Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative

Abstract

1. Introduction

2. Materials and Methods

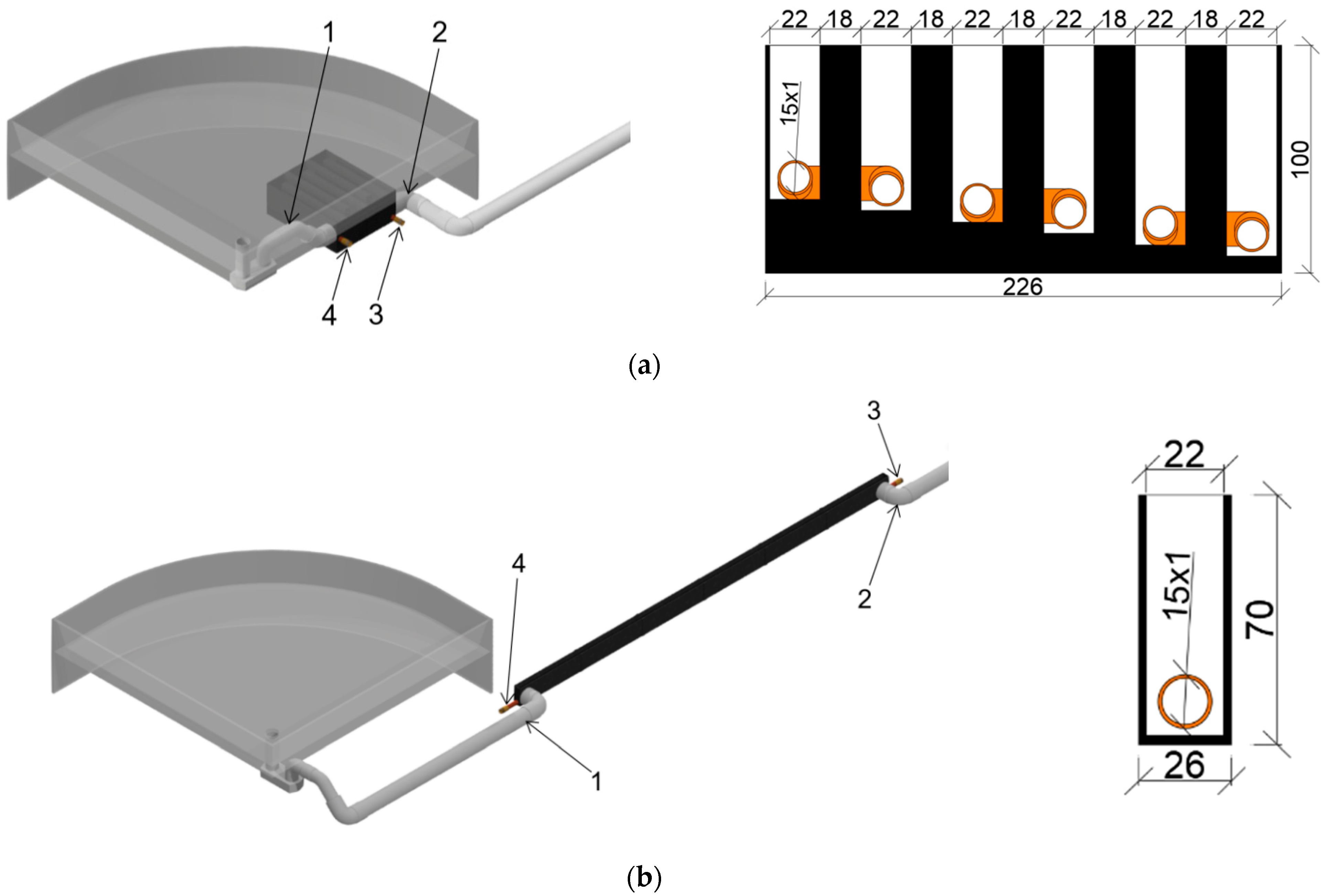

2.1. Characteristics of the Tested Shower Heat Exchangers

2.2. Assessment of the Efficiency of Shower Heat Exchangers

2.3. Financial Analysis of the Compact Shower Heat Exchanger Application

2.4. Sensitivity Analysis

3. Results and Discussion

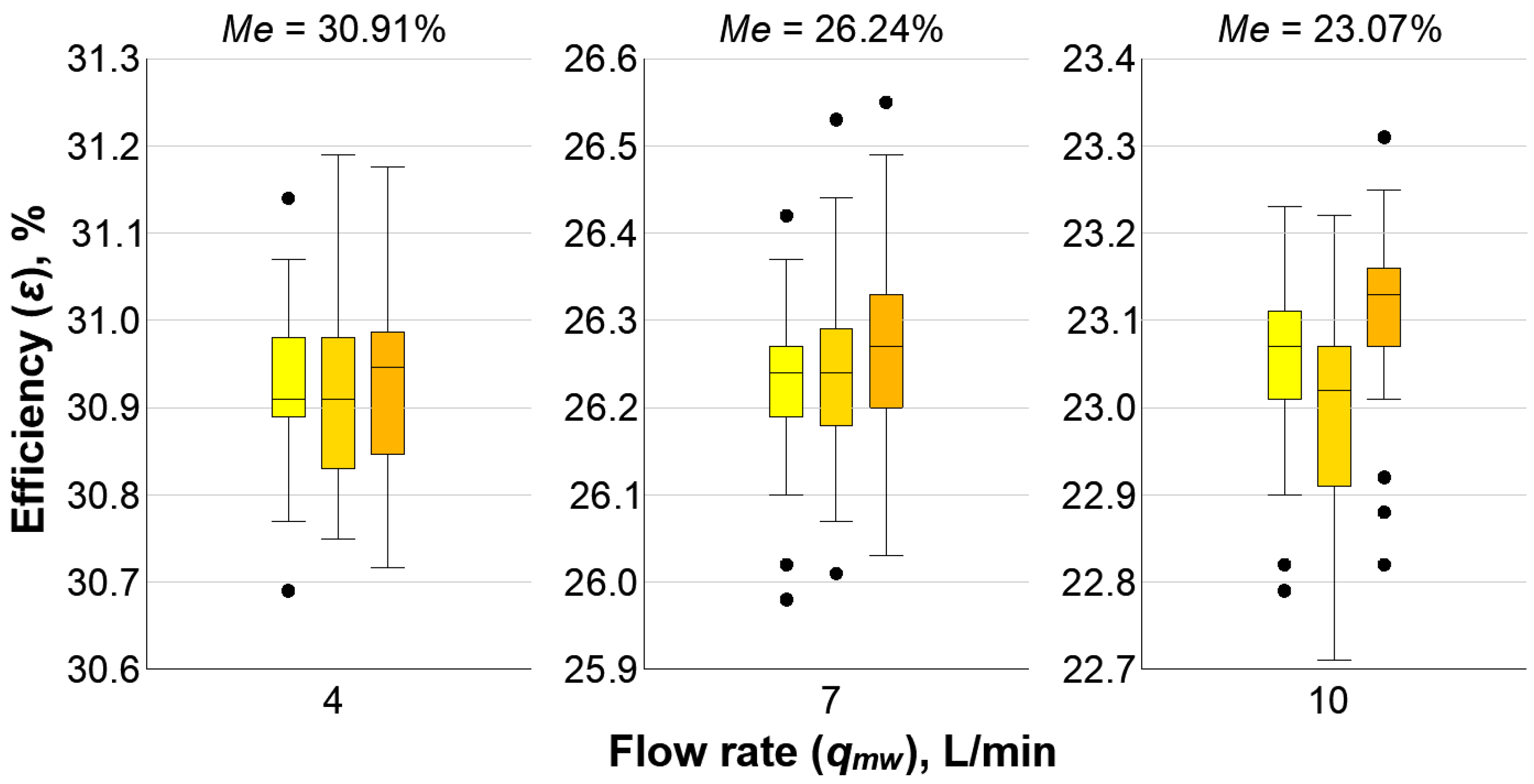

3.1. Evaluation of the Efficiency of the Compact and Linear Shower Heat Exchanger

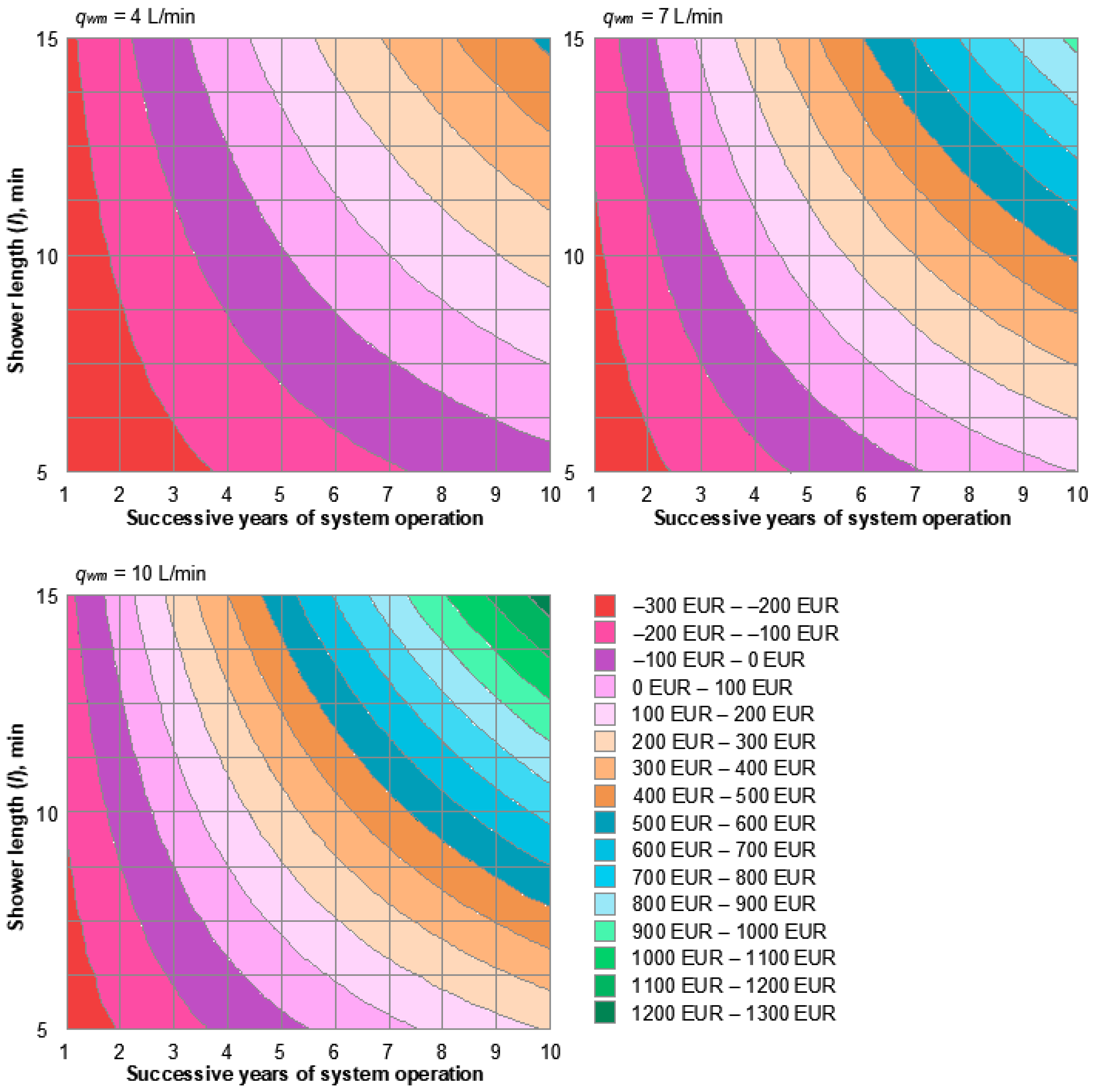

3.2. Financial Analysis of the Application of the Compact Shower Heat Exchanger

3.3. Sensitivity Analysis

3.4. Possibilities and Challenges

4. Conclusions

- The use of both shower heat exchangers allows for the recovery of part of the energy deposited in the drain water. However, the efficiency of the compact DWHR unit is higher;

- An increase in the temperature of cold water reduces the efficiency of shower heat exchangers;

- The impact of the linear DWHR unit bottom slope and water and drain water flow rate on the efficiency of the unit is variable and depends on the values of the other parameters. In most cases, increasing the bottom slope increases the efficiency of the unit;

- In the case of the compact DWHR unit, an increase in media flow results in a reduction in efficiency.

- The use of the compact DWHR unit is particularly advantageous when the hot water source in the building is an electric domestic hot water heater;

- The investment is particularly vulnerable to changes in investment outlays;

- The sensitivity to changes in electricity prices and the discount rate is moderate. The net present value of the investment is unlikely to fall below zero. However, these parameters have a significant impact on the level of financial savings achieved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Núñez-López, J.M.; Rubio-Castro, E.; El-Halwagi, M.M.; Ponce-Ortega, J.M. Optimal design of total integrated residential complexes involving water-energy-waste nexus. Clean Technol. Environ. Policy 2018, 20, 1061–1085. [Google Scholar] [CrossRef]

- Gubernat, S.; Masłoń, A.; Czarnota, J.; Koszelnik, P. Reactive Materials in the Removal of Phosphorus Compounds from Wastewater—A Review. Materials 2020, 13, 3377. [Google Scholar] [CrossRef] [PubMed]

- Cecconet, D.; Raček, J.; Callegari, A.; Hlavinek, P. Energy Recovery from Wastewater: A Study on Heating and Cooling of a Multipurpose Building with Sewage-Reclaimed Heat Energy. Sustainability 2020, 12, 116. [Google Scholar] [CrossRef]

- Preisner, M.; Smol, M.; Neverova-Dziopak, E.; Kowalewski, Z. Application of Activated Sludge Model for phosphorus recovery potential simulation. Desalin. Water Treat. 2021, 232, 199–207. [Google Scholar] [CrossRef]

- Cabling, L.P.B.; Kobayashi, Y.; Davies, E.G.R.; Ashbolt, N.J.; Liu, Y. Life Cycle Assessment of Community-Based Sewer Mining: Integrated Heat Recovery and Fit-For-Purpose Water Reuse. Environments 2020, 7, 36. [Google Scholar] [CrossRef]

- Diaz-Elsayed, N.; Rezaei, N.; Ndiaye, A.; Zhang, Q. Trends in the environmental and economic sustainability of wastewater-based resource recovery: A review. J. Clean. Prod. 2020, 265, 121598. [Google Scholar] [CrossRef]

- Nagpal, H.; Spriet, J.; Murali, M.K.; McNabola, A. Heat Recovery from Wastewater—A Review of Available Resource. Water 2021, 13, 1274. [Google Scholar] [CrossRef]

- Sitzenfrei, R.; Hillebrand, S.; Rauch, W. Investigating the interactions of decentralized and centralized wastewater heat recovery systems. Water Sci. Technol. 2017, 75, 1243–1250. [Google Scholar] [CrossRef]

- Salama, M.; Sharqawy, M.H. Experimental investigation of the performance of a falling-film drain water heat recovery system. Appl. Therm. Eng. 2020, 179, 115712. [Google Scholar] [CrossRef]

- Schestak, I.; Spriet, J.; Styles, D.; Williams, A.P. Introducing a Calculator for the Environmental and Financial Potential of Drain Water Heat Recovery in Commercial Kitchens. Water 2021, 13, 3486. [Google Scholar] [CrossRef]

- Neugebauer, G.; Lichtenwoehrer, P.; Huber, F.; Stoeglehner, G.; Kretschmer, F. Potentials and Integrated Suitability Pre-assessment of Wastewater Treatment Plants as Local Energy Cells. Front. Environ. Sci. 2022, 9, 785557. [Google Scholar] [CrossRef]

- Hadengue, B.; Morgenroth, E.; Larsen, T.A.; Baldini, L. Performance and dynamics of active greywater heat recovery in buildings. Appl. Energ. 2022, 305, 117677. [Google Scholar] [CrossRef]

- Farman Ali, S.; Gillich, A. Opportunities to decarbonize heat in the UK using Urban Wastewater Heat Recovery. Build. Serv. Eng. Res. Technol. 2021, 42, 715–732. [Google Scholar] [CrossRef]

- Živković, M.; Ivezić, D. Utilizing sewage wastewater heat in district heating systems in Serbia: Effects on sustainability. Clean. Technol. Environ. Policy 2022, 24, 579–593. [Google Scholar] [CrossRef]

- Wilson, M.P.; Worrall, F. The heat recovery potential of ‘wastewater’: A national analysis of sewage effluent discharge temperatures. Environ. Sci. Water Res. Technol. 2021, 7, 1760. [Google Scholar] [CrossRef]

- Christodoulides, P.; Agathokleous, R.; Aresti, L.; Aresti, S.A.; Tassou, S.A.; Florides, G.A. Waste Heat Recovery Technologies Revisited with Emphasis on New Solutions, including Heat Pipes, and Case Studies. Energies 2022, 15, 384. [Google Scholar] [CrossRef]

- Reiners, T.; Gross, M.; Altieri, L.; Wagner, H.J.; Bertsch, V. Heat Pump Efficiency in fifth Generation Ultra-Low Temperature District Heating Networks using a Wastewater Heat Source. Energy 2021, 236, 121318. [Google Scholar] [CrossRef]

- Kannoh, S. Heat recovery from warm waste water at dyeing process by absorption heat pump. J. Heat Recov. Syst. 1982, 2, 443–451. [Google Scholar] [CrossRef]

- Ravichandran, A.; Diaz-Elsayed, N.; Thomas, S.; Zhang, Q. An assessment of the influence of local conditions on the economic and environmental sustainability of drain water heat recovery systems. J. Clean. Prod. 2021, 279, 123589. [Google Scholar] [CrossRef]

- Selimli, S.; Eljetlawi, I.A.M. The experimental study of thermal energy recovery from shower greywater. Energy Source Part A 2021, 43, 3032–3044. [Google Scholar] [CrossRef]

- Vranay, F.; Vranayova, Z.; Lis, A. Building´s heat potential on resources in respect to CO2 emissions and primary energy reduction (Case study). IOP Conf. Ser. Mater. Sci. Eng. 2021, 1203, 022139. [Google Scholar] [CrossRef]

- Svintsov, A.P.; Kharun, M.I.; Mukarzel, S.A. Valve head for water fittings with high regulatory capacity. Mag. Civ. Eng. 2015, 58, 8–18. [Google Scholar] [CrossRef][Green Version]

- Piotrowska, B.; Słyś, D.; Kordana-Obuch, S.; Pochwat, K. Critical Analysis of the Current State of Knowledge in the Field of Waste Heat Recovery in Sewage Systems. Resources 2020, 9, 72. [Google Scholar] [CrossRef]

- Eurostat Statistics Explained. Electricity Price Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_household_consumers (accessed on 16 May 2022).

- Gabor, T.; Dan, V.; Tiuc, A.E.; Sur, I.M.; Badila, I.N. Experimental setup for analysis of drain water heat recovery system in civil buildings. J. Environ. Prot. Ecol. 2019, 20, 1960–1969. [Google Scholar]

- Vavřička, R.; Boháč, J.; Matuška, T. Experimental development of the plate shower heat exchanger to reduce the domestic hot water energy demand. Energy Build. 2022, 254, 111536. [Google Scholar] [CrossRef]

- Murr, R.; Khaled, M.; Faraj, J.; Harika, E.; Abdulhay, B. Multi drain heat recovery system—Thermal modeling, parametric analysis, and case study. Energy Build. 2020, 228, 110447. [Google Scholar] [CrossRef]

- Sayegh, M.A.; Ludwińska, A.; Rajski, K.; Dudkiewicz, E. Environmental and energy saving potential from greywater in hotels. Sci. Total Environ. 2021, 761, 143220. [Google Scholar] [CrossRef]

- Kordana, S.; Słyś, D. Analysis of profitability of using a heat recovery system from grey water discharged from the shower (case study of Poland). E3S Web Conf. 2017, 22, 00085. [Google Scholar] [CrossRef]

- Hyun, I.T.; Lee, J.H.; Yoon, Y.B.; Lee, K.H.; Nam, Y. The Potential and Utilization of Unused Energy Sources for Large-Scale Horticulture Facility Applications under Korean Climatic Conditions. Energies 2014, 7, 4781–4801. [Google Scholar] [CrossRef]

- Kovalenko, Y.; Katkov, M.; Ponomarenko, I.; Malovanyy, M.; Tymchuk, I. Utilization of drainage water heat in flooded urban areas. Ecol. Qustions 2022, 33, 31–41. [Google Scholar] [CrossRef]

- Amanowicz, Ł. Peak Power of Heat Source for Domestic Hot Water Preparation (DHW) for Residential Estate in Poland as a Representative Case Study for the Climate of Central Europe. Energies 2021, 14, 8047. [Google Scholar] [CrossRef]

- Deng, Z.; Mol, S.; Van Der Hoek, J.P. Shower heat exchanger: Reuse of energy from heated drinking water for CO2 reduction. Drink. Water Eng. Sci. 2016, 9, 1–8. [Google Scholar] [CrossRef]

- Stec, A.; Mazur, A.; Słyś, D. Evaluating the financial efficiency of energy and water saving installations in passive house. E3S Web Conf. 2017, 22, 00168. [Google Scholar] [CrossRef]

- Zaloum, C.; Lafrance, M.; Gusdorf, J. Drain Water Heat Recovery Characterization and Modeling, 1st ed.; Sustainable Buildings and Communities, Natural Resources Canada: Ottawa, ON, Canada, 2007. [Google Scholar]

- Zhao, L.; Zhang, W.; Wang, W. Recognition of Energy-Saving Influencing Factors of Construction Project Lifecycle Based on Knowledge Map. Int. J. Pattern Recogn. 2021, 35, 2159017. [Google Scholar] [CrossRef]

- Lynggaard, P.; Skouby, K.E. Complex IoT Systems as Enablers for Smart Homes in a Smart City Vision. Sensors 2016, 16, 1840. [Google Scholar] [CrossRef] [PubMed]

- Szpak, D. Method for Determining the Probability of a Lack of Water Supply to Consumers. Energies 2020, 13, 5361. [Google Scholar] [CrossRef]

- Stec, A.; Mazur, A. An Analysis of Eco-Technology Allowing Water and Energy Saving in an Environmentally Friendly House—A Case Study from Poland. Buildings 2019, 9, 180. [Google Scholar] [CrossRef]

- del Carmen Munguía-López, A.; Núñez-López, J.M.; Ponce-Ortega, J.M. Identifying Fair Solutions in the Optimal Design of Integrated Residential Complexes. Chem. Eng. Process. 2020, 157, 108116. [Google Scholar] [CrossRef]

- Raoufi, A.; Gorji, M. Water and energy management in a sustainable site: A case study of a living environment for street children in Tehran, Iran. Sustain. Cities Soc. 2021, 68, 102797. [Google Scholar] [CrossRef]

- Sun, Y.; Deng, L.; Pan, S.Y.; Chiang, P.C.; Sable, S.S.; Shah, K.J. Integration of green and gray infrastructures for sponge city: Water and energy nexus. Water-Energy Nexus 2020, 3, 29–40. [Google Scholar] [CrossRef]

- Østergaard, D.S.; Smith, K.M.; Tunzi, M.; Svendsen, S. Low-temperature operation of heating systems to enable 4th generation district heating: A review. Energy 2022, 248, 123529. [Google Scholar] [CrossRef]

- Kordana-Obuch, S.; Starzec, M.; Słyś, D. Assessment of the Feasibility of Implementing Shower Heat Exchangers in Residential Buildings Based on Users’ Energy Saving Preferences. Energies 2021, 14, 5547. [Google Scholar] [CrossRef]

- Stec, A.; Słyś, D. Financial and Social Factors Influencing the Use of Unconventional Water Systems in Single-Family Houses in Eight European Countries. Resources 2022, 11, 16. [Google Scholar] [CrossRef]

- Cholewa, M.; Mammadov, F.; Nowaczek, A. The obstacles and challenges of transition towards a renewable and sustainable energy system in Azerbaijan and Poland. Miner. Econ. 2022, 35, 155–169. [Google Scholar] [CrossRef]

- Dudkiewicz, E.; Laska, M.; Fidorów-Kaprawy, N. Users’ Sensations in the Context of Energy Efficiency Maintenance in Public Utility Buildings. Energies 2021, 14, 8159. [Google Scholar] [CrossRef]

- Zaloum, C.; Gusdorf, J.; Parekh, A. Performance Evaluation of Drain Water Heat Recovery Technology at the Canadian Centre for Housing Technology—Final Report; Sustainable Buildings and Communities; Natural Resources Canada: Ottawa, ON, Canada, 2007.

- Yang, H.; Kikuta, K.; Hayashi, M. Research on Carbon Reduction of Residential Buildings in Severe Cold Regions Based on Renovation of Envelopes. Energies 2022, 15, 1873. [Google Scholar] [CrossRef]

- Zięty, J.J.; Olba-Zięty, E.; Stolarski, M.J.; Krzykowski, M.; Krzyżaniak, M. Legal Framework for the Sustainable Production of Short Rotation Coppice Biomass for Bioeconomy and Bioenergy. Energies 2022, 15, 1370. [Google Scholar] [CrossRef]

- Van Horne, J.C.; Wachowicz, J.M., Jr. Fundamentals of Financial Management, 13th ed.; Prentice Hall/Pearson Education Limited: Harlow, UK, 2009. [Google Scholar]

- Brigham, E.F.; Ehrhardt, M.C. Financial Management: Theory and Practice, 12th ed.; Thomson Higher Education: Mason, IA, USA, 2008. [Google Scholar]

- Pochwat, K.; Kordana-Obuch, S.; Starzec, M.; Piotrowska, B. Financial Analysis of the Use of Two Horizontal Drain Water Heat Recovery Units. Energies 2020, 13, 4113. [Google Scholar] [CrossRef]

- Shan, Y.; Yang, L.; Perren, K.; Zhang, Y. Household Water Consumption: Insight from a Survey in Greece and Poland. Procedia Eng. 2015, 119, 1409–1418. [Google Scholar] [CrossRef]

- European Commission. Guide to Cost-Benefit Analysis of Investment Projects: Economic Appraisal Tool for Cohesion Policy; European Commission: Brussels, Belgium, 2015.

- Ćetković, J.; Lakić, S.; Žarković, M.; Vujadinović, R.; Knežević, M.; Živković, A.; Cvijović, J. Environmental Benefits of Air Emission Reduction in the Waste Tire Management Practice. Processes 2022, 10, 787. [Google Scholar] [CrossRef]

- European Commission. Economic Appraisal Vademecum 2021–2027: General Principles and Sector Applications; European Commission: Brussels, Belgium, 2021.

- Foltyn-Zarychta, M.; Buła, R.; Pera, K. Discounting for Energy Transition Policies—Estimation of the Social Discount Rate for Poland. Energies 2021, 14, 741. [Google Scholar] [CrossRef]

- OECD. Cost-Benefit Analysis and the Environment: Further Developments and Policy Use; OECD Publishing: Paris, France, 2018; pp. 399–422. [Google Scholar] [CrossRef]

- Kell, G.S. Density, Thermal Expansivity, and Compressibility of Liquid Water from 0° to 150 °C: Correlations and Tables for Atmospheric Pressure and Saturation Reviewed and Expressed on 1968 Temperature Scale. J. Chem. Eng. Data 1975, 20, 97–105. [Google Scholar] [CrossRef]

- Dinçer, İ.; Zamfirescu, C. Drying Phenomena: Theory and Applications, 1st ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 457–459. [Google Scholar]

- Chudzicki, J.; Sosnowski, S. Instalacje Wodociągowe—Projektowanie, Wykonanie, Eksploatacja, 3rd ed.; Seidel-Przywecki: Warsaw, Poland, 2011. [Google Scholar]

- Manouchehri, R.; Collins, M.R. Investigating the Impact of Plumbing Configuration on Energy Savings for Falling-Film Drain Water Heat Recovery Systems. Energies 2022, 15, 1141. [Google Scholar] [CrossRef]

- Al-Sumaiti, A.S.; Kavousi-Fard, A.; Salama, M.; Pourbehzadi, M.; Reddy, S.; Rasheed, M.B. Economic Assessment of Distributed Generation Technologies: A Feasibility Study and Comparison with the Literature. Energies 2020, 13, 2764. [Google Scholar] [CrossRef]

- Mazur, A. The impact of using of a DWHR heat exchanger on operating costs for a hot water preparation system and the amount of carbon dioxide emissions entering the atmosphere. E3S Web Conf. 2018, 45, 00052. [Google Scholar] [CrossRef]

- Gabrielli, P.; Wüthrich, M.; Blume, S.; Sansavini, G. Data-driven modeling for long-term electricity price forecasting. Energy 2022, 244, 123107. [Google Scholar] [CrossRef]

- Ruszel, M.; Masłoń, A.; Ogarek, P. Analysis of biogas from sewage sludge digestion in terms of diversification in the natural gas production structure in Poland. Desalin. Water Treat. 2021, 232, 298–307. [Google Scholar] [CrossRef]

- Boryczko, K.; Szpak, D.; Żywiec, J.; Tchórzewska-Cieślak, B. The Use of a Fault Tree Analysis (FTA) in the Operator Reliability Assessment of the Critical Infrastructure on the Example of Water Supply System. Energies 2022, 15, 4416. [Google Scholar] [CrossRef]

| Input Parameters | Unit | Value |

|---|---|---|

| Mixed water flow rate (qmw) | L/min | 4, 5, 6, 7, 8, 9, 10 |

| Mixed water temperature (Tmw) | °C | 40 |

| Hot water temperature (Thw) | °C | 55 |

| Cold water temperature (Tcw) | °C | 10, 12, 14, 16, 18 |

| Water temperature drop in the shower (ΔTs) [26] | °C | 5 |

| Drain water temperature (Tdw) | °C | 35 |

| Indoor air temperature (Ti) | °C | 24 |

| Linear DWHR unit bottom slope (i) | % | 0, 0.5, 1, 2, 3, 4, 6 |

| Input Parameters | Unit | Value |

|---|---|---|

| Shower length (l) | min | 5, 10, 15 |

| Mixed water flow rate (qmw) | L/min | 4, 7, 10 |

| Cold water temperature (Tcw) | °C | 14 |

| Electric hot water heater efficiency (ηel) | % | 98 |

| Gas hot water heater efficiency (ηg) | % | 80 |

| Electricity price (EP) | €/kWh | 0.160 |

| Natural gas price (GP) | €/kWh | 0.053 |

| Water density (ρ) [60] | kg/m3 | 989.14–996.51 |

| Specific heat of water (cp) [61] | J/(kg·K) | 4181–4183 |

| Discount rate [59] | % | 4.78 |

| The number of years of system operation (n) | years | 10 |

| Type of Expenditure | Expenditure |

|---|---|

| € | |

| Dismantling and reconstruction of wall elements | 130 |

| Modification of existing plumbing installation | 20 |

| Purchase of the shower heat exchanger | 170 |

| Total investment outlays (IO) | 320 |

| Mixed Water Flow Rate (qmw) | Shower Length (l) | Net Present Value (NPV) | Profitability Index (PI) | Discounted Payback Period (DPP) | Internal Rate of Return (IRR) |

|---|---|---|---|---|---|

| L/min | min | € | - | years | % |

| 4 | 5 | −39 | 0.88 | – | 2.22 |

| 10 | 243 | 1.76 | 5.11 | 18.34 | |

| 15 | 524 | 2.64 | 3.27 | 31.62 | |

| 7 | 5 | 98 | 1.31 | 7.21 | 10.65 |

| 10 | 516 | 2.61 | 3.31 | 31.25 | |

| 15 | 933 | 3.92 | 2.15 | 49.27 | |

| 10 | 5 | 205 | 1.64 | 5.54 | 16.41 |

| 10 | 729 | 3.28 | 2.59 | 40.62 | |

| 15 | 1254 | 4.92 | 1.69 | 62.52 |

| Mixed Water Flow Rate (qmw) | Shower Length (l) | Net Present Value (NPV) | Profitability Index (PI) | Discounted Payback Period (DPP) | Internal Rate of Return (IRR) |

|---|---|---|---|---|---|

| L/min | min | € | - | years | % |

| 4 | 5 | −205 | 0.36 | – | −12.10 |

| 10 | −90 | 0.72 | – | −1.49 | |

| 15 | 25 | 1.08 | 9.11 | 6.32 | |

| 7 | 5 | −149 | 0.53 | – | −6.39 |

| 10 | 21 | 1.07 | 9.23 | 6.12 | |

| 15 | 192 | 1.60 | 5.69 | 15.74 | |

| 10 | 5 | −106 | 0.67 | – | −2.70 |

| 10 | 108 | 1.34 | 7.00 | 11.24 | |

| 15 | 323 | 2.01 | 4.41 | 22.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kordana-Obuch, S.; Starzec, M. Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative. Energies 2022, 15, 4829. https://doi.org/10.3390/en15134829

Kordana-Obuch S, Starzec M. Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative. Energies. 2022; 15(13):4829. https://doi.org/10.3390/en15134829

Chicago/Turabian StyleKordana-Obuch, Sabina, and Mariusz Starzec. 2022. "Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative" Energies 15, no. 13: 4829. https://doi.org/10.3390/en15134829

APA StyleKordana-Obuch, S., & Starzec, M. (2022). Horizontal Shower Heat Exchanger as an Effective Domestic Hot Water Heating Alternative. Energies, 15(13), 4829. https://doi.org/10.3390/en15134829