Car Engines Comparative Analysis: Sustainable Approach

Abstract

:1. Introduction

2. Theoretical Background

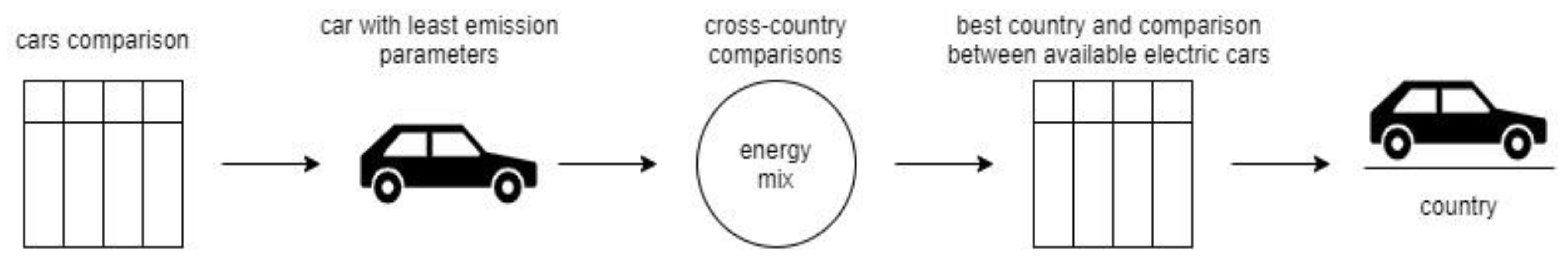

3. Materials and Methods

| Vehicle | Electric—EV 1 | Petrol-Electric | Petrol | Diesel |

|---|---|---|---|---|

| Year of availability/ of production | 2021 | 2021 | 2021 | 2021 |

| Propelled wheels | 4 wheels | 2 wheels | 4 wheels | 4 wheels |

| Power (hp) | 228 | 218 | 224 | 190 |

| Torque (Nm) | 390 | 350 | 350 | 400 |

| Average fuel consumption (l/100 km) | 0 | 1.6/7.6 | 8.4 | 6.1 |

| Average electricity consumption (KWh/100 km) | 17.5 | 17.5 | 0 | 0 |

| Average CO2 emissions (g/km) | 0 | 37/173 | 191 | 161 |

| Acceleration to 100 km/h (s) | 7.7 | 7.1 | 6.7 | 7.3 |

| Weight (kg) | 2105 | 1775 | 1600 | 1670 |

- —Obtaining the Fuel from Crude oil processing (liters),

- —a percentage of obtaining a particular fuel (% as decimal fraction),

- —capacity per barrel of oil (liters),

- —barrels (quantity).

- —CO2 emissions from the fuel (kg),

- —coefficient of global average CO2 emissions from extracting and processing 1 tonne of crude oil (kg)

- —a percentage of obtaining a particular fuel (% as decimal fraction)

- —CO2 emissions generated in 1 L of fuel production (g/L)

- —CO2 emissions per 1 km by ICE (g/km)

- —fuel combustion of the vehicle for 100 km

- —CO2 emissions per 1 km by EV (g/km)

- —CO2 emissions generated from the extraction of 1 KWh (g)

- —energy consumption of the vehicle for 100 km

- —CO2 emissions per 1 km by PHEV (g/km)

- —a minimum range of the vehicle on electricity for 100 km (%)

- —distance traveled on the internal combustion engine when the battery is exhausted [%].

- Detailed calculations and their results are available in Supplementary Materials.

4. Results

4.1. Specifications of the Compared Car Models

4.2. CO2 Emissions Comparison

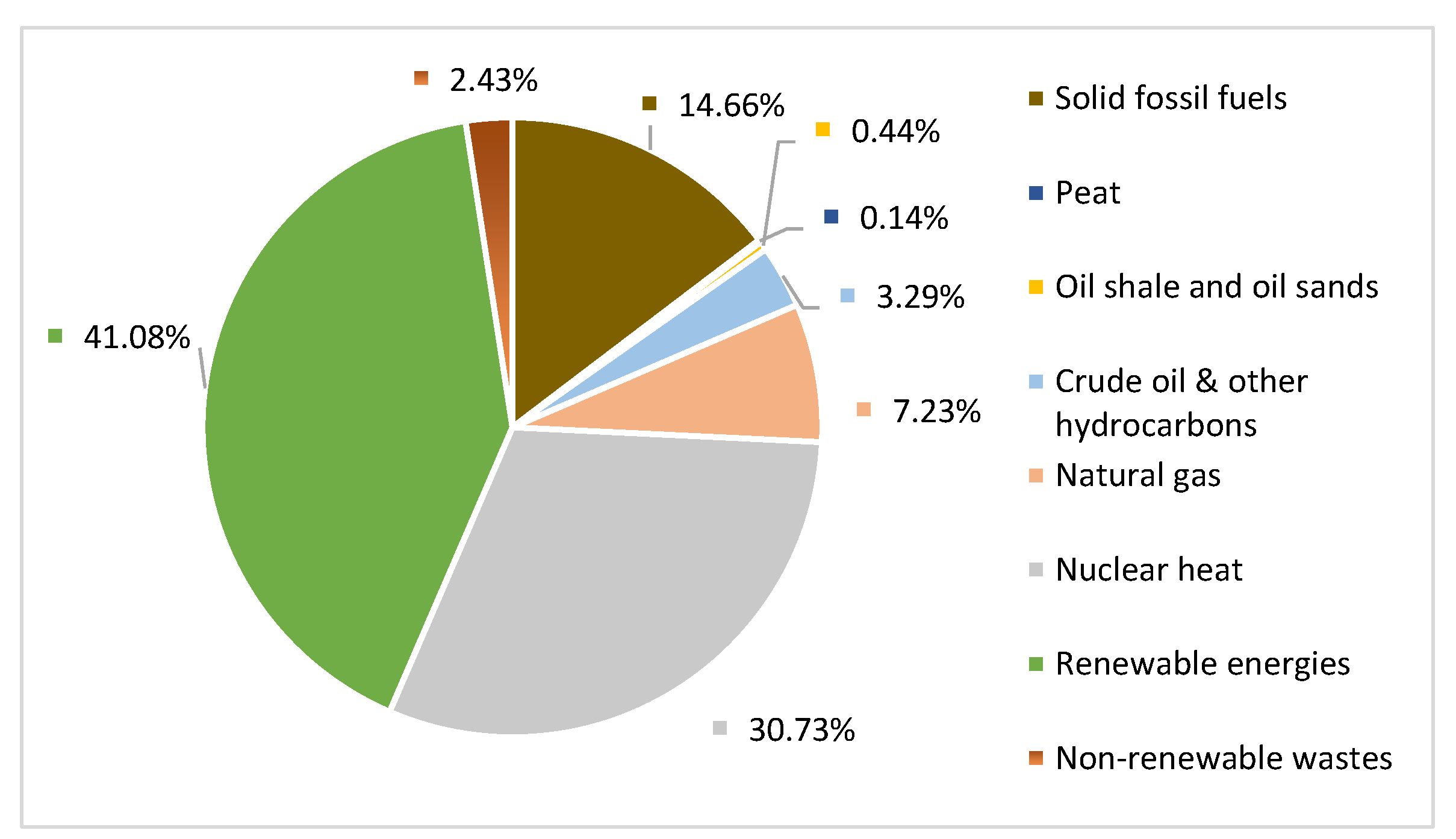

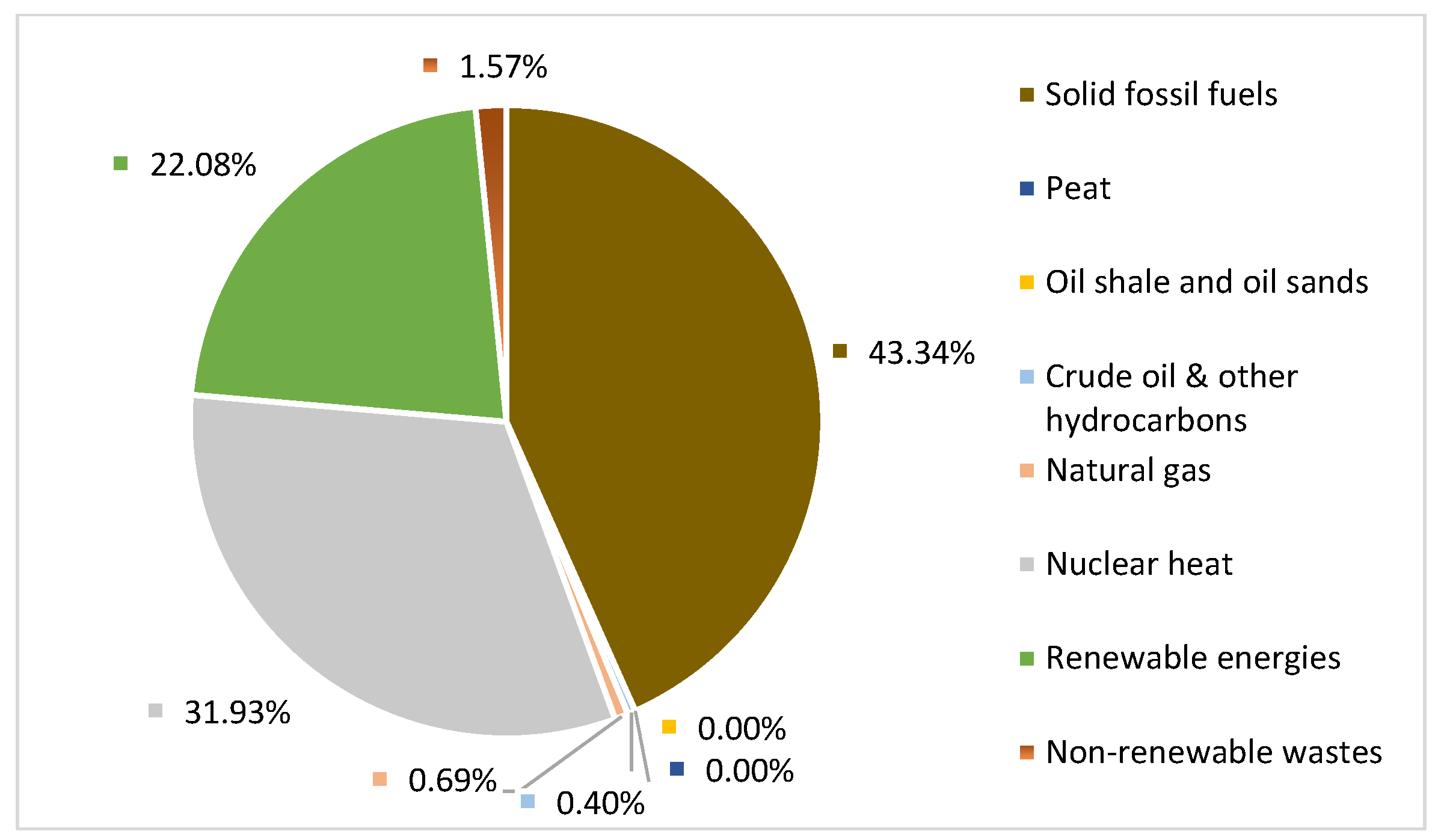

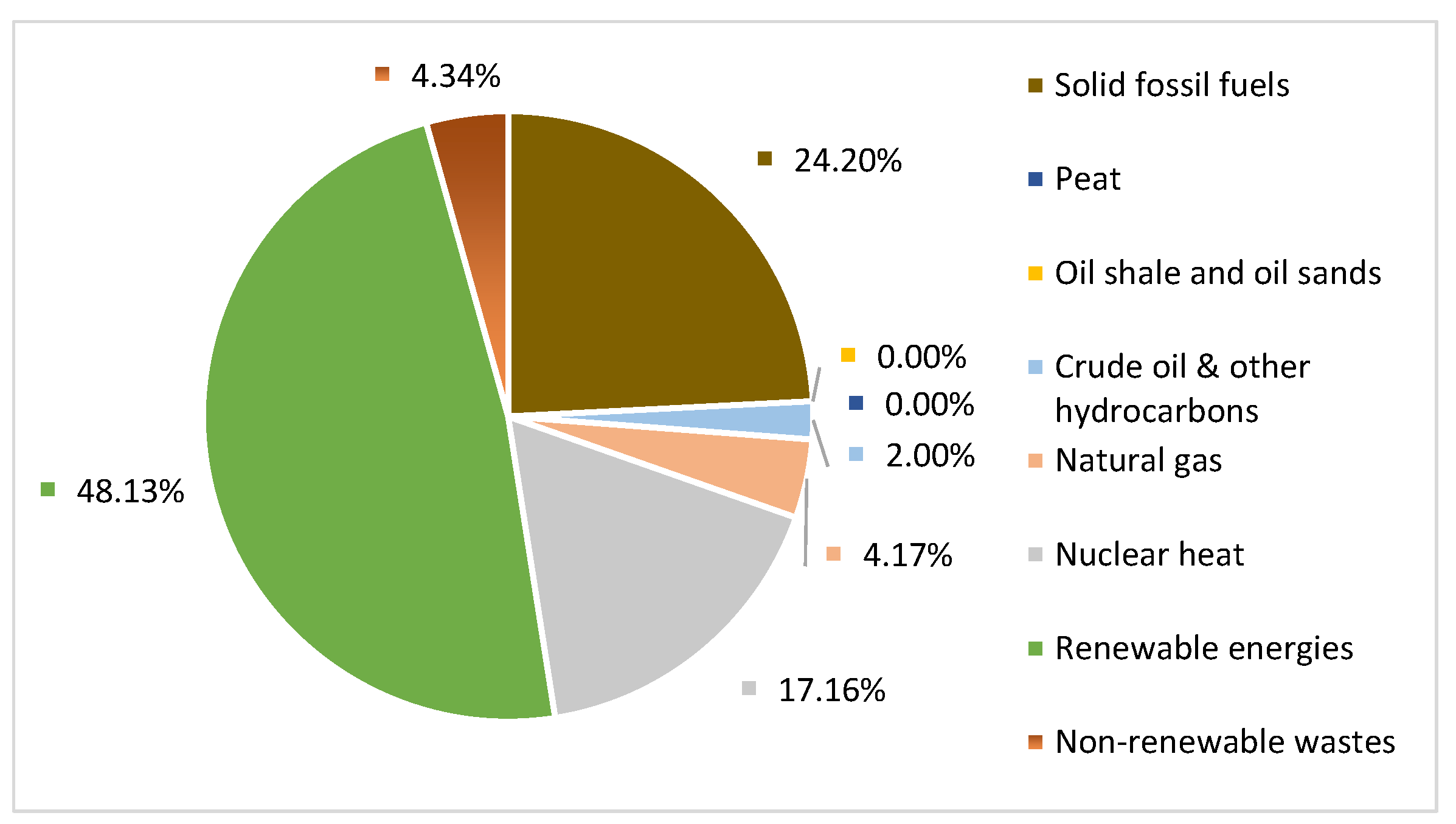

4.3. Electric Car Models and Cross-Country Comparisons

5. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Graczyk, A.M.; Graczyk, A.; Żołyniak, T. System for financing investments in renewable energy sources in Poland. In Springer Proceedings in Business and Economics; Jones, N., Ed.; Springer: Cham, Switzerland, 2020; pp. 153–166. [Google Scholar]

- Filho, W.L.; Rath, K.; Mannke, F.; Vogt, J.; Kotter, R.; Borgqvist, M.; Myklebust, B.; Van Deventer, P. Fostering Sustainable Mobility in Europe: The Contributionsof the Project “E-Mobility North Sea Region”. Green Energy Technol. 2015, 203, 3–25. [Google Scholar] [CrossRef]

- Łuszczyk, M.; Sulich, A.; Siuta-Tokarska, B.; Zema, T.; Thier, A. The development of electromobility in the european union: Evidence from Poland and cross-country comparisons. Energies 2021, 14, 8247. [Google Scholar] [CrossRef]

- Gontarz, M.; Sulich, A. The sustainable transportation solutions: Smart shuttle example. In Vision 2025: Education Excellence and Management of Innovations through Sustainable Economic Competitive Advantage, Proceedings of the 34th International Business Information Management Association Conference (IBIMA), Madrid, Spain, 13–14 November 2019; Soliman, K.S., Ed.; International Business Information Management Association: Madrid, Spain, 2019; pp. 10833–10840. [Google Scholar]

- Franek, J.; Svoboda, O. Productivity and efficiency of automotive companies in the Czech Republic: A DEA approach. In Proceedings of the 13th International Conference on Strategic Management and Its Support by Information Systems, Ostrava, Czech Republic, 21–22 May 2019; pp. 87–98. [Google Scholar]

- Buberger, J.; Kersten, A.; Kuder, M.; Eckerle, R.; Weyh, T.; Thiringer, T. Total CO2-equivalent life-cycle emissions from commercially available passenger cars. Renew. Sustain. Energy Rev. 2022, 159, 112158. [Google Scholar] [CrossRef]

- Quijano, A.; Hernández, J.L.; Nouaille, P.; Virtanen, M.; Sánchez-Sarachu, B.; Pardo-Bosch, F.; Knieilng, J. Towards Sustainable and Smart Cities: Replicable and KPI-Driven Evaluation Framework. Buildings 2022, 12, 233. [Google Scholar] [CrossRef]

- Albatayneh, A.; Assaf, M.N.; Alterman, D.; Jaradat, M. Comparison of the Overall Energy Efficiency for Internal Combustion Engine Vehicles and Electric Vehicles. Rigas Teh. Univ. Zinat. Raksti 2020, 24, 669–680. [Google Scholar] [CrossRef]

- Pszczółkowski, J. Description of Acid Battery Operating Parameters. Energies 2021, 14, 7212. [Google Scholar] [CrossRef]

- Gulzari, A.; Wang, Y.; Prybutok, V. A green experience with eco-friendly cars: A young consumer electric vehicle rental behavioral model. J. Retail. Consum. Serv. 2022, 65, 102877. [Google Scholar] [CrossRef]

- Cieslik, W.; Szwajca, F.; Golimowski, W.; Berger, A. Experimental Analysis of Residential Photovoltaic (PV) and Electric Vehicle (EV) Systems in Terms of Annual Energy Utilization. Energies 2021, 14, 1085. [Google Scholar] [CrossRef]

- Attwood, J.; Attwood, D.; Williams, L.; Collier, A.; Boyd, M.; Gott, M. It all started with a green car... Exploring the meaning of happiness. Dementia 2020, 19, 31–40. [Google Scholar] [CrossRef]

- Klimecka-Tatar, D.; Ingaldi, M.; Obrecht, M. Sustainable Developement in Logistic-A Strategy for Management in Terms of Green Transport. Manag. Syst. Prod. Eng. 2021, 29, 91–96. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Wasiak, A.; Świć, A.; Mieszkalski, L.; Mruk, R.; Gola, A.; Słoma, J.; Botwińska, K.; Gawron, J. A Computer Tool Using Open Modelica for Modelling CO2 Emissions in Driving Tests. Energies 2022, 15, 995. [Google Scholar] [CrossRef]

- Cvancarova, Z.; Franek, J. Corporate governance development in Central and Eastern Europe. Actual Probl. Econ. 2016, 179, 122–133. [Google Scholar]

- Erdelić, T.; Carić, T. Goods Delivery with Electric Vehicles: Electric Vehicle Routing Optimization with Time Windows and Partial or Full Recharge. Energies 2022, 15, 285. [Google Scholar] [CrossRef]

- Pielecha, I.; Cieślik, W.; Borowski, P.; Czajka, J.; Bueschke, W. Reduction of the number of cylinders in internal combustion engines-contemporary trends in downsizing. Combust. Engines 2014, 53, 12–25. [Google Scholar] [CrossRef]

- Verma, S.; Dwivedi, G.; Verma, P. Life cycle assessment of electric vehicles in comparison to combustion engine vehicles: A review. Mater. Today Proc. 2021, 49, 217–222. [Google Scholar] [CrossRef]

- Bryman, A.; Bell, E. Business Research Methods, 2nd ed.; Oxford University Press: Oxford, UK, 2007; ISBN 978-0-19-928498-6. [Google Scholar]

- Matuszewska-Janica, A.; Żebrowska-Suchodolska, D.; Ala-Karvia, U.; Hozer-Koćmiel, M. Changes in electricity production from renewable energy sources in the european union countries in 2005–2019. Energies 2021, 14, 6276. [Google Scholar] [CrossRef]

- Sulich, A.; Sołoducho-Pelc, L. Renewable energy producers’ strategies in the Visegrád Group countries. Energies 2021, 14, 3048. [Google Scholar] [CrossRef]

- Cargill, M.; O’Connor, P. Writing Scientific Research Articles, 2nd ed.; Wiley-Blackwell: Oxford, UK, 2013; ISBN 978-1-118-57069-2. [Google Scholar]

- Bieker, G. A Global Comparison of the Life-Cycle Greenhouse Gas Emissions of Combustion Engine and Electric Passenger Cars; ICCT: The Hague, The Netherlands, 2021. [Google Scholar]

- Campestrini, M.; Mock, P. European Vehicle Market Statistics; ICCT: The Hague, The Netherlands, 2021; pp. 1–50. [Google Scholar]

- Brdulak, J.; Pawlak, P. Electromobility as a factor of quality changes in Polish road transport [Elektromobilność czynnikiem zmian jakościowych polskiego transportu samochodowego]. Kwart. Nauk Przedsiębiorstwie 2021, 58, 31–42. [Google Scholar] [CrossRef]

- Malewska, K. Improving decision-making processes in organisations [Doskonalenie procesów decyzyjnych w organizacjach]. Manag. Sci. [Nauki o Zarządzaniu] 2013, 1, 33–45. [Google Scholar]

- Sulich, A.; Grudziński, A. The analysis of strategy types of the renewable energy sector. Acta Univ. Agric. Silvic. Mendel. Brun. 2019, 67, 1643–1651. [Google Scholar] [CrossRef] [Green Version]

- Borowski, P.F.; Kupczyk, A.; Biernat, K.; Mączyńska-Sęczek, J.; Detka, T.; Golisz, E.; Gawłowska, A.; Di Nardo, M. Problems of Selected Sectors of Biofuels for Transport in Poland. Processes 2021, 9, 1573. [Google Scholar] [CrossRef]

- Oxford Analytica. COP26 coal deal will fall short of needs. Emerald Expert Brief. 2021. [Google Scholar] [CrossRef]

- Kotak, Y.; Marchante Fernández, C.; Canals Casals, L.; Kotak, B.S.; Koch, D.; Geisbauer, C.; Trilla, L.; Gómez-Núñez, A.; Schweiger, H.-G. End of Electric Vehicle Batteries: Reuse vs. Recycle. Energies 2021, 14, 2217. [Google Scholar] [CrossRef]

- Denis, A.; Kuczyński, W. Comparative analysis of the environmental impact of electric cars powered by coal-fired power plants and combustion engine-powered cars [Analiza porównawcza wpływu na środowisko aut elektrycznych zasilanych z elektrowni węglowych oraz aut spalinowych]. Autobusy Tech. Eksploat. Syst. Transp. 2017, 18, 61–64. [Google Scholar]

- Clairotte, M.; Suarez-Bertoa, R.; Zardini, A.A.; Giechaskiel, B.; Pavlovic, J.; Valverde, V.; Ciuffo, B.; Astorga, C. Exhaust emission factors of greenhouse gases (GHGs) from European road vehicles. Environ. Sci. Eur. 2020, 32, 125. [Google Scholar] [CrossRef]

- Skupniewicz, T. Origin and development of vehicle emission standards in the European Union [Geneza i rozwój standardów emisji spalin pojazdów w Unii Europejskiej]. Przegląd Prawno-Ekonomiczny 2019, 47, 319–331. [Google Scholar]

- Jacyna, M.; Zochowska, R.; Sobota, A.; Wasiak, M.; Lee, K.M. Scenario Analyses of Exhaust Emissions Reduction through the Introduction of Electric Vehicles into the City. Energies 2021, 14, 2030. [Google Scholar] [CrossRef]

- Trzensik, E.; Światłoń, M. Impact of the implementation of Euro 5 and Euro 6 emission standards on the automotive industry in terms of introducing new technologies and increasing operating costs [Wpływ implementacji norm emisji spalin Euro 5 i Euro 6 na przemysł motoryzacyjny, w aspekcie wdrażania nowych technologii i wzrostu kosztów]. Zesz. Nauk. Politech. Śląskiej 2011, 72, 83–98. [Google Scholar]

- Merkisz, J.; Siedlecki, M.; Ziólkowski, A.; Fuć, P.; Lijewski, P. Methods for limiting engine emissions from HDVs meeting Euro VI standard [Metody ograniczenia emisji zanieczyszczeń z silników pojazdów HDV spełniających normę Euro VI]. Combust. Engines 2015, 54, 480–486. [Google Scholar]

- Torres, P.; Arents, J.; Marques, H.; Marques, P. Bin-Picking Solution for Randomly Placed Automotive Connectors Based on Machine Learning Techniques. Electronics 2022, 11, 476. [Google Scholar] [CrossRef]

- Brach, J.; Pawłowska, M.; Wojtowski, B. Selected Aspects of Improving Delivery in Last Mile Logistics. Challenges for Modern Cities [Wybrane Aspekty Usprawniania Dostaw w Logistyce Ostatniej Mili. Wyzwania dla Współczesnych Miast]; Wydawnictwo Uniwersytetu Ekonomicznego we Wrocławiu: Wrocław, Poland, 2021. [Google Scholar]

- Brzeżański, M.; Śliwiński, K. Downsizing—A new direction for car engines [Downsizing—nowy kierunek rozwoju silników samochodowych]. Siln. Spalinowe 2004, 43, 3–11. [Google Scholar]

- Jato Dynamics. European New Car Market Starts 2021 with Record Market Share for SUVs. 2021. Available online: https://www.jato.com/european-new-car-market-starts-2021-with-record-market-share-for-suvs/ (accessed on 29 April 2022).

- Wyszomirski, O. Sustainable urban transport and quality of life [Zrównoważony rozwój transportu w miastach a jakość życia]. Transp. Miej. Reg. 2017, 12, 27–32. [Google Scholar]

- Brach, J. Current Developments in the European Market for Road Cargo Vehicles—An Analysis from the Supply Side Perspective [Obecne Zmiany na Europejskim Rynku Pojazdów Samochodowych do Przewozu Ładunków—Analiza z Perspektywy Strony Podażowej]; Wydawnictwo Uniwersytetu Ekonomicznego we Wrocławiu: Wrocław, Poland, 2019. [Google Scholar]

- Trzaska, R.; Sulich, A.; Organa, M.; Niemczyk, J.; Jasiński, B. Digitalization Business Strategies in Energy Sector: Solving Problems with Uncertainty under Industry 4.0 Conditions. Energies 2021, 14, 7997. [Google Scholar] [CrossRef]

- Niemczyk, J.; Sus, A.; Bielińska-Dusza, E.; Trzaska, R.; Organa, M. Strategies of European Energy Producers. Directions of Evolution. Energies 2022, 15, 609. [Google Scholar] [CrossRef]

- Haddadian, G.; Khodayar, M.; Shahidehpour, M. Accelerating the global adoption of electric vehicles: Barriers and drivers. Electr. J. 2015, 28, 53–68. [Google Scholar] [CrossRef]

- Polskie Stowarzyszenie Paliw Alternatywnych [Polish Alternative Fuels Association]. New Mobility Barometer 2020/21; [Barometr Nowej Mobilności 2020/21]; Polskie Stowarzyszenie Paliw Alternatywnych: Warszawa, Poland, 2021. [Google Scholar]

- Żebrowski, K.; Detka, T.; Małek, K. Comparative analysis of report data on CO2 emissions and total cost of ownership (TCO) of an electric vehicle versus a conventionally fuelled vehicle [Analiza porównawcza danych z raportów dotyczących emisji CO2 oraz całkowitych kosztów posiadania (TCO)]. Masz. Elektr. Zesz. Probl. 2018, 3, 161–170. [Google Scholar]

- Neugebauer, M.; Żebrowski, A.; Esmer, O. Cumulative Emissions of CO2 for Electric and Combustion Cars: A Case Study on Specific Models. Energies 2022, 15, 2703. [Google Scholar] [CrossRef]

- Gawron, S.; Bernatt, J. Business experience in electric cars [Doświadczenia z eksploatacji samochodów elektrycznych w działalności gospodarczej]. Masz. Elektr. Zesz. Probl. 2017, 2, 231–238. [Google Scholar]

- Kaznowski, R.; Sztafrowski, D.; Grudek, M.; Gumiela, J. Infrastructure problems related to the transition from internal combustion to electric drive in motor vehicles. Prz. Elektrotechniczny 2021, 97, 113–116. [Google Scholar] [CrossRef]

- Kan, X.; Reichenberg, L.; Hedenus, F. The impacts of the electricity demand pattern on electricity system cost and the electricity supply mix: A comprehensive modeling analysis for Europe. Energy 2021, 235, 121329. [Google Scholar] [CrossRef]

- Eurostat Energy Balances in the MS Excel File Format (2022 Edition). Available online: https://ec.europa.eu/eurostat/web/energy/data/energy-balances (accessed on 28 June 2022).

- Miller, I.; Gençer, E.; O’sullivan, F.M. A General Model for Estimating Emissions from Integrated Power Generation and Energy Storage. Case Study: Integration of Solar Photovoltaic Power and Wind Power with Batteries. Processes 2018, 6, 267. [Google Scholar] [CrossRef] [Green Version]

- Gabryś, H.L. Power generation in Poland 2020 [Elektroenergetyka w Polsce 2020]. Available online: https://elektroenergetyka.pl/upload/file/2020/08/Gabryś_8.pdf (accessed on 27 February 2022).

- European Environment Agency (EEA). Greenhouse gas emission intensity of electricity generation by country. Available online: https://www.eea.europa.eu/data-and-maps/daviz/co2-emission-intensity-9#tab-googlechartid_googlechartid_googlechartid_googlechartid_chart_11111 (accessed on 8 May 2022).

- The International Association of Oil and Gas Producers (IOGP). IOGP Environmental Performance Indicators—2019 Data; International Association of Oil and Gas Producers: London, UK, 2020. [Google Scholar]

- Brandão, P.; Infante, V.; Deus, A.M.; Del Pero, F.; Delogu, M.; Pierini, M. Life Cycle Assessment in the automotive sector: A comparative case study of Internal Combustion Engine (ICE) and electric car. Procedia Struct. Integr. 2018, 12, 521–537. [Google Scholar] [CrossRef]

- Braun, A.; Rid, W. Energy consumption of an electric and an internal combustion passenger car. A comparative case study from real world data on the Erfurt circuit in Germany. Transp. Res. Procedia 2017, 27, 468–475. [Google Scholar] [CrossRef]

- Pielecha, J.; Skobiej, K.; Kurtyka, K. Exhaust Emissions and Energy Consumption Analysis of Conventional, Hybrid, and Electric Vehicles in Real Driving Cycles. Energies 2020, 13, 6423. [Google Scholar] [CrossRef]

- Pilichowska, P. Polish electromobility development programme—Implementation and impact on the development of electromobility in Poland [Polski program rozwoju elektromobilności—Realizacja i wpływ na rozwój elektromobilności w Polsce]. In Regionalne i Lokalne Uwarunkowania Rozwoju Gospodarki Polski; Sobczak, E., Ed.; Uniwersytet Ekonomiczny we Wrocławiu: Wrocław, Poland, 2020; pp. 111–119. [Google Scholar]

- Pietrzyk-Sokulska, E. Recycling as a potential source of mineral resources from selected waste groups [Recykling jako potencjalne źródło pozyskiwania surowców mineralnych z wybranych grup odpadów]. Zesz. Nauk. Inst. Gospod. Surowcami Miner. Energią PAN 2016, 92, 141–161. [Google Scholar]

- Wójcik, M.; Pawłowska, B.; Stachowicz, F. Overview of waste lithium-ion battery recycling technologies [Przegląd technologii recyklingu zużytych akumulatorów litowo-jonowych]. Zesz. Nauk. Politech. Rzesz. Mech. 2017, 89, 107–120. [Google Scholar] [CrossRef]

- Kamińska, E.S.; Pawlak, P. Ecobalance analysis of recycling of waste lithium-ion automotive batteries [Analiza ekobilansowa recyklingu zużytych litowo-jonowych akumulatorów samochodowych w technologii]. Gospod. Mater. Logistyka 2020, 2020, 35–44. [Google Scholar] [CrossRef]

- Hałasik, K.; Kulczycka, J. CSR, environment-friendly investments and innovations-the three elements necessary to build a modern and strong coal mining company? In Proceedings of the E3S Web of Conferences, Kraków, Poland, 17–19 May 2016; Volume 10. [Google Scholar]

- Tatarewicz, I.; Lewarski, M.; Skwierz, S.; Krupin, V.; Jeszke, R.; Pyrka, M.; Szczepański, K.; Sekuła, M. The Role of BECCS in Achieving Climate Neutrality in the European Union. Energies 2021, 14, 7842. [Google Scholar] [CrossRef]

- Haughton, T. An SUV on a Road to Nowhere? Solidarity, Unanimity and Vulnerability in the European Union. Johns Hopkins Univ. SAIS Cent. Transatl. Relat. 2012, 2012, 13–30. [Google Scholar]

- Polski Związek Przemysłu Motoryzacyjnego [Polish Automotive Industry Association]. Automotive Industry Report 2021/2022. Available online: https://www.pzpm.org.pl/en/Automotive-market/Reports/PZPM-Automotive-Industry-Report-2021-2022 (accessed on 28 June 2022).

- Skobiej, K.; Pielecha, J. Plug-in Hybrid Ecological Category in Real Driving Emissions. Energies 2021, 14, 2340. [Google Scholar] [CrossRef]

- Balsalobre-Lorente, D.; Leitão, N.C.; Bekun, F.V. Fresh validation of the low carbon development hypothesis under the ekc scheme in portugal, italy, greece and spain. Energies 2021, 14, 250. [Google Scholar] [CrossRef]

- Polskie Stowarzyszenie Paliw Alternatywnych [Polish Alternative Fuels Association]. Electric Vehicle Catalogue 2021/22 [Katalog Pojazdów Elektrycznych 2021/22]; Polskie Stowarzyszenie Paliw Alternatywnych: Warszawa, Poland, 2021. [Google Scholar]

- Benz, M. EQA Performance Levels and Technical Data. [Stopnie Wydajności i Dane Techniczne EQA]. Available online: https://www.mercedes-benz.pl/passengercars/mercedes-benz-cars/models/eqa/specifications/eqa-h243.module.html (accessed on 28 June 2022).

- Benz, M. Technical Data for GLA Engines [Dane Techniczne Silników GLA]. Available online: https://www.mercedes-benz.pl/passengercars/mercedes-benz-cars/models/gla/gla-h247/specifications/pluginhybrid.module.html (accessed on 28 June 2022).

- Canadian Association of Petroleum Producers. The Petroleum Value Chain: From Crude Oil to Useful Products. Available online: https://context.capp.ca/infographics/2017/ig_petrochemical-value-chain (accessed on 27 February 2022).

- Tauron Polska Energia, S.A. Structure of Fuels and Other Primary Energy Carriers Used to Generate Electricity Sold to Tauron Polska Energia S.A. in 2020 [Struktura Paliw i Innych Nośników Energii Pierwotnej Zużywanych do Wytwarzania Energii Elektrycznej Sprzedanej do Tauron Polska Energia S.A. w Roku 2021. Available online: https://www.tauron.pl/tauron/o-tauronie/struktura-paliw (accessed on 27 February 2022).

- Opel Polska. Price List—New Electric Opel Mokka-e Production Year 2021, Model Year 2021D [Cennik—Nowy Elektryczny Opel Mokka-e Rok Produkcji 2021, Rok Modelowy 2021D]. 2021. Available online: https://www.opel.pl/content/dam/opel/poland/tools/pdf/cenniki/mokka/rp22-rm22/cennik-MokkaE-rp22-22_4.pdf (accessed on 27 February 2022).

| Vehicle | Electric—EV 1 | Petrol and Electric | Petrol | Diesel |

|---|---|---|---|---|

| Average CO2 emissions | 0.00 | 81.31 | 191.00 | 161.00 |

| Vehicle manufacturing | 27.00 | 33.00 | 30.00 | 30.00 |

| Vehicle maintenance | 4.00 | 5.00 | 5.00 | 7.00 |

| Production of batteries | 16.00 | 4.00 | 0.00 | 0.00 |

| Production of fuel/energy | 40.37 | 24.07 | 6.28 | 4.56 |

| Total | 87.37 | 146.38 | 232.28 | 202.56 |

| Vehicle | EV 1 | EV 2 | EV 3 | EV 4 | EV 5 |

|---|---|---|---|---|---|

| Motor | Electric | Electric | Electric | Electric | Electric |

| Year of availability/ of production | 2021 | 2021 | 2021 | 2021 | 2021 |

| Wheel drive | 4 wheels | front | front | rear | front |

| Power (HP) | 228 | 136 | 145 | 170 | 204 |

| Torque (Nm) | 390 | 300 | 270 | 310 | 310 |

| Average electricity consumption (KWh/100 km) | 17.5 | 17.8 | 19.0 | 17.0 | 17.1 |

| Acceleration to 100 km/h (s) | 7.7 | 9.0 | 9.7 | 9.0 | 8.5 |

| Weight (kg) | 2105 | 1598 | 1645 | 1967 | 2109 |

| Czechia | Germany | Poland | |

|---|---|---|---|

| CO2 average emissions [g/1 kWh] | 436.60 | 311.00 | 708.80 |

| Electricity consumption—EV 1 [kWh/100 km] | 17.50 | 17.50 | 17.50 |

| CO2 emissions per 1 km—EV 1 [g/1 km] | 76.41 | 54.43 | 124.04 |

| Electricity consumption—EV 2 [kWh/100 km] | 17.80 | 17.80 | 17.80 |

| CO2 Emissions per 1 km—EV 2 [g/1 km] | 77.71 | 55.36 | 126.17 |

| Electricity consumption—EV 3 [kWh/100 km] | 19.00 | 19.00 | 19.00 |

| CO2 Emissions per 1 km—EV 3 [g/1 km] | 82.95 | 59.09 | 134.67 |

| Electricity consumption—EV 4 [kWh/100 km] | 17.00 | 17.00 | 17.00 |

| CO2 Emissions per 1 km—EV 4 [g/1 km] | 74.22 | 52.87 | 120.50 |

| Electricity consumption—EV 5 [kWh/100 km] | 17.10 | 17.10 | 17.10 |

| CO2 Emissions per 1 km—EV 5 [g/1 km] | 74.66 | 53.18 | 121.20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grzesiak, S.; Sulich, A. Car Engines Comparative Analysis: Sustainable Approach. Energies 2022, 15, 5170. https://doi.org/10.3390/en15145170

Grzesiak S, Sulich A. Car Engines Comparative Analysis: Sustainable Approach. Energies. 2022; 15(14):5170. https://doi.org/10.3390/en15145170

Chicago/Turabian StyleGrzesiak, Sebastian, and Adam Sulich. 2022. "Car Engines Comparative Analysis: Sustainable Approach" Energies 15, no. 14: 5170. https://doi.org/10.3390/en15145170

APA StyleGrzesiak, S., & Sulich, A. (2022). Car Engines Comparative Analysis: Sustainable Approach. Energies, 15(14), 5170. https://doi.org/10.3390/en15145170