Abstract

The industry is a key driver of economic development. However, changes caused by introduction of modern technologies, and increasing complexity of products and production, directly affect the industrial enterprises and workers. The critics of the Industry 4.0 paradigm emphasized its orientation to new technologies and digitalization in a technocratic way. Therefore, the new industrial paradigm Industry 5.0 appeared very soon and automatically triggered a debate about the role of, and reasons for applying, the new paradigm. Industry 5.0 is complementing the existing Industry 4.0 paradigm with the orientation to the worker who has an important role in the production process, and that role has been emphasized during the COVID-19 pandemic. In this research, there is a brief discussion on main drivers and enablers for introduction of these new paradigms, then a literature-based analysis is carried out to highlight the differences between two paradigms from three important aspects—people, organization, and technology. The conclusion emphasizes the main features and concerns regarding the movement towards Industry 5.0, and the general conclusion is that there is a significant change of the main research aims from sustainability towards human-centricity. At the end, the analysis of maturity models that evaluates enterprises’ readiness to introduce features of new paradigms is given as well.

1. Introduction

In the last decade, we have been witnesses of transformations inside production systems, especially in the field of digitalization [1]. Information and communication technologies (ICT) are involved in every step of production [2]. This causes the various complexities in several aspects: technological, logistical, organizational, and environmental. A complex transformation process is taking place that needs to be effectively managed. The application of new technologies has significant impact on people at work and in everyday life [3]. People are involved in the process of transforming industrial paradigms, whether they work as workers in the industry or as customers that require a specific product from the industry [4]. As important participants, both workers and customers need to be flexible in adapting to new working conditions and open to learning and sharing knowledge [5]. Another important segment in industry affected by paradigm transformations is organization. Today, the organization is characterized by decentralization, where the decision-making process has been delegated by top managers to workers who are lower-level managers and sometimes to blue-collar workers [6]. The idea behind the decentralization is to quicken the decision-making process by those who have the most information and ability to react in real time. However, to support this idea, the application of new technologies and digitalization is crucial. The data collection and processing bring the proper information [7] so the worker can react fast.

A new industrial paradigm, Industry 5.0, appeared very soon after Industry 4.0 and triggered a debate about the role of, and reasons for, applying the new paradigm. The Industry 4.0 is based on the concept of smart factory, where smart products, machines, storage systems, and data unite in the form of the cyber-physical production systems [8,9]. In the technical aspect, Industry 4.0 has improved the human–machine interaction, but in the socially sustainable aspect, technological transformations of Industry 4.0 should carefully consider the central role of humans [10]. The role and importance of employees was emphasized during the COVID-19 pandemic, and the pandemic itself triggered rethinking of the Industry 4.0 paradigm [11,12]. Consequently, the idea of Industry 5.0 appeared as the extension to Industry 4.0 with social and environmental dimension [13]. On the one side, Industry 5.0 is focused on the workers’ skills, knowledge, and abilities to cooperate with machines and robots [14,15], and on the other side, on flexibilities in production processes and environmental impact.

The obstacles to introduce Industry 4.0, arising from technological and organizational points of view, lead to rethinking the process about the shortcomings of the Industry 4.0 approach. Several drivers encourage thinking and discussion about the new paradigm. One of the important drivers is personalized product, where customers participate in product design and production for adaptation of the product to their own needs [16,17]. Other drivers originate from the inability of the SMEs (small and medium enterprises) to implement the Industry 4.0 approach [18,19]. There are lot of studies in the context of Industry 4.0 for SMEs, which are pillars of the economy in many countries because of their contribution to gross domestic product (GDP). The new technologies require high investments and knowledge of how to use them and integrate in existing environments to achieve the best results in production [20]. The important question is: Which technologies should the enterprise use to achieve the best results [21]? This opens the question about the assessment of readiness for changes [22,23,24]. Whatever question is opened, it is always necessary to start with the key enablers of production. This is where the rethinking process is justified with the aim of highlighting the human-centric perspective.

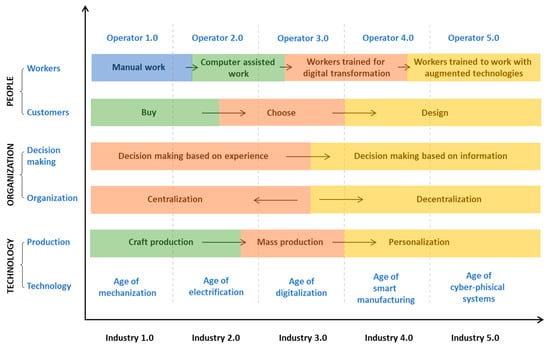

The topics from this article hold a crucial place in each branch of industry. The purpose of this paper is to discuss the main connections between the basic driving concepts of Industry 4.0 and Industry 5.0, but also to emphasize the key enablers: people, organization, and technology, in theoretical and practical context. The key enablers are intensively studied for the last decade in the context of industry progress. The intention of this work is to achieve better understanding of the appearance of Industry 5.0, referring to the key publications which are cited to highlight the directions of research in this field. As a reminder of past trends, Figure 1 shows the transformations through the paradigms according to the important participants and segments of industries. Additionally, better understanding of the appearance of Industry 5.0 represents the base to rethink real industry processes and possibilities to apply appropriate concepts that best suit specific challenges that industry faces, to achieve the best results in each aspect: people, organization, or technology.

Figure 1.

Transformations through the paradigms according to the important participants and segments of industries.

The rest of the paper is organized as follows. Section 2 emphasizes basic driving concepts for each paradigm and the flow of the scientific papers collection. Section 3 introduces the review of existing literature, summarizes main transformations to move towards each paradigm, and represents the connection between key enablers and people, organization, and technology in a practical context. Section 4 discusses the importance of represented connections in Section 3 and readiness to introduce any features of new paradigms. Section 5 gives the concluding remarks.

2. Basic Driving Concepts of Industry 4.0 and Industry 5.0

Industry 4.0 is based on the concept of smart factories. The smart factory initiative was founded by partners from industry and academy as an environment for test future technologies [25] and to learn by doing. There are important key drivers [26,27]:

- Internet of Things, services and data that enable the communication between objects. By placing the intelligence into objects, they are turned into smart objects able not only to collect information from the environment and interact or control the physical world, but also to be interconnected to each other through Internet, to exchange data and information [28,29,30].

- Cloud computing is a driver which supports the Internet of Things, enabling the access to large datasets and its processing to generate new useful information through different types of reports. However, the cybersecurity is a pressing issue; ref. [31] defines cybersecurity as a set of tools, policies and best practices, security concepts, guidelines, risk approaches, actions, assurance, and technologies necessary to protect the cyber environment, organization, and user’s assets.

- Cyber-physical system (CPS) is defined as a new generation system with integrated computational and physical capabilities that can interact with people through new modalities [32,33].

- Artificial intelligence supports the cyber-physical system for filtration of the multitude data incoming from different sensors in a production system and analyzes it through the reports. It offers the data-driven predictive analytics and capacity to assist decision-making in highly complex, nonlinear, and multistage production [34,35].

- Augmented reality (AR) represents the integration of the virtual and real environments where objects in the real world are enhanced by computer-generated information or objects with the help of different technologies. AR can be combined with human abilities to provide efficient and complementary tools to assist manufacturing tasks [36].

- Simulation is a powerful tool used for decision making. The application of simulation methods is becoming increasingly relevant as developments in the field of digitalization lead to more comprehensive, efficient, embedded, and cost-effective simulation methods [37].

- Autonomous robots can detect problems and independently adjust their tasks to ensure that processes runs smoothly. However, there are levels of robot autonomy, ranging from teleoperation to fully autonomous systems, that influence human–robot interaction [38].

These elements enable the connectivity of the virtual and real world in order to achieve better results in production with maximum profit. A completely profit-driven approach is not sustainable for the long term. Instead of taking technology as a crucial element, the document of European Commission [39] sees three key drivers as the center of new industrial paradigm Industry 5.0 (Figure 2):

Figure 2.

Industry 5.0 with three key drivers.

- Human-centric approach, which places human needs at the heart of the production process, asking what technology can do for workers and how can it be useful.

- Sustainability, which focuses on reuse, repurpose, and recycle of natural resources and reduce of waste and environmental impact.

- Resilience, which implies an introduction of robustness in industrial production. This robustness provides support through flexible processes and adaptable production capacities, especially when a crisis occurs.

According to the European Commission, Industry 5.0 is a necessary evolutionary step of Industry 4.0 because of following important issues [40]:

- Industry 4.0 is not the right framework to achieve Europe’s 2030 goals, because the current digital economy is a winner-takes-all model that creates technological monopoly and giant wealth inequality.

- Industry 5.0 is not a technological leap forward, but a way to see the Industry 4.0 approach in a broader context, providing regenerative purpose and directionality to the technological transformation of industrial production for people–planet–prosperity.

- Industry 5.0 is a transformative model that reflects the evolution of our thinking post-COVID-19 pandemic, by taking into consideration learnings from the pandemic and the need to design an industrial system that is inherently more resilient to future shocks and truly integrates social and environmental principles.

The next important thing is to identify key enablers in the enterprise, which correlate with the abovementioned drivers of Industry 5.0. Schiele et al. [41] are interpreting Industry 4.0 future within technology, business, society, and people. Similarly, Sony and Naik [42] are investigating the integration of Industry 4.0 with people, infrastructure, technology, processes, culture, and goals. Akcay Kasapoglu [43] is focused on the aspect of leadership and organization during the process of Industry 4.0 transformation. Kayikci et al. [44] are investigating perspectives of people, process, performance, and technology in the Industry 4.0 food supply chain. Kiepas [45] is, similar to Oks et al. [46], simplifying the focus on key enablers, narrowing them to the three most important: humans (people), organization, and technology.

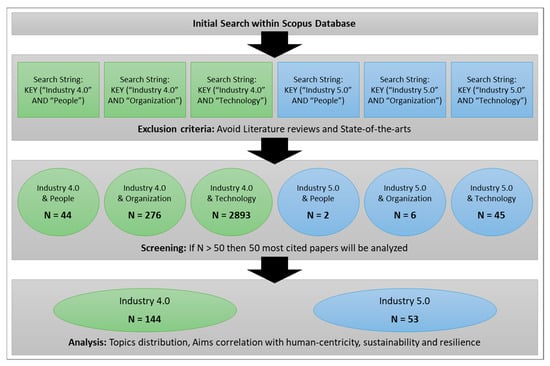

Therefore, a search was carried out within the Scopus database to explore papers related to Industry 4.0/5.0 and three most important enablers: people, organization, and technology (Figure 3). The literature reviews and state-of-the-art papers were excluded from the search.

Figure 3.

Flow of the scientific papers collection using the Scopus database.

Combinations of Industry 4.0 and Industry 5.0 with each of three enablers resulted in six categories of papers. However, the “Industry 4.0 & Organization” category resulted in 276 papers and “Industry 4.0 & Technology” resulted in 2893 papers, so only the 50 most cited papers were analyzed from each of these two categories. This collection of scientific papers gave scientific perspective to this research.

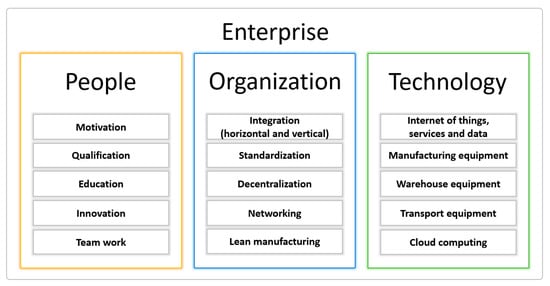

From the practical real-life perspective, some of the manufacturing industry analyses were used. The analysis of Industry 4.0 implementation in the German manufacturing industry by Veile et al. [47] was inspired by Oks et al. and used the same focus on humans (people), organization, and technology. Furthermore, in the analysis of Croatian manufacturing companies, the questionnaires were given to CEOs to identify basic objectives, main priorities, and the most important aspects regarding how to move towards new industrial paradigms [48]. Again, profound analysis of the results collected with questionnaires identified people, organization, and technology as key enablers [49]. As mentioned, studies have pointed out that each of the three enablers has its important subareas. The most important of them are shown in Figure 4.

Figure 4.

The key enablers to move towards new paradigms: people, organization, and technology.

3. Review of Key Enablers in Practical Context of Industry 4.0 and Industry 5.0

Currently, there are many useful studies about the new technologies characteristic for Industry 4.0, its introduction, and benefits [27]. The studies that emerged from the literature seek a clear vision of how Industry 4.0 impacts business models and organizations [50,51]. However, it is stated how smaller efforts have been devoted to the role of humans in the future factory, the appropriate organizational models, the approaches for long-term value creation, and the outcomes on society [52]. These linked aspects in terms of technology, people, their employability, and sustainability-related issues are crucial for long-term improvement.

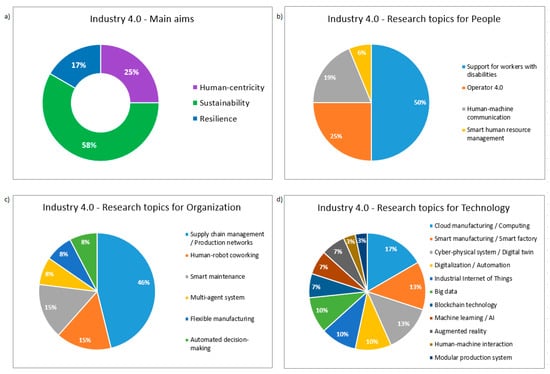

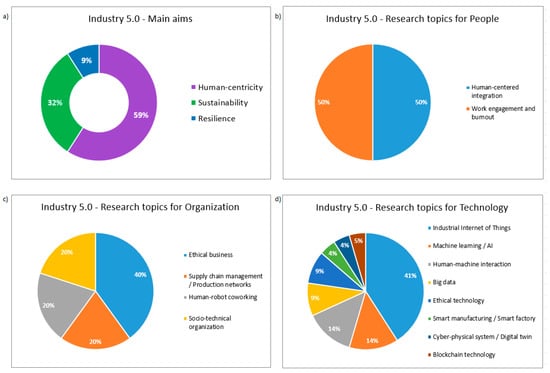

Figure 5 summarizes the literature review on Industry 4.0 in relation to people, organization, and technology. The research topics of each enabler were identified and their distribution is presented. Furthermore, the main research aims of analyzed papers were identified in correlation with drivers of Industry 5.0: human-centricity, sustainability, and resilience (Figure 5a).

Figure 5.

Industry 4.0 literature review: (a) Main research aims correlated to Industry 5.0 drivers; (b) research topics for Industry 4.0 and people; (c) research topics for Industry 4.0 and organization; (d) research topics for Industry 4.0 and technology.

The same summarization of the literature review on Industry 5.0 is presented in Figure 6. The most interesting fact is a switch in research aims. The sustainability was a major research aim in Industry 4.0, but in Industry 5.0 the human-centricity becomes a major research aim. As already mentioned, the lack of human perspective was a major disadvantage of Industry 4.0 and its main critic [39]. Another interesting fact is the rise of ethical research, with a significant share of research on ethical business and on ethical technology, as well. It is also connected with human-centricity and sustainability of Industry 5.0.

Figure 6.

Industry 5.0 literature review: (a) Main research aims correlated to Industry 5.0 drivers; (b) research topics for Industry 5.0 and people; (c) research topics for Industry 5.0 and organization; (d) research topics for Industry 5.0 and technology.

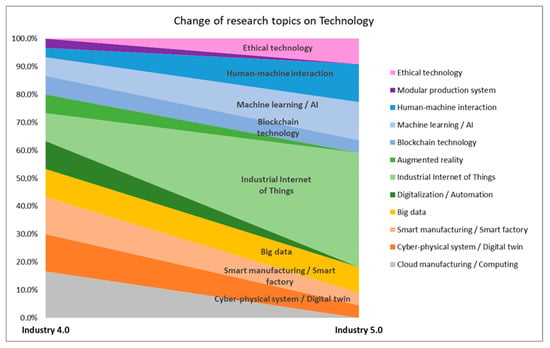

Regarding technology, Industry 4.0 was oriented to every emerging technology. However, with Industry 5.0, some of the emerging technologies are receiving more research focus, and research interest for some others is declining. This change in trends is presented in Figure 7. Again, rise of interest for human–machine interaction and artificial intelligence shows that more focus is being placed on use of technology as a support to the everyday tasks of the human worker. The Industrial Internet of Things has become a major technology research topic, because the 5G cellular network has become a standard nowadays.

Figure 7.

From Industry 4.0 toward Industry 5.0: Change of research topics on technology.

3.1. Towards Human-Centricity

In the context of transformation towards Industry 4.0, in the literature exists the awareness that skills, knowledge, and abilities of people are important in the CPS. Operator 4.0 appeared as the operator of the future. The vision of Operator 4.0 aims to create trusting and interaction-based relationships between humans and machines [53]. The ideal type of the factory worker of the future is participative and proactive [54]. There is still a lack of understanding of the interplay between humans and technology [55]. Even though Industry 4.0 was directed to the workers with disabilities (Figure 5), there was not enough adaptation of technology to people. On the one side, people need enough space to develop their skills and use their own creativity, and on the other side, they need technology only as an aid for harmonious collaboration, not to replace their work. This emphasize on human-centricity is now directed towards all workers (Figure 6), not only towards people with disabilities. Operator 5.0 should collaborate with the equipment by using its own physical, sensorial, and cognitive capabilities in an environment that provides safe work and technological assistance in the segments of work that are necessary for the operator, while technologies provide real-time information for making timely decisions.

The limitations for decision-making originate from lack of information, necessary for people for decision-making, which has changed now that the Internet of Things exists. At the moment, there are new technologies and algorithms able to collect huge amounts of data and sort and filter them, in order to use them for decision-making [56,57,58].

The development of modern tools in ergonomics with the help of Industry 4.0 technologies is becoming of more and more interest in many studies. The International Ergonomics Association offers three main domains of ergonomics: physical ergonomics (working postures, repetitive movements, material handling, safety, and health), cognitive ergonomics (mental workload, decision-making, skilled performances, motor response, trainings, and human–computer interactions), and organizational ergonomics (organizational structures, design of working times, processes, communication, and cooperative work) [59].

The main domains of ergonomics [60]:

- Physical domain—the Industry 4.0 technologies help with the automatization of manual repetitive tasks or hard-muscular tasks [61]; the devices to use on workplace are improving ergonomic feedback and new digital technologies improve internal logistics and transportation [62].

- Cognitive domain—the Industry 4.0 technologies help through virtual models to improve perception and create timely interactions; augmented reality devices contribute to the reduction of mental workload [63]; data sharing is improving cognitive ergonomics.

- Organizational domain—Industry 4.0 provides hybrid production systems to bridge the gap between humans and machines, which affects work organization and requires future skill development.

Digitalization, as a new direction in ergonomics, aims to improve working conditions and the quality of workplaces. The systems to support ergonomics should immediately inform workers about new conditions that appear and about their influence on workers in accordance with analyses that clearly point out requirements for organizationally-technical changes [64]. Other challenges can be found in the studies about the assessment and optimization of postural stress and physical fatigue to identify critical factors and to optimize the assembly operations and workload capabilities at early design stages [65].

The development of technology, namely, in terms of better adaptation to human needs, is oriented towards the following [66]:

- Networked sensors with low-level intelligence that, at the same time, reduce network overload while allowing exchange of important data.

- Creation of the digital twins, which provides monitoring of production and predicting possible scenarios [67].

- Virtual training for workers to avoid possible dangerous situations while learning specific tasks, for example, in critical review for trainings in construction safety [68], numerous VR/AR systems were proven as efficient, usable, and applicable for training and education; however, there are some challenges to deal with for improvement.

- Artificial intelligence, which enables the learning process for different machines or robots, so they are able to learn from humans and perform tasks based on this knowledge [34,69].

Special attention should be paid to the interaction between humans and robots, machines, or any other elements of the system. There are efforts in the literature to create frameworks for evaluation of the human and robot collaboration. In [70], five dimensions from the aspect of human factor in human–robot collaboration are emphasized for the evaluation: workload, trust, robot morphology, physical ergonomics, and usability. The example of a framework where trajectory prediction serves to avoid potential collisions and plan recognition serves to boost the efficiency of collaboration is included in [71]. The integration of the human–robot collaboration in assembly systems is shown in [72], but taking into consideration operations parameters such as waiting times, parallel activities, and functional delays.

By placing human beings back at the center of industrial production, aided by tools, for example, collaborative robots, Industry 5.0 not only gives consumers the products they want today, but gives workers jobs that are more meaningful than factory jobs have been in well over a century [73]. New jobs are, among other things, aimed at programming, organizing and planning, training, and maintenance. It is clear that knowledge in data science, machine learning, and artificial intelligence is very useful for the future jobs. The fear of jobs disappearing when introducing new technologies is justified because there are situations where automatization of processes with machines or robots can replace human work [74]; however, in the background there are many newly created jobs that enable the introduction of mentioned automatization process [75]. To survive an increasingly competitive market, enterprises need people who are able to manage the changes and should be capable of moving from technology to solutions and from solutions to operations, which requires a broad skillset [76]. Bridging the skills gap requires novel user-facing technologies—such as augmented reality (AR) and wearables—for human performance augmentation to improve efficiency and effectiveness of staff delivered through live guidance [77].

The human-centric approach is firmly attached to Lean management, i.e., its philosophy of the people’s engagement in process improvement from shopfloor workers to managers [78]. Lean, as a set of enterprise management tools, represents a strong support for organizing production, managing production, product development, and relationships with suppliers and consumers. To support the sustainable organization, there are studies where Lean management is supported by new technologies characteristic of Industry 4.0 [79]. Lean management is not only based on theory, but is applicable in practice, as many successful companies around the world have proven. Many companies are leading by example, e.g., Toyota production system [80]. They invest very large amounts of money and effort in the development of their own efficient production systems based on lean principles. Many papers carried out research to define frameworks and Lean tools that companies need [81,82,83]. Design and implementation of such a program of continuous improvement can significantly reduce production losses and the company can be more competitive in the market.

3.2. Towards Sustainability

With adoption of new technologies, it is inevitable to develop new business models. By using smart data, this development has to be exploited for anchoring new, sustainable business models [84]. Designing better business models requires insight into rebound effects and the potential for companies to influence sustainability impacts regarding environmental, social, and economic segments [85]. The main challenges in building the sustainable business model are the balance between profits, social and environmental benefits, reconfiguration of resources and processes for new business models, integration of technologies with business model as a multidimensional and complex task, and usage of the existing business modeling methods and tools [86]. Nevertheless, a significant business model was developed by the European Foundation for Quality Management (EFQM): the EFQM 2020 model [87]. It represents an updated EFQM business excellence model with focus on sustainability, and the model is aligned with the United Nations Sustainable Development Goals. It shares many features with Industry 4.0, especially in the context of transformation and improved organizational performance [88].

In the literature, it is stated how the usage of Industry 4.0 technologies has positive effects on organizational performances. Analysis of the data collected by Duman [89] showed improvements in organizational performance after the usage of Industry 4.0 technologies. Important organizational performance indicators, such as production amount and speed, capacity, quality, and profitability, increased and costs decreased after introduction of the Industry 4.0 technologies. Other studies support this opinion of the positive relationship between Industry 4.0 technologies and organizational performances [90,91,92,93].

An important dimension of introduction of technologies related to Industry 4.0 and 5.0 is the efficient usage of energy. New technologies always have an environmental impact, i.e., on the one side, digital technologies demand energy, but on the other side, they save energy. This opens a question: To what extent do industrial paradigms affect environmental sustainability, and is society prepared to deal with those challenges [94]? The adoption of new technologies has negative impacts on the environment, such as air pollution and intensive use of raw materials and energy [95]. However, by adoption of new technologies, the energy can be reduced by analyzing data during the production process and across the supply chain [96]. Furthermore, the process of the technology selection should include environmental and social criteria in order to select technology that is greener and more sustainable, although it can be less productive, at the same time [97].

The important aspect of sustainability and technology is in information logistical waste in the process. The problem with waste of information is recognized during the design and production process and through the supply chain [98,99]. The wastes in the process are related to three parts of data processing: data generation and transfer, data processing, and data storage and data utilization [100]. In data generation, its selection, and evaluation, it is important to collect as much data as necessary and as little as possible to evaluate them according to the content, meaning, and origin. Waste in form of wait periods and data storage matters, particularly regarding data availability in real time. Latencies in the system as well as unprocessed data lead to delays which affect processes. Transfer, movement, and search especially include manual activities, and information is not available in real time, especially when it is written on paper. For data collection or any other work with data, the manual activities should be avoided. The continuous improvement within the manufacturing processes can only be gained by linking and analyzing data.

In existing research about the sustainable energy by using Industry 4.0 technologies, there are data of about 10 to 30 percent of energy reduction for using augmented reality, 5 to 27 percent for using additive manufacturing, around 70 percent of energy savings by using the cloud computing, and 11 to 14 percent global energy reduction using big data and analytics [101].

Another important aspect which has received more attention within Industry 5.0 is the question of ethical use of technology [102,103]. This aspect is closely related to human-centricity, but it is overlapping with sustainability, because low ethical standards produce unsustainable society. Unfortunately, Industry 4.0 also has an ideological aspect in the context of philosophies of transhumanism and posthumanism [104]. These philosophies attack the historical practice in which technology is subordinated to humans, never vice versa. It must be said that, in a way, Industry 4.0 was subordinating human workers to technology. However, the approach of Industry 5.0 is completely ethical and it subordinates technology to the human worker, as the European Commission’s document clearly states [39]: “Rather than asking what we can do with new technology, we ask what the technology can do for us”.

From Section 3.2. and Figure 5a, it is visible how Industry 4.0 relies on technology to achieve sustainability through different segments of data collection and analysis towards cloud computing. However, from Figure 6a, it is clear how Industry 5.0 is oriented towards human-centricity to resolve mentioned questions of technology adaptation to the human workers, including important ethical aspects.

3.3. Towards Resilience

Resilience, as the ability to withstand disruptions and catastrophic events [105], which relies on people, has not been significantly represented in the concept of Industry 4.0 by the research community. At the moment, there is strong orientation of the literature towards resilience in the context of technology [12], which will be discussed in the below paragraph. It is rarely explored how to rely on people when it comes to resilience. In the developed resilience model by [106], people are one of the most important components because they are the first ones to detect the anomalies and their training and education, awareness building, and leadership, as well as skill and talent, are crucial factors. The strategic human resource management is instrumental in developing requisite knowledge, skills, abilities, and other attributes and in invoking the appropriate collective routines and processes to generate the resilience outcomes [107]. The strategic human resource management can be a critical point [108].

Organizational resilience is a multidisciplinary concept that has its internal and external factors. It represents the ability to overcome the problems caused by internal or external factors. An organizational resilience implies the understanding of the situation, adaption to the new situation, and managing the vulnerabilities. The firm’s capacity for developing resilience is derived from a set of specific organizational capabilities, routines, practices, and processes by which a firm orients itself, acts to move forward, and creates a setting of diversity and adjustable integration [107]. Management risk is an important internal factor for resilience. It includes risk plans and prevention techniques. Many studies emphasize information visibility as a crucial factor. Implementation of the key technologies has a positive impact on resilience [109]. New technologies offer the ability to track information that supports organizational resilience. There are positive and negative experiences with introduction of new technology and expectations of it. Each technology should be introduced with special care and consideration about what data it can generate and what benefits it can bring for organization.

Industry 4.0 brought many challenges from the aspects of security, resilience, and efficiency of digital data and systems. Cloud computing is an IT architectural model where computing services are abstracted and delivered to customers on demand, in a self-service way, independent of device and location [110]. Even though there is advanced technology, the information integration across industrial segments, levels, and processes is still a challenge. There are three major integrations in Industry 4.0: horizontal integration, vertical integration, and end-to-end integration. Since the vertical integration represents supply chains, horizontal integration represents collaborative networks [111], also known as production networks, manufacturing networks, and social manufacturing [112]. The COVID-19 pandemic has shown that supply chains can be easily broken, so the collaborative networks are also seen as emergent networks that can replace a broken supply chain and increase the resilience of the manufacturing industry [113].

To achieve integration, it is necessary to change simple information systems to the smart platform [49,112]. In the smart platform there are often high data flow rates and intensive processing requirements, which can cause insufficient system resources for processing to maintain high reliability and resilience [114]. Another challenge is lack of confidence of the industry users in using new technologies, especially from the aspect of data security. To address this, the blockchain technology can support Internet of Things technologies for information exchanges during the different processing stages within a trusted network. Potential applications of blockchain in Industry 4.0 are expected to contribute the following [115]:

- Resilience—being a decentralized peer-to-peer network, blockchain has no single point of failure; it is a durable and immutable ledger; transactions once recorded cannot be altered.

- Scalability—the computing capability of blockchain network scales up as more and more peers join the network.

- Security—all transactions on the blockchain are secured by strong cryptography; as everyone on the network knows about all transactions, they can be easily audited and cannot be disputed.

- Autonomy—blockchain can enable all the components of the CPS to carry out mutual transactions autonomously without the need for a trusted third party; every component has a blockchain account.

However, the blockchain technology is not always an appropriate choice for every firm and has its own challenges, so the need for the blockchain technology in Industry 4.0 can be evaluated according three areas: data exchanges, trusted payments, and data storage [116]. Table 1 summarizes the connection between key enablers for Industry 4.0 and Industry 5.0 and people, organization, and technology.

Table 1.

The connection between key enablers for Industry 4.0 and Industry 5.0 and people, organization, and technology in a practical context.

4. Discussion

The main guideline of why this review and analysis of paradigm shift from Industry 4.0 to Industry 5.0 relies on three segments: people, organization, and technology, comes from existing literature and previous research. In addition, these segments are essential for any manufacturing company, so this paper leads the reader through the basic concepts of each paradigm and essential segments in practical context. The connection between basic concepts of paradigms and these three segments, as is represented in the third section, is important:

- To achieve the goals of each paradigm, where it is crucial to be aware how key enablers are interconnected.

- To review the company’s weak points according to the connections of key enablers, so as to know the areas of further action for improvement.

- To rethink the human centricity approach in a company’s environment, to adapt technology and organization to people and provide good working conditions as people deserve.

- To assess the sustainability when introducing the change from technological, organizational, or any other aspect.

- To question one’s own ability to adapt to changes imposed by either external or internal factors affecting the company.

- To improve a company’s organizational performances.

- To strike a balance between effort and investment in change in terms of manpower, organization, and technology.

Another crucial part which follows up on the importance of the connection between the basic concepts of paradigms is the readiness to introduce any feature of new paradigms. The production system or the process that is observed should be ready for that step. A wide range of maturity models are dedicated to the aspects of technical and social systems maturity [117]. The maturity models are increasingly being applied in the area of information technologies [118,119], but especially in digital readiness [120]. There is strong interest from authors in development of maturity models as crucial to adopt new technologies. There are several maturity and readiness models related to Industry 4.0. Through a brief review of existing maturity and readiness models, it is visible that their assessment approaches have a lot in common (Table 2). Models are focused on items for the maturity indication and the range of items’ levels. However, in Table 2 it is visible how these models do not cover basic driving concepts characteristic for Industry 5.0. In the models there is a very poor orientation towards human-centricity, sustainability, or resilience.

Table 2.

A brief review of some of the existing maturity and readiness models.

The assessment of the company’s readiness and maturity to introduce any aspect of new paradigms represents the basis. Furthermore, the reasons for introduction are different. In the literature, is stated how the intentions to use Industry 4.0 technologies are more influenced by the expected increase in efficiency than by pressures from suppliers, customers, or even competitors [126]. On the other side, other results yield that the market uncertainty of the business is a significant driver for adoption of Industry 4.0 technologies [127]. For whatever reason, the broader consequences of this introduction should be considered, as well as the human aspect. Additionally, a useful aspect will be the development of a measurement system that can give information about how organization and production benefit from the introduction of the concepts of new paradigms.

5. Conclusions

This review and analysis of paradigm shift for the people, organization, and technology highlights the challenges to introduce the concepts of new paradigms in each essential segment of manufacturing. In contrast with previously published reviews, the goal of this review was to develop a connection matrix between key enablers for Industry 4.0 and Industry 5.0 and essential segments of each manufacturing: people, organization, and technology. People will always be the main drivers of the activities in the production system. The humans that create and manage production systems need support in preparation of infrastructure and resources for introduction of new technologies. In further steps, they need support in transferring the knowledge from a virtual to physical world, and vice versa. This requires future research in domains of adaptation of technology to humans. Significant effort should be made in areas of data collection and interpretation through different useful reports, so that people can make their decisions based on the real-time data. In parallel, there is an effort to create robots that are autonomous and that can collaborate with people. However, these efforts should be made keeping in mind the influence on the sustainability and resilience. On the one side, there are organizational, social, and ergonomic aspects where technology should be at people’s disposal, but on the other side, there is energy reduction to satisfy environmental aspects. The crucial aspect is balance between all essential segments in the context of new paradigms, but always keeping human in the center. Generally, the Industry 5.0 paradigm brought the change of main research objectives from sustainability towards human-centricity. From the managerial perspective, it means focusing on workers’ education and lifelong learning, instead of focusing on purchase of new technology, or similar. In comparison with Japan and South Korea, the USA and EU are still not investing enough in education of workers, which is becoming an essential issue. Furthermore, it is also important to consider the limitations of this research that are mainly linked to search criteria (keywords). Sometimes the keywords for the paper are not properly selected; thus, applying the keywords filter during the search excludes some high-quality papers, and perhaps includes some papers of lower quality. The future research could use wider search criteria, such as filtering of abstract instead of keywords, in order to create more profound analysis of this topic. Finally, in the future research, the proposed connection matrix can be extended and discussed within the context of specific subareas (i.e., specific subarea for technology can be augmented reality) and all effects of subareas can be seen from the aspect of basic driving concepts and key enablers for each paradigm.

Author Contributions

Conceptualization, M.C.Z. and M.M.; methodology, M.C.Z.; validation, M.C.Z., M.M., N.G. and L.C.; writing—original draft preparation, M.C.Z. and M.M.; writing—review and editing, M.C.Z., M.M., N.G. and L.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by MZO-VIF INTEMON project.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Parida, V.; Sjodin, A.; Reim, W. Reviewing Literature on Digitalization, Business Model Innovation, and Sustainable Industry: Past Achievements and Future Promises. Sustainability 2019, 11, 391. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J. Digitalization and Intelligentization of Manufacturing Industry. Adv. Manuf. 2013, 1, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Ciffolilli, A.; Muscio, A. Industry 4.0: National and Regional Comparative Advantages in Key Enabling Technologies. Eur. Plan. Stud. 2018, 26, 2323–2343. [Google Scholar] [CrossRef]

- Saniuk, S.; Grabowska, S.; Gajdzik, B. Personalization of Products in the Industry 4.0 Concept and Its Impact on Achieving a Higher Level of Sustainable Consumption. Energies 2020, 13, 5895. [Google Scholar] [CrossRef]

- Lepore, D.; Dubbini, S.; Micozzi, A.; Spigarelli, F. Knowledge Sharing Opportunities for Industry 4.0 Firms. J. Knowl. Econ. 2021, 13, 501–520. [Google Scholar] [CrossRef]

- Molino, M.; Cortese, C.G.; Ghislieri, C. The Promotion of Technology Acceptance and Work Engagement in Industry 4.0: From Personal Resources to Information and Training. Int. J. Environ. Res. Public Health 2020, 17, 2438. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Wang, G. Big Data in Cyber-Physical Systems, Digital Manufacturing and Industry 4.0. Int. J. Eng. Manuf. 2016, 6, 1–8. [Google Scholar]

- Kagermann, H.; Wahlster, W.; Helbig, J.; Hellinger, A.; Stumpf, M.A.V.; Treugut, L.; Blasco, J.; Galloway, H.; Findeklee, U. Recommendations for Implementing the Strategic Initiative Industrie 4.0; National Academy of Science and Engineering: Washington, DC, USA, 2013. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Kong, X.T.R.; Luo, H.; Huang, G.Q.; Yang, X. Industrial Wearable System: The Human-Centric Empowering Technology in Industry 4.0. J. Intell. Manuf. 2019, 30, 2853–2869. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Haq, M.I.U.; Raina, A.; Suman, R. Industry 5.0: Potential Applications in COVID-19. J. Ind. Integr. Manag. 2020, 5, 507–530. [Google Scholar] [CrossRef]

- Xu, X.; Lu, Y.; Vogel-Heuser, B.; Wang, L. Industry 4.0 and Industry 5.0—Inception, Conception and Perception. J. Manuf. Syst. 2021, 61, 530–535. [Google Scholar] [CrossRef]

- Müller, J. Enabling Technologies for Industry 5.0—Results of a Workshop with Europe’s Technology Leaders; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-Working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Iftikhar, H.M.; Iftikhar, L. Post COVID-19 Industrial Revolution 5.0. The Dawn of Cobot, Chipbot and Curbot. Pak. J. Surg. Med. 2020, 1, 122–126. [Google Scholar]

- Hu, S.J. Evolving Paradigms of Manufacturing: From Mass Production to Mass Customization and Personalization. Procedia CIRP 2013, 7, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Mladineo, M.; Crnjac Zizic, M.; Aljinovic, A.; Gjeldum, N. Towards a Knowledge-Based Cognitive System for Industrial Application: Case of Personalized Products. J. Ind. Inf. Integr. 2022, 27, 100284. [Google Scholar] [CrossRef]

- Horváth, D.; Szabó, R.Z. Driving Forces and Barriers of Industry 4.0: Do Multinational and Small and Medium-Sized Companies Have Equal Opportunities? Technol. Forecast. Soc. Chang. 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.; de Freitas Rocha Loures, R.; Ramos, L.F.P. Past, Present and Future of Industry 4.0—A Systematic Literature Review and Research Agenda Proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Haseeb, M.; Hussain, H.I.; Ślusarczyk, B.; Jermsittiparsert, K. Industry 4.0: A Solution towards Technology Challenges of Sustainable Business Performance. Soc. Sci. 2019, 8, 154. [Google Scholar] [CrossRef] [Green Version]

- Medić, N.; Anišić, Z.; Lalić, B.; Marjanović, U.; Brezocnik, M. Hybrid Fuzzy Multi-Attribute Decision Making Model for Evaluation of Advanced Digital Technologies in Manufacturing: Industry 4.0 Perspective. Adv. Prod. Eng. Manag. 2019, 14, 483–493. [Google Scholar] [CrossRef]

- Bai, C.; Dallasega, P.; Orzes, G.; Sarkis, J. Industry 4.0 Technologies Assessment: A Sustainability Perspective. Int. J. Prod. Econ. 2020, 229, 107776. [Google Scholar] [CrossRef]

- Schumacher, A.; Erol, S.; Sihn, W. A Maturity Model for Assessing Industry 4.0 Readiness and Maturity of Manufacturing Enterprises. Procedia CIRP 2016, 52, 161–166. [Google Scholar] [CrossRef]

- Rauch, E.; Unterhofer, M.; Rojas, R.A.; Gualtieri, L.; Woschank, M.; Matt, D.T. A Maturity Level-Based Assessment Tool to Enhance the Implementation of Industry 4.0 in Small and Medium-Sized Enterprises. Sustainability 2020, 12, 3559. [Google Scholar] [CrossRef]

- Zuehlke, D. SmartFactory—Towards a Factory-of-Things. Annu. Rev. Control 2010, 34, 129–138. [Google Scholar] [CrossRef]

- Felsberger, A.; Reiner, G. Sustainable Industry 4.0 in Production and Operations Management: A Systematic Literature Review. Sustainability 2020, 12, 7982. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature Review of Industry 4.0 and Related Technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Borgia, E. The Internet of Things Vision: Key Features, Applications and Open Issues. Comput. Commun. 2014, 54, 1–31. [Google Scholar] [CrossRef]

- Wan, J.; Chin-Feng, L.; Houbing, S.; Muhammad, I.; Dongyao, J. Software-Defined Industrial Internet of Things. IEEE Sens. J. 2016, 16, 7373–7380. [Google Scholar] [CrossRef] [Green Version]

- Wollschlaeger, M.; Thilo, S.; Juergen, J. The Future of Industrial Communication: Automation Networks in the Era of the Internet of Things and Industry 4.0. IEEE Ind. Electron. Mag. 2017, 11, 7–27. [Google Scholar] [CrossRef]

- Tissir, N.; el Kafhali, S.; Aboutabit, N. Cybersecurity Management in Cloud Computing: Semantic Literature Review and Conceptual Framework Proposal. J. Reliab. Intell. Environ. 2021, 7, 69–84. [Google Scholar] [CrossRef]

- Baheti, R.; Gill, H. Cyber-Phisical Systems. Impact Control Technol. 2011, 12, 161–166. [Google Scholar]

- Monostori, L. Cyber-Physical Production Systems: Roots, Expectations and R&D Challenges. Procedia CIRP 2014, 17, 9–13. [Google Scholar]

- Peres, R.S.; Jia, X.; Lee, J.; Sun, K.; Colombo, A.W.; Barata, J. Industrial Artificial Intelligence in Industry 4.0—Systematic Review, Challenges and Outlook. IEEE Access 2020, 8, 220121–220139. [Google Scholar] [CrossRef]

- Patel, P.; Muhammad, I.A.; Amit, S. From Raw Data to Smart Manufacturing: AI and Semantic Web of Things for Industry 4.0. IEEE Intell. Syst. 2018, 33, 79–86. [Google Scholar] [CrossRef]

- Mourtzis, D.; Zogopoulos, V.; Xanthi, F. Augmented Reality Application to Support the Assembly of Highly Customized Products and to Adapt to Production Re-Scheduling. Int. J. Adv. Manuf. Technol. 2019, 105, 3899–3910. [Google Scholar] [CrossRef]

- Sommer, M.; Stjepandic, J.; Stobrawa, S.; von Soden, M. Improvement of Factory Planning by Automated Generation of a Digital Twin. In Proceedings of the Advances in Transdisciplinary Engineering; IOS Press: Amsterdam, The Netherlands, 2020; Volume 12, pp. 453–462. [Google Scholar]

- Beer, J.M.; Fisk, A.D.; Rogers, W.A. Toward a Framework for Levels of Robot Autonomy in Human-Robot Interaction. J. Hum. -Robot. Interact. 2014, 3, 74. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Directorate General for Research and Innovation Industry 5.0—Towards a Sustainable, Human-Centric and Resilient European Industry; Publications Office of the European Union: Luxemburg, 2021. [Google Scholar]

- Renda, A.; Schwaag Serger, S.; Tataj, D. Industry 5.0, A Transformative Vision for Europe: Governing Systemic Transformations towards a Sustainable Industry; Publications Office of the European Union: Luxemburg, 2022. [Google Scholar]

- Schiele, H.; Bos-Nehles, A.; Delke, V.; Stegmaier, P.; Torn, R.J. Interpreting the Industry 4.0 Future: Technology, Business, Society and People. J. Bus. Strategy 2021, 43, 157–167. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 Integration with Socio-Technical Systems the-Ory: A Systematic Review and Proposed Theoretical Model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Akcay Kasapoglu, O. Leadership and Organization for the Companies in the Process of Industry 4.0 Transformation. Int. J. Organ. Leadersh. 2018, 7, 300–308. [Google Scholar] [CrossRef]

- Kayikci, Y.; Subramanian, N.; Dora, M.; Bhatia, M.S. Food Supply Chain in the Era of Industry 4.0: Blockchain Technology Implementation Opportunities and Impediments from the Perspective of People, Process, Performance, and Technology. Prod. Plan. Control 2020, 33, 301–321. [Google Scholar] [CrossRef]

- Kiepas, A. Humanity–Organization–Technology in View of Industry 4.0. Society 5.0. Pol. Political Sci. Yearb. 2021, 3, 21–32. [Google Scholar] [CrossRef]

- Oks, S.J.; Fritzsche, A.; Möslein, K.M. An Application Map for Industrial Cyber-Physical Systems. In Industrial Internet of Things: Cybermanufacturing Systems; Springer: Cham, Switzerland, 2017; pp. 21–46. [Google Scholar]

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.I. Lessons Learned from Industry 4.0 Implementation in the German Manufacturing Industry. J. Manuf. Technol. Manag. 2019, 31, 977–997. [Google Scholar] [CrossRef] [Green Version]

- Veza, I.; Mladineo, M.; Gjeldum, N. Selection of the Basic Lean Tools for Development of Croatian Model of Innovative Smart Enterprise. Teh. Vjesn. 2016, 23, 1317–1324. [Google Scholar]

- Crnjac, M.; Veža, I.; Banduka, N. From Concept to the Introduction of Industry 4.0. Int. J. Ind. Eng. Manag. 2017, 8, 21–30. [Google Scholar]

- Ibarra, D.; Ganzarain, J.; Igartua, J.I. Business Model Innovation through Industry 4.0: A Review. Procedia Manuf. 2018, 22, 4–10. [Google Scholar] [CrossRef]

- Fettig, K.; Gacic, T.; Koskal, A.; Kuhn, A.; Stuber, F. Impact of Industry 4.0 on Organizational Structures. In Proceedings of the 2018 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC 2018), Stuttgart, Germany, 17–20 June 2018. [Google Scholar]

- Tirabeni, L.; de Bernardi, P.; Forliano, C.; Franco, M. How Can Organisations and Business Models Lead to a More Sustainable Society? A Framework from a Systematic Review of the Industry 4.0. Sustainability 2019, 11, 6363. [Google Scholar] [CrossRef] [Green Version]

- Romero, D.; Bernus, P.; Noran, O.; Stahre, J.; Berglund, Å.F. The Operator 4.0: Human Cyber-Physical Systems & Adaptive Automation towards Human-Automation Symbiosis Work Systems. In Proceedings of the IFIP Advances in Information and Communication Technology; Springer: Cham, Switzerland, 2016; Volume 488, pp. 677–686. [Google Scholar]

- Mazali, T. From Industry 4.0 to Society 4.0, There and Back. AI Soc. 2018, 33, 405–411. [Google Scholar] [CrossRef]

- Stentoft, J.; Wickstrøm, K.A.; Philipsen, K.; Haug, A. Drivers and Barriers for Industry 4.0 Readiness and Practice: Empirical Evidence from Small and Medium-Sized Manufacturers. Prod. Plan. Control 2021, 32, 811–828. [Google Scholar] [CrossRef]

- Davidson, R. Cyber-Physical Production Networks, Artificial Intelligence-Based Decision-Making Algorithms, and Big Data-Driven Innovation in Industry 4.0-Based Manufacturing Systems. Econ. Manag. Financ. Mark. 2020, 15, 16–22. [Google Scholar]

- Duft, G.; Durana, P. Artificial Intelligence-Based Decision-Making Algorithms, Automated Production Systems, and Big Data-Driven Innovation in Sustainable Industry 4.0. Econ. Manag. Financ. Mark. 2020, 15, 9–18. [Google Scholar]

- Coatney, K. Milos Poliak Cognitive Decision-Making Algorithms, Internet of Things Smart Devices, and Sustainable Organizational Performance in Industry 4.0-Based Manufacturing Systems. J. Self-Gov. Manag. Econ. 2020, 8, 9–18. [Google Scholar]

- International Ergonomics Association Ergonomic Dimensions. Ergonomic Domains. Available online: https://iea.cc/ (accessed on 12 December 2021).

- Kadir, B.A.; Broberg, O.; da Conceição, C.S. Current Research and Future Perspectives on Human Factors and Ergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [Google Scholar] [CrossRef]

- Erol, S.; Jäger, A.; Hold, P.; Ott, K.; Sihn, W. Tangible Industry 4.0: A Scenario-Based Approach to Learning for the Future of Production. Procedia CIRP 2016, 54, 13–18. [Google Scholar] [CrossRef]

- Winkelhaus, S.; Grosse, E.H. Logistics 4.0: A Systematic Review towards a New Logistics System. Int. J. Prod. Res. 2020, 58, 18–43. [Google Scholar] [CrossRef]

- Jeffri, N.F.S.; Awang Rambli, D.R. A Review of Augmented Reality Systems and Their Effects on Mental Workload and Task Performance. Heliyon 2021, 7, e06277. [Google Scholar] [CrossRef] [PubMed]

- Gašová, M.; Gašo, M.; Štefánik, A. Advanced Industrial Tools of Ergonomics Based on Industry 4.0 Concept. Procedia Eng. 2017, 192, 219–224. [Google Scholar] [CrossRef]

- Alkan, B.; Vera, D.; Ahmad, M.; Ahmad, B.; Harrison, R. A Lightweight Approach for Human Factor Assessment in Virtual Assembly Designs: An Evaluation Model for Postural Risk and Metabolic Workload. Procedia CIRP 2016, 44, 26–31. [Google Scholar] [CrossRef] [Green Version]

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef] [Green Version]

- Stjepandić, J.; Sommer, M.; Stobrawa, S. Digital Twin: Conclusion and Future Perspectives; Springer: Cham, Switzerland, 2022. [Google Scholar]

- Li, X.; Yi, W.; Chi, H.L.; Wang, X.; Chan, A.P.C. A Critical Review of Virtual and Augmented Reality (VR/AR) Applications in Construction Safety. Autom. Constr. 2018, 86, 150–162. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, T.J.Y.; Wang, X.; Kim, M.; Quan, Y.J.; Oh, J.W.; Min, S.H.; Kim, H.; Bhandari, B.; Yang, I.; et al. Smart Machining Process Using Machine Learning: A Review and Perspective on Machining Industry. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 555–568. [Google Scholar] [CrossRef]

- Gervasi, R.; Mastrogiacomo, L.; Franceschini, F. A Conceptual Framework to Evaluate Human-Robot Collaboration. Int. J. Adv. Manuf. Technol. 2020, 108, 841–865. [Google Scholar] [CrossRef]

- Cheng, Y.; Sun, L.; Liu, C.; Tomizuka, M. Towards Efficient Human-Robot Collaboration with Robust Plan Recognition and Trajectory Prediction. IEEE Robot. Autom. Lett. 2020, 5, 2602–2609. [Google Scholar] [CrossRef]

- Aljinovic, A.; Crnjac, M.; Nikola, G.; Mladineo, M.; Basic, A.; Ivica, V. Integration of the Human-Robot System in the Learning Factory Assembly Process. Procedia Manuf. 2020, 45, 158–163. [Google Scholar] [CrossRef]

- Ostergaard, E. Welcome to Industry 5.0; Universal Robots: Odense, Denmark, 2018. [Google Scholar]

- Benedikt Frey, C.; Osborne, M.A. The Future of Employment: How Susceptible Are Jobs to Computerisation? Oxford Martin Programme on Technology and Employment: Oxford, UK, 2013. [Google Scholar]

- Spath, D.; Ganschar, O.; Gerlach, S.; Hämmerle, M.; Krause, T.; Schhlund, S. Produktionsarbeit Der Zukunft—Industrie 4.0; Fraunhofer-IAO: Stuttgart, Germany, 2013. [Google Scholar]

- Broo, G.D.; Kaynak, O.; Sait, S.M. Rethinking Engineering Education at the Age of Industry 5.0. J. Ind. Inf. Integr. 2022, 25, 100311. [Google Scholar] [CrossRef]

- Ras, E.; Wild, F.; Stahl, C.; Baudet, A. Bridging the Skills Gap of Workers in Industry 4.0 by Human Performance Augmentation Tools—Challenges and Roadmap. In Proceedings of the 10th ACM International Conference Proceeding Series, Rhodes, Greece, 21–23 June 2017; Association for Computing Machinery: New York, NY, USA, 2017; pp. 428–432. [Google Scholar]

- Mladineo, M.; Ćubić, M.; Gjeldum, N.; Crnjac Žižić, M. Human-Centric Approach of the Lean Management as an Enabler of Industry 5.0 in SMEs. In Proceedings of the 10th International Conference on Mechanical Technologies and Structural Materials, Split, Croatia, 23–24 September 2021; pp. 111–117. [Google Scholar]

- Langlotz, P.; Aurich, J.C. Causal and Temporal Relationships within the Combination of Lean Production Systems and Industry 4.0. Procedia CIRP 2020, 96, 236–241. [Google Scholar] [CrossRef]

- Liker, J. The Toyota Way; McGraw-Hill Eductaion: New York, NY, USA, 2003. [Google Scholar]

- Belhadi, A.; Touriki, F.E.; el Fezazi, S. A Framework for Effective Implementation of Lean Production in Small and Medium-Sized Enterprises. J. Ind. Eng. Manag. 2016, 9, 786–810. [Google Scholar] [CrossRef] [Green Version]

- Mostafa, S.; Dumrak, J.; Soltan, H. A Framework for Lean Manufacturing Implementation. Prod. Manuf. Res. 2013, 1, 44–64. [Google Scholar] [CrossRef] [Green Version]

- Netland Torbjørn, H. Company-Specific Production Systems: Managing Production Improvement in Global Firms. Ph.D. Thesis, Norvegian University of Science and Technology, Trondheim, Norway, December 2013. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Bocken, N.; Boons, F.; Baldassarre, B. Sustainable Business Model Experimentation by Understanding Ecologies of Business Models. J. Clean. Prod. 2019, 208, 1498–1512. [Google Scholar] [CrossRef]

- Evans, S.; Vladimirova, D.; Holgado, M.; van Fossen, K.; Yang, M.; Silva, E.A.; Barlow, C.Y. Business Model Innovation for Sustainability: Towards a Unified Perspective for Creation of Sustainable Business Models. Bus. Strategy Environ. 2017, 26, 597–608. [Google Scholar] [CrossRef]

- Fonseca, L. The EFQM 2020 Model. A Theoretical and Critical Review. Total Qual. Manag. Bus. Excell. 2022, 33, 1011–1038. [Google Scholar] [CrossRef]

- Fonseca, L.; Amaral, A.; Oliveira, J. Quality 4.0: The EFQM 2020 Model and Industry 4.0 Relationships and Implications. Sustainability 2021, 13, 3107. [Google Scholar] [CrossRef]

- Calış Duman, M.; Akdemir, B. A Study to Determine the Effects of Industry 4.0 Technology Components on Organizational Performance. Technol. Forecast. Soc. Chang. 2021, 167, 120615. [Google Scholar] [CrossRef]

- Kadir, B.A.; Broberg, O. Human Well-Being and System Performance in the Transition to Industry 4.0. Int. J. Ind. Ergon. 2020, 76, 102936. [Google Scholar] [CrossRef]

- Chauhan, C.; Singh, A.; Luthra, S. Barriers to Industry 4.0 Adoption and Its Performance Implications: An Empirical Investigation of Emerging Economy. J. Clean. Prod. 2021, 285, 124809. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Ghadge, A.; Raut, R. A Performance Measurement System for Industry 4.0 Enabled Smart Manufacturing System in SMMEs—A Review and Empirical Investigation. Int. J. Prod. Econ. 2020, 229, 107853. [Google Scholar] [CrossRef]

- Büchi, G.; Cugno, M.; Castagnoli, R. Smart Factory Performance and Industry 4.0. Technol. Forecast. Soc. Chang. 2020, 150, 119790. [Google Scholar] [CrossRef]

- Bonilla, S.H.; Silva, H.R.O.; da Silva, M.T.; Gonçalves, R.F.; Sacomano, J.B. Industry 4.0 and Sustainability Implications: A Scenario-Based Analysis of the Impacts and Challenges. Sustainability 2018, 10, 3740. [Google Scholar] [CrossRef] [Green Version]

- Oláh, J.; Aburumman, N.; Popp, J.; Khan, M.A.; Haddad, H.; Kitukutha, N. Impact of Industry 4.0 on Environmental Sustainability. Sustainability 2020, 12, 4674. [Google Scholar] [CrossRef]

- Rocha, A.D.; Freitas, N.; Alemão, D.; Guedes, M.; Martins, R.; Barata, J. Event-Driven Interoperable Manufacturing Ecosystem for Energy Consumption Monitoring. Energies 2021, 14, 3620. [Google Scholar] [CrossRef]

- Celent, L.; Mladineo, M.; Gjeldum, N.; Zizic, M.C. Multi-Criteria Decision Support System for Smart and Sustainable Machining Process. Energies 2022, 15, 772. [Google Scholar] [CrossRef]

- Tribelsky, E.; Sacks, R. Measuring Information Flow in the Detailed Design of Construction Projects. Res. Eng. Des. 2010, 21, 189–206. [Google Scholar] [CrossRef]

- Maurer, C. The Measurement of Information Flow Efficiency in Supply Chain. Ph.D. Thesis, University of South Africa, Pretoria, South Africa, 2013. [Google Scholar]

- Meudt, T.; Leipoldt, C.; Metternich, J. Der Neue Blick Auf Verschwendungen Im Kontext von Industrie 4.0 Detaillierte Analyse von Verschwendungen in Informationslogistikprozessen. ZWF Z. Fuer Wirtsch. Fabr. 2016, 111, 754–758. [Google Scholar] [CrossRef]

- Hidayatno, A.; Destyanto, A.R.; Hulu, C.A. Industry 4.0 Technology Implementation Impact to Industrial Sustainable Energy in Indonesia: A Model Conceptualization. Energy Procedia 2019, 156, 227–233. [Google Scholar] [CrossRef]

- Longo, F.; Padovano, A.; Umbrello, S. Value-Oriented and Ethical Technology Engineering in Industry 5.0: A Human-Centric Perspective for the Design of the Factory of the Future. Appl. Sci. 2020, 10, 4182. [Google Scholar] [CrossRef]

- Margherita, E.G.; Braccini, A.M. Managing Industry 4.0 Automation for Fair Ethical Business Development: A Single Case Study. Technol. Forecast. Soc. Chang. 2021, 172, 121048. [Google Scholar] [CrossRef]

- Kravchenko, A. The Forth Industrial Revolution: New Paradigm of Society Development or Posthumanist Manifesto. Philos. Cosmol. 2019, 22, 128. [Google Scholar] [CrossRef]

- Acquaah, M.; Amoako-Gyampah, K.; Jayaram, J. Resilience in Family and Nonfamily Firms: An Examination of the Relationships between Manufacturing Strategy, Competitive Strategy and Firm Performance. Int. J. Prod. Res. 2011, 49, 5527–5544. [Google Scholar] [CrossRef]

- Morisse, M.; Prigge, C. Design of a Business Resilience Model for Industry 4.0 Manufacturers. In Proceedings of the Twenty-Third Americas Conference on Information Systems, Boston, MA, USA, 10–12 August 2017. [Google Scholar]

- Lengnick-Hall, C.A.; Beck, T.E.; Lengnick-Hall, M.L. Developing a Capacity for Organizational Resilience through Strategic Human Resource Management. Hum. Resour. Manag. Rev. 2011, 21, 243–255. [Google Scholar] [CrossRef]

- Al-Ayed, S.I. The Impact of Strategic Human Resource Management on Organizational Resilience: An Empirical Study on Hospitals. Bus. Theory Pract. 2019, 20, 179–186. [Google Scholar] [CrossRef]

- Marcucci, G.; Antomarioni, S.; Ciarapica, F.E.; Bevilacqua, M. The Impact of Operations and IT-Related Industry 4.0 Key Technologies on Organizational Resilience. Prod. Plan. Control 2021, 1–15. [Google Scholar] [CrossRef]

- Marston, S.; Li, Z.; Bandyopadhyay, S.; Zhang, J.; Ghalsasi, A. Cloud Computing—The Business Perspective. Decis. Support Syst. 2011, 51, 176–189. [Google Scholar] [CrossRef]

- Torn, I.A.R.; Vaneker, T.H.J. Mass Personalization with Industry 4.0 by SMEs: A Concept for Collaborative Networks. Procedia Manuf. 2019, 28, 135–141. [Google Scholar] [CrossRef]

- Mladineo, M.; Celar, S.; Celent, L.; Crnjac, M. Selecting Manufacturing Partners in Push and Pull-Type Smart Collaborative Networks. Adv. Eng. Inform. 2018, 38, 291–305. [Google Scholar] [CrossRef]

- Lagorio, A.; Cimini, C.; Pinto, R.; Paris, V. Emergent Virtual Networks amid Emergency: Insights from a Case Study. Int. J. Logist. Res. Appl. 2021, 1–21. [Google Scholar] [CrossRef]

- Xu, L.; Xu, E.L.; Li, L. Industry 4.0: State of the Art and Future Trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef] [Green Version]

- Joshi, N. Blockchain Meets Industry 4.0—What Happened Next? 2020. Available online: https://www.allerin.com/blog/5659-2 (accessed on 11 November 2021).

- Fernandez-Carames, T.M.; Fraga-Lamas, P. A Review on the Application of Blockchain to the Next Generation of Cybersecure Industry 4.0 Smart Factories. IEEE Access 2019, 7, 45201–45218. [Google Scholar] [CrossRef]

- Mettler, T. Maturity Assessment Models: A Design Science Research Approach. Int. J. Soc. Syst. Sci. 2011, 3, 81–98. [Google Scholar] [CrossRef] [Green Version]

- Becker, J.; Knackstedt, R.; Pöppelbuß, J. Developing Maturity Models for IT Management. Bus. Inf. Syst. Eng. 2009, 1, 213–222. [Google Scholar] [CrossRef]

- Becker, J.; Knackstedt, R.; Pöppelbuß, J. Entwicklung von Reifegradmodellen Für Das IT-Management. Wirtschaftsinformatik 2009, 51, 249–260. [Google Scholar] [CrossRef]

- de Carolis, A.; Macchi, M.; Negri, E.; Terzi, S. A Maturity Model for Assessing the Digital Readiness of Manufacturing Companies. In Proceedings of the IFIP International Conference on Advances in Production Management Systems, Hamburg, Germany, 3–7 September 2017; Springer: Cham, Switzerland, 2017; pp. 13–20. [Google Scholar]

- Rockwell Automation. The Connected Enterprise Maturity Model; Rockwell Automation: Milwaukee, WI, USA, 2014. [Google Scholar]

- IMPULS Industry 4.0 Readiness Online Self-Check for Businesses; Publications Office of the European Union: Luxemburg, 2017.

- pwc Industry 4.0—Enabling Digital Operations Self Assessment. Available online: www.pwc.com/industry40 (accessed on 19 September 2021).

- Leyh, C.; Bley, K.; Schaffer, T.; Bay, L. The Application of the Maturity Model SIMMI 4.0 in Selected Enterprises. In Proceedings of the 23rd Americas Conference on Information Systems (AMCIS 2017), Boston, MA, USA, 10–12 August 2017. [Google Scholar]

- Mittal, S.; Romero, D.; Wuest, T. Towards a Smart Manufacturing Maturity Model for SMEs (SM3E). In IFIP Advances in Information and Communication Technology; Springer: New York, NY, USA, 2018; Volume 536, pp. 155–163. [Google Scholar]

- Čater, T.; Čater, B.; Černe, M.; Koman, M.; Redek, T. Industry 4.0 Technologies Usage: Motives and Enablers. J. Manuf. Technol. Manag. 2021, 32, 323–345. [Google Scholar] [CrossRef]

- Prause, M. Challenges of Industry 4.0 Technology Adoption for SMEs: The Case of Japan. Sustainability 2019, 11, 5807. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).