Investigation on the Fracture-Pore Evolution and Percolation Characteristics of Oil Shale under Different Temperatures

Abstract

:1. Introduction

2. Experimental Methodology

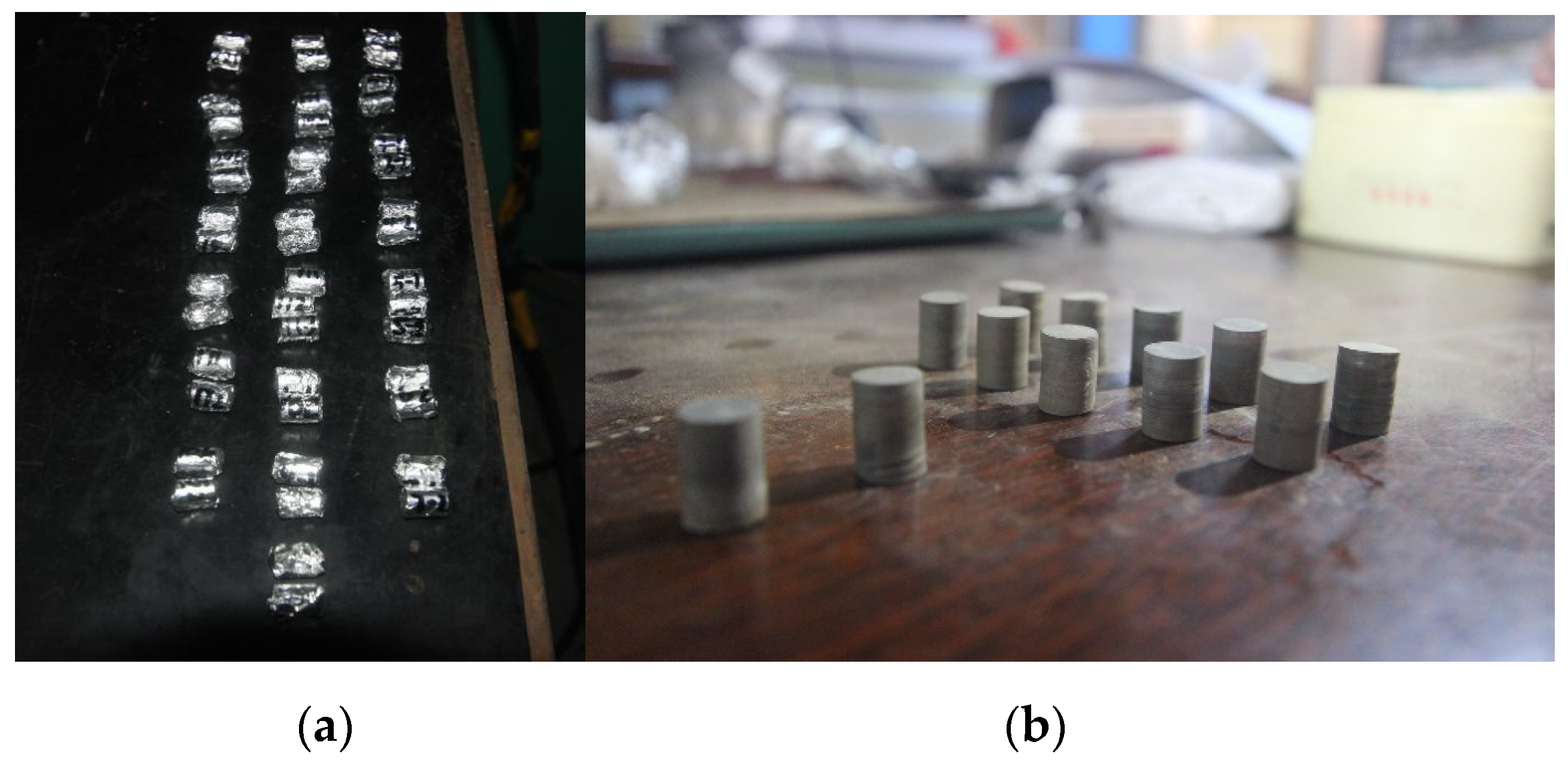

2.1. Sample Preparation and Pyrolysis

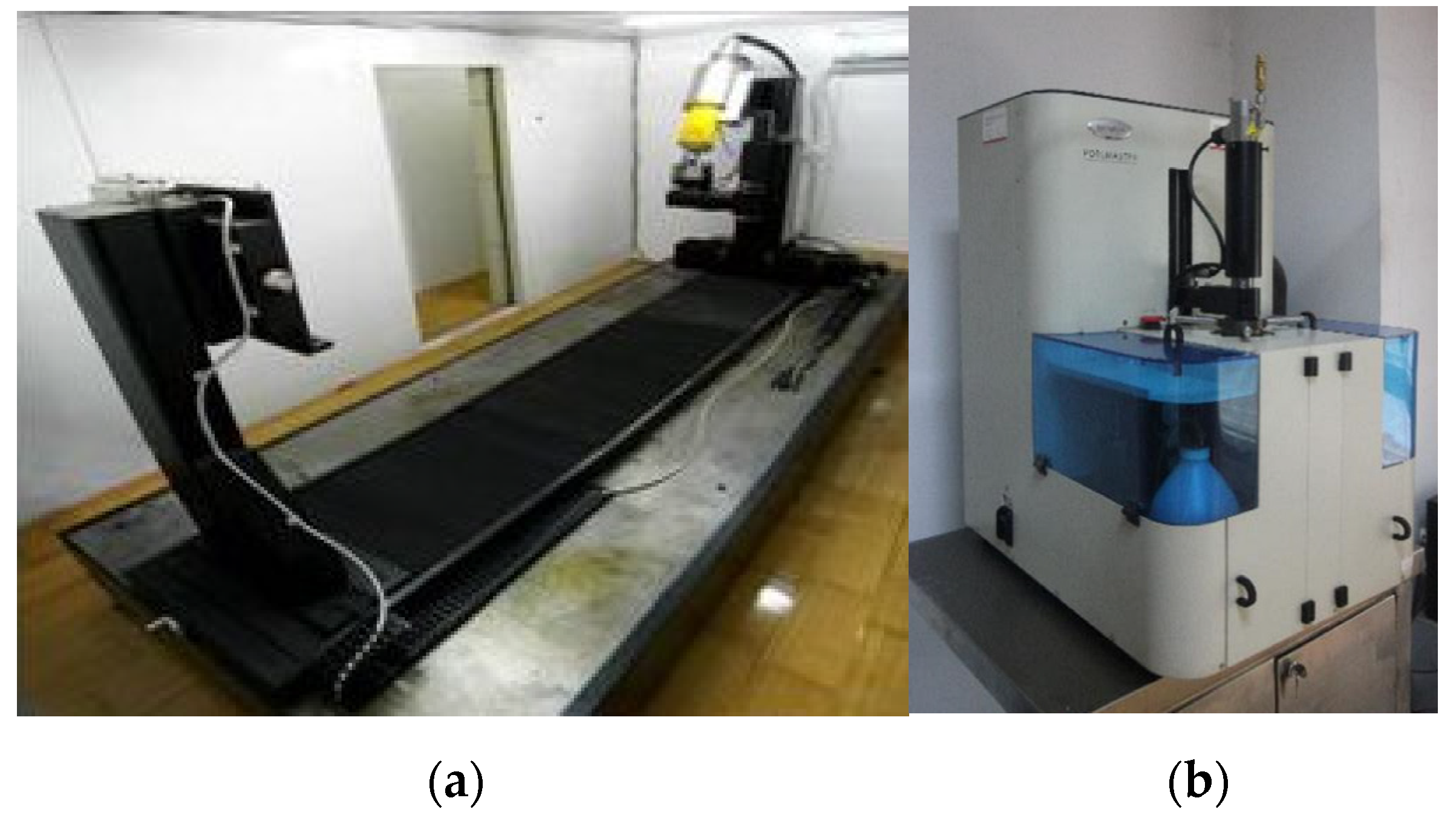

2.2. X-ray Micro Tomography for Fracture Distribution

2.3. Mercury Injection Porosimetry for Pore Structure

2.4. Implementation of 3D Simulation Model

3. Results and Discussion

3.1. Fracture Distribution with Increasing Temperature

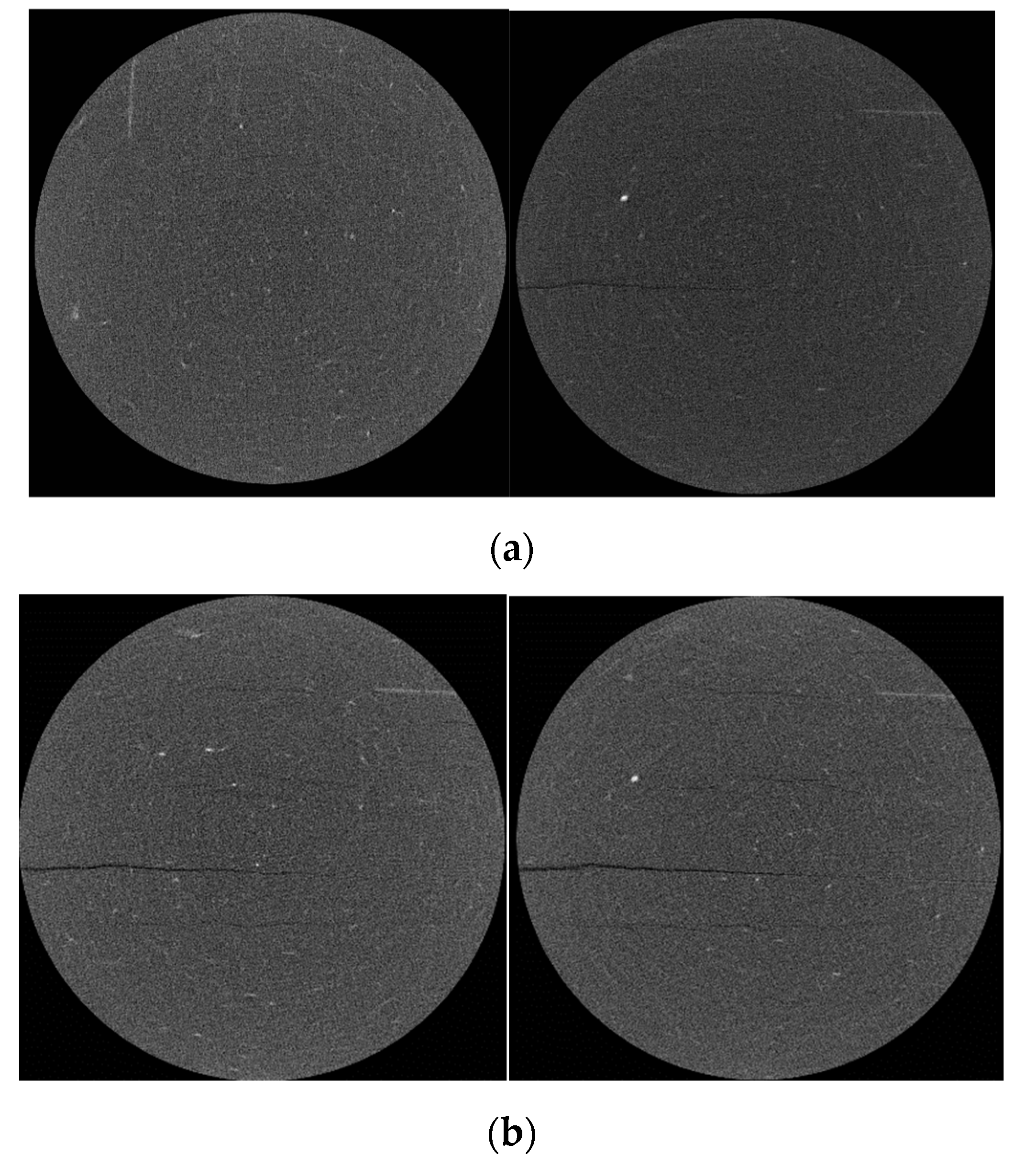

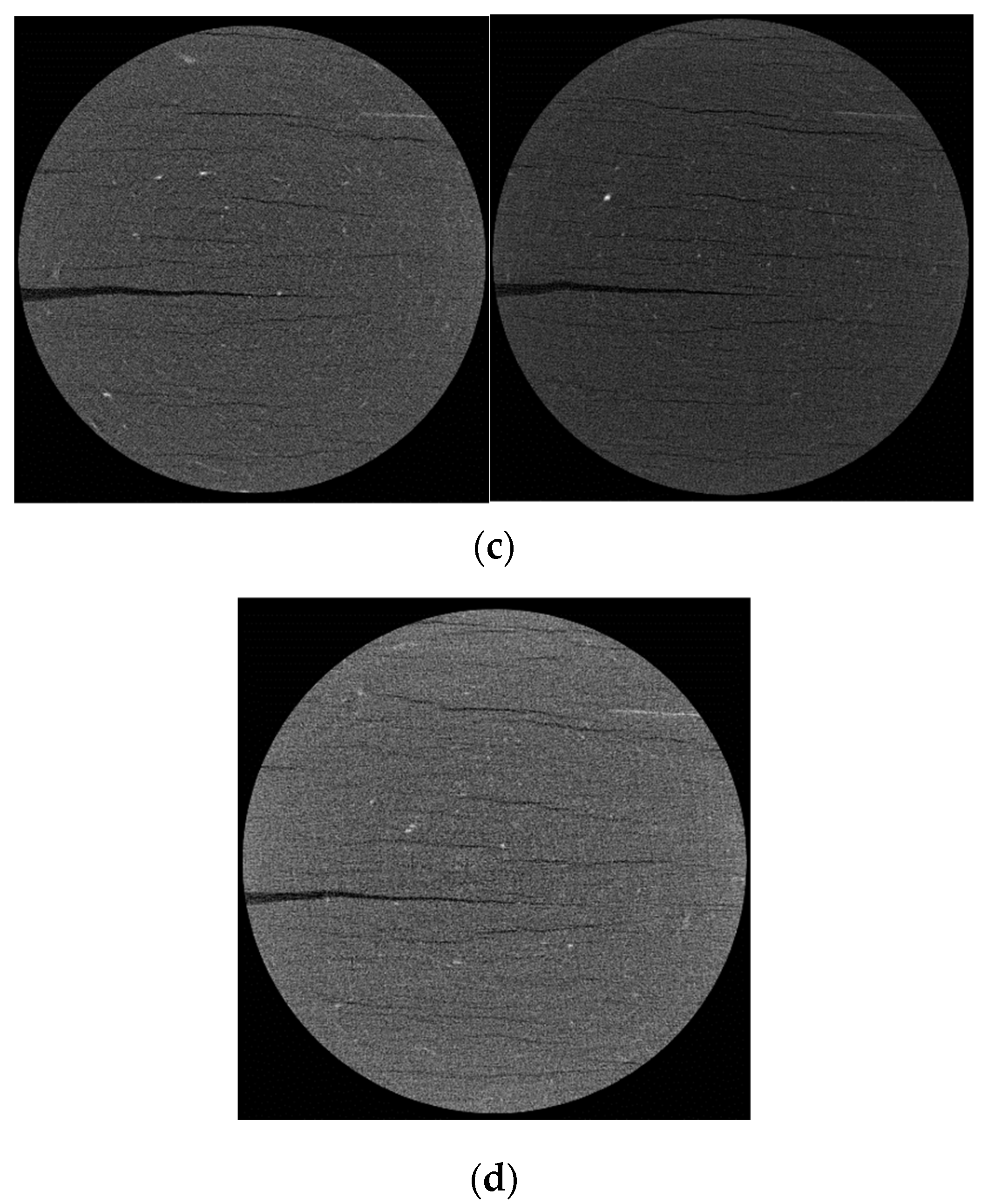

3.1.1. 2D Fracture Distribution

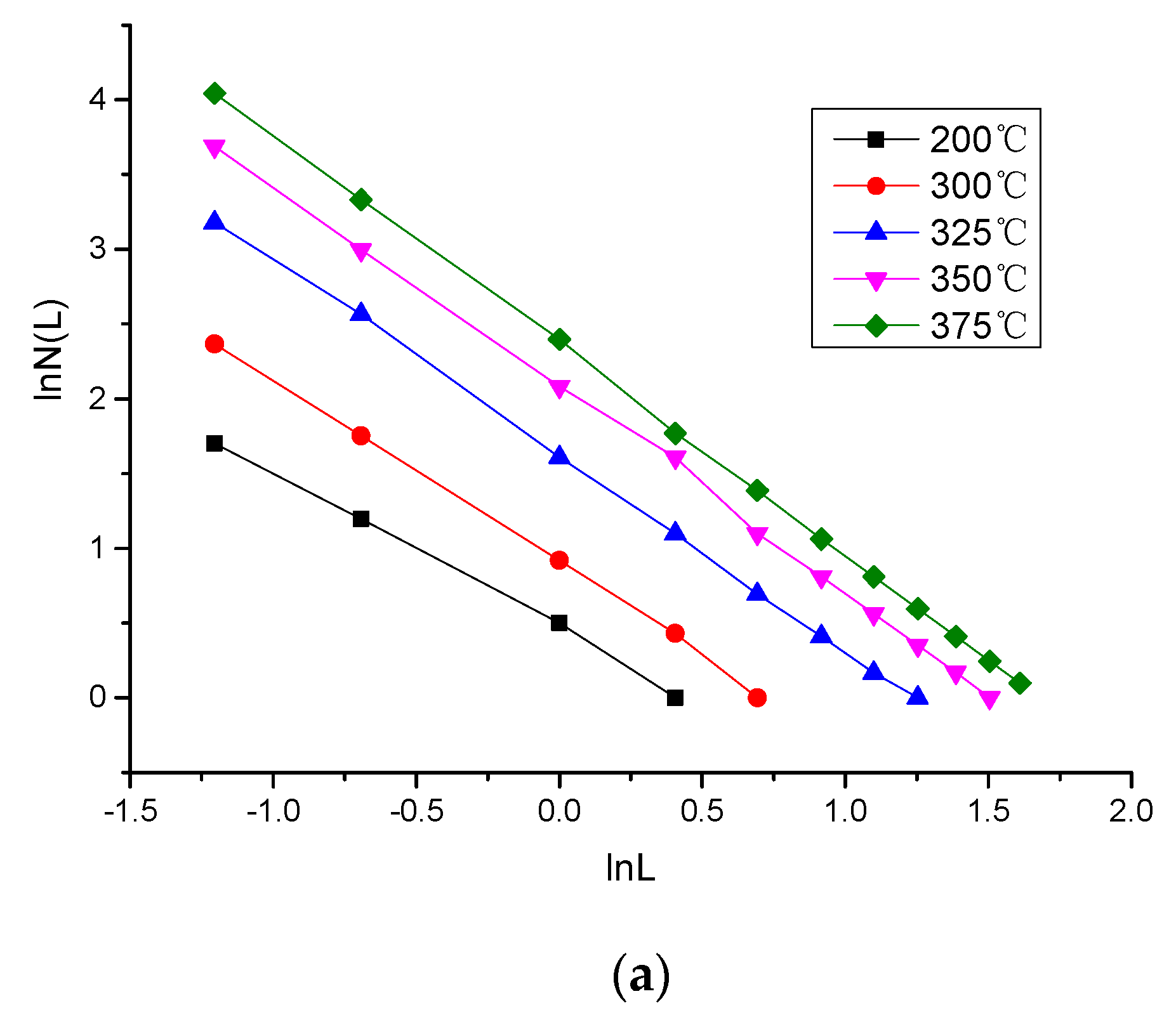

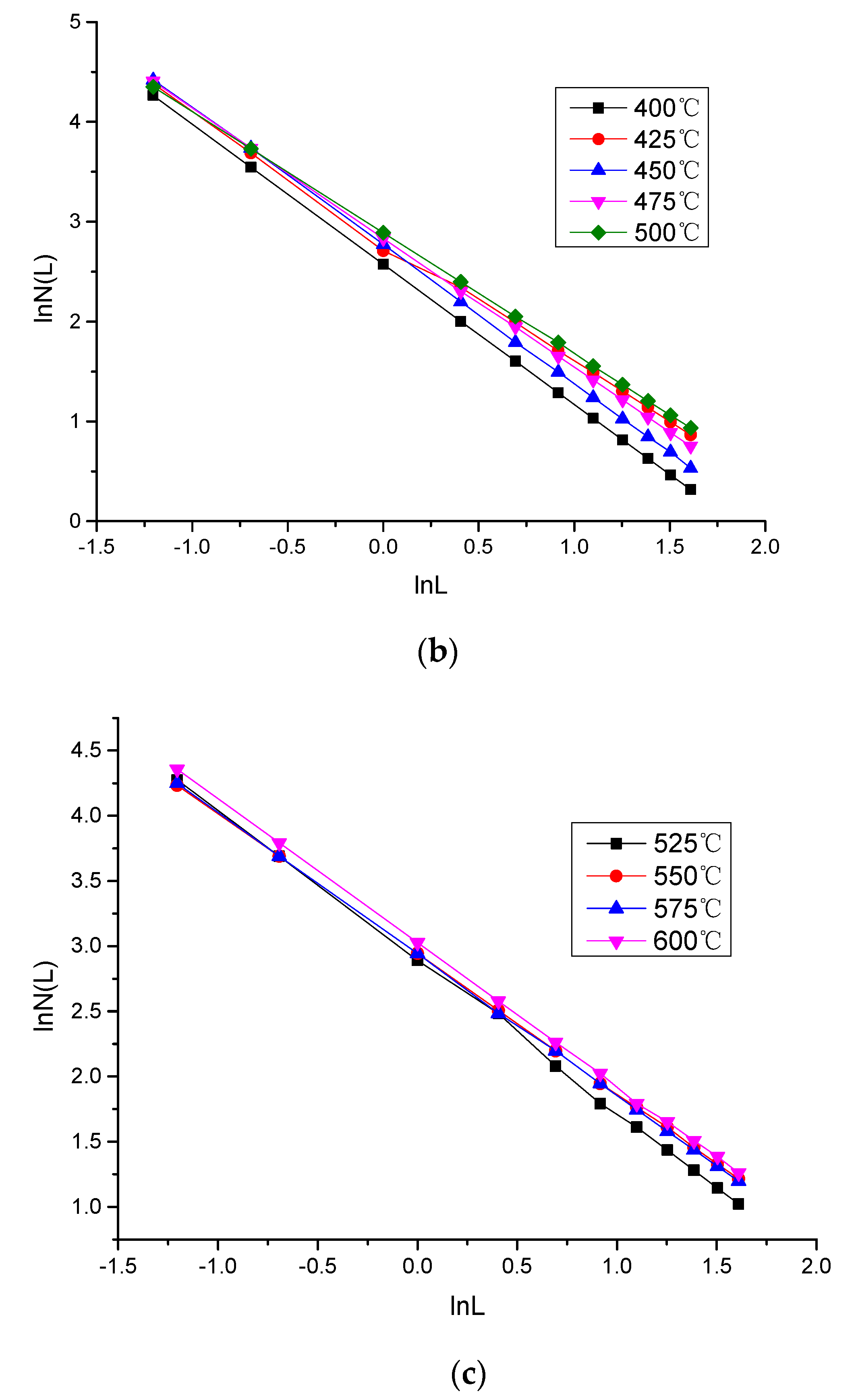

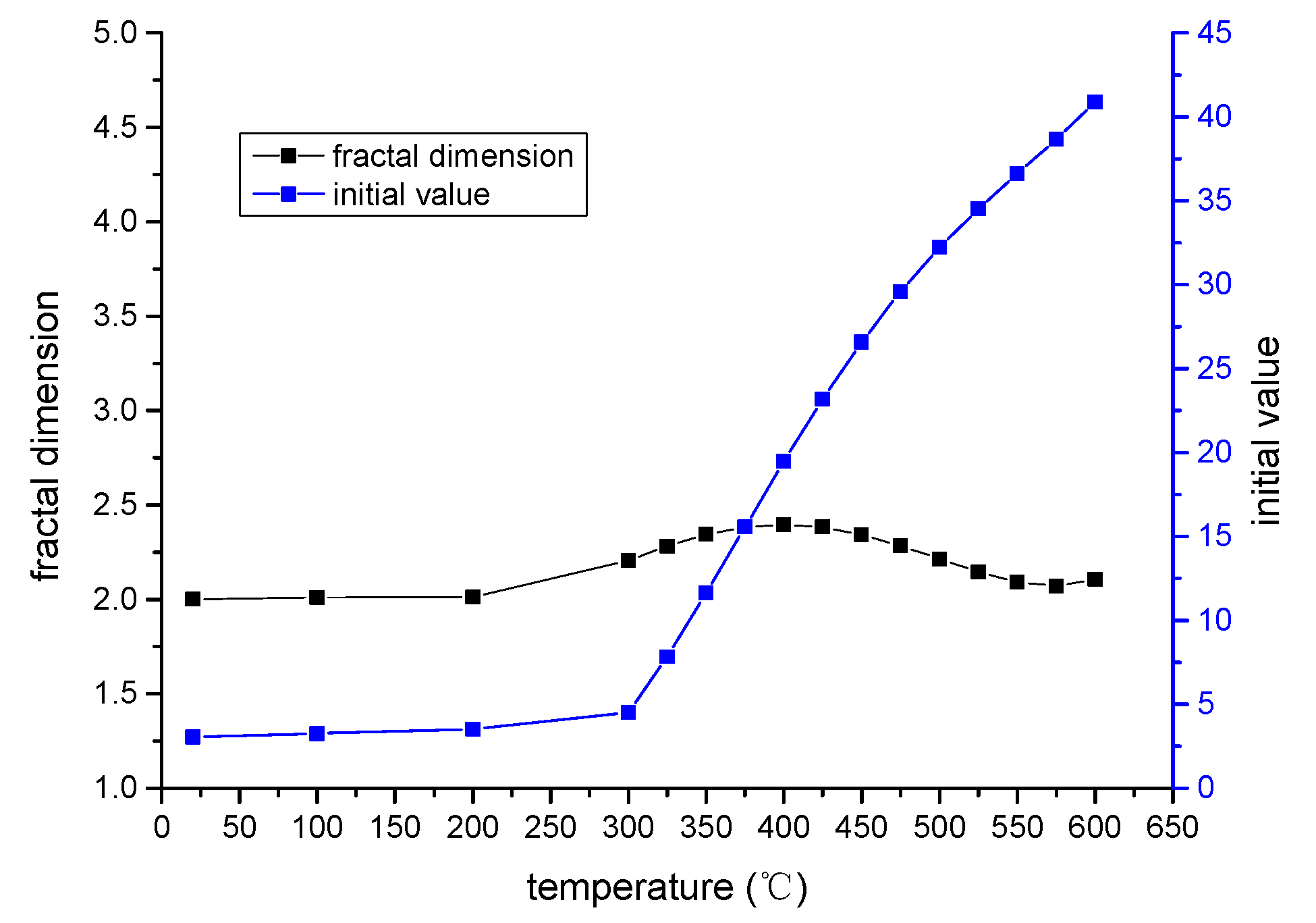

3.1.2. 3D Fracture Distribution

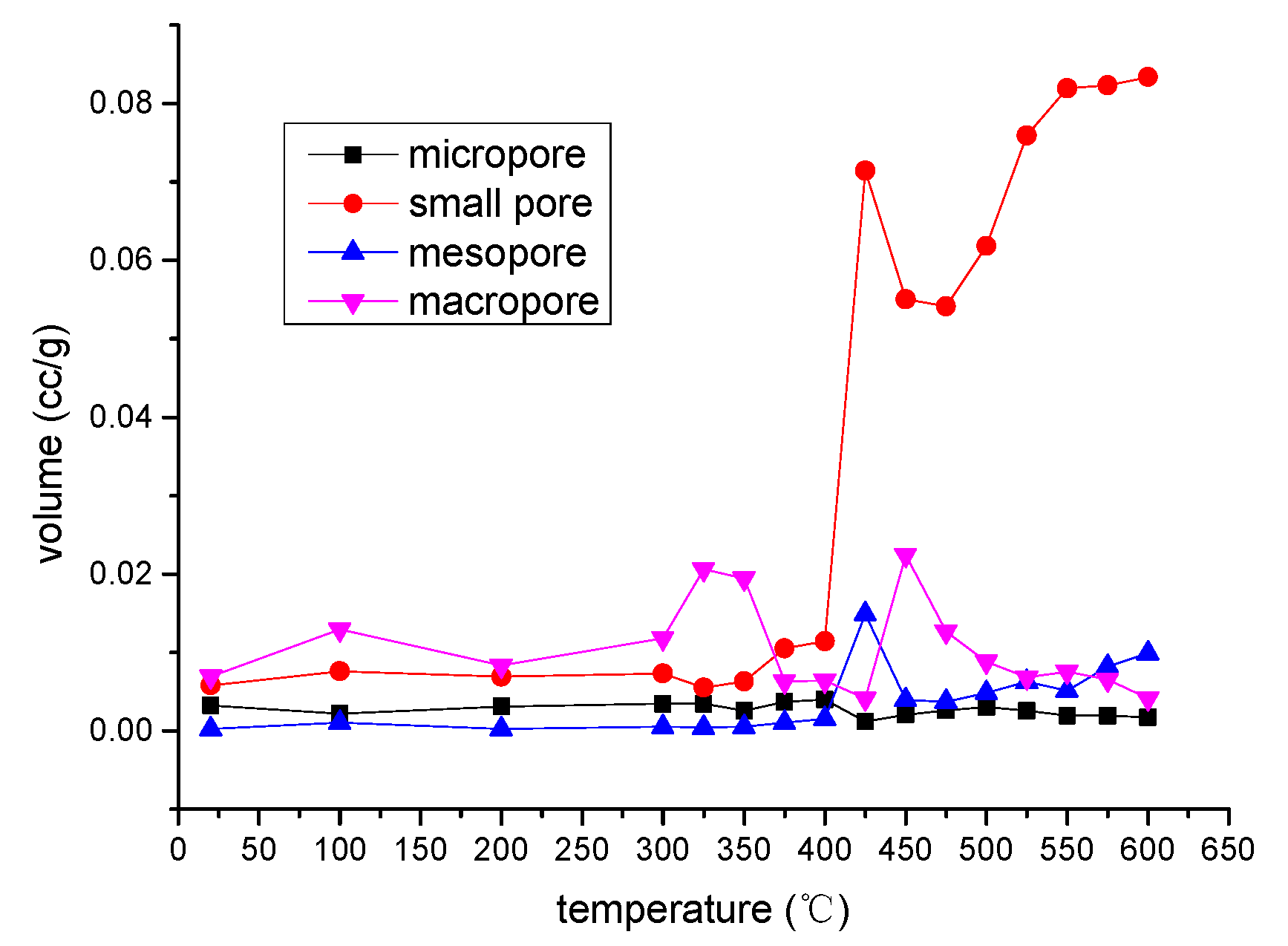

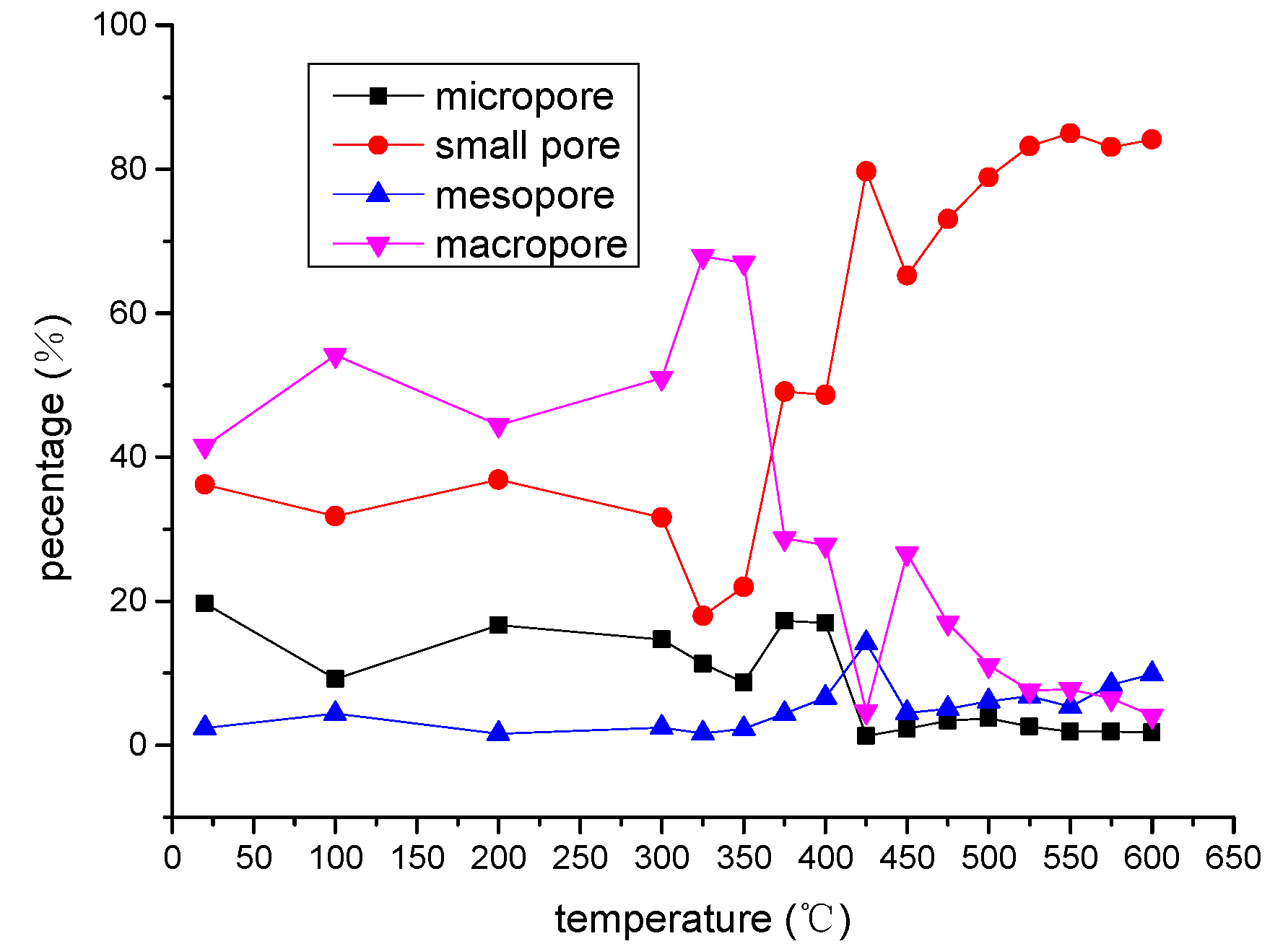

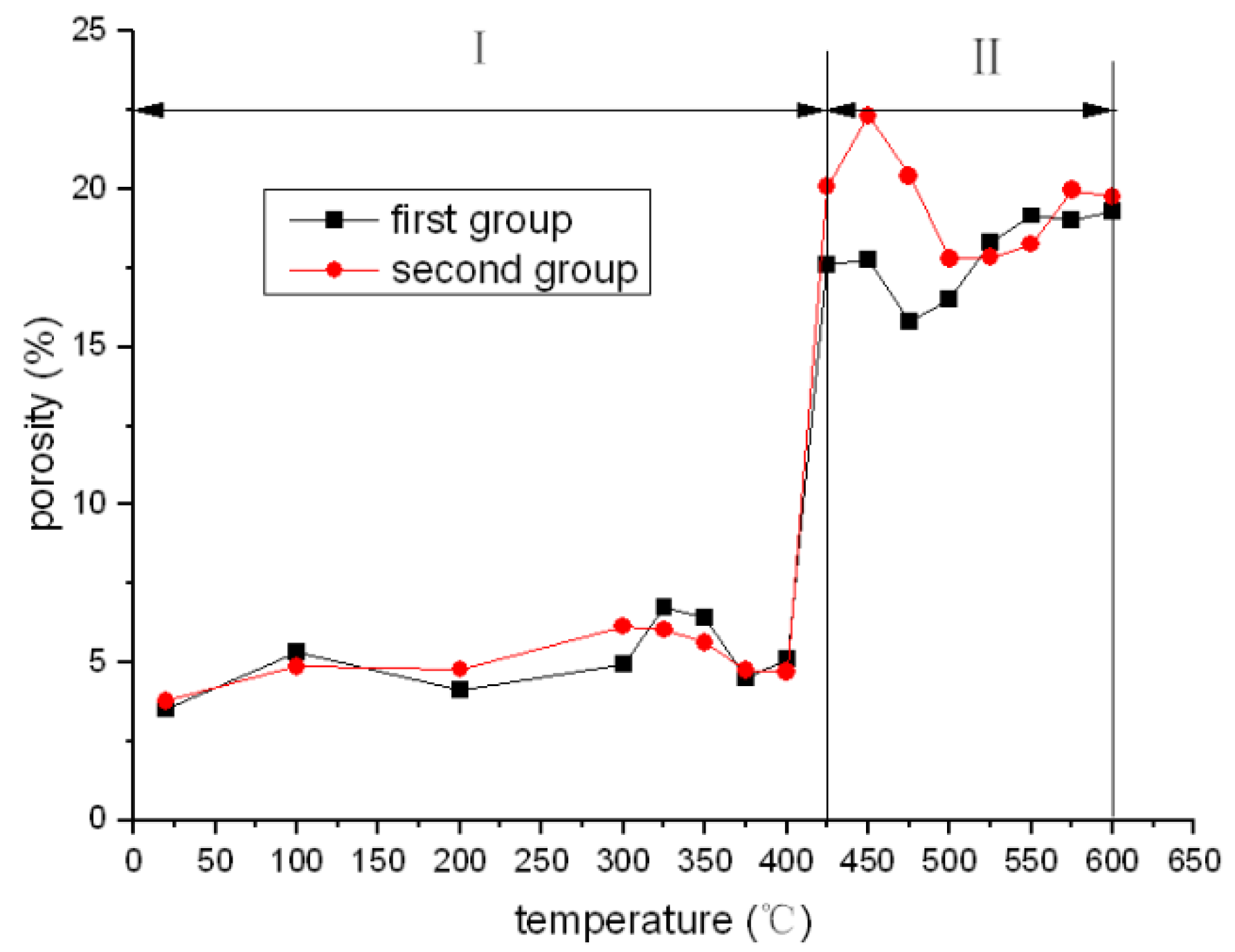

3.2. Pore Characteristic in the Pyrolysis Process

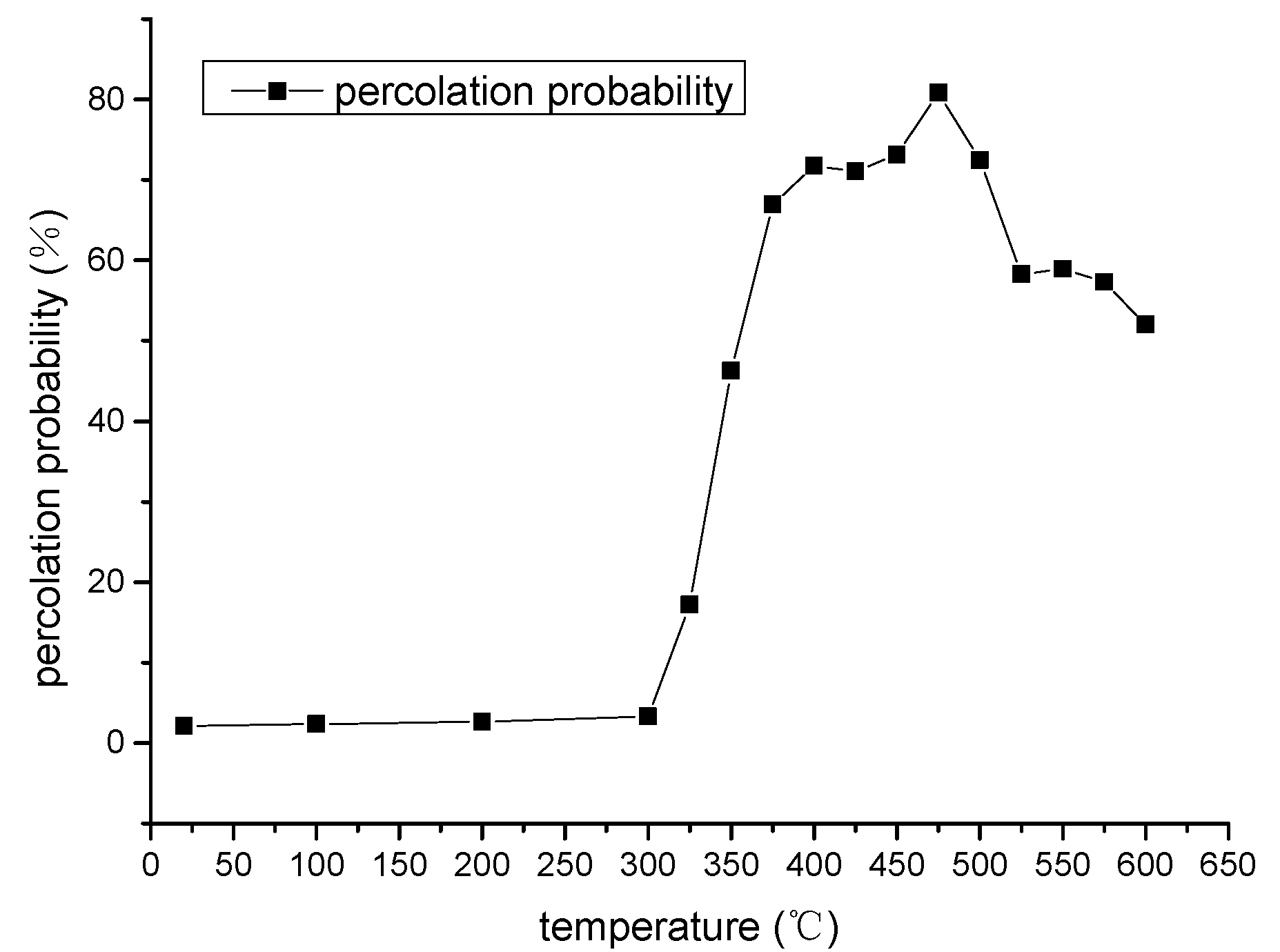

3.3. Percolation Calculation of the Fracture-Pore Dual Medium

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dyni, J.R. Geology and resources of some world oil-shale deposits. In Oil Shale Developments; U.S. Geological Survey: Reston, VA, USA, 2009; ISBN 9781607414759. [Google Scholar]

- Crawford, P.M.; Biglarbigi, K.; Dammer, A.R.; Knaus, E. Advances in world oil shale production technologies. In Proceedings of the SPE Annual Technical Conference and Exhibition, Denver, CO, USA, 21–24 September 2008. [Google Scholar]

- Kang, Z.; Zhao, Y.; Yang, D. Review of oil shale in situ conversion technology. Appl. Energy 2020, 69, 115121. [Google Scholar] [CrossRef]

- Schrodt, J.T.; Ocampo, A. Variations in the pore structure of oil shales during retorting and combustion. Fuel 1984, 63, 1523–1527. [Google Scholar] [CrossRef]

- Tiwari, P.; Deo, M.; Lin, C.L.; Miller, J.D. Characterization of oil shale pore structure before and after pyrolysis by using X-ray micro CT. Fuel 2013, 107, 547–554. [Google Scholar] [CrossRef]

- Zhao, J.; Yang, D.; Kang, Z.; Feng, Z. A micro-CT study of changes in the internal structure of Daqing and Yan’an oil shales at high temperatures. Oil Shale 2012, 29, 357–367. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Yang, D.; Li, X.; Zhao, J.; Wang, G.; Zhao, Y. Macro and meso characteristics of in situ oil shale pyrolysis using superheated steam. Energies 2018, 11, 2297. [Google Scholar] [CrossRef] [Green Version]

- Saif, T.; Lin, Q.; Bijeljic, B.; Blunt, M.J. Microstructural imaging and characterization of oil shale before and after pyrolysis. Fuel 2017, 197, 562–574. [Google Scholar] [CrossRef]

- Saif, T.; Lin, Q.; Butcher, A.R.; Bijeljic, B.; Blunt, M.J. Multi-scale multi-dimensional microstructure imaging of oil shale pyrolysis using X-ray micro-tomography, automated ultra-high resolution SEM, MAPS Mineralogy and FIB-SEM. Appl. Energy 2017, 202, 628–647. [Google Scholar] [CrossRef]

- Kang, Z.Q.; Zhao, Y.S.; Meng, Q.R.; Yang, D.; Xi, B.P. Micro-CT experimental research of oil shale thermal cracking laws. Acta Geophys. Sin. 2009, 52, 842–848. [Google Scholar]

- Kang, Z.; Yang, D.; Zhao, Y.; Hu, Y. Thermal cracking and corresponding permeability of Fushun oil shale. Oil Shale 2011, 28, 273–283. [Google Scholar] [CrossRef] [Green Version]

- Priest, S.D. Determination of discontinuity size distributions from scanline data. Exp. Fluids 2004, 37, 347–368. [Google Scholar] [CrossRef]

- Song, J.J. Estimation of areal frequency and mean trace length of discontinuities observed in non-planar surfaces. Rock Mech. Rock Eng. 2006, 39, 131–146. [Google Scholar] [CrossRef]

- Song, J.J.; Lee, C.I. Estimation of joint length distribution using window sampling. Int. J. Rock Mech. Min. Sci. 2001, 38, 519–528. [Google Scholar] [CrossRef]

- Martyushev, D.A.; Yurikov, A. Evaluation of opening of fractures in the Logovskoye carbonate reservoir, Perm Krai, Russia. Pet. Res. 2021, 6, 137–143. [Google Scholar] [CrossRef]

- Zhukov, V.S.; Kuzmin, Y.O. Experimental evaluation of compressibility coefficients for fractures and intergranular pores of an oil and gas reservoir. J. Min. Inst. 2021, 251, 658–666. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, L.; Li, Y.; Liu, F.; Martyushev, D.A.; Yang, Y. Effects of microfractures on permeability in carbonate rocks based on digital core technology. Adv. Geo-Energy Res. 2022, 6, 86–90. [Google Scholar] [CrossRef]

- Kruhl, J.H. Fractal-geometry techniques in the quantification of complex rock structures: A special view on scaling regimes, inhomogeneity and anisotropy. J. Struct. Geol. 2013, 46, 2–21. [Google Scholar] [CrossRef]

- Bagde, M.N.; Raina, A.K.; Chakraborty, A.K.; Jethwa, J.L. Rock mass characterization by fractal dimension. Eng. Geol. 2002, 63, 141–155. [Google Scholar] [CrossRef]

- Riley, P.; Murray, A.B.; Tikoff, B. Geometric scale invariance, genesis, and self-organization of polygonal fracture networks in granitic rocks. J. Struct. Geol. 2012, 42, 34–48. [Google Scholar] [CrossRef]

- Ghosh, A.; Daemen, J.J.K. Fractal characteristics of rock discontinuities. Eng. Geol. 1993, 34, 1–9. [Google Scholar] [CrossRef]

- Xie, H. Fractals in Rock Mechanics; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Andrade, J.S.; Street, D.A.; Shinohara, T.; Shibusa, Y.; Arai, Y. Percolation disorder in viscous and nonviscous flow through porous media. Phys. Rev. E 1995, 51, 5725. [Google Scholar] [CrossRef]

- Stanley, H.E.; Andrade, J.S.; Havlin, S.; Makse, H.A.; Suki, B. Percolation phenomena: A broad-brush introduction with some recent applications to porous media, liquid water, and city growth. Phys. A Stat. Mech. Appl. 1999, 266, 5–16. [Google Scholar] [CrossRef]

- Mészáros, C.; Farkas, I.; Bálint, Á. A new application of percolation theory for coupled transport phenomena through porous media. Math. Comput. Simul. 2001, 56, 395–404. [Google Scholar] [CrossRef]

- Mo, H.; Bai, M.; Lin, D.; Roegiers, J.C. Study of flow and transport in fracture network using percolation theory. Appl. Math. Model. 1998, 22. [Google Scholar] [CrossRef]

- Kimmich, R.; Klemm, A.; Weber, M.; Seymour, J.D. Flow, diffusion, dispersion, and thermal convection in percolation clusters: NMR experiments and numerical FEM/FVM simulations. MRS Online Proc. Libr. 2001, 651, 271. [Google Scholar] [CrossRef]

- Berkowitz, B. Analysis of fracture network connectivity using percolation theory. Math. Geol. 1995, 27, 467–483. [Google Scholar] [CrossRef]

- Sahimi, M. Non-linear and non-local transport processes in heterogeneous media: From long-range correlated percolation to fracture and materials breakdown. Phys. Rep. 1998, 306, 213–395. [Google Scholar] [CrossRef]

- Tsakiroglou, C.D.; Klint, K.E.S.; Nilsson, B.; Theodoropoulou, M.A.; Aggelopoulos, C.A. From aperture characterization to hydraulic properties of fractures. Geoderma 2012, 181–182. [Google Scholar] [CrossRef]

- Wettstein, S.J.; Wittel, F.K.; Arajo, N.A.M.; Lanyon, B.; Herrmann, H.J. From invasion percolation to flow in rock fracture networks. Phys. A Stat. Mech. Appl. 2012, 391, 264–277. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Y.; Feng, Z.; Lv, Z.; Zhao, D.; Liang, W. Percolation laws of a fractal fracture-pore double medium. Fractals 2016, 24, 1650053. [Google Scholar] [CrossRef] [Green Version]

- Ponomarev, A.A.; Zavatsky, M.D.; Nurullina, T.S.; Kadyrov, M.A.; Galinsky, K.A.; Tugushev, O.A. Application of core x-ray microtomography in oilfield geology. Georesursy 2021, 23, 34–43. [Google Scholar] [CrossRef]

- Masihi, M.; Shams, R.; King, P.R. Pore level characterization of Micro-CT images using percolation theory. J. Pet. Sci. Eng. 2022, 211, 110113. [Google Scholar] [CrossRef]

- Wei, Z.; Sheng, J.J. Study of thermally-induced enhancement in nanopores, microcracks, porosity and permeability of rocks from different ultra-low permeability reservoirs. J. Pet. Sci. Eng. 2022, 209, 109896. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, D.; Liu, Z.; Feng, Z.; Liang, W. Problems of Evolving Porous Media and Dissolved Glauberite Micro-scopic Analysis by Micro-Computed Tomography: Evolving Porous Media (1). Transp. Porous Media 2015, 107, 365–385. [Google Scholar] [CrossRef]

- De Las Cuevas, C. Pore structure characterization in rock salt. Eng. Geol. 1997, 47, 17–30. [Google Scholar] [CrossRef]

- Mou, W.W.; Xu, X.L. Percolation simulation of the infection growth models. Wuli Xuebao/Acta Phys. Sin. 2006, 55, 2871–2876. [Google Scholar] [CrossRef]

- Specht, E.; Goyal, A.; Kroeger, D. 2D and 3D percolation in high-temperature superconductors. Phys. Rev. B Condens. Matter Mater. Phys. 1996, 53, 3585. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, Z.; Liang, W.; Yang, D.; Hu, Y.; Kang, T. Investigation of fractal distribution law for the trace number of random and grouped fractures in a geological mass. Eng. Geol. 2009, 109, 224–229. [Google Scholar] [CrossRef]

- Yangsheng, Z.; Zengchao, F.; Dong, Y.; Weiguo, L.; Zijun, F. Three-dimensional fractal distribution of the number of rock-mass fracture surfaces and its simulation technology. Comput. Geotech. 2015, 65, 136–146. [Google Scholar] [CrossRef]

- Geng, Y.; Liang, W.; Liu, J.; Cao, M.; Kang, Z. Evolution of Pore and Fracture Structure of Oil Shale under High Temperature and High Pressure. Energy Fuels 2017, 31, 10404–10413. [Google Scholar] [CrossRef]

- Kang, Z.; Zhao, J.; Yang, D.; Zhao, Y.; Hu, Y. Study of the evolution of micron-scale pore structure in oil shale at different temperatures. Oil Shale 2017, 34, 42–54. [Google Scholar] [CrossRef] [Green Version]

- Yang, D.; Wang, L.; Zhao, Y.; Kang, Z. Investigating pilot test of oil shale pyrolysis and oil and gas upgrading by water vapor injection. J. Pet. Sci. Eng. 2021, 196, 108101. [Google Scholar] [CrossRef]

- Jan, N.; Stauffer, D.; Aharony, A. An infinite number of effectively infinite clusters in critical percolation. J. Stat. Phys. 1998, 92, 325–330. [Google Scholar] [CrossRef]

| Temperature (°C) | Single Pore Media | Dual Fracture-Pore Medium | ||

|---|---|---|---|---|

| Void Grid Number | Percolation Probability (%) | Void Grid Number | Percolation Probability (%) | |

| 20 | 7 | 0.0007 | 21,351 | 2.14 |

| 100 | 10 | 0.001 | 23,526 | 2.35 |

| 200 | 8 | 0.0008 | 26,136 | 2.61 |

| 300 | 9 | 0.0009 | 33,288 | 3.33 |

| 325 | 9 | 0.0009 | 17,1625 | 17.16 |

| 350 | 9 | 0.0009 | 462,657 | 46.27 |

| 375 | 8 | 0.0008 | 669,835 | 66.98 |

| 400 | 8 | 0.0008 | 717,382 | 71.74 |

| 425 | 57 | 0.0057 | 710,953 | 71.10 |

| 450 | 70 | 0.007 | 731,324 | 73.13 |

| 475 | 51 | 0.0051 | 803,843 | 80.84 |

| 500 | 49 | 0.0049 | 724,975 | 72.50 |

| 525 | 48 | 0.0048 | 582,760 | 58.28 |

| 550 | 71 | 0.0071 | 589,301 | 58.93 |

| 575 | 70 | 0.007 | 573,126 | 57.31 |

| 600 | 53 | 0.0053 | 520,158 | 52.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, H.; Zhao, Y.; Kang, Z.; Lv, Z.; Yang, D.; Wang, K. Investigation on the Fracture-Pore Evolution and Percolation Characteristics of Oil Shale under Different Temperatures. Energies 2022, 15, 3572. https://doi.org/10.3390/en15103572

Tang H, Zhao Y, Kang Z, Lv Z, Yang D, Wang K. Investigation on the Fracture-Pore Evolution and Percolation Characteristics of Oil Shale under Different Temperatures. Energies. 2022; 15(10):3572. https://doi.org/10.3390/en15103572

Chicago/Turabian StyleTang, Haibo, Yangsheng Zhao, Zhiqin Kang, Zhaoxing Lv, Dong Yang, and Kun Wang. 2022. "Investigation on the Fracture-Pore Evolution and Percolation Characteristics of Oil Shale under Different Temperatures" Energies 15, no. 10: 3572. https://doi.org/10.3390/en15103572

APA StyleTang, H., Zhao, Y., Kang, Z., Lv, Z., Yang, D., & Wang, K. (2022). Investigation on the Fracture-Pore Evolution and Percolation Characteristics of Oil Shale under Different Temperatures. Energies, 15(10), 3572. https://doi.org/10.3390/en15103572