1. Introduction

Pneumatic actuators (PAs) are widely employed in a variety of applications, especially those that require automatic control due to their advantages, which include low cost, a high power-to-weight ratio, and the use of air as an operating medium [

1]. However, the air leakage, friction, air compressibility, and uncertainty in the parameters of the pneumatic actuator system make precise position control a challenge [

2,

3]. Additionally, the modeling of the empirical pneumatic actuator system is considered difficult due to the limitations and complexity of the system.

System identification (SI) is a technique for solving system modeling and unknown parameters, as well as for linearizing the system to overcome the drawbacks of mathematical models [

4]. Additionally, system identification can be utilized to derive the plant system’s linear mathematical model (transfer function) from the experimental data. A further significant factor to be addressed is the restrictions or constraints of the system while designing a controller for actual system applications [

5,

6]. Non-compliance with the system’s limitations could cause system damage and component harm, as well as a decrease in control system performance.

Numerous control mechanisms have been developed to maintain the position of the pneumatic system; for instance, a PI controller was developed in 2010 and used for the first time to control the positioning system of an intelligent pneumatic actuator (IPA) [

7,

8]. Two years later, another study presented a pole-placement feedback controller for the same task [

9]. In 2013, a bang–bang controller and a PI controller were implemented to access the real-time position control of the IPA system [

10]. During the last years, researchers have tried to control the position of IPA systems using a predictive controller [

11,

12,

13,

14,

15,

16].

Earlier research did not address the IPA system’s limits such as the control signal to the valve, especially during the actual implementation of control systems. Furthermore, noncompliance with the required limitations may be dangerous to the components of the IPA system and the general performance of the control system. Additionally, the majority of the previously described control systems were unable to achieve high speed response, robustness, and accuracy all at the same time, especially when implemented in real-time scenarios.

In this study, the fuzzy fractional order proportional integral derivative controller (fuzzy FOPID) is proposed. The FOPID provides more design flexibility than traditional PID controllers. In addition, it has a bigger stability region, selectivity, and other benefits. This is due to the acceptance of fraction orders of derivatives and integrals [

17,

18,

19,

20,

21]. In addition, numerous researchers have adopted FOPID controllers in recent years due to the additional factors that make the system more durable and successful in a variety of applications. Moreover, according to the results of the investigation, numerous systems, such as motor control systems [

22], robotics systems [

23], and time-delay systems [

24] used FOPID as a controller. The performance of the FOPID controller is superior to that of traditional PID controllers in terms of time response characteristics.

In comparison with traditional PID control, fractional order PID control is more difficult to fine tune due to the presence of two additional parameters (integration order, γ, and fractional derivative order, µ). Nonetheless, as evidenced by the literature, the emergence of meta-heuristic approaches, such as the big bang big crunch algorithm [

25], genetic algorithms [

26,

27], bees algorithm [

28], and cuckoo search algorithm [

18,

29], has made it much easier to tune constraints in recent years [

30,

31,

32]. Despite the development of numerous natural-inspired algorithms, PSO has maintained a certain level of popularity among researchers due to its simplicity, straightforward calculation, large amount of flexibility in modifying the algorithm’s structure, and its ability to provide a substitute solution to the non-linear complex optimization problem (NLO). In this study, the PSO algorithm was employed for the optimization of the parameters of the suggested controller in this work.

This study offers a novel fuzzy logic control structure design for an intelligent pneumatic actuator system, with the following contributions and objectives:

Develop a fuzzy logic control configuration for IPA and investigate its performance in the positioning system. This design is based on a two-input-one-output fuzzy controller. FOPID is coupled to the fuzzy controller’s output terminal, resulting in the proposed fuzzy FOPID controller.

Particle swarm optimization (PSO) technique is utilized in this study to determine the optimum values of the suggested controller parameters. In order to accomplish this task, seven parameters are to be adjusted in order to achieve the best fuzzy FOPID dynamic behavior.

Validate the predominance of the introduced design by comparing the obtained results to fuzzy PID in simulation and real environments.

The rest of this research is structured as follows.

Section 2 presents the modeling of the IPA system.

Section 3 discusses the proposed fuzzy FOPID design.

Section 4 discusses the optimization tool that was suggested and the objective function that was employed.

Section 5 presents the primary simulation results obtained using the suggested fuzzy FOPID design; it also includes a comparison to other simulation and real-time outcomes. Finally,

Section 6 summarizes the key outcomes for this research.

3. Controller Design

This paper proposes the design strategy for the fuzzy FOPID controller. To control the position tracking of the PA system, the fuzzy FOPID controller is developed and validated through simulation and real-time experiments.

The PID controller remains one of the most commonly used controllers recently because it can be easily developed and installed; it also works well even when there is uncertainty in the system. For the PID controller, the transfer function can be written as in Equation (2):

Additionally, there are two extra design parameters in the FOPID, namely, the fractional integration order, λ, and the fractional derivative order µ [

3,

33,

34]. Equation (3) represents the transfer function of the FOPID controller.

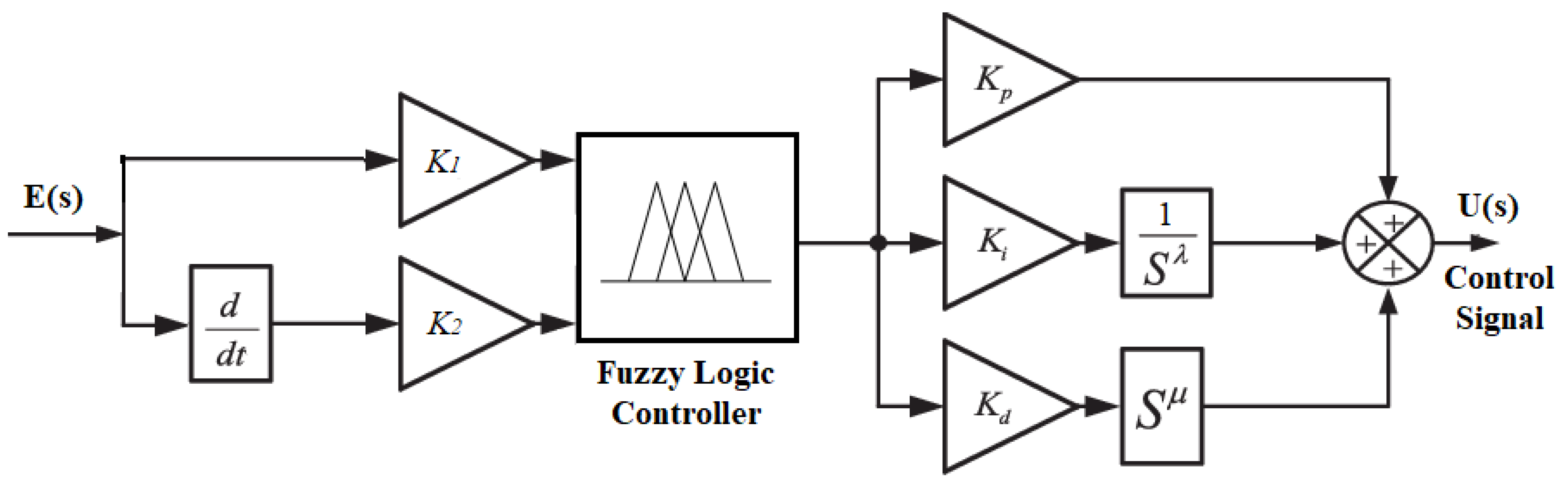

In this study, the suggested controller fuzzy FOPID is reliant on fuzzy logic control that was performed using the fuzzy logic toolbox in the MATLAB/Simulink platform. As illustrated in

Figure 7, the fuzzy controller is made of three components: a fuzzification, rule basis, and defuzzification.

The block diagram of the proposed Fuzzy FOPID controller is shown in

Figure 8. As illustrated, there are two inputs to the controller, the error (e (t)) and the rate of change of error (∆e (t)), and only one output (u). For the inputs, the scaling factor gains are (K

1 and K

2), while those for the output are (

and μ). To obtain the desired dynamic response of the researched system, seven parameters (

and μ) must be tuned.

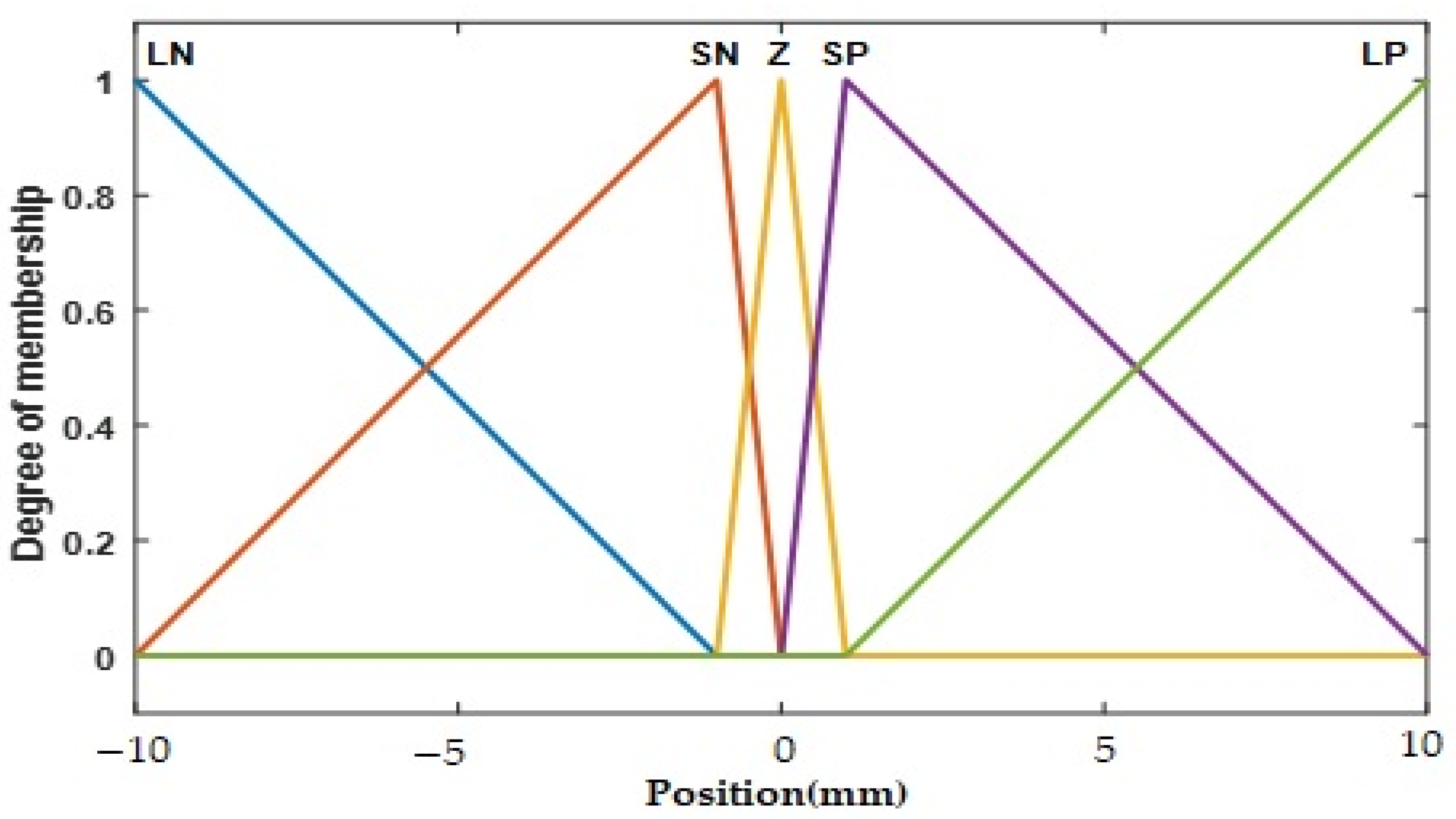

Figure 9 shows that 5 triangle membership functions (MF), namely ‘Large Negative’ (LN), ‘Small Negative’ (SN), ‘Zero’ (Z), ‘Small Positive’ (SP) and ‘Large Positive’ (LP) are utilized for input1 and input 2. The range of MF for input 1 is normalized between [−10, 10] and for input 2 is between [−5, 5], respectively. The output for the fuzzy design is singular and the linear value and the value for each variable are V2 = −255, V2

k = −100, off = 0, V1

k = 200, and V1 = 255.

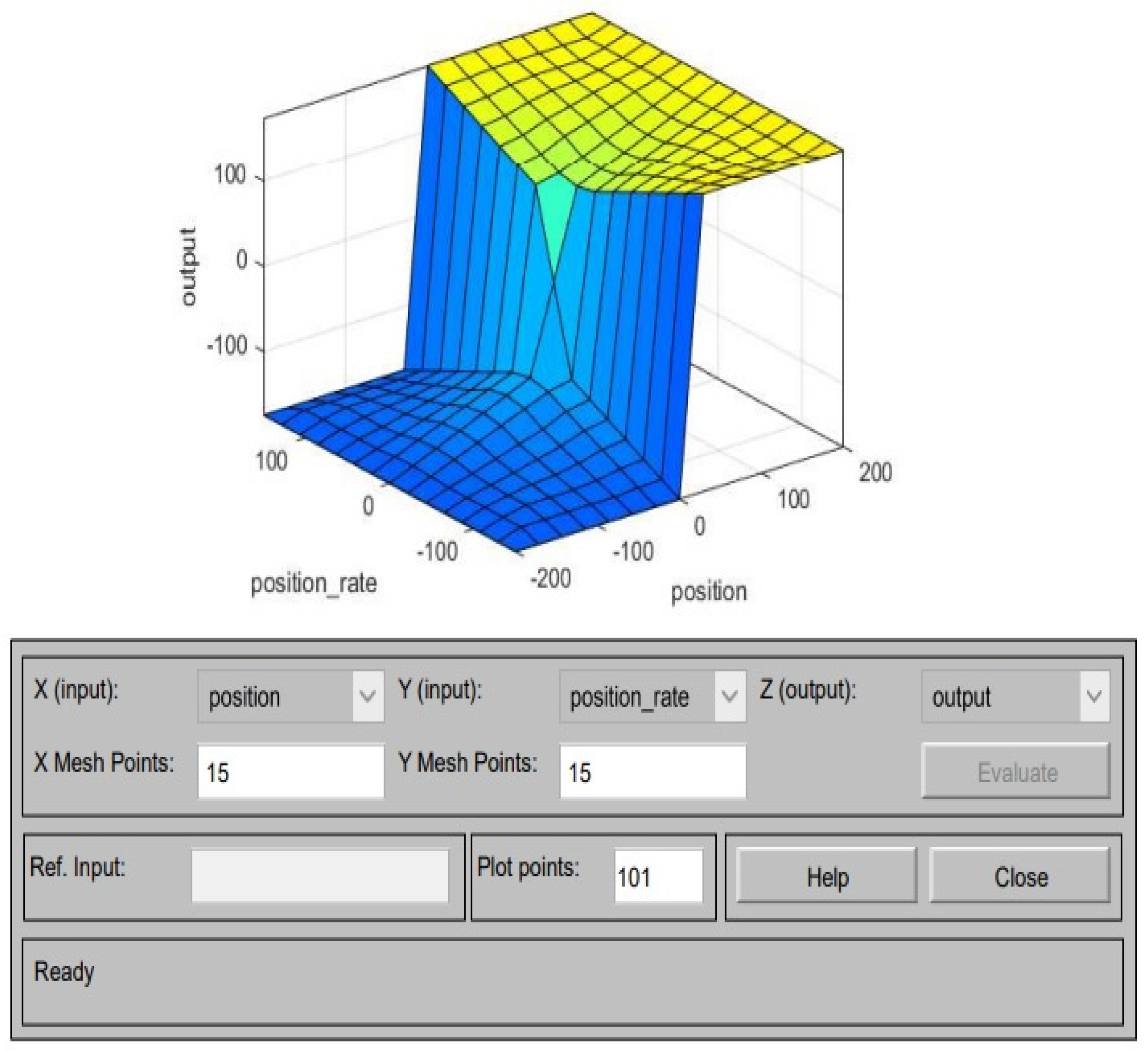

Table 2 showed that 25 rule bases are needed for the generation of the controller’s fuzzy output. The tabulated rules are derived from a detailed analysis of the researched pneumatic actuator’s dynamic behavior, which is necessary because the controller’s performance is dependent on them. Additionally, this design employs the Sugeno-type inference system for fuzzification and the “Centroid” tool for defuzzification. The surface viewer of the fuzzy is shown in

Figure 10.

All design characteristics of the fuzzy FOPID controller will be discussed in this part, such as membership functions, linguistic variables, rule base, interface engine, and the defuzzification mechanism.

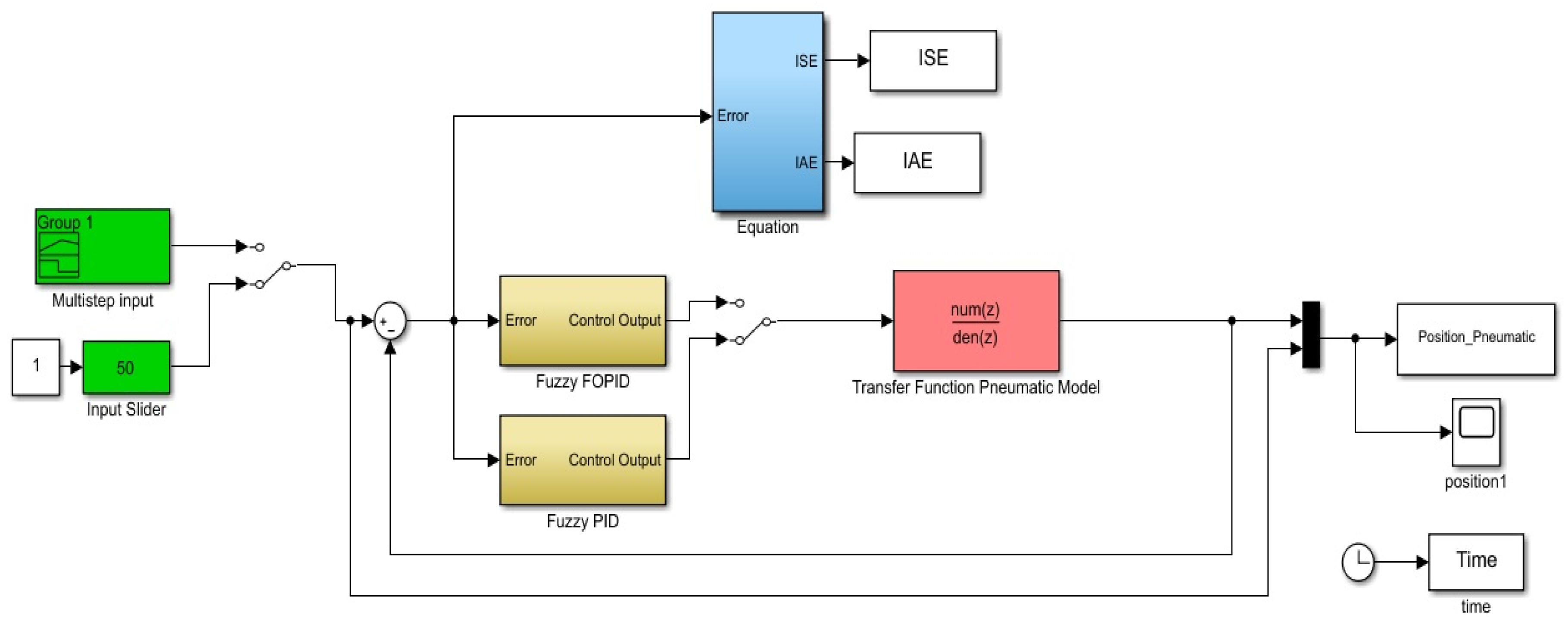

The platform used in this research is MATLAB-Simulink.

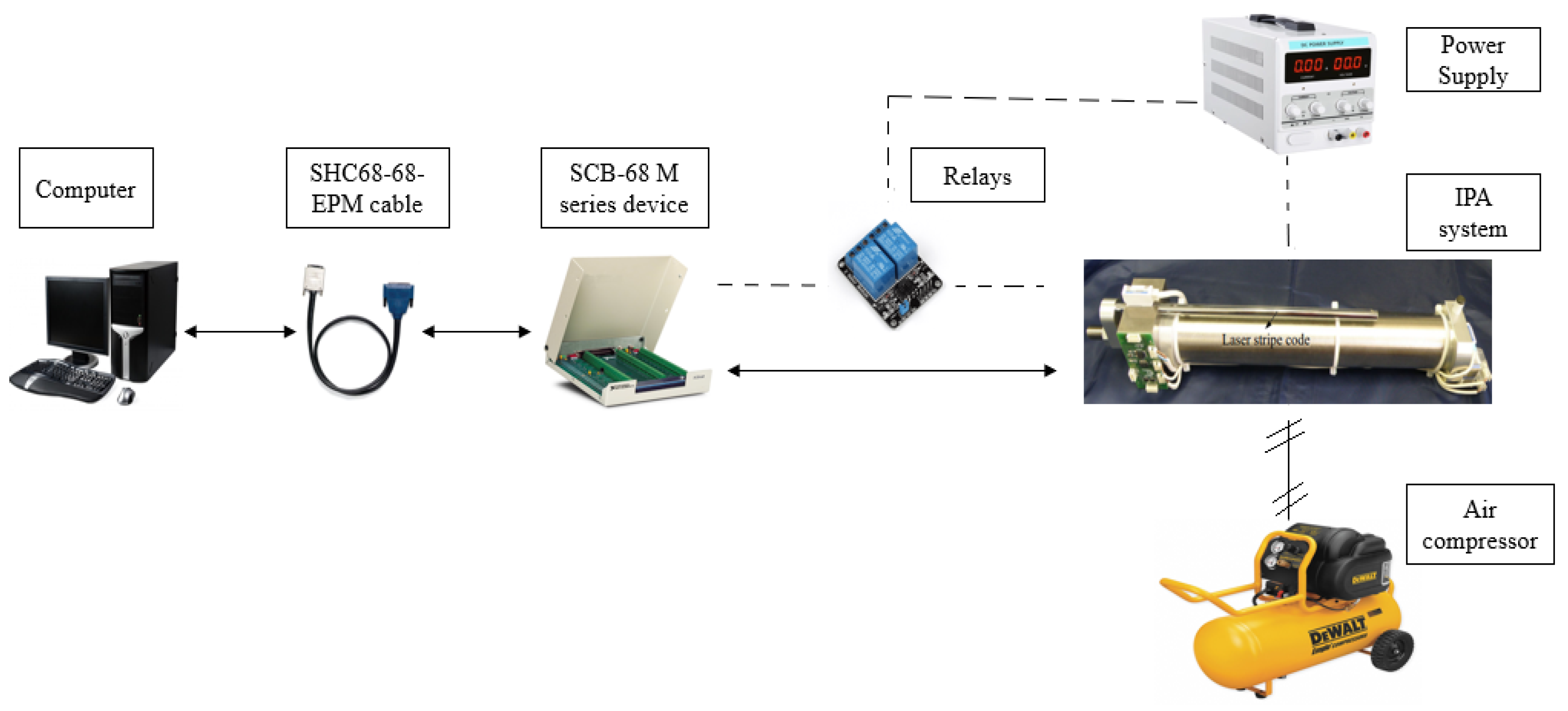

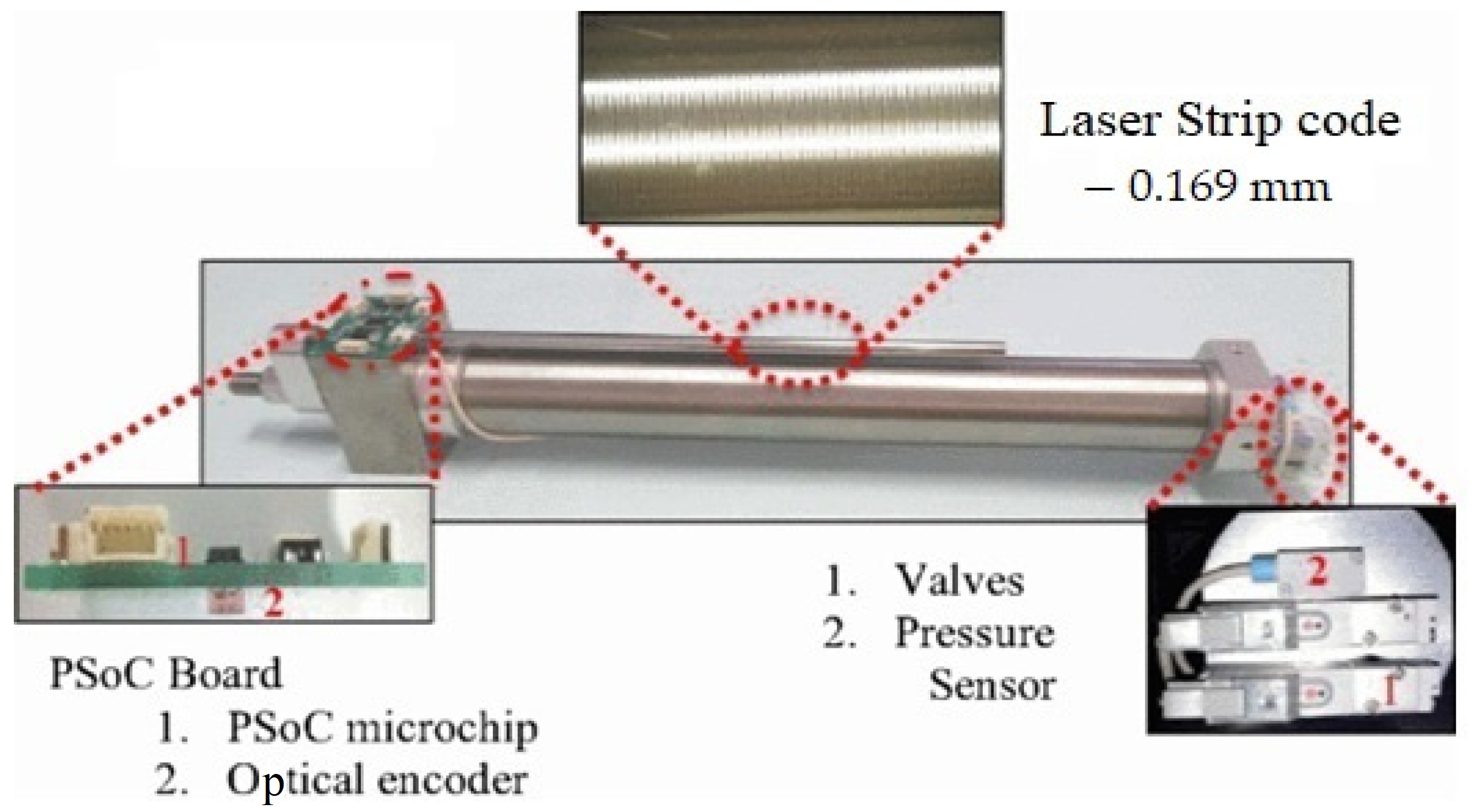

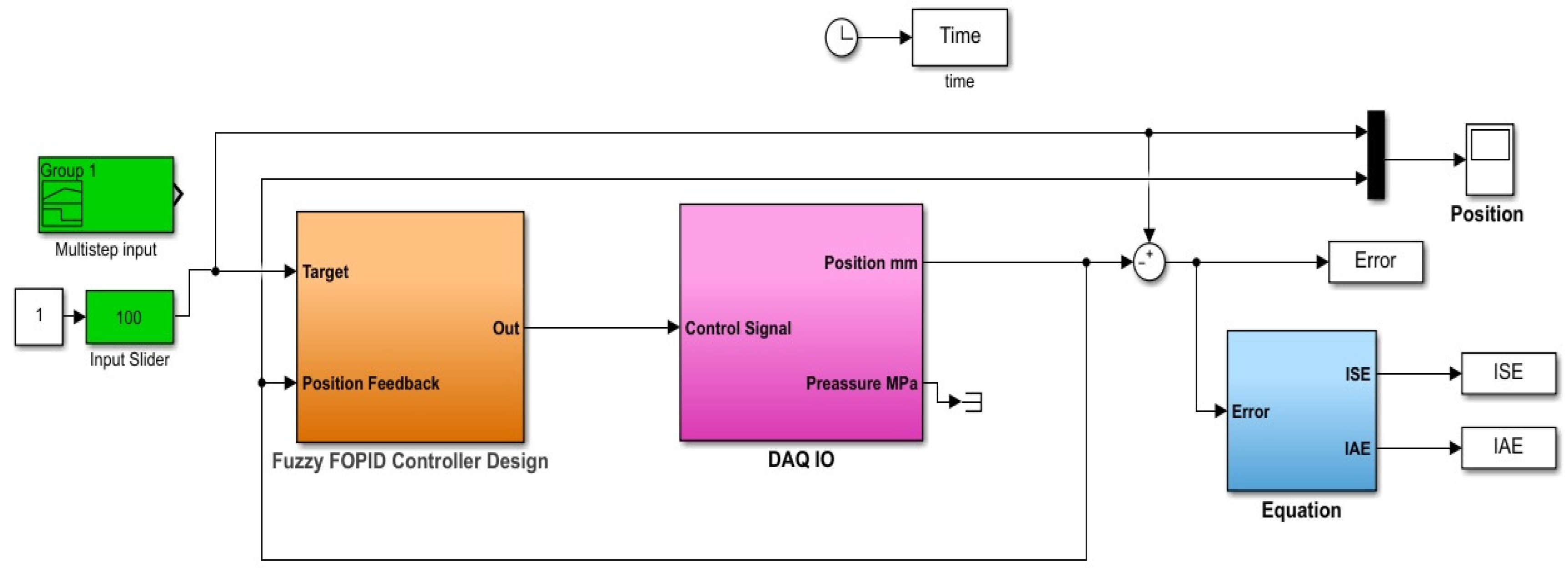

Figure 11 shows the Simulink block diagram for simulation. In this figure, the controller block consists of the fuzzy FOPID controller or fuzzy PID controller, and the IPA model as in Equation (1). Meanwhile,

Figure 12 is the Simulink block diagram for the real-time experiment setup. The block diagram design consists of five parts which are input (position setpoint), controller part, DAQ configuration (I/O), performance index, and the output. The type of input signal used in this experiment is the same as in the simulation where the same parameters of the fuzzy FOPID and fuzzy PID controllers were implemented to the real-time experiment for validation purpose.

4. The Proposed Optimization Technique and Objective Function

PSO optimization is a heuristic search approach based on the social behavior of birds and fish schools that has gained popularity in modern times. Studies show that it is effective in nonlinear optimization problems [

35,

36]. When performing PSO optimization, the first step is to create the optimization target, which is the fitness function, followed by encoding of the parameters to be searched.

PSO makes use of an adaptive swarm of particles investigating promising sections of the D-dimension search space [

37]. It will continue to run until the stop condition is met. The optimal particle position for the controller is determined by finding the best particle position. The popularity of PSO in recent decades can be attributed to its straightforward structure and the fact that only a few parameters are required to alter the optimization of any type of issue.

Typically, numerous fitness criteria are used to evaluate the performance of new optimization strategies, these include integral of square errors (ISE), integral absolute errors (IAE), and integral of time square errors (ITSE). The overshoot, rising time, settling time, and steady-state error are all included in these performance criteria. The IAE fitness function, as indicated in Equation (6), is employed as the metric for evaluating the output response of the system in this study:

This technique allows for the movement of a large number of particles through multidimensional search space [

38]. The position and speed of the particles were updated according to Equations (5) and (6):

where

is the particle velocity,

is the current particle position, W is the inertia weight, pbest(t) is the best position for the current particle, and gbest(t) is the best position obtained by all particles, while C

1 and C

2 are learning factors.

The PSO steps for finding the optimal values of the fuzzy FOPID parameters are summarized as follows:

Define the pneumatic actuator model and PSO parameters;

Create an initial swarm of particles with random position and velocity;

Calculate the fitness function in Equation (4) for each initial parameter;

Evaluate pbest(t) of each particle and gbest(t) of the population;

Update the velocity of each particle according to Equation (5);

Upgrade the position of each particle according to Equation (6);

If the number of iterations reaches the maximum, then go to the next step; otherwise, proceed to step 3;

Save the latest optimal parameters of pbest(t).

The values of µ and λ are tuned with the same method used for tuning the P, I, and D. We have set the search space of the algorithm from 0 to 1 for µ and λ as recommended in different references [

30,

34,

39]. However, with the P, I, and D, the search space of the algorithm is set from 0 to 30.

Table 3 illustrates the parameters of the PSO algorithm that were employed in this investigation, while

Table 4 summarizes the optimal parameter values for the fuzzy FOPID as determined by PSO.

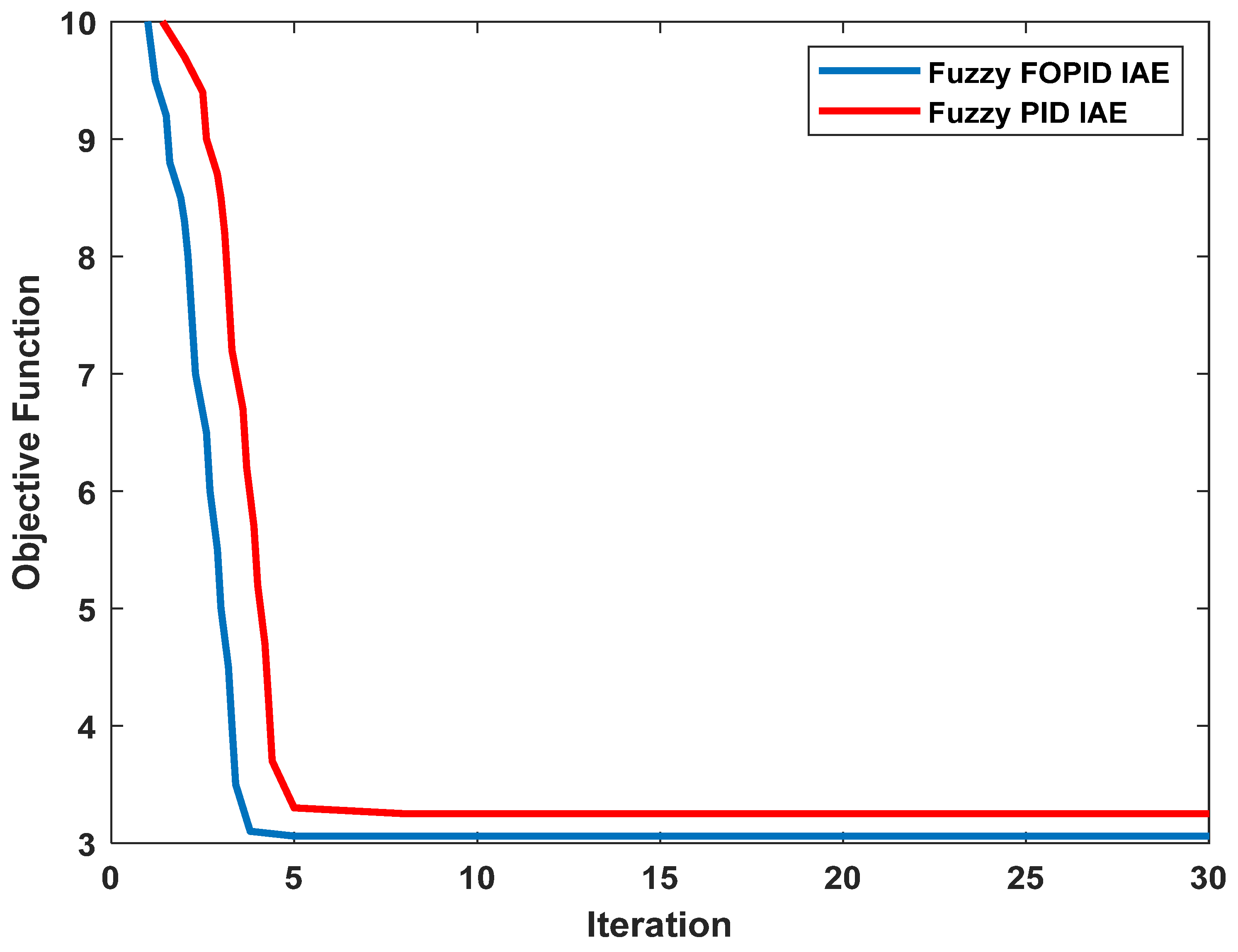

The convergence of the PSO is shown in

Figure 13.

5. Results and Discussion

The aim of this work is to improve the precision and accuracy of the cylinder stroke of PAs by ensuring that it is positioned at the appropriate level; this was accomplished through simulation and experimental works in this study. Accordingly, the suggested strategy is intended to increase the system’s transient response while reducing the rise time (tr), overshoot (OS%), and settling time (ts) of the general system’s performance. The whole system is modeled in the Matlab/Simulink environment and tested in simulation and real time to evaluate the system’s performance. The optimization of the controllers was carried out by executing the algorithm with 10 agents (Np = 10) for 30 iterations (Ni = 30).

The step response of the system with the fuzzy FOPID controller for a range of different values of µ and λ is shown in

Figure 14.

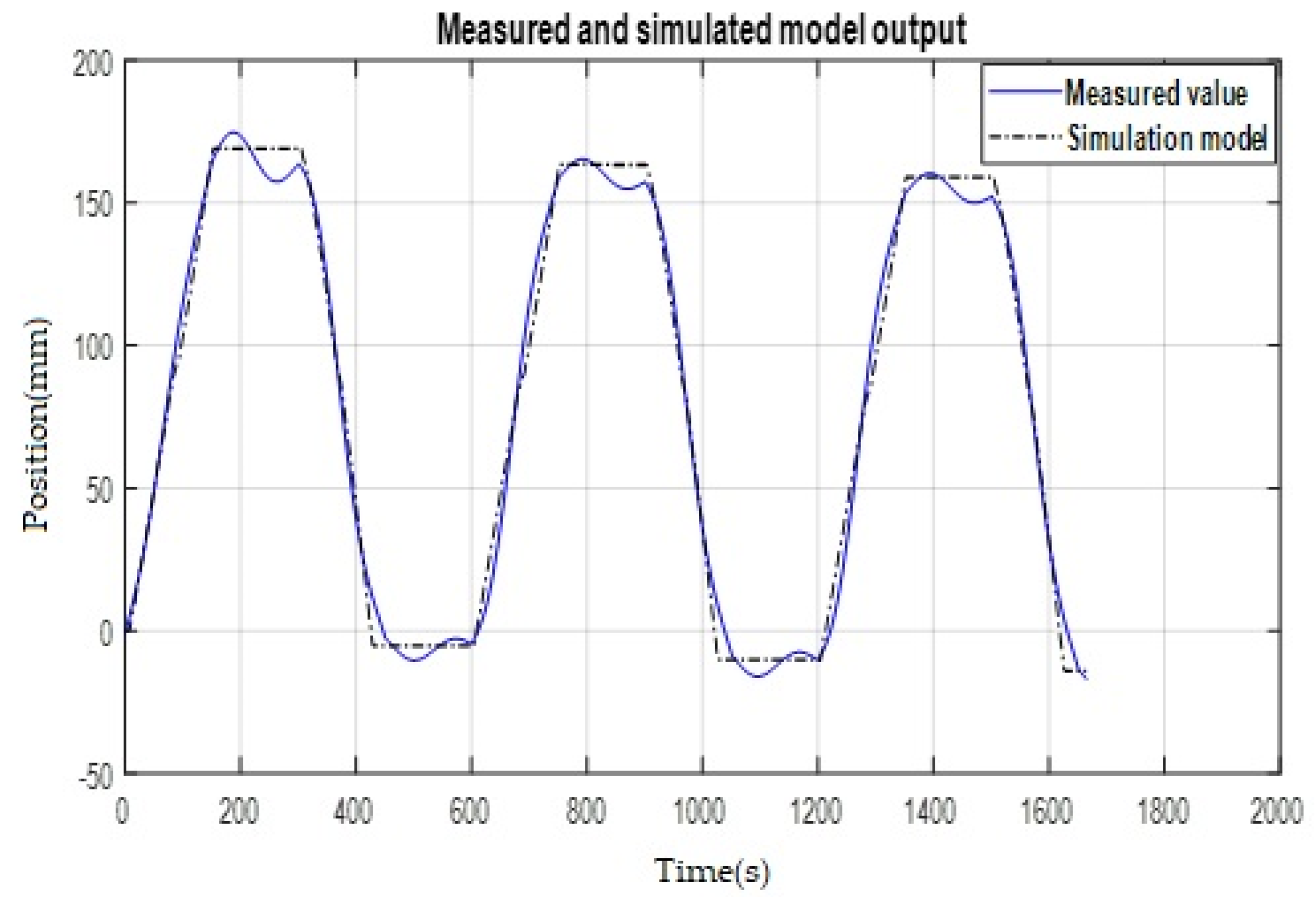

5.1. Main Results and System Identification Validation

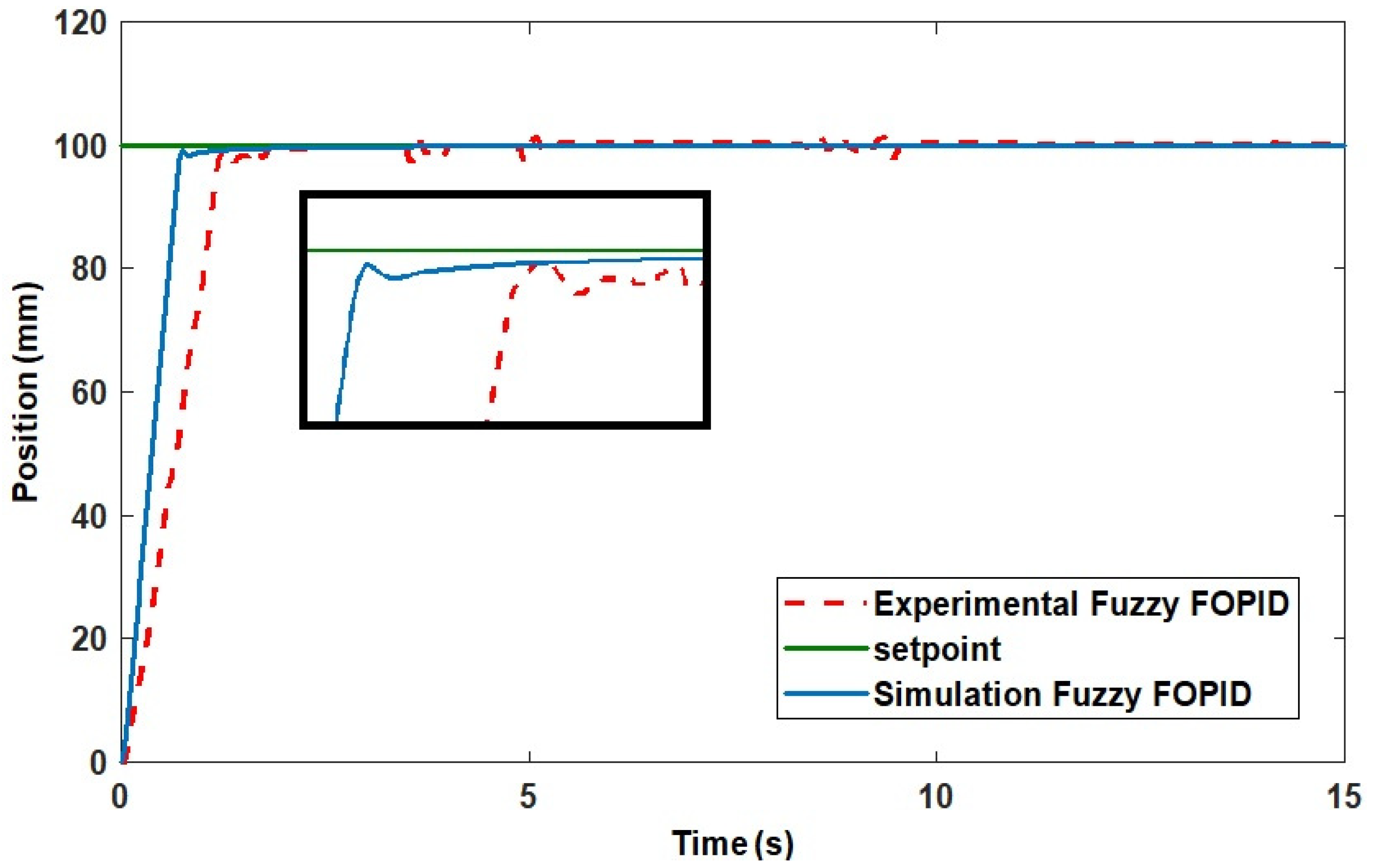

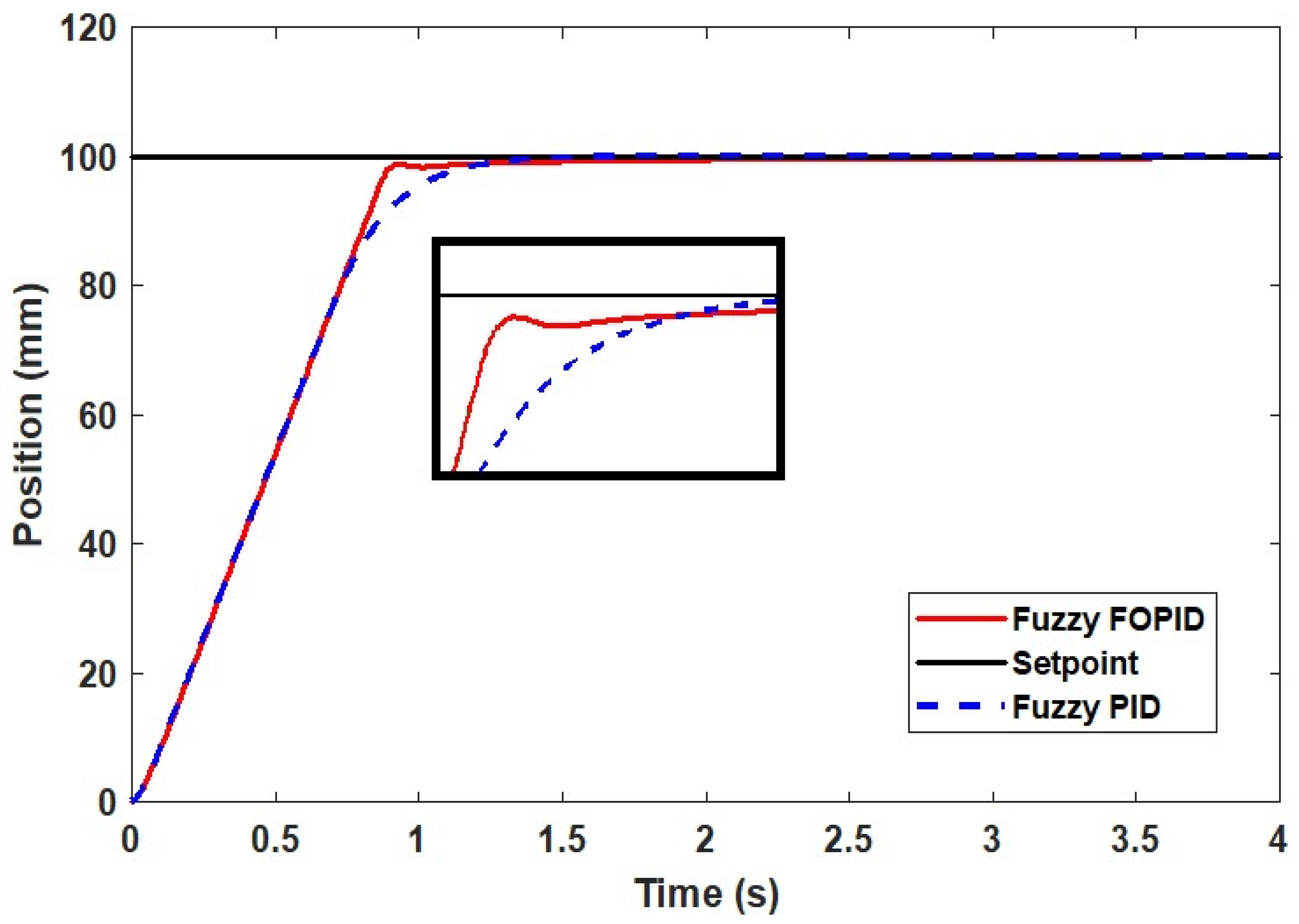

The outcome of the real and simulated studies reveals the ability of the fuzzy FOPID controller to control and maintain the position of the cylinder stroke of the IPA system at the desired positions as shown in

Figure 15.

5.2. Superiority Analysis

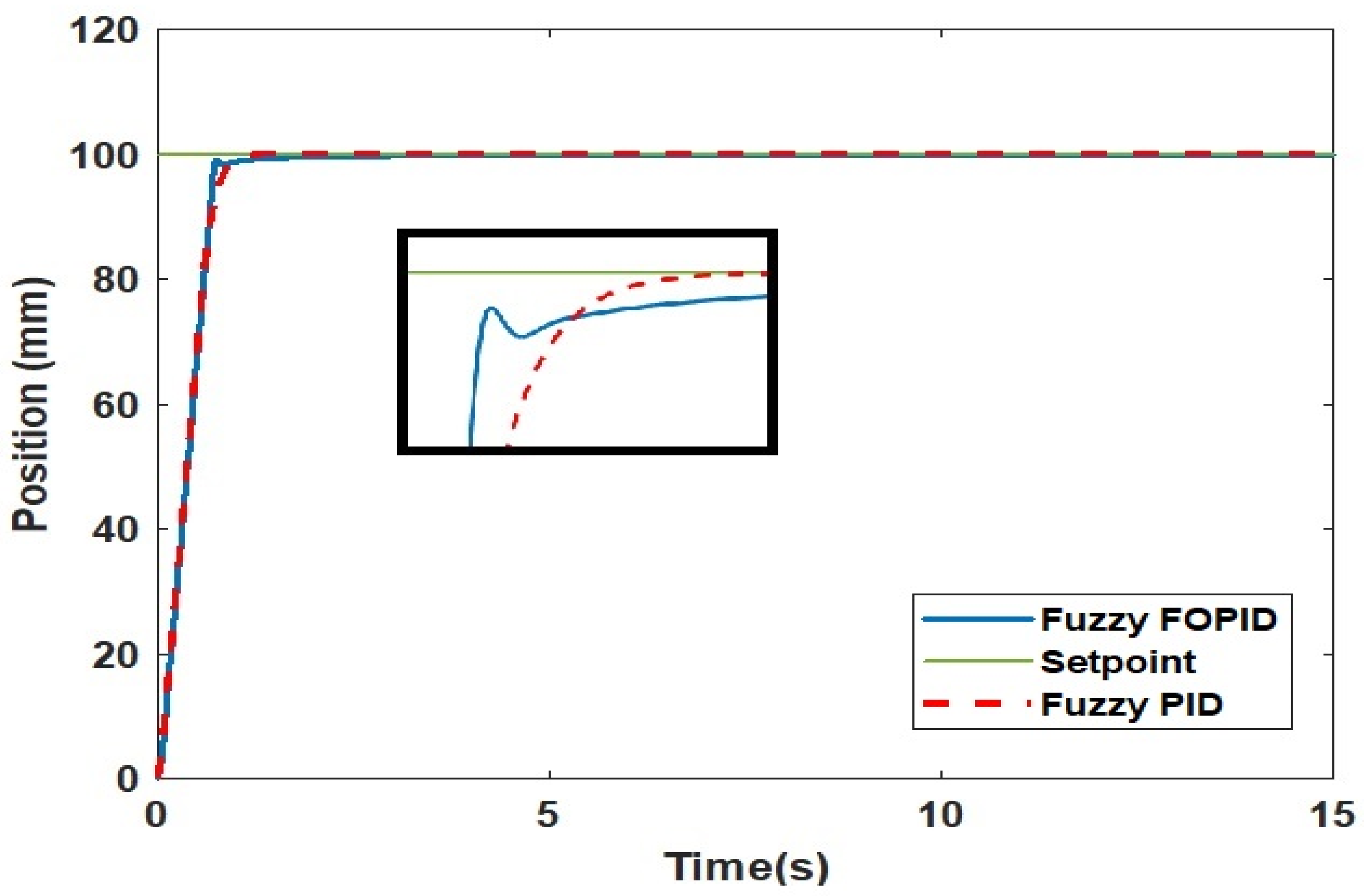

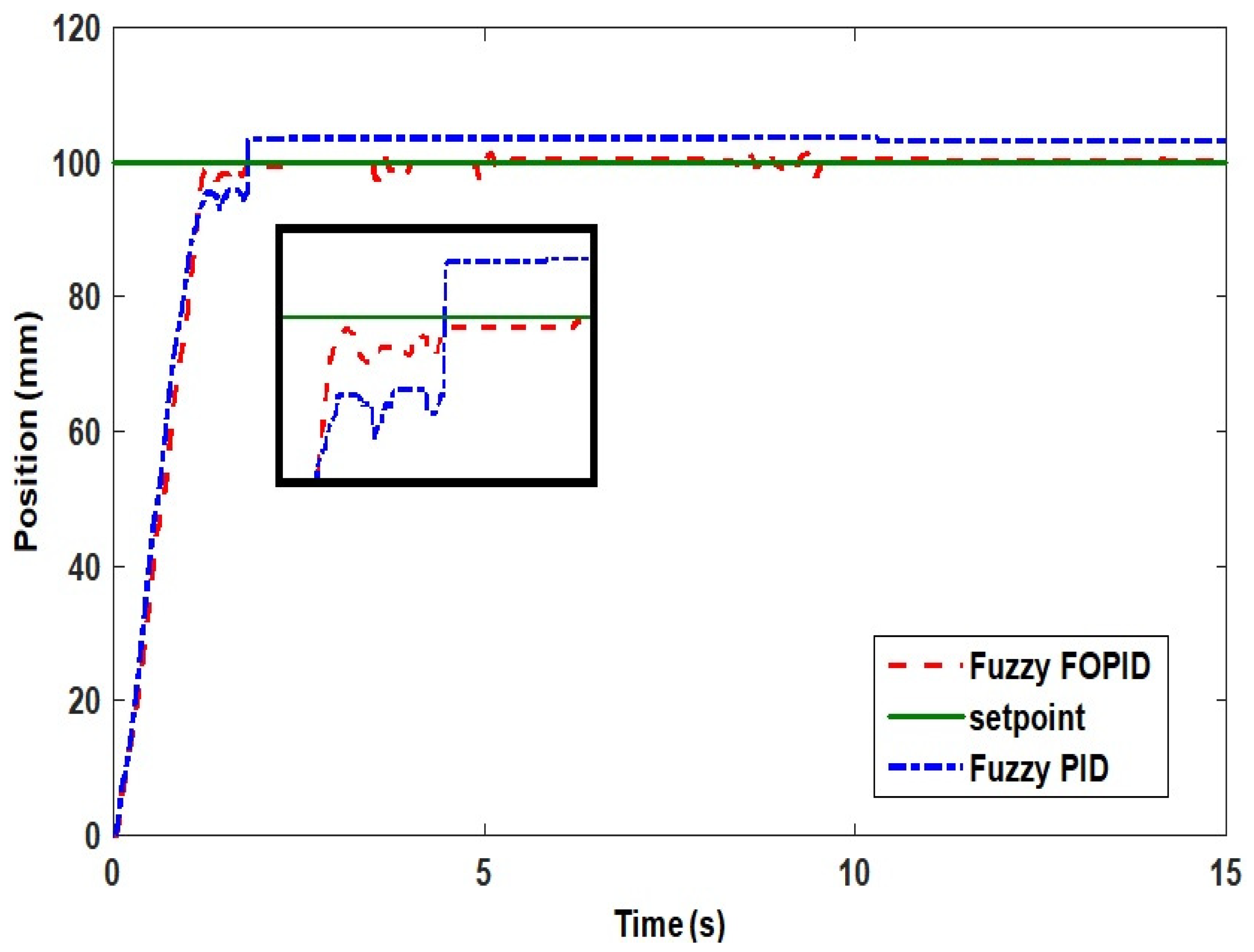

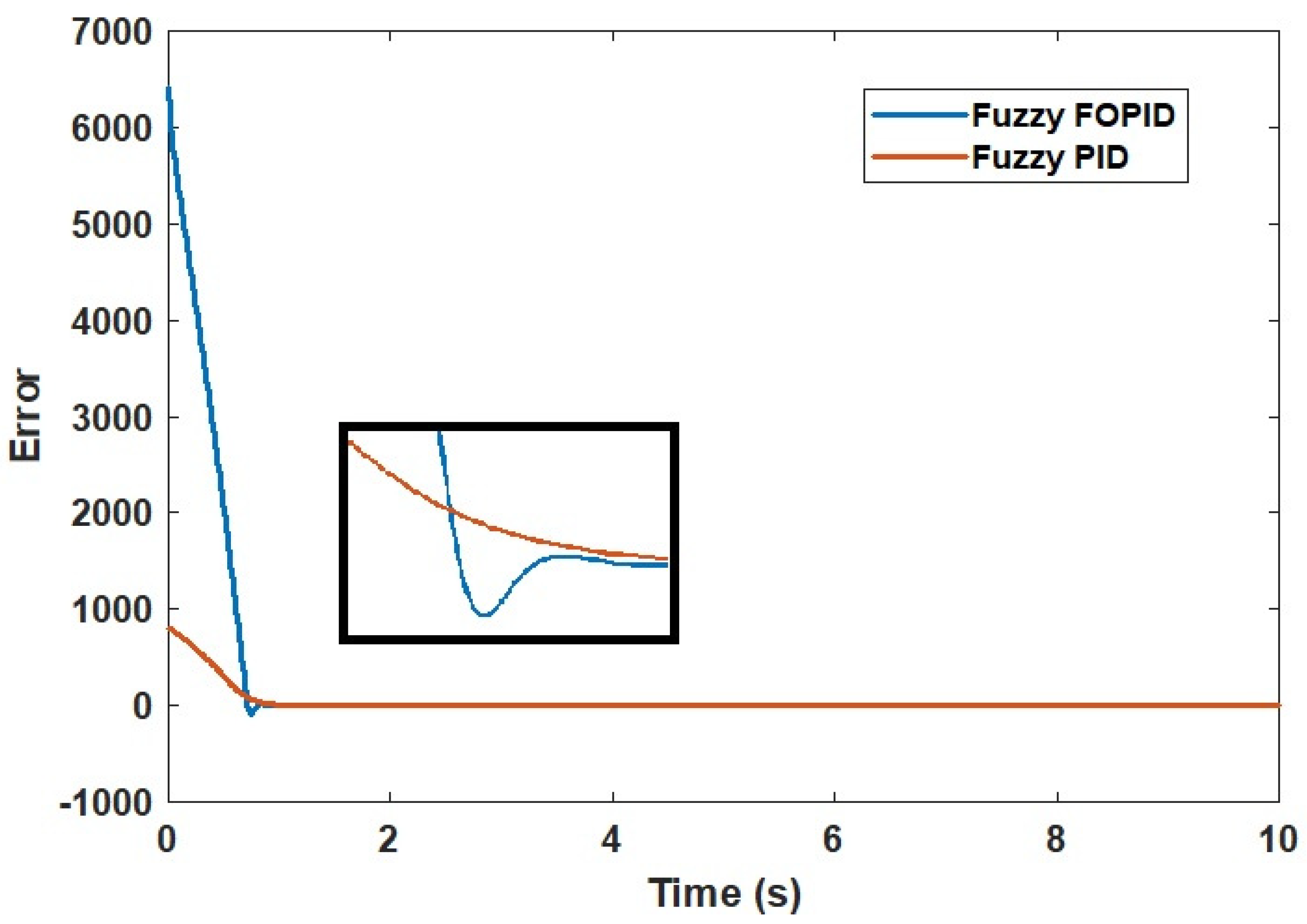

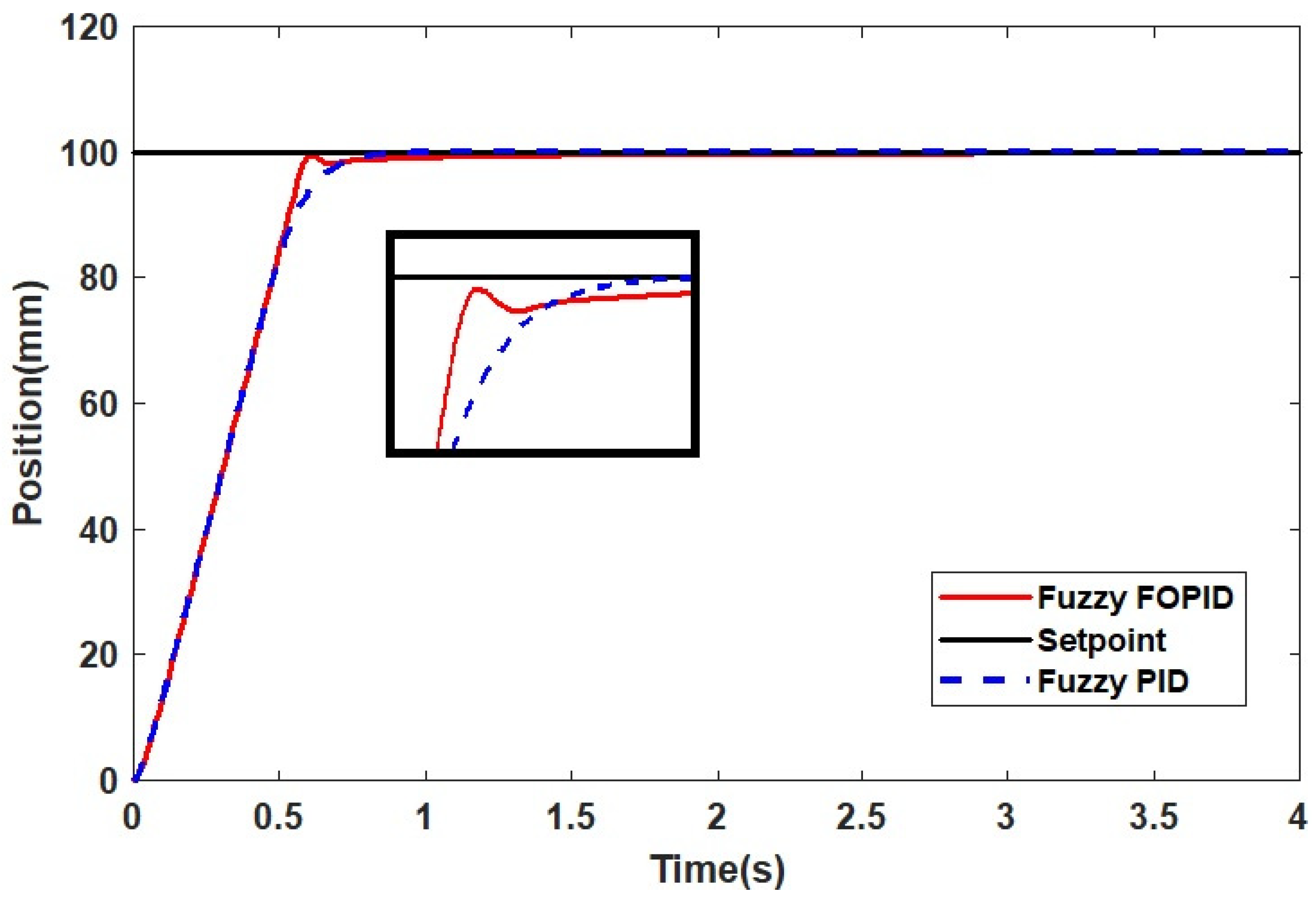

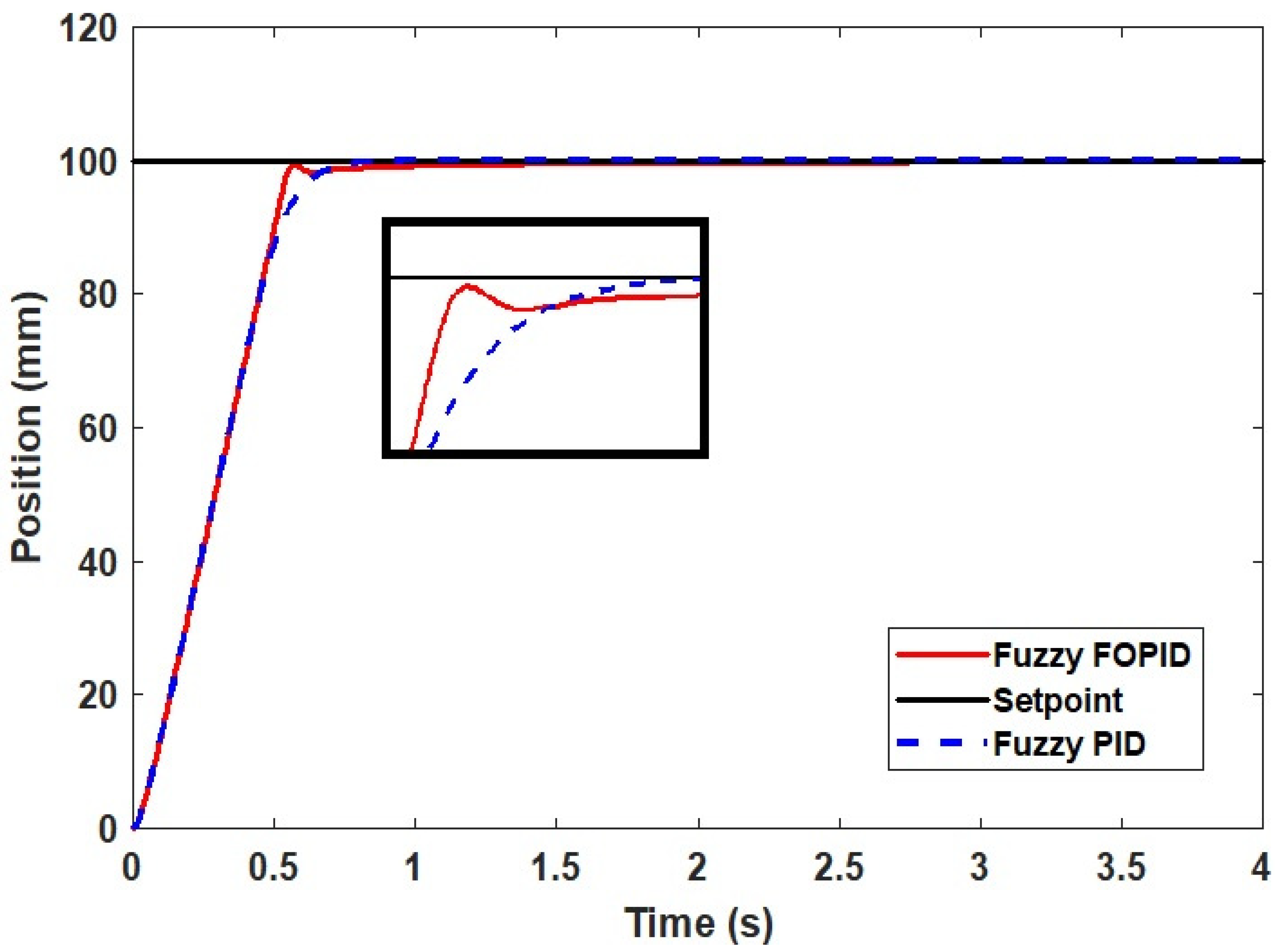

From

Figure 16 and

Figure 17, the fuzzy FOPID controller’s simulation performance indicates that the stroke deviated by about 0 mm as well as with the actual experiment compared with 2.5830 mm with the fuzzy PID controller as shown in

Figure 18. It appears from the fuzzy PID simulation results in

Figure 16 and

Figure 17 that the stroke strayed from its original position by approximately 0.0002 mm within 0.0602 sec of simulation time. This simulation finding was subsequently validated in an actual experiment where the cylinder stroke was found to exceed its original position by more than 2.5830% with e

ss as shown in

Figure 18.

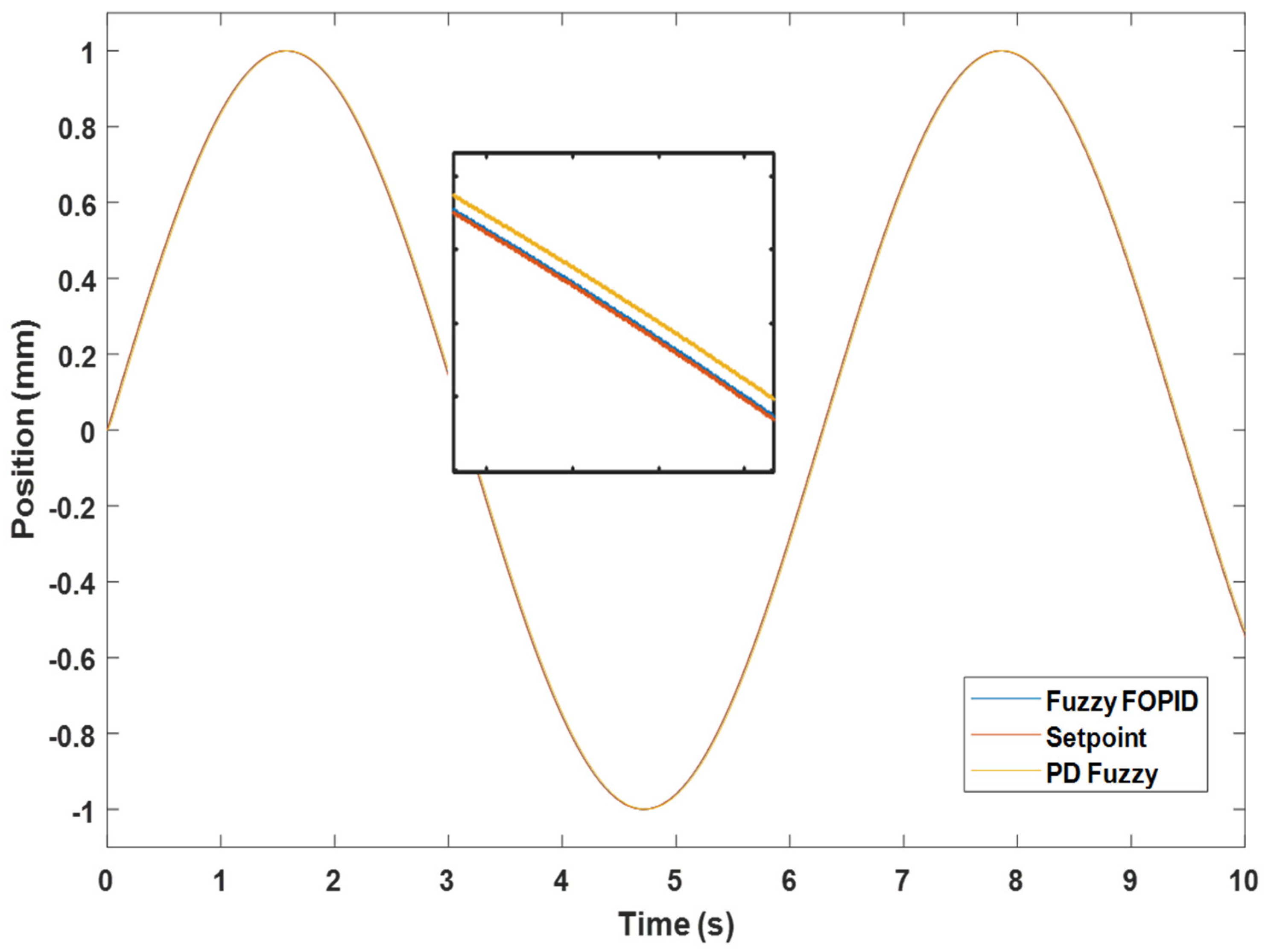

Figure 19 illustrates the performance of the fuzzy FOPID controller when testing the obtained position by the stroke with sinewave input. This demonstrates that the fuzzy FOPID controller successfully minimizes the overshoot in the system’s response.

A significant amount of the system’s response overshoot was identified as the primary issue preventing the achievement of the accurate positional control of the PAs. This could be attributed to the uncertainties in the system, such as leakage, friction, air compressibility, valve dead zone, etc.

To summarize the findings,

Table 5 combines results from the modeling and experimentation of the fuzzy FOPID and fuzzy PID controllers. This clearly demonstrates the superior performance of the fuzzy FOPID controller in comparison with the fuzzy PID controller.

Figure 20 depicts the control signals of the controllers, with the smooth response of the fuzzy FOPID controller being demonstrated in comparison to the fuzzy PID controller, which prevents damage to sensitive components in the plant.

Furthermore, in order to demonstrate the superiority of the fuzzy FOPID controller, the results obtained are compared with those from published articles based on the generalized predictive controller (GPC) presented in [

12], model predictive controller (MPC) presented in [

40], and predictive functional controller (PFC) with the novel observer method presented in [

41] employed for the same system. The performances of these controllers are shown in

Table 6.

Table 6 provides further proof of the supremacy of the proposed controller over those proposed in previous works. It is noted that with the proposed fuzzy FOPID controller optimized by PSO algorithm, the overall performance of the system witnessed a remarkable improvement.

5.3. Robustness Analysis

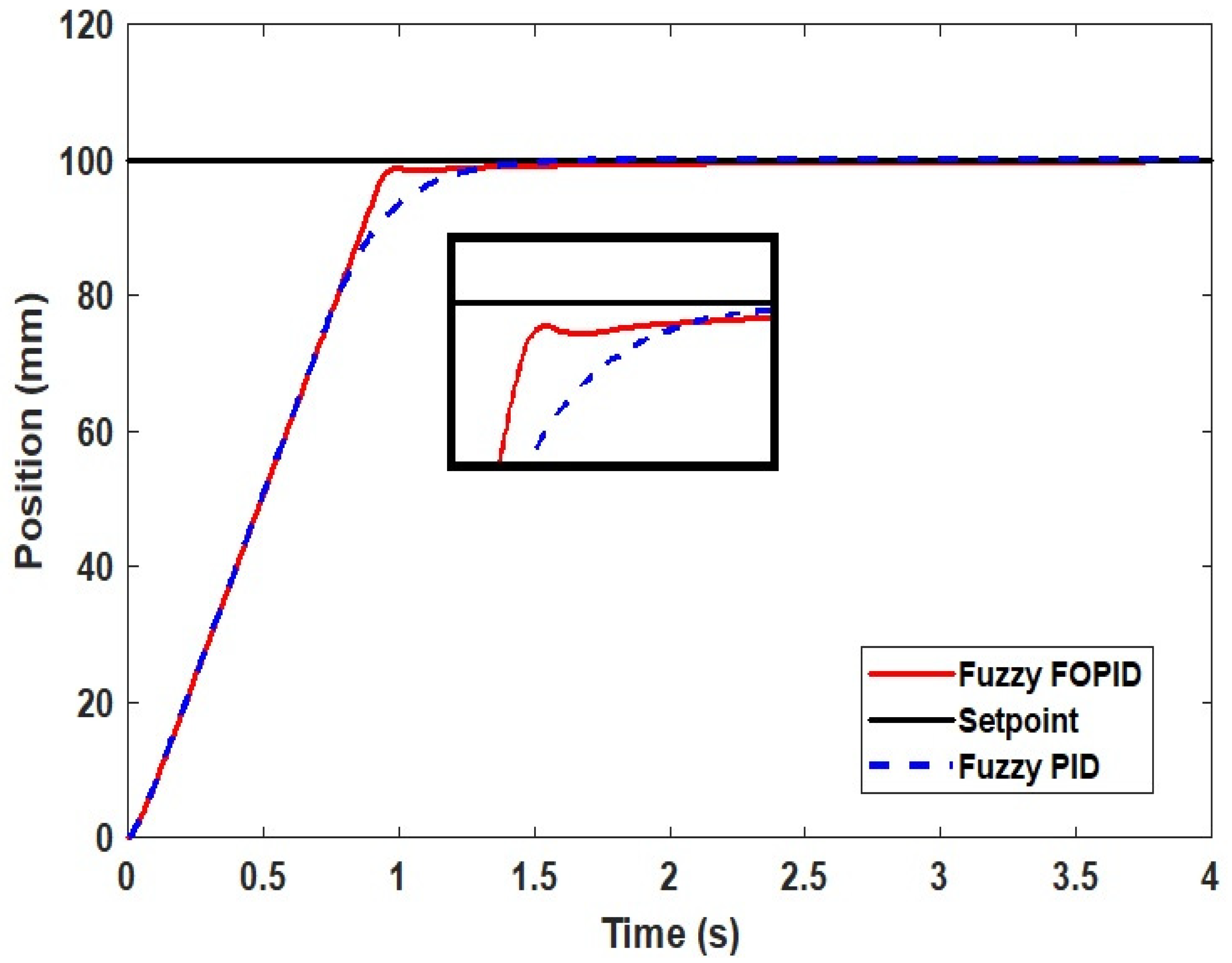

In order to examine the robustness of the proposed fuzzy FOPID controller, the parameters of the testbed system are simultaneously varied by ±25% from their nominal values. These scenarios could represent the most common conditions of parametric uncertainties that the testbed system may experience in real-time operation. The optimal gains obtained during the normal condition will not be retuned when the model is subjected to variation in system parameters.

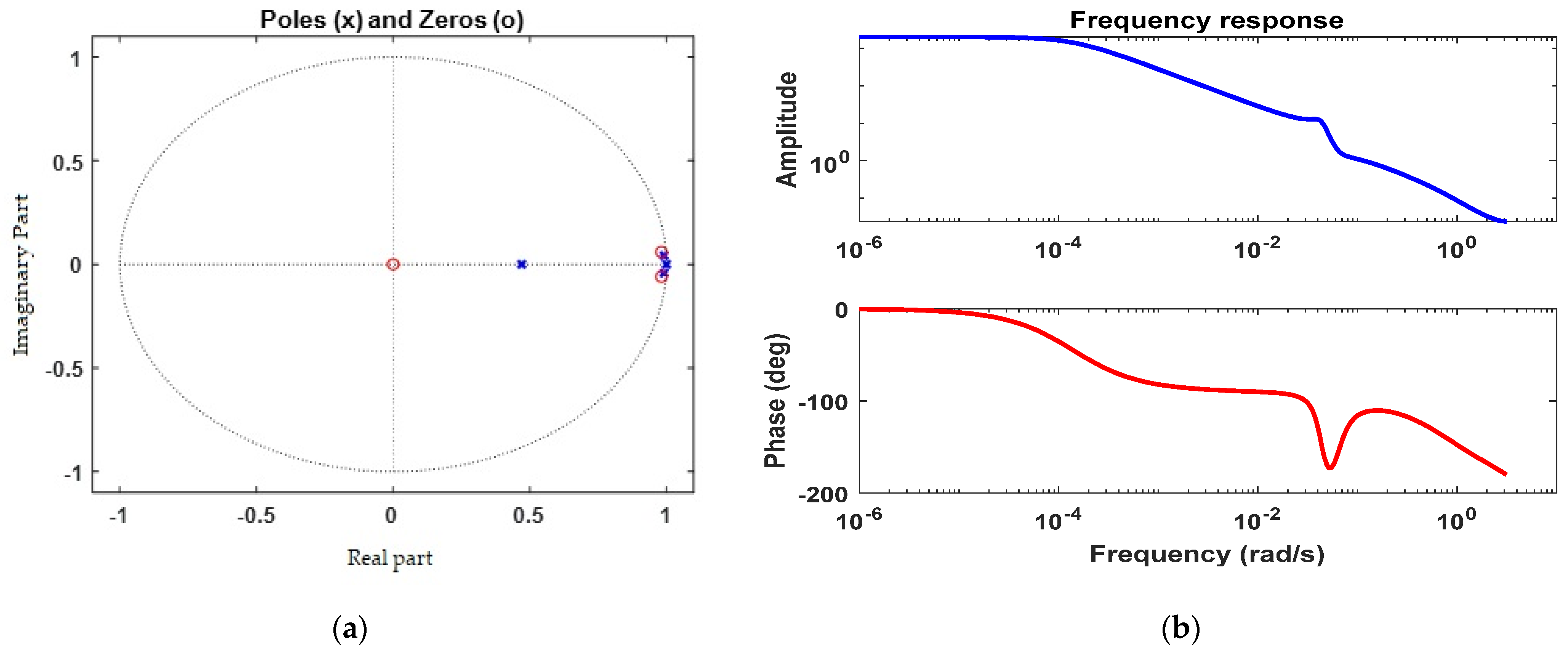

In case 1, the poles of the system are varied by +25% and the equation of the system is shown below:

where the pole values are: P1 = −1.35, P2= −0.103 + 0.328i, and P3 = −0.103 − 0.328i, while the zero values are: Z1 = −2.87, Z2 = 0.497.

In case 2, the zeros of the system are varied by +25% and the equation of the system is shown below:

where the pole values are: P1 = −0.209, P2 = 0.764, and P3 = 1, while the zero values are: Z1 = −0.318, Z2 = 0.497.

In case 3, the poles of the system are varied by −25% and the equation of the system is shown below:

where the pole values are: P1 = −0.209, P2 = 0.764, and P3 = 1, while the zero values are: Z1 = −2.87, Z2 = 0.497.

In case 4, the zeros of the system are varied by −25% and the equation of the system is shown below:

where the pole values are: P1 = −0.209, P2 = 0.764, and P3 = 1, while the zero values are: Z1 = −2.87, Z2 = 0.497.

As illustrated in

Figure 21,

Figure 22,

Figure 23 and

Figure 24 and

Table 7, the implemented fuzzy FOPID controller demonstrated its robustness against a wide variety of parametric uncertainties in the researched IPA system; additionally, the superiority of this controller over other controllers was examined and proven.