1. Introduction

Desalination, as the name suggests, is to obtain fresh water by removing salt from seawater. The seawater resources on earth are inexhaustible. Therefore, desalination offers a method that can guarantee a long-term supply of fresh water and fundamentally solve the water problem of residents in coastal areas [

1]. However, seawater desalination is an energy-intensive industrial process, i.e., the entire process needs to consume an enormous amount of energy. Currently, regardless of whether heat or electricity is used for seawater desalination, these energies mainly come from conventional energy sources, i.e., fossil fuels such as petroleum and coal. As the scale of desalination in the world continues to expand, the shortage of fresh water has been eased to a certain extent, but the huge pollution generated at the same time also brings new challenges to the world’s energy and human living environment. These issues put forward higher requirements for the energy consumption of desalination from global environmental protection and ecologically sustainable development [

2].

High-temperature gas-cooled reactor (hereinafter referred to as “HTGR”) is an internationally recognized fourth-generation nuclear energy technology. The development of this advanced nuclear energy technology is one of the most eye-catching technological achievements of Tsinghua University [

3]. HTGR can be used for safe and efficient power generation because of its outstanding inherent safety characteristics, and due to the high temperature at the core outlet. Moreover, it can be used as a high-temperature heat source to provide process heat for seawater desalination and other processes so that the use of nuclear energy can be extended to a wider range of industrial fields. It helps to greatly reduce the consumption of fossil fuels and the pollution generated, while meeting the development requirements of energy saving, emission reduction, and low-carbon environmental protection, and strives to build a “resource-saving and environment-friendly” society [

4].

The development process of HTGR has gone through many stages. The first reactor was built with graphite as a neutron moderator, CO

2 as a heat carrier, and natural uranium as fuel, i.e., the Magnox reactor [

5]. From the 1950s to the early 1970s, Britain, France, and other countries built 36 gas-cooled nuclear power plants [

6]. The feature of this technology is the use of natural uranium, which has laid some foundations for the development of nuclear power plants in the future [

7]. To solve the problem that the outlet temperature of the Magnox reactor is limited by materials, the concept of an advanced gas-cooled reactor (AGR) was proposed in the 1960s [

8]. In the 1980s, three different conceptual modular HTGRs appeared in the world, namely HTR-Module from Siemens/Interatom in Germany, HTR-100 from BBC/HRB in Germany, and MHTGR-350 from GA in the United States [

5]. These three types of reactors are characterized by miniaturization and inherent safety and have the advantages of modular combination, standardized production, and short construction time. After entering the 21st century, the United States, France, Japan, and other countries have further formulated plans to develop modular HTGRs [

9].

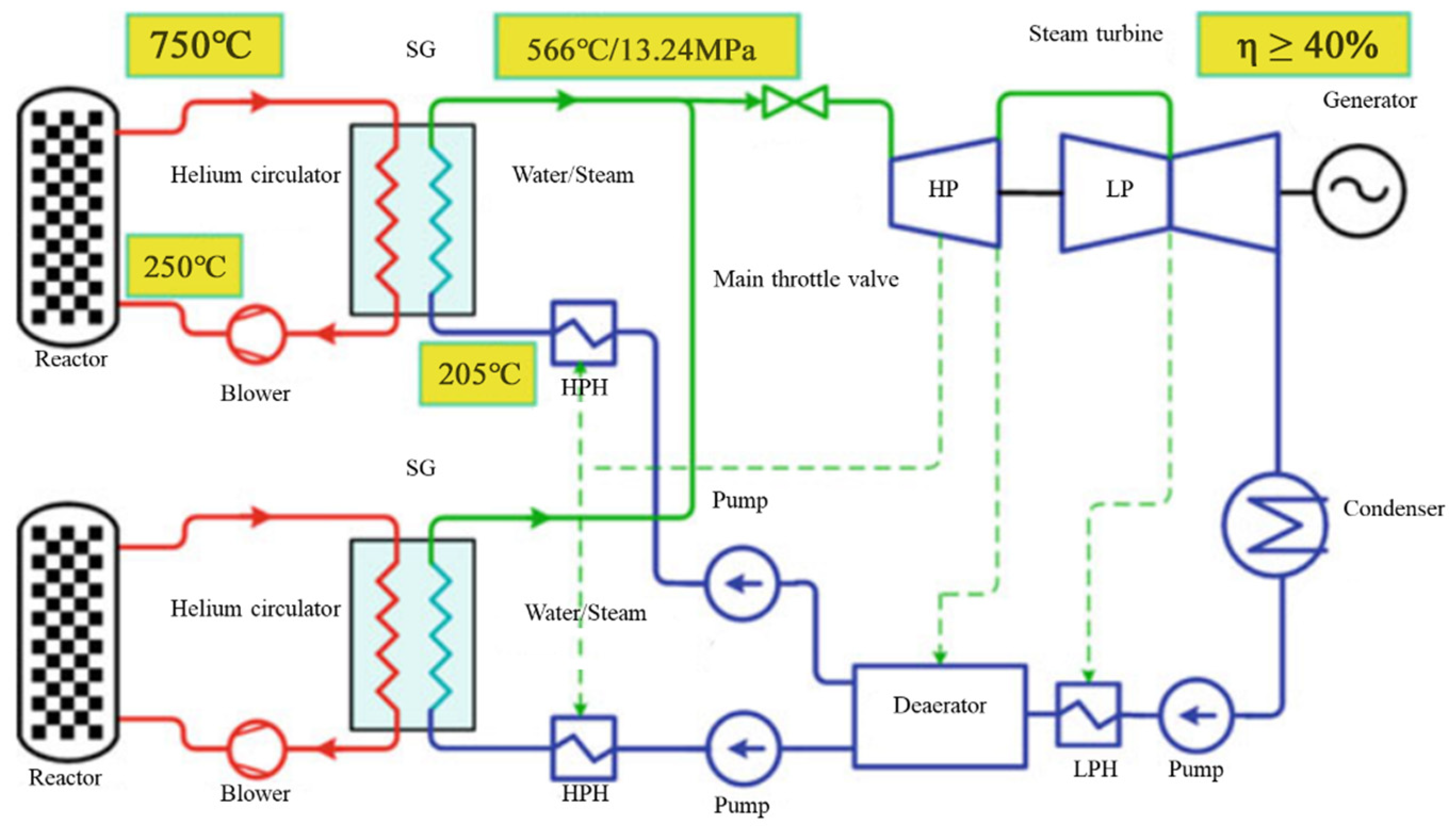

Although the gas-cooled reactor technology originated in Britain, Germany, and the United States, China’s development of HTGR technology has achieved international leadership. After the successful design, construction, commissioning, and operation of a 10 MWth test reactor, HTR-10, an industrial-scale pebble-bed modular HTGR (HTR-PM), has been developed. On 9 December 2012, the world’s first commercial modular HTGR power plant, the HTR-PM demonstration project, in which two modules are coupled to one steam turbine (as shown in

Figure 1), was officially approved to start construction at the Shidao Bay site, Rongcheng, Shandong Province. With breakthroughs in the R&D and manufacturing of the HTGR fuel and main components, the HTR-PM project is progressing smoothly. Civil construction, installation, and commissioning have been completed, and it was connected to the grid for power generation on 20 December 2021. Based on HTR-PM, Tsinghua University and the China National Nuclear Corporation (CNNC) have begun planning the deployment of a multiple-module HTGR power plant with a power of 600 MWe. With its unique advantages, HTGR will play an important role in the development of nuclear energy in China and some other countries.

More than 20 countries in the world are suffering from water shortages or severe water shortages. With the development of seawater desalination technology, it has become one of the important sources of freshwater resources. According to incomplete statistics, the total amount of freshwater produced by all desalination devices in the world reaches 100 million tons per day [

10]. In the 1950s, Frankel and Silver created the multi-stage flash (MSF) technology and proposed the concept of the flash method. By separating the evaporation equipment from the heating equipment, they tried to solve the scaling problem on the surface of the heating tube and achieved better results. Before the 1960s, seawater desalination mainly employed distillation equipment, which was commonly used in the chemical industry, such as natural circulation submerged evaporators. Since the 1980s, the cost of reverse osmosis (RO) technology has gradually decreased. This is mainly because the performance of reverse osmosis membranes has gradually improved, the price has continued to fall, and the energy recovery efficiency has been gradually improved. At present, the RO method is the most widely used in the field of seawater desalination, accounting for about 60%. It is followed by the MSF technology and low-temperature multi-effect distillation (MED) method, accounting for about 26% and 5%, respectively [

1,

2,

11].

The Chinese government attaches great importance to the desalination of seawater. The earliest desalination technology in China was electrodialysis, which began in 1958. The first desalination plant was built in 1981 on Yongxing Island, Xisha, using electrodialysis technology [

12]. Of all the desalination technologies, China’s application of reverse osmosis and low-temperature multi-effect desalination technology is more effective and can reach the international advanced level.

The first nuclear desalination plants were built in Japan and Kazakhstan in the 1960s. From a global perspective, nuclear desalination research began in the 1960s. Nuclear desalination plants in Japan use hot steam or electricity from nuclear power plants to produce water for steam generators and plant drinking water. The seawater desalination technology adopts RO, MSF, and MED, and the daily freshwater output capacity ranges from 1000 to 3000 m

3. The nuclear desalination plant in Kazakhstan employed a sodium-cooled fast reactor to supply water to nearby residents. The device operated successfully for 26 years and was closed in early 1999. Theoretically, nuclear reactors can be combined with any conventional desalination process, because nuclear reactors can be used for heating on the one hand and power generation on the other hand [

13,

14]. However, it is generally believed that in nuclear desalination, small- and medium-sized reactors are more appropriate, and large-scale desalination devices are more advantageous. In recent decades, nuclear reactor technology has continued to be developed and mature. The breakthrough in large-scale desalination technology has made it possible to develop commercial-scale desalination production, and it has been proven technically feasible to replace conventional energy with nuclear energy for desalination [

15,

16,

17]. At the beginning of this century, Tsinghua University employed the seawater desalination economic evaluation program (DEEP 2.0 software) developed by IAEA to evaluate the economic performance of the HTGR coupled reverse osmosis method (HTGR-RO), which could produce fresh water 480,000 m

3/d, and the results showed that it was more economical than fossil fuels [

18]. South Korea optimized the coupling scheme of high-temperature gas-cooled reactor and seawater desalination technology (HTGR+MED) and developed a matching KAIST-DEEP code to evaluate the economic performance of the coupling scheme [

19].

To sum up, as a clean energy system, HTGR can be used for seawater desalination. While solving the shortage of fresh water, they can also reduce fossil fuel consumption and pollution, and promote energy conservation, emission reduction and low-carbon development.

Factors such as the geographical location, climatic conditions, and freshwater resource conditions, as well as the increasing demand for water for living, industry, agriculture, and animal husbandry in the Kingdom of Saudi Arabia, determine that the development of large-scale desalination is a long-term and unswerving basic national policy to ensure the sustainable development of industry and agriculture and the growth of people’s living needs. Based on the principle of reducing emissions of combustion pollutants and leaving precious natural resources of oil and natural gas for future generations, actively seeking large-scale alternative energy sources and making strategic adjustments to the energy consumption structure have gradually become the consensus of the Saudi Arabian government.

Relying on the seawater desalination project of Saudi Arabia’s HTGR nuclear power plant, this paper proposes the technical design and energy efficiency analysis of the project plan. The organization structure of this paper is as follows:

Section 1 is the introduction, which analyzes the development of HTGR and seawater desalination;

Section 2 is the analysis of the technical scheme of the HTGR seawater desalination project;

Section 3 is the economic analysis of the project;

Section 4 is the comprehensive analysis of the program;

Section 5 is the summary.

2. Technical Solution

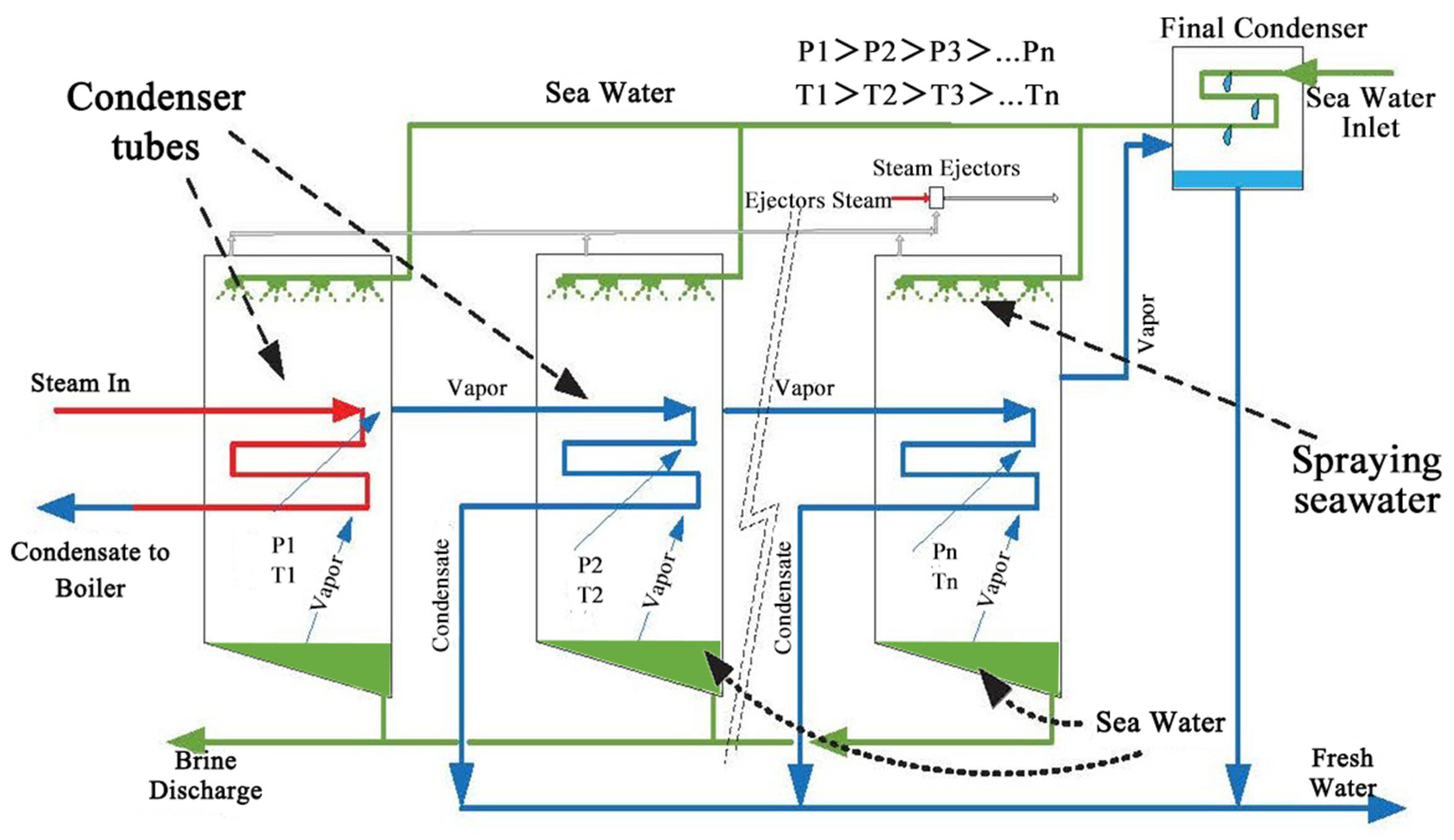

2.1. Multi-Effect Distillation (MED)

MED can be divided into high-temperature MED (maximum evaporation temperature is higher than 90 °C) and low-temperature MED (maximum evaporation temperature is not higher than 70 °C). High-temperature MED can arrange higher heat transfer efficiency and achieve a higher gain output ratio due to its high operating temperature. However, it has several disadvantages, such as easy scaling on the surface of the heat transfer tubes, fast corrosion speed, high requirements for equipment material, frequent equipment cleaning, and stringent high requirements for pretreatment. Because of these shortcomings of high-temperature multi-effect distillation, low-temperature multi-effect distillation seawater desalination technology (LT-MED) was developed in the 1960s. The horizontal tube falling-film distiller is commonly used in water treatment, which is characterized by a series of spraying falling-film evaporators arranged in series. Heated steam (70 °C, corresponding saturated steam pressure of about 31 kPa.A) is introduced into the first effect, whose condensing heat causes almost the same amount of seawater to evaporate. After repeated evaporation and condensation, the evaporation temperature of the next effect is lower than that of the previous effect, so as to obtain distilled water more than times the amount of steam. The first effect condensate can be returned, and the other effect condensate is collected as product water. The working diagram of MED is shown in

Figure 2.

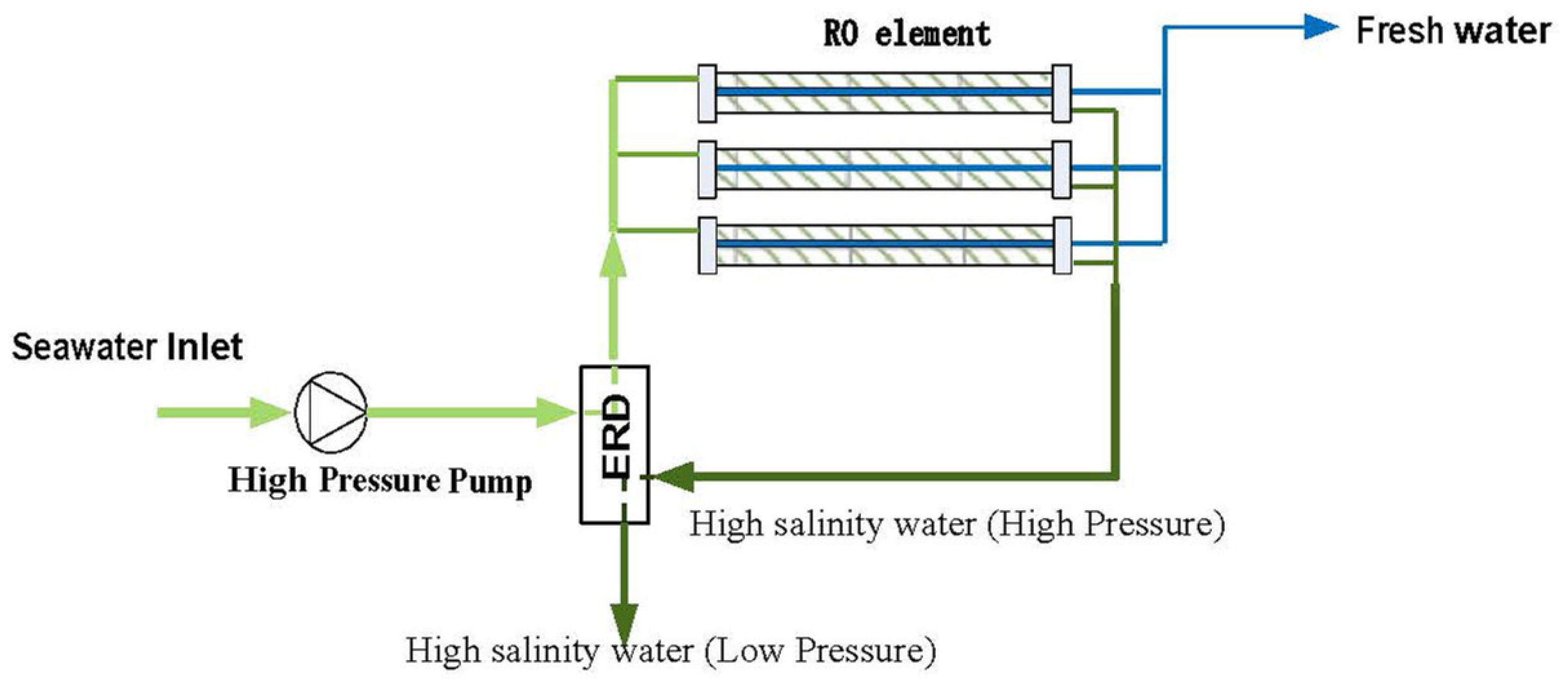

2.2. Membrane Technology (RO)

Reverse osmosis (RO) seawater desalination is the use of external pressure to make seawater pass through the reverse osmosis membrane. The salt in the seawater does not pass through, and the concentrated water is discharged so as to achieve the purpose of the separation of salt and water.

In order to pass seawater through the reverse osmosis membrane, the applied pressure should be greater than the osmotic pressure of seawater. Generally, the applied pressure is between 4.5 and 8.0 MPa.

Figure 3 shows the schematic diagram of the reverse osmosis seawater desalination system.

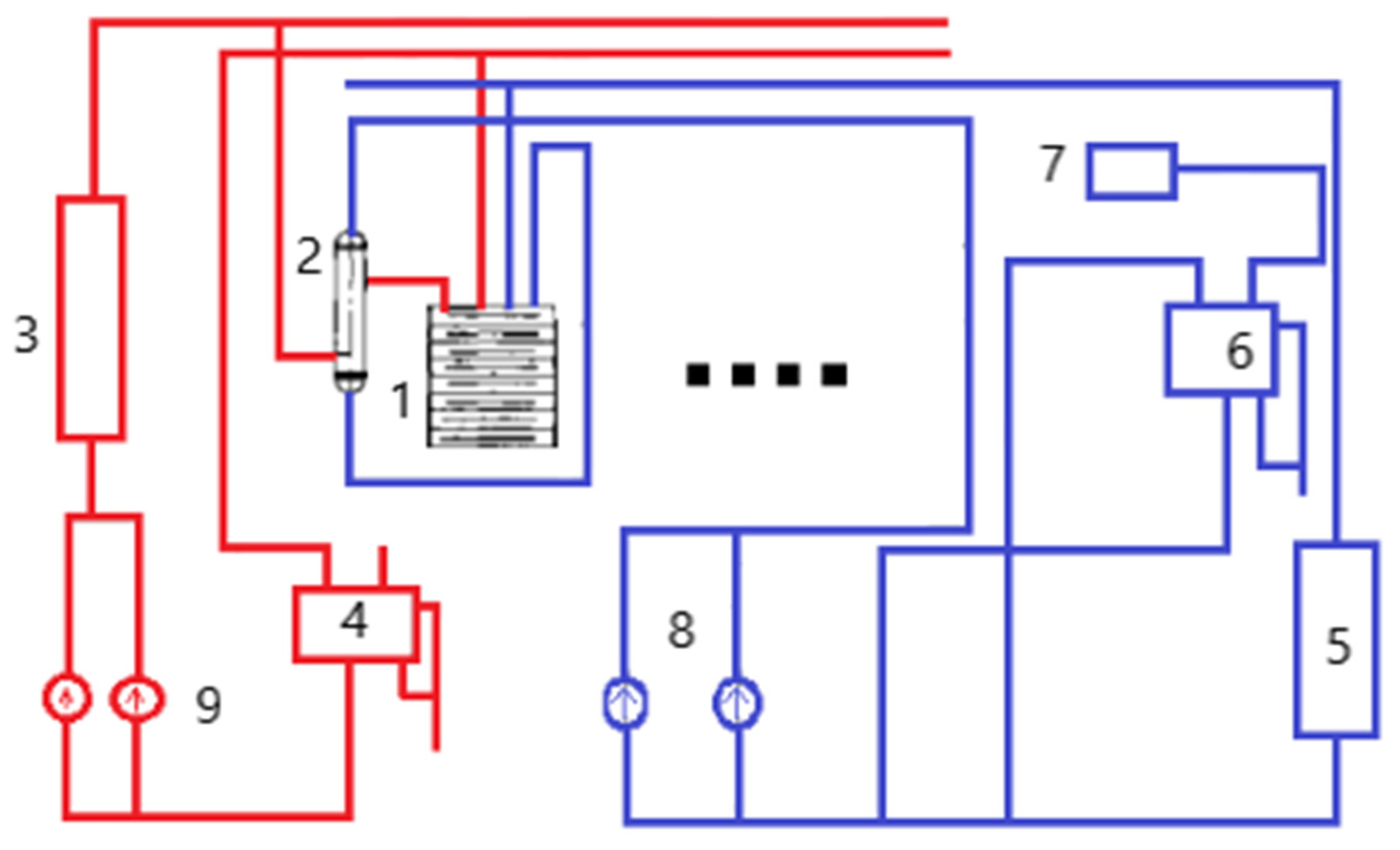

2.3. Tertiary Circuit Design for HTGR Power and Water Cogeneration

The inherent safety features of the HTGR itself greatly enhance the safety of the entire combined power and water system, but there are operational safety issues with the HTGR and desalination system. In the event of a radioactive leak, there is the potential for contamination of fresh water, which would have a serious impact on water safety issues.

So, to solve this problem, a triple circuit is set up between the main circuit of the HTGR and the desalination unit, forming radioactive physical isolation, according to the main technical characteristics of the HTGR. In the event of damage to the pipes of the main heat exchanger, radioactive water from the main circuit can be effectively prevented from entering the triple circuit. This effectively avoids the radiation hazard to the surrounding environment caused by the migration and release of radioactive material from the reactor under accident conditions and safeguards the desalination unit from contamination.

The tertiary circuit system is a closed-loop, including steam/water (secondary circuit) -water (tertiary circuit) parallel heat exchanger series, circulation pump, make-up pump (or make-up water system), decontamination, condensation tank, condensate pump, water treatment equipment, and other components.

In addition to the various components mentioned above, the system must also be fitted with thermal testing and safety protection devices, both of which are primarily intended to ensure the safe and stable operation of the tertiary circuit.

The tertiary circuit design is shown in

Figure 4. The secondary circuit system, in addition to its normal function of generating electricity, partially pumps steam for heat exchange with this tertiary circuit system. This tertiary circuit system exchanges heat with the desalination system for seawater desalination. The red part of the diagram shows the secondary circuit steam extraction heat source, and the blue part shows the tertiary circuit system.

2.4. HTGR Nuclear Desalination Project Proposal

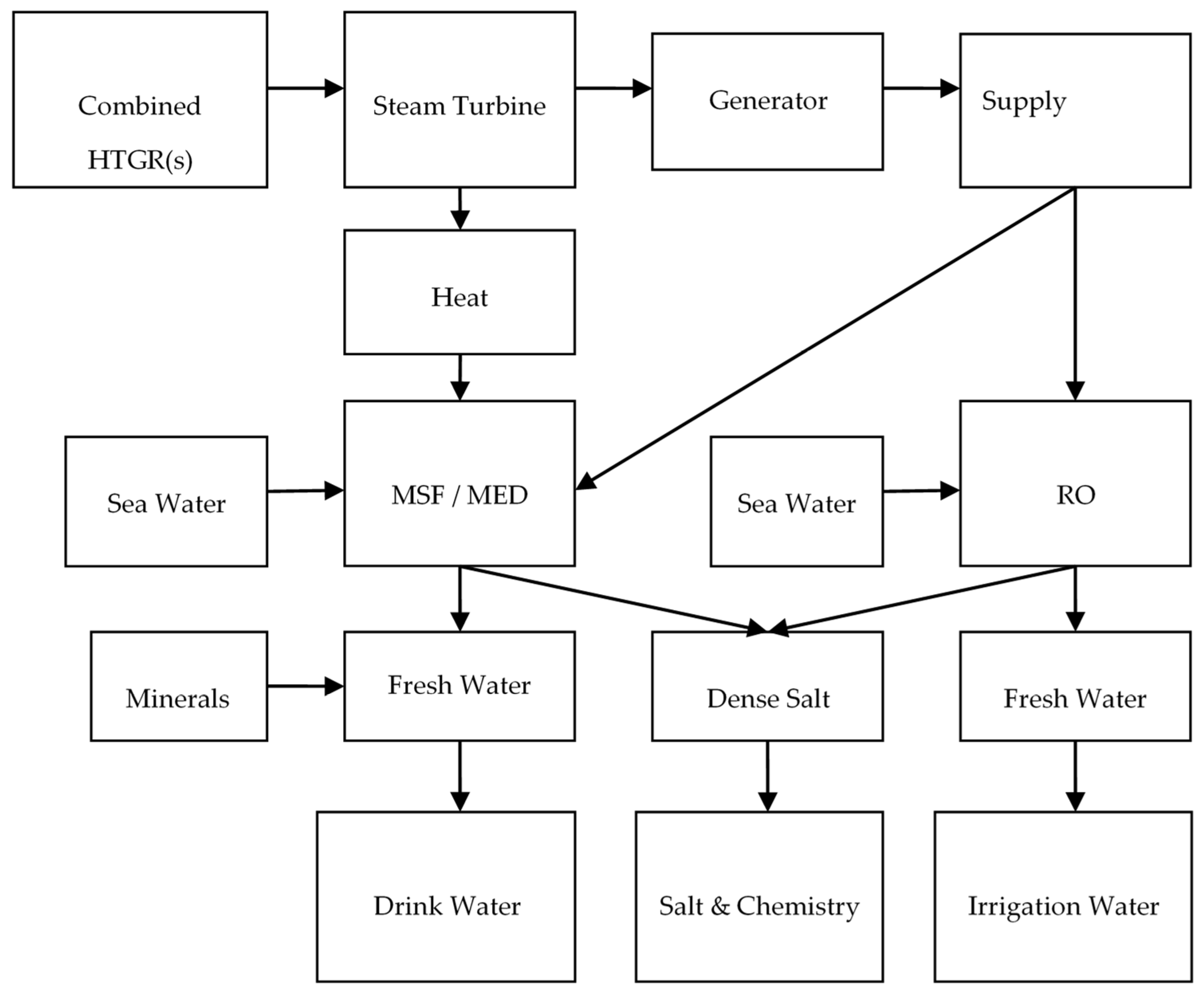

The seawater desalination project of the HTGR nuclear power plant maximizes the advantages of nuclear power plants in producing heat and electricity and considers the water quality of the seas around Saudi Arabia. The combination of the mature distillation method and reverse osmosis method (MSF /MED-RO) is adopted to meet the demand of local people for fresh water. The overall technical scheme is shown in

Figure 5.

The low-pressure extraction steam of the steam turbine set (superheated steam, pressure 0.50 MPa, temperature 163.2 °C) entering the isolation heat exchanger is employed as the thermal power source of MSF or MED. The capacity of the desalination device is designed according to the maximum steam extraction capacity of the steam turbine set. The design ratio of the steam is MSF/MED = 1:9.5. The total dissolved salts (TDS) produced by the thermal desalination device is TDS ≤ 10 mg/L (ppm), which meets the World Health Organization’s (WHO) “Guidelines for Drinking Water Quality”. After mineralization, it can be provided to residents for direct drinking. The power generated by the steam turbine generator set is used as the power source of the high-pressure seawater pump of the RO device. The seawater is desalinated through the first-level reverse osmosis membrane group, and the TDS produced by the membrane reverse osmosis device is TDS ≤ 500 mg/L (ppm), which meets the United Nations’ Food and Agriculture Organization’s (FAO) “standards for Agricultural water”. It can be directly used as farmland irrigation water or industrial circulating cooling water, or it can be mixed with the freshwater produced by the “thermal method” in a certain proportion to adjust the quality of fresh water to meet the various needs of freshwater users. The concentrated brine residue produced by the desalination device is discharged to specific sea areas through concentrated brine pumps and pipelines; or, after technical–economic evaluation, it can be used comprehensively, such as raw materials for salt production or the salt chemical industry.

The specific scheme is as follows:

The HTGR seawater desalination technology plant includes 2 × 2 standard HTGR modules, 2 × 200 MWe extraction condensing steam turbine generator sets, and auxiliary system equipment and facilities for nuclear power plants. The total thermal power of the nuclear power plant is 2 × 500 MWt, and the maximum power generation is about 2 × 220 MWe.

The high-temperature and high-pressure steam are partly used to drive the steam turbine to generate electricity used in the seawater reverse osmosis desalination system, and part of the heat source is used in desalination by the “thermal” MED system. Because membrane and thermal seawater desalination systems have very different costs in terms of production, operation, and maintenance, it is necessary to propose a variety of different technical schemes and compare their technical feasibility and economic effectiveness by adjusting the extraction parameters and the amount of steam used in the desalination system to finally achieve the optimum scheme.

2.4.1. Scheme 1: Using Pure Condensing Unit

By using pure condensing units, shown in

Table 1, the rated operating power of the turbine generator is 212 MW.

The electricity generated is all used in the seawater reverse osmosis desalination system. Considering the characteristics of Saudi Arabian seawater and the policy of irrigation water quality, the water output of the seawater desalination SWRO system needs to be treated deeply with second-level reverse osmosis BWRO. Supposing the average power consumption for membrane desalination is about 5 kWh/m3, the final water output of the seawater reverse osmosis desalination system in the straight condensing scheme is 42,400 m3/h.

A total of 52 sets of first-level reverse osmosis SWRO and second-level reverse osmosis BWRO membrane seawater desalination equipment with an output of 21,200 m3/d can be employed. The desalination workshop is an independent building with a total area of about 117,120 m2 (384 m × 305 m), excluding the pretreatment part. The membrane treatment area is a single layer with an area of 90,240 m2 (384 m × 235 m) and headroom of 8 m. Various types of water tanks and recovery pools are arranged outdoors.

2.4.2. Scheme 2: Condensate Pumping Unit (Large-Turbine Extraction Steam Plus Back-Pressure Small Turbine)

By using the condensate pumping unit (large-turbine extraction steam plus back-pressure small turbine), shown in

Table 1, the rated operating power of the turbine generator is 134 MW, the extraction steam is 400 t/h, and the extraction parameters are 0.8 MPa and 201.9 °C, respectively. The extraction steam drives the small turbine and its corresponding seawater reverse osmosis high-pressure pump (estimated 41.4 MW), and the exhaust steam (0.06 MPa, 85.95 °C) of the small turbine is sent to the MED system.

The electricity generated is all used in the reverse osmosis desalination system. Supposing the average SWRO power consumption is about 5 kWh/m3, the SWRO water output of this scheme is 26,800 m3/h.

The amount of fresh water produced by the reverse osmosis membrane seawater desalination system driven by the steam-driven high-pressure pump is estimated to be 8275 m3/h according to the power.

Due to the special quality of the Saudi Arabia Sea, according to studies, the water output ratio is usually 1:5. The water output of the MED system is 2080 m

3/h.

Table 2 summarizes the technical data of MED.

The total water output in this scheme is 37,200 m3/h.

Based on seawater containing 5.5 mg/L of boron at a temperature of 35 °C, the boron content of the first-level reverse osmosis SWRO effluent is 1.5 mg/L, and the boron content of the second-level reverse osmosis BWRO effluent is 0.7 mg/L (the recovery rate of the second-level reverse osmosis BWRO is 85%). Considering that the boron content in the effluent of MED is extremely low and close to zero, after mixing the effluent of MED and the effluent of the first-level reverse osmosis, 31,350 m3/h of water produced by the second-level reverse osmosis BWRO is still required to meet the requirements of irrigation. The system is equipped with a set of MED devices with an output of 50,000 t/d, a first-level reverse osmosis SWRO with an output of 3755 m3/h, and a first-level reverse osmosis SWRO + second-level reverse osmosis BWRO device with an output of 31,350 m3/h. That is, it is equipped with 44 sets of first-level reverse osmosis SWRO with an output of 25,000 m3/d and 40 sets of second-level reverse osmosis BWRO with an output of 20,900 m3/d.

The total area of the desalination treatment workshop is about 104,850 m2, excluding the pretreatment part. The desalination membrane treatment area is a single layer with an area of 704,850 m2 (330 m × 235 m) and headroom of 8 m. Various types of water tanks and recycling pools are arranged outdoors, with a total area of about 100,650 m2 (330 m × 305 m). A set of MED thermal desalination devices with an output of 50,000 m3/d is established, occupying an area of 105 m × 40 m, which can be arranged near the HTGR.

2.4.3. Scheme 3: Condensate Pumping Unit (Back-Pressure Large-Turbine Exhaust Steam)

By using the condensate pumping unit (back-pressure large-turbine exhaust steam), the rated operating power of the steam turbine generator is 184 MW, and the extraction steam is 506 t/h. As shown in

Table 1, the extraction parameters are 0.06 MPa and 85.95 °C, respectively, and they are sent to the MED system.

The electricity generated is all used in the seawater reverse osmosis desalination system. Supposing the average SWRO power consumption is 5 kWh/m3, the water output of the first-level seawater reverse osmosis SWRO in this scheme is 36,800 m3/h.

The MED water output is 2688 m3/h. The total water output in this scheme is 39,500 m3/h.

Considering that the effluent of MED is mixed with the effluent of the first-level reverse osmosis SWRO (the boron content of the effluent is 1.5 mg/L), 32,385 m3/h of water produced by the second-level reverse osmosis BWRO is still required to meet the requirements of irrigation. The system is equipped with 2 sets of MED devices with an output of 32,250 t/d, a first-level reverse osmosis SWRO with an output of 4415 m3/h, and a first-level reverse osmosis SWRO + second-level reverse osmosis BWRO device with an output of 32,385 m3/h. That is, it is equipped with 44 sets of first-level reverse osmosis SWRO with an output of 25,510 m3/d and 40 sets of second-level reverse osmosis BWRO with an output of 21,590 m3/d.

3. Economic Analysis

For the HTGR desalination technology project in Saudi Arabia, the investment estimates and economic analysis were carried out according to three technical solutions: pure condensing units, condensate pumping units (large-turbine extraction steam plus back-pressure small turbine), and condensate pumping unit (back-pressure large-turbine exhaust steam). The investment estimation only includes the equipment purchase and installation costs of the desalination project and excludes the costs of other items in the project.

Other calculation basis is explained as follows:

- (1)

Compilation principle: The preparation methods of investment estimates, cost composition and calculation standards, nature of costs and project planning, etc., are implemented, respectively, in accordance with “Nuclear Power Plant Construction Project Construction Budget Preparation Method” and “Nuclear Power Plant Construction Project Cost Nature and Project Division Guidelines”, “Regulations on the Preparation of Other Costs for Nuclear Power Plant Construction Projects” and “Regulations on the Preparation and Calculation of Construction Budgets for Thermal Power Generation Projects”, and other relevant Chinese documents.

- (2)

Quantity of projects: Calculated based on equipment and plant drawings provided by the design institute and, where insufficient, based on similar projects.

- (3)

Prescribed amount: It is implemented in accordance with the series of documents revised in the 2013 edition, such as “Electric Power Construction Engineering Quota Valuation Table-Construction Engineering”, “Electric Power Construction Engineering Quota Valuation Table-Thermal Equipment Installation Engineering”, etc.

- (4)

Material price: The cost of installation equipment is calculated based on the price in the “Comprehensive Budget Price of Installation Materials for Power Generation Projects (2013 Edition)”, and the base period differential for the main materials, calculated and prepared in accordance with the prices in the 2017 “Reference Cost Index for Thermal Power Engineering Quota Design”. Price of construction materials: The base period spreads are calculated based on the recent local market information price for the project.

- (5)

Main equipment cost:

Table 3 shows the investment estimation for three different seawater desalination schemes in the 200 MWe turbine seawater desalination project. Among them, this investment only includes installation engineering costs of the seawater desalination equipment and the electrical thermal control equipment, as well as construction costs of the seawater desalination workshop and the MED workshop for three schemes.

Based on the calculation basis above,

Table 4 shows the estimation of the seawater desalination project using pure condensing units.

Table 5 shows an estimation of the seawater desalination project using a condensate pumping unit (large-turbine extraction steam plus back-pressure small turbine).

Table 6 shows an estimation of the seawater desalination project using a condensate pumping unit (back-pressure large-turbine exhaust steam).

The following is an analysis of the cost of producing fresh water. The original data are as follows:

- (a)

The annual operating time is calculated as 8760 h;

- (b)

The capacity is 100 people;

- (c)

The depreciation period is 20 years;

- (d)

The repair rate is 3%;

- (e)

The cost of electricity is 0.85 Yuan/kWh;

The benefit–cost analysis of the investment is shown in

Table 7.

According to the above comparison (this time only comparing the seawater desalination system), it can be concluded that the membrane desalination scheme has the largest water output and the least static investment shown in

Table 7. However, due to the high operation and maintenance costs, the production cost of desalinated water is the highest. The desalination technology employing the back-pressure turbine exhaust steam scheme combines the MED scheme and the membrane seawater desalination scheme, which offers the lowest production cost for desalinated water.

4. Comprehensive Analysis

Comprehensive analysis based on the following conditions:

The power of a single steam turbine is considered as 200 MWe;

MED seawater desalination consumes 1.2 kWh/t; RO seawater desalination consumes 5.5 kWh/t; the plant power consumption ratio is 10%; the energy loss caused by the addition of the tertiary circuit steam converter is 20%.

The Engineering Procurement Construction (EPC) cost of MED seawater desalination is about 9500 Yuan/t/d; the EPC cost of SWRO seawater desalination is about 7000 Yuan/t/d;

Water and electricity prices for residents in Saudi Arabia are shown in

Table 8 and

Table 9, respectively.

The average household water cost is 30 SR (51 Yuan)/month.

The cost of seawater desalination is 12.5 SR/t, which is approximately 21.25 Yuan/t.

The average household electricity is 8161 kWh/year, and the cost is 35 SR/month, which is approximately 59.5 Yuan/month.

The average electricity cost is 0.152 SR/kWh, which is approximately 0.2584 Yuan/kWh.

Based on the analysis of the above conditions, the results are as follows (shown in

Table 10).

According to the above results, the main equipment parameters of MED were selected initially, and the alternatives obtained are shown in

Table 11.

In addition, the results of the comprehensive analysis show that the steam turbine set operates in the TMCR extraction power generation conditions and conducts the “thermal” seawater desalination process to extract steam; the nuclear power plant uses 10% of the electricity generated: 20% is used for the high-pressure water pump of the ”membrane” seawater desalination process, and the rest is supplied externally. The entire process has a high production capacity and low cost, indicating that the design of the scheme is reasonable. This article recommends scheme 3 as the optimal solution.