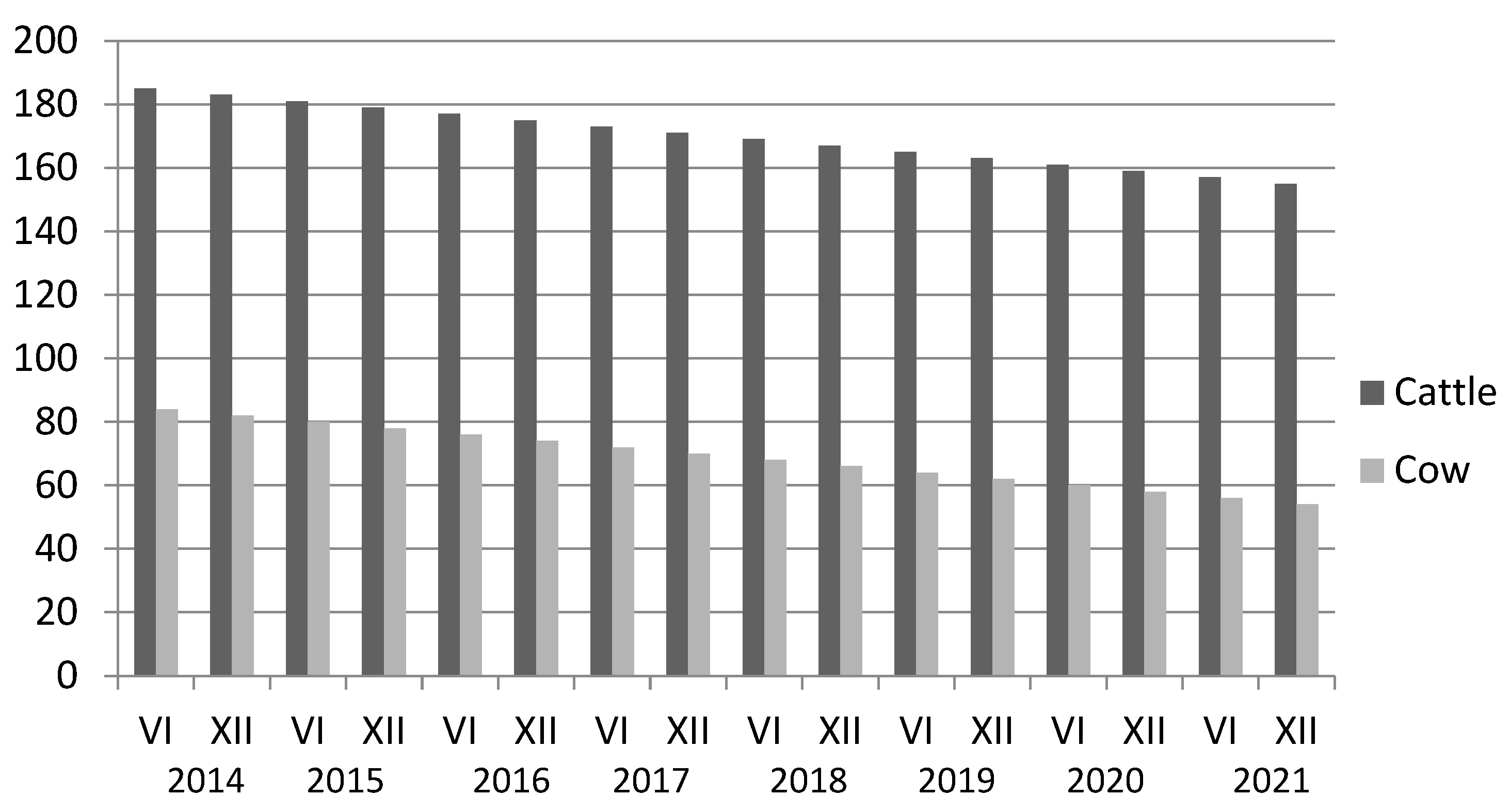

- 46% of the producers who use liquid manure observe a significant decrease in the number of cattle and pigs in their area, which may be a threat to the further operation of their biogas plant;

- (f)

- 87% of those surveyed in Poland and 48% of those surveyed in Germany consider the process of setting up a biogas plant to be costly and without a quick return on investment;

- (g)

- 45% of those surveyed in Germany consider the technology they are using to be outdated and do not intend to modernise it for the time being;

- (h)

- 88% of respondents indicate that state aid and support could facilitate the development of biogas plants and their modernisation;

- (i)

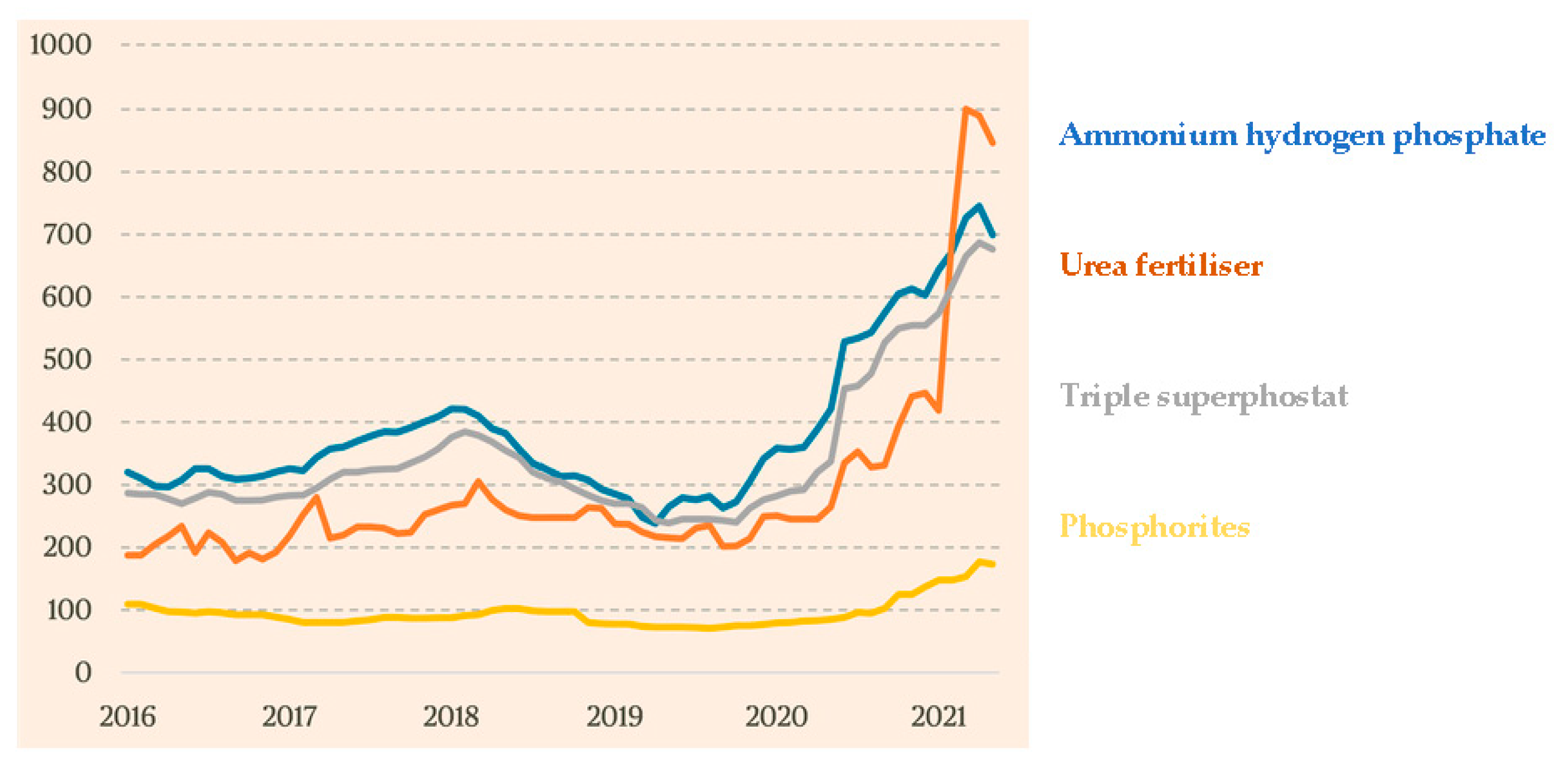

- 86% of respondents indicate that changes in substrate acquisition are necessary due to the increasing costs of obtaining substrate from maize or other crops, which are grown only for use in biogas plants.

- (a)

- Work on the most effective use of existing biogas plants, so that they do not lack raw material and at the same time the substrates used in biogas plants solve the waste problems of particular communes or areas;

- (b)

- Solutions should be sought so that individual biogas plants deal with waste that is located in the immediate vicinity of the biogas plant so as to reduce the cost of transporting the raw material;

- (c)

- Cooperation of companies that produce waste with large companies that own biogas plants so that their investments are correlated with the plans of companies that have waste, because only then can changes in the substrate acquisition process be responded to;

- (d)

- Promotion of knowledge about biogas plants among cattle, pig and poultry farmers to encourage investment in biogas plants.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Psomopoulos, C.S.; Kiskira, K.; Kalkanis, K.; Leligou, H.C.; Themelis, N.J. The role of energy recovery from wastes in the decarbonization efforts of the EU power sector. IET Renew. Power Gener. 2022, 16, 48–64. [Google Scholar] [CrossRef]

- Hanif, M.U.; Zwawi, M.; Algarni, M.; Bahadar, A.; Iqbal, H.; Capareda, S.C.; Hanif, M.A.; Waqas, A.; Hossain, N.; Siddiqui, M.T.H.; et al. The Effects of Using Pretreated Cotton Gin Trash on the Production of Biogas from Anaerobic Co-Digestion with Cow Manure and Sludge. Energies 2022, 15, 490. [Google Scholar] [CrossRef]

- Laayati, O.; El Hadraoui, H.; Guennoui, N.; Bouzi, M.; Chebak, A. Smart Energy Management System: Design of a Smart Grid Test Bench for Educational Purposes. Energies 2022, 15, 2702. [Google Scholar] [CrossRef]

- Piwowar, A.; Dzikuć, M. Bioethanol Production in Poland in the Context of Sustainable Development-Current Status and Future Prospects. Energies 2022, 15, 2582. [Google Scholar] [CrossRef]

- European Commission 2014 Brussels: A Policy Framework for Climate and Energy in the Period from 2020 to 2030 (COM (2014) 15 Final) Commission of the European Communities. Available online: https://ec.europa.eu/clima/policies/eu-climate-action_en (accessed on 24 April 2022).

- Mazurkiewicz, J. Energy and Economic Balance between Manure Stored and Used as a Substrate for Biogas Production. Energies 2022, 15, 413. [Google Scholar] [CrossRef]

- Norouzi, O.; Dutta, A. The Current Status and Future Potential of Biogas Production from Canada’s Organic Fraction Municipal Solid Waste. Energies 2022, 15, 475. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Sobczak, A.; Soboń, D. Wind Energy Market in Poland in the Background of the Baltic Sea Bordering Countries in the Era of the COVID-19 Pandemic. Energies 2022, 15, 2470. [Google Scholar] [CrossRef]

- Zupančič, M.; Možic, V.; Može, M.; Cimerman, F.; Golobič, I. Current Status and Review of Waste-to-Biogas Conversion for Selected European Countries and Worldwide. Sustainability 2022, 14, 1823. [Google Scholar] [CrossRef]

- Eder, A.; Mahlberg, B. Size, Subsidies and Technical Efficiency in Renewable Energy Production: The Case of Austrian Biogas Plants. Energy J. 2018, 39, 185–210. Available online: https://www.jstor.org/stable/26534411 (accessed on 9 June 2022). [CrossRef] [Green Version]

- Scarlat, N.; Fahl, F.; Dallemand, J.F.; Monforti, F.; Motola, V. A spatial analysis of biogas potential from manure in Europe. Renew. Sustain. Energy Rev. 2018, 94, 915–930. [Google Scholar] [CrossRef]

- Scarlat, N.; Dallemand, J.F.; Fahl, F. Biogas: Developments and perspectives in Europe. Renew. Energy 2018, 129, 457–472. [Google Scholar] [CrossRef]

- Institut für Energetik und Umwelt GmbH. Leipzig. Biogaz Produkcja Wykorzystanie. 2005. Available online: https://www.ieo.pl/dokumenty/obszary_badan/Biogaz%20-%20Produkcja%20Wykorzystywanie.pdf (accessed on 20 April 2022).

- Curkowski, A.; Mroczkowski, P.; Oniszk-Popławska, A.; Wiśniewski, G. Biogaz Rolniczy, Produkcja i Wykorzystanie; Mazowiecka Agencja Energetyczna: Warszawa, Poland, 2009. [Google Scholar]

- Kolodziej, A.U. Biogazownie Rolnicze—Mity i Fakty, Fundacja na Rzecz Rozwoju Polskiego Rolnictwa; Nazwa Projektu: Warszawa, Poland, 2011; Volume 4. [Google Scholar]

- Gołasa, P. Gospodarstwa rolne, jako producenci substratów do produkcji biogazu rolniczego. Rocz. Nauk. Stowarzyszenia Ekon. Rol. Agrobiz. 2014, 16, 132–136. [Google Scholar]

- Gołasa, P. Potencjał produkcji biogazu w województwach zachodniopomorskim i lubuskim oraz jego wykorzystanie. Logistka Odzysku 2014, 2, 34–37. [Google Scholar]

- Hall, C.A.S.; Cleveland, C.J.; Kaufmann, R. Energy and Resource Quality: The Ecology of the Economic Process; Wiley: New York, NY, USA, 1986. [Google Scholar]

- Chomać-Pierzecka, E.; Sobczak, A.; Soboń, D. The Potential and Development of the Geothermal Energy Market in Poland and the Baltic States—Selected Aspects. Energies 2022, 15, 4142. [Google Scholar] [CrossRef]

- Chomać-Pierzecka, E.; Kokiel, A.; Rogozińska-Mitrut, J.; Sobczak, A.; Soboń, D.; Stasiak, J. Analysis and Evaluation of the Photovoltaic Market in Poland and the Baltic States. Energies 2022, 15, 669. [Google Scholar] [CrossRef]

- Niemcy Inwestuja w oze 80 Procent Energii z Odnawialnych Źrodeł. Available online: https://swiatrolnika.info/ekologia/oze/niemcy-inwestuja-w-oze-80-procent-energii-z-odnawialnych-zrodel.html (accessed on 10 July 2022).

- Goddard, E.; Weersink, A.; Chen, K.; Turvey, C.G. Economics of structural change in agriculture. Can. J. Agric. Econ. 1993, 41, 475–489. [Google Scholar]

- Balmann, A.; Dautzenberg, K.; Happe, K.; Kellermann, K. On the Dynamics of Structural Change in Agriculture: Internalc Frictions, Policy Threats and Vertical Integration. Outlook Agric. 2006, 35, 115–121. [Google Scholar] [CrossRef]

- Appel, F.; Ostermeyer-Wiethaup, F.; Balmann, A. Effects of the German Renewable Energy Act on structural change in agriculture—The case of biogas. Util. Policy 2016, 41, 172–182. [Google Scholar] [CrossRef]

- Kung, C.C.; Zhang, L.; Chang, M.S. Promotion policies for renewable energy and their effects in Taiwan. J. Clean. Prod. 2017, 142, 965–975. [Google Scholar] [CrossRef]

- Braun, J.; Lorleberg, W.; Wacup, H. Vorläufiger Bericht zum Projekt Regionale Struktur-und Einkommenswirkungen der Biogasproduktion in NRW, University of Applied Sciences Südwestfalen, [Electronic]. Available online: http://www.umwelt.nrw.de/umwelt/pdf/endbericht_biogas07.pdf (accessed on 12 July 2015).

- Kilian, S.; Antón, J.; Roder, N.; Salhofer, K. Impacts of 2003 CAP reform on land prices: From Theory to Empirical Results (No. 694-2016-47562). In Proceedings of the European Association of Agricultural Economists (EAAE) 109th Seminar, Viterbo, Italy, 20–21 November 2008. [Google Scholar]

- Habermann, H.; Breustedt, G. Einfluss der Biogaserzeugung auf landwirtschaftliche Pachtpreise in Deutschland. Ger. J. Agric. Econ. 2011, 60, 85–100. [Google Scholar]

- Huettel, S.; Odening, M.; Kataria, K.; Balmann, A. Price formation on land market auctions in East Germany–An empirical analysis. Ger. J. Agric. Econ. 2013, 62, 99–115. [Google Scholar]

- Murphy, D.J.; Hall, A.S. Year in review—EROI or energy return on (energy) invested. Ann. N. Y. Acad. Sci. Ecol. Econ. Rev. 2010, 1185, 102–118. [Google Scholar] [CrossRef] [PubMed]

- Wykorzystanie Odchodów Zwierzęcych i Odpadów Przemyslu Rolno-Spożywczego do Produkcji Biogazu Rolniczego. Available online: https://www.researchgate.net/publication/283046596_Wykorzystanie_odchodow_zwierzecych_i_odpadow_przemyslu_rolno-spozywczego_do_produkcji_biogazu_rolniczego (accessed on 23 April 2022).

- Morales-Polo, C.; Cledera-Castro, M.D.M.; Revuelta-Aramburu, M.; Hueso-Kortekaas, K. Enhancing Energy Recovery in Form of Biogas, from Vegetable and Fruit Wholesale Markets By-Products and Wastes, with Pretreatments. Plants 2021, 10, 1298. [Google Scholar] [CrossRef] [PubMed]

- Morales-Polo, C.; Cledera-Castro, M.D.M.; Rvuelta-Aramburu, M.; Hueso-Kortekaas, K. Bioconversion Process of Barley Crop Residues into Biogas—Energetic-Environmental Potential in Spain. Agronomy 2021, 11, 640. [Google Scholar] [CrossRef]

- Biofuels Barometer. 2020. Available online: https://www.eurobserv-er.org/biofuels-barometer-2020/ (accessed on 24 April 2022).

- REPowerEU: Affordable, Secure and Sustainable Energy for Europe. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal/repowereu-affordable-secure-and-sustainable-energy-europe_en (accessed on 24 April 2022).

- Energy Policy of Poland until 2040. Available online: https://www.gov.pl (accessed on 24 April 2022).

- Perissi, I.; Jones, A. Investigating European Union Decarbonization Strategies: Evaluating the Pathway to Carbon Neutrality by 2050. Sustainability 2022, 14, 4728. [Google Scholar] [CrossRef]

- Johnston, A.; van Der Marel, E. How Binding are the EU’s ‘Binding’ Renewables Targets? Camb. Yearb. Eur. Leg. Stud. 2016, 18, 176–214. [Google Scholar] [CrossRef]

- The Impact of the War in Ukraine on Euro Area Energy Markets. Available online: https://www.ecb.europa.eu/pub/economic-bulletin/focus/2022/html/ecb.ebbox202204_01~68ef3c3dc6.en.html (accessed on 6 July 2022).

- Wiceprezes PGNiG dla e24: Niemcy Maja Ponad 10 tys. Biogazowni, a Polska ok. 300 - to Dziwne [WYWIAD]. Available online: https://energetyka24.com/gaz/wiceprezes-pgnig-dla-e24-niemcy-maja-ponad-10-tys-biogazowni-a-polska-ok-300-to-dziwne (accessed on 17 April 2022).

- Banja, M.; Jégard, M.; Motola, V.; Sikkema, R. Support for biogas in the EU electricity sector—A comparative analysis. Biomass Bioenergy 2019, 128, 105313. [Google Scholar] [CrossRef]

- Jégard, M.; Banja, M.; Dallemand, J.-F.; Motola, V.; Sikkema, R.; Taylor, N.; Monforti-Ferrario, F. Renewables in the EU an Overview of Support Schemes and Measures. Available online: https://op.europa.eu/en/publication-detail/-/publication/83d9ab2f-647d-11e8-ab9c-01aa75ed71a1/language-en (accessed on 9 June 2022).

- Piekut, M. The Consumption of Renewable Energy Sources (RES) by the European Union Households between 2004 and 2019. Energies 2021, 14, 5560. [Google Scholar] [CrossRef]

- Energy Supply Options for Lithuania. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/te_1408_web.pdf (accessed on 17 April 2022).

- Landfill Gas and Biogas. Available online: https://www.eia.gov/energyexplained/biomass/landfill-gas-and-biogas.php (accessed on 17 April 2022).

- Is Anaerobic Digestion Right for Your Farm? Available online: https://www.epa.gov/agstar/anaerobic-digestion-right-your-farm (accessed on 17 April 2022).

- Caruso, M.C.; Braghieri, A.; Capece, A.; Napolitano, F.; Romano, P.; Galgano, F.; Altieri, G.; Genovese, F. Recent Updates on the Use of Agro-Food Waste for Biogas Production. Appl. Sci. 2019, 9, 1217. [Google Scholar] [CrossRef] [Green Version]

- Kacprzak, A.; Michalska, K. Technologie i urządzenia dla biogazowni. Rozdział w monografii. In Inwestowanie w Energetykę Odnawialną; PAN, Oddział w Łodzi, Komisja Ochrony Środowiska: Łódź, Poland, 2011. [Google Scholar]

- Latocha, L. Materials from the training. Renew. Energy Sources Home Bus. 2010. [Google Scholar]

- Dudek, J.; Zaleska-Bartosz, J. Production and use of biogas for energy purposes. Probl. Ecol. 2010, 14. [Google Scholar]

- Buraczewski, G.; Bartoszek, B. Biogaz. Wytwarzanie i Wykorzystanie; PWN: Warszawa, Poland, 1990. [Google Scholar]

- Janas, M.; Zawadzka, A. Assessment of environmental impact of agricultural biogas plants. Acta Innov. 2018, 27, 24–30. [Google Scholar] [CrossRef]

- Romaniuk, W. Kierunki zrównoważonego rozwoju technologii i budownictwa w chowie zwierząt. Problemy Inżynierii Rolniczej 2010, 4, 14. [Google Scholar]

- Recykling Organiczny I Odzysk Energiiz Segregowanych u źródła Bioodpadów Pochodzenia Komunalnego. Available online: https://www.proakademia.eu/gfx/baza_wiedzy/358/technologiczne_recykling_i_odzysk.pdf (accessed on 6 July 2022).

- Jabłoński, S.; Vogt, A.; Kułażyński, M.; Łukaszewicz, M. Monitoring i Sterowanie Procesem Technologicznym Biogazowni; Politechnika Wrocławska: Wrocław, Poland, 2014; ISBN 978-83-63503-29-1. [Google Scholar]

- Nowak, D. Warunki Przechowywania Nawozów Naturalnych Oraz Postępowanie z Odciekami. Available online: https://iung.pl/dpr/Mat_szkoleniowe/2.pdf (accessed on 23 April 2022).

- Ginalski, Z. Substrates for Agricultural Biogas Plants CDR O/Radom. Available online: https://cdr.gov.pl/pol/OZE/substraty.pdf (accessed on 23 April 2022).

- Annual Crop Statistics. Available online: https://ec.europa.eu/eurostat/cache/metadata/Annexes/apro_cp_esms_an1.pdf (accessed on 17 April 2022).

- Curkowski, A.; Mroczkowski, P.; Oniszk-Popławska, A. Surowce do Produkcji Biogazu—Uproszczona Metoda Obliczenia Wydajności Biogazowni Rolniczej; Czysta Energia–nr 1/2010; Instytut Energetyki Odnawialnej: Warszawa, Poland, 2010. [Google Scholar]

- Jak Dobrać Właściwie Substraty na Biodaz do Biogazowani. Available online: https://www.farmer.pl/energia/oze/jak-dobrac-wlasciwe-substraty-na-biogaz-do-biogazowni,91672.html (accessed on 18 April 2022).

- Jędrczak, A. Biologiczne Przetwarzanie Odpadów; PWN: Warszawa, Poland, 2007. [Google Scholar]

- Kacprzak, A.; Michalska, K.; Romanowska-Duda, Z.; Grzesik, M. Rośliny energetyczne jako cenny surowiec do produkcji biogazu. Kosmos 1961, 2, 281–293. [Google Scholar]

- Kołodziej, A.U. Biogazownie rolnicze—mity i fakty, Zachodniopomorski Magazyn Rolniczy, Nr 61/210-2011.

- Chmielewski, A.G. Nuclear Fissile Fuels Worldwide Reserves. Nukleonika 2008, 53 (Suppl. 2), 11–14. [Google Scholar]

- Kochańska, E.; Kacprzak, A.; Michalska, K.; Staniszewska, M.; Łysek, M.; Grabowski, P. Mikrotechnologie Biogazowe Jako Innowacyjne Narzędzie Stymulowania Rynku Lokalnego; Perspektywy aplikacyjne w województwie łódzkim: Łódź, Poland, 2012. [Google Scholar]

- Vergara, F.; Lakes, T.M. Maizification of the landscape for biogas production? Identifying the likelihood of silage maize for biogas in Brandenburg from 2008-2018. In Agricultural Land Markets—Efficiency and Regulation; FORLand-Working Paper; DFG Research Unit 2569 FORLand; Humboldt-Universität zu Berlin: Berlin, Germany, 2019. [Google Scholar] [CrossRef]

- Biogazownie w Niemczech dwa Kroki do Przodu i Jeden do Tyłu. Available online: https://energia.rp.pl/gaz/art19183961-biogazownie-w-niemczech-dwa-kroki-do-przodu-jeden-do-tylu (accessed on 14 April 2022).

- Pogłowie Bydła w Całej UE Spadło o Ponad 800 tys. Sztuk. Available online: https://www.tygodnik-rolniczy.pl/articles/hodowla-zwierzat/poglowie-bydla-w-calej-ue-spadlo-o-ponad-800-tys-szt-ile-bydla-jest-w-polsce-niemczech-francji-i-innych-krajach/ (accessed on 15 April 2022).

- Pogłowie Bydła Według Stanu w Czerwcu. 2021. Available online: https://stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/produkcja-zwierzeca-zwierzeta-gospodarskie/poglowie-bydla-wedlug-stanu-w-czerwcu-2021-roku,9,5.html (accessed on 15 April 2022).

- Tiere und Tierische Erzeugung Schweinebestand 2022 im Vergleich zum Vorjahr Gesunken. Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Landwirtschaft-Forstwirtschaft-Fischerei/Tiere-Tierische-Erzeugung/schweine.html (accessed on 15 April 2022).

- Oszacowanie Wielkości Produkcji Oraz Jednostkowej Zawartości Azotu Nawozów Naturalnych, Powstałych w Różnych Systemach Utrzymania Zwierząt Gospodarskich w Polsce. Available online: http://www.rzgw.gda.pl/cms/fck/uploaded/ZGPW_rozporzadzenia/Ekspertyza%20IZ_MRiRW.pdf (accessed on 15 April 2022).

- Jakie Są Perspektywy Dla Cen Nawozów. Available online: https://www.pb.pl/jakie-sa-perspektywy-dla-cen-nawozow-1140506 (accessed on 9 June 2022).

| Substrate | Dry Matter Content (%) | Organic Dry Matter Content (%) | Biogas Yield (m3 /t s.m.o.) | Methane Contentch4 (%vol.) |

|---|---|---|---|---|

| cattle slurry | 8–11 | 75–82 | 200–500 | 60 |

| pig manure | approx. 7 | 75–86 | 300–700 | 60–70 |

| cattle manure | approx. 25 | 68–76 | 210–300 | 60 |

| pig manure | 20–25 | 75–80 | 270–450 | 60 |

| chicken manure | approx. 32 | 63–80 | 250–450 | 60 |

| maize silage | 20–35 | 85–95 | 450–700 | 50–55 |

| rye | 30–35 | 92–98 | 550–680 | approx. 55 |

| grass silages | 25–50 | 70–95 | 550–620 | 54–55 |

| brewers’ pulp | 20–25 | 70–80 | 580–750 | 59–60 |

| cereal broth | 6–8 | 83–88 | 430–700 | 58–65 |

| potato stock | 6–7 | 400–700 | 58–65 | |

| fruit marc | 25–45 | 85–95 | 590–660 | 65–70 |

| shop waste | 5–20 | 80–90 | 400–600 | 60–65 |

| gastric contents | 12–15 | 75–86 | 250–450 | 60–70 |

| grass cuttings | approx. 12 | 83–92 | 550–680 | 55–65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobczak, A.; Chomać-Pierzecka, E.; Kokiel, A.; Różycka, M.; Stasiak, J.; Soboń, D. Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies 2022, 15, 5239. https://doi.org/10.3390/en15145239

Sobczak A, Chomać-Pierzecka E, Kokiel A, Różycka M, Stasiak J, Soboń D. Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies. 2022; 15(14):5239. https://doi.org/10.3390/en15145239

Chicago/Turabian StyleSobczak, Anna, Ewa Chomać-Pierzecka, Andrzej Kokiel, Monika Różycka, Jacek Stasiak, and Dariusz Soboń. 2022. "Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany" Energies 15, no. 14: 5239. https://doi.org/10.3390/en15145239

APA StyleSobczak, A., Chomać-Pierzecka, E., Kokiel, A., Różycka, M., Stasiak, J., & Soboń, D. (2022). Economic Conditions of Using Biodegradable Waste for Biogas Production, Using the Example of Poland and Germany. Energies, 15(14), 5239. https://doi.org/10.3390/en15145239