Abstract

Slum/informal settlements are an integral part of a city, with a population projected to reach 3 billion by 2030. It is also expected that the rate of waste generation will more than triple by 2050 in the cities of low-income countries of sub-Saharan Africa. At this rate, the risk to the environment and health of inhabitants are enormous, because the current waste management practices are not guided by legislation on proper use and disposal. This paper proposes the conversion of waste to energy as a solution to this problem. The aim of this study is to apply the PROMETHEE technique with a combination weighting method to obtain the most appropriate waste-to-energy technology for the slum/informal settlements of the Greater Karu Urban area in Nigeria. The findings reveal that the gasification technology outperformed the other technologies, and the affordability of electricity supply from this technology was determined by a general survey conducted on the slum/informal settlements.

1. Introduction

The major challenge of this era is rapid urbanization and, by the year 2050, 66% of global population will reside in cities and urban areas [1]. In the periphery and inner parts of the cities, slum/informal settlements exist that emerge from the influx of people who travel to these cities to benefit from their growth and development. These settlements are generally characterized by low-income households, with zero compliance with planning regulations and poor access to electricity infrastructure on a daily basis [2,3,4].

According to the United Nations descriptive report on sustainable indicators, the number of people living in slum/informal settlements reached about 1 billion in 2018 [1]. When cities grow and develop from the consumption of materials, energy, and natural resources, more waste is generated, which has adverse effects on the environment [5].

The global waste generation rate is recorded as 2.0 billion tonnes of municipal solid waste (MSW) every year and, at the rate of 0.267 tonnes per capita, it can be deduced that 267 million tonnes of solid waste is obtained from informal settlements [1,6]. By 2050, the informal settlement population is projected to become 3 billion, which also implies that 801 million tonnes of municipal waste will be generated; this equates to 26.7% of the total waste projected to be generated globally (3.40 billion tonnes) [6]. In Nigeria, the total waste generated is 25 million tonnes per year, with an average per capita generation rate of 0.55 kg per day [7].

Sub-Saharan Africa, and the eastern and southern parts of Asia, are the fastest-growing regions for waste generation and informal settlement growth, where most of the waste management practices are below international standards in comparison to countries in the Organization for Economic Cooperation and Development (OECD) [8]. The problem of waste management in the developing regions will only worsen as urbanization rates increase; therefore, adequate waste handling measures must be put in place to abate the degradation of the environment. The waste collection rate in these regions is about 26% in the cities and even less in the informal settlements. The majority of the collected waste is either burnt in the air or disposed of in open dumpsites without following proper regulatory standards [9,10,11].

In slum/informal settlements of low- and middle-wage countries, the waste is usually collected by street sweepers, scavengers, and local waste pickers who transport and trade waste with public and private sector municipal waste services. This is beneficial to the overall waste collection for the area; however, general disputes can arise between the informal waste collectors and the public/private sector when competition over waste collection occurs, thereby leading to the loss of livelihood, which impacts negatively on the overall waste collection rate [12]. It is for this reason that proper integration of informal waste pickers and formal sector waste collection services should be the top priority for municipalities, city planners, and energy policy makers.

The slum/informal settlements are often characterized by low access to electricity, so fossil fuel energy sources such as coal, firewood, and kerosene are often used to meet the energy demand from domestic activities, e.g., cooking and lighting in major households. The use of fossil fuels as an energy source contributes to global warming from the release of CO2 gas into the atmosphere, making it necessary to seek cleaner fuel options [13].

Renewable energy sources such as urban solid waste, wind, solar, and hydropower have been identified as a means of providing sustainable energy sources for informal settlers. The problem of intermittency associated with the use of wind, solar, and hydropower to provide energy gives MSW an added advantage, since it is not affected by changes in weather conditions.

MSW refers to materials generally disposed of in urban areas, which include waste from houses, businesses, streets, and commercial and recreational centers. Generally, MSW consists of decomposable and non-decomposable portions [14,15,16]. The amount of energy that can be obtained from MSW is related to the quantity that is available and the efficiency of the conversion pathway. Other factors such as the population size and income level of a region or municipality are also important [17,18,19]. The factors that determine the amount of energy recovered from MSW are easily controllable, hence giving it a stable and predictable attribute as a renewable energy source to tackle waste issues, mitigate against global warming, and produce electricity that can be assessed by informal settlers.

In this study, the authors propose a sustainable solution for managing waste in slums/informal settlement by applying the Multi-criteria Decision Making Method (MCDM) to select the most appropriate waste-to-energy technology.

Generally, waste-to-energy technologies utilize biochemical and thermochemical pathways to obtain energy from MSW in order to produce heat and electricity. These technologies include landfill gas recovery, anaerobic digestion, incineration, and gasification. These technologies perform differently when subjected to technical, economic, environmental, and social criteria. The evaluation of their performance under multi-criteria optimizes the selection of the technology that best meets the requirements of the region or municipality under analysis.

1.1. Literature Survey Connected to the Application of MCDM

The popularity of MCDM methods has seen its vast application in different categories such as energy, business, commerce, and political sectors of the economy. In the energy industry, several MCDM methods have been used to select the most suitable waste-to-energy technologies. Some examples include Analytic Hierarchy Process (AHP), Analytic Network Process (ANP), Technique for Order of Preference by Similarity to Ideal Solution (TOPSIS), VIseKriterijumska Optimizacija I Kompromisno Resenje (VIKOR), Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE), Elimination Et Choix Traduisant la Realite, Combined Compromise Solution (ELECTREE), Decision-Making Trial and Evaluation Labor (DEMATEL), and Grey Relational Analysis (GRA). The general principle applied by these MCDM methods is to evaluate and determine the importance of the criteria by assigning different weights, which is the basis for the ranking of the alternatives [14,20,21,22,23]. Shahnazari et al. [24] applied the TOPSIS method to select thermochemical waste-to-energy recovery technologies that utilize municipal solid waste. The study revealed that plasma gasification technology performed the best, followed by the incinerator technology. Rahman et al. [25] applied the AHP method to select the ideal waste-to-energy conversion technology for residential homes in Bangladesh, by considering biochemical and thermochemical conversion technology options. The findings from this study also revealed that plasma gasification technology performed the best when the selection process was subjected to technological, economical, and environmental criteria. The AHP method has previously been used to evaluate, appraise, and rank waste-to-energy technologies in Moscow, Oman, and Indonesia [26,27,28]. Other studies focus on integrating two or more MCDM methods to make up for the shortcoming of the other(s). Generally, MCDM methods require the decision makers to rank criteria weights based on importance, and in doing so the process is associated with some level of uncertainty and bias from the decision maker. Therefore, the inclusion of fuzzy logic in the decision-making process helps in eliminating inconsistencies associated with the judgement. Several studies have integrated two or more MCDM methods with fuzzy logic to carry out an optimal selection of waste-to-energy technology. Belhadi et al. [29] highlighted the importance of integrating internal fuzzy values with AHP, VIKOR, life cycle assessment, and life cycle cost to carry out the selection of sustainable waste technologies in Africa. The findings revealed that the combination of incineration, chemical disinfection methodology, and ultraviolet irradiation is the best approach for handling infectious solid and water waste. Shah et al. [30] integrated the DEMATEL, ANP, and VIKOR methods with fuzzy set theory to select the ideal waste-to-energy technology in Pakistan, and a decision-making framework based on the principles and ideology of energy trilemma was proposed. Gasification was selected as the ideal waste-to-energy technology, whereas torrefaction was the least favorable. Wang et al. [31] proposed an evaluating system for ranking four alternative waste-to-energy technologies in China by combining the interval value fuzzy GRA method and DEMATEL. Of the four scenarios, anaerobic digestion was adjudged to be the best, followed by gasification, incineration, and landfill, in order of decline. Ebadi et al. [32] applied the combination of ELECTREE, VIKOR, and the fuzzy approach to select the ideal waste-to-energy technology in Iran, where plasma technology was given the first rank from different scenarios of criteria weight.

In the review of literature on the search for municipal solid waste management and integrated MCDM techniques, nine studies highlighted the use of PROMETHEE MCDM. Of the nine studies, six focused on the selection of waste-to-energy technologies [33,34,35,36,37,38]. Arikan et al. [34] applied the combination of PROMETHEE, TOPSIS, and Fuzzy TOPSIS to select waste disposal methods in Turkey. In the study conducted by Herva and Roca [35], four alternative waste-to-energy technologies were ranked firstly with the use of ecological footprint and with MCDM. The MCDM combined AHP and PROMETHEE, alongside the Geometrical Analysis for Interactive Aid (GAIA) [39]. The findings from the study revealed that thermal plasma gasification was the best technology. Coban et al. [33] applied the combination of TOPSIS and PROMETHEE I and II techniques for managing sold waste in Turkey, and the findings revealed the importance of landfill technology. The remaining studies applied the PROMETHEE technique for the selection of sites for the development of MSW facilities [40,41,42].

The advantage of the PROMETHEE method is in its ability to carry out the partial and complete ranking of alternatives. It also allows for the integration of subjective and objective criteria when evaluating alternatives [43,44]. In this study, the subjective and objective criteria were integrated into the PROMETHEE technique by applying the combination weight method.

The MCDM methods used previously for selecting waste-to-energy technology in Nigeria include the work of Alao et al. [14], which focused on the use of TOPSIS [23]. Another study applied the TOPSIS technique to solve the issue of site location for landfill gas in Nigeria [45]. Mohammed et al. [46] analyzed the multi-criteria evaluation method for landfill sites in Nigeria. Previous work on the selection of waste-to-energy technology in Nigeria is scarce, with TOPSIS being the most frequently used technique.

1.2. Purpose, Scope, and Contribution of the Article

This study aimed to select the most appropriate waste-to-energy for the slum/informal settlements of the Greater Karu Urban Area (GKUA) of Nasarawa State in Nigeria.

This work’s general contribution is the implementation of MCDM in informal sector waste management practices and the development of a sustainable electricity system for informal and slum settlers. Over the years, several studies have been carried out on the Greater Karu Urban Area because of the significance of its rapid population growth rate. However, the majority of these studies focus on the problem of inadequate housing and infrastructure for the inhabitants, paying no attention to energy recovery from waste [10,11,47,48,49,50,51], thus prompting the need to conduct this study. To the best of the authors’ knowledge, this is the first study to apply MCDM to the selection of waste-to-energy technologies for slum/informal settlements, both in Nigeria and more widely.

The remainder of this paper is structured as follows: Section 2 presents the study area, which includes the description of the typologies of slum/informal households and categories of productive enterprises. The waste-to-energy technologies and the criteria used in the selection process are listed in Section 3. The methodology is described in detail in Section 4 and the criteria are evaluated with the use of formulas. The results of the MCDM selection and the general survey on the slum/informal settlements are detailed in Section 5. Finally, we conclude in Section 6.

2. Study Area

The Greater Karu Urban Area is situated between latitude 8.996456 and longitude 7.632282. It is a conurbation of hybrid formal and informal settlements, and it is approximately 28 km from Abuja, the capital city of Nigeria [47]. This makes it a strategic location for informal workers to live and travel to and from, in order to escape the expensive cost of living in Abuja. The population growth rate peaked at 40% per annum, giving it one of the fastest urbanization rates in the world [47,52]. Some of the settlements include Ado, New Karu, Masaka, Mararaba, Orozo, Karshi, Kurudu, and Uke. The informal workers resort to erecting illegal structures in the Greater Karu Urban Area to shelter their families. The face me-I-face you (tenement building) represents the prototype of the informal housing structures that are prevalent in GKUA. The average number of hours of electricity supply in the Greater Karu Urban Area (GKUA) is 5 h per day [53].

2.1. Current Waste Handling Method

Urban solid waste in GKUA includes food, plastics, paper clothes/ textiles, and wood materials; their percentage compositions are depicted in Table 1, and the ultimate and proximate analysis of the waste components is presented in Table 2. The current waste handling methods in GKUA include open burning, pit dumping, and composting. In the four informal settlements examined in this study (i.e., Ado, New Karu, Mararaba and Masaka) see Figure 1, open burning is the most popular waste handling method. This is followed closely by direct dumping in pits and bins, and lastly by composting [9]. The problem with burning waste is associated with the amount of uncontrollable toxic gases released into the atmosphere. Furthermore, the direct dumping and composting method can also be disadvantageous as a result of land space requirements, bad odor, and other environmental hazards when not properly controlled [7,14,54].

Table 1.

Percentage composition of waste in GKUA.

Table 2.

Ultimate and proximate analysis of waste components in Nigeria.

Figure 1.

The informal settlements of the Greater Karu Urban Area [55].

Generally, the waste hierarchy method ranks waste management options, with the top and least priorities given to the prevention and disposal methods, respectively. The option of recycling waste is an effective waste disposal method and is given priority over the waste-to-energy recovery method, but only on the condition that the waste available for collection is recyclable. Recycling avoids the need for the usage of fresh raw materials, thereby contributing to the reduction in energy consumption, and water and air pollution. Through recycling, global warming is contained, pollution is minimized, the environment is protected from the activity of deforestation, the amount of waste in landfills is drastically reduced, and more jobs are created. However, with regards to the waste composition in GKUA, there is a higher percentage of food waste in comparison to paper, plastic, bottle, metal, and clothes. Even though food waste is considered a recyclable waste, the waste separation technique has not been fully implemented in Nigeria, unlike for paper, plastic, and other recyclables. This is a result of poor knowledge about the handling and separation of the organic components in food waste, which often ends up in landfills, thereby contributing to leachate formation. Furthermore, recycling food waste in the form of compost creation to produce fertilizers is still not properly regulated by quality checks. There are instances where food waste recycled from homes includes materials such as cooked meat and fish, which find their way into compost vessels, thereby disrupting the overall process of decomposition. In the context of this study, even though recycling is an effective waste handling method, it significantly meets the demand for fertilizers from the activity of composting, whereas waste-to-energy technologies are implemented to meet the demand for electricity for the informal settlements of GKUA.

The importance of awareness about the segregation of waste cannot be overemphasized. The knowledge about waste has been proven to have a positive correlation with waste management and collection efficiencies. Generally, different waste compositions are deemed appropriate for the available waste-to energy technologies. The identification of waste as either biodegradable and non-biodegradable, or as wet and dry waste, enables the improvement in the overall collection efficiency of the waste. Wet and biodegradable waste is selected for the use in anaerobic digestion waste-to- energy technology, whereas dry waste is used in the gasification and incineration waste-to-energy technologies. In the case of GKUA, the segregation of waste is shown in Table 3 [56].

Table 3.

Waste classification according to the applicable energy recovery technology.

The selection of the appropriate waste-to-energy method with the use of PROMETHEE will assist in adopting a sustainable means of waste disposal in GKUA. The benefit of the preferentially selected waste-to-energy technology also extends to the provision of electricity for the underserved informal settlements in this study. The electricity requirement for the informal settlements in the GKUA was obtained with the use of descriptive statistics from the sampling of houses and productive enterprises.

2.2. Sampling Method

The sampling of houses and productive enterprises was carried out using Cochran’s formula, which can be obtained by applying Equation (34). The formula is used to determine the sample size. From the standard distribution table, at a 95% confidence level, a standard deviation of 0.5, and a 5% error, the sample size was obtained as 384.

Data Collection

The selection involved random sampling of household members and owners of productive enterprises. The primary data was collected using the sample questionnaires see Supplementary Questionnaires S1 and S2 which were completed on the spot, rather than via the use of emails and telephones, which are restricted due to poor Internet and telephone services in these areas. The reliability of the questionnaires was validated using the Cronbach alpha and the analysis was carried out using Microsoft Excel.

2.3. Typology of Informal Houses and Productive Enterprises

The classification of household and productive enterprises was conducted to establish the difference in the electricity consumption pattern. There are two typologies of informal houses and two categories of productive enterprises, which were obtained from the survey; these are: hybrid slum/informal house (typology A), stand-alone slum/informal house (typology B), commercial enterprise (category A), and agriculture-based enterprise (category B).

2.3.1. Hybrid Slum/Informal House

The hybrid informal house is described as a municipal bungalow building provided by the government with a backyard and illegally erected front-gate shacks. This is very common in the inner parts of GKUA.

2.3.2. Stand-Alone Slum/Informal House

The stand-alone informal house is a shack or make-shift tent built on land designated for the construction of infrastructure such as roads, electricity poles, and gas pipelines.

2.3.3. Commercial Enterprises

The commercial enterprises are seen as being most popular in GKUA, where the majority of the slum/informal settlers engage in activities such as food vending, phone charging services, tire repairs, pepper blending, and selling of ice blocks.

2.3.4. Agriculture-Based Enterprises

The agriculture-based enterprises are owned by informal settlers who specialize in farming activities that include the production of milk from cows, and the cultivation of rice, maize, and sorghum.

3. Waste-to-Energy Technologies

Generally, waste-to-energy technology is capable of converting urban waste that is generated in the informal/slum settlements of GKUA to electricity through thermochemical and biochemical processes in a sustainable manner.

3.1. Description of Technologies

In this study, the four waste-to-energy technologies that were taken into consideration in the selection of the most appropriate for the GKUA are briefly described below:

3.1.1. Anaerobic Digestion (ANR)

This technology utilizes a biochemical pathway that recovers energy from waste through the putrefaction of organic matter in the presence of microbes in an environment with little or no oxygen to produce biogas. The biogas produced in the digester vessel is rich in methane (about 50–75%) and (25–50%) carbon dioxide, which can be used to generate electricity [57].

3.1.2. Landfill Gas Recovery (LFILL)

With this technology, landfill gas is produced from a landfill site in a biochemical process that follows the same principle as the anaerobic digestion technology. The landfill gas obtained can be used to generate electricity.

3.1.3. Incineration (INC)

This technology involves a thermochemical process where the urban solid waste is subjected to burning at high temperatures that range between 600 and 1200 °C [58,59,60]. The heat produced from the process can be used to generate electricity [14].

3.1.4. Gasification (GAS)

Gasification technology is a thermochemical process that converts waste with carbon content into syngas and other valued products at a high-temperature range between 750 to 1000 °C, with the aid of controlled air and steam. The syngas can be used to produce electricity [61,62,63,64].

3.2. Criteria Description

The criteria required for selecting the most appropriate waste-to-energy technology are based on technical, environmental, financial, and economic parameters [64]. For each criterion, there are sub-criteria, which are described in Table 4 below:

Table 4.

Sub-criteria description for the selection of the best waste-to-energy technology.

3.3. Criteria Weight Determination

The MCDM applies the use of criteria weights to attribute varying levels of importance, in order to filter the less preferred alternatives during the selection process. The significance of this is that, the bigger the weight, the more influential the criterion. The criteria weights determine the success of a decision-making process; however, a major challenge is the determination of the accuracy in its measurement. Generally, the weights of the criteria can be obtained either by a subjective or an objective method.

3.3.1. Subjective Weight Method

Subjective weights are determined by expert evaluation. These weights express the opinions of experts and are associated with bias and vagueness on the part of the decision maker. Examples of subjective weighting methods include Stepwise Weight Assessment Ratio Analysis (SWARA), Simple Multi-attribute Ranking, (SMART) [65], Analytical Hierarchy Process (AHP), Delphi, and Kemeny Median Indicator Ranks Accordance (KEMIRA) [66,67,68,69]. The bias in the judgment of the decision maker can be attributed to lack of experience and the insubstantial nature of the criteria. Some studies have explored the use of surrogate weights in eliciting methods to improve the decision-making process [70,71,72].

3.3.2. Objective Weight Method

Generally, objective weights consider the criteria values of the data array provided in the decision matrix. They are represented by mathematical equations, which determine their values without the input of the decision maker [73]. They are not as common as the subjective weight methods. Examples of objective weighing methods include Criteria Importance Through Intercriteria Correlation (CRITIC) [74,75] and ENTROPY [76,77,78]. Other examples include Criterion Impact Loss (CILOS) [79], Linear Programming Technique for Multidimensional analysis of Preference (LINMAP) [80], Integrated Determination of Objective Criteria Weights (IDOCRIW), and standard deviation [81]. The objective weights are employed to eliminate bias by carrying out a dispersion analysis of the criteria values in the data of the array [65].

Over the years, several studies involving MCDM made use of subjective and objective weights separately, without the inclusion of a common formula in the decision-making analysis. Biswajik [82] performed an analysis using Pythagorean fuzzy numbers with the TOPSIS method to eliminate uncertainties from the decision-making process. The AHP and entropy weights were used in a fuzzy MCDM to rank shipping companies [83]. Chung et al. [84] assessed the vulnerability characteristics of regional population size by considering the Delphi technique and Shannon entropy as subjective and objective weights, respectively.

3.3.3. Combined Weight (CWM)

To overcome the shortcoming of the above methods and improve the accuracy of criteria weight determination, the integration of subjective and objective weights into one single component was achieved using the integrated method proposed in the work of Ma et al. [85]. The integrated weight method is also supported in these studies [86,87,88]. However, Jahan et al. [89] proposed the combination weighting method after criticizing the accuracy of the integrated weight formula and noting the inconsistencies observed with the inclusion of objective weight values. The application of the combined weight formula can be found in these studies [90,91,92]. The combined weight method was tested on other MCDMs in the work of Vinogradov et al. [92].Therefore, this study applied the combination weighting method to obtain an accurate measurement of the objective and subjective criteria.

4. Methodology

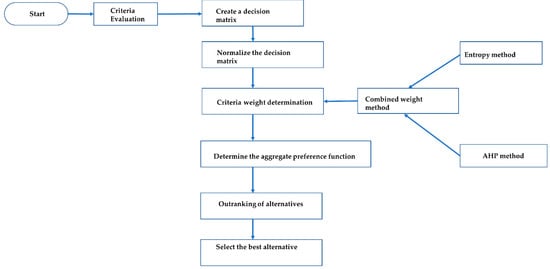

The methodological approach of this study is depicted in Figure 2. This section also presents the formulas used for analysis in this study, which consisted of four subsections:

Figure 2.

Methodological framework.

- Evaluating the sub-criteria with mathematical expressions.

- Determining the criteria weights using the combined weight method.

- Application of PROMETHEE to select the most appropriate waste-to-energy technology for the informal settlements of GKUA.

- The sampling of slum houses and productive enterprises to determine their electricity requirement.

4.1. Formulas and Equations for Evaluating the Sub-Criteria

Mathematical expressions are used to estimate the quantitative criteria, whereas the qualitative criteria (land availability and community acceptance) are evaluated with the use of the Likert scale.

4.1.1. Waste Generation Potential

Electricity can be obtained from waste, and in this study, the waste generated in the informal settlements of the Greater Karu Urban Area is utilized for power generation. The Greater Karu Urban Area is located in Nasarawa State and the waste generation per capita is given as 0.65 kg/capita/day [93]. The population of the Greater Karu Urban Area is estimated at 2 million from the last census conducted in 2006 [11,94]. The estimated amount of waste generated (Waste(GR)) over a specific number of years (t), can be obtained by applying Equations (1)–(3) presented below:

where recon is the per capita waste generation rate, which is linked to the gross domestic production (GDP) of the Nigerian economy [19], ro is the population growth rate of the country, and Wfrac is the collection efficiency of the waste. The values for recon, ro, and Wfrac are given as 3.4%, 3.5%, and 74% respectively [14,19,95,96].

4.1.2. Evaluating the Technical Criteria

The two technical sub-criteria used in this study are the electricity generating potential and the efficiency of the waste-to-energy plant. The quantity of electricity produced is dependent on the type of waste recovery technology that is applied. The formulas used to represent the amount of electricity generated from the different waste-to energy technologies are presented in Equations (4)–(8):

where QCH4 represents the annual methane generation from the landfill site (m3/year) and Mi is the waste disposal index (T/year). The US EPA (United States, Environmental Protection Agency) Land GEM model was used to estimate the value for QCH4. The values for the methane generation rate (k) and the potential methane generation capacity Lo were taken as 0.040 (1/year) and 100 (m3/Mg). The percentage fractions of waste utilized for each technology are represented as FANR, FLFILL, FINC, and FGAS, respectively. The values for the methane generation potential from organic waste for anaerobic digestion and landfill gas recovery technologies (MANR and MLFILL) are taken as 80 and 120 Nm3/ton, respectively [97]. The lower heating values for ANR and LFILL are the same as that of methane gas, which is given as 37.2 MJ/Nm3 [98,99]. The value for LHVGAS is obtained as 15.3 MJ/kg [100] and the value for LHVINC is obtained as 10.4 MJ/kg from [14], and the LHV of the waste is obtained by applying Equations (24) and (25).

The value for the efficiency of ANR is taken as 33% from previous studies [14,101,102]. The efficiency of the gasification technology is obtained as 64% [102,103], whereas that of incineration technology is taken as 12% [104,105,106,107]. The efficiency of landfill gas recovery technology is also obtained as 33% from previous studies [14,108].

4.1.3. Evaluation of the Economic Criteria

The economic criteria measure the cost effectiveness and affordability of the given waste-to-energy technology to the end-user, and this is dependent on the amount of money required to produce every kilowatt of electricity. These criteria are non-beneficial/minimum because an alternative with a smaller value is preferentially selected over an alternative with a larger value. The sub-criteria include the investment cost (IC), operation and maintenance cost (O&M), and the cost of energy (COE). The sub-criteria can be obtained using the Equations (10)–(19) presented below:

where IC(i) is the investment cost of the waste-to-energy recovery technologies, PC(i) is the capacity of the waste-to-energy plant, operating at 8000 h per year, and UC(i) is the unit investment cost in USD/kW. The fixed O&M cost is obtained as a percentage of the investment cost, and for ANR technology, we assume a value of 3%. The variable O&M cost is a fraction of the production output; in this instance we use 4.2% for the ANR technology. We also assume the values of 4%, 4.3%, and 10% for LFILL, INC, and GAS technologies, respectively [14,104]. The value for the fixed operation and maintenance cost for LFILL technology is obtained as 11.0% [109]. The values for UCANR, UCLFILLI, UC INC, and UCGAS are obtained as 2200 USD/kW, 1900 USD/kW, 600 USD/ton, and 2700 USD/kW, respectively [14,104,109,110]. The operation and maintenance cost is presented in Equations (13)–(16) as follows:

Consequently, the capital recovery factor (CRF) is obtained using Equation (18):

where Rate(inf) represents the inflation rate of Nigeria, which is obtained as 15.70% [111]. The value for the interest rate, Rateint, in the country is given as 11.50% [112], and t represents the number of years for the plant project. The value for the cost of energy is obtained using Equation (19) as follows:

where IC(i) and O&M(i) are the investment cost, operation and maintenance cost, and the electricity generated for each technology (i) obtained using Equations (4)–(7).

4.1.4. Evaluating the Environmental Criteria

The impact on the environment from utilizing any given waste-to-energy technology was assessed with the use of these criteria. Air pollutants such as carbon dioxide (CO2), methane (CH4), particulate matter (PM), nitrous oxides (N2O), and sulfur (S) are associated with the operation of these technologies. CO2 and CH4 are the main greenhouse gases examined in this study as a result of their global warming potential (GWP). The sub-criterion is non-beneficial/minimum, meaning that high values for the emissions of greenhouse gases places the waste-to-energy technology at a disadvantage with respect to the multi-criteria selection process. We assume that 5% of the methane leaked out of the digester and only 75% of the landfill gas is successfully collected, while 25% escapes into the atmosphere, which is consistent with the guidelines stipulated by the IPCC (Intergovernmental Panel on Climate Change) [14,113]. The CO2 equivalent measure of the greenhouse gases is used to measure the amount of emissions from any given waste-to-energy technology, and the values are obtained using the Equations (20)–(23) presented below:

where the value for the density of methane is given as 0.717 kg/m3, which is the same as that for the ANR and LFILL waste-to-energy technologies [114]. The GWP for methane is 32 times that of CO2 [115].

The CO2 emission from the incineration technology is broadly determined by applying the IPCC guidelines for national greenhouse gas inventories [116].

where the fossil content (FC) is obtained as 34% [117]. The oxidation factor (OF) is obtained as 1, the dry matter content in the waste (DM) is taken as 91%, and the fraction of carbon in the dry matter (CF) is obtained as 47.4% [118]. MCO2 is given as 44 kg/mol and MC is 12 kg/mol; these both constitute the conversion factor [119].

The emission factors for methane and carbon dioxide from a gasification process are obtained as Emf(CH4), 0.0000035 kg/MJ, and EmfCO2, 0.06675 kg/MJ [14]

The ultimate analysis gives the breakdown of the elements in the HHV formula, which consists of the elements carbon, hydrogen, oxygen, nitrogen, sulfur, and ash, which are represented as C, H, O, N, S, and A, respectively. The values for the elements are obtained from Table 2.

4.1.5. Evaluating the Social Criteria

The measurement of these criteria is conducted with the use of the Likert scale. The sub-criteria are assigned numbers from 1 to 5, with 1 being the lowest score and 5 being the highest. The measure is qualitative, so it requires the input of experts to rank the available waste-to-energy technologies based on their performances with respect to the score attributed to each criterion. The land availability sub-criterion is defined as the amount of space available after the construction of any given waste-to-energy technology. A score of 1 is attributed to a waste-to energy-technology that creates little or no space for other productive use of land after its construction is completed. This also applies to the community acceptance sub-criterion, for which the most accepted waste-to-energy technology is given a score of 5.

4.2. Criteria Weight Determination

The accuracy in the measurement of the criteria weight is ensured with the use of the combined weighting method, which prevents any bias in judgment obtained from the objective or subjective criteria. The subjective and objective criteria are first determined separately, before the collective evaluation is conducted with the combination weighting method.

4.2.1. AHP Method

The AHP method is the subjective method used in this study, and the steps are described below:

- (1)

- The first step in the AHP method is to develop a hierarchical structure with the objective of the selection process placed on the top level, the criteria on the second level, and the alternative waste-to-energy technologies on the third level.

- (2)

- The second step is to create a pair-wise comparison matrix using the scale of relative importance with respect to the objective of selecting the most appropriate waste-to-energy technology.

- (3)

- The criteria weights are then determined from the normalized pair-wise comparison matrix.

- (4)

- The value for Ʌmax is determined.

- (5)

- Equation (27) is applied to check for consistency.

- (6)

- It is confirmed that the consistency ratio is <0.1 with the use of the random index table.

4.2.2. Entropy Method (EWM)

The value for the objective weight is obtained from applying Equations (28)–(31):

where the value of the degree of diversification and the objective weight vector are given as dj and wjo, respectively.

4.2.3. Combined Weight Method (CWM)

The objective weight and subjective weights are combined using Equation (32), where ω(Rj) and ω(X/Rj) are two independent events that represent the objective and the subjective weights, respectively:

4.3. Application of PROMETHEE MCDM

The combined weight obtained from using Equation (32) is the criteria weight (Wj) that is applied to the PROMETHEE technique described below:

Step 1: The first step in the application of the PROMETHEE method is to determine the criteria (gdj = 1, k) and create a matrix table of the possible alternatives for the selection process.

Step 2: The next step is to normalize the decision matrix using Equations (33) and (34), where Xij is the value provided by the decision maker during the selection process (i = 1, 2., n and j = 1,2…m).

Step 3: Determine the preference function from the deviation of the alternatives by pairwise comparison:

where ej(a,b) represents the difference between the value evaluations of a and b for each criterion used in the decision-making process.

where Pj denotes the evaluation of one alternative a with respect to another b on each criterion within a range of 0 to 1, with the value 1 indicating greater criteria performance.

Step 4: Determine the aggregate preference function.

where wj is the weight of each criterion determined by a subjective, objective, or integrated method.

Step 5: This step involves the ranking of the alternatives, which is performed completely. The entering flow and leaving flow are obtained using Equations (38) and (39):

The net flow outranking flow ϕ(a) is obtained using Equation (40):

4.4. Sampling Method Using Cochran’s Formula

The Cochrans formula is used to estimate the sample size used in the survey analysis and it is provided below:

where no is the sample size, e is the margin of error, (p) is the standard deviation, and Z2 is the value obtained from the standard distribution table at a 95% confidence interval.

4.5. Energy Price Comparison Using the Levelized Cost of Electricity

The levelized cost of electricity is used to compare the price of energy from the different waste to energy technologies over their respective lifetime. The equation is provided below:

where IC(i) is the investment cost of the waste-to-energy technology, O&M(i) is the operation and maintenance cost, and r is the discount rate. Generated(i) is the amount of electricity generated from the waste-to-energy technology. The values for IC(t) and O&M(i) were previously determined by using Equations (9)–(16). The values for Generated(i) were also previously obtained using Equations (4)–(8). The number of years (t) for the plant project is 25 years.

5. Results and Discussion

This section presents the results of the selection process for the evaluation of the sub-criteria, the criteria weight determination, the preferential selection of the most appropriate waste-to-energy technology, and the energy requirement of the informal settlements.

5.1. Decision Matrix

The quantitative and qualitative evaluation of the sub-criteria was carried out with the use of mathematical expressions and the Likert scale, respectively. The quantitative analysis includes the technical, economic, and environmental sub-criteria T1, T2, EC1, EC2, EC3, and ENV1, while the qualitative analysis was performed on the social sub-criteria (S1 and S2). The results are presented in Table 5.

Table 5.

Decision matrix.

The results in Table 5 show that the waste-to-energy technologies perform differently under each sub-criterion. For the technical sub-criterion T1, GAS and INC have the highest electricity generation potential of 147 and 30.7 GWh, respectively. The technology with the least electricity-generating potential is LFILL. However, the investment required to build and construct a LFILL plant is less than that for the other technologies when sub-criteria EC1 is taken into consideration. The LFILL technology also performs the best under sub-criterion EC2, as it requires USD 4.8 million for its operation and maintenance, which is the lowest value required in comparison to the other technologies. The LFILL and INC technologies perform the worst under the social sub-criteria S1 and S2. The sub-criterion S1, which is the amount of space available for other productive uses of land for the slum settlers, gives leverage to ANR and GAS over INC and LFILL. This is due to the proliferation of small size ANR and GAS units for household usage in comparison to INC and LFILL technologies. The S1 sub-criterion easily influences the S2 sub-criterion, as there is a higher level of acceptance for ANR and GAS technologies by the informal settlers. With respect to the environmental sub-criterion EC1, the ANR technology performs better than the other alternatives. This is attributed to the smaller amount of carbon dioxide it emits into the environment by the consideration of the global warming potential of each technology. Conversely, the INC technology performs the best with the economic sub-criterion EC3, by having the lowest cost of energy at 0.04 USD/kWh. The GAS technology is the most expensive, costing 0.06 USD/kWh, which raises questions about its affordability for the slum settlers, even though it shows the best performance for electricity generation. There is clear evidence of the existing conflict in obtaining a desirable outcome due to the performance of the waste-to-energy-technologies in terms of the different sub-criteria. Hence, there is a need to rank the alternatives based on the importance of the sub-criteria. This was carried out with the PROMETHEE technique and the combined weighting method.

5.2. Normalized Decision Matrix

When applying the PROMETHEE method, the first step is to normalize the values already provided in the decision matrix using Equations (33) and (34). The result of this is presented in Table 6.

Table 6.

Normalized decision matrix.

5.3. Criteria Weight Determination

The accuracy of the criteria weight is improved by inputting the objective weight vector from the entropy method ω(Rj) and the subjective weight ω(X/Rj) from the AHP method into Equation (32). The results of the different weight categories are presented in Table 7.

Table 7.

Criteria weights from the different methods.

From Table 7, the sub-criterion EC1 has the highest value for criteria weight using the EWM method and the fifth highest value with the AHP method. In addition, the sub-criterion EC3 has the highest value using the AHP method, but is ranked fourth with the EWM method. This indicates inconsistencies in determining the actual criteria weights, thereby affecting the outcome of the decision making; thus the inconsistencies are corrected by combining the weights. The sub-criterion T1 has the highest weight measured with the CWM, which is followed by the EC3 and EC1 sub-criteria. This strongly indicates the relevance of the technical and economic criteria in determining the outcome of the decision-making process. The least important sub-criteria are T2 and S2; however, the sub-criterion S1 is more important than the environmental sub-criterion ENV1. This is because of the highly dense area of the informal settlements, which consider the availability of land space more important than the emissions of CO2. The aggregate preference function of one alternative over the other is obtained by applying Equations (35)–(37). This is performed with the use of the criteria weights determined by the CMW method, and the results are presented in Table 8.

Table 8.

Aggregate preference function.

5.4. Ranking of the Alternatives

The complete ranking of the alternatives is determined from the net outranking flow value. The leaving flow and the entering flow values are obtained from the 4 by 4 matrix using Equations (38)–(40). The results are presented in Table 9 and Table 10.

Table 9.

Determining the leaving and entering flow.

Table 10.

Ranking of the alternatives.

From Table 10, the results show that the most appropriate waste-to-energy technology for slum/informal settlements is the gasification technology (GAS), which is followed by the incineration technology (INC), using the combined weight method. The consistency in the results is further ascertained from the use of the AHP method. The deviation in the ranking observed with the use of the entropy weight method (EWM) proves the effectiveness of the application of the combined weight method. The combined weight method corrects any errors or bias obtained from the use of the subjective or objective weights by taking into consideration the weighted sum value. The landfill gas waste-to-energy technology (LFILL) has the lowest ranking from the application of the PROMETHEE MCDM.

5.5. Energy Requirement of the Informal Settlements

The results from the application of the PROMETHEE technique reveal that the sub-criteria electricity generating potential (T1) and the cost of energy (EC1) are the most influential, and are given priority over the other criteria. Due to this importance, this study conducted a further analysis to examine the energy requirement of the informal settlements and to determine the affordability of the gasification waste-to-energy technology.

A map showing the four informal settlements (Ado, Mararaba, New Karu, and Masaka) is depicted in Figure 1. From the random sampling, the two typologies of houses identified are the hybrid and stand-alone shack, and agriculture and commercial enterprises are identified as the major productive users of electricity.

The survey questionnaire was sent to 100 respondents from each of the four informal settlements. The total sample size of 381, which was rounded up to 400, was estimated by applying Equation (41). A value of 0.834 was obtained for Cronbach’s alpha, which validates the results by checking for consistency. The results of the survey are summarized in Table 11, Table 12, Table 13 and Table 14. The response from the questionnaires sent out shows that 20% of the total participants were females and 80% of the participants were males, which suggests male dominance in the society. The age of the participants ranged between 16 to 80 years. A share of 49.5% of the participants are owners of category A productive enterprises, 15.5% own category B productive enterprises, 9% are technicians, and the remainder accounts for participants who are apprentices or have other vocational jobs. A share of 56.25% earn NGN 50,000 per month, 17.5% of the participants earn between NGN 1 and 30,000 per month, and about 22.75% of the participants are unemployed. A share of 76% of the participants pays NGN 4000 for their electricity per month and 12% of the participants do not pay electricity bills; this reflects the number of illegal connections to pre-paid and post-paid electricity meters. A share of 9.5% of the participants pays between NGN 1000 and 4000 for electricity per month. The conversion factors for 1 liter of kerosene and 1 kg of dry wood are is 10 and 5.5 kWh, respectively [120,121].

Table 11.

Results of the survey of the informal settlements.

Table 12.

Results of the survey on typology A informal house.

Table 13.

Results of the survey on the typology B informal house.

Table 14.

Results from the survey on category A productive use enterprises.

The affordability of the gasification technology, which was selected as the most appropriate waste-to-energy technology, was determined from the results of the survey presented in Table 11, Table 12, Table 13, Table 14 and Table 15. The levelized cost of electricity (LCOE) for the gasification technology obtained in this study using Equation (42) was 0.039 USD/kWh. The value for the levelized cost of energy (LCOE) of the gasification technology was validated with the studies conducted on a similar community within the sub-Saharan region of Africa and Brazil [122,123]. In these studies, the values for the LCOE are obtained as 0.15 and 0.12 USD/kWh., respectively The variation in the values of the LCOE obtained from these studies in comparison with this research work can be attributed to the amount of electricity produced, which is also a function of the plant size provided that other variables remain constant. In these studies, the plant sizes were small, having a capacity of 200 kW, compared to 0.14 TW (terawatts) obtained in this research work. The value of the LCOE obtained in this work was compared to the cost of the other forms of energy for the informal settlements of Ado, New Karu, Masaka, and Mararaba. Table 11 shows that kerosene, diesel, gasoline, and electricity are the major energy sources for domestic and productive activities. According to the National Bureau of Statistics, the costs of kerosene, diesel, and gasoline are 450, 311, and 170 NGN per liter, respectively [111]. By applying the energy conversion factors for fuels and the official exchange rate of the Naira to the US dollar, the unit costs for kerosene, diesel, and gasoline were obtained as 0.104, 0.074, and 0.045 USD/kWh, respectively [112,121]. GKUA falls under the electricity distribution franchise area from the national grid. Under the franchise agreement with the Federal Government of Nigeria, the Abuja Electricity Distribution Company (AEDC) is responsible for the distribution and sale of electricity to the Federal Capital Territory, Niger, Kogi, and Nasarawa States. The electricity tariff for the residential class under the multi-year tariff order (MYTO) is set at 53 NGN/kWh, which is equivalent to 0.127 USD/kWh [124].

Table 15.

Results of the survey on the category B productive use enterprise.

The significance of this finding is that the incineration technology is the cheapest waste-to-energy technology, with the value of 0.043 USD/kWh as its cost of energy (COE). When we consider the multi-criteria effect, the gasification technology was obtained as the most appropriate. However, in comparison to the major sources of energy used in the household or productive sector in GKUA, the gasification technology is cheaper than grid electricity, kerosene, diesel, and gasoline. In addition, it is clean and environmentally friendly in comparison to the fossil fuel sources that release CO2 emissions when consumed.

The average income for men and women in GKUA is NGN 40,000 per month, and the average energy bill is about NGN 3750 Naira. The energy requirement for typology A and B slum/informal houses is 742.5 and 543 kWh/month, respectively; see Table 12 and Table 13. This means that USD 28.95 and 21.17 are required, respectively, to pay for a constant electricity supply from the gasification technology each month. The average income of NGN 40,000 (USD 96) is sufficient to pay for electricity, and the remainder can be used to pay for other needs, such as food and clothing. From the survey, 287 of the respondents indicated they were willing to pay the same price as their current electricity bill in exchange for a cleaner and stable electricity supply. A total of 64 respondents indicated that they can pay for an alternative source, even if it is more expensive than the rate from their current electricity provider. This suggests that the gasification technology is well received and affordable for household and domestic use. The energy requirements for category A and B productive enterprises (see Table 14 and Table 15) were obtained as 3567 and 11,421 kW, respectively, which means their required monthly payments for electricity are USD 139.11 and 445.4, respectively, using the gasification technology. These costs can only be afforded by productive enterprises that make enough profit; from the results of the survey, only 4.75% of the respondents earn above NGN 50,000 per month.

The significance of these findings is that the government can provide the enabling environment for the proliferation of the gasification technology to the slum/informal settlements in GKUA and other parts of the country. In the case when the levelized cost of energy for a small-scale gasification plant rises to 0.1–0.15 USD/kWh, the application of hybrid waste-to-energy technologies will be necessary to drive down the cost. Financial support can come in the form of grants and subsidies to productive enterprises to enhance their profitability. The general consideration of informal waste management should be finally implemented and incorporated into the existing energy policies. Furthermore, the policies should be adapted to include sanctions against uncontrolled burning of waste in the slums and informal settlements.

6. Conclusions

This study evaluated the sub-criteria needed for the selection of the most appropriate waste-to-energy technology for the slum/informal settlements of the Greater Karu Urban Area. The results from the study showed that the gasification technology received the highest ranking using the PROMETHEE technique. The combined weighting method improved the accuracy in determining the criteria weights, thereby ensuring a reliable outcome for decision making. The findings of this work also extend to the provision of electricity for the underserved inhabitants of the informal settlements. These results showed that the gasification technology is affordable and commensurate with income levels for the household sector. In comparison to grid electricity, diesel, and kerosene, gasification technology offers the cheapest and cleanest source of energy for slum/informal settlements.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/en15103481/s1. The supplementary materials include the sample of the questionnaires and assessment of the results S1 and S2.

Author Contributions

D.U. initiated the ideas, and drafted and designed the structure of the article, while J.T.-C. and M.J.H.-O. reviewed the results. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Acknowledgments

The data provision assistance and access to software and library resources from the Centre of Advanced Studies in Energy and Environment, University of Jaen is hereby acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- SDG Indicators. Available online: https://unstats.un.org/sdgs/report/2019/goal-11 (accessed on 11 March 2022).

- Development-OECD. Available online: https://www.oecd.org/development/ (accessed on 11 March 2022).

- Arimah, B.C.; Branch, C.M. Slums as expressions of social exclusion: Explaining the prevalence of slums in African countries. In Proceedings of the OECD International Conference on Social Cohesion and Development, Paris, France, 20 January 2011; pp. 20–21. [Google Scholar]

- Samper, J.; Shelby, J.A.; Behary, D. The paradox of informal settlements revealed in an ATLAS of informality: Findings from mapping growth in the most common yet unmapped forms of urbanization. Sustainability 2020, 12, 9510. [Google Scholar] [CrossRef]

- Malinauskaite, J.; Jouhara, H.; Czajczyńska, D.; Stanchev, P.; Katsou, E.; Rostkowski, P.; Thorne, R.J.; Colon, J.; Ponsá, S.; Al-Mansour, F.; et al. Municipal solid waste management and waste-to-energy in the context of a circular economy and energy recycling in Europe. Energy 2017, 141, 2013–2044. [Google Scholar] [CrossRef]

- Trends in Solid Waste Management. Available online: https://datatopics.worldbank.org/what-a-waste/trends_in_solid_waste_management.html (accessed on 27 February 2022).

- Ogunjuyigbe, A.S.O.; Ayodele, T.R.; Alao, M.A. Electricity generation from municipal solid waste in some selected cities of Nigeria: An assessment of feasibility, potential and technologies. Renew. Sustain. Energy Rev. 2017, 80, 149–162. [Google Scholar] [CrossRef]

- About the OECD-OECD. Available online: https://www.oecd.org/about/ (accessed on 20 March 2022).

- Anyanwu, N.C.; Adefila, J.O. Nature and management of solid waste in Karu Nasarawa State, Nigeria. Am. Int. J. Contemp. Res. 2014, 4, 149–159. [Google Scholar]

- Ogah, A.T.; Alkali, M.; Opaluwa, O.D. Efficiency of solid waste management methods in Karu Local Government Area, Nasarawa State, North Central, Nigeria. World J. Adv. Res. Rev. 2020, 8, 318–329. [Google Scholar] [CrossRef]

- Onazi, O.; Gaiya, N.S.; Ola-Adisa, E.O.; Mangden, Y.P.E. An appraisal of Waste Management Practices in Selected Peri-Urban Communities in North Central Nigeria. J. Sci. Eng. Res. 2018, 5, 349–359. [Google Scholar]

- Guibrunet, L. What is “informal” in informal waste management? Insights from the case of waste collection in the Tepito neighbourhood, Mexico City. Waste Manag. 2019, 86, 13–22. [Google Scholar] [CrossRef]

- Buthelezi, S.A.; Kapwata, T.; Wernecke, B.; Webster, C.; Mathee, A.; Wright, C.Y. Household fuel use for heating and cooking and respiratory health in a low-income, South African coastal community. Int. J. Environ. Res. Public Health 2019, 16, 550. [Google Scholar] [CrossRef]

- Alao, M.A.; Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Popoola, O.M. Multi-criteria decision based waste to energy technology selection using entropy-weighted TOPSIS technique: The case study of Lagos, Nigeria. Energy 2020, 201, 117675. [Google Scholar] [CrossRef]

- Cheng, H.; Hu, Y. Municipal solid waste (MSW) as a renewable source of energy: Current and future practices in China. Bioresour. Technol. 2010, 101, 3816–3824. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Alao, M.A.; Ogunjuyigbe, A.S.O. Effect of collection efficiency and oxidation factor on greenhouse gas emission and life cycle cost of landfill distributed energy generation. Sustain. Cities Soc. 2020, 52, 101821. [Google Scholar] [CrossRef]

- Gohlke, O. Efficiency of energy recovery from municipal solid waste and the resultant effect on the greenhouse gas balance. Waste Manag. Res. 2009, 27, 894–906. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, J.; Chong, K.; Bridgwater, A. V A techno-economic analysis of energy recovery from organic fraction of municipal solid waste (MSW) by an integrated intermediate pyrolysis and combined heat and power (CHP) plant. Energy Convers. Manag. 2018, 174, 406–416. [Google Scholar] [CrossRef]

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Economic and environmental assessment of electricity generation using biogas from organic fraction of municipal solid waste for the city of Ibadan, Nigeria. J. Clean. Prod. 2018, 203, 718–735. [Google Scholar] [CrossRef]

- Torkayesh, A.E.; Malmir, B.; Asadabadi, M.R. Sustainable waste disposal technology selection: The stratified best-worst multi-criteria decision-making method. Waste Manag. 2021, 122, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Ervural, B.C.; Zaim, S.; Demirel, O.F.; Aydin, Z.; Delen, D. An ANP and fuzzy TOPSIS-based SWOT analysis for Turkey’s energy planning. Renew. Sustain. Energy Rev. 2018, 82, 1538–1550. [Google Scholar] [CrossRef]

- Diemuodeke, E.O.; Addo, A.; Oko, C.O.C.; Mulugetta, Y.; Ojapah, M.M. Optimal mapping of hybrid renewable energy systems for locations using multi-criteria decision-making algorithm. Renew. Energy 2019, 134, 461–477. [Google Scholar] [CrossRef]

- Alao, M.A.; Popoola, O.M.; Ayodele, T.R. Selection of waste-to-energy technology for distributed generation using IDOCRIW-Weighted TOPSIS method: A case study of the City of Johannesburg, South Africa. Renew. Energy 2021, 178, 162–183. [Google Scholar] [CrossRef]

- Shahnazari, A.; Rafiee, M.; Rohani, A.; Nagar, B.B.; Ebrahiminik, M.A.; Aghkhani, M.H. Identification of effective factors to select energy recovery technologies from municipal solid waste using multi-criteria decision making (MCDM): A review of thermochemical technologies. Sustain. Energy Technol. Assess. 2020, 40, 100737. [Google Scholar] [CrossRef]

- Rahman, S.M.S.; Azeem, A.; Ahammed, F. Selection of an appropriate waste-to-energy conversion technology for Dhaka City, Bangladesh. Int. J. Sustain. Eng. 2017, 10, 99–104. [Google Scholar] [CrossRef]

- Kurbatova, A.; Abu-Qdais, H.A. Using multi-criteria decision analysis to select waste to energy technology for a mega city: The case of Moscow. Sustainability 2020, 12, 9828. [Google Scholar] [CrossRef]

- Qazi, W.A.; Abushammala, M.F.M. Multi-criteria decision analysis of waste-to-energy technologies. In Waste-to-Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 265–316. [Google Scholar]

- Siregar, S.R.H.; Saragih, B.R.; Surjosatyo, A. Evaluation of waste energy conversion technology using analitycal hierarchy process in Bantargebang landfill, Indonesia. In Proceedings of the E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 67, p. 2012. [Google Scholar]

- Belhadi, A.; Kamble, S.S.; Khan, S.A.R.; Touriki, F.E.; Kumar, M.D. Infectious waste management strategy during COVID-19 pandemic in Africa: An integrated decision-making framework for selecting sustainable technologies. Environ. Manag. 2020, 66, 1085–1104. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Longsheng, C.; Solangi, Y.A.; Ahmad, M.; Ali, S. Energy trilemma based prioritization of waste-to-energy technologies: Implications for post-COVID-19 green economic recovery in Pakistan. J. Clean. Prod. 2021, 284, 124729. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ren, J.; Goodsite, M.E.; Xu, G. Waste-to-energy, municipal solid waste treatment, and best available technology: Comprehensive evaluation by an interval-valued fuzzy multi-criteria decision making method. J. Clean. Prod. 2018, 172, 887–899. [Google Scholar] [CrossRef]

- Ebadi Torkayesh, A.; Fathipoir, F.; Saidi-Mehrabd, M. Entropy-based multi-criteria analysis of thermochemical conversions for energy recovery from municipal solid waste using fuzzy VIKOR and ELECTRE III: Case of Azerbaijan region, Iran. J. Energy Manag. Technol. 2019, 3, 17–29. [Google Scholar]

- Coban, A.; Ertis, I.F.; Cavdaroglu, N.A. Municipal solid waste management via multi-criteria decision making methods: A case study in Istanbul, Turkey. J. Clean. Prod. 2018, 180, 159–167. [Google Scholar] [CrossRef]

- Arıkan, E.; Şimşit-Kalender, Z.T.; Vayvay, Ö. Solid waste disposal methodology selection using multi-criteria decision making methods and an application in Turkey. J. Clean. Prod. 2017, 142, 403–412. [Google Scholar] [CrossRef]

- Herva, M.; Roca, E. Ranking municipal solid waste treatment alternatives based on ecological footprint and multi-criteria analysis. Ecol. Indic. 2013, 25, 77–84. [Google Scholar] [CrossRef]

- Makan, A.; Malamis, D.; Assobhei, O.; Loizidou, M.; Mountadar, M. Multi-criteria decision aid approach for the selection of the best compromise management scheme for the treatment of municipal solid waste in Morocco. Int. J. Environ. Waste Manag. 2013, 12, 300–317. [Google Scholar] [CrossRef]

- Vego, G.; Kučar-Dragičević, S.; Koprivanac, N. Application of multi-criteria decision-making on strategic municipal solid waste management in Dalmatia, Croatia. Waste Manag. 2008, 28, 2192–2201. [Google Scholar] [CrossRef]

- Chenayah, S.; Takeda, E. Promethee Multicriteria Analysis for Evaluation of Recycling Strategies in Malaysia, Osakan, Japan. Grad. Sch. Econ. Osaka Sch. Int. Public Policy 2005, 2, 1–5. [Google Scholar]

- Brans, J.-P.; Vincke, P. Note—A Preference Ranking Organisation Method: (The PROMETHEE Method for Multiple Criteria Decision-Making). Manag. Sci. 1985, 31, 647–656. [Google Scholar] [CrossRef]

- Kapepula, K.-M.; Colson, G.; Sabri, K.; Thonart, P. A multiple criteria analysis for household solid waste management in the urban community of Dakar. Waste Manag. 2007, 27, 1690–1705. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, J.; Hu, Y.; Ke, Y.; Li, L. An extended TODIM-PROMETHEE method for waste-to-energy plant site selection based on sustainability perspective. Energy 2018, 156, 1–16. [Google Scholar] [CrossRef]

- Vaillancourt, K.; Waaub, J.-P. Environmental site evaluation of waste management facilities embedded into EUGENE model: A multicriteria approach. Eur. J. Oper. Res. 2002, 139, 436–448. [Google Scholar] [CrossRef]

- Oubahman, L.; Duleba, S. Review of Promethee method in transportation. Prod. Eng. Arch. 2021, 27, 69–74. [Google Scholar] [CrossRef]

- Abdullah, L.; Chan, W.; Afshari, A. Application of PROMETHEE method for green supplier selection: A comparative result based on preference functions. J. Ind. Eng. Int. 2019, 15, 271–285. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Babatunde, D.E. Evaluation of landfill gas plant siting problem: A multi-criteria approach. Environ. Health Eng. Manag. J. 2019, 6, 1–10. [Google Scholar] [CrossRef]

- Mohammed, H.I.; Majid, Z.; Yusof, N.B.; Yamusa, Y.B. Analysis of multi-criteria evaluation method of landfill site selection for municipal solid waste management. In Proceedings of the E3S Web of Conferences, Les Ulis, France, 10–12 December; 2018; 34, p. 2010. [Google Scholar]

- Rikko, S.L. Monitoring Urban Sprawl in Greater Karu Urban Area (Gkua), Nasaraw State, Nigeria. J. Environ. Earth Sci. 2013, 3, 1–10. [Google Scholar]

- Rikko, L.S.; Wapwera, S.D. Perception and Conditions of the Urban Poor in Greater Karu Urban Area (GKUA) Nasarawa, Nigeria. IOSR J. Humanit. Soc. Sci. 2016, 21, 80–87. [Google Scholar]

- Joshua, J.K.; Anyanwu, N.C.; Ahmed, A.J. Land suitability analysis for agricultural planning using GIS and multi criteria decision analysis approach in Greater Karu Urban Area, Nasarawa State, Nigeria. Afr. J. Agric. Sci. Technol. 2013, 1, 14–23. [Google Scholar]

- Asadullah, M.; Muhammad, C.M. An exploratory use of SLEUTH urban growth model in the spatiotemporal growth simulation of greater Karu urban area. Int. J. Eng. Sci. Comput. 2000, 10, 24420–24426. [Google Scholar]

- Kanayochukwu, E.C.; Dogo, B. Profiling the Characteristics of Karu Slum, Nasarawa State, Nigeria. J. Serv. Sci. Manag. 2019, 12, 605–619. [Google Scholar] [CrossRef]

- Isma’il, M.; Ishaku, E.; Yahaya, A.M.; Tanko, M.A.; Ahmed, H.T. Urban growth and housing problems in Karu local government area of Nasarawa State, Nigeria. Glob. J. Res. Rev 2015, 2, 45–57. [Google Scholar]

- Market Intelligence–Rural Electrification Agency. Available online: http://rea.gov.ng/market-intelligence/ (accessed on 28 March 2022).

- Henry, R.K.; Yongsheng, Z.; Jun, D. Municipal solid waste management challenges in developing countries–Kenyan case study. Waste Manag. 2006, 26, 92–100. [Google Scholar] [CrossRef]

- Copy of Waste to Energy Map–Google My Maps. Available online: https://www.google.com/maps/d/viewer?mid=1P9zb_Mf6d-b1BRrZH1bc0baKpITdMsin&ll=8.942352368706047%2C7.66116424999999&z=11 (accessed on 27 March 2022).

- Bhawal Mukherji, S.; Sekiyama, M.; Mino, T.; Chaturvedi, B. Resident knowledge and willingness to engage in waste management in Delhi, India. Sustainability 2016, 8, 1065. [Google Scholar] [CrossRef]

- Li, Y.; Alaimo, C.P.; Kim, M.; Kado, N.Y.; Peppers, J.; Xue, J.; Wan, C.; Green, P.G.; Zhang, R.; Jenkins, B.M. Composition and toxicity of biogas produced from different feedstocks in California. Environ. Sci. Technol. 2019, 53, 11569–11579. [Google Scholar] [CrossRef]

- Solheimslid, T.; Harneshaug, H.K.; Lümmen, N. Calculation of first-law and second-law-efficiency of a Norwegian combined heat and power facility driven by municipal waste incineration—A case study. Energy Convers. Manag. 2015, 95, 149–159. [Google Scholar] [CrossRef]

- Defra Incineration of Municipal Solid Waste. 2013. Available online: www.defra.gov.uk (accessed on 22 February 2022).

- Matee, V.E.; Manyele, S.V. Analysis of temperature profiles and cycle time in a large-scale medical waste incinerator. Engineering 2015, 7, 717. [Google Scholar] [CrossRef][Green Version]

- Doherty, W.; Reynolds, A.; Kennedy, D. Aspen Plus Simulation of Biomass Gasification in a Steam Blown Dual Fluidised Bed; Mendez-Vilas, A., Ed.; Formartex Research Centre: Badajoz, Spain, 2013. [Google Scholar]

- Hanping, C.; Bin, L.; Haiping, Y.; Guolai, Y.; Shihong, Z. Experimental investigation of biomass gasification in a fluidized bed reactor. Energy Fuels 2008, 22, 3493–3498. [Google Scholar] [CrossRef]

- Lv, P.M.; Xiong, Z.H.; Chang, J.; Wu, C.Z.; Chen, Y.; Zhu, J.X. An experimental study on biomass air–steam gasification in a fluidized bed. Bioresour. Technol. 2004, 95, 95–101. [Google Scholar] [CrossRef] [PubMed]

- Afrane, S.; Ampah, J.D.; Jin, C.; Liu, H.; Aboagye, E.M. Techno-economic feasibility of waste-to-energy technologies for investment in Ghana: A multicriteria assessment based on fuzzy TOPSIS approach. J. Clean. Prod. 2021, 318, 128515. [Google Scholar] [CrossRef]

- Ozkaya, G.; Erdin, C. Evaluation of smart and sustainable cities through a hybrid MCDM approach based on ANP and TOPSIS technique. Heliyon 2020, 6, e05052. [Google Scholar] [CrossRef] [PubMed]

- Karabašević, D.; Stanujkić, D.; Urošević, S. The MCDM Model for Personnel Selection Based on SWARA and ARAS Methods. Manag. 2015, 20, 43–52. [Google Scholar]

- Aziz, N.F.; Sorooshian, S.; Mahmud, F. MCDM-AHP method in decision makings. ARPN J. Eng. Appl. Sci. 2016, 11, 7217–7220. [Google Scholar]

- Solangi, Y.A.; Tan, Q.; Mirjat, N.H.; das Valasai, G.; Khan, M.W.A.; Ikram, M. An integrated Delphi-AHP and fuzzy TOPSIS approach toward ranking and selection of renewable energy resources in Pakistan. Processes 2019, 7, 118. [Google Scholar] [CrossRef]

- Krylovas, A.; Zavadskas, E.K.; Kosareva, N.; Dadelo, S. New KEMIRA method for determining criteria priority and weights in solving MCDM problem. Int. J. Inf. Technol. Decis. Mak. 2014, 13, 1119–1133. [Google Scholar] [CrossRef]

- Alemi-Ardakani, M.; Milani, A.S.; Yannacopoulos, S.; Shokouhi, G. On the effect of subjective, objective and combinative weighting in multiple criteria decision making: A case study on impact optimization of composites. Expert Syst. Appl. 2016, 46, 426–438. [Google Scholar] [CrossRef]

- de Almeida Filho, A.T.; Clemente, T.R.N.; Morais, D.C.; de Almeida, A.T. Preference modeling experiments with surrogate weighting procedures for the PROMETHEE method. Eur. J. Oper. Res. 2018, 264, 453–461. [Google Scholar] [CrossRef]

- Danielson, M.; Ekenberg, L. The CAR method for using preference strength in multi-criteria decision making. Gr. Decis. Negot. 2016, 25, 775–797. [Google Scholar] [CrossRef]

- Odu, G.O. Weighting methods for multi-criteria decision making technique. J. Appl. Sci. Environ. Manag. 2019, 23, 1449–1457. [Google Scholar] [CrossRef]

- Adalı, E.A.; Işık, A.T. CRITIC and MAUT methods for the contract manufacturer selection problem. Eur. J. Multidiscip. Stud. 2017, 2, 93–101. [Google Scholar] [CrossRef]

- Babatunde, O.M.; Munda, J.L.; Hamam, Y. Selection of a hybrid renewable energy systems for a low-income household. Sustainability 2019, 11, 4282. [Google Scholar] [CrossRef]

- Jee, D.-H.; Kang, K.-J. A method for optimal material selection aided with decision making theory. Mater. Des. 2000, 21, 199–206. [Google Scholar] [CrossRef]

- Hussain, S.A.I.; Mandal, U.K. Entropy based MCDM approach for Selection of material. In Proceedings of the National Level Conference on Engineering Problems and Application of Mathematics, La Rochelle, France, 4–8 July 2016; pp. 1–6. [Google Scholar]

- Wang, T.-C.; Lee, H.-D. Developing a fuzzy TOPSIS approach based on subjective weights and objective weights. Expert Syst. Appl. 2009, 36, 8980–8985. [Google Scholar] [CrossRef]

- Podvezko, V.; Zavadskas, E.K.; Podviezko, A. An extension of the new objective weight assessment methods cilos and idocriw to fuzzy MCDM. Econ. Comput. Econ. Cybern. Stud. Res. 2020, 54, 59–75. [Google Scholar]

- Dong, J.-Y.; Wan, S.-P. Virtual enterprise partner selection integrating LINMAP and TOPSIS. J. Oper. Res. Soc. 2016, 67, 1288–1308. [Google Scholar] [CrossRef]

- Dahooie, J.H.; Zavadskas, E.K.; Firoozfar, H.R.; Vanaki, A.S.; Mohammadi, N.; Brauers, W.K.M. An improved fuzzy MULTIMOORA approach for multi-criteria decision making based on objective weighting method (CCSD) and its application to technological forecasting method selection. Eng. Appl. Artif. Intell. 2019, 79, 114–128. [Google Scholar] [CrossRef]

- Sarkar, B.; Biswas, A. Pythagorean fuzzy AHP-TOPSIS integrated approach for transportation management through a new distance measure. Soft Comput. 2021, 25, 4073–4089. [Google Scholar] [CrossRef]

- Chou, T.-Y.; Liang, G.-S. Application of a fuzzy multi-criteria decision-making model for shipping company performance evaluation. Marit. Policy Manag. 2001, 28, 375–392. [Google Scholar] [CrossRef]

- Chung, E.-S.; Won, K.; Kim, Y.; Lee, H. Water resource vulnerability characteristics by district’s population size in a changing climate using subjective and objective weights. Sustainability 2014, 6, 6141–6157. [Google Scholar] [CrossRef]

- Ma, J.; Fan, Z.-P.; Huang, L.-H. A subjective and objective integrated approach to determine attribute weights. Eur. J. Oper. Res. 1999, 112, 397–404. [Google Scholar] [CrossRef]

- Zoraghi, N.; Amiri, M.; Talebi, G.; Zowghi, M. A fuzzy MCDM model with objective and subjective weights for evaluating service quality in hotel industries. J. Ind. Eng. Int. 2013, 9, 1–13. [Google Scholar] [CrossRef]

- Zha, S.; Guo, Y.; Huang, S.; Wang, S. A hybrid MCDM method using combination weight for the selection of facility layout in the manufacturing system: A case study. Math. Probl. Eng. 2020, 2020, 1320173. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kumar, S.P.; Saravanakumar, K. An integrated fuzzy MCDM based approach for robot selection considering objective and subjective criteria. Appl. Soft Comput. 2015, 26, 31–41. [Google Scholar] [CrossRef]

- Jahan, A.; Mustapha, F.; Sapuan, S.M.; Ismail, M.Y.; Bahraminasab, M. A framework for weighting of criteria in ranking stage of material selection process. Int. J. Adv. Manuf. Technol. 2012, 58, 411–420. [Google Scholar] [CrossRef]

- Xu, X. A note on the subjective and objective integrated approach to determine attribute weights. Eur. J. Oper. Res. 2004, 156, 530–532. [Google Scholar] [CrossRef]

- Chen, C.-H. A Hybrid Multi-Criteria Decision-Making Approach Based on ANP-Entropy TOPSIS for Building Materials Supplier Selection. Entropy 2021, 23, 1597. [Google Scholar] [CrossRef]

- Vinogradova, I.; Podvezko, V.; Zavadskas, E.K. The recalculation of the weights of criteria in MCDM methods using the bayes approach. Symmetry 2018, 10, 205. [Google Scholar] [CrossRef]

- Emankhu, S.E.; Yamusa, V.L. An Analysis of Municipal Solid Waste in Lafia, Nasarawa State, Nigeria, West Africa. Int. J. Geog. Reg. Pln. Res 2017, 2, 1–9. [Google Scholar]

- Census Enumeration–National Population Commission. Available online: https://nationalpopulation.gov.ng/core-activities/census-enumeration/ (accessed on 28 February 2022).

- Home|National Bureau of Statistics. Available online: https://www.nigerianstat.gov.ng/ (accessed on 23 February 2022).

- Commission, N.P. Nigeria’s population now 182 million–NPC. 2017. Available online: https://www.vanguardngr.com/2016/11/nigerias-population-now-182-million-npc/ (accessed on 5 May 2022).

- Ayodele, T.R.; Ogunjuyigbe, A.S.O.; Alao, M.A. Life cycle assessment of waste-to-energy (WtE) technologies for electricity generation using municipal solid waste in Nigeria. Appl. Energy 2017, 201, 200–218. [Google Scholar] [CrossRef]

- Rodrigue, K.; Essi, K.; Cyril, K.; Albert, T. Estimation of methane emission from Kossihouen sanitary landfill and its electricity generation potential (Côte d’Ivoire). J. Power Energy Eng. 2018, 6, 22–31. [Google Scholar] [CrossRef][Green Version]

- Huang, W.; Fooladi, H. Economic and environmental estimated assessment of power production from municipal solid waste using anaerobic digestion and landfill gas technologies. Energy Rep. 2021, 7, 4460–4469. [Google Scholar] [CrossRef]

- Salman, C.A.; Omer, C.B. Process modelling and simulation of waste gasification-based flexible polygeneration facilities for power, heat and biofuels production. Energies 2020, 13, 4264. [Google Scholar] [CrossRef]

- Beegle, J.R.; Borole, A.P. Energy production from waste: Evaluation of anaerobic digestion and bioelectrochemical systems based on energy efficiency and economic factors. Renew. Sustain. Energy Rev. 2018, 96, 343–351. [Google Scholar] [CrossRef]

- Li, H.; Mehmood, D.; Thorin, E.; Yu, Z. Biomethane production via anaerobic digestion and biomass gasification. Energy Procedia 2017, 105, 1172–1177. [Google Scholar] [CrossRef]

- Cohce, M.K.; Rosen, M.A.; Dincer, I. Efficiency evaluation of a biomass gasification-based hydrogen production. Int. J. Hydrogen Energy 2011, 36, 11388–11398. [Google Scholar] [CrossRef]