Impact of Window Frames on Annual Energy Consumption of Residential Buildings and Its Contribution to CO2 Emission Reductions at the City Scale

Abstract

:1. Introduction

2. Methodology

2.1. Step 1: U-Value of the Frame

2.2. Step 2: Impact of Window Frame on Building Thermal Load, Energy Consumption, and CO2 Emissions

2.3. Step 3: Impact of Window Frame on CO2 Emissions at City Scale

3. Simulation for U-Value of the Frame (Step 1)

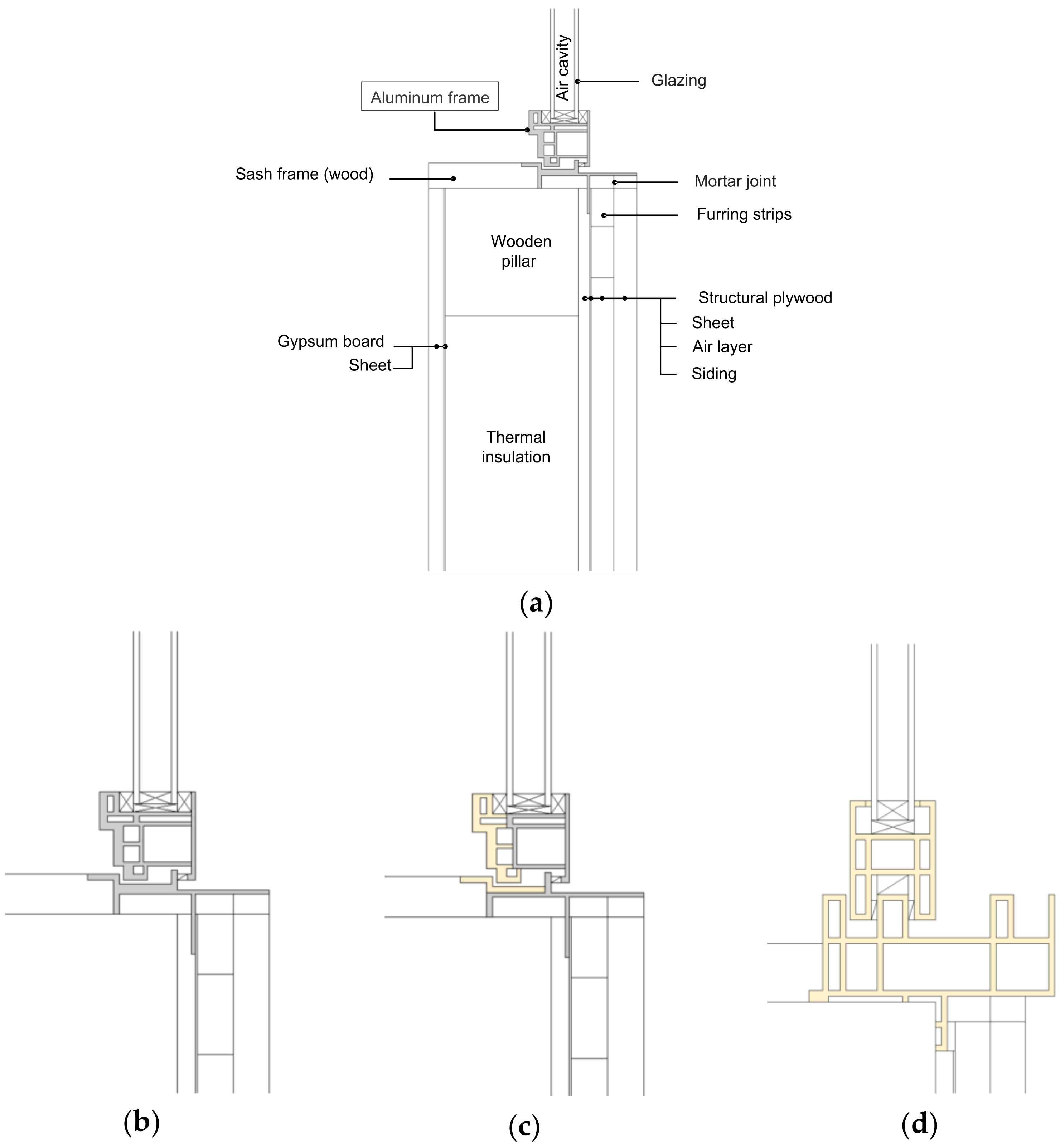

3.1. Description of the Examined Window Configurations

3.2. Simulation Conditions

3.3. Simulation Results: U-Value of Frames

4. Impact of the Window Frame on Annual Building Thermal Load, Energy Consumption, and CO2 Emissions (Steps 2 and 3)

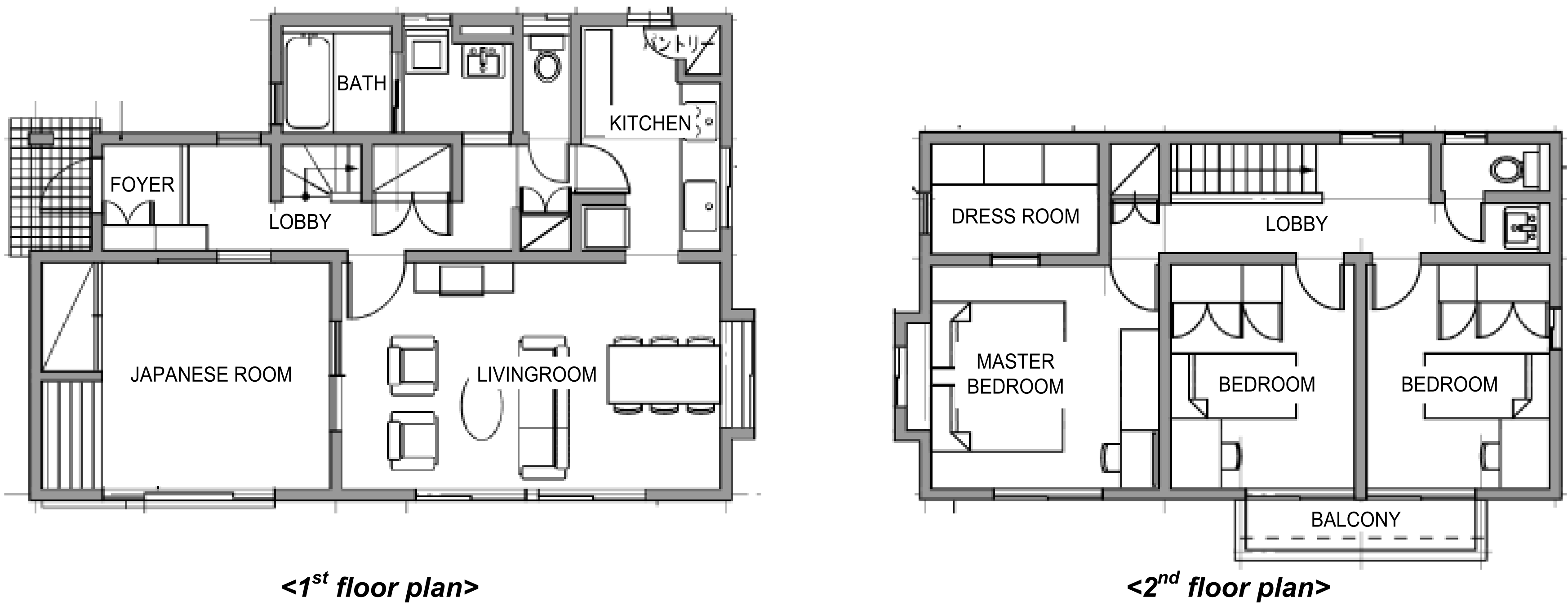

4.1. Description of Reference Building and Window Configurations

4.2. Simulation Conditions

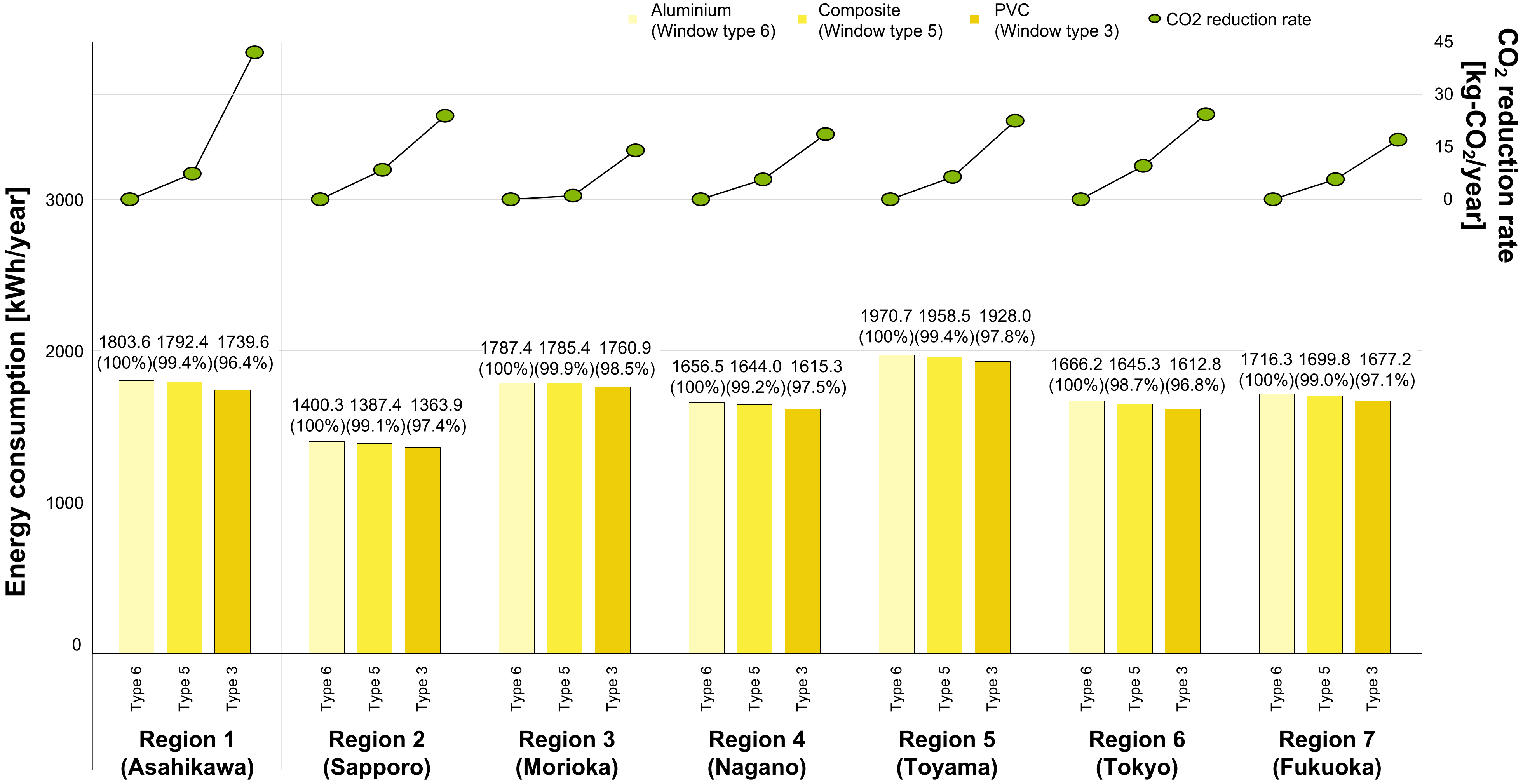

4.3. Simulation Results: Impact of the Window Frame Material on Annual Energy Consumption and CO2 Emissions (Step 2)

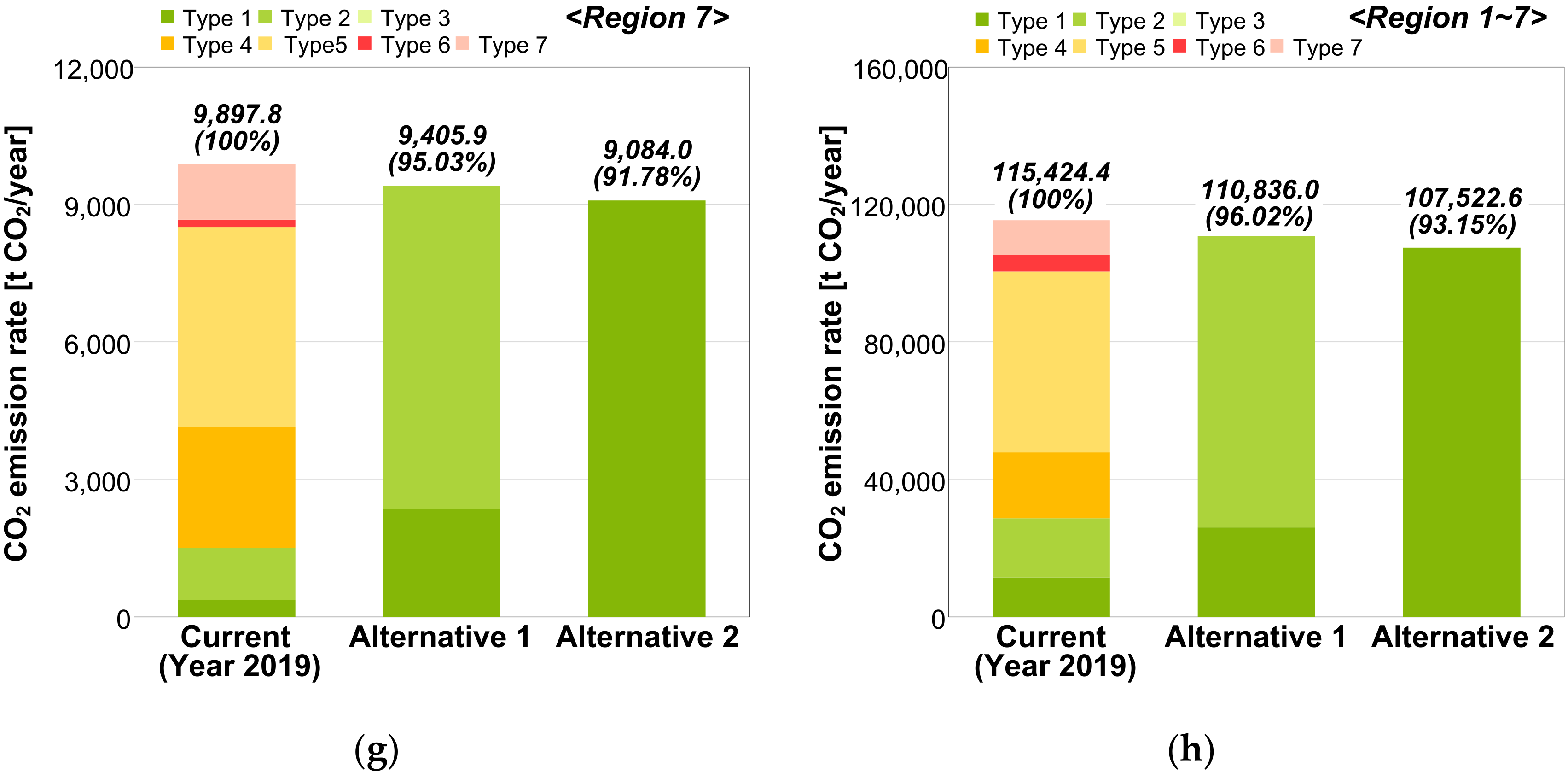

4.4. Simulation Results: Impact of the Window Frame on CO2 Emissions at the City Scale (Step 3)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References and Note

- IPCC. Climate Change 2007: Synthesis Report, Summ. For Policymakers; IPCC: Geneva, Switzerland, 2007. [Google Scholar]

- Heydari, A.; Sadati, S.E.; Gharib, M.R. Effects of different window configurations on energy consumption in building: Optimization and economic analysis. J. Build. Eng. 2021, 35, 102099. [Google Scholar] [CrossRef]

- De Gastines, M.; Correa, É.; Pattini, A. Heat transfer through window frames in EnergyPlus: Model evaluation and improvement. Adv. Build. Energy Res. 2019, 13, 138–155. [Google Scholar] [CrossRef] [Green Version]

- Sinha, A.; Kutnar, A. Carbon Footprint versus Performance of Aluminum, Plastic, and Wood Window Frames from Cradle to Gate. Buildings 2012, 2, 542. [Google Scholar] [CrossRef] [Green Version]

- Gustavsen, A.; Jelle, B.P.; Arasteh, D.; Kohler, C. State-of-the-Art Highly Insulating Window Frames–Research and Market Review; Norges Byggforskningsinstitutt: Oslo, Norway, 2007. [Google Scholar]

- Appelfeld, D.; Hansen, C.S.; Svendsen, S. Development of a slim window frame made of glass fibre reinforced polyester. Energy Build. 2010, 42, 1918–1925. [Google Scholar] [CrossRef]

- Misiopecki, C.; Bouquin, M.; Gustavsen, A.; Jelle, B.P. Thermal modeling and investigation of the most energy-efficient window position. Energy Build. 2018, 158, 1079–1086. [Google Scholar] [CrossRef]

- Takada, K.; Hayama, H.; Mori, T.; Kikuta, K. Thermal insulated PVC windows for residential buildings: Feasibility of insulation performance improvement by various elemental technologies. J. Asian Archit. Build. Eng. 2020, 20, 340–355. [Google Scholar] [CrossRef]

- Rahman, W.A.W.A.; Sin, L.T.; Rahmat, A.R. Injection moulding simulation analysis of natural fiber composite window frame. J. Mater. Process. Technol. 2008, 197, 22–30. [Google Scholar] [CrossRef]

- Khetib, Y.; Alotaibi, A.A.; Alshahri, A.H.; Rawa, M.; Cheraghian, G.; Sharifpur, M. Impact of phase change material on the amount of emission in the double-glazed window frame for different window angles. J. Energy Storage 2021, 44, 103320. [Google Scholar] [CrossRef]

- International Energy Agency. Technology Roadmap Energy Efficient Building Envelopes; IEA: Paris, France, 2013. [Google Scholar]

- El-Darwish, I.; Gomaa, M. Retrofitting strategy for building envelopes to achieve energy efficiency. Alex. Eng. J. 2017, 56, 579–589. [Google Scholar] [CrossRef] [Green Version]

- Survey on the Use of Building Materials for Residential Buildings. 2021. Available online: https://www.jsma.or.jp/ (accessed on 16 May 2022).

- Survey on the Use of Building Materials for Residential Buildings. 2013. Available online: https://www.jsma.or.jp/ (accessed on 16 May 2022).

- Baldinelli, G.; Lechowska, A.; Bianchi, F.; Schnotale, J. Sensitivity Analysis of Window Frame Components Effect on Thermal Transmittance. Energies 2020, 13, 2957. [Google Scholar] [CrossRef]

- Laustsen, J.B.; Svendsen, S. Improved windows for cold climates. In Proceedings of the 7th Nordic Symposium on Building Physics, Reykjavik, Iceland, 13–15 June 2005; pp. 987–994. [Google Scholar]

- Zajas, J.; Heiselberg, P. Parametric study and multi objective optimization of window frame geometry. Build. Simul. 2014, 7, 579–593. [Google Scholar] [CrossRef]

- Asdrubali, F.; Roncone, M.; Grazieschi, G. Embodied energy and embodied GWP of windows: A critical review. Energies 2021, 14, 3788. [Google Scholar] [CrossRef]

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build. 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Ozaki, A.; Tsujimaru, T. Prediction of hygrothermal environment of buildings based upon combined simulation of heat and moisture transfer and airflow. In Proceedings of the IBPSA 2005—International Building Performance Simulation Association, Montréal, QC, Canada, 15–18 August 2005. [Google Scholar]

- Choi, Y.; Cho, W.; Ozaki, A.; Lee, H. Influence of the moisture driving force of moisture adsorption and desorption on indoor hygrothermal environment and building thermal load. Energy Build. 2021, 253, 111501. [Google Scholar] [CrossRef]

- BS EN ISO 10077-2:2017; BSI Standards Publication Thermal Performance of Windows, Doors and Shutters—Calculation of Thermal Transmittance. B.S.I. Standards: London, UK, 2017.

- Konisi, T.; Saito, H.; Isikawq, K. Energy Conservation Standards, Inst. Build. Environ. Energy Conserv. Available online: https://www.ibec.or.jp/ee_standard/build_standard.html (accessed on 16 May 2022).

- Ministry of the Environment, Japan. CO2 Emission Factor by Electric Power Company. 2020. Available online: https://www.env.go.jp/press/files/jp/115373.pdf (accessed on 16 May 2022).

- Area Classification for Energy Saving, Japan. 2020. Available online: https://www.mlit.go.jp/jutakukentiku/shoenehou_assets/img/library/chiikikubun-sinkyuu.pdf (accessed on 16 May 2022).

- Number of newly built households by region in Japan, Tokyo, n.d.

- ISO 15099:2003; Thermal Performance of Windows, Doors and Shading Devices—Detailed Calculations. International Organization for Standardization (I.S.O.): Geneva, Switzerland, 2003.

- Number of Houses Built in Japan; Nomura Research Institute (NRI): Tokyo, Japan, 2020; Available online: https://www.nri.com/jp/news/newsrelease/lst/2020/cc/0609_1 (accessed on 16 May 2022).

- Nishizawa, S. Explanation of Energy Consumption Calculation Method in Criteria of Housing Business; Institute for Building Environment and Energy Conservation (IBEC): Tokyo, Japan, 2009; pp. 35–47. [Google Scholar]

- Expanded AMeDAS Weather Data, Japan Meteorol. Agency. 2021. Available online: https://www.jma.go.jp/bosai/map.html#5/34.5/137/&elem=temp&contents=amedas&interval=60 (accessed on 16 May 2022).

- Uetake, J.; Tobo, Y.; Kobayashi, S.; Tanaka, K.; Watanabe, S.; DeMott, P.J.; Kreidenweis, S.M. Visualization of the seasonal shift of a variety of airborne pollens in western Tokyo. Sci. Total Environ. 2021, 788, 147623. [Google Scholar] [CrossRef] [PubMed]

- Yamada, T.; Saito, H.; Fujieda, S. Present state of Japanese cedar pollinosis: The national affliction. J. Allergy Clin. Immunol. 2014, 133, 632–639. [Google Scholar] [CrossRef] [PubMed]

- How Much Carbon Dioxide Does the Forest Absorb? Ministry of Agriculture, Forestry and Fisheries: Tokyo, Japan, 2014. Available online: https://www.rinya.maff.go.jp/j/sin_riyou/ondanka/20141113_topics2_2.html (accessed on 16 May 2022).

| Region | Frame Application Frequency by Households (Number of Households, %) | Sum (Number of Newly Built Households, %) | |||

|---|---|---|---|---|---|

| PVC | Composite | Aluminum | Wood | ||

| Entire area | 35,571 (23.47%) | 97,709 (64.47%) | 18,155 (11.98%) | 24 (0.02%) | 151,569 (100%) |

| Region 1 (Asahikawa) | 1495 (99.00%) | 0 (0.00%) | 14 (0.90%) | 2 (0.10%) | 1510 (100%) |

| Region 2 (Sapporo) | 15,839 (99.00%) | 0 (0.00%) | 144 (0.90%) | 6 (0.10%) | 15,999 (100%) |

| Region 3 (Morioka) | 1063 (53.60%) | 893 (45.00%) | 26 (1.30%) | 2 (0.10%) | 1984 (100%) |

| Region 4 (Nagano) | 433 (18.50%) | 1729 (73.80%) | 176 (7.50%) | 5 (0.20%) | 2343 (100%) |

| Region 5 (Toyama) | 1102 (35.50%) | 1983 (63.90%) | 19 (0.60%) | 0 (0.00%) | 3103 (100%) |

| Region 6 (Tokyo) | 12,982 (11.80%) | 81,195 (73.80%) | 15,733 (14.30%) | 10 (0.10%) | 110,020 (100%) |

| Region 7 (Fukuoka) | 2658 (16.00%) | 11,909 (71.70%) | 2043 (12.30%) | 0 (0.00%) | 16,610 (100%) |

| Category | Layer | Thickness [m] | Thermal Conductivity [W/(m·K)] | Specific Heat [J/(kg·K)] | Specific Weight [kg/m3] |

|---|---|---|---|---|---|

| Exterior wall | Gypsum board | 0.009 | 0.220 | 870.0 | 706.0 |

| Thermal insulation (glass wool) * | 0.130/0.080/0.040 | 0.045 | 840.0 | 56.0 | |

| Structural plywood | 0.012 | 0.160 | 1880.0 | 556.0 | |

| Ventilated cavity | 0.022 | 0.024 | 1005.0 | 1.2 | |

| Siding | 0.015 | 0.140 | 760.0 | 1110.0 | |

| Ceiling | Interior finishing materials | 0.012 | 0.160 | 1880.0 | 556.0 |

| Ventilated cavity | 0.030 | 0.024 | 1005.0 | 1.2 | |

| Thermal insulation (glass wool) * | 0.280/0.210/0.090 | 0.050 | 840.0 | 56.0 | |

| Structural Plywood | 0.012 | 0.160 | 1880.0 | 556.0 | |

| Sheet | 0.001 | 0.160 | 840.0 | 1270.0 | |

| Roof finish | 0.030 | 0.349 | 800.0 | 2000.0 | |

| Floor | Plywood | 0.012 | 0.111 | 1880.0 | 550.0 |

| Thermal insulation (glass wool) * | 0.150/0.110/0.050 | 0.045 | 840.0 | 56.0 | |

| Plywood | 0.012 | 0.160 | 1880.0 | 556.0 |

| Classification | Type of Window | ||||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 * | 4 | 5 * | 6 * | 7 | |

| Frame | PVC | PVC | PVC | AL+PVC | AL+PVC | AL | AL |

| Glazing | Low-E triple | Low-E double | Low-E double | Low-E double | Low-E double | Low-E double | Single |

| Cavity | Argon | Argon | Air | Argon | Air | Air | Air |

| 15 mm × 2 | 16 mm | 16 mm | 16 mm | 16 mm | 16 mm | 16 mm | |

| Region | Type of Window | Sum | ||||||

|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 * | 4 | 5 * | 6 * | 7 | ||

| Region 1 (Asahikawa) | 881 (58.42%) | 613 (40.65%) | 0 (0.00%) | 0 (0.00%) | 0 (0.00%) | 14 (0.93%) | 0 (0.00%) | 1508 (100%) |

| Region 2 (Sapporo) | 9345 (58.47%) | 6494 (40.63%) | 0 (0.00%) | 0 (0.00%) | 0 (0.00%) | 144 (0.90%) | 0 (0.00%) | 15,983 (100%) |

| Region 3 (Morioka) | 239 (12.06%) | 824 (41.57%) | 0 (0.00%) | 264 (13.32%) | 629 (31.74%) | 26 (1.31%) | 0 (0.00%) | 1982 (100%) |

| Region 4 (Nagano) | 42 (1.80%) | 391 (16.72%) | 0 (0.00%) | 294 (12.57%) | 1435 (61.38%) | 176 (7.53%) | 0 (0.00%) | 2338 (100%) |

| Region 5 (Toyama) | 177 (5.71%) | 924 (29.79%) | 0 (0.00%) | 508 (16.38%) | 1475 (47.55%) | 8 (0.26%) | 10 (0.32%) | 3102 (100%) |

| Region 6 (Tokyo) | 2298 (2.09%) | 10,684 (9.72%) | 0 (0.00%) | 21,029 (19.13%) | 60,165 (54.74%) | 5727 (5.21%) | 10,006 (9.10%) | 109,909 (100%) |

| Region 7 (Fukuoka) | 691 (4.16%) | 1967 (11.84%) | 0 (0.00%) | 4514 (27.17%) | 7396 (44.52%) | 276 (1.66%) | 1767 (10.64%0 | 16,611 (100%) |

| (a) | |||||||

|---|---|---|---|---|---|---|---|

| Region | Annual Heating Load [kWh/year] | ||||||

| Window Type 1 | Window Type 2 | Window Type 3 | Window Type 4 | Window Type 5 | Window Type 6 | Window Type 7 | |

| Region 1 (Asahikawa) | 915.0 | 1655.7 | 1611.1 | 1896.5 | 1849.2 | 1751.0 | 1795.7 |

| Region 2 (Sapporo) | 695.1 | 1221.8 | 1183.5 | 1301.6 | 1259.3 | 1169.0 | 1296.4 |

| Region 3 (Morioka) | 869.1 | 883.3 | 872.7 | 880.2 | 867.8 | 828.2 | 916.4 |

| Region 4 (Nagano) | 2344.8 | 2585.0 | 2561.8 | 2666.0 | 2644.0 | 2577.0 | 3518.4 |

| Region 5 (Toyama) | 3097.6 | 3373.2 | 3352.7 | 3479.4 | 3457.2 | 3406.3 | 4469.3 |

| Region 6 (Tokyo) | 4165.3 | 4511.1 | 4495.2 | 4652.9 | 4635.2 | 4597.9 | 5963.1 |

| Region 7 (Fukuoka) | 4720.4 | 5087.1 | 5070.2 | 5223.4 | 5206.3 | 5165.3 | 6529.1 |

| |||||||

| (b) | |||||||

| Region | Annual Cooling Load [kWh/year] | ||||||

| Window Type 1 | Window Type 2 | Window Type 3 | Window Type 4 | Window Type 5 | Window Type 6 | Window Type 7 | |

| Region 1 (Asahikawa) | 8762.1 | 8255.6 | 8478.4 | 8303.0 | 8546.6 | 8709.9 | 10,466.6 |

| Region 2 (Sapporo) | 7025.2 | 6539.3 | 6727.0 | 6583.2 | 6787.7 | 6952.7 | 8397.5 |

| Region 3 (Morioka) | 8784.1 | 9201.8 | 9340.3 | 9304.1 | 9487.7 | 9538.8 | 10,905.3 |

| Region 4 Nagano) | 6582.2 | 6689.0 | 6806.7 | 6729.8 | 6891.1 | 7030.8 | 7484.7 |

| Region 5 (Toyama) | 7477.7 | 7675.5 | 7829.4 | 7731.4 | 7902.0 | 8023.6 | 8756.8 |

| Region 6 (Tokyo) | 4705.6 | 4742.5 | 4859.2 | 4779.3 | 4907.4 | 5066.3 | 5325.2 |

| Region 7 (Fukuoka) | 4420.8 | 4492.0 | 4599.7 | 4533.7 | 4652.7 | 4789.3 | 5118.6 |

| |||||||

| (c) | |||||||

| Region | Annual Total Heat Load [kWh/year] | ||||||

| Window Type 1 | Window Type 2 | Window Type 3 | Window Type 4 | Window Type 5 | Window Type 6 | Window Type 7 | |

| Region 1 (Asahikawa) | 9677.1 | 9911.2 | 10,089.5 | 10,199.5 | 10,395.8 | 10,460.9 | 12,262.3 |

| Region 2 (Sapporo) | 7720.3 | 7761.0 | 7910.5 | 7884.8 | 8047.0 | 8121.7 | 9693.9 |

| Region 3 (Morioka) | 9653.2 | 10,085.0 | 10,213.0 | 10,184.3 | 10,355.5 | 10,367.0 | 11,821.7 |

| Region 4 (Nagano) | 8927.0 | 9274.0 | 9368.6 | 9395.8 | 9535.1 | 9607.8 | 11,003.1 |

| Region 5 (Toyama) | 10,575.3 | 11,048.6 | 11,182.1 | 11,210.8 | 11,359.2 | 11,429.9 | 13,226.1 |

| Region 6 (Tokyo) | 8870.9 | 9253.6 | 9354.4 | 9432.2 | 9542.6 | 9664.2 | 11,288.4 |

| Region 7 (Fukuoka) | 9141.2 | 9579.1 | 9669.9 | 9757.1 | 9859.0 | 9954.6 | 11,647.7 |

| |||||||

| Region | Alternative 1 | Alternative 2 | ||

|---|---|---|---|---|

| CO2 Reduction Rate [t CO2] | Frequency of CO2 Reduction Rate [%] | CO2 Reduction Rate [t CO2] | Frequency of CO2 Reduction Rate [%] | |

| Region 1 (Asahikawa) | 1.06 | 0.02% | 17.43 | 0.22% |

| Region 2 (Sapporo) | 6.26 | 0.14% | 36.50 | 0.46% |

| Region 3 (Morioka) | 26.65 | 0.58% | 87.03 | 1.10% |

| Region 4 (Nagano) | 41.56 | 0.91% | 98.66 | 1.25% |

| Region 5 (Toyama) | 65.17 | 1.42% | 176.92 | 2.24% |

| Region 6 (Tokyo) | 3955.81 | 86.21% | 6671.42 | 84.43% |

| Region 7 (Fukuoka) | 491.89 | 10.72% | 813.87 | 10.30% |

| Sum | 4588.41 | 100% | 7901.82 | 100% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, Y.; Ozaki, A.; Lee, H. Impact of Window Frames on Annual Energy Consumption of Residential Buildings and Its Contribution to CO2 Emission Reductions at the City Scale. Energies 2022, 15, 3692. https://doi.org/10.3390/en15103692

Choi Y, Ozaki A, Lee H. Impact of Window Frames on Annual Energy Consumption of Residential Buildings and Its Contribution to CO2 Emission Reductions at the City Scale. Energies. 2022; 15(10):3692. https://doi.org/10.3390/en15103692

Chicago/Turabian StyleChoi, Younhee, Akihito Ozaki, and Haksung Lee. 2022. "Impact of Window Frames on Annual Energy Consumption of Residential Buildings and Its Contribution to CO2 Emission Reductions at the City Scale" Energies 15, no. 10: 3692. https://doi.org/10.3390/en15103692

APA StyleChoi, Y., Ozaki, A., & Lee, H. (2022). Impact of Window Frames on Annual Energy Consumption of Residential Buildings and Its Contribution to CO2 Emission Reductions at the City Scale. Energies, 15(10), 3692. https://doi.org/10.3390/en15103692