1. Introduction

The Middle East region, including the United Arab Emirates, is facing a growing energy demand and a surge in CO

2 emissions [

1,

2], leading the region into looking for new sources of energy with low carbon footprint.

The region’s climatic advantages provide a suitable fit for solar energy [

1,

2,

3,

4,

5,

6,

7], from sunlight abundance to the vast open areas of deserts [

8]. A few projects and plans to exploit the UAE’s solar potential, such as concentrated solar power (CSP) and photovoltaics (PV), are already afoot, but addressing its full capabilities is still a distant milestone. Only 2% of the UAE’s electricity came from renewable resources by the year 2018 [

6], and that comes as a result of the large economic investment renewables require compared to the current traditionally applied technologies [

1].

Hydrogen’s ability to store surplus energy from renewable sources, such as solar energy, makes it a key player in the future of renewables and global decarbonization efforts by guaranteeing long term sustainability [

9,

10,

11,

12]. The global demand for hydrogen is on the rise, especially in the mobility sector [

13]. Japan already has plans to integrate hydrogen into their future energy mix [

14], but as domestic supply of hydrogen fails to meet its targets in CO

2 emissions reduction, importing zero-carbon produced H

2 from overseas seems like a viable option [

15,

16,

17]. For instance, to realize its goal of a hydrogen-based society, Japan aims to establish an international hydrogen supply chain [

18]. A deal to co-operate on the development of such a supply chain has already been established between Japan and the United Arab Emirates, as the UAE and other countries in the Middle East region aspire to becoming major international suppliers of low-carbon hydrogen in the future [

19]. The profits from exporting green hydrogen from excess energy in the UAE can provide an incentive to decision makers to seek a higher renewable energy target.

Concentrated solar power plants are deemed as one of the favorable pathways for large-scale hydrogen production from solar power [

20]. Its compatibility with thermal energy storages (TES) that can store energy in the form of heat can overcome the challenge of fluctuating energy supply from solar technologies. It can also prevent the intermittent functioning of water electrolyzers and provide more stable hydrogen production [

20]. Another advantage of CSP and TES is that the electricity supply can be adapted to the demand, providing more flexible hydrogen production for export, and abating the need for H

2 storage at production site.

Although the UAE’s potential for renewable energy and hydrogen production was addressed in a few previous studies, none addresses the possible use of hydrogen as a means for maximum solar energy potential fulfilment. While some studies consider a hydrogen future for the UAE, the focus is only on official targets and cost analysis, or the use of energy from photovoltaics and nuclear plants only for hydrogen production [

21,

22,

23]. In addition, hydrogen production and utilization are confronted with a spatial gap which infrastructure can solve [

9], but the United Arab Emirates’ infrastructure is yet to be analyzed with a full plan for hydrogen delivery and transport. Thus, a clear gap between renewable energy application and hydrogen supply chain is present in the case of the United Arab Emirates.

Therefore, this study aims to bridge this gap by using the excess energy from two different scenarios of large-scale solar energy application in the UAE for hydrogen production for the purpose of export, by comparing electricity and hydrogen production from PV and CSP and analyzing two different delivery pathways while examining the UAE’s current infrastructure and highlighting the constraints. This will provide an adequate and detailed model for hydrogen production from solar technologies in the UAE with a well-to-ship supply chain for the delivery of hydrogen from plants to ports. The resultant predicted income from hydrogen sales would make large-scale solar energy application feasible, while keeping the UAE as a major energy exporter in the market. This paper also proposes some solutions to the limitations in the UAE’s infrastructure capabilities to deliver the produced hydrogen, and analyzes how this will affect the hydrogen supply chains.

2. Materials and Methods

This study investigates the technical potential of hydrogen production from excess electricity of CSP and PV application in the UAE based on our previous study [

24], where the potential of solar energy in the United Arab Emirates was estimated by analyzing the suitable areas for solar energy application, satisfying a solar irradiance of 5 kWh/m

2/day and higher and a slope lower than 3% based on the National Renewable Energy Laboratory’s (NREL) model for the estimation of rural utility-scale PV and CSP [

25]. Depending on the distance from roads, electrical grid, and water supply, these areas were then divided into three different scenarios after the exclusion of populated and protected areas with 10, 25, and 40 km distances, as 40 km is the furthest distance for a buffer zone from main roads and electrical grid before it crosses the UAE borders, and then this distance was divided into three different scenarios for more simple representation. The results show that the two scenarios with distances of 25 km and 40 km from the mentioned parameters can leave extra electricity for hydrogen production, after satisfying the future electricity demand of the UAE and the 27% green energy obligations for the year 2023 [

6,

26].

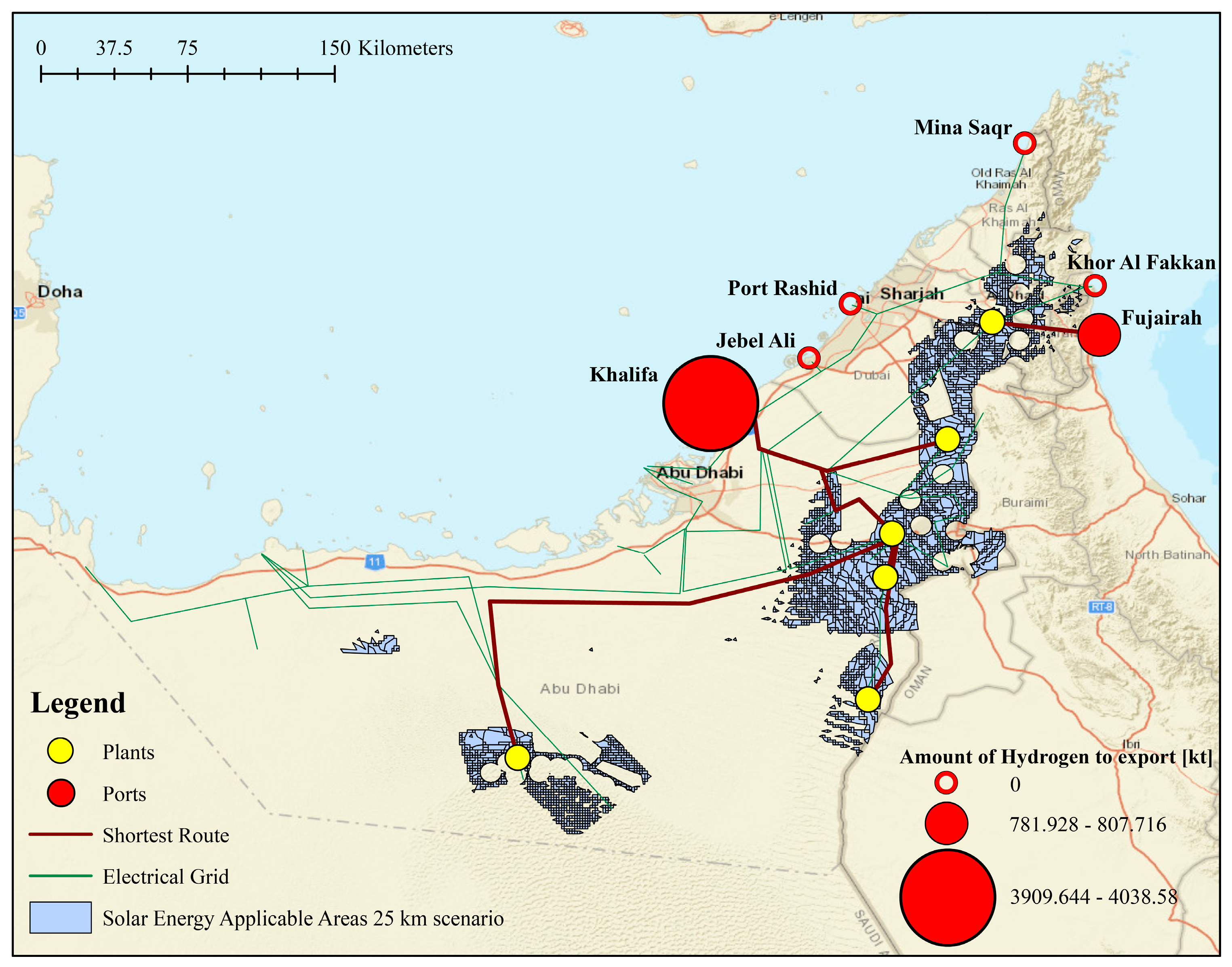

Figure 1 shows the GIS results of the areas of the UAE that are suitable for solar energy application in the 25 km and 40 km scenarios.

In

Figure 2 we explain the flow of the study by using the areas suitable for solar energy production in the UAE to calculate PV and CSP potentials to having the final amounts of liquid hydrogen ready for export.

The equation used to evaluate the UAE’s technical potential of solar energy in MWh is derived from the NREL’s technical report as follows [

25]:

The CSP system assumed in our study is a tower system with dry cooling, with salt as a heat fluid, coupled with a 10-h thermal storage and a solar multiple of 2.4. The power density of this system is 14.9 MW/km

2 according to NREL’s module [

27]. Following the assessments of NREL, a region capacity factor of 31.5% is used for areas with 5 kWh/m

2/day irradiance or higher [

25]. As for the PV system, a one-axis tracking collector with the axis of rotation aligned north-south with zero-degree tilt from horizon as per the NREL model for utility-scale photovoltaics was assumed [

25], power density of 30 MW/km

2 is assumed [

28], and the UAE’s capacity factor of 16% is used as per Al Ali et al.’s analysis for PV application in Abu Dhabi [

29].

Table 1 presents the area and expected energy production results after applying all assumptions of both systems in Equation (1).

The hydrogen supply chain model is similar to those of Strachan et al. [

30], Balta-Ozkan et al. [

31], Reuß et al. [

9,

32], and Tlili et al. [

33], where different delivery pathways are compared and travel distances to demand areas are assessed.

This study proposes two delivery pathways based on the location of H

2 electrolyzers. The first pathway allocates hydrogen plants at the same site as solar energy plants; six main locations are chosen for the plants, covering all areas of the UAE suitable for solar energy application, with direct access to the main road grid and electricity transmission lines in the UAE. In this pathway, trucks are assumed to carry the produced hydrogen to the six main seaports for export in the UAE [

34]. Using Geographical Information System (GIS), the shortest distances from plants to ports are analyzed to investigate the applicability of this scenario (road network data from OpenStreetMap [

35] is used).

In the second pathway we place hydrogen plants at the port sites, assuming that the excess electricity from solar plants is transmitted through the electrical transmission lines of the UAE towards export ports, and assuming that 3% of the electricity is lost in the grid for every 1000 km traveled in the selected electricity grid lines of 220 kV and above of the UAE [

36]. To ensure the least loss of electricity possible in the network, GIS is used to optimize the shortest routes that electricity can travel in this scenario. The second pathway also uses the same CSP plants and ports assumed in the first pathway. The layout of the pathway study methodology is shown in

Figure 3.

The network analyst function of GIS is used to carry out the spatial analysis after uploading the road network of the UAE and specifying the use of only main roads and highways where hydrogen trailers are allowed to drive. Similarly, the data of the UAE’s electric grid are inserted, and lines with 220 voltage and above are chosen for the analysis. Then, the six plants and chosen ports are fixed on the map. Finding the closest facility tool is then used to estimate the shortest routes between each plant and each port for both pathways.

As for H

2 production, solid oxide electrolyzers (SOECs) are used where the electrolyte is a solid ceramic membrane. Although it is a less-mature technology than other electrolyzers, such as alkaline and proton exchange membrane (PEM), and has higher investment cost, SOEC promises greater efficiencies [

37]. This electrolyzer is assumed as a higher heating value (HHV), as high-temperature electrolyzers use heat as part of their energy demand [

38], making it a perfect fit for thermal solar technologies such as CSP. SOEC electrolyzers use high-temperature steam electrolysis (HTE) at temperatures in the range of 700 °C to 800 °C [

39]. This is why, when coupled to high-temperature heat sources such as solar thermal plants, this type of steam electrolyzer offers great advantages in both power requirements and heat provided, and the thermal energy storage integrated into the CSP plants ensures that fast load variations over the electrolyzer could be avoided [

40]. The biggest disadvantage of the SOEC electrolyzer is that it is still in the development phase [

41]. Chosen efficiencies for the electrolyzer are explained in

Table 2. When coupled with PV, a heater is required to increase the temperature of water entering the electrolyzer to the needed levels, and an 11.5 kWh [

41] extra energy consumption will be conducted from the PV electricity production for each kg of hydrogen.

For the second pathway, where the hydrogen plants are located at the ports, the SOEC would require extra energy to heat the water at the ports in the amount of 11.5 kWh/kg-H

2 [

41]. Desalinated seawater using reverse osmosis (RO) desalination is assumed as the water source for electrolysis in this scenario, and electrical expenses for water desalination are added to the energy demand of electrolyzers. The energy needed can be determined by multiplying the energy need per cubic meter with the amount of water that is necessary, which is [

42]:

where

(kg/s) is the production rate of hydrogen, M is the molar mass of hydrogen,

is the efficiency of water use, and

is the molar mass of water.

We assume that hydrogen will be transported and exported in liquid form; liquification will be conducted at solar energy sites in the first pathway, and then transported to ports to be shipped overseas, while in the second pathway hydrogen is to be liquified at port sites to then board the H

2 carrier ships. Liquification is assumed to consume 6.78 kWh for each kg of H

2 [

32] that is added to the electricity expenses of the electrolyzer. The Boil Off Gas (BOG) during liquification is neglected in this study.

Table 2.

Electrolyzer efficiencies [

43].

Table 2.

Electrolyzer efficiencies [

43].

| Electrolyzer | Efficiency | Efficiency |

|---|

| SOEC | 39.4 kWh/kg-H2 | 82% |

4. Conclusions

In this study we develop a model to evaluate solar power’s potential for hydrogen production in the United Arab Emirates. We compare hydrogen output from PV and CSP technologies using solid oxide electric cell water electrolyzer technology, and then investigate the UAE’s infrastructure for a H2 supply chain from well to ship in two different pathways depending on the location of the electrolyzers by estimating the shortest routes using Geographical Information System (GIS), while highlighting the constraints in the UAE’s infrastructure and then proposing solutions for these limitations. Produced hydrogen is to be exported as a means of profit to make the investment in large-scale solar energy application in the UAE feasible and set the UAE to become a main green hydrogen exporter in the future.

We have found that the integration of concentrated solar power plants coupled with SOEC electrolyzers for hydrogen production at solar plant sites is the most favorable way to utilize areas suitable for solar energy application in the UAE for large-scale solar hydrogen production. Although PV technology shows an advantage in energy potential, with 42 GWh/km2 compared to 41.1 GWh/km2 for CSP, the production of hydrogen from SOEC coupled to CSP plants at the same sites brings about over 1.1 extra megatons of liquid hydrogen to those produced from PV in the same pathway. The second pathway, with electrolyzers positioned at port sites, shows lower levels of hydrogen from both PV and CSP technologies due to the electricity lost in the UAE’s electrical grid and the extra energy demands for water heating.

The results from the two delivery paths also show that four ports can be used for export after delivering the liquid hydrogen by trucks from various solar plants in the first one, providing more flexibility to delivery options. In the second pathway, only the Khalifa and Fujairah ports are chosen as the efficient options for electricity transmission and hydrogen production sites.

The proposed shorter routes made the gap of hydrogen produced in both pathways smaller, to around 0.1 megatons of hydrogen. In addition, a third port is added as a suitable option for hydrogen production in the electrolyzers-at-ports scenario. Even with addressing the UAE’s infrastructure constraints, the first pathway is still more favorable when it comes to hydrogen generation, while the second pathway addresses the water shortage issue of the UAE and results in hydrogen production levels comparable to those in the first pathway.

A future cost analysis to estimate the levelized cost of energy and hydrogen in each scenario and pathway, along with a life cycle assessment of the environmental impacts, is needed to provide a wider perspective on which pathway and technology is a better fit for the UAE and assures higher hydrogen export profits and the lowest harmful emissions.