Investigation of the Temperature Sensitivity of 20-Years Old Field-Aged Photovoltaic Panels Affected by Potential Induced Degradation

Abstract

:1. Introduction

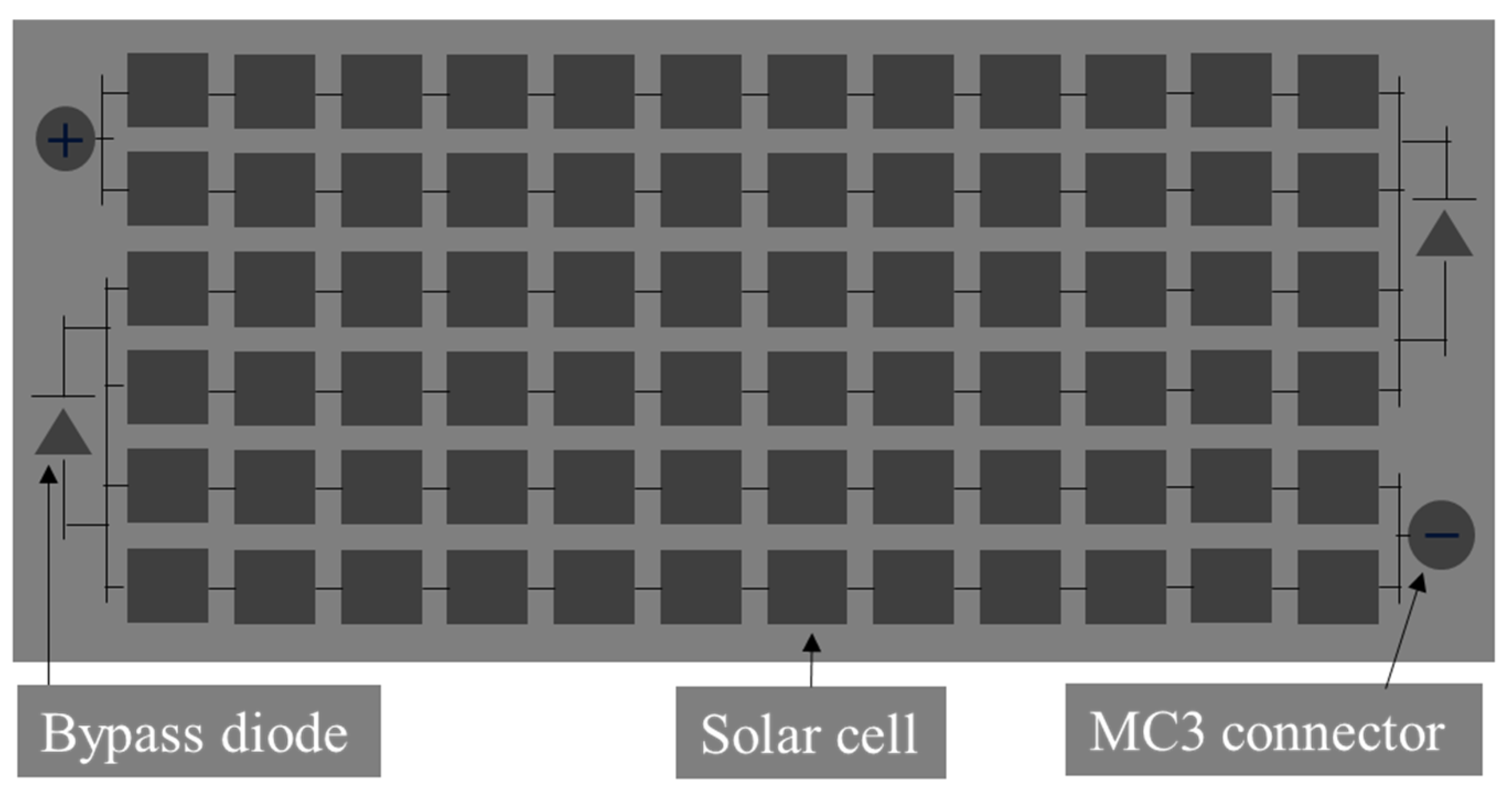

2. Materials and Methods

2.1. I-V Measurements

2.2. Temperature Coefficient Profiling

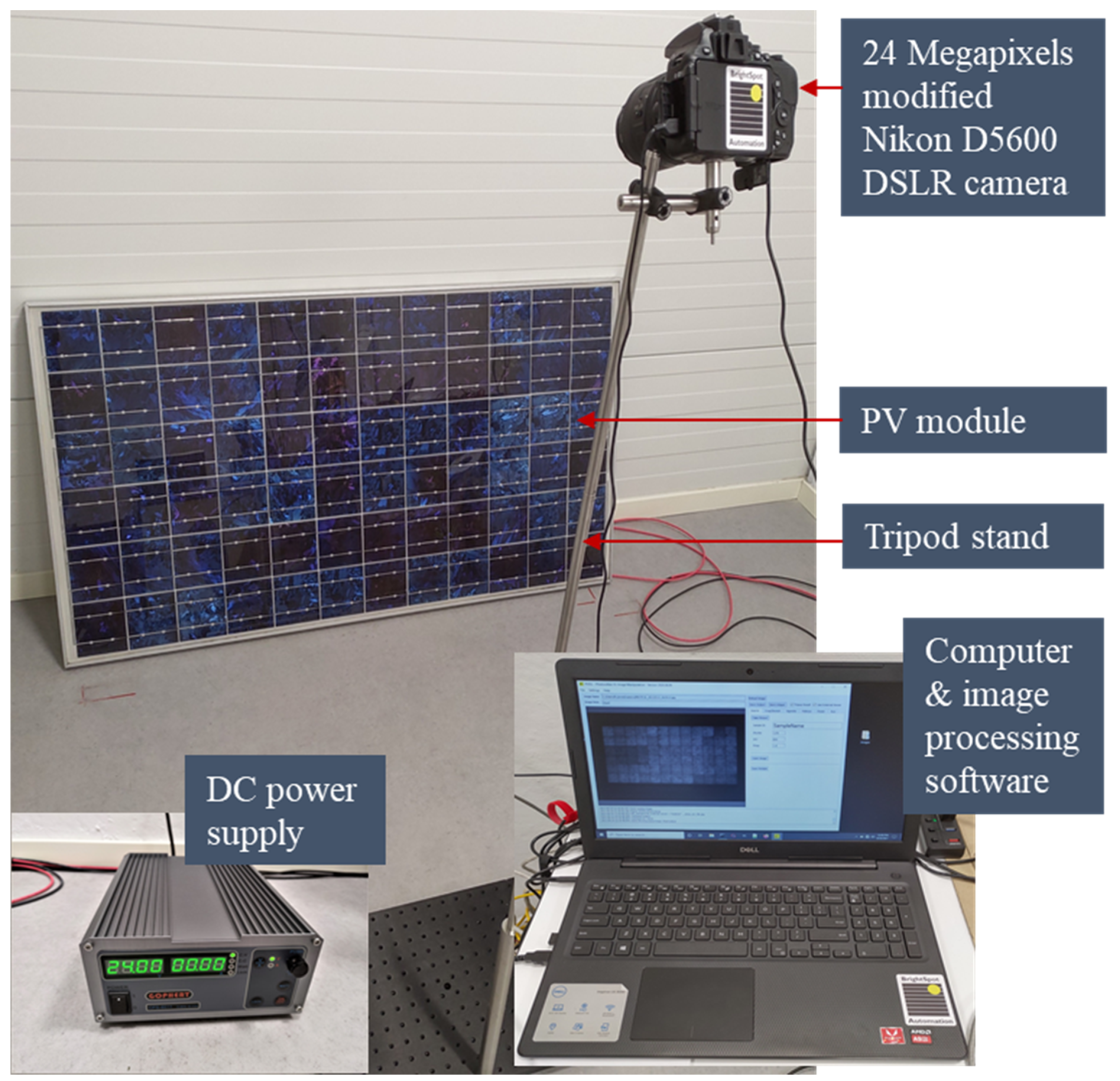

2.3. Electroluminescence (EL) Tomography

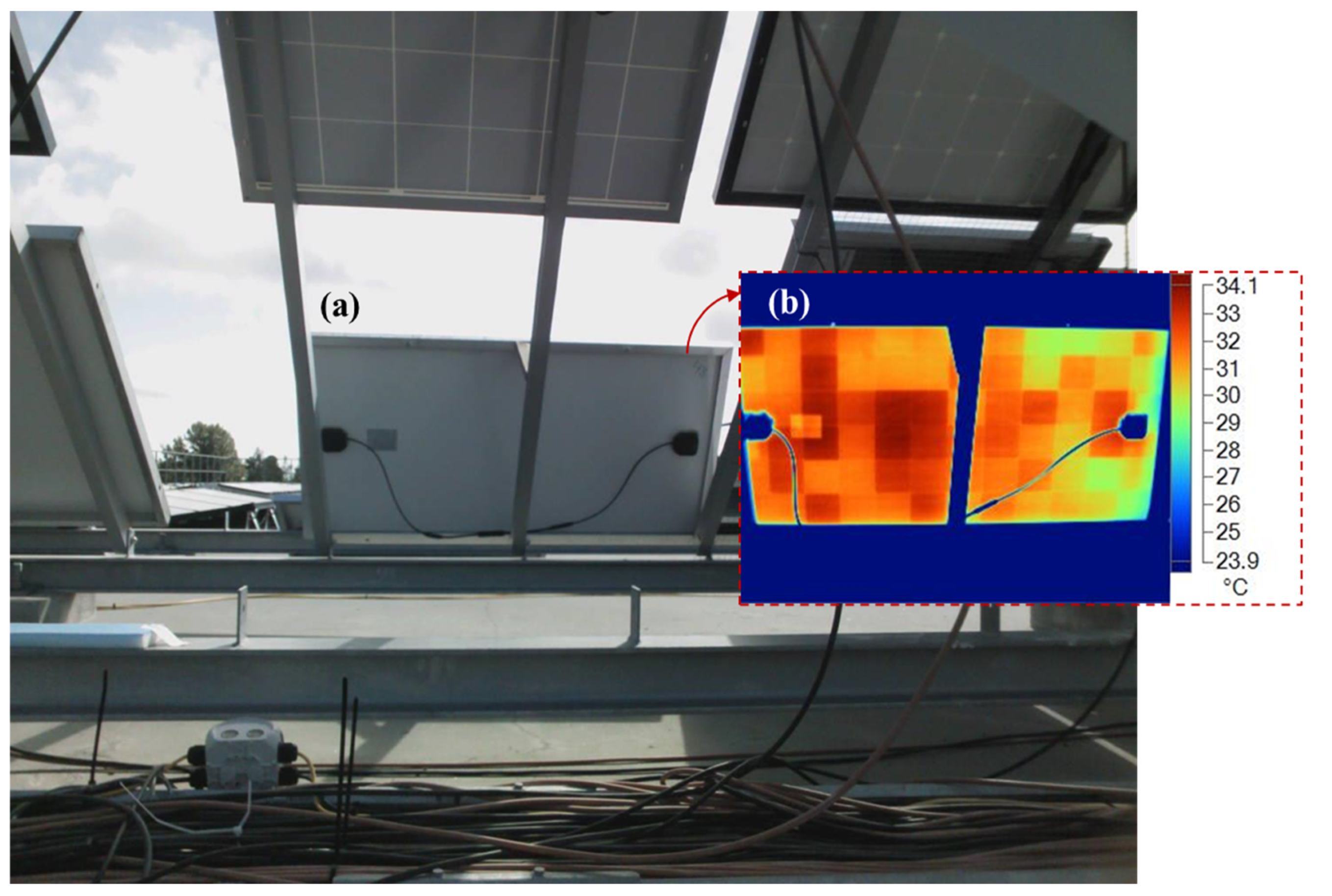

2.4. Infrared (IR) Thermal Imaging

3. Results and Discussion

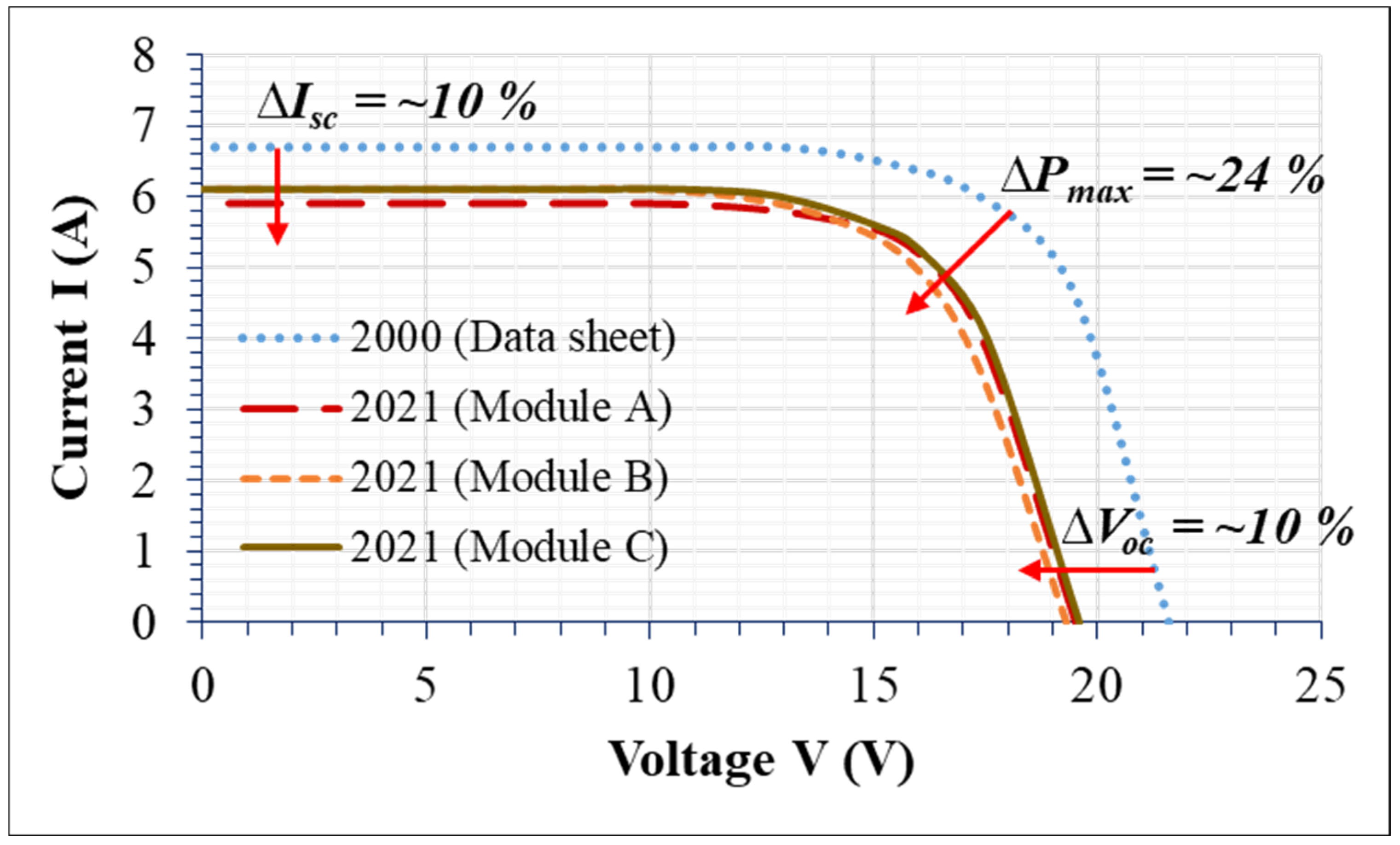

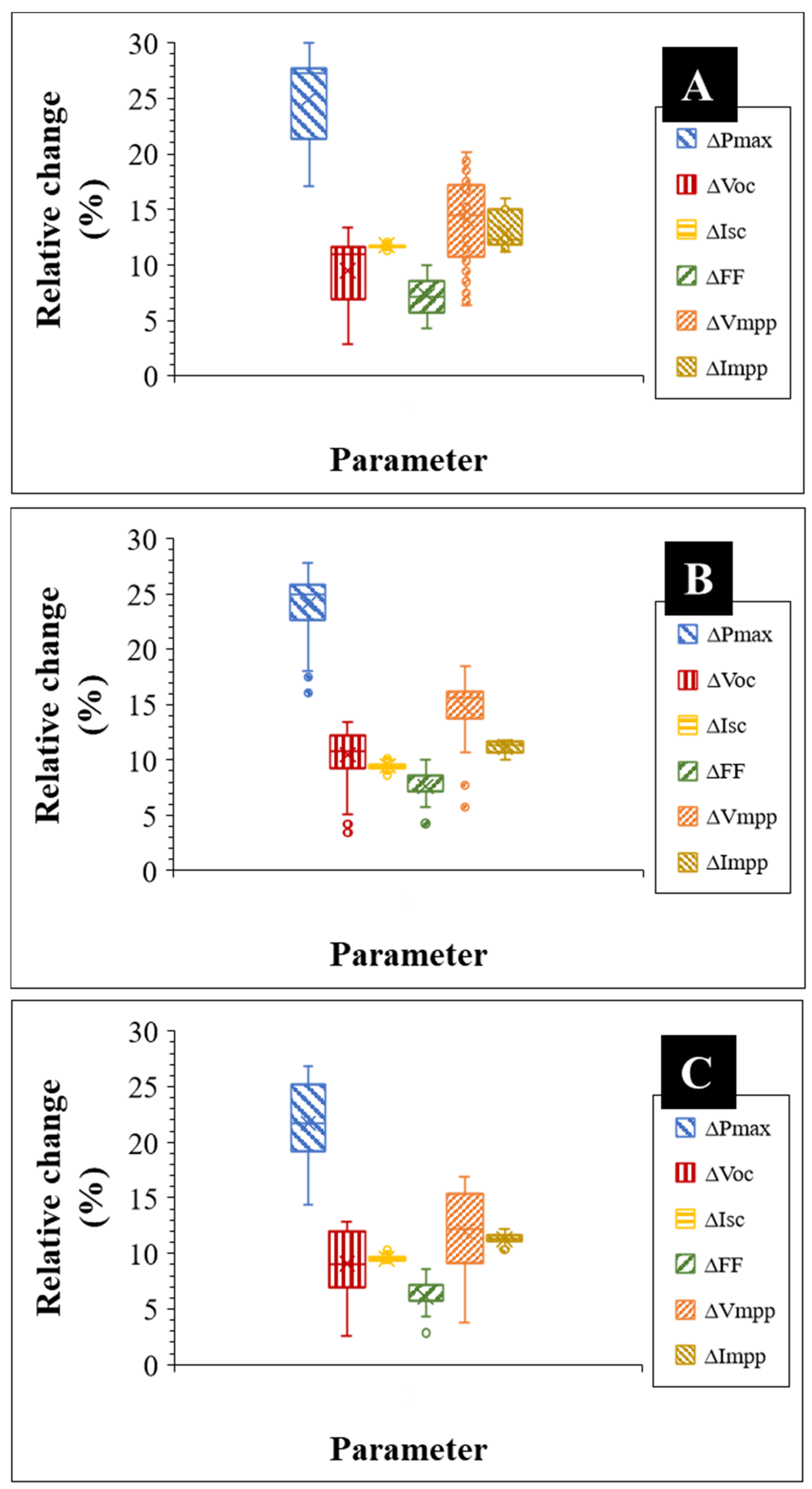

3.1. I-V Characteristics of the PV Panels

3.2. Electroluminescence Characteristics

3.3. IR Thermal Image Characteristics

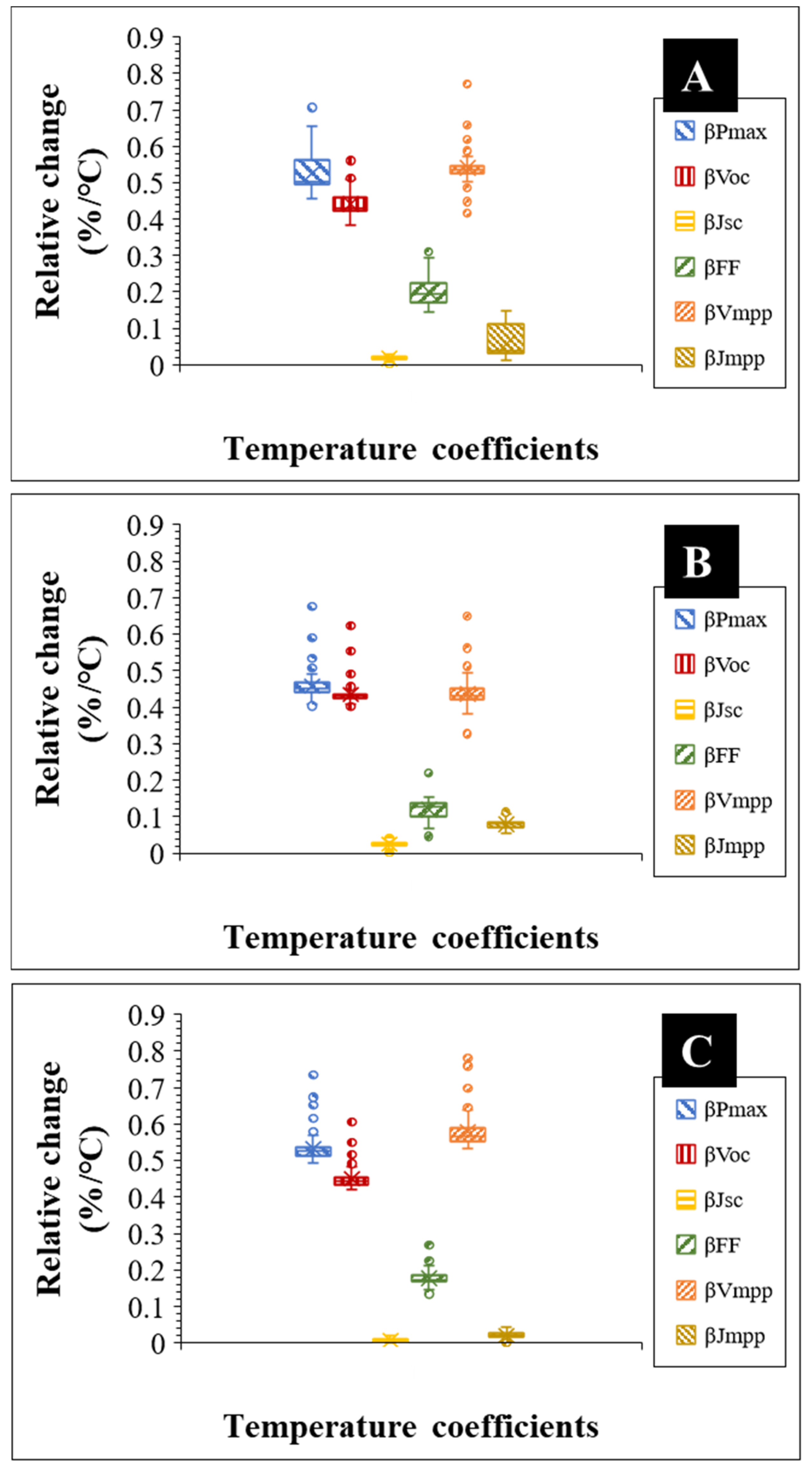

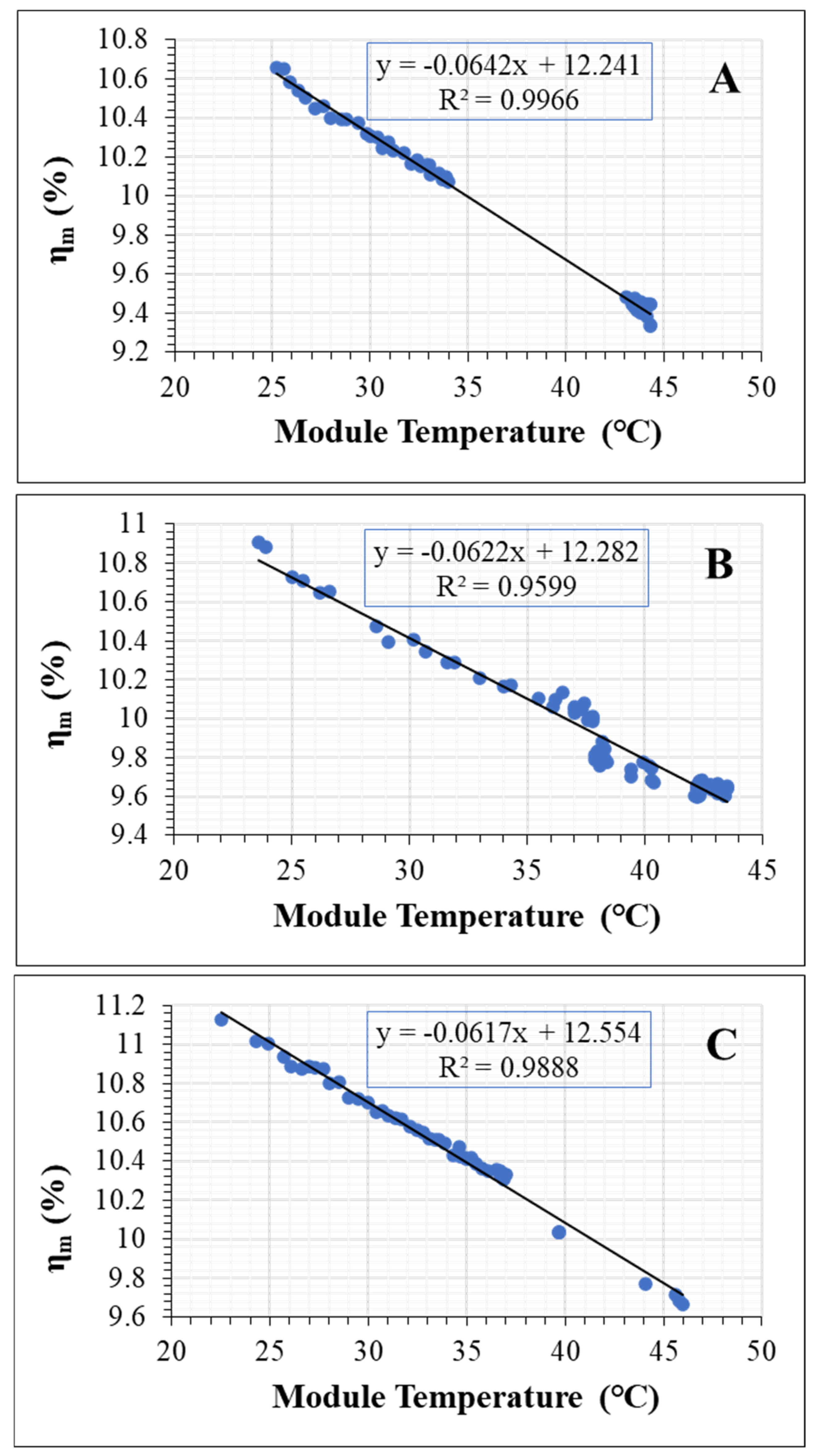

3.4. Temperature Coefficient Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Segbefia, O.K.; Imenes, A.G.; Saetre, T.O. Moisture ingress in photovoltaic modules: A review. Sol. Energy 2021, 224, 889–906. [Google Scholar] [CrossRef]

- Luo, W.; Khoo, Y.S.; Hacke, P.; Naumann, V.; Lausch, D.; Harvey, S.P.; Singh, J.P.; Chai, J.; Wang, Y.; Aberle, A.G.; et al. Potential-induced degradation in photovoltaic modules: A critical review. Energy Environ. Sci. 2017, 10, 43–68. [Google Scholar] [CrossRef] [Green Version]

- Köntges, M.; Kurtz, S.; Packard, C.; Jahn, U.; Berger, K.A.; Kato, K. Performance and Reliability of Photovoltaic Systems: Subtask 3.2: Review of Failures of Photovoltaic Modules: IEA PVPS Task 13: External Final Report IEA-PVPS; International Energy Agency, Photovoltaic Power Systems Programme: Paris, France, 2014. [Google Scholar]

- Hoffmann, S.; Koehl, M. Effect of humidity and temperature on the potential-induced degradation. Prog. Photovolt. 2014, 22, 173–179. [Google Scholar] [CrossRef]

- Hacke, P.; Terwilliger, K.; Smith, R.; Glick, S.; Pankow, J.; Kempe, M.; Bennett, S.K.I.; Kloos, M. System voltage potential-induced degradation mechanisms in PV modules and methods for test. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 000814–000820. [Google Scholar]

- Virtuani, A.; Annigoni, E.; Ballif, C. One-type-fits-all-systems: Strategies for preventing potential-induced degradation in crystalline silicon solar photovoltaic modules. Prog. Photovolt. 2019, 27, 13–21. [Google Scholar] [CrossRef]

- Lausch, D.; Naumann, V.; Breitenstein, O.; Bauer, J.; Graff, A.; Bagdahn, J.; Hagendorf, C. Potential-Induced Degradation (PID): Introduction of a Novel Test Approach and Explanation of Increased Depletion Region Recombination. IEEE J. Photovolt. 2014, 4, 834–840. [Google Scholar] [CrossRef]

- Pingel, S.; Frank, O.; Winkler, M.; Daryan, S.; Geipel, T.; Hoehne, H.; Berghold, J. Potential induced degradation of solar cells and panels. In Proceedings of the 2010 35th IEEE Photovoltaic Specialists Conference, Honolulu, HI, USA, 20–25 June 2010; pp. 002817–002822. [Google Scholar]

- Hylský, J.; Strachala, D.; Vyroubal, P.; Čudek, P.; Vaněk, J.; Vanýsek, P. Effect of negative potential on the extent of PID degradation in photovoltaic power plant in a real operation mode. Microelectron. Reliab. 2018, 85, 12–18. [Google Scholar] [CrossRef]

- Naumann, V.; Geppert, T.; Grosser, S.; Wichmann, D.; Krokoszinski, H.J.; Werner, M.; Hagendorf, C. Potential-induced degradation at interdigitated back contact solar cells. In Proceedings of the 4th International Conference on Crystalline Silicon Photovoltaics (Siliconpv 2014), ‘s-Hertogenbosch, The Netherlands, 25–27 March 2014; Volume 55, pp. 498–503. [Google Scholar]

- Yamaguchi, S.; Yamamoto, C.; Ohshita, Y.; Ohdaira, K.; Masuda, A. Influence of emitter position of silicon heterojunction photovoltaic solar cell modules on their potential-induced degradation behaviors. Sol. Energy Mater. Sol. Cells 2020, 216, 110716. [Google Scholar] [CrossRef]

- Schütze, M.; Junghänel, M.; Koentopp, M.B.; Cwikla, S.; Friedrich, S.; Müller, J.W.; Wawer, P. Laboratory study of potential induced degradation of silicon photovoltaic modules. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011; pp. 000821–000826. [Google Scholar]

- Kwembur, I.M.; McCleland, J.L.C.; van Dyk, E.E.; Vorster, F.J. Detection of Potential Induced Degradation in mono and multi-crystalline silicon photovoltaic modules. Phys. B—Condens. Matter 2020, 581, 411938. [Google Scholar] [CrossRef]

- Carolus, J.; Tsanakas, J.A.; van der Heide, A.; Voroshazi, E.; de Ceuninck, W.; Daenen, M. Physics of potential-induced degradation in bifacial p-PERC solar cells. Sol. Energy Mater. Sol. Cells 2019, 200, 109950. [Google Scholar] [CrossRef] [Green Version]

- Jahn, U.; Herz, M.; Köntges, M.; Parlevliet, D.; Paggi, M.; Tsanakas, I. Review on Infrared and Electroluminescence Imaging for PV Field Applications: International Energy Agency Photovoltaic Power Systems Programme: IEA PVPS Task 13, Subtask 3.3: Report IEA-PVPS T13-12; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Tsanakas, J.A.; Ha, L.; Buerhop, C. Faults and infrared thermographic diagnosis in operating c-Si photovoltaic modules: A review of research and future challenges. Renew. Sustain. Energy Rev. 2016, 62, 695–709. [Google Scholar] [CrossRef]

- Köntges, M.; Oreski, G.; Jahn, U.; Herz, M.; Hacke, P.; Weiß, K.-A. Assessment of Photovoltaic Module Failures in the Field: International Energy Agency Photovoltaic Power Systems Programme: IEA PVPS Task 13, Subtask 3: Report IEA-PVPS T13-09; International Energy Agency: Paris, France, 2017. [Google Scholar]

- Halm, A.; Schneider, A.; Mihailetchi, V.D.; Koduvelikulathu, L.J.; Popescu, L.M.; Galbiati, G.; Chu, H.F.; Kopecek, R. Potential-induced degradation for encapsulated n-type IBC solar cells with front floating emitter. In Proceedings of the 5th International Conference on Silicon Photovoltaics, SiliconPV 2015, Konstanz, Germany, 25–27 March 2015; pp. 356–363. [Google Scholar]

- Swanson, R.; Cudzinovic, M.; DeCeuster, D.; Desai, V.; Jürgens, J.; Kaminar, N.; Mulligan, W.; Rodrigues-Barbarosa, L.; Rose, D.; Smith, D. The surface polarization effect in high-efficiency silicon solar cells. In Proceedings of the 15th PVSEC, Shanghai, China, 10–15 October 2005. [Google Scholar]

- Naumann, V.; Lausch, D.; Hahnel, A.; Bauer, J.; Breitenstein, O.; Graff, A.; Werner, M.; Swatek, S.; Grosser, S.; Bagdahn, J.; et al. Explanation of potential-induced degradation of the shunting type by Na decoration of stacking faults in Si solar cells. Sol. Energy Mater. Sol. Cells 2014, 120, 383–389. [Google Scholar] [CrossRef]

- Oh, K.S.; Bae, S.; Lee, K.J.; Kim, D.; Chan, S.I. Mitigation of potential-induced degradation (PID) based on anti-reflection coating (ARC) structures of PERC solar cells. Microelectron. Reliab. 2019, 100, 113462. [Google Scholar] [CrossRef]

- Masuda, A.; Akitomi, M.; Inoue, M.; Okuwaki, K.; Okugawa, A.; Ueno, K.; Yamazaki, T.; Hara, K. Microscopic aspects of potential-induced degradation phenomena and their recovery processes for p-type crystalline Si photovoltaic modules. Curr. Appl. Phys. 2016, 16, 1659–1665. [Google Scholar] [CrossRef]

- Islam, M.A.; Hasanuzzaman, M.; Rahim, N.A. Investigation of the potential induced degradation of on-site aged polycrystalline PV modules operating in Malaysia. Measurement 2018, 119, 283–294. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, X.L.; Yang, H.; He, W.S.; Chen, Z.L.; Xu, L.H.; Song, D.Y. Potential-induced degradation: Recombination behavior, temperature coefficients and mismatch losses in crystalline silicon photovoltaic power plant. Sol. Energy 2019, 188, 258–264. [Google Scholar] [CrossRef]

- Dupré, O.; Vaillon, R.; Green, M.A. Physics of the temperature coefficients of solar cells. Solar energy materials and solar cells. Sol. Energy Mater. Sol. Cells 2015, 140, 92–100. [Google Scholar] [CrossRef]

- Dubey, R.; Batra, P.; Chattopadhyay, S.; Kottantharayil, A.; Arora, B.M.; Narasimhan, K.; Vasi, J. Measurement of temperature coefficient of photovoltaic modules in field and comparison with laboratory measurements. In Proceedings of the 2015 IEEE 42nd Photovoltaic Specialist Conference (PVSC), New Orleans, LA, USA, 14–19 June 2015; pp. 1–5. [Google Scholar]

- Kaden, T.; Lammers, K.; Moller, H.J. Power loss prognosis from thermographic images of PID affected silicon solar modules. Sol. Energy Mater. Sol. Cells 2015, 142, 24–28. [Google Scholar] [CrossRef]

- Mattei, M.; Notton, G.; Cristofari, C.; Muselli, M.; Poggi, P. Calculation of the polycrystalline PV module temperature using a simple method of energy balance. Renew. Energy 2006, 31, 553–567. [Google Scholar] [CrossRef]

- Skoplaki, E.; Palyvos, J.A. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- King, D.L.; Kratochvil, J.A.; Boyson, W.E. Temperature coefficients for PV modules and arrays: Measurement methods, difficulties, and results. In Proceedings of the Conference Record of the Twenty Sixth IEEE Photovoltaic Specialists Conference-1997, Anaheim, CA, USA, 29 September–3 October 1997; pp. 1183–1186. [Google Scholar]

- Evans, D.; Florschuetz, L. Terrestrial concentrating photovoltaic power system studies. Sol. Energy 1978, 20, 37–43. [Google Scholar] [CrossRef]

- Segbefia, O.K.; Imenes, A.G.; Sætre, T.O. Outdoor Fault Diagnosis of Field-Aged Multicrystalline Silicon Solar Modules. In Proceedings of the 37th EU PVSEC, Lisbon, Portugal, 7–11 September 2020. [Google Scholar]

- Segbefia, O.K.; Paudyal, B.R.; Burud, I.; Sætre, T.O. Temperature Coefficients of Photovoltaic Modules under Partial Shading Conditions. In Proceedings of the 38th EU PVSEC, Lisbon, Portugal, 6–10 September 2021; pp. 1180–1186. [Google Scholar]

- Islam, M.A.; Hasanuzzaman, M.; Rahim, N.A. A comparative investigation on in-situ and laboratory standard test of the potential induced degradation of crystalline silicon photovoltaic modules. Renew. Energy 2018, 127, 102–113. [Google Scholar] [CrossRef]

- Green, M.A. General temperature dependence of solar cell performance and implications for device modelling. Prog. Photovolt. Res. Appl. 2003, 11, 333–340. [Google Scholar] [CrossRef]

- Buerhop, C.; Schlegel, D.; Niess, M.; Vodermayer, C.; Weigmann, R.; Brabec, C.J. Reliability of IR-imaging of PV-plants under operating conditions. Sol. Energy Mater. Sol. Cells 2012, 107, 154–164. [Google Scholar] [CrossRef]

- Segbefia, O.K.; Imenes, A.G.; Burud, I.; Sætre, T.O. Temperature profiles of field-aged multicrystalline silicon photovoltaic modules affected by microcracks. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Fort Lauderdale, FL, USA, 20–25 June 2021; pp. 0001–0006. [Google Scholar]

- Cheng, X.; Dong, Y.; Yang, T.; Zhou, T.; Wang, H.; Yu, H. Investigation on Temperature Coefficients of Crystalline Silicon Solar Modules before and after Potential-induced Degradation. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 1942–1945. [Google Scholar]

- Spataru, S.; Hacke, P.; Sera, D.; Packard, C.; Kerekes, T.; Teodorescu, R. Temperature-dependency analysis and correction methods of in situ power-loss estimation for crystalline silicon modules undergoing potential-induced degradation stress testing. Prog. Photovolt. 2015, 23, 1536–1549. [Google Scholar] [CrossRef]

- Green, M.; Emery, K.; Blakers, A. Silicon solar cells with reduced temperature sensitivity. Electron. Lett. 1982, 18, 97–98. [Google Scholar] [CrossRef]

- Dupré, O.; Vaillon, R.; Green, M.A. Experimental assessment of temperature coefficient theories for silicon solar cells. IEEE J. Photovolt. 2015, 6, 56–60. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Robinson, S.; Green, M. Reduced temperature coefficients for recent high-performance silicon solar cells. Prog. Photovolt. Res. Appl. 1994, 2, 221–225. [Google Scholar] [CrossRef]

- Reise, C.; Müller, B.; Moser, D.; Belluardo, G.; Ingenhoven, P. Uncertainties in PV System Yield Predictions and Assessments; IEA: Paris, France, 2018. [Google Scholar]

- Berghold, J.; Koch, S.; Böttcher, A.; Ukar, A.; Leers, M.; Grunow, P. Potential-induced degradation (PID) and its correlation with experience in the field. Photovolt. Int. 2013, 19, 87–93. [Google Scholar]

| PV Module | Pmax (W) | Voc (V) | Isc (A) | Vmpp (V) | Impp (A) | FF (%) | η (%) | |

|---|---|---|---|---|---|---|---|---|

| 2000 (Data sheet) | 100 | 21.6 | 6.7 | 16.7 | 6.0 | 70 | 13.0 | |

| A | 75.0 | 19.5 | 5.9 | 14.3 | 5.2 | 65 | 9.7 | |

| 2021 | B | 75.9 | 19.3 | 6.1 | 14.2 | 5.3 | 65 | 9.9 |

| C | 78.3 | 19.6 | 6.1 | 14.7 | 5.3 | 66 | 10.2 | |

| PV Module | R2 | ||||

|---|---|---|---|---|---|

| ∆Voc | ∆Vmpp | ∆FF | ∆Impp | ∆Isc | |

| A | 0.98 | 0.99 | 0.86 | 0.23 | 0.47 |

| B | 0.98 | 0.98 | 0.57 | 0.55 | 0.17 |

| C | 0.99 | 0.99 | 0.88 | 0.06 | 0.04 |

| PV Module | Temperature (°C) | ∆T (°C) | |

|---|---|---|---|

| TcH | TcL | ||

| A | 36.9 | 29.5 | 7.4 |

| B | 51.3 | 36.7 | 14.6 |

| C | 49.5 | 40.5 | 9.0 |

| PV Module | Temperature Coefficient (%/°C) | |||||

|---|---|---|---|---|---|---|

| βVoc | βJsc | βFF | βηm | βVmpp | βJmpp | |

| A | −0.4 | 0.02 | −0.2 | −0.5 | −0.5 | −0.06 |

| B | −0.4 | 0.03 | −0.1 | −0.5 | −0.4 | −0.09 |

| C | −0.4 | 0.01 | −0.2 | −0.5 | −0.5 | −0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segbefia, O.K.; Sætre, T.O. Investigation of the Temperature Sensitivity of 20-Years Old Field-Aged Photovoltaic Panels Affected by Potential Induced Degradation. Energies 2022, 15, 3865. https://doi.org/10.3390/en15113865

Segbefia OK, Sætre TO. Investigation of the Temperature Sensitivity of 20-Years Old Field-Aged Photovoltaic Panels Affected by Potential Induced Degradation. Energies. 2022; 15(11):3865. https://doi.org/10.3390/en15113865

Chicago/Turabian StyleSegbefia, Oscar Kwame, and Tor Oskar Sætre. 2022. "Investigation of the Temperature Sensitivity of 20-Years Old Field-Aged Photovoltaic Panels Affected by Potential Induced Degradation" Energies 15, no. 11: 3865. https://doi.org/10.3390/en15113865

APA StyleSegbefia, O. K., & Sætre, T. O. (2022). Investigation of the Temperature Sensitivity of 20-Years Old Field-Aged Photovoltaic Panels Affected by Potential Induced Degradation. Energies, 15(11), 3865. https://doi.org/10.3390/en15113865