3.1.1. Transverse Flow

The secondary flow is classified into two kinds by the physical mechanism [

33]. Secondary flows of the first kind, driven by pressure, occur in both laminar and turbulent flows. Secondary flows of the second kind due to the non-isotropic Reynolds stress distribution only occur in turbulent flow in straight pipes of a noncircular cross-section. In the present study, these two kinds of secondary flows both exist under the effect of cross-section, boiling, and rolling motion. This flow perpendicular to the main direction of fluid motion is referred to here as transverse flow.

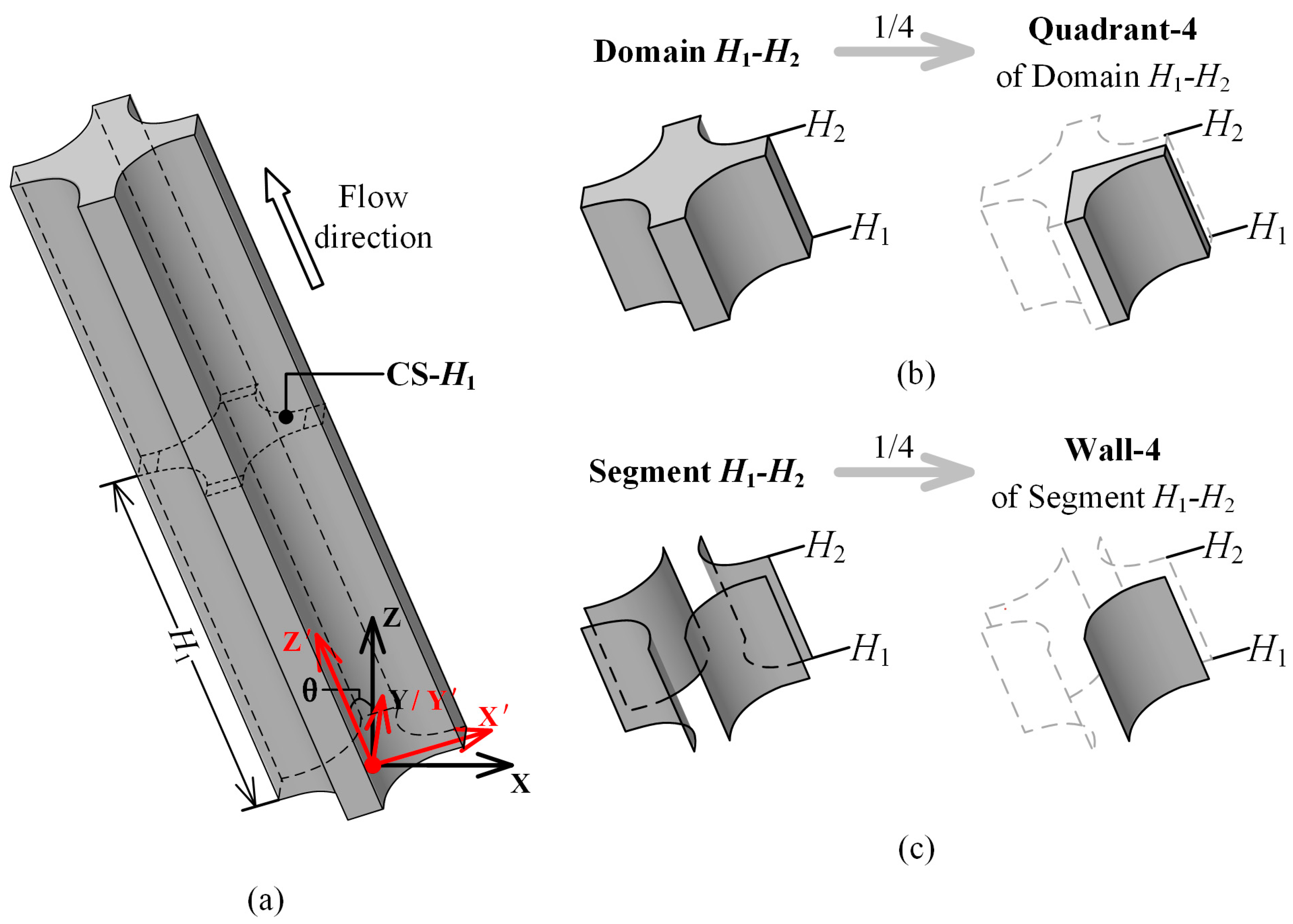

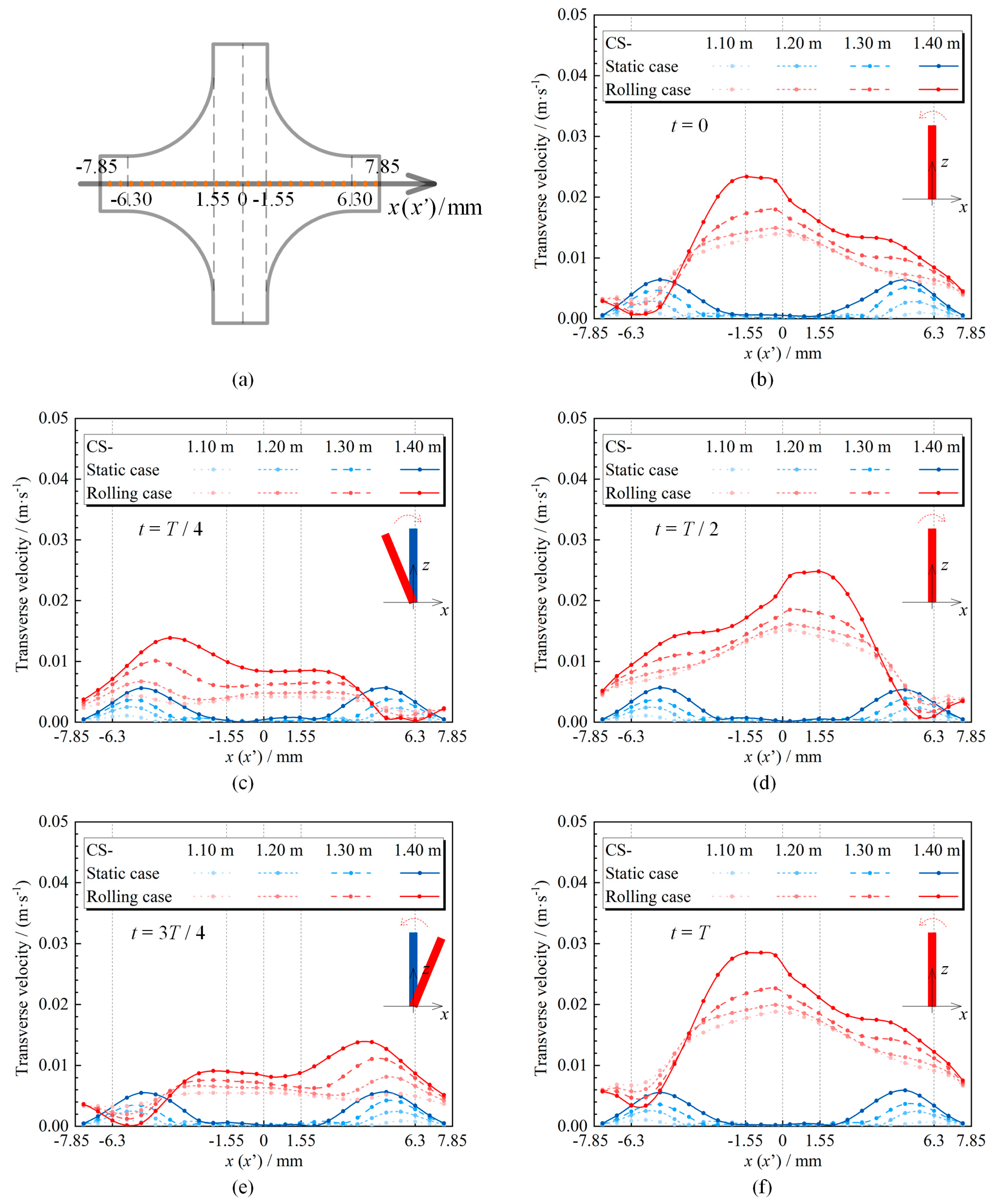

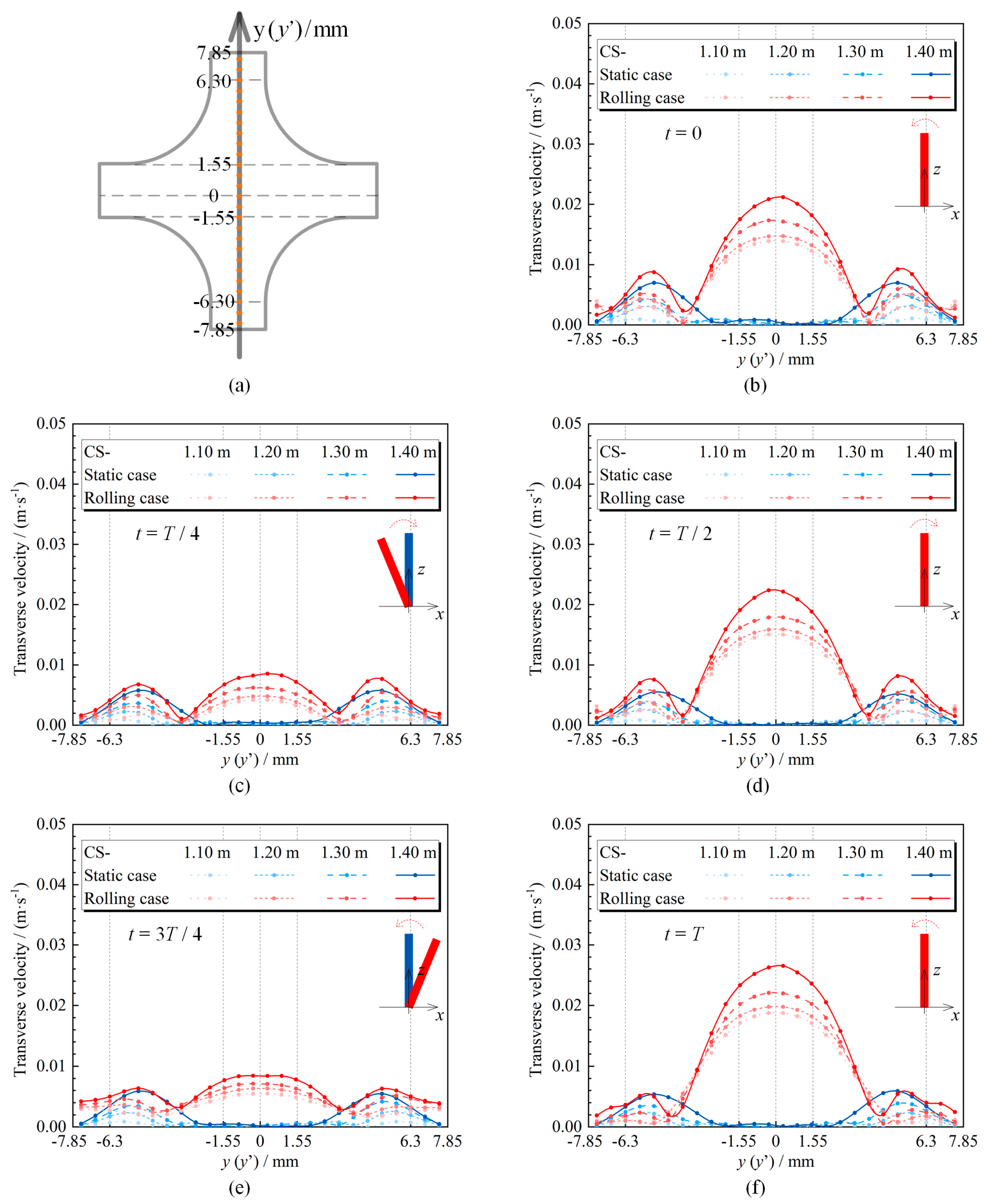

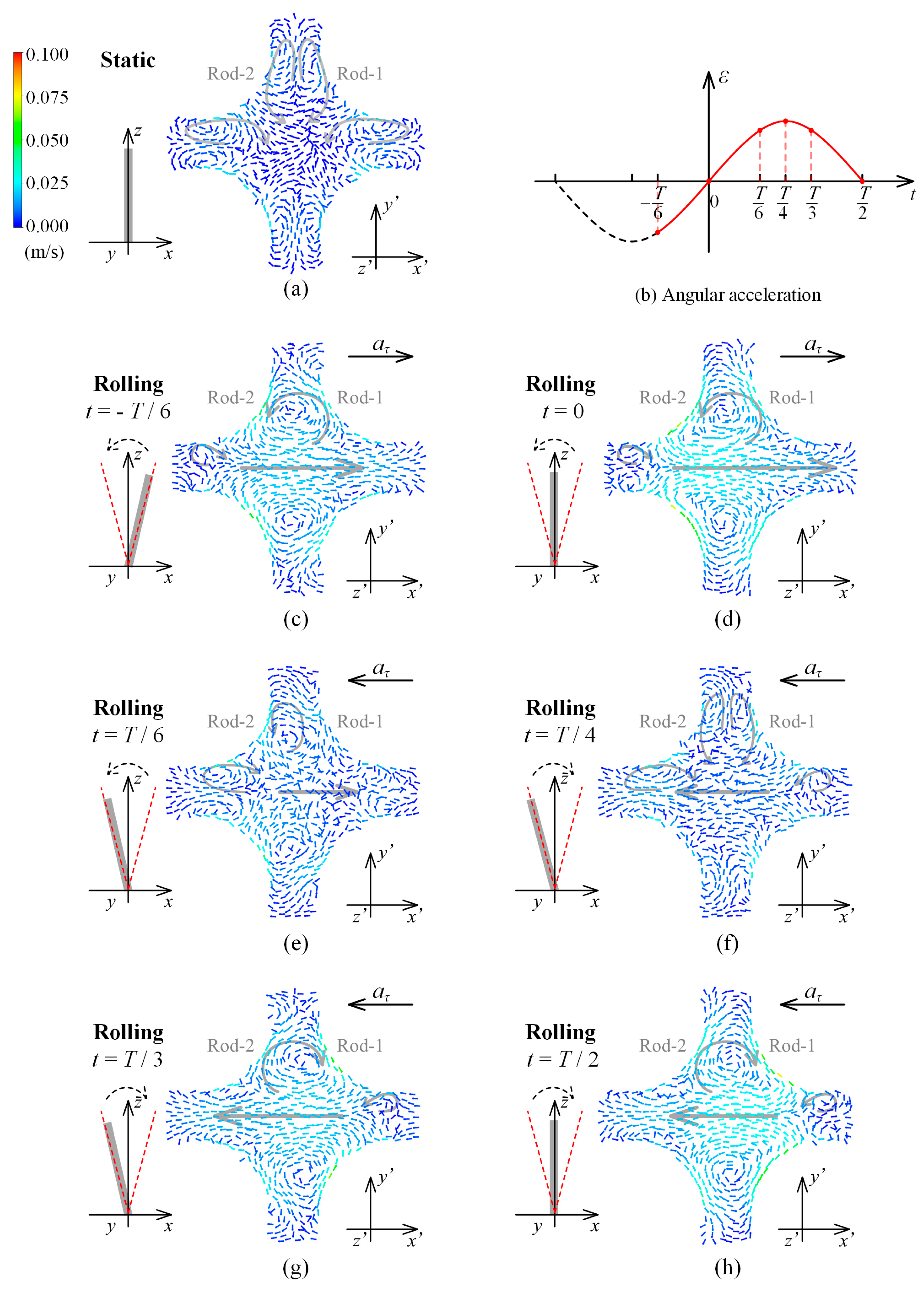

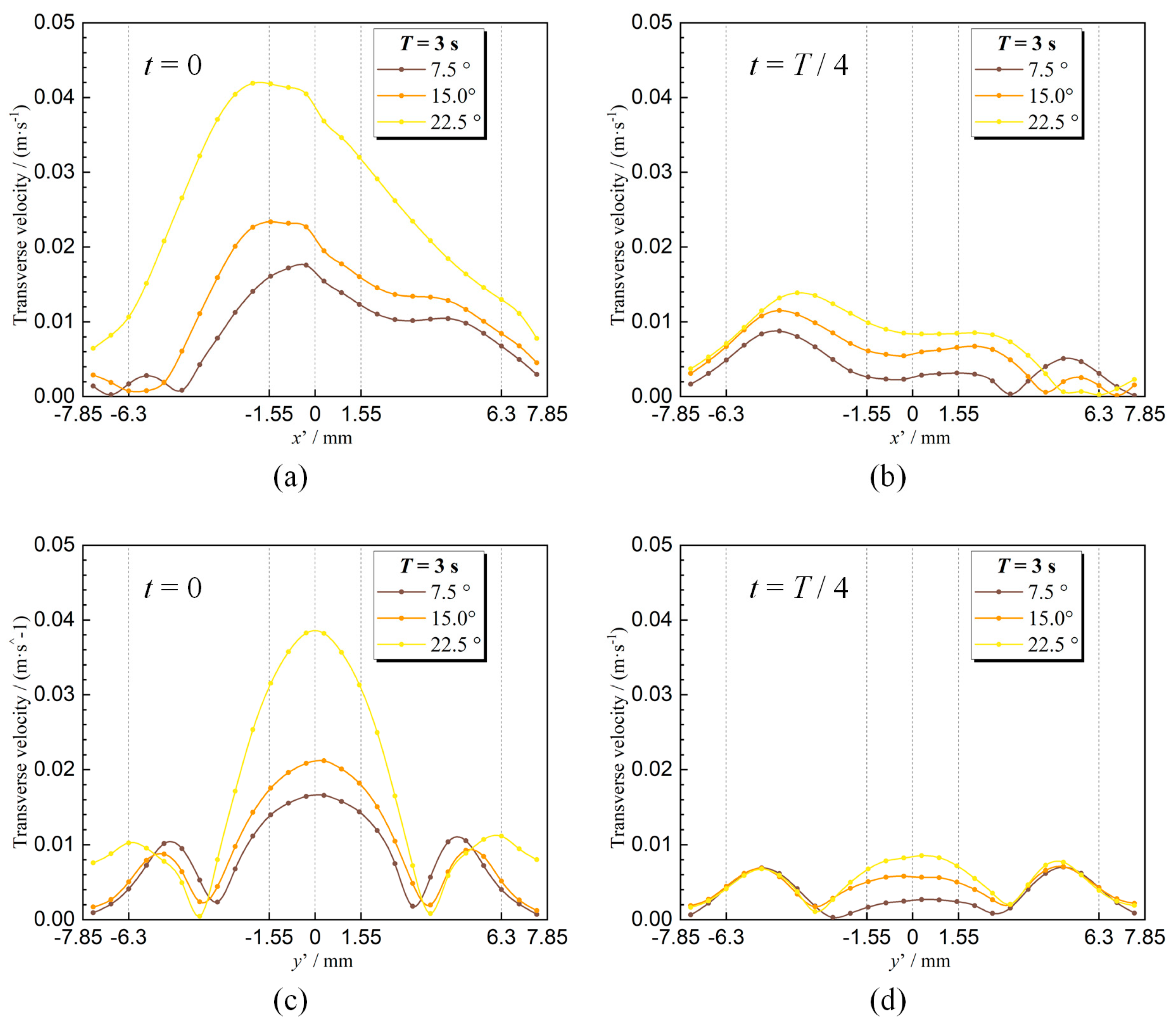

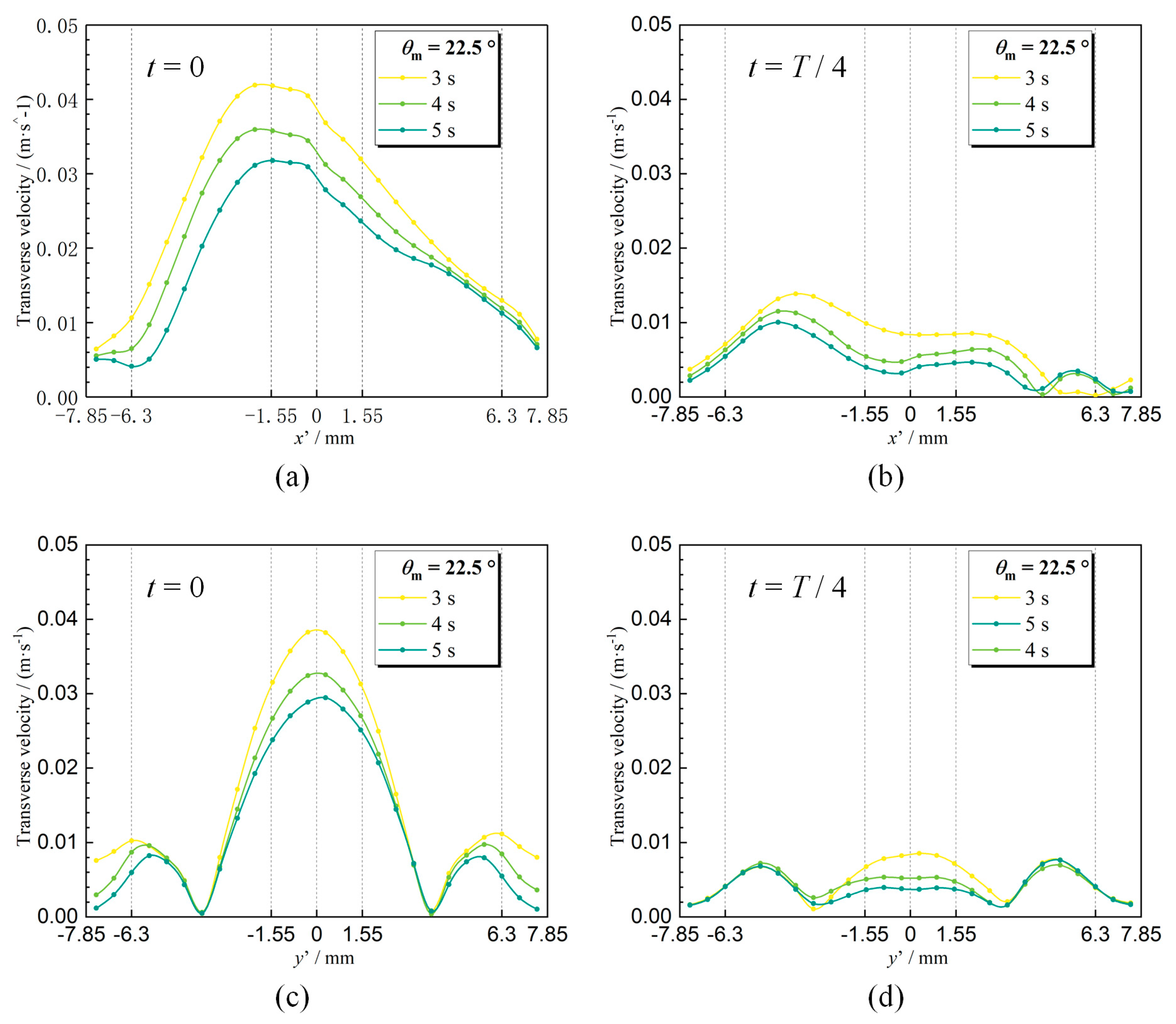

Figure 3 depicts the transverse velocities on the

-axis (

-axis) of CS-1.10 m, CS-1.20 m, CS-1.30 m, and CS-1.40 m. The transverse velocities on the

-axis (

-axis) are shown in

Figure 4.

The transverse velocities in all the cross-sections are nearly constant with time under static state. The profiles of the transverse velocity on the -axis and the -axis are similar and feature two peaks. The transverse velocities are almost zero in the middle of the cross-section, whereas they reach the peaks in the rod gap. The transverse velocities in the rod gap increase with the height of the cross-section.

The transverse velocities under rolling motion differ significantly from those under static state. They change periodically. Firstly, transverse velocity profiles at the beginning of the period (

Figure 3b and

Figure 4b) are almost the same as those at the end (

Figure 3f and

Figure 4f). Secondly, the profiles of the transverse velocity on the

-axis at the moments

and

are symmetric with respect to the

-axis. Thirdly, when the subchannel is in the equilibrium position, which is the same as that under static state, the transverse velocity under rolling motion is far more than that under static state, especially in the middle of the cross-section (

Figure 3b,d).

The above-mentioned transverse flow is induced mainly by boiling and rolling motion. The liquid subcooling is too high to permit bubble nucleation near the subchannel inlet. The heat transfer regime is forced convection. With increasing height, boiling initiates when the liquid in the vicinity of the heated surface reaches saturated. Mass transfer between the liquid phase and the vapor phase and the disturbance of bubbles lead to transverse flow inside the subchannel.

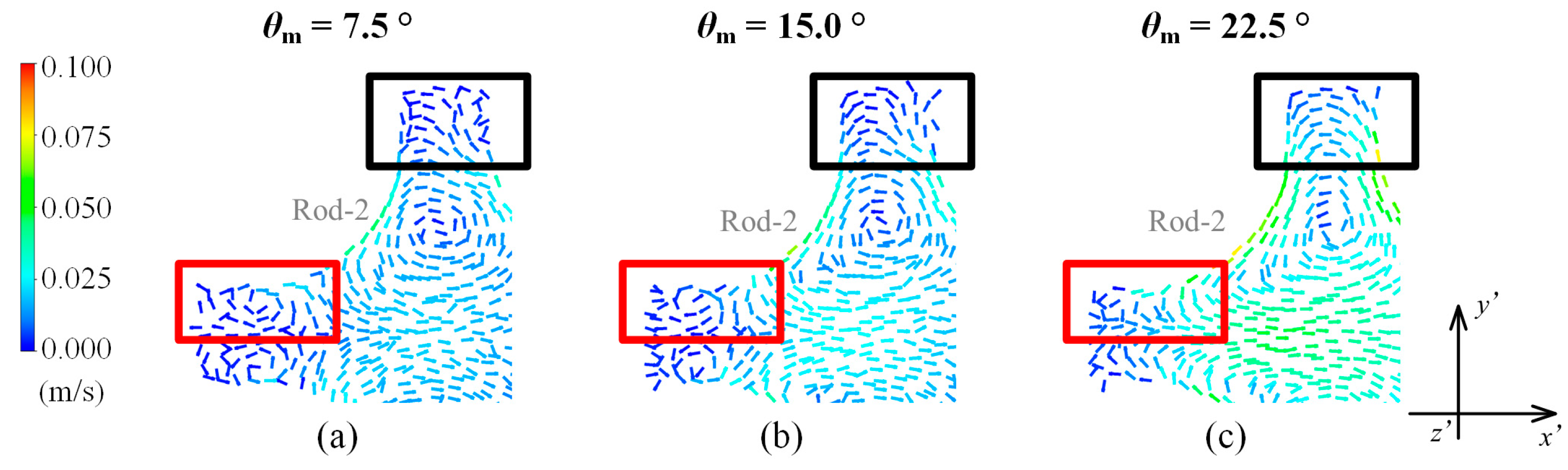

Under static state, due to the symmetrical geometry of the subchannel, the transverse velocity fields at the cross-sections are axially symmetrical with two vortices rotating reversely in the rod gaps (

Figure 5a), with a sketch of the subchannel in the lower left corner). A similar transverse flow field is also obtained in Bieder et al.’s study [

34]. Further downstream, the nucleate boiling intensifies, and the transverse velocity increases. The nucleate boiling occurs only in the vicinity of the heated surface while the bulk liquid is still subcooled. As a result, there is almost no transverse flow at the cross-section center under static state. Moreover, flow and heat transfer in the subchannel are stable, and the transverse flow is independent of time.

Boiling will promote the transverse flow of fluid, whereas rolling motion has a predominant role under rolling motion. The formation and evolution of the transverse flow under rolling motion are interpreted with the transverse flow fields.

When the subchannel rotates anticlockwise to the equilibrium position, the angular acceleration is negative (

Figure 5b), and the Euler force on the fluid is positive along the

-axis (Equation (11)). Meanwhile, a region consisting of the middle of the cross-section and the two gaps around the

-axis is free of wall impediment. Fluid in this open region flows along the

-axis to the positive direction under the action of the Euler force, and two secondary vortices of the reverse direction emerge at the cross-section (

Figure 5c). On the negative side of the

-axis, the transverse velocity induced by boiling and rolling motion is in the opposite direction. Therefore, the secondary vortex on the negative side of the

-axis is weakened by the rolling motion and smaller than that under static state. On the positive side of the

-axis, the secondary vortex induced by boiling merges into that induced by rolling motion because of the same direction.

When the subchannel reaches the equilibrium position (

), the Euler force decreases to zero. The transverse velocity in the middle of the cross-section reaches the maximum, far more than that under static state, whereas the secondary vortices in the middle still prevail at the cross-section (

Figure 5d). The maximum transverse velocity on the

-axis occurs in the vicinity between Rod-2 and Rod-3 due to the promotion of boiling. Under the effect of boiling and rolling motion, transverse flow in the connected area comes up. However, the velocity profiles differ between the two sides of the

-axis due to the combined effect of boiling and rolling motion. On the two sides of the

-axis, the transverse velocity is slightly greater than that under static state, but rapidly decreases to zero near the middle of the secondary vortices.

Then, the subchannel rotates anticlockwise to the extreme position. The angular acceleration is positive during this process, and the Euler force on the fluid is negative along the

-axis. Transverse velocity around the

-axis decreases gradually and then increases reversely, and new secondary vortices emerge (

Figure 5e). In the meantime, transverse velocity around the positive and negative sides of the

-axis also decreases gradually, and the effect of boiling on the transverse flow field comes into view gradually.

When the subchannel reaches the extreme position (

), the Euler force increases to its maximum. The transverse flow field is similar to that under static state (

Figure 5f). However, the transverse velocity at this time is far less than that at the other moments in the rolling motion process. The transverse velocity around the negative side of the

-axis is strengthened due to the same direction of the transverse flow induced by boiling and rolling motion. In contrast, the transverse velocity around the positive side is weakened due to the opposite direction. Consequently, transverse velocity on the

-axis decreases along the positive direction. The rolling motion almost does not affect the transverse flow around the positive and negative sides of the

-axis. Two secondary vortices are formed in the rod gap, and the transverse velocity profile is the same as that under static state.

Next, the subchannel changes to rotate clockwise from the extreme position to the equilibrium position. During this process, the angular acceleration and the Euler force on the fluid still point to the

-axis in the positive and negative directions, respectively. The transverse velocity in the middle of the cross-section increases, and two secondary vortices of reverse direction emerge (

Figure 5g). When the subchannel reaches the equilibrium position (

) again, the Euler force is zero, and the transverse velocity in the middle of the cross-section increases to its maximum. The two transverse velocity profiles on the

-axis are symmetrical around the axis of

= 0 (

Figure 5h).

The evolution of the transverse flow during the next half period is similar to those during the above-mentioned first half period.

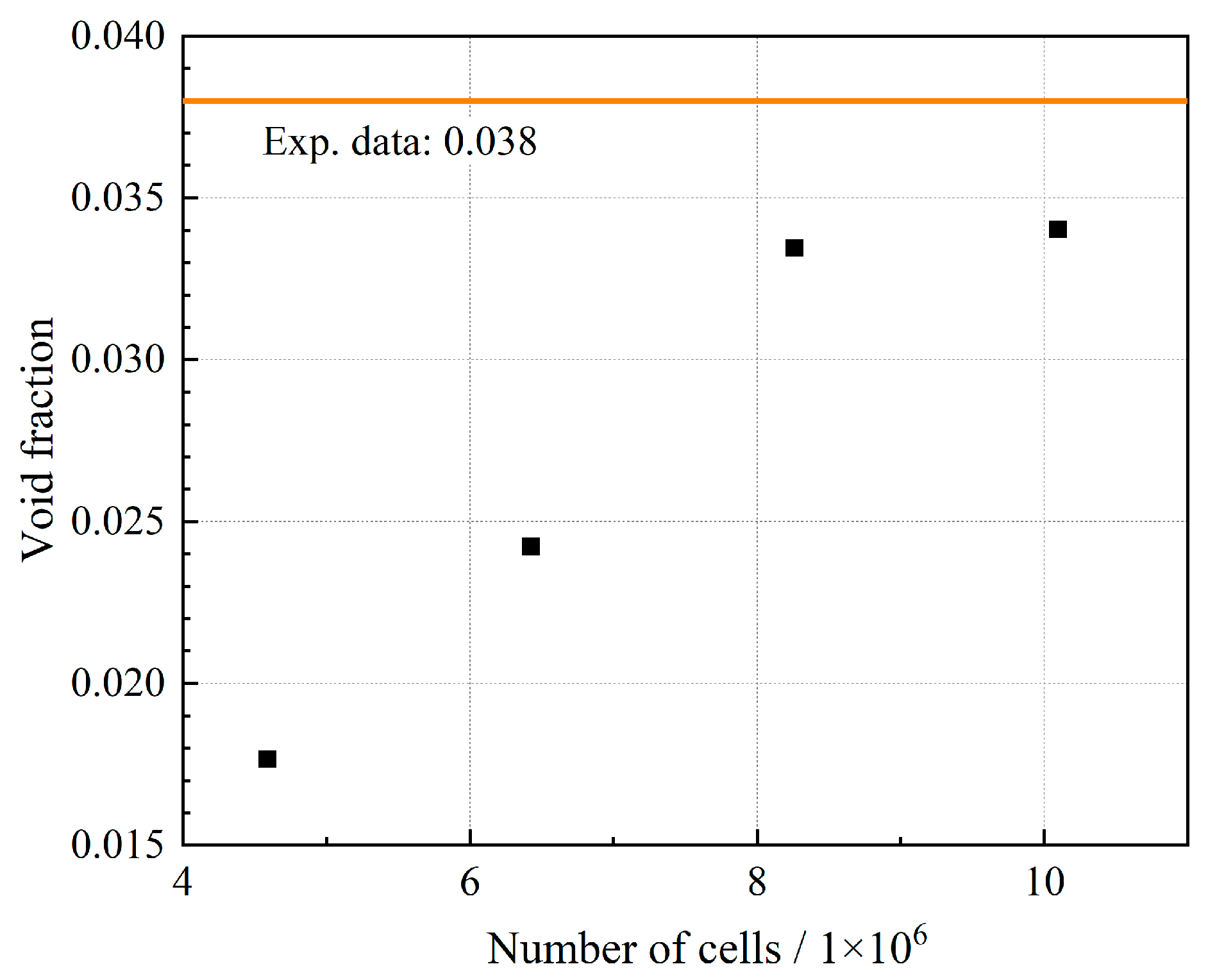

3.1.2. Vapor Volume Fraction

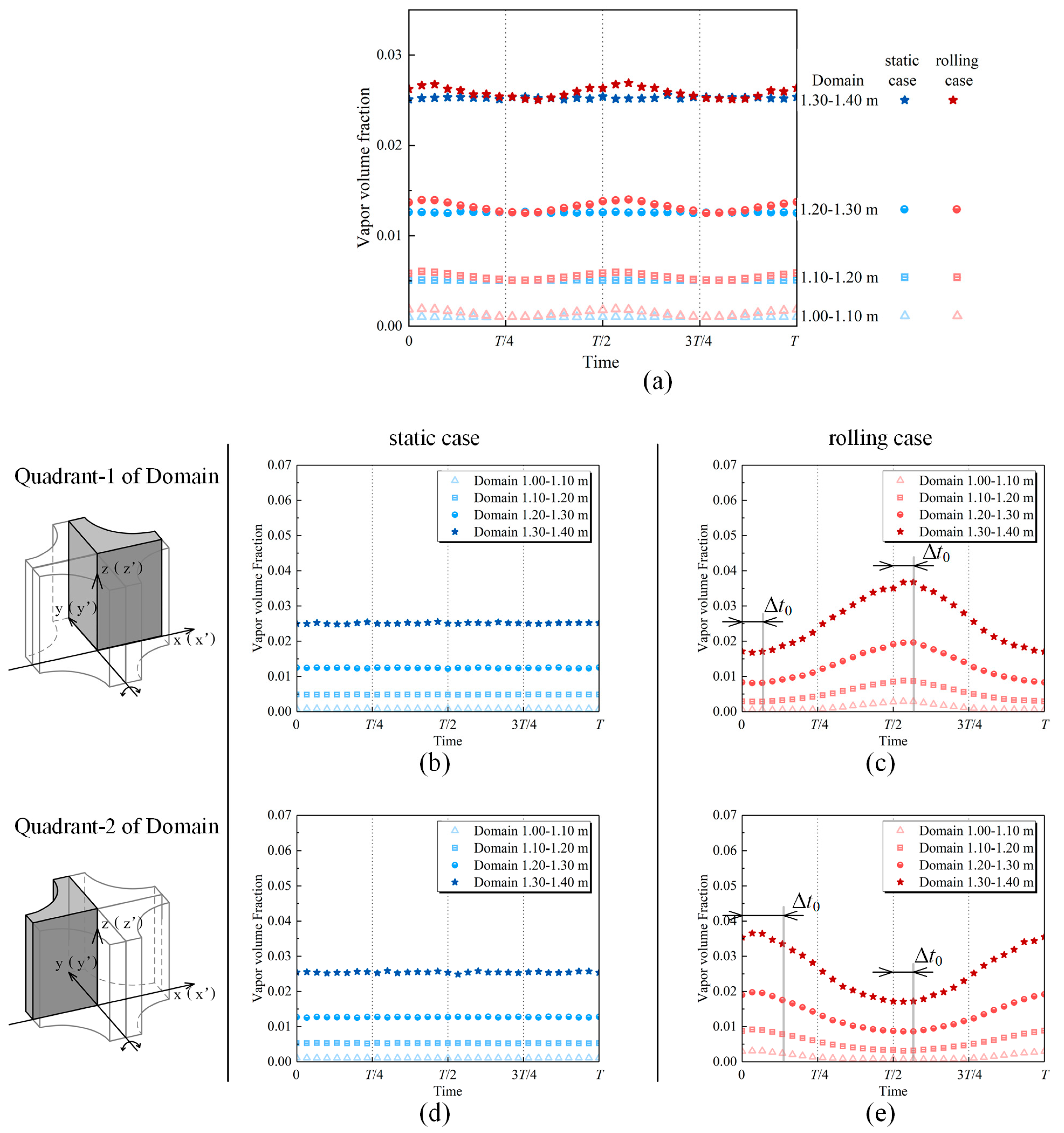

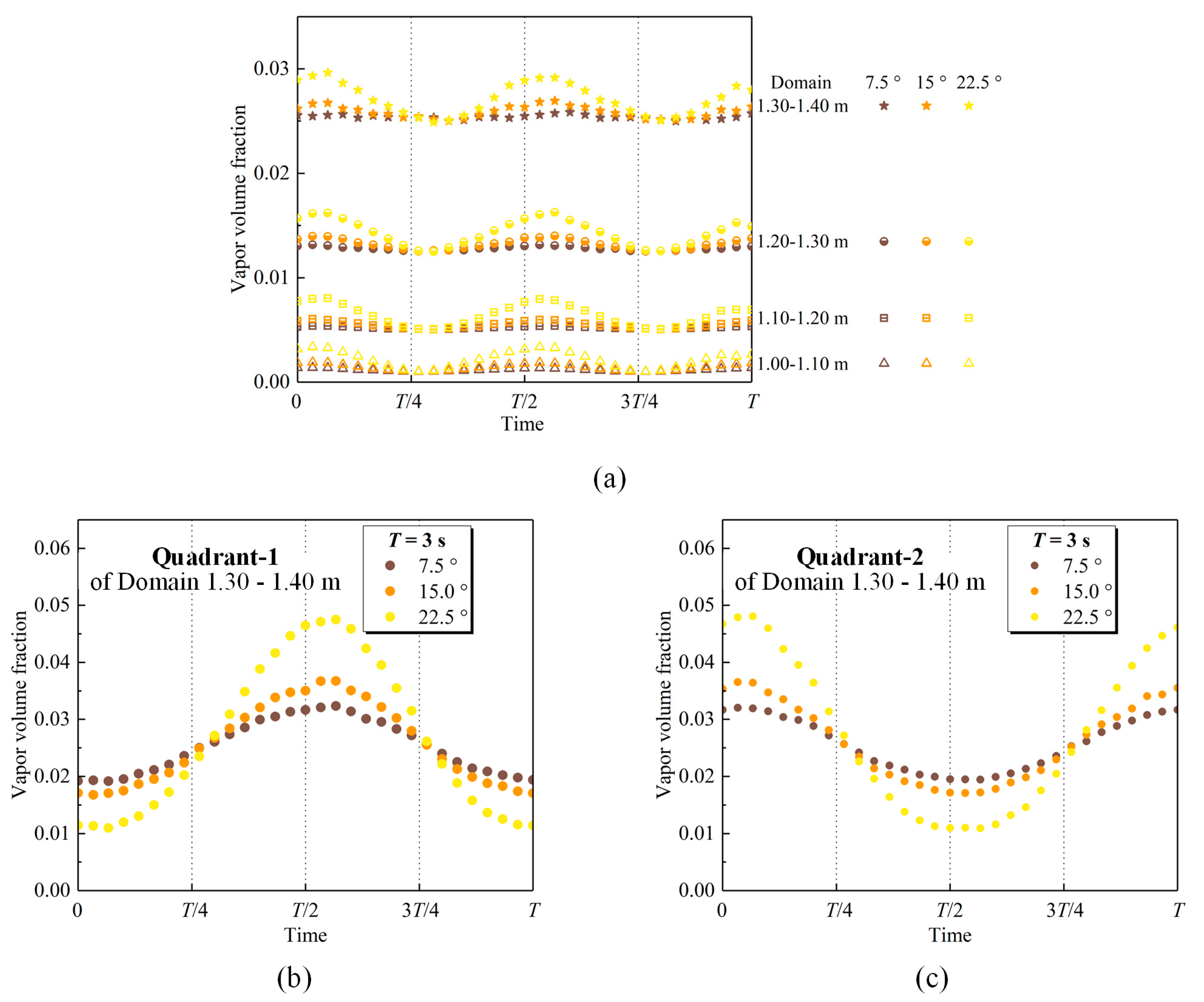

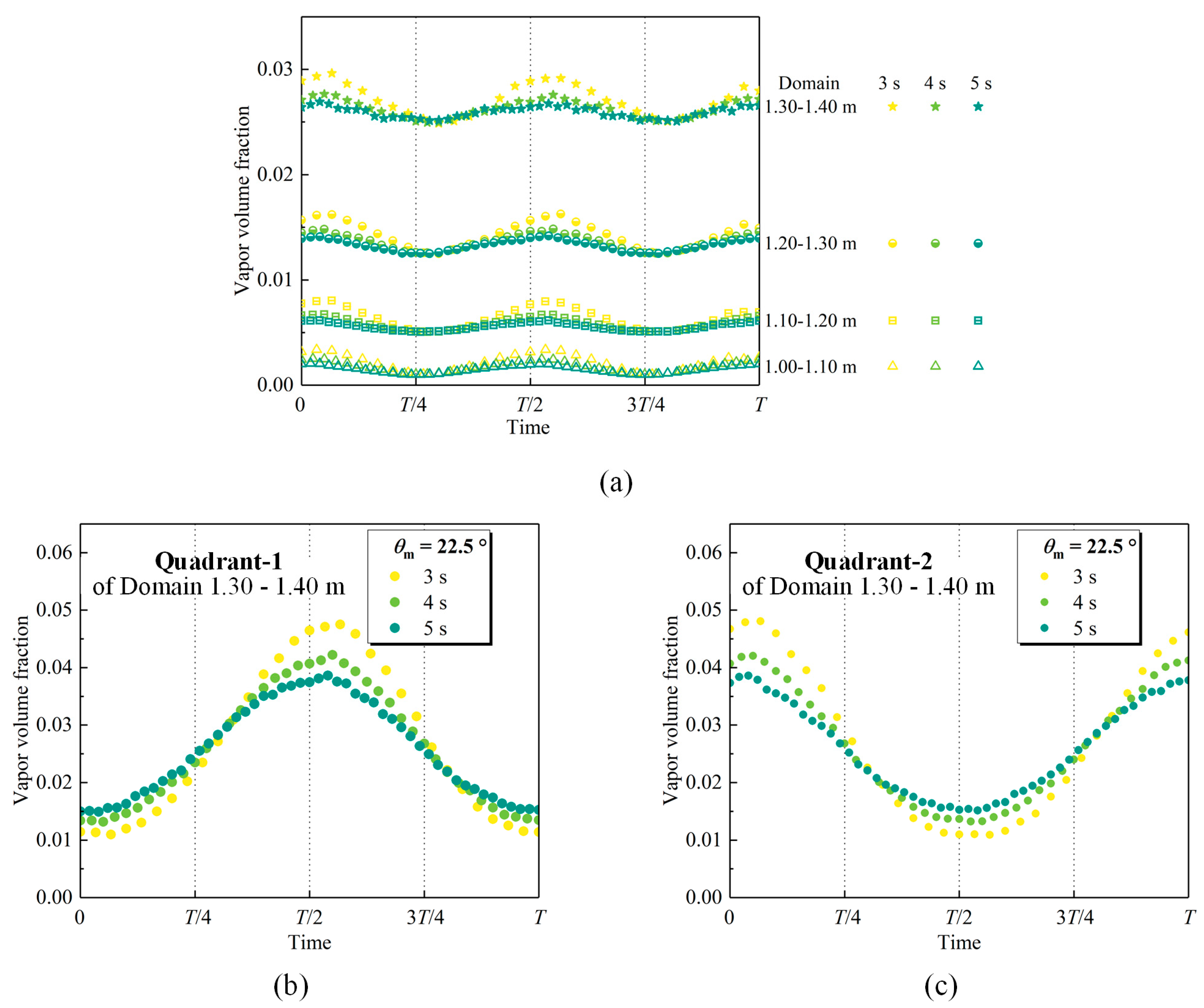

Transverse flow under static state is very different from that under rolling motion, as is vapor volume fraction in the two-phase domain. Tendencies of vapor volume fraction in the domain are shown in

Figure 6a, in which the vapor volume fraction is the area-averaged value in each domain of 0.10 m height. The results in four domains from CS-1.00 m to CS-1.40 m are displayed. At any moment, the vapor volume fraction increases along the flow direction in the static and the rolling cases. However, the tendencies of the vapor volume fraction are different. The vapor volume fraction in each domain is constant under static state, whereas it oscillates under rolling motion. The period of vapor volume fraction under rolling motion is almost half that of the rolling motion. Moreover, vapor volume fraction under rolling motion is always greater than that under static state for each domain.

Under static state, the vapor volume fraction in Quadrant-1 and Quadrant-2 are constant and approximately equal to each other (

Figure 6b,d). The tendency of vapor volume fraction in each quadrant features a similar pattern to that of the whole domain. The vapor volume fraction increases along the flow direction in both quadrants. Under rolling motion, the tendency of the vapor volume fraction in each quadrant differs from that in the whole domain (

Figure 6c,e). In each domain, vapor volume fraction in both quadrants oscillates with the period equal to that of rolling motion but is in phase opposition.

The difference in vapor volume fraction between the static and rolling case is primarily attributed to the difference in transverse flow field. The transverse flow fields in both the quadrants are similar and constant with time under static state, whereas they differ significantly and oscillate periodically under rolling motion. The reason is explained below in chronological order.

The transverse flow pattern at the cross-section remains the same during the process when the subchannel rotates anticlockwise to the equilibrium position. Highly subcooled bulk fluid flows successively by Rod-1 and Rod-2, and the fluid temperature nearby Rod-1 is lower. As a result, the vapor volume fraction in Quadrant-1 is far less than that in Quadrant-2 when the subchannel is in the equilibrium position (

), when

. The vapor volume fraction in Quadrant-1 and Quadrant-2 reaches the minimum and the maximum, respectively. After that, the subchannel continues to rotate anticlockwise, and the transverse flow field begins to reverse. A portion of the bulk fluid and fluid in the connected area flow to the vicinity of Rod-2. Bubbles in Quadrant-2 condense quickly, leading to vapor volume fraction decreases therein. A portion of the bulk fluid still flows to the vicinity of Rod-1. However, the flow rate decreases with time, and the vapor volume fraction increases therein. When the subchannel reaches the extreme position (

), the vapor volume fractions in Quadrant-1 and Quadrant-2 are approximately equal to their values under static state. After that, the subchannel rotates clockwise, and the transverse flow pattern at the cross-section does not change after

(

Figure 5g,h). Highly subcooled bulk fluid flows successively by Rod-2 and Rod-1, and the bulk fluid temperature nearby Rod-1 is higher. As a result, the vapor volume fraction continues to decrease in Quadrant-1 and increase in Quadrant-2.

The tendencies of vapor volume fraction in both quadrants in the next half period reversed those in the above-mentioned first half period.

Noteworthy, in the rolling case, the vapor volume fraction in Quadrant-1 and Quadrant-2 oscillates around that under static state and is in phase opposition. The summation of the vapor volume fraction in each quadrant, i.e., the vapor volume fraction in a domain, is equal to or greater than that in the static case. This is because the increment under rolling motion is larger than the decrement all the time. Especially in Domain 1.0–1.1 m, the vapor volume fraction in each quadrant is equal to or greater than that under static state due to the lower position where the boil begins.

3.1.3. Vapor Adhesion Ratio

For subcooled flow boiling in the subchannel, the vapor volume fraction remains small in the computation domain and typically no more than a few percent. However, the bubbles adjacent to the wall may crowd sufficiently, and a growing bubble layer may form eventually. The departure from nucleate boiling (DNB) occurs without a sustained macroscopic contact between the liquid and the surface, even though the bulk flow in the subchannel may still be highly subcooled. Predictions of the vapor volume fraction and vapor adhesion are essential. The vapor adhesion ratio at the wall can be defined as

The denominator denotes the area of the wall, and the numerator denotes the area of the wall covered with vapor.

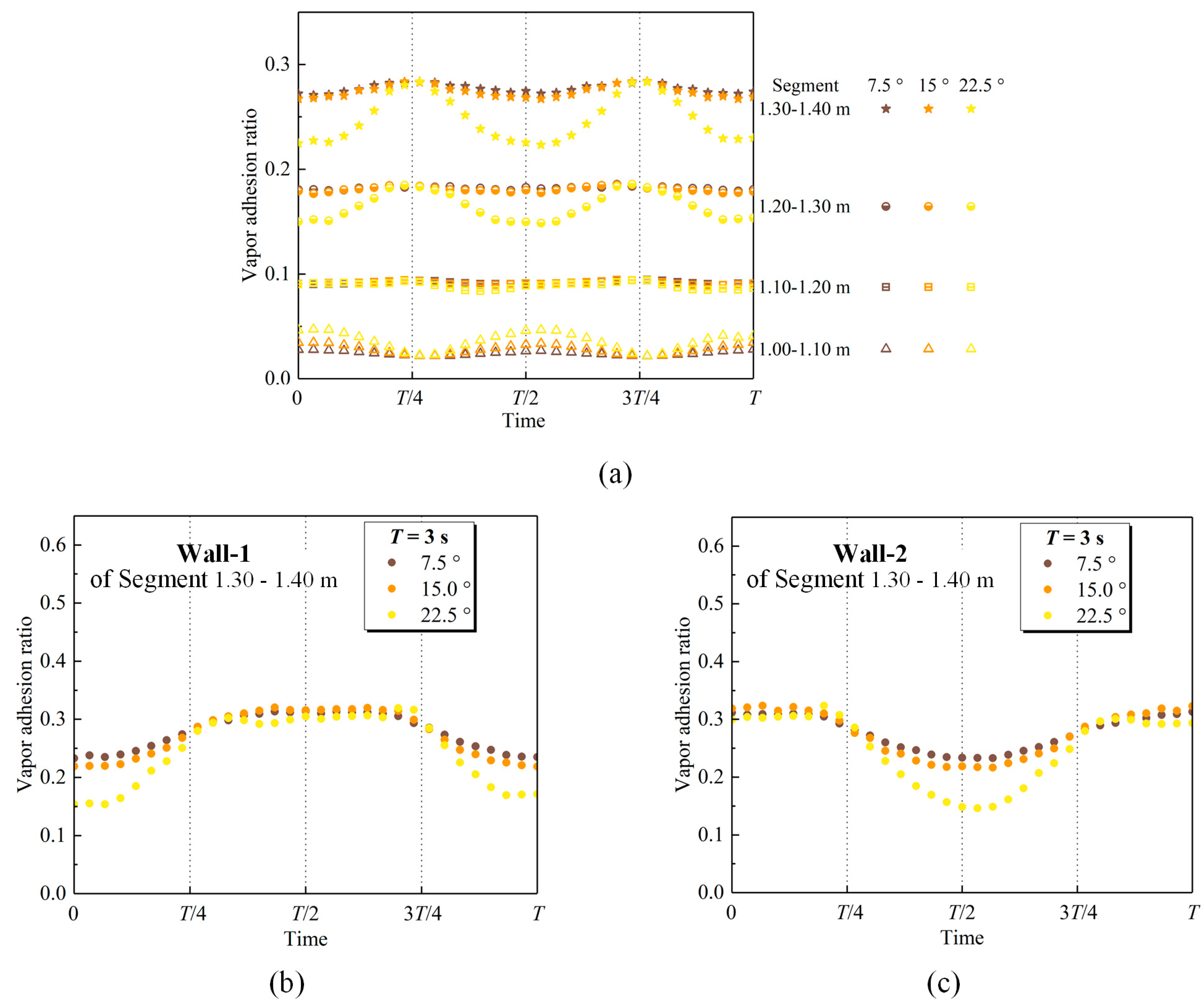

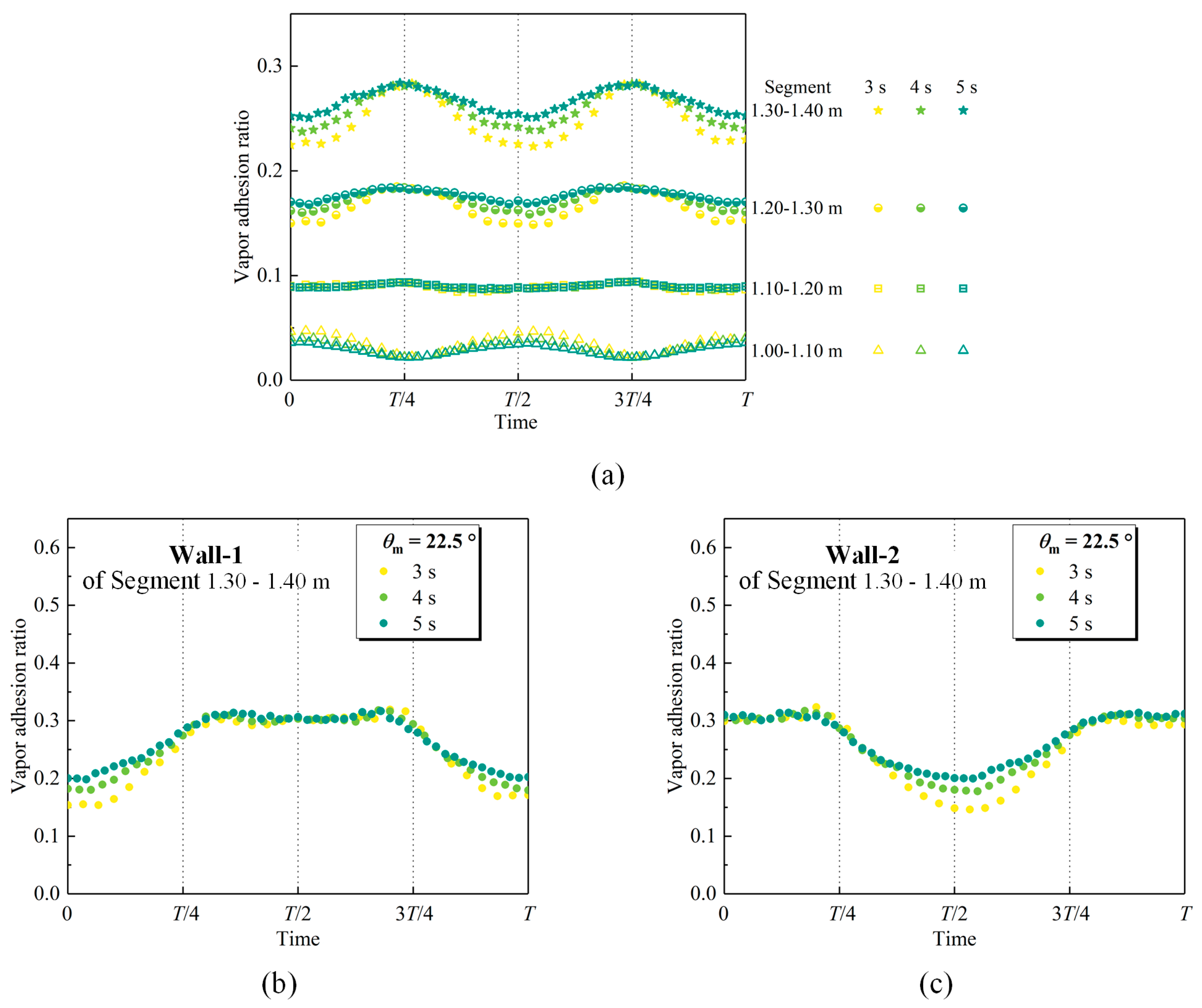

The tendencies of the vapor adhesion ratio at the wall are shown in

Figure 7a. The vapor adhesion ratio is an area-averaged value at the wall, including both the heated and unheated surface in each domain 0.1 m high. It is defined in this way because the bubbles can not only be formed adjacent to the heated surface but also be pushed to the unheated surface. The vapor adhesion ratios increase along the flow direction under both static and rolling cases. The vapor adhesion ratio of Segment 1.00–1.10 m under rolling motion is greater than that under static state, whereas the vapor adhesion ratio of Segment 1.10–1.40 m is lower than that under static state.

For the static case, all the walls have axial symmetry, and the vapor adhesion ratio at them is identical and stable (

Figure 7b,d). For the rolling case, the vapor adhesion ratios at both walls oscillate with a period equal to that of rolling motion (

Figure 7c,e). Interestingly, the vapor adhesion ratio at Wall-2 is essentially constant when the vapor adhesion ratio at Wall-1 decreases or increases, and vice versa.

The vapor adhesion ratio at each wall increases along the flow direction. The effect of the transverse flow on the vapor adhesion ratio is slight at the lower position (Segment 1.00–1.20 m) under rolling motion. In Segment 1.00–1.10 m, the variation in the vapor adhesion ratio with time can be divided into three phases on both walls: increase, constant, and decrease. Furthermore, the vapor adhesion ratios under rolling motion are always greater than those under static state on both walls. They oscillate with the period half as much as that of rolling motion. In Segment 1.10–1.20 m, the vapor adhesion ratios under rolling motion on both walls oscillate around that under static state.

The tendencies of the vapor adhesion ratio are different at the upper position (Segment 1.20–1.40 m) due to the combined effects of the vapor volume fraction and the transverse flow. At the beginning of rolling motion (), the vapor adhesion ratio at Wall-1 is less than that under static state due to transverse flow. Then, it gradually increases to approximately the value under static state when the subchannel reaches the extreme position (). After that, the incoming fluid temperature in the vicinity of Rod-1 begins to increase, and more fluid reaches saturated to boil. In the meantime, the vapor volume fraction in Quadrant-1 and the vapor adhesion ratio at Wall-1 increase.

When the subchannel rotates anticlockwise from the extreme to the equilibrium position, the vapor volume fraction in Quadrant-1 increases continuously, and bubbles on the heated surface shift along the transverse flow. Finally, a great quantity of bubbles accumulate near the boundary between the heated surface and the unheated surface by the entrainment and flush of transverse flow. The vapor layer thickness increases as the vapor volume fraction increases, while the vapor adhesion ratio is constant (

Figure 7d). The subcooled fluid in the middle of the cross-section and the gap between Rod-1 and Rod-2 flows to Rod-1 after the subchannel reaches the equilibrium position (

). The vapor volume fraction in Quadrant-1 decreases gradually. The bubbles, far from the heated surface in the boundary between the heated surface and the unheated surface, are apt to be affected by transverse flow and begin to condense. Therefore, the maximum vapor layer thickness at Wall-1 decreases while the vapor adhesion ratio is constant.

When the subchannel reaches the extreme position again (), the transverse velocity in the vicinity of Rod-1 begins to increase. After that, the vapor volume fraction in Quadrant-1 decreases gradually. The bubbles shift to the center of the heated surface slowly, which leads to the decrease in the vapor adhesion ratio at Wall-1.

The tendencies of the vapor adhesion ratio at other walls follow the same pattern as that at Wall-1. In conclusion, although the vapor volume fraction under rolling motion is always higher than that under static state at the upper position of the flow domain, the transverse flow tends to cause bubble accumulation, and the vapor adhesion ratio is less than that under static state all the time.

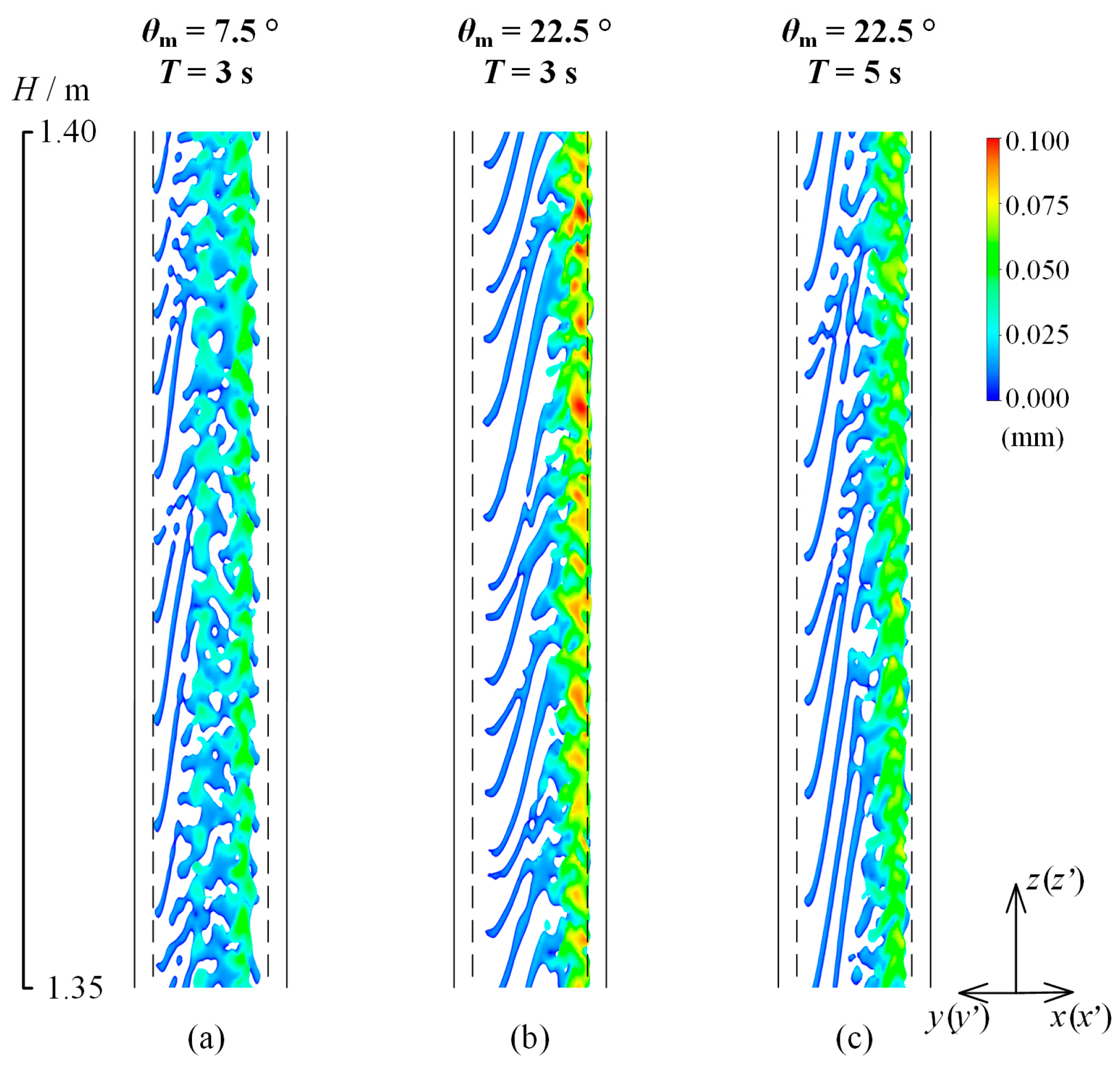

3.1.4. Phase Distribution

For PWRs at normal operation, local boiling occurs at a higher elevation of the reactor core. Vapor bubbles grow attached to the fuel rod while the bulk flow is still highly subcooled. As the height increases, multiple bubbles coalesce to form thin and discontinuous vapor layers. Therefore, the flow pattern in the present study is quite different from that in saturated boiling. In addition, the phase distribution in the subchannel is significantly different from that in the circular and rectangular tubes under the effect of the geometrical configuration.

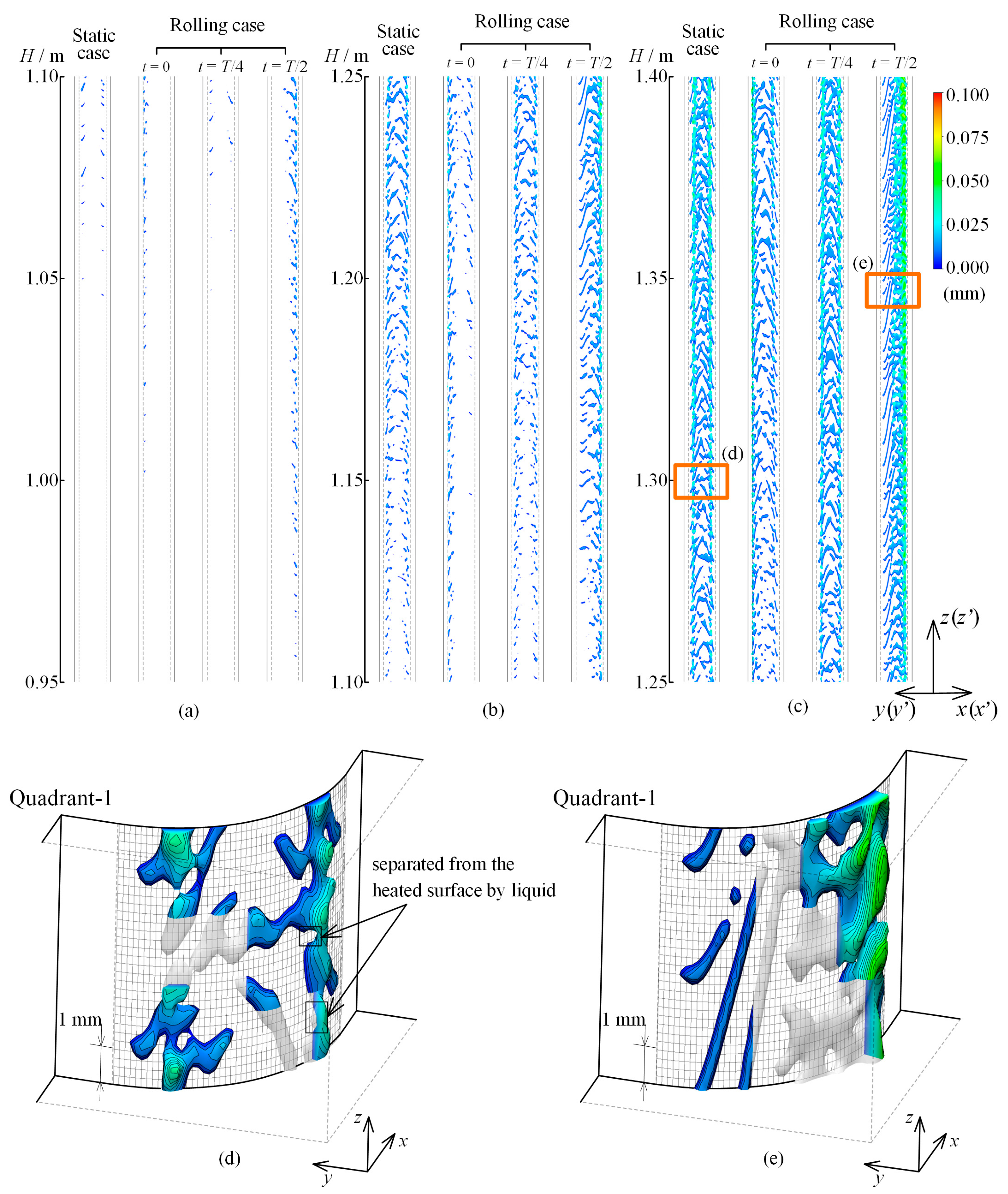

The vapor–liquid phase distribution in Quadrant-1 is shown in

Figure 8. Only the vapor phase is shown in the figure, with color indicating the perpendicular distance between the interface and the heated surface. The region inside the black dashed line is the heated surface. The regions between the continuous and dashed lines are the rectangular unheated surfaces adjacent to the rod.

Flow and heat transfer in the subchannel are stable under static state. The OSV occurs around CS-1.05 m. Even though the heat flux of the fuel rod is uniform, fluid along both sides of the heated surface reaches saturated earlier under the effect of the channel sectional configuration (

Figure 8a).

As the height increases, fluid along both sides and the center of the heated surface begins to boil (

Figure 8b). The bubble is not the typical sphere but is long and narrow due to the transverse flow (

Figure 5a). The fluid near the heated surface flows from both sides to the center, and the bubbles will be elongated to incline towards the center of the heated surface. Some bubbles will break into multiple small bubbles to merge with bubbles in the center of the heated surface. Bubbles in the center of the heated surface will grow continuously and bridge bubbles on both sides.

Further downstream, two vapor columns come into being due to more bubbles accumulating on both sides of the heated surface (

Figure 8c). It should be emphasized that part of the vapor column herein is separated from the heated surface by liquid and does not cover the heated surface absolutely (

Figure 8d). Vapor near the surface is submerged in the boundary layer with low velocity, and vapor far away from the surface flows downstream with high velocity. They detach from each other due to the velocity difference. Vapor far away from the surface interconnects together as a column, whereas the vapor phase and the liquid phase are separated near the surface.

Under rolling motion, the vapor–liquid phase distribution in the subchannel varies with time due to transverse flow, which features the following characteristics. When the subchannel reaches the equilibrium position (

or

), which is the same as that under static state, the phase distribution is significantly different from that under static state. The OSV point under rolling motion is much lower than that under static state (

Figure 8a). Further downstream, vapor bubbles are swept by the transverse flow and the amount of the vapor increases along the direction of the transverse flow. Although the transverse flow fields are similar when

and

, the phase distributions are slightly different. Different directions of the transverse flow not only result in different positions where bubbles accumulate but also affect the vapor volume fraction. When

, transverse flow heated by Rod-2 then flows to Rod-1, causing more liquid to boil (

Figure 8e). Bubbles on the left side of the heated surface grow in length and eventually break into discrete bubbles. Multiple bubbles on the right side coalesce and collect at the boundary of the heated and unheated surface. When the subchannel reaches the extreme position (

or

), the vapor–liquid phase distribution is similar to that under static state due to a similar transverse flow field.