Study on a Discharge Circuit Prediction Model of High-Voltage Electro-Pulse Boring Based on Bayesian Fusion

Abstract

:1. Introduction

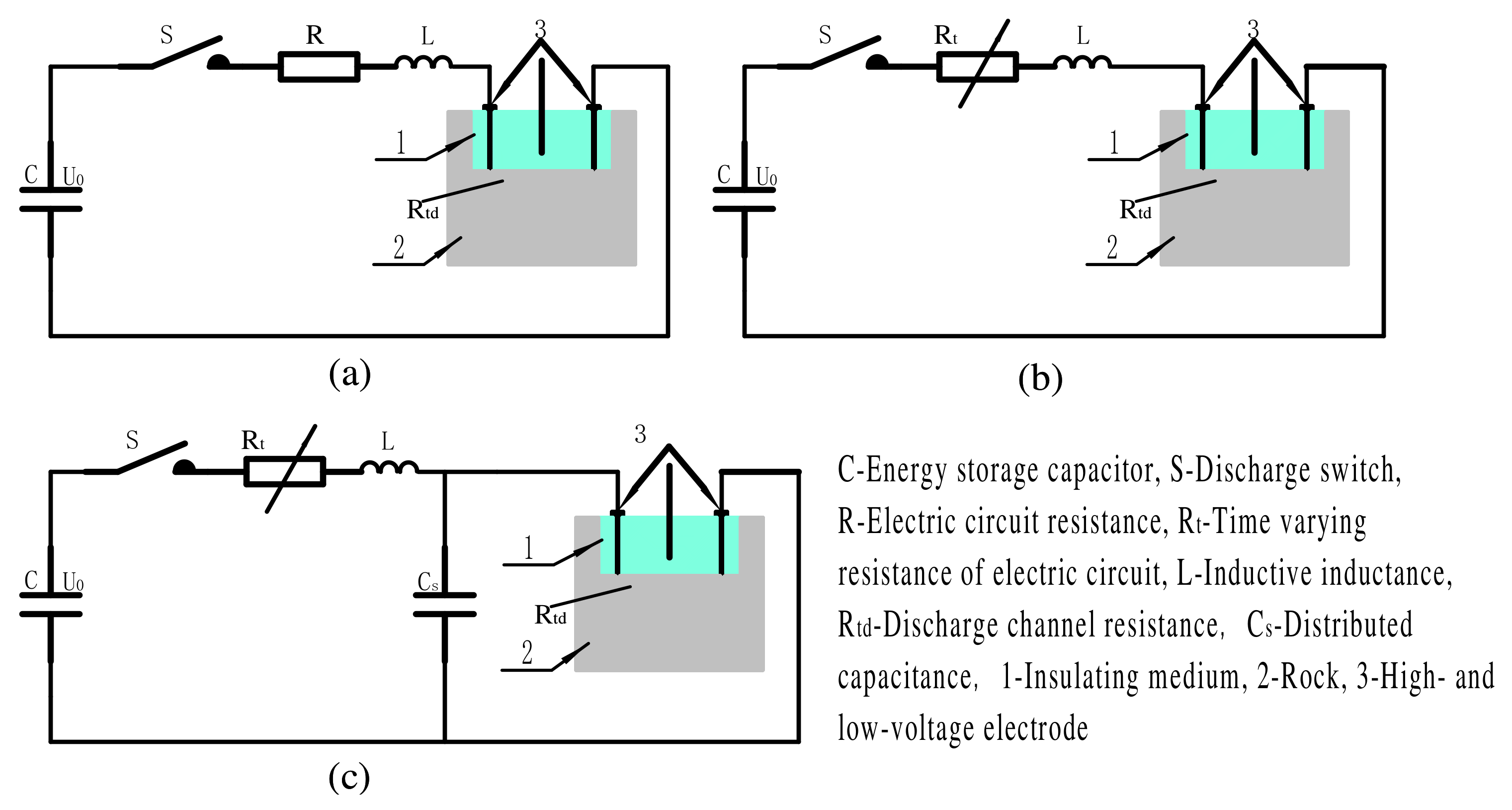

2. Prediction Model of Discharge Circuit in EPB

2.1. RLC Model

2.2. TV-RLC Model

2.3. TV-CRLC Model

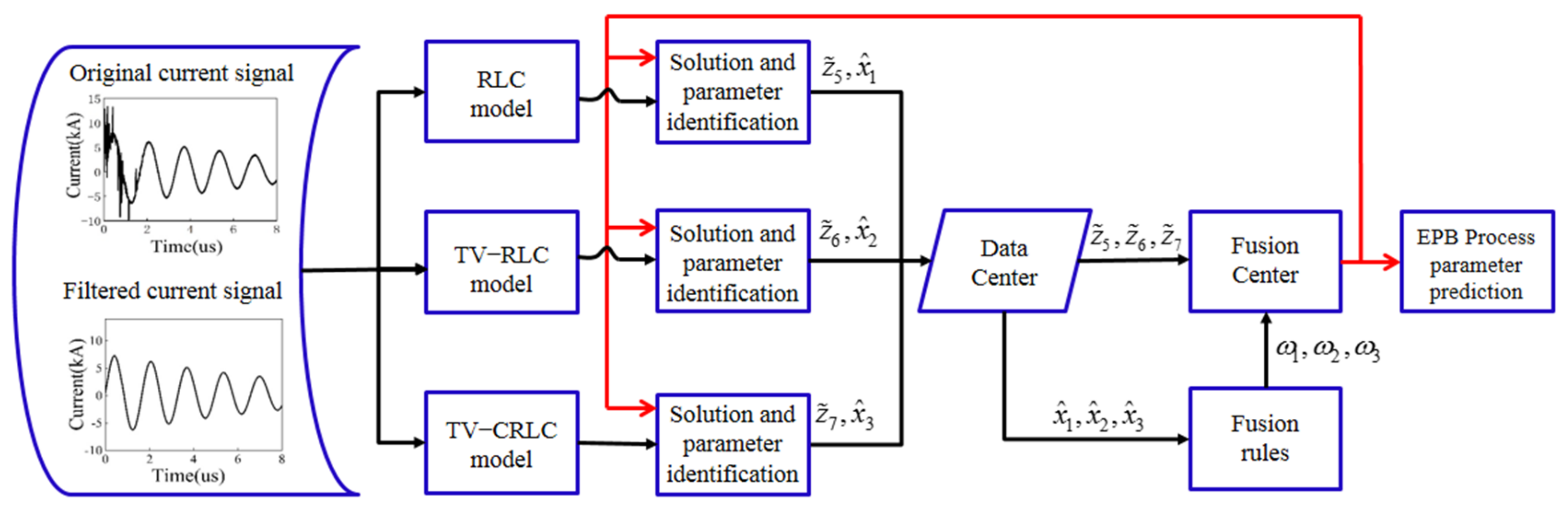

3. Parameter Identification and Bayesian Fusion Algorithm

3.1. Parameter Identification for the Prediction Model

3.2. Fusion Algorithm based on Bayesian Theorem

4. Results and Discussion

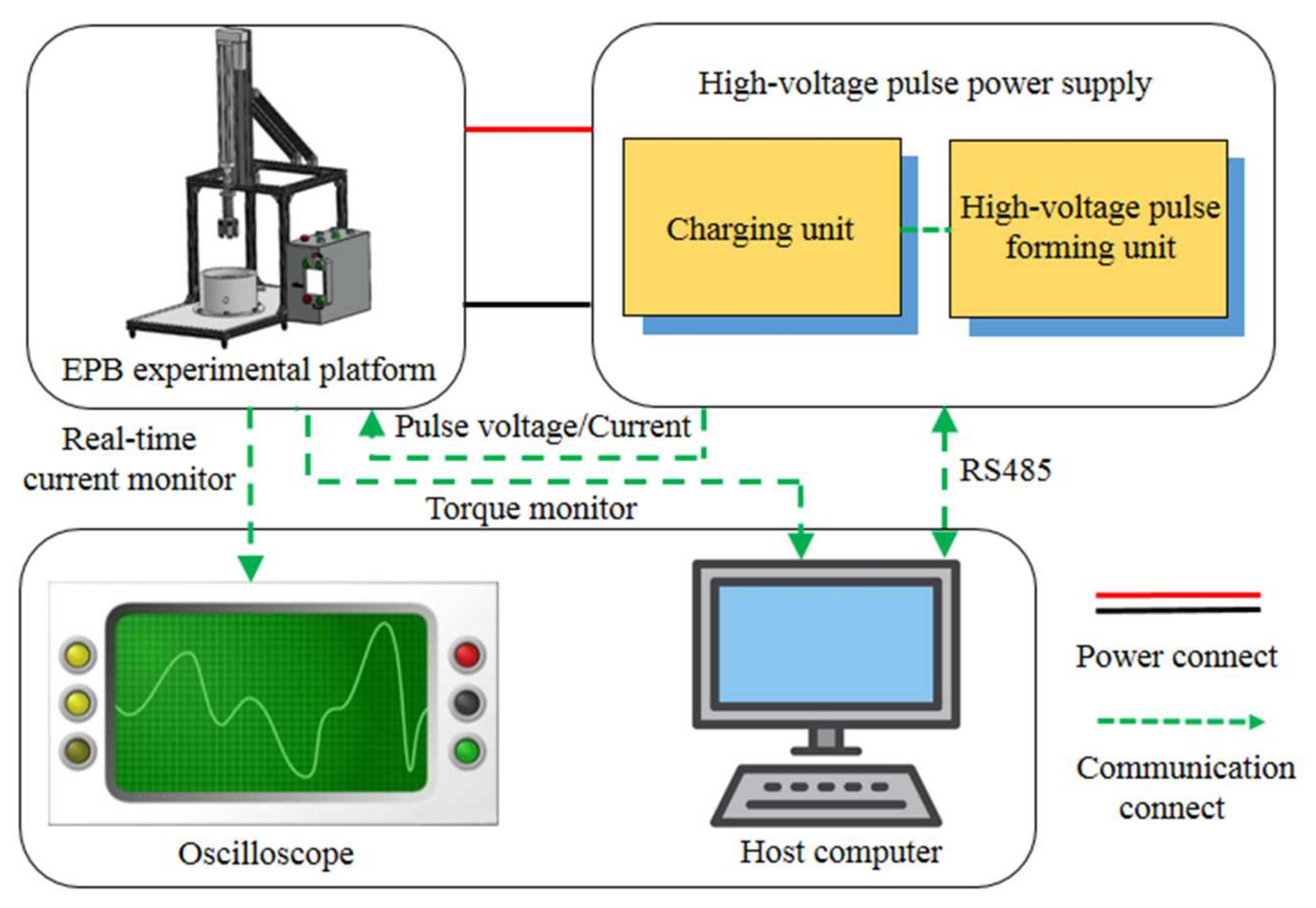

4.1. High-Voltage EPB Process Test

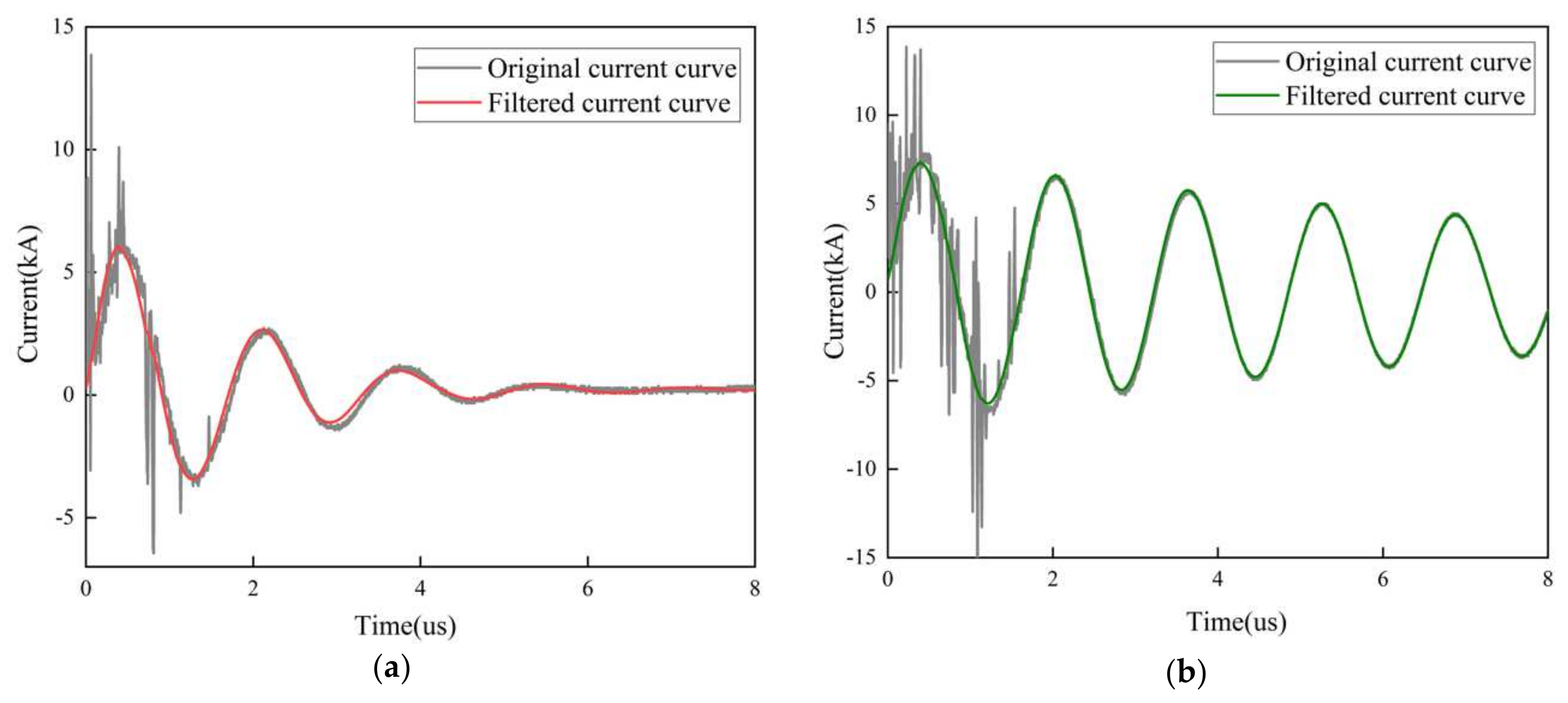

4.2. Parameter Identification Results of EPB Prediction Model

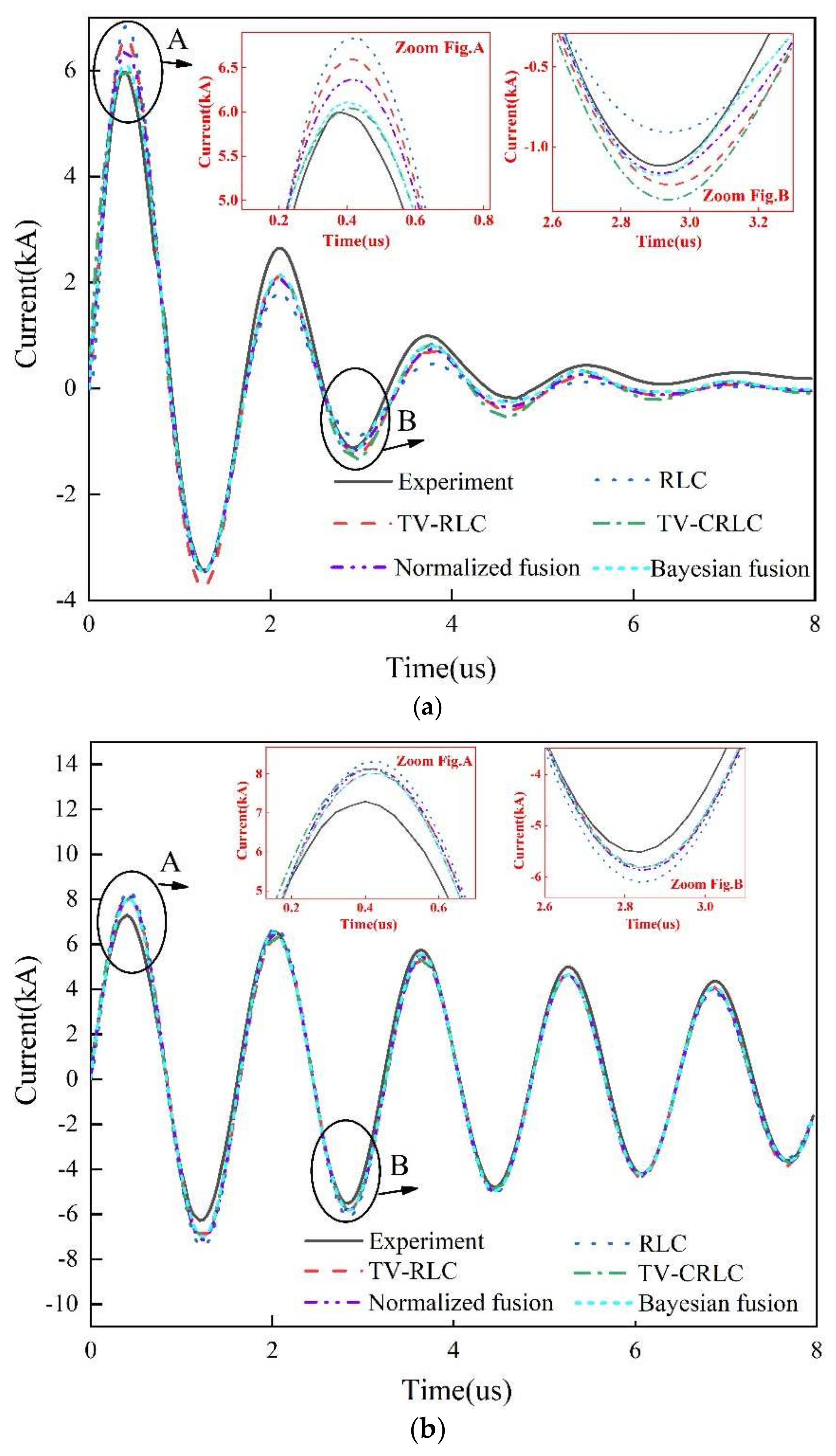

4.3. Model Fusion Results of EPB Prediction Model

5. Conclusions

- The parameters of the RLC, TV-RLC, and TV-CRLC model are identified by PSO-GA. There is a bigger resistance coefficient and a smaller coefficient length parameter of the plasma channel of granite by EPB in comparison with the ones of red sandstone by EPB. The identified parameters are within a reasonable range and are consistent with the actual EPB effects. At the same time, the effective drilling of red sandstone and granite is realized by conducting the EPB experiment.

- TV-CRLC model has the highest prediction accuracy for EPB current, followed by the TV-RLC model, and then the RLC model. The weight of the TV-CRLC model is higher when Bayesian fusion is used for current prediction. Different models have different prediction accuracy distribution in different time intervals. Model fusion is applied to improve the prediction accuracy of process parameters in high-voltage EPB rock-breaking.

- The prediction accuracy based on the Bayesian fusion method is more accurate than that based on the normalization fusion method. Meanwhile, the model fusion method has higher prediction accuracies compared with the single model for EPB process parameters prediction. Compared with the single models for EPB current prediction, the average relative error reduction rate based on Bayesian fusion and current residual normalization fusion method is 25.5% and 9.5%, respectively. The validity of the discharge circuit prediction model based on Bayesian fusion is proved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Diaz, M.B.; Kim, K.Y.; Shin, H.; Zhuang, L. Predicting rate of penetration during drilling of deep geothermal well in Korea using artificial neural networks and real-time data collection. J. Nat. Gas. Sci. Eng. 2019, 67, 225–232. [Google Scholar] [CrossRef]

- Wu, F.; Fan, X.; Liu, J.; Li, X. Analytical interpretation of hydraulic fracturing initiation pressure and breakdown pressure. J. Nat. Gas. Sci. Eng. 2020, 76, 103185. [Google Scholar] [CrossRef]

- Rossi, E.; Adams, B.; Vogler, D.; Rudolf Von Rohr, P.; Kammermann, B.; Saar, M.O. Advanced drilling technologies to improve the economics of deep geo-resource utilization. In Proceedings of the 2nd Applied Energy Symposium: MIT A+ B (MITAB 2020) (virtual), 2020, ETH Zurich, Geothermal Energy & Geofluids, Cambridge, MA, USA, 14–18 August 2020; p. 148. [Google Scholar]

- Schiegg, H.O.; Rødland, A.; Zhu, G.; Yuen, D.A. Electro-pulse-boring (EPB): Novel super-deep drilling technology for low cost electricity. J. Earth Sci. China 2015, 26, 37–46. [Google Scholar] [CrossRef]

- Usov, A.; Tsukerman, V.; Potokin, A.; Ilin, D. The experience in development of technique and technology of electric pulse disintegration of rocks and ores. In REWAS 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 325–332. [Google Scholar]

- Kusaiynov, K.; Nussupbekov, B.R.; Shuyushbayeva, N.N.; Tanasheva, N.K.; Shaimerdenova, K.M.; Khassenov, A.K. On electric-pulse well drilling and breaking of solids. Tech. Phys. 2017, 62, 867–870. [Google Scholar] [CrossRef]

- Yudin, A.S.; Zhurkov, M.Y.; Martemyanov, S.M.; Datskevich, S.Y.; Vazhov, V.F. Electrical discharge drilling of granite with positive and negative polarity of voltage pulses. Int. J. Rock Mech. Min. 2019, 123, 104058. [Google Scholar] [CrossRef]

- Kuznetsova, N.S.; Lopatin, V.V.; Yudin, A.S. Effect of Electro-Discharge Circuit Parameters on the Destructive Action of Plasma Channel in Solid Media. J. Phys. Conf. Ser. 2014, 552, 012029. [Google Scholar] [CrossRef] [Green Version]

- Zhu, X.; Luo, Y.; Liu, W. On the rock-breaking mechanism of plasma channel drilling technology. J. Petrol. Sci. Eng. 2020, 194, 107356. [Google Scholar] [CrossRef]

- Zhu, X.; Luo, Y.; Liu, W.; He, L.; Gao, R.; Jia, Y. On the Mechanism of High-Voltage Pulsed Fragmentation from Electrical Breakdown Process. Rock Mech. Rock Eng. 2021, 54, 4593–4616. [Google Scholar] [CrossRef]

- Burkin, V.V.; Kuznetsova, N.S.; Lopatin, V.V. Dynamics of electro burst in solids: I. Power characteristics of electro burst. J. Phys. D Appl. Phys. 2009, 42, 185204. [Google Scholar] [CrossRef]

- Burkin, V.V.; Kuznetsova, N.S.; Lopatin, V.V. Dynamics of electro burst in solids: II. Characteristics of wave process. J. Phys. D Appl. Phys. 2009, 42, 235209. [Google Scholar] [CrossRef]

- Walsh, S.D.; Vogler, D. Simulating electropulse fracture of granitic rock. Int. J. Rock Mech. Min. 2020, 128, 104238. [Google Scholar] [CrossRef] [Green Version]

- Lopatin, V.V.; Noskov, M.D.; Usmanov, G.Z.; Cheglokov, A.A. Modeling of impulse electric discharge propagation in a condensed dielectric. Russ Phys. J. 2006, 49, 243–250. [Google Scholar] [CrossRef]

- Usmanov, G.Z.; Lopatin, V.V.; Noskov, M.D.; Cheglokov, A.A. Simulation of electrical discharge development at interface of solid and liquid dielectric. Izv. Vyssh. Uchebn. Zaved. Fiz. 2006, 10, 231–234. [Google Scholar]

- Kuznetsova, N.S.; Yudin, A.S.; Voitenko, N.V. Simulation of Pre-Breakdown Phase of Electrical Discharge in Reinforced Concrete. J. Phys. Conf. Ser. 2017, 830, 012046. [Google Scholar] [CrossRef] [Green Version]

- Hu, Q. Experimental Researches on Pulse Plasma Discharge for Deep-Ocean Thin-Layer Mineral Resources Crushing. Thalass. Int. J. Mar. Sci. 2019, 35, 405–412. [Google Scholar] [CrossRef]

- Li, C.; Duan, L.; Tan, S.; Chikhotkin, V. Influences on High-Voltage Electro Pulse Boring in Granite. Energies 2018, 11, 2461. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Duan, L.; Wu, L.; Tan, S.; Zheng, J.; Chikhotkin, V. Optimization of discharge circuit model based on electro pulse boring experiment. J. Nat. Gas. Sci. Eng. 2021, 86, 103730. [Google Scholar] [CrossRef]

- Burkin, V.V.; Kuznetsova, N.S.; Lopatin, V.V. Wave dynamics of electric explosion in solids. Tech. Phys. 2009, 54, 644–650. [Google Scholar] [CrossRef]

- Kuznetsova, N.; Lopatin, V.; Burkin, V.; Golovanevskiy, V.; Zhgun, D.; Ivanov, N. Theoretical and experimental investigation of electro discharge destruction of non-conducting materials. In Proceedings of the 2011 IEEE Pulsed Power Conference, Chicago, IL, USA, 19–23 June 2011; pp. 267–273. [Google Scholar]

- Li, C.; Duan, L.; Tan, S.; Chikhotkin, V.; Fu, W. Damage Model and Numerical Experiment of High-Voltage Electro Pulse Boring in Granite. Energies 2019, 12, 727. [Google Scholar] [CrossRef] [Green Version]

- Takaki, K.; Akiyama, H. The resistance of a high-current pulsed discharge in nitrogen. Jpn. J. Appl. Phys. 2001, 40, 979. [Google Scholar] [CrossRef]

- Usmanov, G.Z.; Lopatin, V.V.; Noskov, M.D.; Cheglokov, A.A. Mathematical modeling of the solid dielectric brittle destruction as a result of pulse electrical breakdown. In Proceedings of the 15th International Symposium on High-Current Electronics, Tomsk, Russia, 21–26 September 2008. [Google Scholar]

- Biela, J.; Marxgut, C.; Bortis, D.; Kolar, J.W. Solid state modulator for plasma channel drilling. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1093–1099. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, S.; Sun, H.; Wang, R.; Tu, X.; Shao, T. Highly efficient conversion of methane using microsecond and nanosecond pulsed spark discharges. Appl. Energy 2018, 226, 534–545. [Google Scholar] [CrossRef]

- Hobejogi, T.; Biela, J. Performance Evaluation of Pulse Compressor-Based Modulators with Very Fast Rise Times for Plasma Channel Drilling. IEEE Trans. Plasma Sci. 2014, 42, 2891–2898. [Google Scholar] [CrossRef]

- Wang, X.; Gao, Y.; Zhang, S.; Sun, H.; Li, J.; Shao, T. Nanosecond pulsed plasma assisted dry reforming of CH4: The effect of plasma operating parameters. Appl. Energ 2019, 243, 132–144. [Google Scholar] [CrossRef]

- Gao, J.; Liu, Y.; Liu, J.; Yang, J.; Zhang, J. Development of a repetitive wave erection Marx generator. IEEE Trans. Plasma Sci. 2009, 37, 1936–1942. [Google Scholar]

- Jia, K.; Li, Y.; Fang, Y.; Zheng, L.; Bi, T.; Yang, Q. Transient current similarity based protection for wind farm transmission lines. Appl. Energy 2018, 225, 42–51. [Google Scholar] [CrossRef]

- Chatterjee, S.; Bandopadhyay, S.; Machuca, D. Ore grade prediction using a genetic algorithm and clustering based ensemble neural network model. Math. Geosci. 2010, 42, 309–326. [Google Scholar] [CrossRef]

- Fernández Álvarez, J.P.; Fernández Martínez, J.L.; Menéndez Pérez, C.O. Feasibility analysis of the use of binary genetic algorithms as importance samplers application to a 1-D DC resistivity inverse problem. Math. Geosci. 2008, 40, 375–408. [Google Scholar] [CrossRef]

- Bouktif, S.; Fiaz, A.; Ouni, A.; Serhani, M.A. Optimal deep learning lstm model for electric load forecasting using feature selection and genetic algorithm: Comparison with machine learning approaches. Energies 2018, 11, 1636. [Google Scholar] [CrossRef] [Green Version]

- Mu, H. Research on Robustness State of Charge Estimation of Lithium-Ion Power Battery for Electric Vehicles. Ph.D. Thesis, Beijing Institute of Technology, Beijing, China, 2016. [Google Scholar]

- Mu, H.; Xiong, R.; Sun, F. A novel multi-model probability based battery state-of-charge fusion estimation approach. Energy Procedia 2016, 88, 840–846. [Google Scholar] [CrossRef] [Green Version]

- Lin, C.; Mu, H.; Xiong, R.; Shen, W. A novel multi-model probability battery state of charge estimation approach for electric vehicles using H-infinity algorithm. Appl. Energy 2016, 166, 76–83. [Google Scholar] [CrossRef]

- Lin, C.; Mu, H.; Xiong, R.; Cao, J. Multi-model probabilities based state fusion estimation method of lithium-ion battery for electric vehicles: State-of-energy. Appl. Energy 2017, 194, 560–568. [Google Scholar] [CrossRef]

- He, M.; Jiang, J.; Huang, G.; Liu, J.; Li, C. Disintegration of rocks based on magnetically isolated high voltage discharge. Rev. Sci. Instrum. 2013, 84, 024704. [Google Scholar] [CrossRef]

- Brouwer, G.K.; Fokker, P.A.; Wilschut, F.; Zijl, W. A direct inverse model to determine permeability fields from pressure and flow rate measurements. Math. Geosci. 2008, 40, 907–920. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, T.; Gómez-Hernández, J.J.; Zanini, A. Contaminant Spill in a Sandbox with Non-Gaussian Conductivities: Simultaneous Identification by the Restart Normal-Score Ensemble Kalman Filter. Math. Geosci. 2021, 53, 1587–1615. [Google Scholar] [CrossRef]

- Jou, Y.; Lin, Z.; Chen, F. Improved Design of Two-Channel Quadrature Mirror Filter Using Explicit Toeplitz Expressions. In Proceedings of the 2018 IEEE 7th Global Conference on Consumer Electronics (GCCE), Nara, Japan, 9–12 October 2018; pp. 1–2. [Google Scholar]

- Zhou, F.; Jiang, J.; Shui, P. Fast design of 2D fully oversampled DFT modulated filter bank using Toeplitz-block Toeplitz matrix inversion. Signal Process 2015, 111, 194–198. [Google Scholar] [CrossRef]

- Sanjeevini, S.; Bernstein, D.S. Counting Zeros Using Observability and Block Toeplitz Matrices. IEEE Trans. Autom. Control 2020, 66, 1301–1305. [Google Scholar] [CrossRef]

- Townsend, A.; Webb, M.; Olver, S. Fast polynomial transforms based on Toeplitz and Hankel matrices. Math. Comput. 2018, 87, 1913–1934. [Google Scholar] [CrossRef]

- Gao, F.; Chi, H.; Shao, X. Forecasting residential electricity consumption using a hybrid machine learning model with online search data. Appl. Energy 2021, 300, 117393. [Google Scholar] [CrossRef]

- Ghimire, S.; Deo, R.C.; Raj, N.; Mi, J. Deep solar radiation forecasting with convolutional neural network and long short-term memory network algorithms. Appl. Energy 2019, 253, 113541. [Google Scholar] [CrossRef]

| Model | Red Sandstone | Granite |

|---|---|---|

| RLC | ||

| TV-RLC | ||

| TV-CRLC |

| Rock Samples | Model | vs. RLC | vs. TV-RLC | vs. TV-CRLC | Average Reduction Rate |

|---|---|---|---|---|---|

| Red sandstone | Bayesian fusion | 44.3% | 30.3% | 24% | 32.9% |

| Normalized fusion | 28.8% | 11% | 2.9% | 14.2% | |

| Granite | Bayesian fusion | 28.4% | 15.4% | 10.4% | 18.1% |

| Normalized fusion | 16.8% | 1.7% | −4.1% | 4.8% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Wang, X.; Duan, L.; Lei, B. Study on a Discharge Circuit Prediction Model of High-Voltage Electro-Pulse Boring Based on Bayesian Fusion. Energies 2022, 15, 3824. https://doi.org/10.3390/en15103824

Li C, Wang X, Duan L, Lei B. Study on a Discharge Circuit Prediction Model of High-Voltage Electro-Pulse Boring Based on Bayesian Fusion. Energies. 2022; 15(10):3824. https://doi.org/10.3390/en15103824

Chicago/Turabian StyleLi, Changping, Xiaohui Wang, Longchen Duan, and Bo Lei. 2022. "Study on a Discharge Circuit Prediction Model of High-Voltage Electro-Pulse Boring Based on Bayesian Fusion" Energies 15, no. 10: 3824. https://doi.org/10.3390/en15103824

APA StyleLi, C., Wang, X., Duan, L., & Lei, B. (2022). Study on a Discharge Circuit Prediction Model of High-Voltage Electro-Pulse Boring Based on Bayesian Fusion. Energies, 15(10), 3824. https://doi.org/10.3390/en15103824