Logistics and Costs of Agricultural Residues for Cellulosic Ethanol Production

Abstract

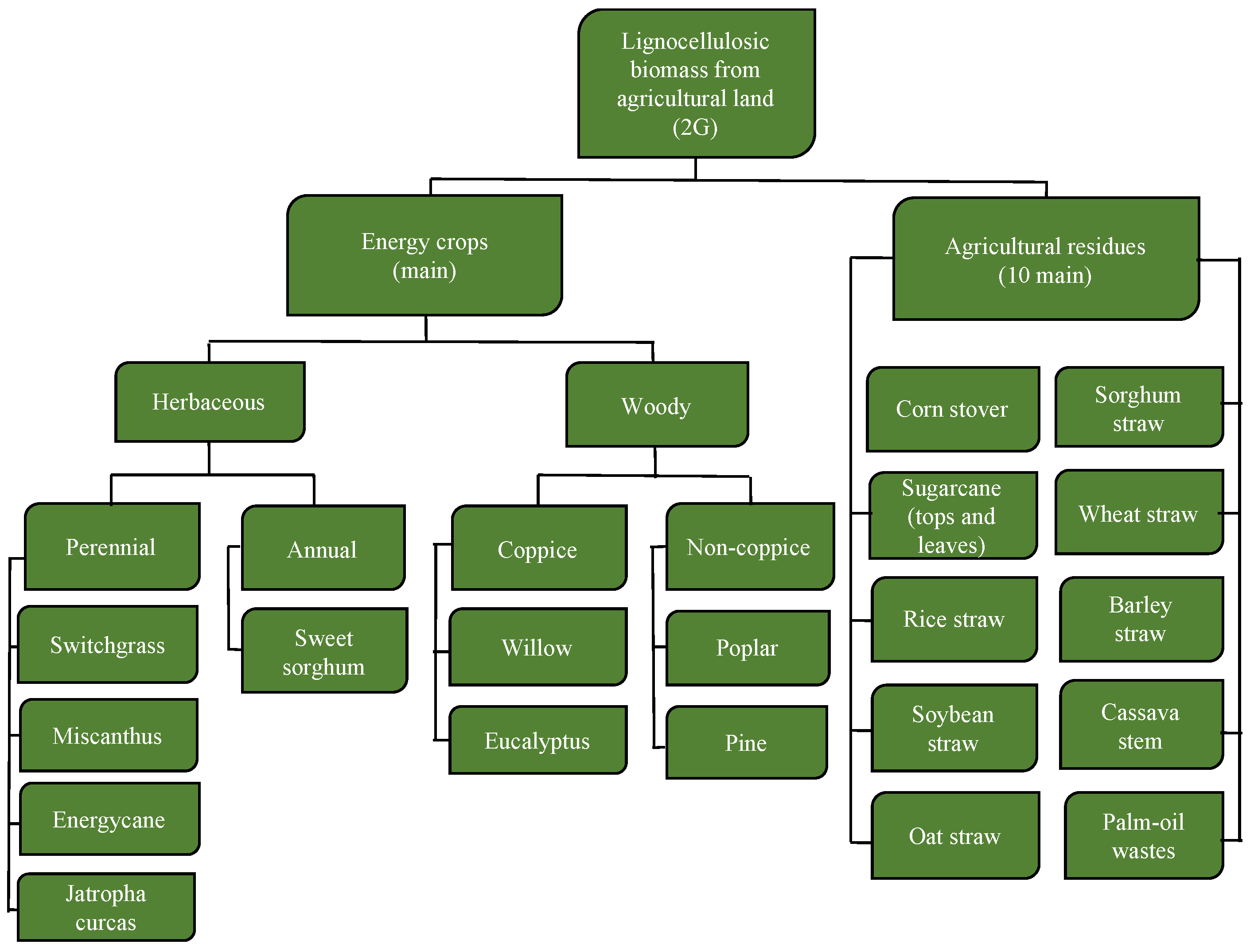

1. Introduction

2. Materials and Methods

2.1. Study Area and Data

- (a)

- Exclude rainfed agricultural land, given its high dependence on climatic conditions, which generates uncertainty regarding the production of residues. In addition, a large portion of this type of agriculture is for self-consumption, and farmers also carry out livestock activities, which makes it very unlikely that they will decide to sell their agricultural residues.

- (b)

- Include only regions with sown areas larger than 100,000 ha. The objective is to have a sufficient volume of agricultural residues for at least one cellulosic ethanol plant.

- (c)

- The set of selected regions must represent at least 80% of the total area of the country, so that most of the agricultural area in the country is included in the analysis.

2.2. Agricultural Residue Logistics

2.3. Fieldwork

3. Results and Discussion

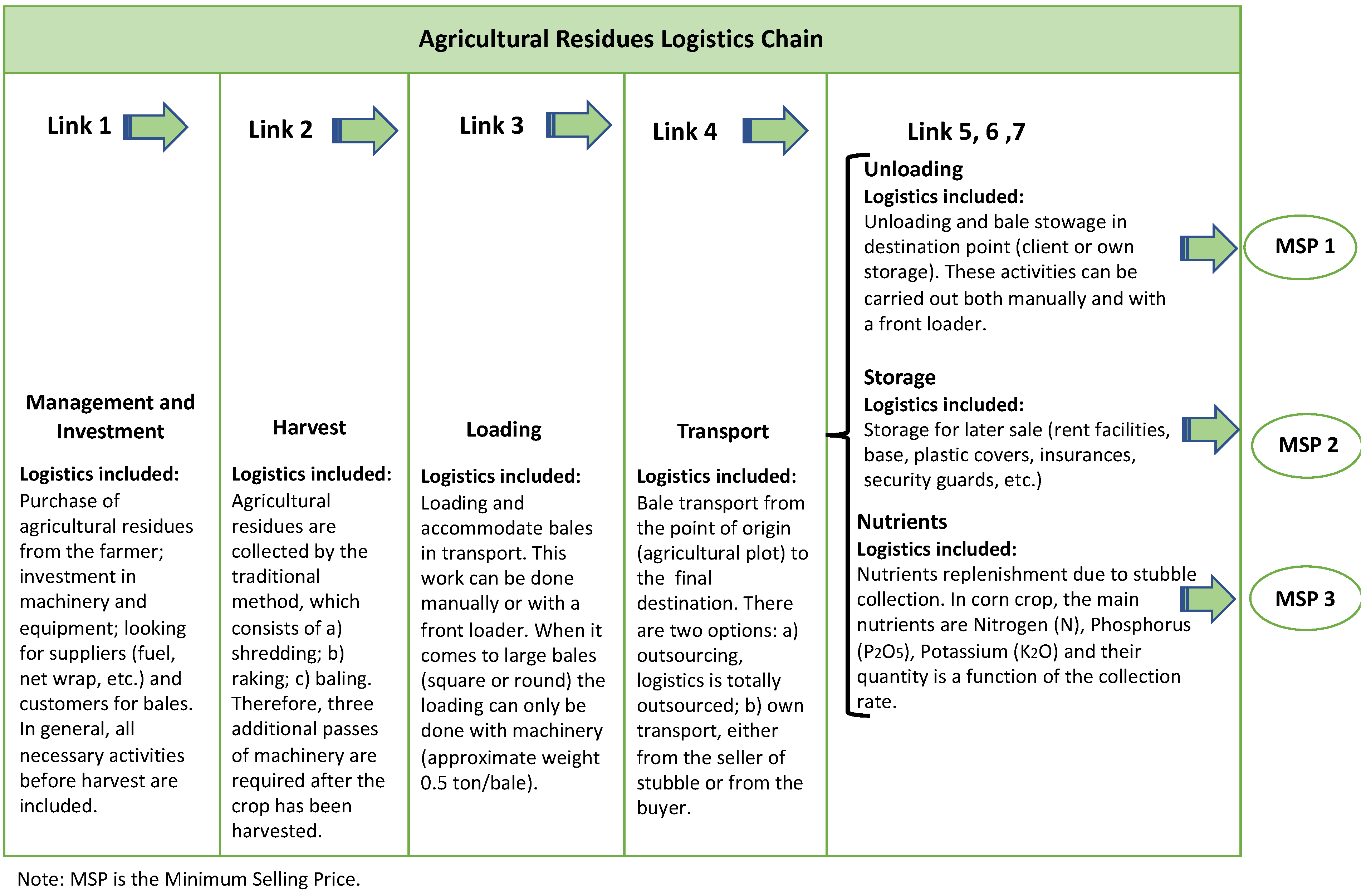

3.1. Agricultural Residue Logistics Chain

3.2. Harvest Index and Crop Residue Index

3.3. Replacement of Nutrients

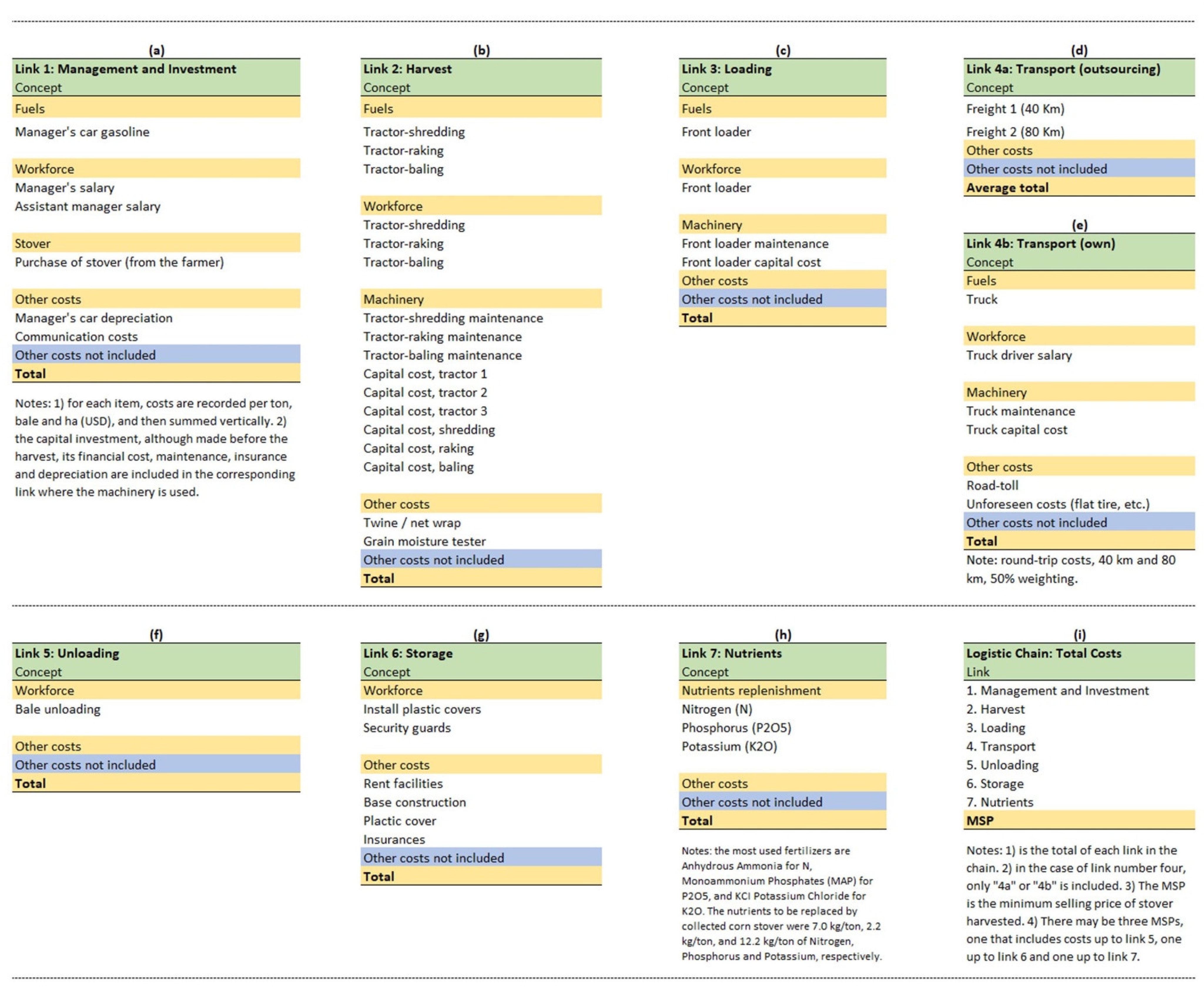

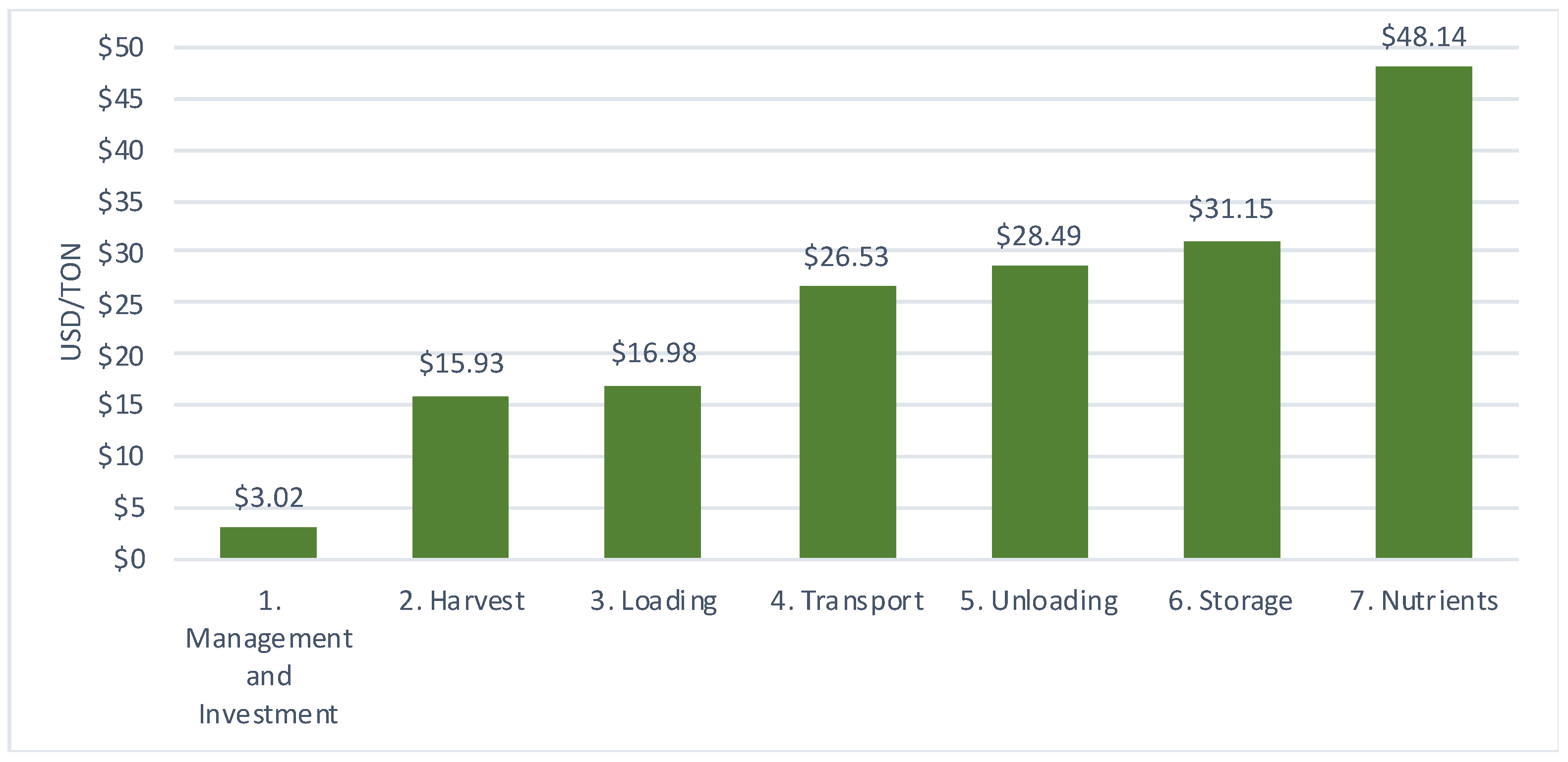

3.4. Cost Structure of the Agricultural Residue Logistics Chain

3.5. Case Study: Corn Stover Harvest Costs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Survey to Determine the Use of Corn Stover by the Farmer

References

- Jarabo Friedrich, F.; Pérez Domínguez, C.; Elortegui Escartin, N.; Fernández González, J.; Macías Hernández, J.J. El Libro de las Energías Renovables; S.A. de Publicaciones Técnicas: Madrid, Spain, 1998; ISBN 84-86913-01-2. [Google Scholar]

- Fernandes, L.H.S.; De Araújo, F.H.A.; Silva, I.E.M.; Neto, J.S.P. Macroeconophysics indicator of efficiency. Phys. A 2021, 573, 125946. [Google Scholar] [CrossRef]

- Timmons, D.; Harris, J.M.; Roach, B. La economía de las energías renovables. In A GDAE Teaching Module on Social and Environmental Issues in Economics; Global Development and Environment Institute, Tufts University: Medford, MA, USA, 2014. [Google Scholar]

- IPCC (Intergovernmental Panel on Climate Change). Climate Change 2021, the Physical Sciences Basis. Sixth Assessment Report of the IPCC. Working Group I (WGI) Contribution to the Sixth Assessment Report of the IPCC, 2021. WMO, UNEP. Available online: https://www.ipcc.ch/report/ar6/wg1/#FullReport (accessed on 24 March 2022).

- Paris Agreement. United Nations Climate Change (Pdf Version). 2015. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 24 March 2022).

- Mediavilla Pascual, M. ¿Qué Está Pasando con el Petróleo? 2019. Available online: https://theconversation.com/que-esta-pasando-con-el-petroleo-125260 (accessed on 24 March 2022).

- Shell International. World Energy Model, A View to 2100. 2017. Available online: www.shell.com/scenarios (accessed on 11 February 2022).

- Radionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Lan, J.C.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.; Allakhverdiev, S.I. A comprehensive review on lignocellulosic biomass biorefinery for sustainable biofuel production. Int. J. Hydrogen Energy 2022, 47, 1481–1498. [Google Scholar] [CrossRef]

- US/DOE. Billion-Ton Report: Advancing Domestic Resources for a Thriving Bioeconomy, Economic Availability of Feedstocks; ORNL/TM-2016/160; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016. Available online: http://energy.gov/eere/bioenergy/2016-billion-ton-report (accessed on 25 April 2022).

- Becerra-Pérez, L.A.; Tyner, W.E.; García-Paez, B. Cellulosic Ethanol in Mexico: An Appraisal as Industrial Feedstock. In Advances in Renewable Energy Engineering; Digambar, N.P., Ed.; Akinik Publications: New Delhi, India, 2019; Volume 1, ISNB 978-93-5335-557-9; ISBN 978-5335-558-6. [Google Scholar]

- Becerra-Pérez, L.A.; Gastélum-Delgado, M.A.; Posada-Duque, J.A. Deseño, costos y suministro de la cadena de rastrojo de maíz para etanol celulósico en México. In Proceedings of the Congreso Internacional de Energía 2021, Mexico City, Mexico, 20–24 September 2021. [Google Scholar]

- Bentsen, N.S.; Felby, C.; Thorsen, B.J. Agricultural residue production and potential for energy and materials services. Prog. Energy Combust. Sci. 2014, 40, 59–73. [Google Scholar] [CrossRef]

- Cherubin, M.R.; Oliveira, D.M.D.S.; Feigl, B.J.; Pimentel, L.G.; Lisboa, I.P.; Gmach, M.R.; Varanda, L.L.; Morais, M.C.; Satiro, L.S.; Popin, G.V.; et al. Crop residue harvest for bioenergy production and its implications on soil functioning and plant growth: A review. Sci. Agric. 2018, 75, 255–272. [Google Scholar] [CrossRef]

- Gauder, M.; Graeff-Hönninger, S.; Claupein, W. Identifying the regional straw potential for energetic use on the basis of statistical information. Biomass Bioenergy 2011, 35, 1646–1654. [Google Scholar] [CrossRef]

- Weiser, C.; Zeller, V.; Reinicke, F.; Wagner, B.; Majer, S.; Vetter, A.; Thraen, D. Integrated assessment of sustainable cereal straw potential and different straw-based energy applications in Germany. Appl. Energy 2014, 114, 749–762. [Google Scholar] [CrossRef]

- Gradziuk, P.; Gradziuk, B.; Trocewicz, A.; Jendrzejewski, B. Potential of Straw for Energy Purposes in Poland—Forecasts Based on Trend and Causal Models. Energies 2020, 13, 5054. [Google Scholar] [CrossRef]

- Ekman, A.; Wallberg, O.; Joelsson, E.; Börjesson, P. Possibilities for sustainable biorefineries based on agricultural residues—A case study of potential straw-based ethanol production in Sweden. Appl. Energy 2013, 102, 299–308. [Google Scholar] [CrossRef]

- Lantz, M.; Prade, T.; Ahlgren, S.; Björnsson, L. Biogas and Ethanol from Wheat Grain or Straw: Is There a Trade-Off between Climate Impact, Avoidance of iLUC and Production Cost? Energies 2018, 11, 2633. [Google Scholar] [CrossRef]

- Zhang, C.; Xie, G.; Li, S.; Ge, L.; He, T. The productive potentials of sweet sorghum ethanol in China. Appl. Energy 2010, 87, 2360–2368. [Google Scholar] [CrossRef]

- Valdez-Vazquez, I.; Acevedo-Benítez, J.A.; Hernández-Santiago, C. Distribution and potential of bioenergy resources from agricultural activities in Mexico. Renew. Sustain. Energy Rev. 2010, 14, 2147–2153. [Google Scholar] [CrossRef]

- Rios, M.; Kaltschmitt, M. Bioenergy potential in Mexico—Status and perspectives on a high spatial distribution. Biomass Convers. Biorefin. 2013, 3, 239–254. [Google Scholar] [CrossRef]

- Reyes-Muro, L.; Camacho-Villa, T.C.; Guevara-Hernández, F. Rastrojos: Manejo, Uso y Mercado en el Centro y Sur de México; INIFAP: Aguascalientes, Mexico, 2013; ISBN 978-607-37-0170-9. [Google Scholar]

- Borja-Bravo, M.; Reyes-Muro, L.; Espinosa-García, J.A.; Vélez-Izquierdo, A. Crop residues production and consumption in Mexico. In Rastrojos: Manejo, Uso y Mercado en el Centro y Sur de México; Reyes-Muro, L., Camacho-Villa, T.C., Guevara-Hernández, F., Eds.; INIFAP: Aguascalientes, Mexico, 2013; ISBN 978-607-37-0170-9. [Google Scholar]

- Aleman-Nava, G.S.; Meneses-Jácome, A.; Cárdenas-Chávez, D.L.; Díaz-Chávez, R.; Scarlat, N.; Dallemand, J.F.; Ornelas-Soto, N.; García-Arrazola, R.; Parra-Saldivar, R. Bioenergy in Mexico: Status and Perspective. Biofuels Biorefin. 2015, 9, 8–20. [Google Scholar] [CrossRef]

- Tauro, R.; Ghilardi, A.; García, C.A.; Masera, O. Recursos Biomásicos. In Estado del Arte de la Bioenergía en México; García, C.A., Masera, O., Eds.; Red Temática de Bioenergía (RTB) del Conacyt: Mexico City, Mexico, 2016; ISBN 978-607-8389-11-7. [Google Scholar]

- Sadhukhan, J.; Martinez-Hernandez, E.; Amezcua-Allieri, M.A.; Aburto, J.; Honorato-Salazar, J.A. Economic and environmental impact evaluation of various biomass feedstock for bioethanol production and correlation to lignocellulosic composition. Bioresour. Technol. Rep. 2019, 7, 100230. [Google Scholar] [CrossRef]

- Hernández, C.; Escamilla-Alvarado, C.; Sánchez, A.; Alarcón, E.; Ziarelli, F.; Musule, R.; Valdez-Vazquez, I. Wheat straw, corn stover, sugarcane, and agave biomasses: Chemical properties, availability, and cellulosic-bioethanol production potential in Mexico. Biofuels Bioprod. Biorefin. 2019, 13, 1143–1159. [Google Scholar] [CrossRef]

- Honorato-Salazar, J.A.; Sadhukhan, J. Annual biomass variation of agricultural crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food Bioprod. Process. 2020, 119, 1–19. [Google Scholar] [CrossRef]

- SIAP (Sistema de Información Agrolimentario y Pesquero). Atlas Agoalimentario, 2020; Secretaría de Agricultura, Ganadería y Desarrollo Rural, Gobierno de México: Mexico City, Mexico, 2021. [Google Scholar]

- SIACON-NG. Base de Datos de Secretaría de Agricultura, Ganadería y Desarrollo Rural; Gobierno de México: Mexico City, Mexico, 2021. [Google Scholar]

- Brechbill, S.C.; Tyner, W.E. The Economics of Biomass Collection, Transportation, and Supply to Indiana Cellulosic and Electric Utility Facilities; Working Paper #08-03; Department of Agricultural Economics, Purdue University: West Lafayette, IN, USA, 2008. [Google Scholar]

- INEGI (Instituto Nacional de Estadísticas y Geogrofía). Sistema de Cuentas Nacionales de México; Producto Interno Bruto por Entidad Federativa: Mexico City, Mexico, 2021.

- Padilla-Pérez, R.; Oddone, N. Manual para el Fortalecimiento de Cadenas de Valor; LC/MEX/L.1218; CEPAL-FIDA: Mexico City, Mexico, 2016. [Google Scholar]

- Smeets, E.; Faaij, A.; Lewandowski, I. A Quick Scan of Global Bio-Energy Potentials to 2050: An Analysis of the Regional Availability of Biomass Resources for Export in Relation to the Underlying Factors; Report NWS-E2004-109; Copernicus Institute, Department of Science, Technology and Society, Utrech University: Utrech, The Netherlands, 2004; ISBN 90-393-3909-0. [Google Scholar]

- Unkovich, M.; Baldock, J.; Forbes, M. Variability in Harvest Index of grain crops and potential significance for carbon accounting: Examples from Australian agriculture. In Advances in Agronomy; Sparks, D.L., Ed.; Academic Press: Burlington, VT, USA, 2010; Volume 105, pp. 173–219. [Google Scholar] [CrossRef]

- Johnson, J.M.; Wilhelm, W.W.; Karlen, D.L.; Archer, D.W.; Wienhold, B.J.; Lightle, D.T.; Laird, D.; Baker, J.; Ochsner, T.E.; Novak, J.M.; et al. Nutrient Removal as a Function of Corn Stover Cutting Height and Cob Harvest. Bio Energy Res. 2010, 3, 342–352. [Google Scholar] [CrossRef]

- Rosillo-Calle, F.; De Groot, P.; Hemstock, S.L.; Woods, J. (Eds.) Non-woody biomass and secondary fuels. In The Biomass Assessment Handbook; Earthscan: London, UK, 2007; ISNB-10 1-84407-285-1; ISBN-13 978-1-84407-285-9. [Google Scholar]

- Venugopal, P.D.; Coffey, P.L.; Dively, G.P.; Lamp, W.O. Adjacent Habitat Influence on Stick Bug (Hemiptera: Pentatomidae) Densities and the Associated Damage at Field Corn and Soybean Edges. PLoS ONE 2014, 9, e109917. [Google Scholar] [CrossRef]

- David, F.R.; David, F.R. Strategic Management. A Competitive Advantage Approach, Concepts and Cases, 6th ed.; Pearson Education: London, UK, 2017; ISBN-10 1-292-14849-7; ISBN-13 978-1-292-14849-6. [Google Scholar]

- Gupta, S.C.; Onstad, C.A.; Larson, W.E. Predicting the effects of tillage and crop residue management on soil erosion. J. Soil Water Conserv. 1979, 34, 77–79. [Google Scholar]

- Larson, W.E.; Swan, J.B.; Pierce, F.J. Agronomic implications of using crop residues for energy. In Agriculture as A Producer and Consumer of Energy; Lockertz, W., Ed.; Westview Press for the American Association for the Advancement of Science: Boulder, CO, USA, 1982; ISBN-13 978-0865313811; ISBN-10 0865313814. [Google Scholar]

- Stout, B.A. Handbook of Energy for World Agric; Elsevier Science: New York, NY, USA, 1990. [Google Scholar]

- Lal, R. The role of residue management in sustainable agricultural systems. J. Sustain. Agric. 1995, 5, 51–78. [Google Scholar] [CrossRef]

- Kartha, S.; Larson, E.D. Bioenergy primer. In Modernized Biomass Energy for Sustainable Development; United Nations Development Programmer: New York, NY, USA, 2000. [Google Scholar]

- Lang, B. Estimating the Nutrient Value in Corn and Soybean Stover. In Iowa State University Extension Fact Sheet BL-112; Iowa State University: Ames, IA, USA, 2002. [Google Scholar]

- Pordesimo, L.O.; Edens, W.C.; Sokhansanj, S. Distribution of Aboveground Biomass in Corn Stover. Biomass Bioenergy 2004, 26, 337–343. [Google Scholar] [CrossRef]

- Lal, R. World crop residues production and implications of its use as a biofuel. Environ. Int. 2005, 31, 575–584. [Google Scholar] [CrossRef] [PubMed]

- Johnson, J.M.; Allmaras, R.R.; Reicosky, D.C. Estimating Source Carbon from Crop Residues, Roots and Rhizo deposits Using the National Grain-Yield Database. Agron. J. 2006, 98, 622–636. [Google Scholar] [CrossRef]

- Wortmann, C.S.; Klein, R.N.; Shafiro, C.A. Harvesting crop residues. In NebGuide University of Nebraska—Lincoln Extension; G1846; Institute of Agriculture and Natural Resources: Lincoln, NE, USA, 2012. [Google Scholar]

- Thompson, J.L.; Tyner, W.E. Corn stover for bioenergy production: Cost estimates and farmer supply response. Biomass Bioenergy 2014, 62, 166–173. [Google Scholar] [CrossRef]

- IRENA (International Renewable Energy Agency). Global Bioenergy Supply and Demand Projections. A Working Paper for Remap 2030. 2014. Available online: www.irena.org/remap (accessed on 15 January 2022).

- Aldana, H.; Lozano, F.J.; Acevedo, J. Evaluating the potential for producing energy from agricultural residues in Mexico using MILP optimization. Biomass Bioenergy 2014, 67, 372–389. [Google Scholar] [CrossRef]

- Caballero-Salinas, J.C.; Moreno-Reséndez, A.; Reyes-Carrillo, J.L.; García-Valdez, J.S.; López-Baez, W.; Jiménez-Trujillo, J.A. Competencia del uso del rastrojo de maíz en sistemas agropecuarios mixtos en Chiapas. Rev. Mex. De Cienc. Agropecu. 2017, 8, 91–104. [Google Scholar] [CrossRef][Green Version]

- Tauro, R.; García, C.A.; Skutsch, M.; Masera, O. The potential for sustainable biomass pellets in Mexico: An analysis of energy potential, logistic costs and market demand. Renew. Sustain. Energy Rev. 2018, 81, 380–389. [Google Scholar] [CrossRef]

- Lozano-García, D.F.; Santibañez-Aguilar, J.E.; Lozano, F.J.; Flores-Tlacuahuac, A. GIS-based modeling of residual biomass availability for energy and production in Mexico. Renew. Sustain. Energy Rev. 2020, 120, 109610. [Google Scholar] [CrossRef]

- Molina-Guerrero, C.E.; Sanchez, A.; Vázquez-Nuñez, E. Energy potential of agricultural residues generated in Mexico and their use for butanol and electricity production under a biorefinery configuration. Environ. Sci. Pollut. Res. 2020, 27, 28607–28622. [Google Scholar] [CrossRef]

- Bautista-Herrera, A.; Ortiz-Arango, F.; Álvarez-García, J. Profitability Using Second-Generation Bioethanol in Gasoline Produced in Mexico. Energy 2021, 14, 2294. [Google Scholar] [CrossRef]

- English, A.; Tyner, W.E.; Sesmero, J.; Owens, P.; Muth, D. Environmental Impacts of Stover Removal in the Corn Belt. In Proceedings of the Agricultural & Applied Economics Association’s 2012 AAEA Annual Meeting, Seattle, WA, USA, 12–14 August 2012. [Google Scholar]

- Blanco-Canqui, H.; Lal, R. Crop residue removal impacts on soil productivity and environmental quality. Crit. Rev. Plant Sci. 2009, 28, 139–163. [Google Scholar] [CrossRef]

- Blanco-Canqui, H. Crop residue removal for bioenergy reduces soil carbon pools: How can we offset carbon losses? Bioenergy Res. 2013, 6, 358–371. [Google Scholar] [CrossRef]

- Dam, R.F.; Mehdi, B.B.; Burgess, M.S.E.; Madramootoo, C.A.; Mehuys, G.R.; Callum, I.R. Soil bulk density and crop yield under eleven consecutive years of corn with different tillage and residue practices in a sandy loam soil in central Canada. Soil Tillage Res. 2005, 84, 41–53. [Google Scholar] [CrossRef]

- Fernandez, F. What is the Nutrient Value of Corn Stover Removal? Bull. Univ. Ill. 2007, 23. Available online: http://bulletin.ipm.illinois.edu/article.php?id=860 (accessed on 10 March 2022).

- Coulter, J.A.; Nafziger, E.D. Continuous Corn Response to Residue Management and Nitrogen Fertilization. Agron. J. 2008, 100, 1774–1780. [Google Scholar] [CrossRef]

- DeJong-Hughes, J.; Coulter, J. Considerations for Corn Residue Harvest in Minnesota; University of Minnesota: Minneapolis, MN, USA, 2009; Available online: http://www.extension.umn.edu/distribution/cropsystems/M1243.html (accessed on 25 January 2022).

- USDA-NRCS (United States Department of Agricultural—Natural Resources Conservation Service). Carbon to Nitrogen Ratios in Cropping Systems; In Cooperation with North Dakota NRCS; USDA-NRCS East National Technology Support Center: Greensboro, NC, USA, 2011. [Google Scholar]

- Schechinger, T.M.; Hettenhaus, J. Corn Stover Harvesting: Grower, Custom Operator, and Processor Issues and Answers; ORNL/SUB-04-4500008274-01; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2004. [Google Scholar]

- Nielsen, R.L. Questions Relative to Harvesting and Storing Corn Stover; WP, AGRY-95-09; Department of Agronomy, Purdue University: West Lafayette, IN, USA, 1995. [Google Scholar]

- Petrolia, D.R. The Economics of Harvesting and Transporting Corn Stover for Conversion to Fuel Ethanol: A Case Study for Minnesota; Staff Paper P06-12; Department of Applied Economics, University of Minnesota: Minneapolis, MN, USA, 2006. [Google Scholar]

- Fixen, P. Potential Biofuels Influence on Nutrient Use and Removal in the US. Better Crops 2007, 91, 12–14. [Google Scholar]

- Karlen, D.L.; Kovar, J.L.; Birrell, S.J. Corn stover nutrient removal estimates for Central Iowa, USA. Sustainability 2015, 7, 8621. [Google Scholar] [CrossRef]

| Ranking | Region | Planted Area (Irrigated Hectares, Annual Average 2016–2020) | Share among Regions Considered | Primary GDP (Share, 2019) | Main Crops (%) |

|---|---|---|---|---|---|

| 1 | Sinaloa | 853,476 | 20.1% | 8.0% | corn (65%), bean (10%) |

| 2 | Sonora | 479,912 | 11.3% | 6.3% | wheat (53%), corn (12%) |

| 3 | Guanajuato | 431,902 | 10.2% | 4.6% | corn (31%), sorghum (21%) |

| 4 | Chihuahua | 364,679 | 8.6% | 6.5% | corn (36%), cotton (29%) |

| 5 | Tamaulipas | 341,470 | 8.0% | 2.4% | sorghum (63%), corn (28%) |

| 6 | Michoacán | 255,827 | 6.0% | 10.4% | corn (50%), wheat (17%) |

| 7 | Jalisco | 168,604 | 4.0% | 13.3% | fodder corn (27%), corn (25%) |

| 8 | Zacatecas | 135,233 | 3.2% | 2.2% | corn (22%), dry chili (21%) |

| 9 | Durango | 127,523 | 3.0% | 3.0% | fodder corn (34%), corn (23%) |

| 10 | Puebla | 127,404 | 3.0% | 3.5% | corn (36%), ear of corn (13%) |

| 11 | México | 124,149 | 2.9% | 3.1% | corn (63%), fodder oat (13%) |

| 12 | Baja Ca. | 121,135 | 2.9% | 2.8% | wheat (38%), cotton (19%) |

| 13 | Rest | 717,497 | 16.9% | 34% | |

| Total | 4,248,810 | 100.0% | 100% |

| Ranking | Region | Annual Production (ton, 2020) | Individual Share | Accumulated Share |

|---|---|---|---|---|

| 1 | Sinaloa | 6,204,815 | 46% | 46% |

| 2 | Guanajuato | 1,380,260 | 10% | 56% |

| 3 | Chihuahua | 1,226,803 | 9% | 65% |

| 4 | Michoacán | 930,624 | 7% | 72% |

| 5 | Sonora | 633,971 | 5% | 77% |

| 6 | Tamaulipas | 520,807 | 4% | 81% |

| Rest | 2,668,827 | 19% | 100% | |

| Total | 13,566,107 | - | - |

| Harvest Index (HI) | Crop Residue Index (CRI) | Applied on | Reference |

|---|---|---|---|

| 0.40 | 1.50 | Global | Gupta et al., 1979 [40] |

| 0.65 | 0.55 | Global | Larson et al., 1982 [41] |

| 0.65 | 0.55 | Global | Stout, 1990 [42] |

| 0.40 | 1.50 | USA | Lal, 1995 [43] |

| 0.40 | 1.50 | Global | Kartha and Larson, 2000 [44] |

| 0.50 | 1.00 | USA | Lang, 2002 [45] |

| 0.56 | 0.80 | USA | Pordesimo et al., 2004 [46] |

| 0.40 | 1.50 | USA | Lal, 2005 [47] |

| 0.53 | 0.89 | USA | Johnson et al., 2006 [48] |

| 0.40 | 1.50 | Mexico | Valdez-Vazquez et al., 2010 [20] |

| 0.51 | 0.98 | USA | Wortmann et al., 2012 [49] |

| 0.46 | 1.20 | Mexico | Borja-Bravo et al., 2013 [23] |

| 0.50 | 1.00 | Mexico | Rios and Kaltschmitt, 2013 [21] |

| 0.51 | 0.95 | USA | Thompson and Tyner, 2014 [50] |

| 0.40 | 1.50 | 118 Countries | IRENA, 2014 [51] |

| 0.50 | 1.00 | Mexico | Aldana et al., 2014 [52] |

| 0.48 | 1.10 | Mexico | Caballero-Salinas et al., 2017 [53] |

| 0.40 | 1.50 | Mexico | Tauro et al., 2018 [54] |

| 0.56 | 0.80 | Mexico | Hernández et al., 2019 [27] |

| 0.42 | 1.41 | Mexico | Honorato-Salazar; Sadhukhan; 2020 [28] |

| 0.55 | 0.83 | Mexico | Lozano-García et al., 2020 [55] |

| 0.33 | 2.00 | Mexico | Molina-Guerrero et al., 2020 [56] |

| 0.55 | 0.82 | Mexico | Bautista-Herrera et al., 2021 [57] |

| 0.48 | 1.15 | Average | |

| 0.45 | 1.21 | Mexico | This investigation |

| Nitrogen (N) | Phosphorus (P2O5) | Potassium (K2O) | Source |

|---|---|---|---|

| 3.2 | 15.9 | Schechinger; Hettenhaus, 2004 [66] | |

| 6.8 | 2.7 | 11.3 | Lang, 2002 [45] |

| 6.2 | 1.6 | 8.9 | Nielsen, 1995 [67] |

| 2.8 | 15.0 | Petrolia, 2006 [68] | |

| 8.6 | 2.6 | 14.5 | Fixen, 2007 [69] |

| 6.5 | 0.6 | 7.6 | Karlen et al., 2015 [70] |

| 7.0 | 2.2 | 12.2 | Average |

| Link | Total Costs | |||||

|---|---|---|---|---|---|---|

| $USD/ton | Share (%) | $USD/bale | Share (%) | $USD/ha | Share (%) | |

| 1. Management and Investment | $3.02 | 6% | $1.51 | 6% | $13.58 | 6% |

| 2. Harvest | $12.91 | 27% | $6.45 | 27% | $58.09 | 27% |

| 3. Loading | $1.06 | 2% | $0.53 | 2% | $4.76 | 2% |

| 4. Transport | $9.55 | 20% | $4.77 | 20% | $42.97 | 20% |

| 5. Unloading | $1.95 | 4% | $0.98 | 4% | $8.78 | 4% |

| 6. Storage | $2.67 | 6% | $1.33 | 6% | $12.00 | 6% |

| 7. Nutrients | $16.99 | 35% | $8.49 | 35% | $76.43 | 35% |

| MCSSP 3 | $48.14 | 100% | $24.07 | 100% | $216.62 | 100% |

| Corn Stover Prices for Cellulosic Ethanol (USD/ton) | |

|---|---|

| MCSSP 1 (up to link 5) | $28.49 |

| MCSSP 2 (up to link 6) | $31.15 |

| MCSSP 3 (up to link 7) | $48.14 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Becerra-Pérez, L.A.; Rincón, L.; Posada-Duque, J.A. Logistics and Costs of Agricultural Residues for Cellulosic Ethanol Production. Energies 2022, 15, 4480. https://doi.org/10.3390/en15124480

Becerra-Pérez LA, Rincón L, Posada-Duque JA. Logistics and Costs of Agricultural Residues for Cellulosic Ethanol Production. Energies. 2022; 15(12):4480. https://doi.org/10.3390/en15124480

Chicago/Turabian StyleBecerra-Pérez, Luis Armando, Luis Rincón, and John A. Posada-Duque. 2022. "Logistics and Costs of Agricultural Residues for Cellulosic Ethanol Production" Energies 15, no. 12: 4480. https://doi.org/10.3390/en15124480

APA StyleBecerra-Pérez, L. A., Rincón, L., & Posada-Duque, J. A. (2022). Logistics and Costs of Agricultural Residues for Cellulosic Ethanol Production. Energies, 15(12), 4480. https://doi.org/10.3390/en15124480