Abstract

Building renovation was declared a key point for sustainable development, however, the renovation rate of residential buildings in the European Union is insufficient to meet the climate and energy targets set. This paper analyses the main circular economy models used in the construction sector, as well as the situation of the building renovation market, to set a framework for circular economy models in building renovation. Of all the existing strategies in this sector, design, material recovery, building renovation and end-of-life actions would be the best, respectively. It also includes a market analysis consisting of a literature review covering PEST perspectives (political, economic, social and technical) and a SWOT analysis (strengths, weaknesses, opportunities and threats), concluding with a market gap analysis. The results of these analyses allow the development of a series of suggestions and strategies to be followed in order to solve the main barriers that hinder the implementation of the circular economy in the building´s renovation sector.

1. Introduction

The increasing demand for sustainable solutions to today’s problems, together with the goals to be met in the future, requires action in multiple sectors. Among all the sectors, one of the most interesting to resolve this situation is the construction sector, specifically building construction and renovation. This is because it is one of the most resource- and waste-intensive economic activities [1]. In the European Union, cement, iron and steel production, vital industrial processes for the construction industry, are some of the main emitters of greenhouse gases (GHG), accounting for 40% of emissions [2]. The generation of construction and demolition waste (CDW) is also a major challenge for the construction industry due to the increasing volume of waste produced and its associated environmental impacts. CDW is the largest waste stream, accounting for 35.9% of the waste produced in 2018 in Europe [3].

1.1. Representativeness of the European Building Sector

The construction building sector is being considered a key area to meet the United Nations Sustainable Development Goals (SDG) on sustainable production and consumption (goal 12), improving the efficient use of natural resources (goal 12.2) and reducing waste generation (goal 12.5) [2]. Associated environmental impacts include land degradation, landfill depletion, carbon and greenhouse gas emissions, water pollution, high energy consumption and resource depletion [4].

Europe’s housing stock is as unique and heterogeneous as it is old. This age was addressed by renovation, but the pace at which this is taking place is very slow. Currently, 8–5% of the EU’s building stock, i.e., more than 220 million buildings, are over 21 years old, of which up to 95% will still be standing in 2050 [5], and virtually none of them are energy efficient. This is due, among other reasons, to the fact that they are dependent on fossil fuels for heating and cooling, which means that there is considerable potential for energy savings.

Overall, buildings are responsible for 40% of the EU’s total energy consumption as well as 36% of its greenhouse gas emissions [6]. Therefore, and taking into account the implications of the “Clean Energy for All Europeans” package, a 40% reduction in greenhouse gas (GHG) emissions compared to 1990 levels, a 32% share of renewable energy consumption and 32.5% energy savings compared to 2005 levels [7], it is clear that the building construction sector is key to achieving the objectives set and that one of the best methods to achieve this will be through building renovation.

Currently, the energy renovation rate of buildings is 1%, when it should be 3% to reach the EU’s energy efficiency and climate targets according to the European Commission’s (EC) estimates. As a consequence, more effort will be needed from European countries, an intention that is reflected in the updated renovation strategies in 2020 [8].

In addition to the sector’s great influence in environmental areas, it is also characterised by its relevance in social and economic aspects, given the large number of jobs it generates and its considerable contribution to gross domestic product (GDP). However, this sector would also present certain barriers that hinder its development, as well as the generation of certain environmental problems throughout the building project life cycles, especially in the operational and end-of-life phases [4].

One of the main problems in this sector is the large volumes of waste that are deposited in landfills or even dumped illegally, despite the growing interest in applying recovery practices such as reuse and recycling [4].

1.2. Circular Economy for Building Renovation at EU Level

Circular Economy (CE) is an established concept with multiple perspectives depending on the targeted sector. It is considered by academics, practitioners, and society as an alternative to allow companies to function sustainably under the concept of sustainable development. That is why the main objective of CE is to promote economic growth that reduces impacts on the environment through new production practices and technological developments that meet the needs of consumers within sustainability.

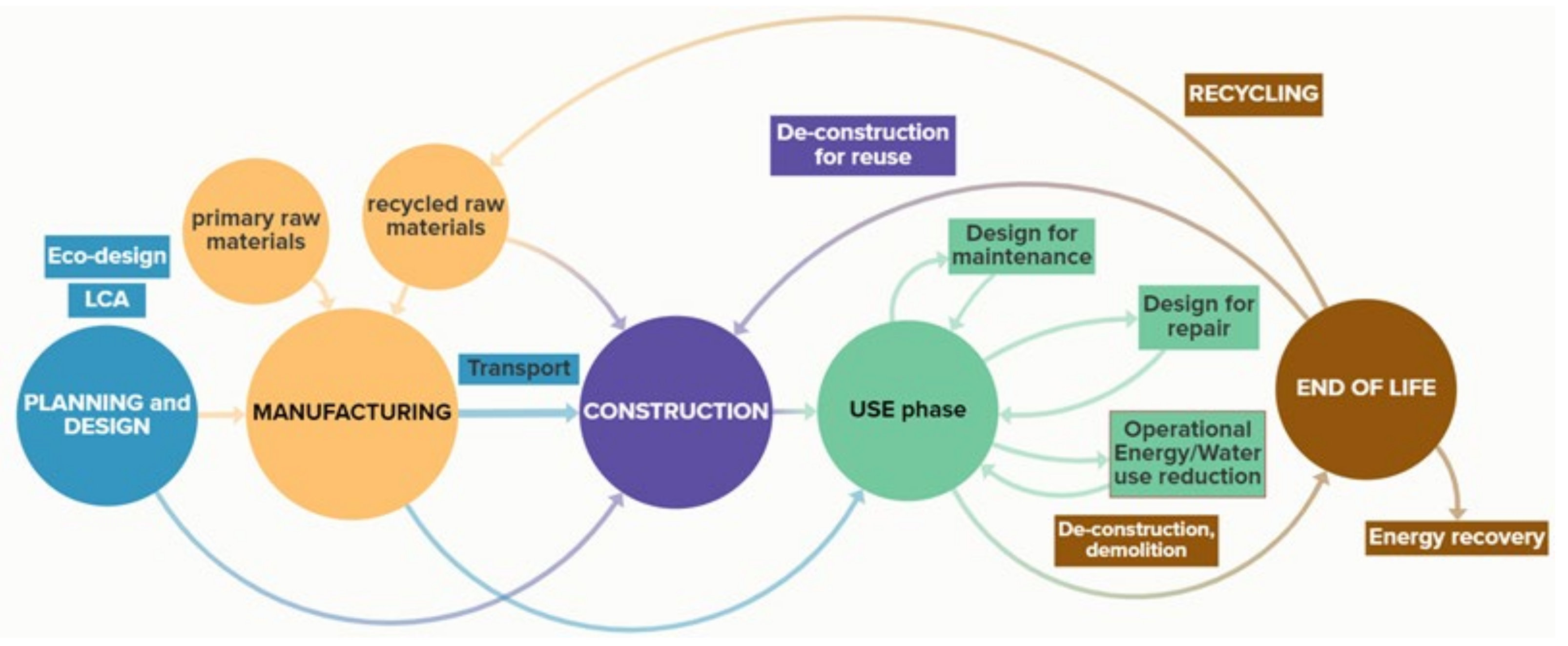

At the building level, different actions are being carried out to move towards a production and consumption model where waste is reduced as much as possible. The main circular strategies applicable to the building general framework are depicted in Figure 1.

Figure 1.

CE framework for buildings. Own elaboration based on Fundación Conama, 2018 [9].

In this context, the transition to a CE reduces environmental impacts while contributing to economic growth. In this way, CE becomes a novel regenerative system that not only makes the use of materials more efficient and optimises their value throughout their life cycle phases but also minimises waste [4]. Because of the problems generated by such waste and the overall sector environmental impacts, interest in the CE as a source of strategies and solutions has increased in recent years [2]. The CE concept has gained academic, government and organisational recognition in recent years. Such is the importance of this concept that the European Union has made it one of its central aspects in the development of policies and strategies, an example of which is the Circular Economy Action Plan [4].

This plan is one of the main building blocks of the European Green Deal, Europe’s new agenda for sustainable growth. This transition to a circular economy will reduce pressure on natural resources and will create sustainable growth and jobs, while acting as a prerequisite for achieving climate neutrality targets, i.e., reducing greenhouse gases by 55% compared to 1990 levels by 2030 and achieving net-zero greenhouse gas (GHG) emissions in the EU by 2050 [10].

However, for the building industry, the transition towards a circular economy requires systemic innovation throughout the value chain, as well as best management practices for CDW and more extensive implementation of the CE model in the sector.

In view of the extensive literature in the field of circular economy strategies in the construction sector, with the exception of building renovation, this paper proposes a comprehensive methodology based on a literature review to identify the different barriers that hinder the sustainable development of the sector through the building renovation market. In addition to this, the study will present the following objectives:

- Summarise the current state of knowledge of the CE in the building and building renovation sector;

- Identify and evaluate applicable CE strategies and their advantages and limitations in the building and building renovation sector;

- Analyse the obstacles to the application of CE strategies to building refurbishment

This review paper is divided into two major parts. The first part describes the methodology followed to conduct the literature review. The second part presents a comprehensive summary of what was carried out and found about circular economy strategies in building construction and the analysis of the building renovation market, as well as the current state of the art for the analysis of its circularity. In addition, a discussion section is provided with the aim to remark, describe, analyse, and interpret the main findings. Finally, a conclusion section including a proposal for future research work is presented.

2. Research Methodology

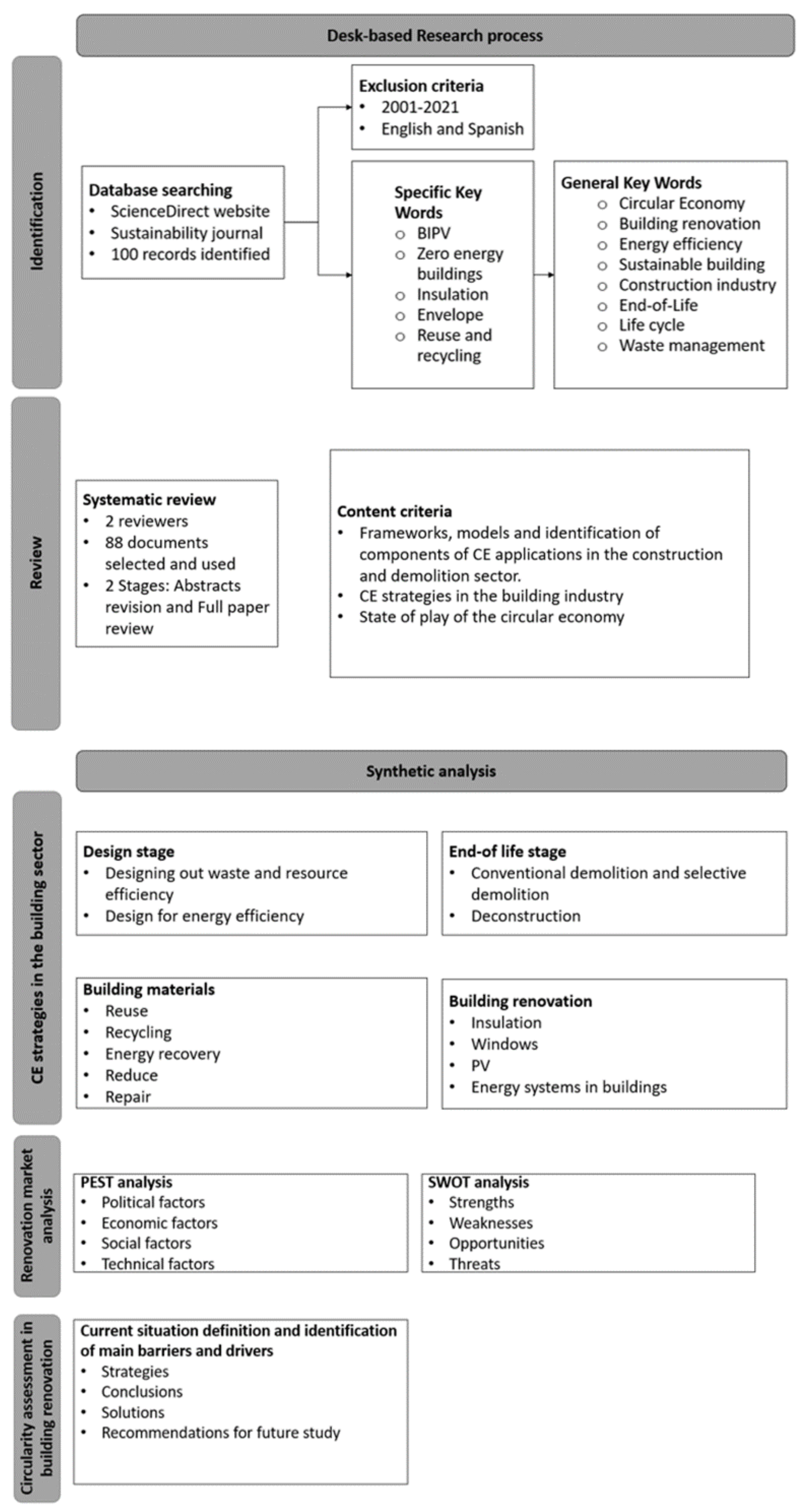

As part of the work carried out in the European Commission RINNO project, a preliminary analysis of publications on the building sector was carried out. This analysis showed that despite the great importance of the building renovation sector in the development of the circular economy, its contribution in the form of articles, analyses and other types of documents is currently relatively scarce. This situation was the initial motivation for writing this article, which reviews the literature and presents the main circular economy strategies used in the renovation of buildings.

A series of studies published in the last 20 years (2001–present) was compiled without geographical restrictions but prioritising those from the European area. This period was chosen in view of the wide temporal breadth of information in this sector, however, the vast majority of the data finally used would pertain to the last ten years, given the increased political attention on the circular economy [11]. The bibliography compiled comes mostly from the ScienceDirect website and the Sustainability journal, given their recognition, their review processes and their large number of articles with a wide geographical scope. In addition to these sources, published documents from different company and industry associations were also used, as well as from European Commission regulations and other sources of interest. In the case of companies and associations, a search was carried out among the important ones in the sector for their studies and publications. With regard to the European Commission’s regulations, the objectives and actions proposed were analysed, as well as the results of studies on the opinion of interested parties. The search was carried out using a series of keywords that could be differentiated between more general and more specific, consisting of:

- General

- ○

- Circular Economy;

- ○

- Building renovation;

- ○

- Energy efficiency;

- ○

- Sustainable building;

- ○

- Construction industry;

- ○

- End-of-Life;

- ○

- Life cycle;

- ○

- Waste management.

- Specific

- ○

- Building integrated photovoltaic (BIPV);

- ○

- Zero-energy buildings;

- ○

- Insulation;

- ○

- Envelope;

- ○

- Reuse and recycling.

Along with the keywords, a number of exclusion criteria were applied, including the aforementioned time period and language (English and Spanish only).

Based on these searches, a new selection was made taking into account the following content criteria:

- Studies that provide frameworks, models and identification of components of CE applications in the construction and demolition sector;

- Studies that assess the application of CE strategies in the building industry;

- Reviews on the current state of play of the circular economy in general and in the building construction sector.

In addition to the previously mentioned criteria, the articles were selected by two reviewers with more than 10 years of professional experience in the fields of sustainability and circularity assessment to ensure the quality of the search process.

The methodology followed is based on a systematic review due to its ability to provide the basis for improving knowledge of the research area and identifying gaps in published studies. In addition, it allows us to answer specific questions, as well as to evaluate the studies in an objective way [12].

The review was divided into stages, firstly, the abstract revision, which allowed an initial selection, and finally, the full paper review, to allow the final selection. From this procedure, more than 100 documents were collected, including articles, analyses, strategies, etc. of which 88 were finally selected and used.

The literature review is followed by a synthetic analysis of the most important CE strategies. In the case of technologies, they are presented according to the following outline:

- Description;

- CE application;

- Benefits;

- Barriers.

Last but not least, an examination of the building renovation market was developed through a Political, Economic, Social and Technical Dimensions (PEST) approach, as well as its Strengths, Weaknesses, Opportunities and Threats (SWOT), with the aim of generating strategies and solutions for this market.

Figure 2 below shows a diagram summarising the methodology used in the development of this document.

Figure 2.

Research design.

3. Results

3.1. CE Strategies in the Building Sector

The circular economy is a model of production and consumption, which has emerged from a combination of ideas from various scientific fields, that seeks to reduce waste, emissions and energy leakage through a series of principles. In the case of the building sector, these principles are summarised in the ReSOLVE framework [13,14,15,16]. This framework identifies a set of six actions that companies and governments can take to transition to a circular economy (Regenerate, Share, Optimise, Link, Virtualise and Exchange), as can be seen in Table 1.

Table 1.

CE Principles.

These six principles can be used in a multitude of ways, from small things such as a product or a single building to entire neighbourhoods, cities and even economies. The following shows how these elements are used in the built environment [18]:

- Regenerate

From regeneration in the building sector, it is possible to generate more efficient and resilient buildings that in short reduce the consumption of raw materials, waste generation and other negative aspects, while at the same time returning nutrients to the environment through different processes (composting, anaerobic digestion, ...).

- Share

This principle maximises the amortisation of all types of assets, increases their efficiency and improves collaboration between the various parties (operators, owners, etc.).

- Optimise

As with the previous principles, optimisation maximises efficiency, reduces waste generation, in this case by increasing the longevity of assets, and reduces resource requirements through the implementation of various closed-loop strategies (reuse, repair, remanufacturing, renovation or recycling).

- Loop

As it was observed, the use of strategies consisting of cycles (recycling, remanufacturing, refurbishing, ...) reduces waste generation among other aspects by creating new uses for materials while reducing the need to use more virgin materials.

- Virtualise

As in many other sectors, virtualisation can be used in the construction industry to replace physical resources, products, services, and locations with virtual ones, generating efficiency gains, reducing waste and extending the life of assets.

- Exchange

Selecting better sources of energy and other materials, as well as more advanced technologies to replace those previously employed, can have a positive impact in terms of increased efficiency and reduced waste generation and other negative externalities.

There are three stages of great importance when considering the adoption of circular economy strategies: material and component manufacture, design and planning, and end-of-life [4].

Table 2 shows the overview of the circular strategies developed and discussed in the literature for the three selected lifecycle phases.

Table 2.

Overview of the circular strategies developed and discussed in the literature for the three selected lifecycle phases.

3.1.1. Design Stage

In construction projects, design plays a role that has a major influence on life cycle economic and environmental impacts [19].

Because of this, decisions made in the design phase determine the degree of realisation of circular strategies at the end of a building’s lifespan. Furthermore, only through proactive adjustment of the building design can the reuse of secondary components [1] obtain the most work out of the energy that is supplied.

Having analysed all the strategies used in the market, the following distribution of the strategies to be followed during the design phase to achieve the circular economy in the building construction sector can be expanded upon:

Designing out Waste and Resource Efficiency

Designing out waste is an idea that is often subdivided into the following five principles:

- Design for reuse and recovery

Research has identified that the reuse of material components and/or entire buildings has considerable potential to reduce the key environmental burdens (e.g., embodied energy, CO2, waste, etc.) resulting from construction. In this sector, reuse often focuses on the reuse of existing materials on site or the use of materials with a high level of recycled material.

- Design for off-site construction

It is well established that off-site factory production in the construction sector offers a number of benefits including the potential to significantly reduce waste and significantly change site operations, reducing the number of trades and site activities. All of this results in faster assembly of parts, which brings all sorts of environmental, commercial and social benefits.

The use of prefabricated elements is the use of products that are manufactured, assembled and pre-assembled in external facilities. It should be noted that the use of these elements not only reduces labour-intensive construction trades but also minimises several waste streams. It is estimated that the prefabrication system can reduce between 65–80% of total construction and demolition waste (CDW) [2].

- Design for material optimisation

This principle focuses on the efficient use of materials, i.e., using less of them in their manufacture and/or producing less waste during construction.

In order to achieve such an objective, the following types of designs can be used:

- ○

- Designing long-life products

This type of design consists of extending the period of use of the products. To achieve this goal, this type of design focuses primarily on physical durability as well as reliability, i.e., that the product can withstand wear and tear without breaking down and that as long as the manufacturer’s instructions are followed there are hardly any billable failures [20].

- ○

- Design for product-life extension

This design consists of extending the period of use of goods through the use of service loops that extend the useful life of the product, which would include product reuse, maintenance, repair and technical improvement [20].

- Design for waste-efficient procurement

A considerable part of the waste generated in the sector could be avoided through more efficient coordination of materials procurement activities.

Designers should therefore be aware of work sequences that affect the generation of construction waste and collaborate with contractors, usually through the application of contractual targets.

- Design for deconstruction and flexibility

Designers should consider how materials can be effectively recovered during the life of the building when maintenance and renovation work is carried out or when the building reaches the end of its service life. Depending on the amount of potentially reusable and recyclable materials and the ease of recovery practices the value of this strategy (closely related to the use of prefabricated components) will vary. In summary, it can significantly reduce waste produced during multiple phases (construction and renovation phase and during demolition/deconstruction activities) [4].

Design for Energy Efficiency

In order to achieve desirable environmental conditions while minimising energy consumption, the most common approach in the field of energy efficiency is to use energy supply [21]. Among the most effective methods to reduce the energy cost of buildings, proper heating and cooling design could be highlighted [22]. While to design an energy-efficient building, design variables and construction parameters need to be optimised [23].

When designing a building with this objective in mind, these are the different aspects that are taken into account [24]:

- Influence of shape on the energy optimisation of buildings

One of the aspects considered when designing a building with energy optimisation in mind is its shape. This is due to the great influence it has on the total energy consumption of the building [25]. Depending on the amount of radiation that hits a building, its cooling energy needs can increase by up to 25% [26]. In other words, the shape of the building is responsible not only for the total area of the façade and roof that receives solar radiation but also for the area that is exposed to the outside and thus for energy losses. Therefore, the smaller the ratio between its external surface area and the total built volume, the lower the energy consumption [24].

- Orientation

Despite the importance of shape, orientation is undoubtedly the most important and studied parameter involved in the passive solar design of buildings [27] This is because the orientation angle of the building is closely related to the azimuth of the wall, which determines the level of direct solar radiation received [25]. In addition, façade orientation also plays a key role in other passive design parameters, such as shading [28] or solar envelope performance [27]. From an optimal orientation, buildings can benefit from the following points [24]:

- ○

- Lower energy demand.

- ○

- Reduces the use of more sophisticated passive systems.

- ○

- Increased performance of other complex passive techniques.

- ○

- More natural daylight.

- ○

- Reduced internal heating load of the building.

- ○

- Improves the performance of solar collectors.

- Influence of the building envelope on the energy demand

With regard to the total energy consumption of the building, the building envelope and the operating period of the heating system are the most influential factors [29]. The quality of the building envelope will determine the indoor climatic conditions and is therefore largely related to the additional energy demand for heating and cooling. This is why actions carried out on the elements that make up the building envelope can have a positive impact on certain energy needs and have a negative effect on others [30].

- Shading on buildings

The shading that is projected onto the building façade is another parameter that is often used to control the amount of solar radiation received. This strategy is particularly useful when used on the glazed openings of the building façades, as these are the elements that transmit the highest level of radiation to the interior of the building [24].

- Passive systems

These mechanisms are based on the natural convective movement caused by the different densities of cold and hot air [31]. However, the term passive does not exclude the use of a fan or pump to enhance system performance. Even though passive systems highlight the use of natural heating or cooling sources, some type of power is necessary to initially start operation. Since the passive heat transfer system is low cost and simple, the ratio of power consumption to the total consumption of the installation is relatively low [32]. That is why the right selection of a proper window-to-wall ratio and a window glazing material is so important.

- Glazing

Window glazing is considered to be one of the weakest thermal control points inside buildings, losing up to 60% of its energy. Therefore, parameters such as heat transfer, thermal comfort, light transmission, and appearance are so important in glazing design [33]. Another very important aspect to consider is the fact that glazing that reduces the entry of solar radiation is more efficient in summer and reduces the cooling demand. However, in winter, this type of glazing increases the need for heating because it makes it more difficult to use solar energy for passive heating [24].

3.1.2. Building Materials

It is widely accepted that within the construction and demolition sector the best approach to adopt, given its greater potential for environmental benefits and business opportunities, is one based on reuse, recycling, and other recovery practices. [34].

To contribute to closing resource loops during the production of construction material, it is critical that materials and components are designed for long life and recycling and/or secondary material input is used [2].

Through the recirculation of recovered resources, new construction materials can be generated, which implies a reduced use of virgin materials. As a result, a series of environmental benefits are generated, such as energy savings and a reduction in the use of natural resources and pollution [2].

Within construction projects, reuse, recycling, energy recovery, reduction, repair and renovation were identified as the most significant strategies in terms of CDW waste management and its future recirculation.

Reuse

This strategy basically consists of recovering materials (building elements and construction materials) to be reused in their original function [35]. In this way, materials and components can be used again without any intermediate steps or with only a little reprocessing beforehand.

Strategies that can be used when designing for adaptability, disassembly and reuse include:

- Develop a plan containing key information to facilitate retrofitting or dismantling.

- Use of simple structural systems and standardised modular components and assemblies.

- Use of materials that are not only durable but also worth recovering for reuse and/or recycling.

- Reduce the use of some types of materials and make connections more visible and accessible.

- Reduce sealant and adhesive consumption by using mechanical fasteners such as screws, bolts, and nails.

- Plan the movement of workers during the adaptation, repair and dismantling of the building to ensure their safety and the safety of the process.

Recycling

Another fundamental strategy in CE is recycling, as this not only has environmental benefits on the use of raw materials but also reduces the amount of CDW landfilled and the natural resources demand. It also reduces the energy consumption of manufacturing processes for the construction industry and other industries [35].

In a general framework, recycling treatments can be classified into three typologies:

- Closed-loop recycling, in which the recovered material can replace virgin material indefinitely without losing its properties.

- Semi-closed-loop recycling, where the recovered material can only replace the original virgin material to a certain extent, which is why raw materials must be added to meet quality requirements.

- Open-loop recycling, a recycling process in which part of the material is recovered and usually used for a new purpose.

Among the most important recycled materials given their impact and volume are steel, aluminium, and copper and although there is not much information on this, it is estimated, in global terms, that the recycled content of these three materials, respectively, could reach 59%, 33% and 37% [36].

Energy Recovery

Energy recovery is placed among the least preferable options in terms of circular economy and should be used as a last resort. When the other strategies are not possible, incineration of materials with high calorific potentials such as wood and plastics allows the production of energy that could be reintroduced into the system.

Although reduce, reuse and recycling strategies are preferable, energy recovery can be applied instead of landfilling.

Reduce

As in other sectors, reduction takes priority over recycling. The following reduction measures are used to reduce the production of, or demand for, building materials [37]:

- Designing for a purpose, not surplus. Design in which only the necessary materials are used, in the right place and without excess, thus reducing the demand for materials and energy.

- Building life extension. Measures to facilitate adaptability and maintain the value of buildings so that they are maintained for their entire lifetime and not just a fraction of it, thereby reducing costs, emissions and materials used.

- Material options. The construction sector uses mainly four materials (steel, reinforced concrete, timber and masonry), which could generally be reused, thereby reducing the need for new materials. In addition, new buildings could be designed for deconstruction.

On the other hand, the main actions to reduce waste and loss of construction material on the construction site itself are:

- Proper handling and storage of materials.

- Prepare the construction site for the receipt of materials before ordering them, thus avoiding disorder, waste, and loss of materials.

- Avoid over-ordering and ask suppliers and other subcontractors to reduce nonessential packing and packaging.

Repair

One of the most important strategies for extending the lifespan of materials and components is through good maintenance and repair design. “Design for Maintenance and Repair” allows products to be kept in good condition for a longer time than those that are not, which means less demand for materials [20]. Among the many repair techniques available, the following are the most common:

- Repairing of defects such as cracks and other defects.

- Checking and repairing elements such as electrical wiring, water pipes, gas pipes and plumbing services.

- Re-building non-structural walls, chimneys, boundary walls, etc.

- Re-plastering of walls as required.

However, if the defects extend to considerable damage, renovation is necessary.

3.1.3. Building Renovation

With the aim of reducing energy consumption in buildings, the Energy Performance of Buildings Directive (EPBD) introduced the concept of the nearly zero-energy building (NZEB). According to the EPBD recast, Member States shall ensure that new buildings occupied and owned by public authorities are NZEBs after 31 December 2018, and that all new buildings are NZEBs by 31 December 2020, [38]. In addition, Member States are increasingly recognising the high impact of the existing building stock and are starting to set targets and implement building renovation measures with the aim of reaching the minimum energy performance requirements, using some NZEB requirements, as the EPBD definition of NZEB does not differentiate between new and existing buildings [38]. Based on the findings of reviews and the EPBD requirements, a potential NZEB renovation is defined by having one or more of the following characteristics [39]:

- Compliance with nZEB requirements for new buildings as defined at EU Member State and regional level.

- After renovation there is a reduction of the primary energy consumption of the building by 75% compared to the previous state.

- No more than 50–60 kWh/m2/year Global Buildings Performance Network (GBPN) energy consumption for heating/cooling, domestic hot water, and ventilation energy consumption of the building’s auxiliary systems.

- At least 50% of the energy consumed must come from renewable sources.

- Emit no more than 3 kg CO2/m2/year.

Based on the renovation strategies pursued in the current market, these can be summarised in the following main types: upgrading/improving energy systems, insulation and windows and installing photovoltaic (PV) products.

Insulation

Due to recent increasing energy prices [40] and the need to reduce CO2 equivalent emissions, the use of thermal insulation materials is being enforced in buildings. Thermal insulation is a material or combination of materials that retard the rate of heat flow by conduction, convection, and radiation when properly applied [41].

There are currently a variety of thermal insulation materials for buildings on the market. Some have been around for a long time, while others have been recently and/or are still under development to increase the energy efficiency of buildings. According to their chemical composition, thermal insulation materials for buildings can be classified into four categories: inorganic, organic, combined and gaseous.

One problem that results from this strategy is waste generation. Although the amount of waste generated during installation can vary depending on the type of insulation, during demolition and renovation projects it is usually the most abundant waste. The most commonly used ones include glass and rock wool, polystyrene, sheep wool, spray foam, polyurethane and fibreboard.

Generally, the main reasons for insulation waste are over-ordering and disposal of unused materials, ordering the wrong type or thickness of insulation, oversized projects, poorly performed design and poor storage and handling.

Recent studies show that, although negligible in terms of mass, thermal insulation materials are highly relevant in terms of environmental impacts.

However, the transition to a more circular economy could solve or counteract the problem mentioned above, since in the CE, products, materials and resources are held and circulated in the economy for as long as possible. To this end, the implementation of this strategy can be carried out in combination with these other CE strategies:

- Repair: For those buildings with facades of high aesthetic value, the use of repair plasters with proven thermal insulation performance is presented as a good option to reduce energy consumption and meet thermal requirements. [42].

- Reuse and Recycling: for insulation to be reused or recycled, many factors must be taken into account, one of the most important is its type. Among the types of insulation, the following are worth mentioning because of their implications for reuse and recycling:

- ○

- Cellulose insulation is not only made from recycled materials (typically made up of about 80% recycled newsprint and 20% fire-retardant materials) but it also can be reused and repurposed on-site (assuming it has not been damaged). However, the proper extraction of this material for reuse is often complicated and expensive.

- ○

- Similarly, fiberglass insulation is often made with recycled glass. Additionally, fiberglass insulation is often installed in battens, which makes removal or deconstruction easier. Once removed, battens (if undamaged) can be reused or put back in place. However, it is common that the material has lost its insulating capacity due to the action of bacteria and mould.

In terms of insulation, it is more common to create new insulation from recycled materials than recycling the insulation itself. Generally, these materials focus on the recycling of aggregates or some type of fibres such as cotton or some plastics [43,44,45,46,47].

Using thermal insulation products helps in reducing the dependence on heating, ventilation, and air conditioning (HVAC) systems to manage buildings comfortably. Therefore, it conserves energy and decreases the use of natural resources [41].

The use of thermal insulation is one of the most feasible solutions for saving energy in existing buildings. The incorporation of such materials is both practical and cost-effective. Their effectiveness is based on their ability to reduce the heat transfer of the building. [48].

However, there are certain barriers that limit or prevent the implementation of end-of-life strategies, including the following [49]:

- Difficulties in insulations reuse or recycling: Despite the progress that has been made in recycling both in terms of quality and quantity of material recovered the reuse or recycling of insulation materials is still quite uncommon. Generally, only a small proportion of insulation material is recycled, while the majority is incinerated or landfilled.

- Lack of specialised recycling facilities: Due to the fact that the insulation is glued, the recovery of the material in a single material flow is quite complicated during deconstruction. In addition, the number of insulation materials that can be recycled is currently limited to Expanded Polystyrene (EPS), rock wool, glass wool and wood fibreboards. This is without considering the fact that oil-based insulation materials must be incinerated due to hexabromocyclododecane (HBCD) contamination.

- Low value of insulation material: Materials from renewable sources are usually more expensive than those from non-renewable sources. Legal requirements are mainly focused on insulation capacity, regardless of the type of material, therefore not fostering the interest in the use of materials with lower environmental impact.

To overcome these barriers and to be able to exploit in the best possible way the different options that the market offers, research highlight the following actions:

- Increase the material circularity: In this case, the best way to increase circularity is to take into account the design aspects of the circular system, such as reversible building construction, improved in situ separation [50], and a process for the separation of insulation material and flame retardant.

- Reduce environmental impacts: When it comes to reducing the environmental impact of insulation, the best options are to increase recycling and to replace materials such as oil-based materials with materials that have a lower impact (renewable materials) [51,52].

- At least a partial shift of the financial burden of recycling to the customer would reduce recycling costs to the deconstruction phase, thus making it more feasible.

- Pricing strategies: The introduction of an advanced recycling fee would relieve deconstruction companies of the financial burden of recycling and remove the existing barrier to collecting and recycling used insulation materials [49].

- Other strategies: Within the circularity strategies, there are preferable options over recycling. However, in the specific case of insulation, the reduction is not feasible as the energy savings from the use of insulation systems offset the energy consumed during production. In terms of reuse, a service-oriented model, i.e., rental of insulation materials, could be established. However, this idea is often rejected given the long lifetime of the material in buildings. To ensure greater circularity in the future, modular construction should be considered as this would simplify the assembly and disassembly of building materials and allow for their reuse [49].

Windows

Windows are one of the main contributors to heat losses in a building, which are usually generated by air infiltrations through the window pane and the frames, through conduction and convection of air between the panes of glass and/or due to thermal radiation [53]. Therefore, windows are also subject to renovation when it comes to reducing heat transfer.

Generally, windows in old buildings are characterised by a wooden frame and a single pane of glass. Nowadays, windows can be classified based on the material into the following types:

- Aluminium windows: Aluminium window frames, though having poor insulating properties, combine their lightweight strength with a lower cost than wood or fiberglass frames, do not need much maintenance and are recyclable and reusable in most cases.

- Wooden windows: Wood has the greatest potential for repair, providing a longer lifespan when properly preserved. However, a wooden window frame is more expensive than vinyl or aluminium, though less expensive than fiberglass. In addition, wood is extremely prone to warping, cracking, and rot from changes in temperature and humidity.

- PVC and Plastic windows: PVC Vinyl or PVC window frames require very little maintenance and are usually the cheapest option. They also have good thermal performance, and significant savings can be made by using recycled PVC waste compared to virgin PVC resin [54]. However, they are more difficult to repair/recycle, and their lifespan is shorter than other types of window frames.

- Steel windows: Steel windows are stronger than any alternative material. The design flexibility offered by steel windows and doors, together with exceptional durability and life cycle, make steel windows and doors an excellent choice in renovation projects.

- Glass-fiber-reinforced plastic windows (GFRP): Fiberglass window frames are extremely strong, require little maintenance, are highly energy-efficient, and are very well suited for environments with drastically changing temperatures. However, fiberglass frames are significantly more expensive than wooden frames and are nearly impossible to recycle.

Apart from the frames, windows are also classified according to the number of panes of glass. As a replacement for the old models with only one pane, double, triple and quadruple panes of glass are now being used.

The main problem identified for windows in the frame of the circular economy lies in the fact that, while glass bottles are highly recyclable, the same is not true for window glass. They have sufficiently different chemical compositions and melting temperatures and they cannot be recycled together. In addition, there are various aspects that make recycling more difficult, such as tinting or the diversity of window glass that cannot be recycled together. Despite all the obstacles to recycling, there are other EC strategies that can be applied, reuse would be the most interesting given the energy savings achieved (Reuse 48% vs. Recycling 26%) [55]. In addition, among the non-structural components, windows can be easily disassembled and reused [56].

During demolition works, windows can be collected and disassembled to recover the glass so that they can be assembled into new windows with a new frame and a second layer to meet energy efficiency standards [57]. Another option would be to melt them down to create fiberglass, incorporate them into asphalt or combine them with reflective road paints.

In addition, through design and with the aim of creating energy-efficient buildings, so-called smart windows were developed. Smart windows have reversible behaviour toward activators. The activators may be the environment or electricity [58]. ‘Smart’ windows typically possess one or more of the following functions: Control of optical transmittance, thermal transmittance, thermal absorption and control of view.

Among the most common smart windows, Photochromic windows, Electrochromic windows, Thermochromic windows, Thermotropic windows, Liquid crystal device windows and Suspended particle device windows are found [58].

Considering their main functions, such windows generate the following benefits [59]: Vary the amount of heat (Solar Heat Gain Coefficient; SHGC) and light (Visible Light Transmission; VLT) penetrating through the glass surfaces as required, while maintaining the view to the exterior, reduce heat losses, reduce energy consumption for lighting and air conditioning and provide greater comfort to users.

These novel windows also present difficulties for recycling, as management systems are needed to dismantle the windows or glazing of the buildings before their demolition, the collection of the windows themselves and the segregation of the glass from the rest of the components before their recycling in a glass furnace.

EU instruments and policy measures needed could comprise [60]:

- The revision of Waste Framework Directive/recycling targets and national waste management plans.

- The ban on disposal of recyclable flat glass products in landfills.

- The legislation should be complemented by EU Guidelines on the recycling of end-of-life flat glass products from buildings.

- The deployment of new technologies that enable dismantling of glazing and/or windows from the building, segregation of different window components and treatment should be promoted.

PV

The building sector is responsible for 36% of global energy consumption and 39% of global carbon dioxide emissions [61]. Therefore, it is one of the main sectors being addressed through the deployment of renewable energies to alleviate energy dependence and carbon emissions [62].

Photovoltaic energy is recognised as essential to meet the energy targets related to European directives. It is therefore not surprising that the market for photovoltaics has been growing in recent years [48]. Technologies such as building integrated photovoltaic (BIPV) stand out among others because of their aesthetics and modularity [62].

In addition, photovoltaic modules can be integrated into almost all building surfaces. These modules can be grouped into four broad categories [63]: PV-facades, PV-roofs, PV-sunshades and PV-windows and overhead glazing.

CE principles are embedded within the technology, since they can replace conventional building materials such as glass, ceramic or stone facades or roof tiles, providing weather protection, thermal insulation, shading and noise protection. In addition, solar equipment, like many other durable building products and materials, has a long service life of up to decades. In some cases, they can be given a second life through reuse or refurbishment, while some components can be recycled as e-waste and other metals.

In terms of the benefits related to the use of circular economy strategies in the PV market, the following ones stand out [64]:

- Reducing scarcity of rare materials and maximising resource use.

- Cost savings through reuse and recycling of materials.

- Improvement of the company’s environmental image, which will have an impact on consumer and stakeholder confidence.

- Reduced dependence on imported materials through reuse and recycling.

- Through recovery and recycling, the discharge of hazardous materials is reduced, which at the same time minimises risks to human health.

- Reduced greenhouse gas emissions.

In terms of barriers related to the circular economy, the following aspects can be observed [64]:

- The recovery process is more costly than the recovered materials themselves, as well as the production of new ones from virgin materials. Therefore, it results in low effectiveness of current business models or collection policies in attracting producers to collect or consumers to return PV panels and EU business support schemes.

- The regulation neither sets collection and recycling targets for PV panels and Battery Energy Storage Systems (BESS) nor does it address the financial and non-financial responsibilities of actors along the supply chain. Few, if any, incentives are offered to promote recollection and recycling activities.

- Difficulties in determining the best method for recycling given the reluctance of producers to share product information in the face of market competition.

- Low confidence in refurbished and recycled PV panels and BESS.

- During the recycling process, high energy demand is produced and chemicals, heat treatments and machinery are intensively used, leading to several emissions and pollution.

- Possible actions to address some of these barriers include the following [64]:

- Develop a PV and BESS market capable of recycling enough PV EoL and BESS panels to make them more affordable.

- Promote the collection of PV panels and supporting systems based on improved environmental awareness among consumers.

- Encourage producers to recycle PV panels and support systems as a sign of their social and environmental responsibility despite the lack of profitability.

- Achieve more cost-effective technologies for the recycling of waste PV panels and BESS, increasing the recovery rate of materials through increased investment in research and development.

Energy Systems in Buildings

A large part of the energy demand in buildings is spent on heating, cooling and ventilation [65]. That is why systems such as ventilation and hot water production have a major impact and focusing certain measures on these technologies can have a considerable effect on achieving the nZEB target, being therefore aligned intrinsically with circular economy principles. One of the main measures that was applied from the Circular Economy perspective is the integration of systems (Space heating, cooling, DHW, ventilation) [66].

To meet this objective, manufacturers of energy systems must improve their efficiency, through lower consumption of natural resources and lower emissions during product manufacture, as well as being more environmentally friendly during their use and at the end of their useful life. Some strategies can be considered in this sense, such as:

- Renewable electricity use: The amount and source of electricity used is a key defining characteristic of heating and ventilation concepts. Electricity has traditionally been largely responsible for abiotic depletion, global warming and terrestrial ecotoxicity. Therefore, the use of electricity from renewable sources and locally generated PV panels is beneficial in meeting the targets. In addition, the use of more efficient technologies results in lower consumption and thus lower emissions.

- Extended service life: By extending the lifetime of one of these systems, the production and disposal of materials during the use phase of a dwelling should be reduced, thereby reducing the overall environmental impact. Of all the systems, those with the highest material content will benefit most from this extension. To achieve this extended service life, both maintenance and repair activities are enhanced.

- Replacement: There are many buildings in need of renovation today. For many of these buildings, even if their energy systems life expectancy has not been exceeded, it may be appropriate that they are replaced with a more efficient one.

- Service-oriented model: In some cases, the service model is used, according to which end consumers only pay for the service they receive, while the companies, in the case of energy services, install and maintain the equipment and recover the investment through periodic payments. Thanks to this model, SMEs have greater access to sustainable technologies, while reducing their technological risk and being incentivised to lower their energy consumption. It also offers energy services providers the opportunity to optimise equipment operation to reduce operating costs, thus offering the customer the most efficient technologies on the market. In addition, this model is supported by the concept of circular economy, which encourages energy service providers to use their equipment in a modular way with reusable and recyclable parts.

- Decentralised systems: Based on small-scale electricity or heat generation close to where it is used, reducing transmission losses and increasing security of supply. In addition, this type of system can offer more competitive prices than traditional energy in the long term, while reducing carbon emissions, as most of them use renewable sources.

- End-of-life: For a long time, landfills and incineration were the only available options in the end-of-life stage of energy systems. However, with the development of materials recycling, the impact of energy systems, as well as the need for virgin materials, is further reduced.

There are certain factors to be considered that hinder the commercialisation of efficient energy systems. For example:

- General definition for nearly zero-energy buildings: The future commercialisation of efficient or novel technologies will largely depend on both the definition of the architecture and the assessment of the efficiency of zero-energy buildings [67]. Without a standardised definition, different meanings can arise, leading to different specifications and standards for energy savings [68].

- Novelty of technology: The limited technical capabilities of local companies in the sector in areas such as engineering, research and production of new products and facilities are insufficient for the commercialisation of novel technologies [68].

- Public awareness: nZEB and related technologies are either not well known or are considered very expensive by owners or users [69].

- Formulation of policies and incentives: Despite the progress of nZEB being limited, the policy for funding zero-energy demonstration projects is inadequate hence making the social impact of nZEB highly insignificant [68].

3.1.4. End-of-Life Stage

The end-of-life stage is a phase characterised by the high amount of waste generated, in which the recovery of materials and their preparation for reintegration into the value chain should be considered. This requires the disassembly and sorting of components and materials for their reuse with the highest possible value [2].

This phase presents two general practices, conventional demolition and selective demolition or deconstruction. The demolition technique, as well as the type of building, will determine the possibility of recovering the materials [4,70].

The most widely used method is conventional demolition, which reduces the chances of recovering valuable materials, making it difficult to differentiate different types of recoverable materials [71]. Selective deconstruction consists of reversing the building assembly process. From this disassembly, the recovery of building components and materials is maximised and facilitated, which increases the chances of closing material loops [4]. Two phases prevail in this strategy: the disassembly of recoverable materials and the demolition of structural elements, which is preceded by the separation of hazardous materials [71].

Another practice to be carried out at this stage is pre-construction/demolition audits, which, in addition to minimising waste generation at this stage, allows for planning and implementing more efficient waste management strategies and maximising the volume, quality and potential cost savings of recovered materials [72].

3.2. Renovation Market Analysis

Having observed the main CE strategies employed in the building construction sector, a PEST analysis and a SWOT analysis of the building renovation market were carried out to determine the current situation and explore ways of facilitating the development of new strategies to help address the main barriers affecting this sector.

The renovation market was selected for further analysis because, in addition to being closely related to the other strategies, the interest of the institutions in this market, its potential to contribute to achieving the objectives set by the European Commission and the existence of barriers to achieving the necessary renewal ratios were clearly demonstrated.

3.2.1. PEST Analysis of Building Renovation

PEST is an acronym for Political, Economic, Social and Technological. It is an analytical tool for determining the influence of these factors on the growth or decline of the market under study, which makes it easier to plan a more effective strategy for its development [73].

Political Factors

As a means of aligning the construction sector with the circular economy in Europe, the following initiatives are in place:

- Directive 2008/98/EC on waste [74], establishes a series of measures to protect the environment and human health while preventing or reducing the adverse impacts of waste generation and management and the overall impacts of resource use and improving resource use efficiency.

- Level(s), the EU’s common framework of core sustainability indicators for residential and office buildings [75], is a common EU framework of indicators and metrics to measure the performance of offices and residential buildings throughout their life cycle.

- Circular economy action plan [76], created with the aim of harnessing the potential to increase material efficiency and reduce climate impact, the Commission will establish a new comprehensive strategy for a sustainable built environment that will ensure coherence across all relevant policy areas.

- Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laid down harmonised conditions for the marketing of construction products and repealed Council Directive 89/106/EEC [77]. This Regulation establishes a set of harmonised rules on the ways to provide information about the performance of construction products in relation to their essential characteristics and on the use of the CE marking on such products [77].

- EU action plan for the Circular Economy [78]. The recycling of construction and demolition waste is encouraged by an EU-wide mandatory target but challenges on the ground still have to be addressed if waste management in this sector is to improve.

- Energy Performance of Buildings directive 2010/31/EU and the Energy Efficiency Directive 2012/27/EU [79]. Both directives were amended, as part of the clean energy for all Europeans package, in 2018 and 2019. Together, the directives promote policies that will help achieve a highly energy-efficient and decarbonised building stock by 2050, creating a stable environment for investment decisions, and enabling consumers and businesses to make more informed choices to save energy and money.

- A Renovation Wave for Europe—Greening our buildings, creating jobs, improving lives [80]. This strategy covers a wide range of areas, such as life cycle, accessibility and decarbonisation, but always prioritising energy efficiency, since buildings are one of the largest energy consumers in Europe, responsible for over a third of EU emissions. The responses of stakeholders (business associations, different types of organisations and citizens) to the consultations carried out, enabled the identification of the following barriers in the political sphere [81]:

- ○

- Lack of attractive and accessible public incentive measures for renovation (e.g., grants or tax incentives).

- ○

- Regulatory and administrative barriers and complexity in planning, including permits required, etc.

- ○

- Perceived lack of government support, unambitious policies.

- ○

- Restrictive rules on procurement, annual budgeting and accounting.

Economic Factors

The importance of the energy renovation market in the economy is not in doubt, considering that in 2015 it reached a value of EUR 109 billion and generated 882,900 jobs in Europe [82].

In addition, this market has an increasing potential in view of the ageing of the EU building stock and the related policy objectives. If Member States were to follow the EU guidelines in their policies, this would provide more opportunities for players in the sector to position themselves in the market if they offer a differentiated value proposition to their customers [83].

EU directives have emphasised the need to increase both the level and the rate of building renovation, and to promote the use of sustainable energy sources in heating and cooling through appropriate incentives [84]. However, at present, the stakeholders encounter the following barriers [81]:

- Limited resources to finance building renovation.

- Energy renovation does not pay off in an acceptable timeframe.

- Problematic procedures and/or financial constraints for accessing public financial support.

- Lack of mainstream financing products that also offer coverage for the building renovation costs in a single package.

Social Factors

According to Eurobarometer, among Europeans’ main concerns, the environment and climate change have moved from fourth place to equal second place. This, among other things, can be translated into increased potential for renovation of buildings with the aim of making them more sustainable [85].

Generally, homeowners do not carry out more than one or two major renovations in the lifetime of their homes, but this decision is often influenced by different aspects. The most relevant are knowledge networks that may be misinformed, and advice from renovation companies, which may have their own interests and constraints to promote certain actions and avoid others [86].

Another barrier to consider is historical buildings, as the interest in preserving historical and cultural values limits the scope of a thorough renovation, making it difficult, if not impossible, to improve the insulation of the building envelope.

Among the main barriers in the social dimension indicated by stakeholders are the following [81]:

- Insufficient understanding of energy use and savings related to different energy efficiency measures.

- Disagreement between various owners (e.g., multi-apartment buildings);

- Lack of information/ awareness about available public and/or private financing products for building renovation.

- Lack of trust or guarantee that renovation will deliver the energy and money savings or other benefits, lack of quality assurance.

- Different interests between the house owner and house occupant.

- Lack of interest. Renovation to decrease energy consumption is usually not attractive enough for tenants, need for additional advantages.

The European Commission is aware of this lack of information on the current energy and resource use of buildings and the potential benefits of renovation, as well as the lack of confidence in actual energy savings and the distribution of incentives between owners and tenants.

In view of the European Commission’s awareness, some Member States have introduced different performance targets to be achieved by different deadlines, as such requirements provide an anchor for investors’ and companies’ expectations. This type of regulation is expected to simplify decision-making in multi-owner buildings and, by reflecting energy performance in the value of a building, partly remedy the general lack of awareness of the benefits of renovation [80].

The Commission also intends to establish a set of mandatory minimum energy performance standards in the framework of the revision of the Energy Performance of Buildings Directive (EPBD) to facilitate the linking of specific national, regional and local incentives and to support compliance with these minimum standards [80].

Technical Factors

The market for housing renovation (especially for single-family houses) is mainly made up of small and medium-sized enterprises (SMEs), which promote their own products and services. This diversity of expertise and competing interests hampers complete renovations. In addition, technology is much more advanced than current codes and standards, resulting in barriers to innovation in energy efficiency [86].

But from the stakeholders’ point of view, the main technical barrier is the lack of staff in public/private entities with the skills to deal with the renovation process. For this reason, extensive training and educational programmes are considered necessary for workers in the sector, but also for civil servants and employees of financial institutions. The training and educational programmes are particularly needed for civil servants and employees of financial institutions. Programmes are particularly needed in green skills, new technologies and services, methods and materials, and environmental, circular and digitisation of renovation [81].

This is why the European Commission intends to take the following actions:

- Scaling up technical assistance.

- Bringing such assistance closer to regional and local actors.

- Fund training initiatives, in close cooperation with the social partners.

3.2.2. SWOT Analysis

SWOT is a well-known market analysis technique used to analyse internal market strengths and weaknesses and identify external opportunities and threats. In this case, the SWOT analysis was conducted on the basis of the results of the PEST analysis and stakeholder consultations carried out in other studies, while identifying the key internal characteristics and external influences of the building renovation market.

In this field, the main strengths are considered to be a better quality of life, greater thermal comfort and significant energy savings [86].

In contrast, this market is weakened by unambitious or unproductive regulation, as well as high renovation costs that hamper the market uptake. It should be noted that there is also a lack of social and technical knowledge and confidence in this sector [86].

There are currently multiple aspects and opportunities that could be exploited by the market for its expansion. For these renovations to take place, there must be an interest in climate change mitigation and sustainability. Moreover, rising energy prices and financial packages to fund the intensive necessary investment can act as a lever for market uptake.

In the same way that owners tend to be less interested in these types of renovation projects because of the higher initial cost, construction companies tend to be more interested in the construction of new buildings rather than renovation, given the higher revenues [86]. In addition to this, there is the possibility of misuse of the installed solutions, which could lead to a partial or total loss of energy savings.

The outcomes of this analysis can be found in Table 3:

Table 3.

SWOT elements for building renovation market.

One of the most effective ways to eliminate or transform the weaknesses listed above into strengths and make the renovation market more profitable can be through policy actions. These actions should be aimed at simplifying the current legal requirements and generating mechanisms that promote this activity, such as loans.

In addition, whether it is in the interest of fighting against climate change or taking measures against rising energy prices or improving comfort, the social interest in this kind of action is an indisputable lever. Alternatively, grants or other attractive financing tools for homeowners are an instrument to motivate sceptical neighbours in communities and to decrease the long payback times. In any case, and as stated in the paper, the market renovation potential is huge and growing, as buildings age or need to adapt to the requirements of new regulations.

Despite the difficulties or weaknesses, the increasing social interest in renovation and the potential policy and economic actions applicable may motivate the market to switch its current interest in new building construction to renovation as well. With more companies entering the building renovation market, more competition, and therefore, more interest in offering a high-quality service will result, creating a virtuous circle leveraging renovation actions.

3.3. Circularity Assessment in Building Renovation

As reviewed, the application of the different CE strategies in the building construction and renovation sector would bring great benefits given the reduction of pressure on non-renewable resources and waste generated in the sector.

Other benefits to consider would be reduced energy demand and dependence on scarce materials, resulting in greater resilience to environmental and economic crises [9]. In recent years a passionate debate has raged around the distinction between the widely known definition of a “sustainable building”, i.e., a building designed and constructed to minimise negative environmental, social, and economic impacts, and the new concept of a “circular building” [16].

Nevertheless, no comprehensive procedure for the assessment of the Circularity in the building sector exists yet. Some initiatives and certifications are arising, as can be seen in Table 4, but these address the sustainable building rather than the Circular building, although the indicators should be fully compatible.

Table 4.

Initiatives and certification in the field of Circularity and the Building sector.

Considering the principles of CE summarised in Section 3, an analysis of the circularity of a building renovation would have to take into consideration all life cycle stages. According to current reference standards for the Sustainability assessment of buildings EN 15978, the life cycle of a building can be phased into four main stages divided into several modules: Product stage; Construction stage; Use stage; and End-of-Life stage [87].

In terms of requirements to be measured, based on “Level(s)—A common EU framework of core sustainability”, which constitutes a common EU framework for building sustainability assessment under a life cycle thinking and circularity perspective intended to be used throughout the EU, the focus of sustainability analysis in buildings should be [88]:

- Greenhouse gas emissions over the life cycle of a building.

- Resource-efficient and circular material life cycles.

- Efficient use of water resources.

- Healthy and comfortable spaces.

- Adaptation and resilience to climate change.

- Optimised life cycle cost and value.

After the comparison of these requirements with the parameters and criteria of other standards and certifications [75,89,90], the following indicators were proposed by some authors as presented by González et al. (2021) that developed a methodology to be used for the analysis of the circularity of building construction and renovation [16]:

- Energy circularity (kWh of primary energy).

- Material circularity (kg of materials).

- Water circularity (m3).

- Social circularity (number of social impacts addressed within the new building or major renovation project to the total number of potential impacts potentially addressable).

- Life cycle economic value (Level(s) proposal based on ISO 15686-5 or EN 16627).

4. Discussion

It is undebatable that the building sector has a huge impact on sustainability, being responsible for creating environmental impacts throughout its life cycle, particularly in the use and end-of-life stages [4]. Materials used and design strongly determine these impacts [4,13,49,91]. The objective of the paper is the revision of the recent progress on the transition towards CE in the building sector and specifically in the building renovation sector. To that end, the exploration of the current applicable CE strategies, the identification of their advantages and limitations, and the evaluation of their feasibility are included in the work. This work offers a revision, from a generalist or initial perspective, that can be useful for the adoption or development of CE actions or strategies.

Among the diversity of actions applicable to the building and building renovation sector, it is observed that the design stage is the determinant for the transition towards a circular economy, including measures such as reversible building construction, design for improved in situ separation and service models applied to building systems [50]. On the other hand, there is a major barrier in the end-of-life stage, due to the long life that might hinder the reintroduction of materials in the loop because of ageing or obsolescence, together with the scarcity of end-of-life management systems for the recirculation of materials according to the CE principles, because of technical and economic reasons [49,57,64]. The ban on the disposal of certain recyclable building materials could lever the development of strategies for the second life of materials more aligned with CE principles.

As a result of the work carried out, several necessary steps to be taken were identified, to overcome the obstacles and deploy CE strategies in the building renovation sector.

On the one hand, current technological developments in the construction sector might be transferred to new human resources and improve competencies in the design and management of deep renovation.

Alternatively, renovation packages that fit into the owner’s annual renovation budget to encourage the owner towards the implementation of a renovation project might be used to lever the renovation market, since having a positive attitude towards climate change mitigation and sustainability may not be enough. In addition, appropriate annual financial incentives could make progressive renovation more attractive [64,68,81,86]. Existing municipal subsidies for advisory services, energy audit reports and energy certificates could be used to promote the deep renovation of buildings. More homeowners could be encouraged to go for deep renovation if the current property tax system were to become more progressive in terms of energy efficiency, with tax credits for energy-efficient buildings, while penalising poorly performing buildings.

From the awareness perspective, informing and facilitating access to guidance/advice from the municipality will help increase homeowners’ recognition of the benefits of deep renovation, sequencing, and prioritisation of actions in the deep renovation process [64,80,81,86].

Despite the increasing importance of the Circular Economy principles worldwide, it was noted from the search results that scientific research on the CE is still an emerging topic in the building and renovation sector. This is revealed by the fact that most of the studies were undertaken from 2017 to the present, which might be seen as a limitation of this work. Furthermore, no comprehensive procedure for the assessment of the Circularity in the building sector exists yet. Future work can focus on procedures for the assessment of the Circularity in the building sector and on evaluating the results of the strategies implemented.

5. Conclusions

This paper has highlighted the need for action for the transition to a more aligned CE building and building renovation sector. The most representative CE strategies that can serve to foster CE actions in these sectors were presented along the main stages of a building, from the design stage and building materials selection to the building renovation and end-of-life stages. This document also contains the perspectives, needs and opinions of stakeholders and can help in the development of guidelines to support the incorporation of CE in building renovation.

As elaborated throughout this work, the current situation has many advantages in favour of encouraging the renovation of buildings, such as society’s interest, its contribution to achieving energy and environment objectives, availability of technologies, models and strategies, etc. However, there are still certain aspects that act as barriers to the uptake of this market, presented in this document.

Future work should focus on specific actions that can be implemented to overcome the existing barriers towards the large-scale implementation of CE strategies in the building and building renovation sectors, in the procedures to evaluate the circularity in this specific sector and how the existing strategies contribute.

Author Contributions

Investigation, D.Z.-V., A.S.-d.-G. and V.F.; Methodology, V.F.; Supervision, D.Z.-V., A.S.-d.-G. and C.B.; Writing—Original draft, V.F.; Writing—Review and editing, D.Z.-V., A.S.-d.-G., V.F. and C.B. All authors have read and agreed to the published version of the manuscript.

Funding

This contribution was developed in the framework of the RINNO project “An augmented intelligence-enabled stimulating framework for deep energy renovation delivering occupant-centered innovations”, funded by the European Union under the H2020 Innovation Framework Programme, project number 892071.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- EU Construction Sector: In Transition towards a Circular Economy European Construction Sector Observatory Trend Paper Series. 2019. Available online: http://appsso.eurostat.ec.europa.eu/nui/show.do?lang=en&dataset=env_wasgen (accessed on 30 November 2021).

- Nußholz, J.L.K.; Milios, L. Applying Circular Economy Principles to Building Materials: Front-Running Companies’ Business Model Innovation in the Value Chain for Buildings. 2017. Available online: https://www.researchgate.net/publication/320831772 (accessed on 23 November 2021).

- Eurostat Waste Statistics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 15 November 2021).

- Ruiz, L.A.L.; Ramón, X.R.; Domingo, S.G. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- European Commission. Renovation Wave Communication. 2020. Available online: https://ec.europa.eu/energy/sites/ener/files/eu_renovation_wave_strategy.pdf (accessed on 25 November 2021).

- United Nations Environment Programme. Emissions Gap Report 2019; UNEP: Nairobi, Kenya, 2019. [Google Scholar]

- Navarro, J.; Filippidou, F. Achieving the Cost-Effective Energy Transformation of Europe’s Buildings; Energy Renovations via Combinations of Insulation and Heating & Cooling Technologies Methods and Data; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- De Arriba Segurado, P.; Rousselot, M.; Morgan-Price, S. Policy Brief Energy Renovation of Buildings in Spain and the EU. Lessons Learned and Main Recommendations. Background: Retrofitting as a Key Element of the Energy Planning. 2021. Available online: https://www.odyssee-mure.eu/publications/policy-brief/spanish-building-retrofitting-energy-efficiency-odyssee-mure.pdf (accessed on 26 November 2021).

- Carrascosa, D.H.; van Hove, E.P.; Bolea, J.; Toran, J.I.T.; Muñoz, L.R. Grupo de trabajo GT-6 Congreso Nacional del Medio Ambiente 2018 Fundación Conama. Available online: http://www.conama.org/conama/download/files/conama2018/GTs%202018/6_final.pdf (accessed on 16 November 2021).

- European Commision. European Green Deal: Commission Proposes Transformation of EU Economy and Society to Meet Climate Ambitions. 2021. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_21_3541 (accessed on 14 March 2022).