Integrated Life Cycle Assessment Modelling of Densified Fuel Production from Various Biomass Species

Abstract

1. Introduction

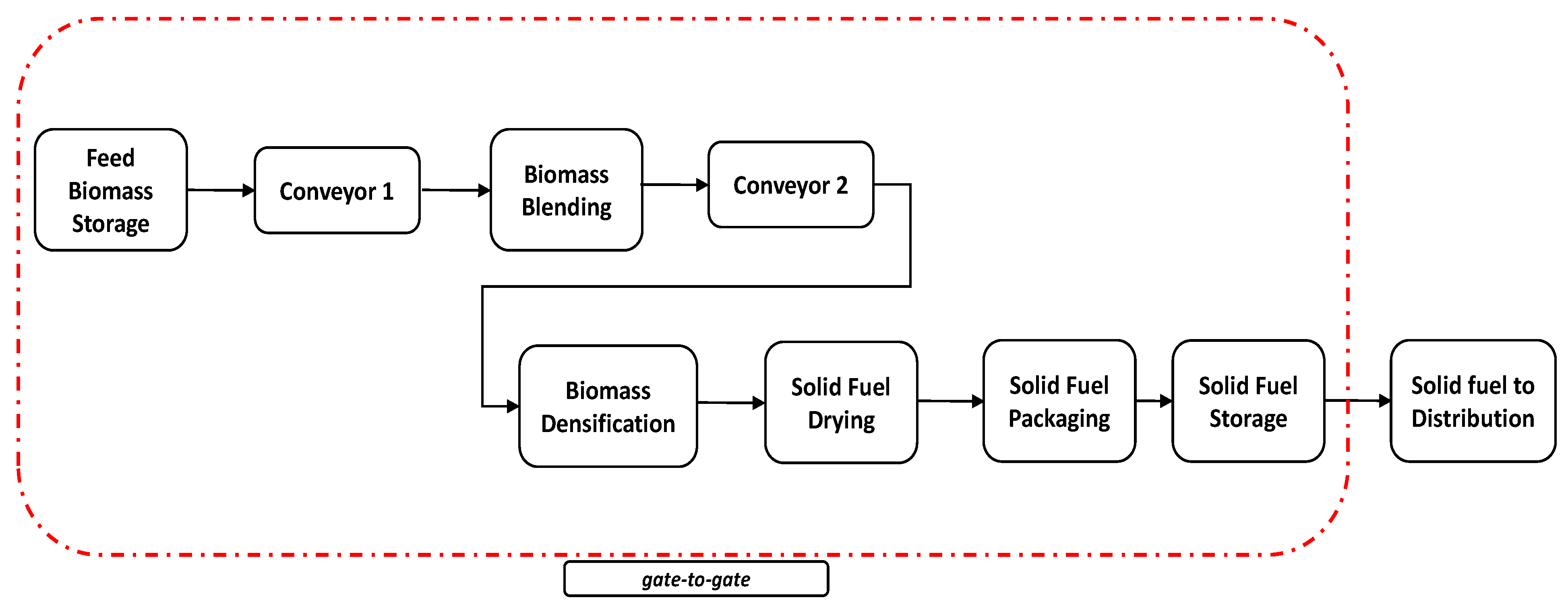

2. Materials and Methods

| Species Source | Biomass | Moisture (%) | Moisture for Densification (%) | Density (kg/m3) | Heating Value (MJ/kg) | Type | Green Density by Compaction (kg/m3) | Relaxed Density (kg/m3) | REF |

|---|---|---|---|---|---|---|---|---|---|

| Pinus spp. | Apapaxco Sawdust | 25 | 12 | 257 | 16.91 | Woody Biomass | 1100 | 990 | [20,21,22,23] |

| Chichicaxtla Sawdust | 25 | 12 | 257 | 16.91 | Woody Biomass | 1100 | 990 | ||

| El Brillante Sawdust | 25 | 12 | 257 | 16.91 | Woody Biomass | 1100 | 990 | ||

| INAFO Sawdust | 25 | 12 | 257 | 16.91 | Woody Biomass | 1100 | 990 | ||

| Ixtlán Sawdust | 25 | 12 | 257 | 16.91 | Woody Biomass | 1100 | 990 | ||

| La Victoria Sawdust | 25 | 12 | 257 | 16.91 | Woody Biomass | 1100 | 990 | ||

| Pinus cooperi | Cooperi pine wood | 25 | 12 | 500 | 20.3 | Woody Biomass | 920 | 828 | [23] |

| Pinus duranguensis | Duranguensis pine | 25 | 12 | 500 | 20.3 | Woody Biomass | 920 | 828 | |

| Pinus teocote | Teocote pine wood | 25 | 12 | 500 | 20.3 | Woody Biomass | 920 | 828 | |

| Pinus spp. | Sawmill slabs Apapaxco | 25 | 12 | 177 | 18.3 | Woody Biomass | 980 | 882 | [6,21,24,25] |

| Sawmill slabs Chichicaxtla | 25 | 12 | 177 | 18.3 | Woody Biomass | 980 | 882 | ||

| Sawmill slabs El Brillante | 25 | 12 | 177 | 18.3 | Woody Biomass | 980 | 882 | ||

| Sawmill slabs INAFO | 25 | 12 | 177 | 18.3 | Woody Biomass | 980 | 882 | ||

| Sawmill slabs Ixtlán | 25 | 12 | 177 | 18.3 | Woody Biomass | 980 | 882 | ||

| Sawmill slabs La Victoria | 25 | 12 | 177 | 18.3 | Woody Biomass | 980 | 882 | ||

| Alnus spp. | Alder wood | 25 | 12 | 450 | 18.9 | Woody Biomass | 886 | 797.4 | [26,27] |

| Ochroma pyramidale | Balsa wood | 25 | 12 | 130 | 16 | Woody Biomass | 900 | 810 | [26] |

| Ceiba pentandra | Ceiba wood | 25 | 12 | 230 | 17.78 | Woody Biomass | 800 | 716 | [28] |

| Hevea brasiliensies | Rubberwood | 25 | 12 | 560 | 19.4 | Woody Biomass | 1089 | 980.1 | [29] |

| Agave salmiana | Agave bagasse | 50 | 17 | 160 | 16.8 | Agro-Residue | 950 | 855 | [30,31,32] |

| Saccharum officinarum | Sugarcane bagasse | 50 | 17 | 173 | 19 | Agro-Residue | 1022 | 919.8 | [19] |

| Malus domestica | Apple bagasse | 50 | 17 | 150 | 17.9 | Agro-Residue | 950 | 855 | [31,32] |

| Oryza sativa | Rice husks | 15 | 8 | 354 | 16 | Agro-Residue | 796 | 696 | [19] |

| Hordeum vulgare | Barley husks | 15 | 8 | 350 | 15.6 | Agro-Residue | 705 | 687 | [20] |

| Triticum aestivum | Wheat straw | 15 | 8 | 62.75 | 17.2 | Agro-Residue | 699 | 629.1 | [33] |

| Cenchurs echinatus | Sandbur grass | 50 | 17 | 100 | 16.9 | Grasses | 850 | 765 | [34,35] |

| Rottboellia cochinchinensis | Itchgrass | 50 | 17 | 100 | 16.9 | Grasses | 850 | 765 | |

| Panicum maximum | Guinea grass | 50 | 17 | 100 | 16.9 | Grasses | 850 | 765 | |

| Pennisetum purpureum | Elephant grass | 50 | 17 | 100 | 16.3 | Grasses | 850 | 765 | |

| Coffea arabica | Coffee pulp | 50 | 17 | 740.35 | 18.2 | Agro-Residue | 1110 | 999 | [36,37] |

| Zea mays | Corn stover | 15 | 8 | 80.24 | 18 | Agro-Residue | 842 | 757.8 | [33] |

| Sorghum bicolor | Sweet sorghum stalks | 15 | 8 | 59.3 | 18 | Agro-Residue | 559.9 | 503.91 | [38,39] |

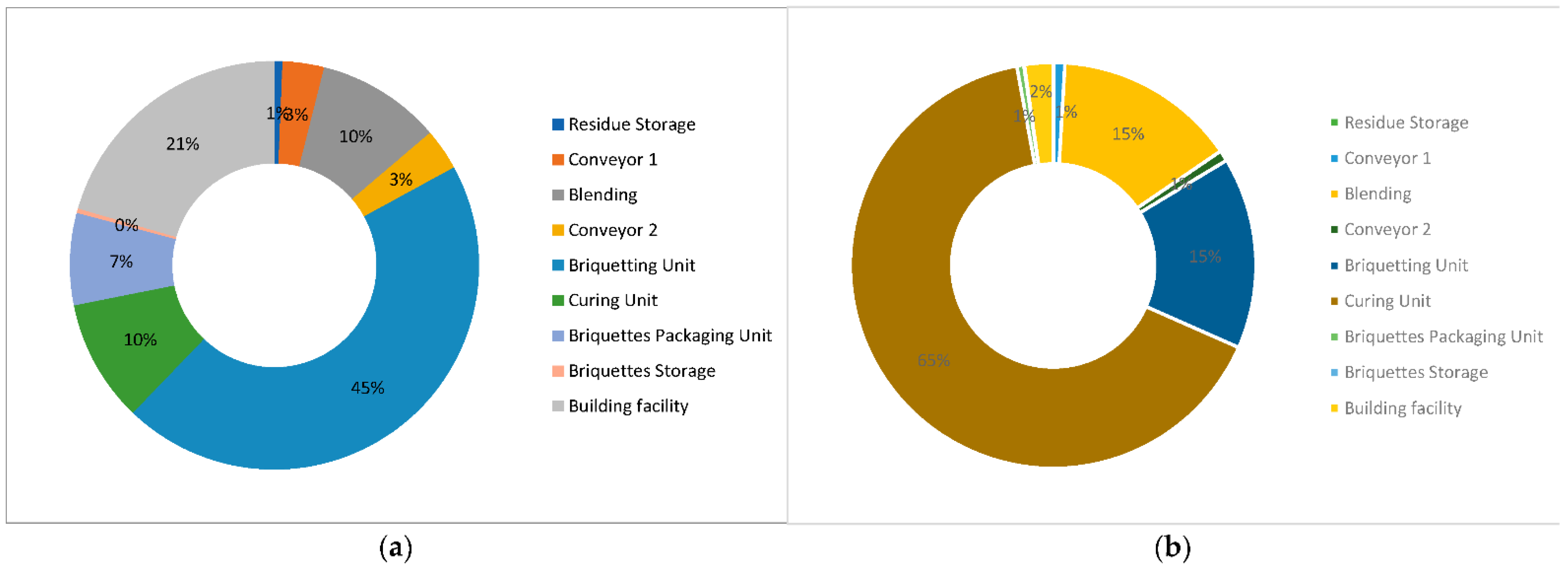

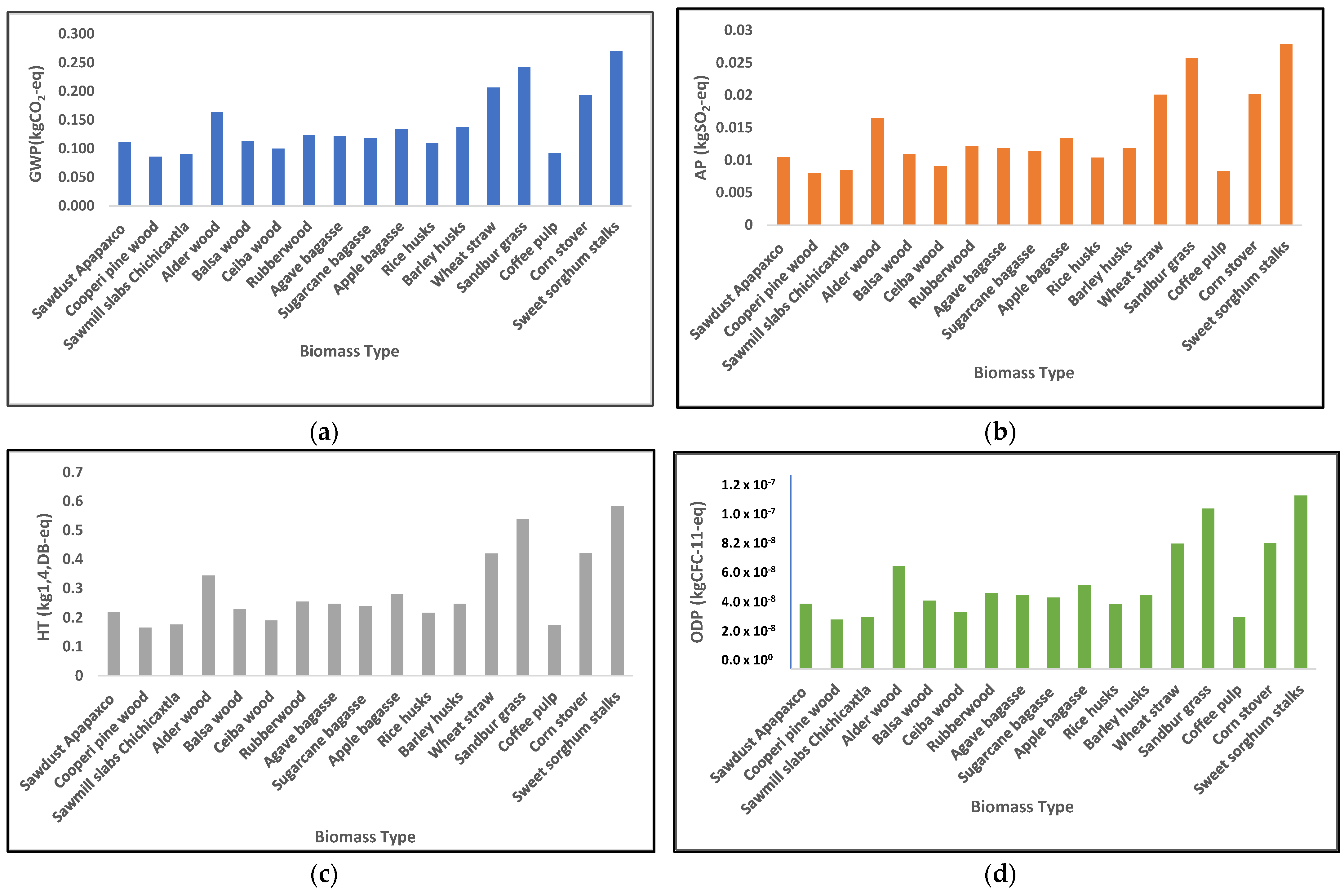

3. Results and Discussion

3.1. Life Cycle Energy and Carbon Emissions from Densification of Various Biomass Species

3.1.1. Life Cycle Environmental Impact Assessment

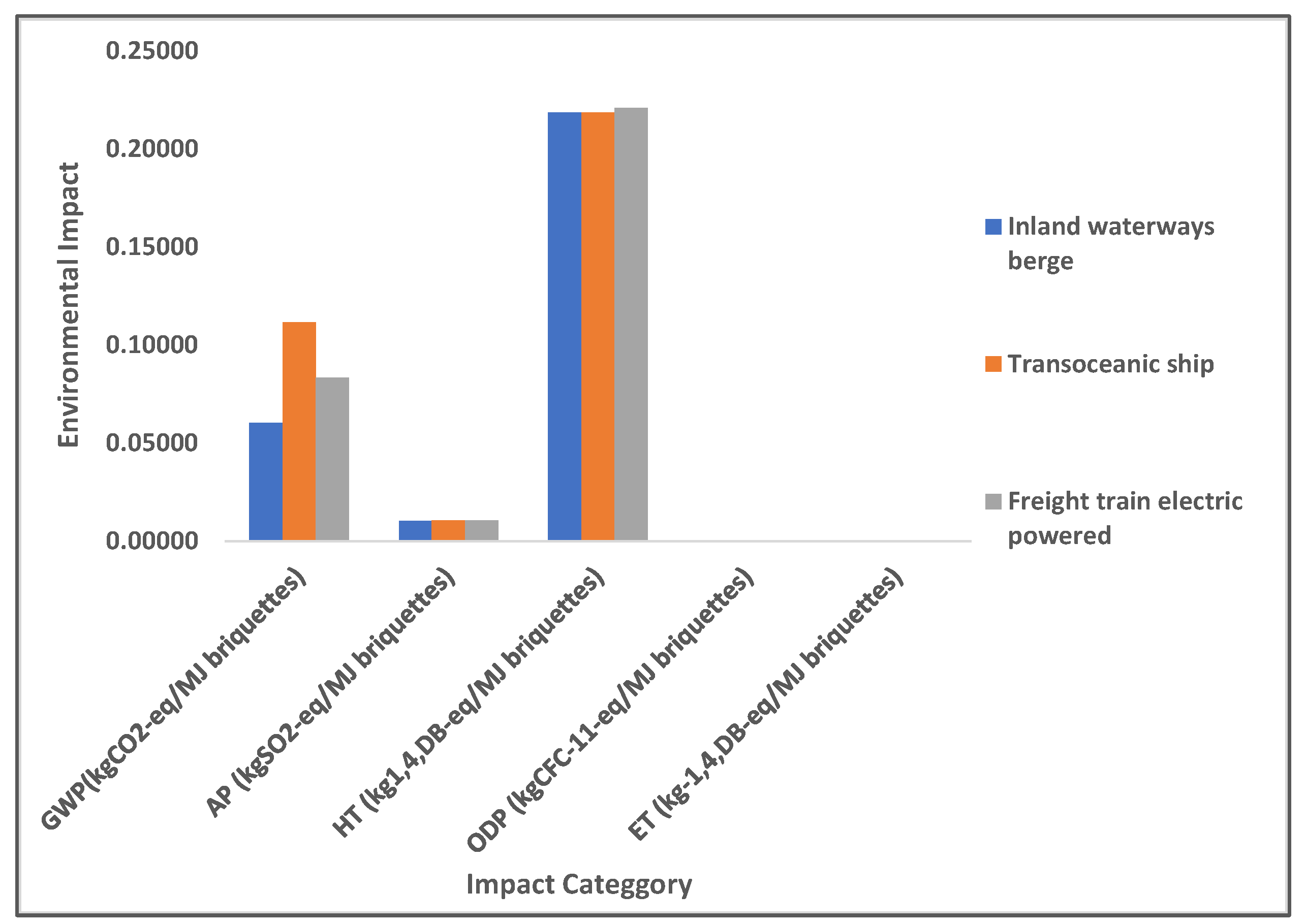

3.1.2. Sensitivity Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alemán-nava, G.S.; Ambientales, C.D.B.; Latina, A. On the Map Bioenergy in Mexico: Status and perspective. Biofuels Bioprod. Bioref. 2014, 9, 8–20. [Google Scholar] [CrossRef]

- Honorato-salazar, J.A.; Sadhukhan, J. Food and Bioproducts Processing Annual biomass variation of agriculture crops and forestry residues, and seasonality of crop residues for energy production in Mexico. Food Bioprod. Process. 2019, 119, 1–19. [Google Scholar] [CrossRef]

- Sadhukhan, J. Net zero electricity systems in global economies by life cycle assessment (LCA) considering ecosystem, health, monetization, and soil CO2 sequestration impacts. Renew. Energy 2022, 184, 960–974. [Google Scholar] [CrossRef]

- Sadhukhan, J.; Martinez-hernandez, E.; Amezcua-allieri, M.A.; Aburto, J. Bioresource Technology Reports Economic and environmental impact evaluation of various biomass feedstock for bioethanol production and correlations to lignocellulosic composition. Bioresour. Technol. Rep. 2019, 7, 100230. [Google Scholar] [CrossRef]

- Vusic, Z.; Vujanic, D.; Pešic, F.; Šafran, K.; Jurišic, B.; Zecic, V. Variability of Normative Properties of Wood Chips and Implication to Quality control. Energies 2021, 14, 3789. [Google Scholar] [CrossRef]

- Marreiro, H.M.; Peruchi, R.S.; Lopes, R.M.; Andersen, S.L.; Eliziário, S.A.; Rotella Junior, P. Empirical Studies on Biomass Briquette Production: A Literature Review. Energies 2021, 14, 8320. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A review of biomass densifi cation systems to develop uniform feedstock commodities for bioenergy application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Tabil, L.G.; Song, Y.; Iroba, K.L.; Meda, V. Impact of process conditions on the density and durability of wheat, oat, canola, and barley straw briquettes. Bioenergy Res. 2015, 8, 388–401. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Biosolids and microalgae as alternative binders for biomass fuel briquetting. Fuel 2017, 194, 339–347. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Factors affecting strength and durability of densified biomass products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Ramírez-Ramírez, M.A.; Carrillo-Parra, A.; Ruíz-Aquino, F.; Pintor-Ibarra, L.F.; González-Ortega, N.; Orihuela-Equihua, R.; Carrillo-Ávila, N.; Luján-Álvarez, C.; Rutiaga-Quinones, J.G. Valorization of briquettes fuel using Pinus spp. sawdust from five regions of Mexico. BioResources 2021, 16, 2249–2263. [Google Scholar] [CrossRef]

- Zimon, D.; Woźniak, J.; Domingues, P.; Ikram, M.; Kuś, H. Proposition of Improving Selected Logistics Processes of Pellet Production. Int. J. Qual. Res. 2014, 15, 387–402. [Google Scholar] [CrossRef]

- Hu, J.; Lei, T.; Wang, Z.; Yan, X.; Shi, X.; Li, Z.; He, X.; Zhang, Q. Economic, environmental and social assessment of briquette fuel from agricultural residues in China e A study on fl at die briquetting using corn stalk. Energy 2014, 64, 557–566. [Google Scholar] [CrossRef]

- Fantozzi, F.; Buratti, C. Life cycle assessment of biomass chains: Wood pellet from short rotation coppice using data measured on a real plant. Biomass Bioenergy 2010, 34, 1796–1804. [Google Scholar] [CrossRef]

- Kylili, A.; Christoforou, E.; Fokaides, P.A. Biomass and Bioenergy Environmental evaluation of biomass pelleting using life cycle assessment. Biomass Bioenergy 2016, 84, 107–117. [Google Scholar] [CrossRef]

- Muazu, R.I.; Borrion, A.L.; Stegemann, J.A. Life cycle assessment of biomass densification systems. Biomass Bioenergy 2017, 107, 384–397. [Google Scholar] [CrossRef]

- Muazu, R.I.; Borrion, A.L.; Stegemann, J.A. Life Cycle Assessment Model for Biomass Fuel Briquetting. Waste Biomass Valorization 2021, 13, 0123456789. [Google Scholar] [CrossRef]

- Black, M.J.; Sadhukhan, J.; Day, K.; Drage, G.; Murphy, R.J. Chemical Engineering Research and Design Developing database criteria for the assessment of biomass supply chains for biorefinery development. Chem. Eng. Res. Des. 2015, 107, 253–262. [Google Scholar] [CrossRef]

- Muazu, R.I.; Stegemann, J.A. Effects of operating variables on durability of fuel briquettes from rice husks and corn cobs. Fuel Process. Technol. 2015, 133, 137–145. [Google Scholar] [CrossRef]

- BinMaster. Bulk Density of Various Materials. 2021. Available online: https://www.binmaster.com/_resources/dyn/files/75343622z9caf67af/_fn/Bulk+Density.pdf (accessed on 9 February 2022).

- RuralTech.org. Chips, Sawdust, Planer Shavings, Bark, and Hog Fuel. 2005. Available online: http://www.ruraltech.org/projects/conversions/briggs_conversions/briggs_ch07/chapter07_combined.pdf (accessed on 9 February 2022).

- Morales-Máximo, M.; García, C.A.; Pintor-Ibarra, L.F.; Alvarado-Flores, J.J.; Velázquez-Martí, B.; Rutiaga-Quiñones, J.G. Evaluation and Characterization of Timber Residues of Pinus spp. as an Energy Resource for the Production of Solid Biofuels in an Indigenous Community in Mexico. Forests 2021, 12, 977. [Google Scholar] [CrossRef]

- Ruiz-Aquino, F.; Ruiz-Ángel, S.; Santiago-García, W.; Fuente-Carrasco, M.E.; Sotomayor-Castellanos, J.R.; Carrillo-Parra, A. Energy Characteristics of Wood and Charcoal of Selected Tree Species in Mexico. Wood Res. 2019, 64, 71–82. [Google Scholar]

- Gendek, A.; Aniszewska, M.; Chwedoruk, K. Bulk Density of Forest Energy Chips; Agriculture No 67 (Agricultural and Forest Engineering); Annals of Warsaw University of Life Sciences—SGGW: Warsaw, Poland, 2016; pp. 101–111. [Google Scholar]

- Iyiola, K. Heat Energy From Value-Added Sawdust Briquettes Of Albizia Zygia. Ethiop. J. Environ. Stud. Manag. 2019, 2. [Google Scholar]

- ToolBox, T.E. Densities of Various Wood Species. 2022. Available online: https://www.engineeringtoolbox.com/wood-density-d_40.html (accessed on 9 February 2022).

- Rizhikovs, J.; Dobele, G. Improvement of the plasticity of grey alder wood and its granulating ability by hydrothermal treatment and upgrading of granulation techniques. In Proceedings of the 17th European Biomass Conference & Exhibition, Hamburg, Germany, 29 June–3 July 2009. [Google Scholar]

- FAO. List of Wood Densities for Tree Species from Tropical America, Africa and Asia. 1997. Available online: https://www.fao.org/3/w4095e/w4095e0c.htm, (accessed on 26 January 2022).

- Wizard, M.W. Rubberwood. It Is a Light Hardwood, and Light to Moderately Heavy. Rubberwood in Its Natural Form, Attack by Fungi and Insects. 2022. Available online: http://mtc.com.my/wizards/mtc_tud/items/report(105).php (accessed on 9 February 2022).

- Flores-Sahagun, T.H.S.; Dos Santos, L.P. Composites: Part A Characterization of blue agave bagasse fibers of Mexico. Compos. Part A Appl. Sci. Manuf. 2013, 45, 153–161. [Google Scholar]

- Sangare, D.; Missaoui, A.; Bostyn, S.; Belandria, V. Modeling of Agave Salmiana bagasse conversion by hydrothermal carbonization (HTC) for solid fuel combustion using surface response methodology. AIMS Energy 2020, 8, 538–562. [Google Scholar] [CrossRef]

- Huerta-cardoso, O.; Durazo-cardenas, I.; Marchante-rodriguez, V.; Longhurst, P.; Coulon, F.; Encinas-oropesa, A. Results in Materials Up-cycling of agave tequilana bagasse-fibres: A study on the effect of fi bre-surface treatments on interfacial bonding and mechanical properties. Results Mater. 2020, 8, 100158. [Google Scholar] [CrossRef]

- Chevanan, N.; Womac, A.R. Bulk density and compaction behavior of knife mill chopped switchgrass, wheat straw, and corn stover. Bioresour. Technol. 2010, 101, 207–214. [Google Scholar] [CrossRef]

- Mcnulty, A.P.B.; Kennedy, S. Density Measurements of Grass by Toluene Displacement and Air Comparison Pycnometry Published by: TEAGASC-Agriculture and Food Development Authority Stable URL. 1982, Volume 21, pp. 75–83. Available online: https://www.jstor.org/stable/25556019 (accessed on 10 February 2022).

- Waliszewska, B.; Grzelak, M.; Gaweł, E.; Spek-Dźwigała, A.; Sieradzka, A.; Czekała, W. Chemical Characteristics of Selected Grass Species from Polish Meadows and Their Potential Utilization for Energy Generation Purposes. Energies 2021, 14, 1669. [Google Scholar] [CrossRef]

- Velasquez, S.; Peña, N.; Bohórquez, J.C.; Bohórquez, J.C.; Published, G. Determination of the complex permittivity of cherry, pulped, green, and roasted coffee using a planar dielectric platform and a coaxial probe between 0.3 and 6 GHz. Int. J. Food Prop. 2018, 21, 1332–1343. [Google Scholar] [CrossRef]

- Cubero-abarca, R.; Moya, R.; Valaret, J. Use of Coffee (coffee arabica) Pulp for the Production of Briquettes and Pellets for Heat Generation. Agric. Sci. 2014, 38, 461–470. [Google Scholar] [CrossRef]

- Ivanova, T.; Muntean, A.; Havrland, B.; Hutla, P. Quality assessment of solid biofuel made of sweet sorghum biomass Quality assessment of solid biofuel made of sweet sorghum biomass. BIO Web Conf. 2018, 10, 02007. [Google Scholar] [CrossRef][Green Version]

- Theerarattananoon, K.; Xu, F.; Wilson, J.; Ballard RMckinney, L.; Staggenborg, S.; Vadlani PPei, Z.J.; Wanga, D. Physical properties of pellets made from sorghum stalk, corn stover, wheat straw, and big bluestem. Ind. Crops Prod. 2011, 33, 325–332. [Google Scholar] [CrossRef]

- Goedkoop, E.; Oele, M.; Leijting, M.; Tommie, J.; Meijer, P. Introduction to LCA with SimaPro. 2016. Available online: https://pre-sustainability.com/ (accessed on 4 July 2019).

- Shie, J.-L.; Chang, C.-Y.; Chen, C.-S.; Shaw, D.-G.; Chen, Y.-H.; Kuan, W.-H. Energy life cycle assessment of rice straw bio-energy derived from potential gasification technologies. Bioresour. Technol. 2011, 102, 6735–6741. [Google Scholar] [CrossRef] [PubMed]

- Alanya-rosenbaum, S.; Bergman, R. Using Life Cycle Assessment to Evaluate Environmental Impacts of Torrefied Briquette Production from Forest Residues. Gen. Tech. Rep. 2018, 262, 2–24. [Google Scholar]

- Bergman, R.; Ganguly, I.; Pierobon, F. A Comparative Life Cycle Assessment of Briquetting Logging Residues and Lumber Manufacturing Coproducts in Western United States. Appl. Eng. Agric. 2018, 34, 10–24. [Google Scholar]

- Wang, X.; Lei, Z.; Yang, T.; Lia, M.; Tian, Z.; Qi, T.; Xin, X.; He, X.; Ajayebi, A.; Yan, X. Life cycle environmental impacts of cornstalk briquette fuel in China. Appl. Energy 2017, 192, 83–94. [Google Scholar] [CrossRef]

- European Union. International Reference Life Cycle Data System; Analysis of Existing Environmental Impact Assessment Methodologies for use in Life Cycle Assessment, 1st ed.; European Commission: Brussels, Belgium, 2010; pp. 1–12. [Google Scholar]

- Martinez, E.; Sadhukhan, J. Modelling to analyse the process and sustainability performance of forestry—based bioenergy systems. Clean Technol. Environ. Policy 2022, 0123456789. [Google Scholar] [CrossRef]

- Milousi, M.; Souliotis, M.; Arampatzis, G.; Papaefthimiou, S. Evaluating the Environmental Performance of Solar Energy Systems Through a Combined Life Cycle Assessment and Cost Analysis. Sustainability 2019, 11, 2539. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ibrahim Muazu, R.; Gadkari, S.; Sadhukhan, J. Integrated Life Cycle Assessment Modelling of Densified Fuel Production from Various Biomass Species. Energies 2022, 15, 3872. https://doi.org/10.3390/en15113872

Ibrahim Muazu R, Gadkari S, Sadhukhan J. Integrated Life Cycle Assessment Modelling of Densified Fuel Production from Various Biomass Species. Energies. 2022; 15(11):3872. https://doi.org/10.3390/en15113872

Chicago/Turabian StyleIbrahim Muazu, Rukayya, Siddharth Gadkari, and Jhuma Sadhukhan. 2022. "Integrated Life Cycle Assessment Modelling of Densified Fuel Production from Various Biomass Species" Energies 15, no. 11: 3872. https://doi.org/10.3390/en15113872

APA StyleIbrahim Muazu, R., Gadkari, S., & Sadhukhan, J. (2022). Integrated Life Cycle Assessment Modelling of Densified Fuel Production from Various Biomass Species. Energies, 15(11), 3872. https://doi.org/10.3390/en15113872