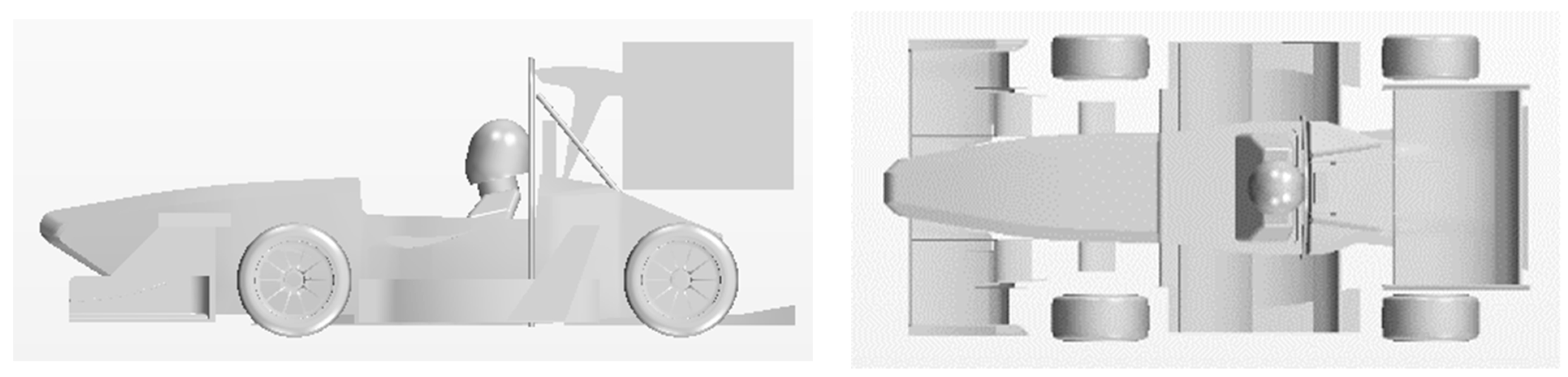

Figure 1.

Simplified racing model.

Figure 1.

Simplified racing model.

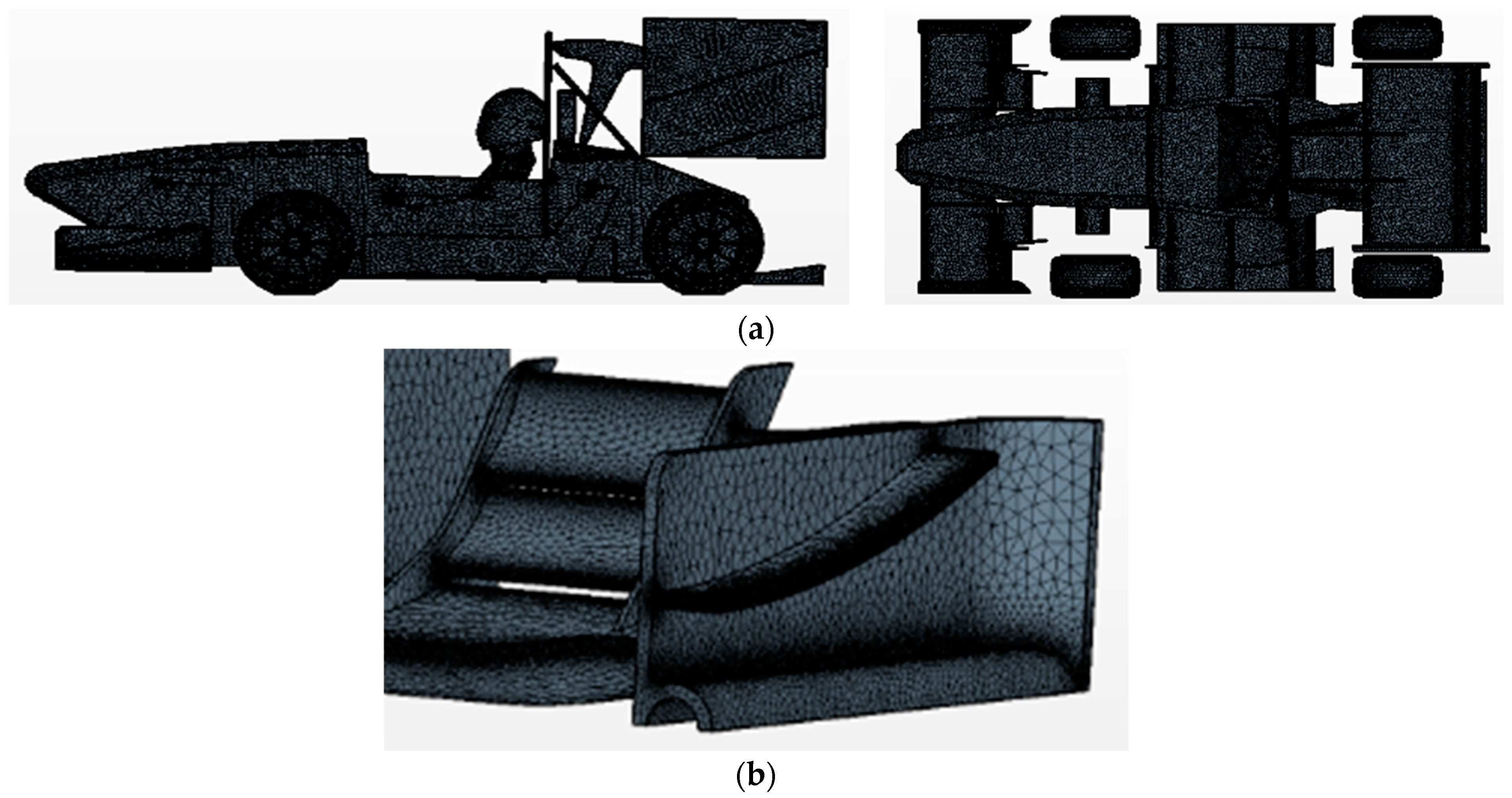

Figure 2.

Surface mesh and local detail surface mesh of simplified racing model: (a) vehicle surface grid and (b) front wing local surface mesh.

Figure 2.

Surface mesh and local detail surface mesh of simplified racing model: (a) vehicle surface grid and (b) front wing local surface mesh.

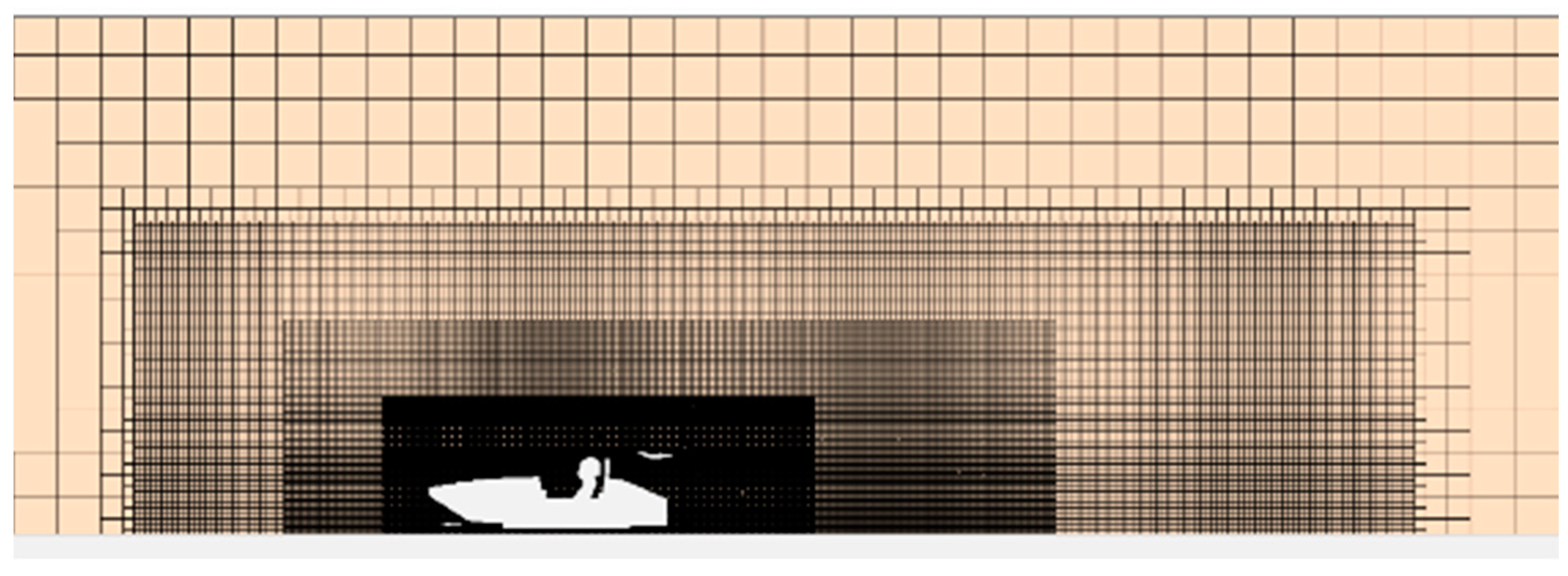

Figure 3.

Volume mesh encryption domain.

Figure 3.

Volume mesh encryption domain.

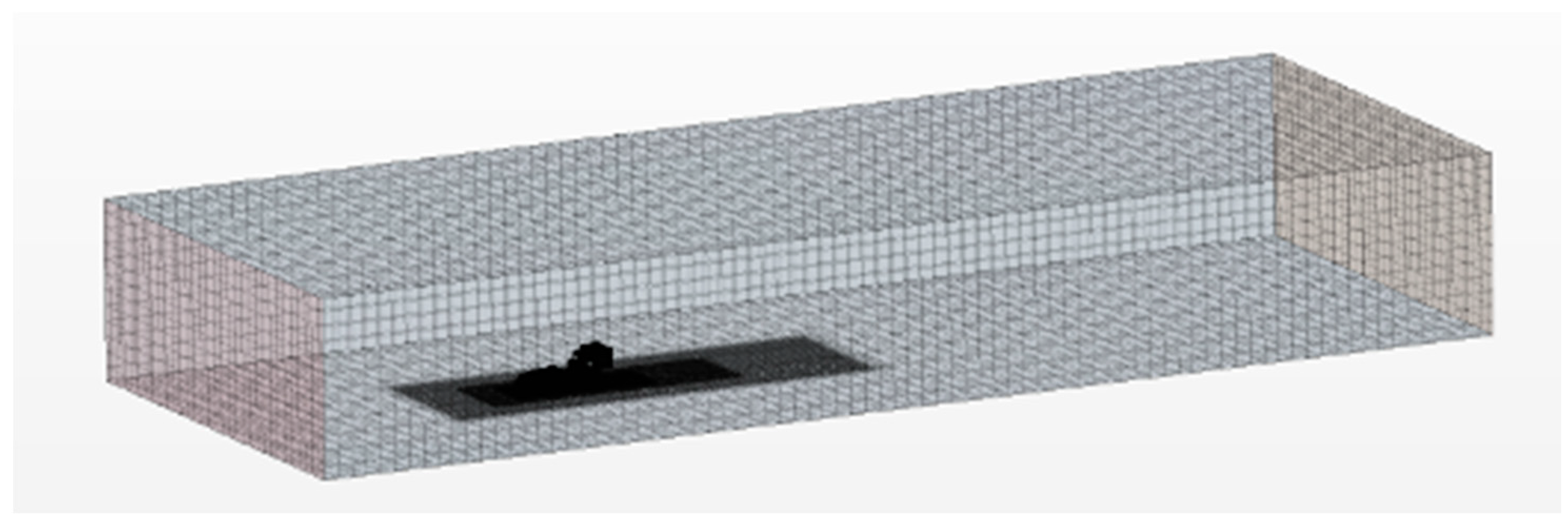

Figure 4.

Encrypted computing domain.

Figure 4.

Encrypted computing domain.

Figure 5.

FSAE racing car of Jilin University.

Figure 5.

FSAE racing car of Jilin University.

Figure 6.

Lifting drag characteristic curve at 15–30 m/s wind velocity in straight-line condition.

Figure 6.

Lifting drag characteristic curve at 15–30 m/s wind velocity in straight-line condition.

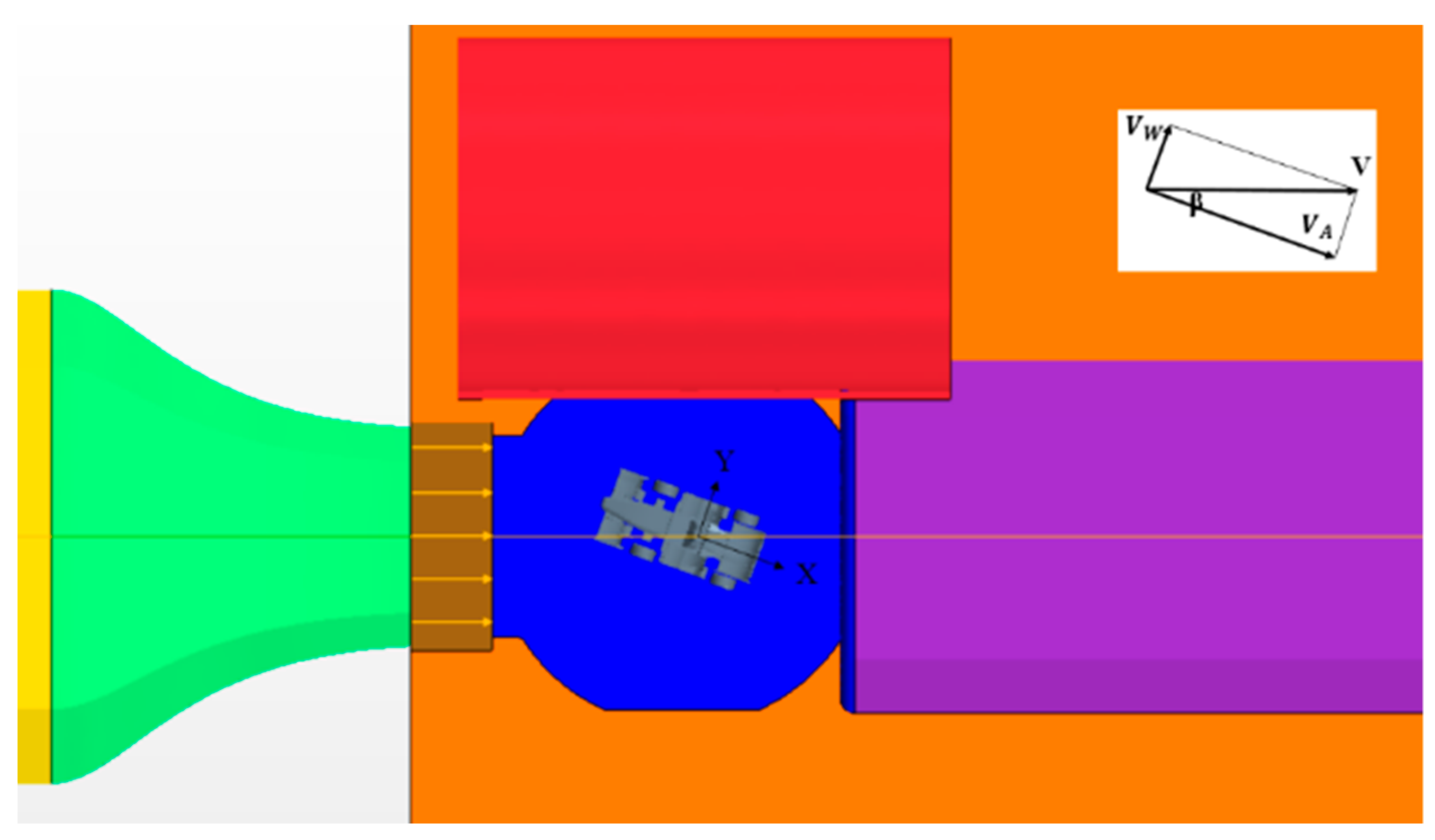

Figure 7.

Yaw model method for wind tunnel test.

Figure 7.

Yaw model method for wind tunnel test.

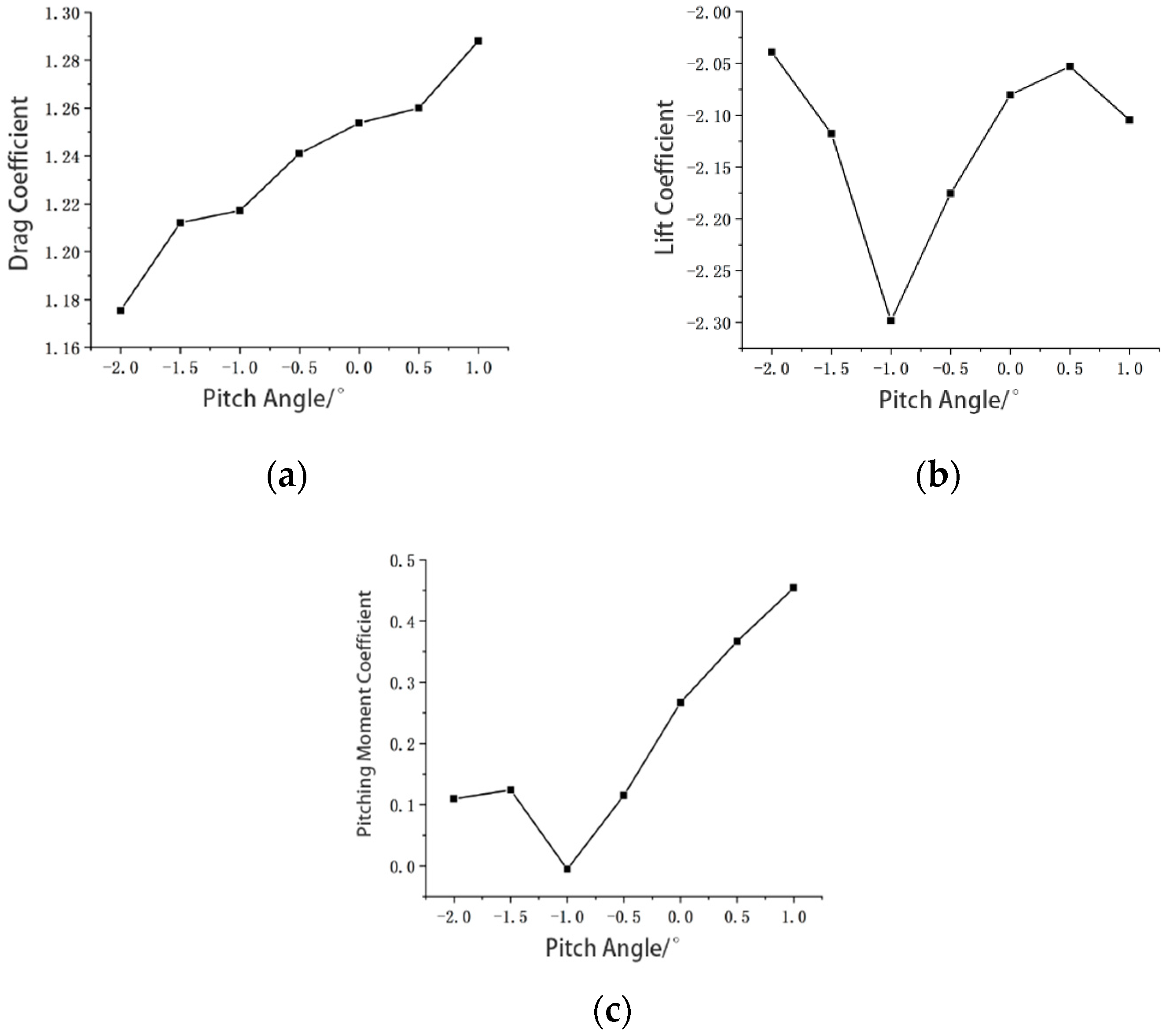

Figure 8.

Pitch working condition of the car drag coefficient, lift coefficient and pitching moment curve: (a) drag coefficient, (b) lift coefficient and (c) pitching moment.

Figure 8.

Pitch working condition of the car drag coefficient, lift coefficient and pitching moment curve: (a) drag coefficient, (b) lift coefficient and (c) pitching moment.

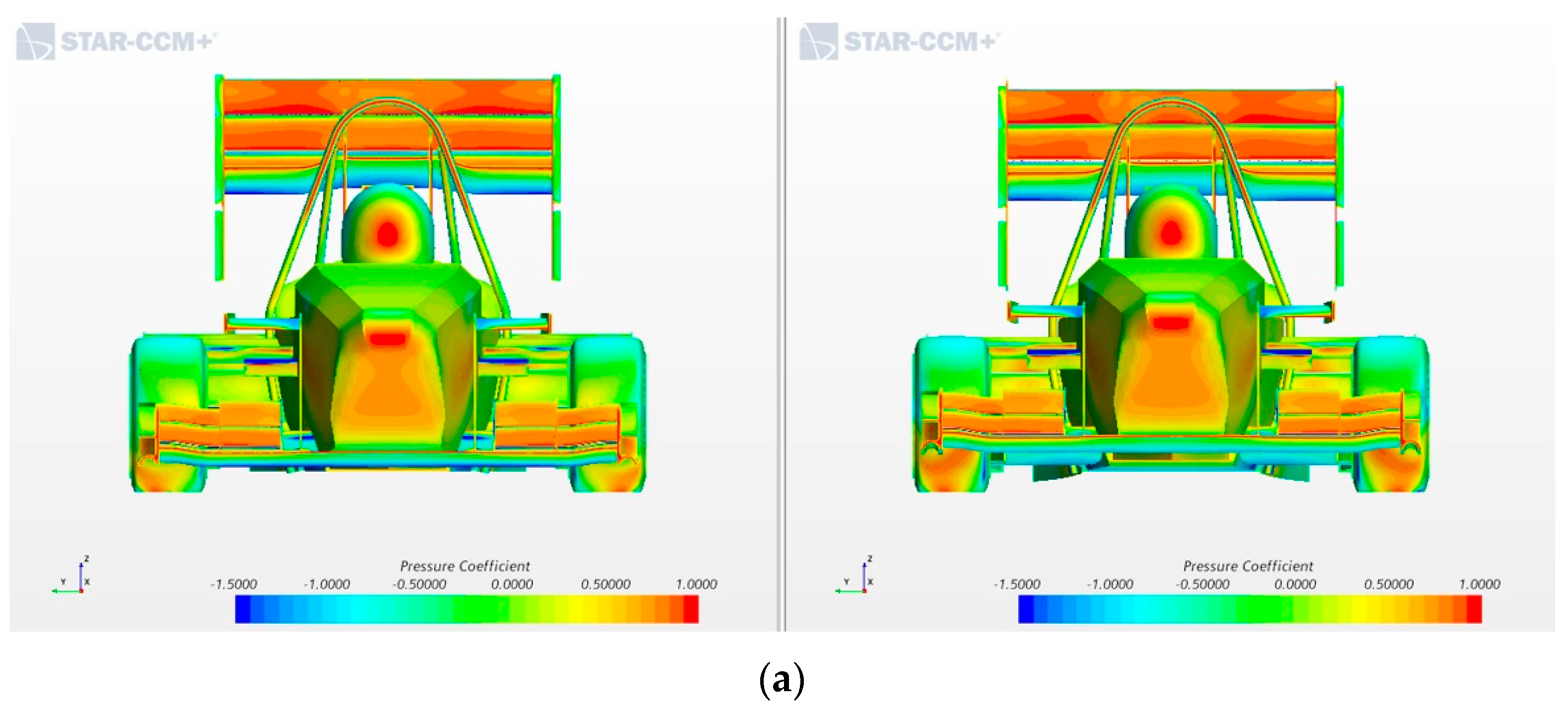

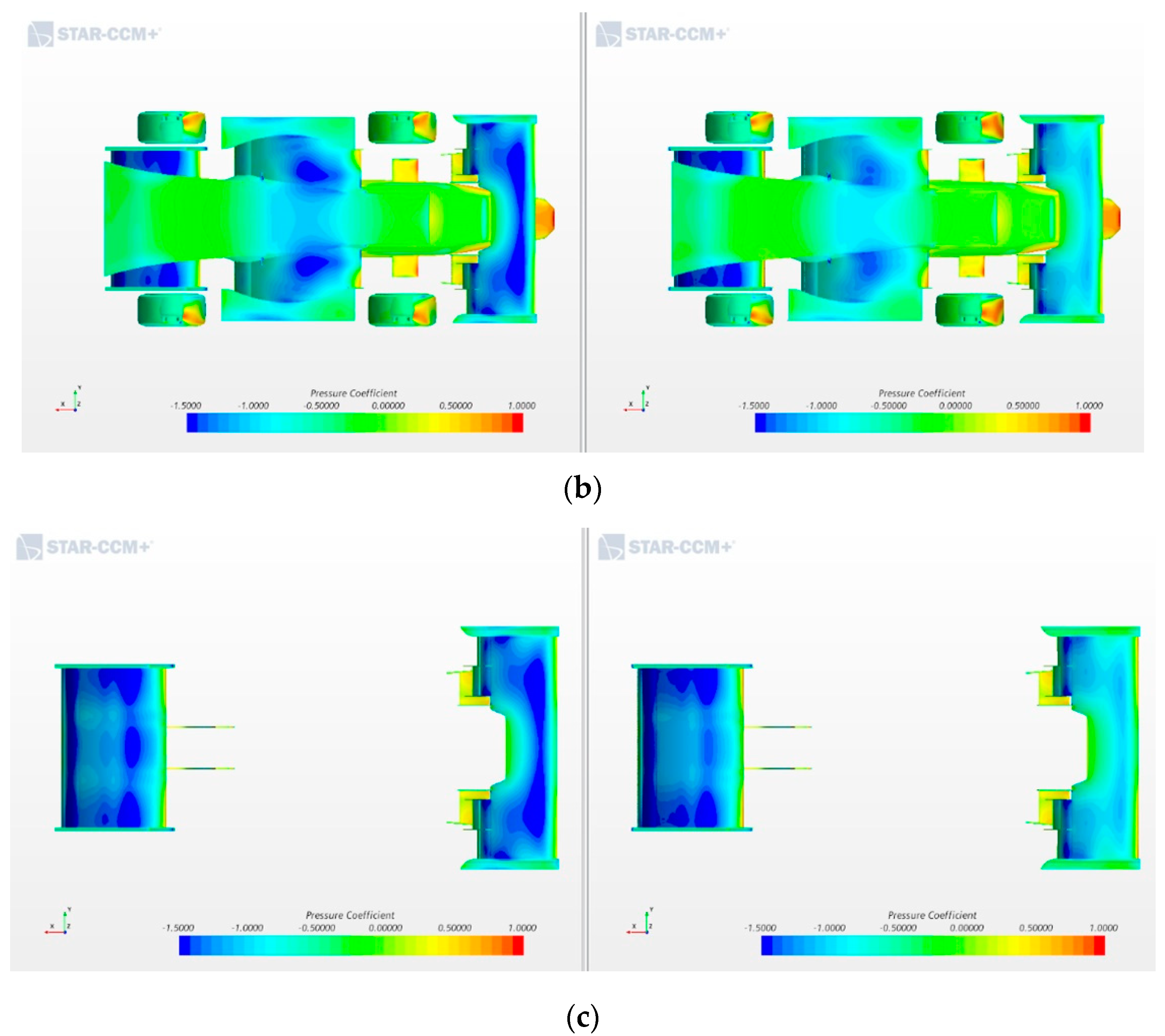

Figure 9.

Comparison of pressure cloud images of racing cars in pitching condition of −1.0° (left) and 0.5° (right): (a) the main view of the vehicle, (b) the vehicle and (c) the front wing and the side wing.

Figure 9.

Comparison of pressure cloud images of racing cars in pitching condition of −1.0° (left) and 0.5° (right): (a) the main view of the vehicle, (b) the vehicle and (c) the front wing and the side wing.

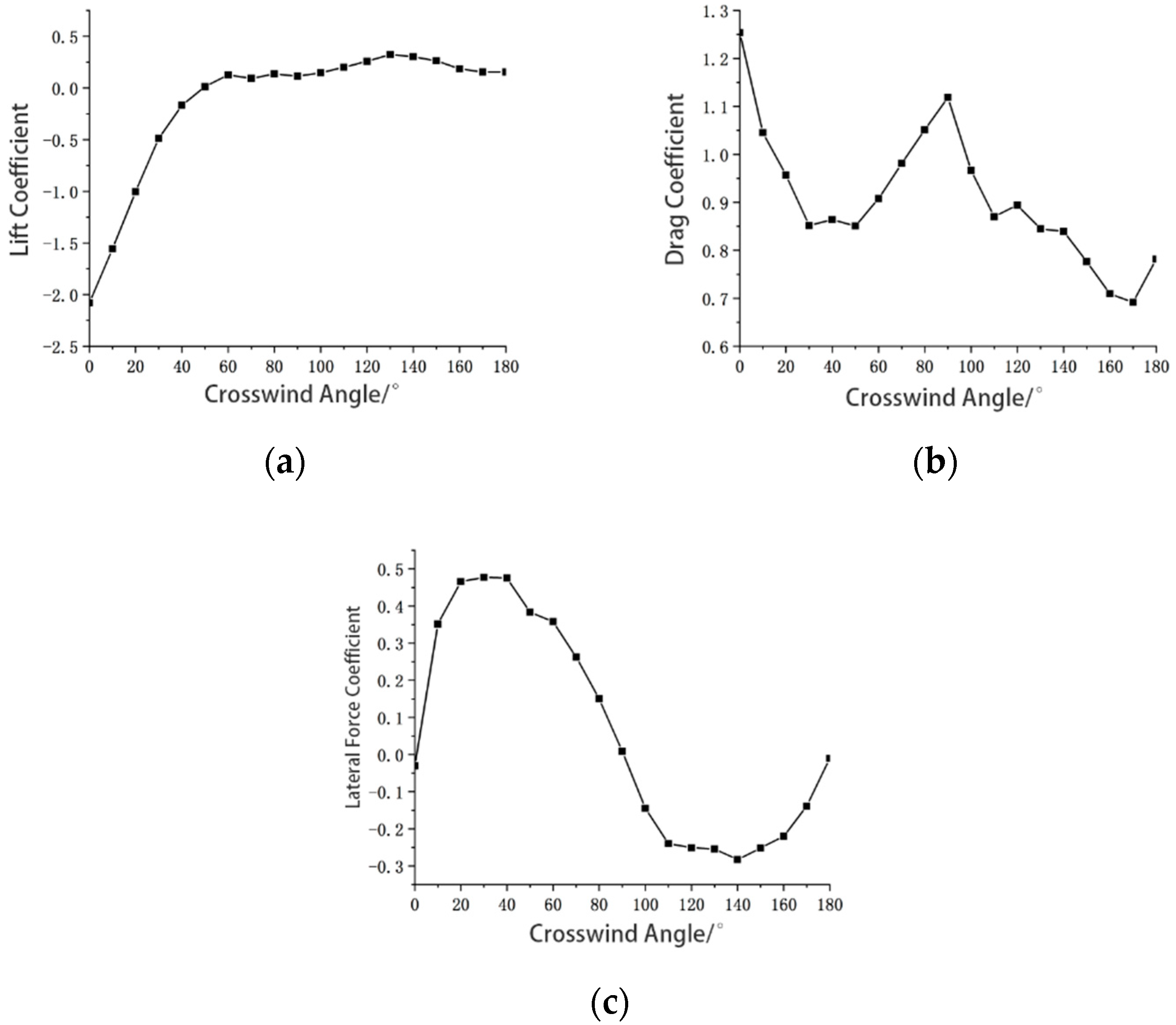

Figure 10.

Variation curves of lift coefficient, drag coefficient and lateral force coefficient at 0°~180° crosswind angle: (a) lift coefficient, (b) drag coefficient and (c) lateral force coefficient.

Figure 10.

Variation curves of lift coefficient, drag coefficient and lateral force coefficient at 0°~180° crosswind angle: (a) lift coefficient, (b) drag coefficient and (c) lateral force coefficient.

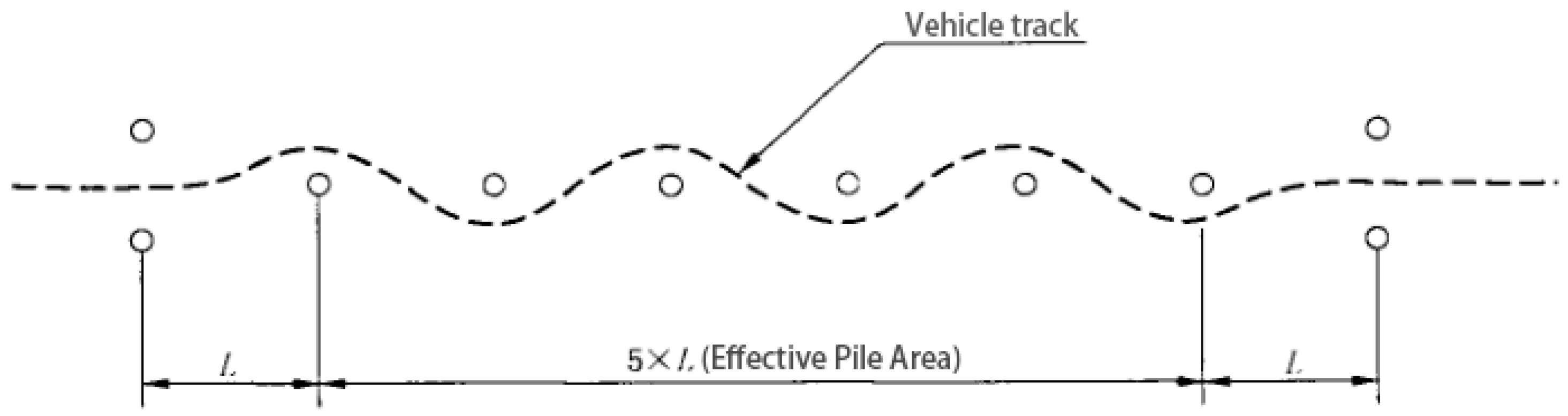

Figure 11.

Pile-arrangement diagram of snake test.

Figure 11.

Pile-arrangement diagram of snake test.

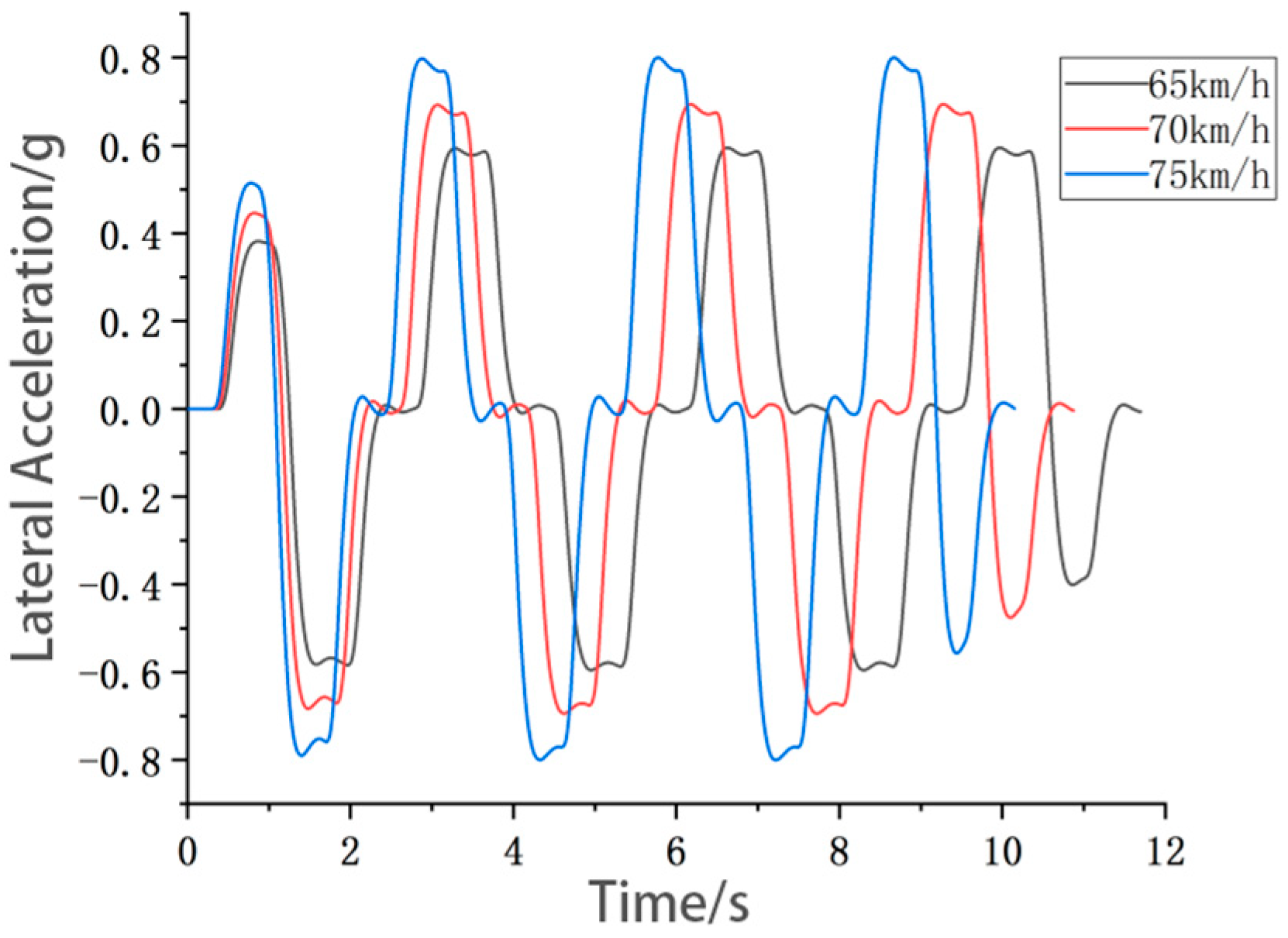

Figure 12.

Simulation curve of lateral acceleration without crosswind effect.

Figure 12.

Simulation curve of lateral acceleration without crosswind effect.

Figure 13.

Peak curve without crosswind effect: (a) average crosswind angle velocity and (b) average steering-wheel angle.

Figure 13.

Peak curve without crosswind effect: (a) average crosswind angle velocity and (b) average steering-wheel angle.

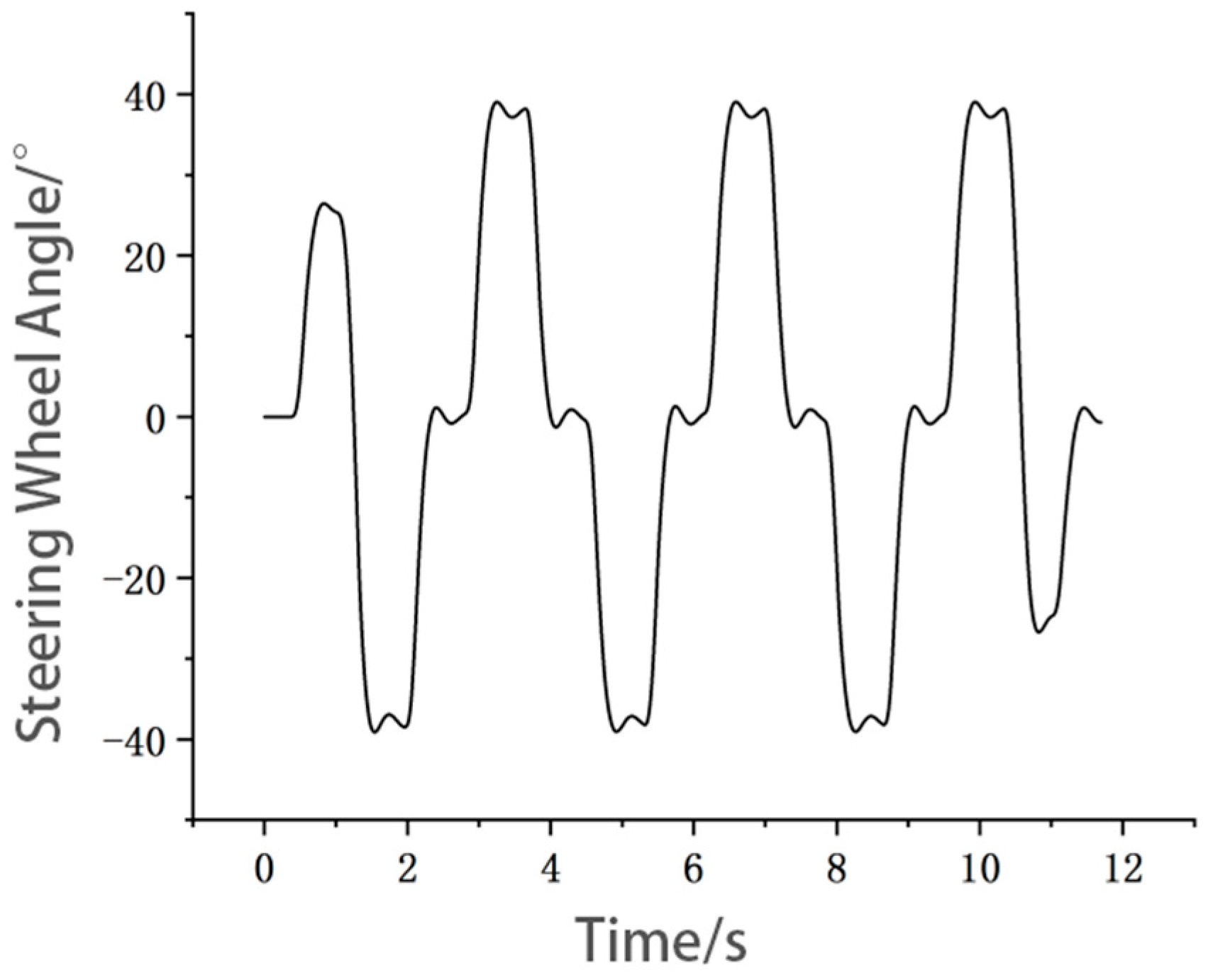

Figure 14.

Input curve of steering-wheel angle in open-loop test.

Figure 14.

Input curve of steering-wheel angle in open-loop test.

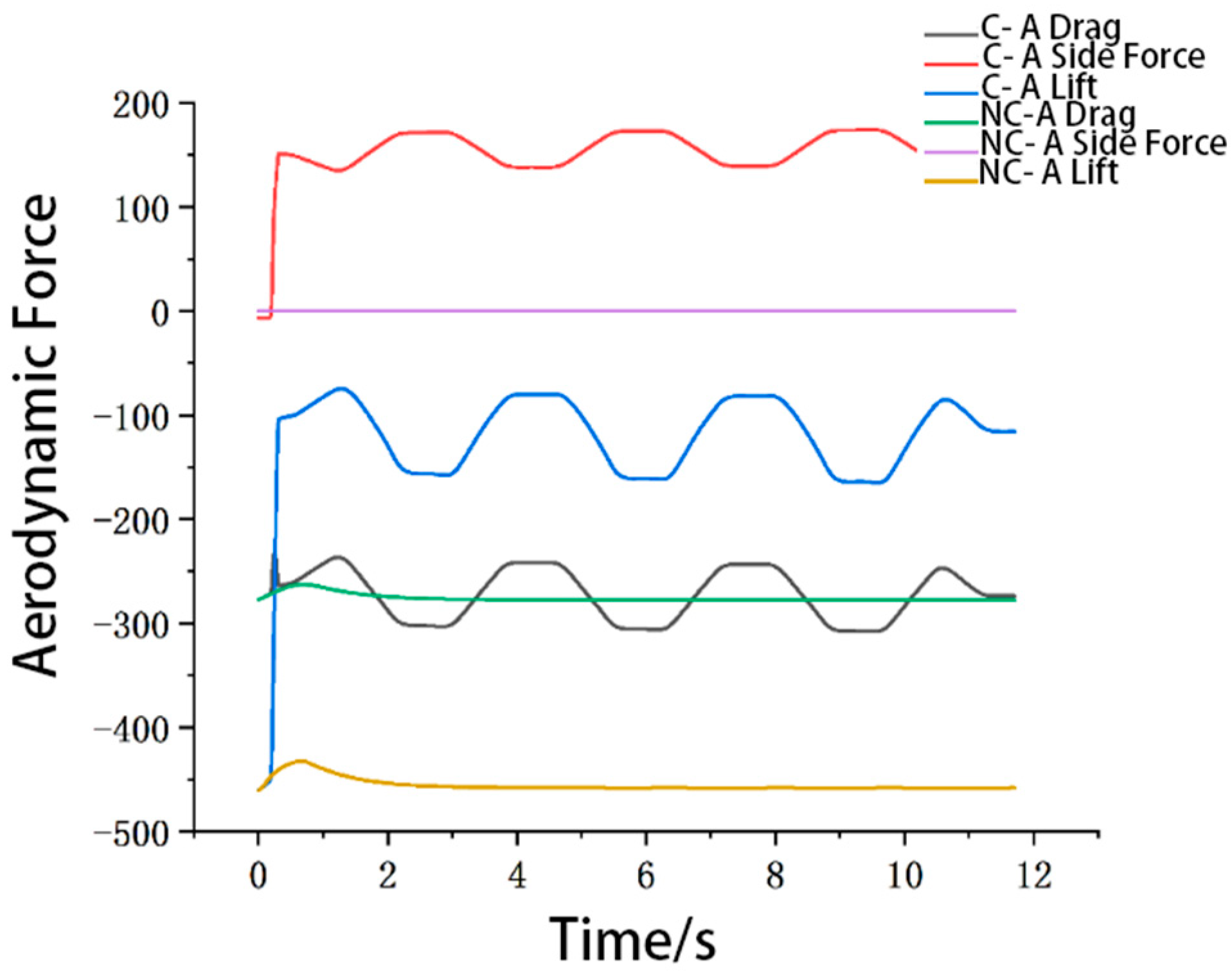

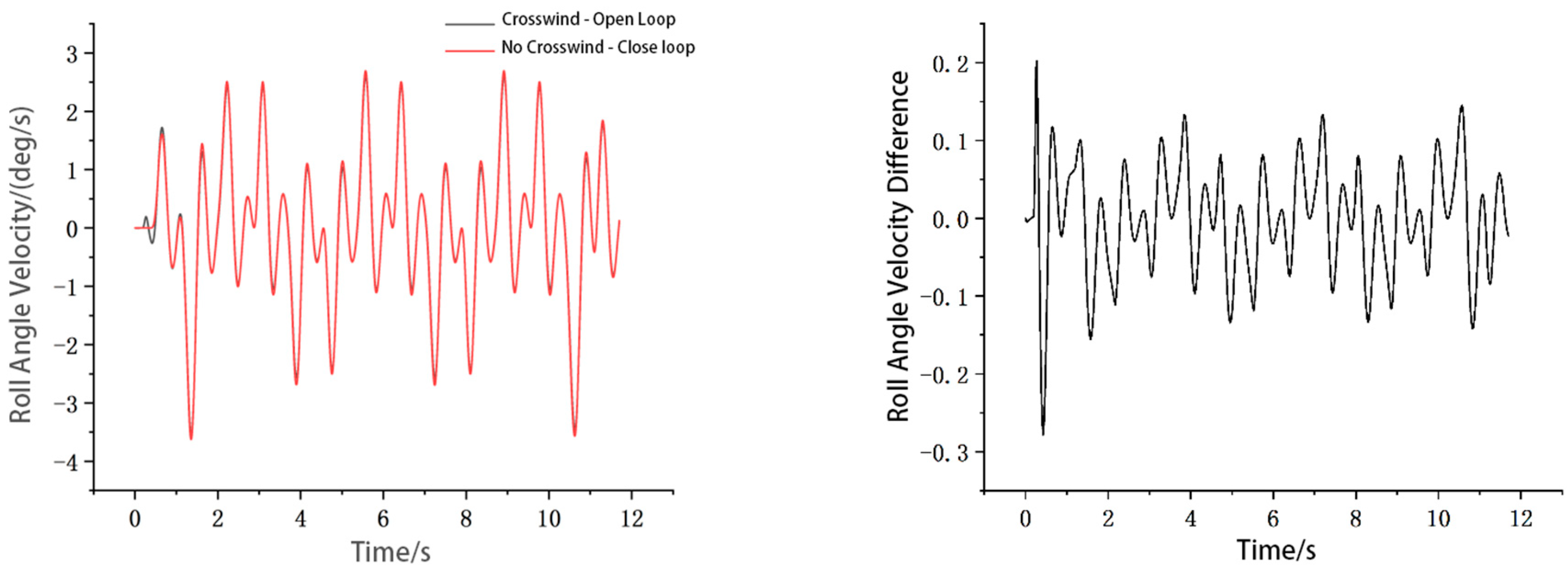

Figure 15.

Comparison curves of aerodynamic force and aerodynamic torque with and without crosswind over time: C—A is the crosswind-aerodynamic, NC—A is the no crosswind aerodynamic, C is the crosswind and NC is the no crosswind.

Figure 15.

Comparison curves of aerodynamic force and aerodynamic torque with and without crosswind over time: C—A is the crosswind-aerodynamic, NC—A is the no crosswind aerodynamic, C is the crosswind and NC is the no crosswind.

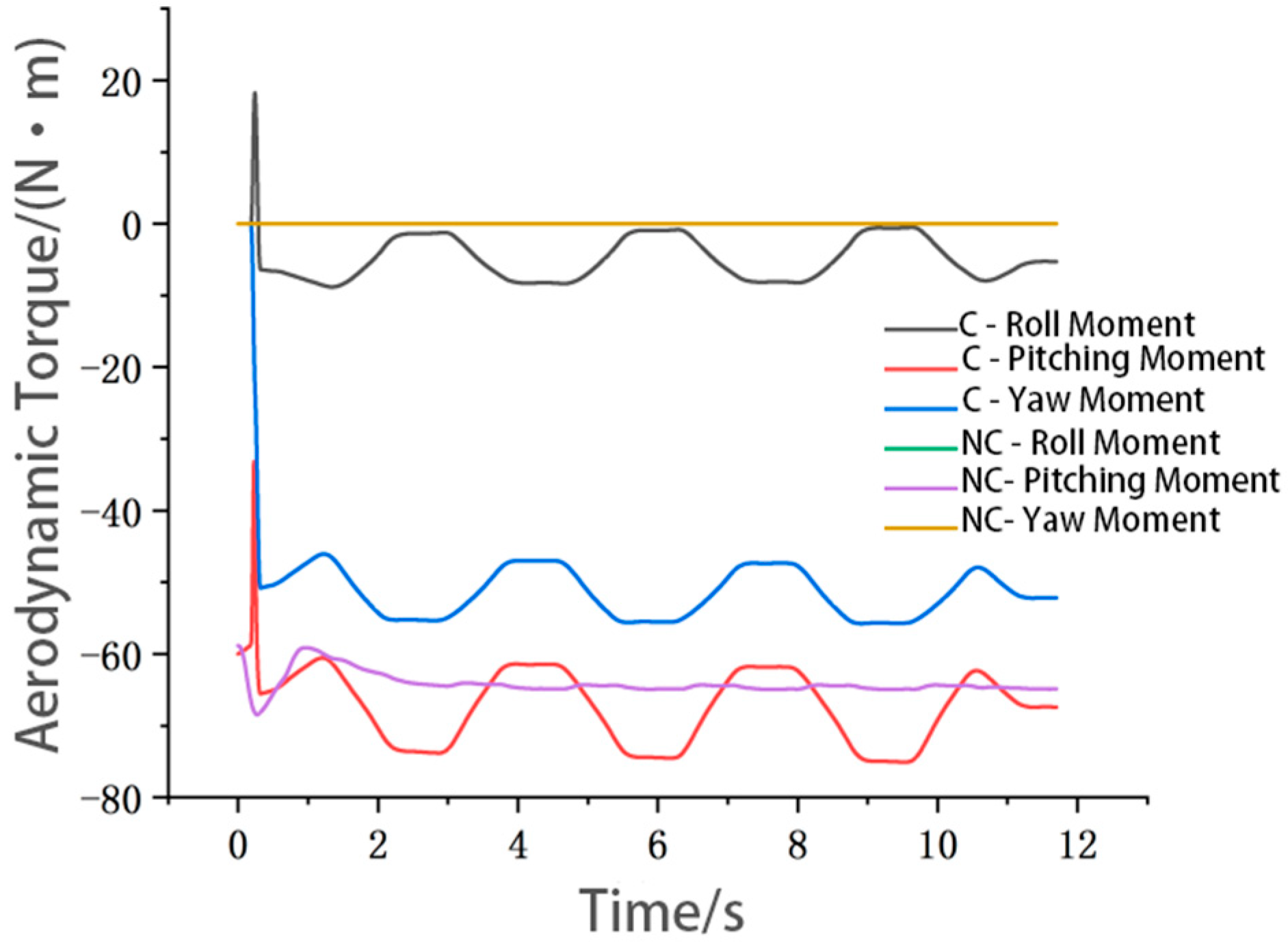

Figure 16.

Comparison curve and difference curve of lateral acceleration with and without crosswind effect.

Figure 16.

Comparison curve and difference curve of lateral acceleration with and without crosswind effect.

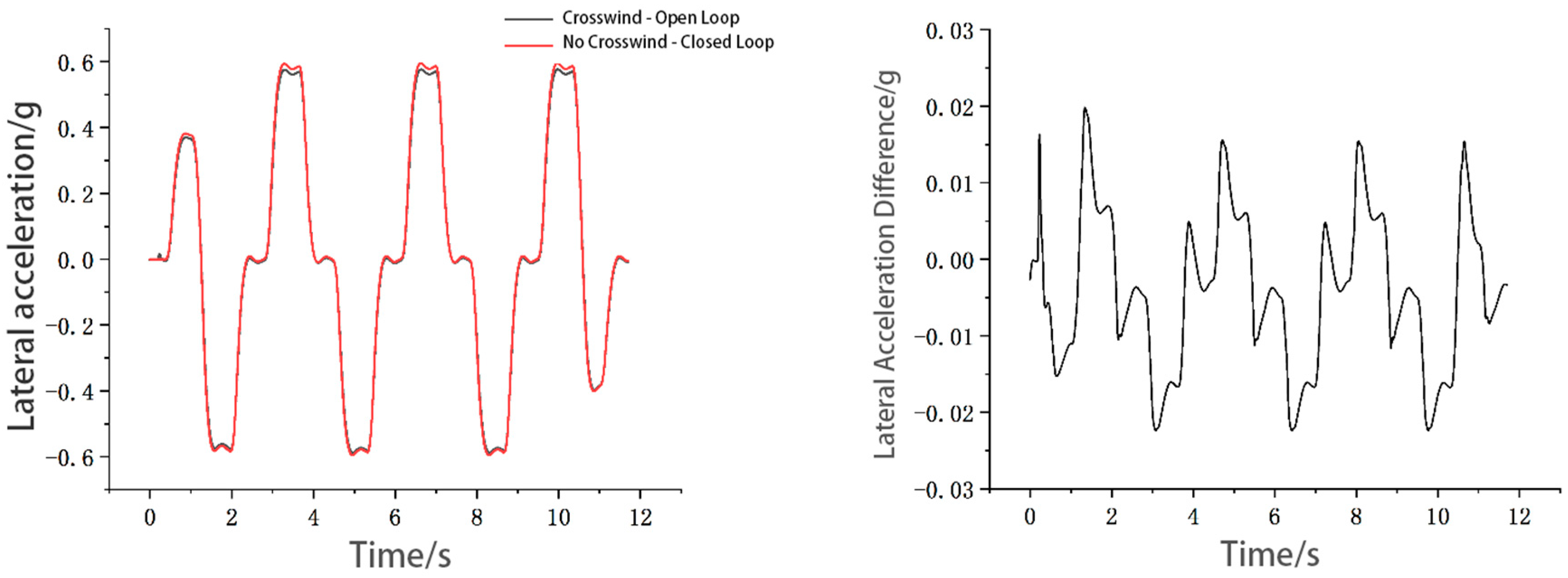

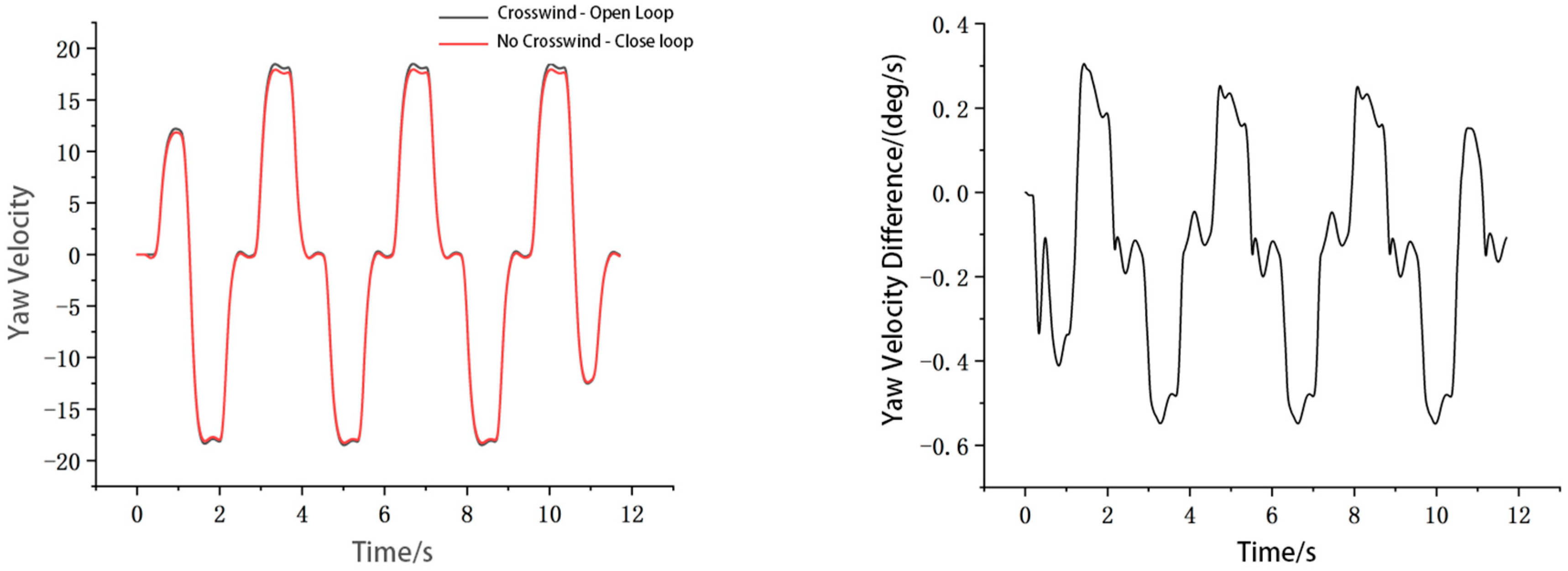

Figure 17.

Comparison curves and difference curves of roll angle velocity with and without crosswind effect.

Figure 17.

Comparison curves and difference curves of roll angle velocity with and without crosswind effect.

Figure 18.

Comparison curves and difference curves of crosswind offset velocity with and without crosswind action.

Figure 18.

Comparison curves and difference curves of crosswind offset velocity with and without crosswind action.

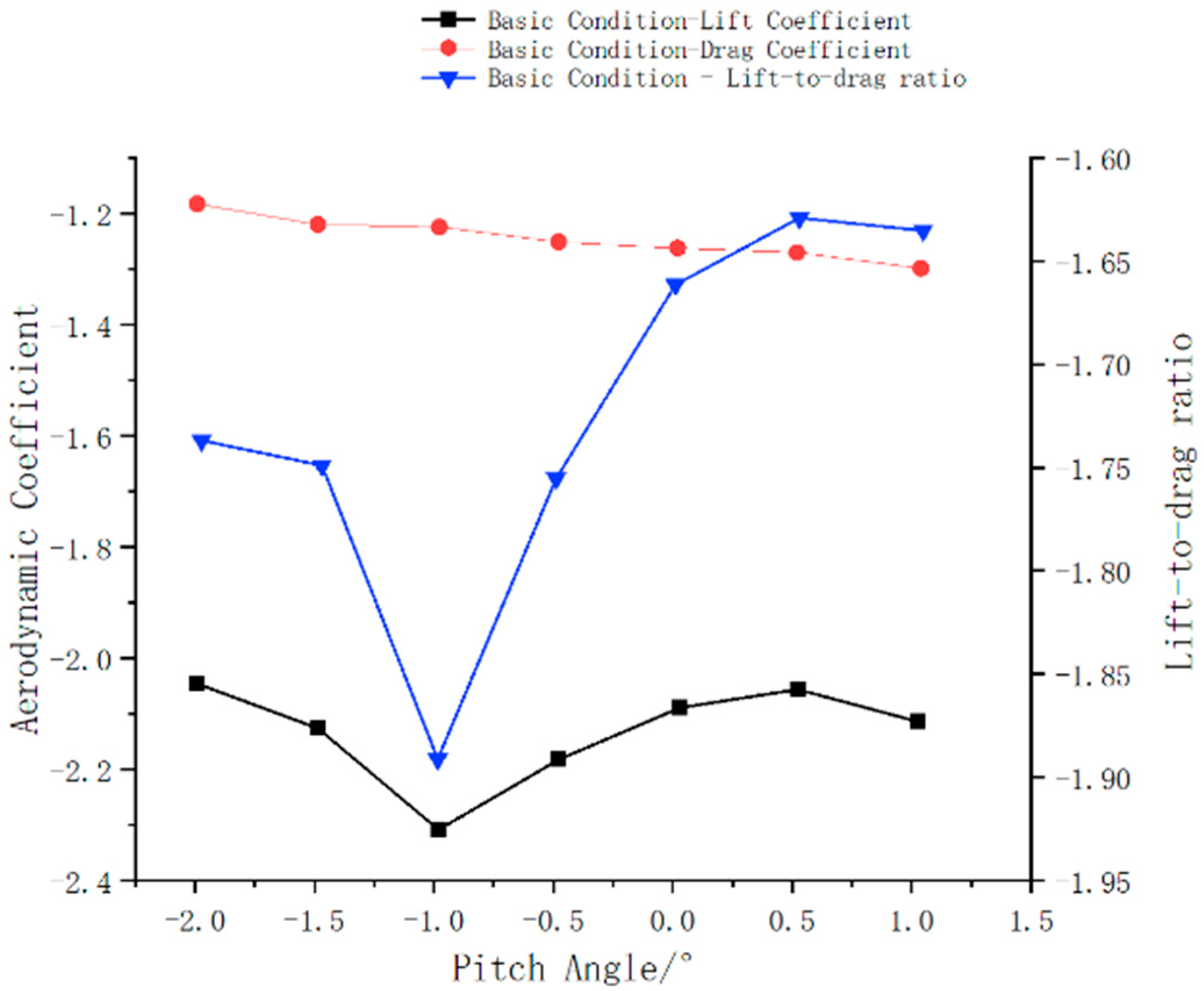

Figure 19.

Curves of lift coefficient, drag coefficient and lift–drag ratio.

Figure 19.

Curves of lift coefficient, drag coefficient and lift–drag ratio.

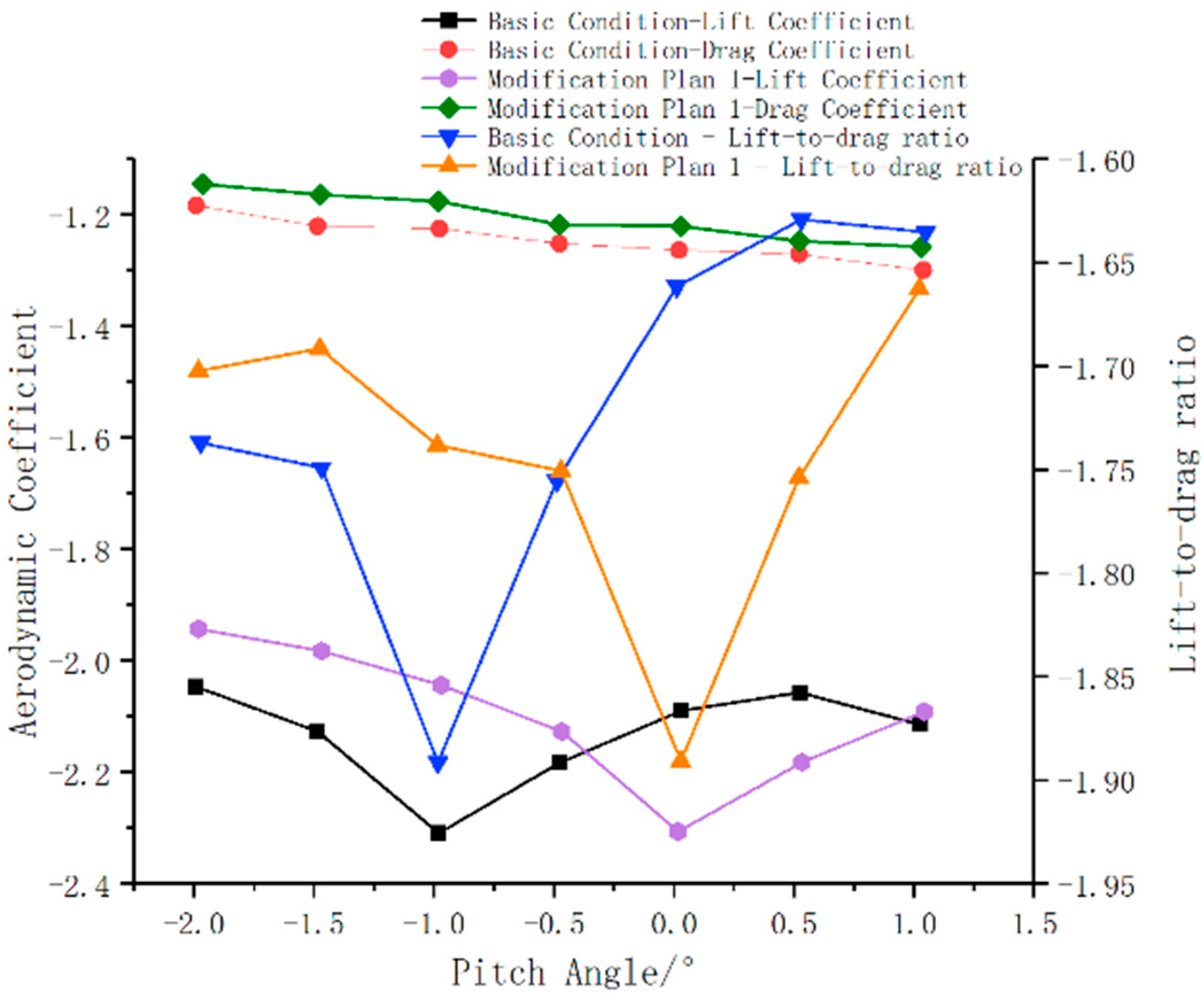

Figure 20.

Curves of lift coefficient, drag coefficient and lift-to-drag ratio after adjusting aerodynamic parameters in pitching condition.

Figure 20.

Curves of lift coefficient, drag coefficient and lift-to-drag ratio after adjusting aerodynamic parameters in pitching condition.

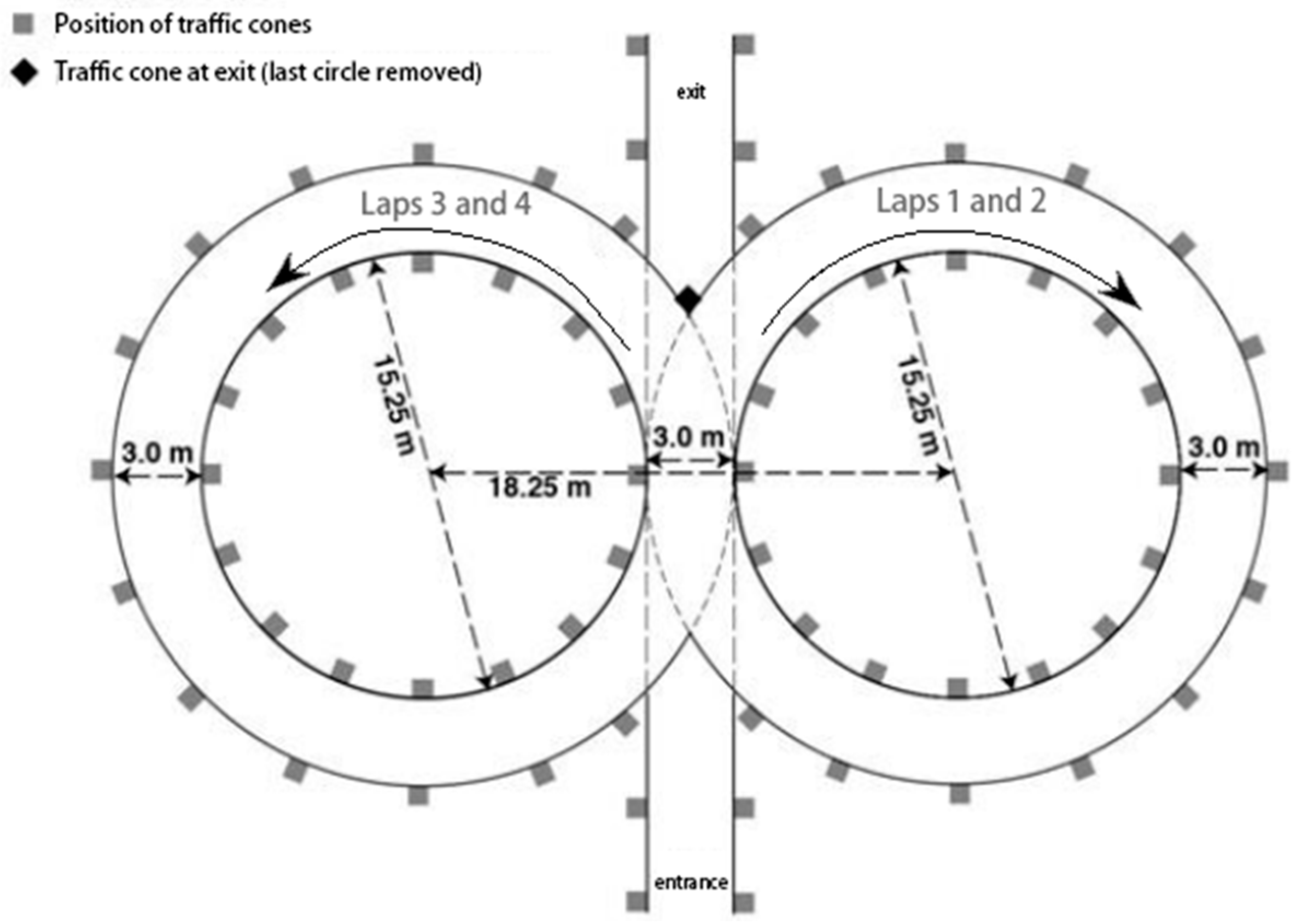

Figure 21.

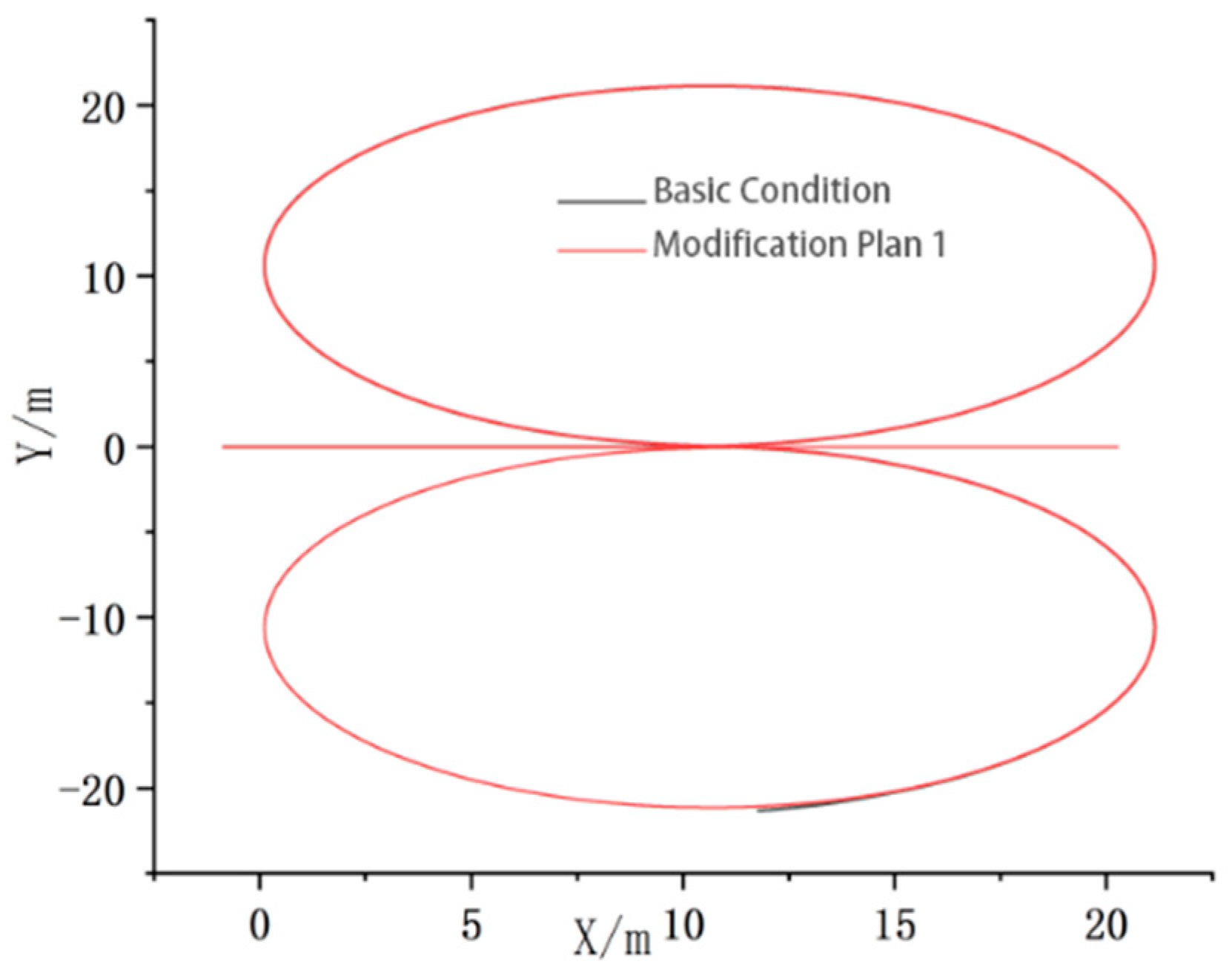

Figure-eight surround test layout.

Figure 21.

Figure-eight surround test layout.

Figure 22.

Comparison curve of simulation trajectory of figure-eight surround with aerodynamic parameters modification.

Figure 22.

Comparison curve of simulation trajectory of figure-eight surround with aerodynamic parameters modification.

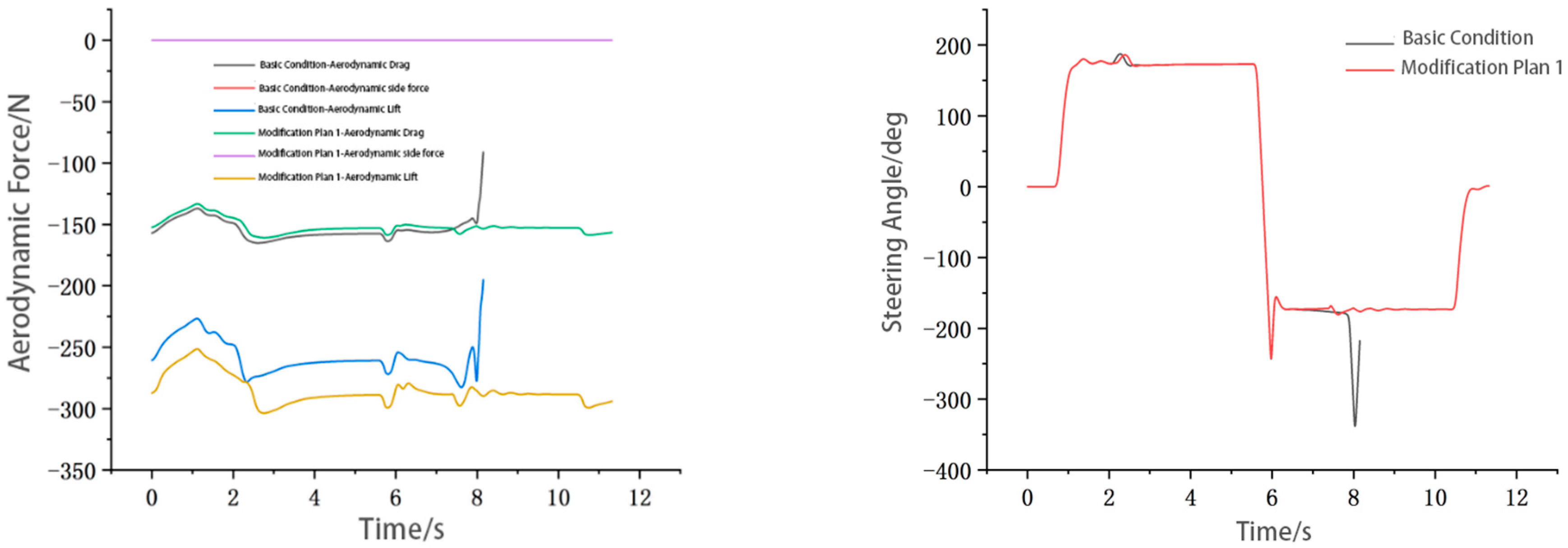

Figure 23.

Comparison curve of aerodynamic force and steering–wheel angle in figure-eight surround simulation.

Figure 23.

Comparison curve of aerodynamic force and steering–wheel angle in figure-eight surround simulation.

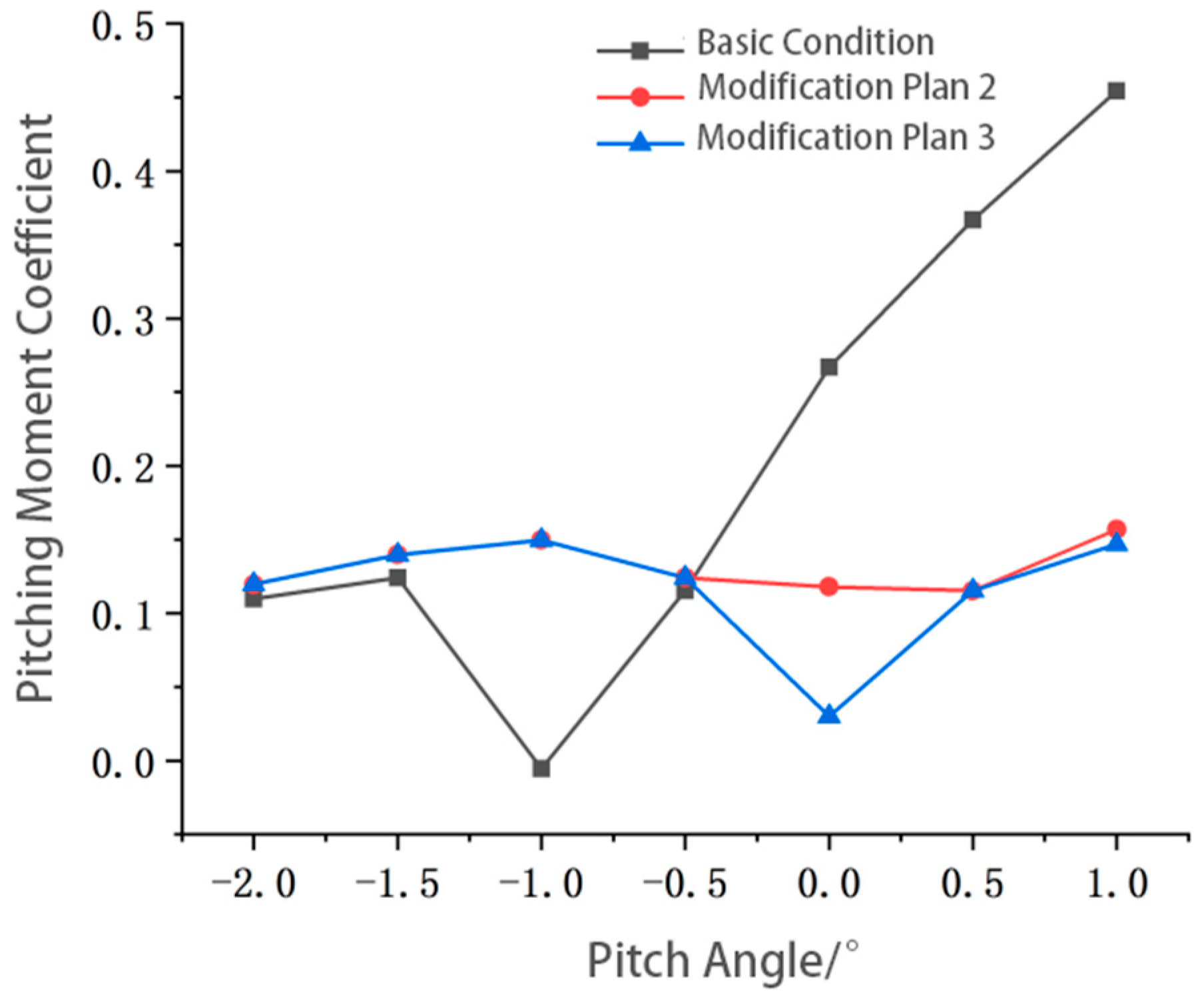

Figure 24.

Comparison curve of pitching moment coefficient modification.

Figure 24.

Comparison curve of pitching moment coefficient modification.

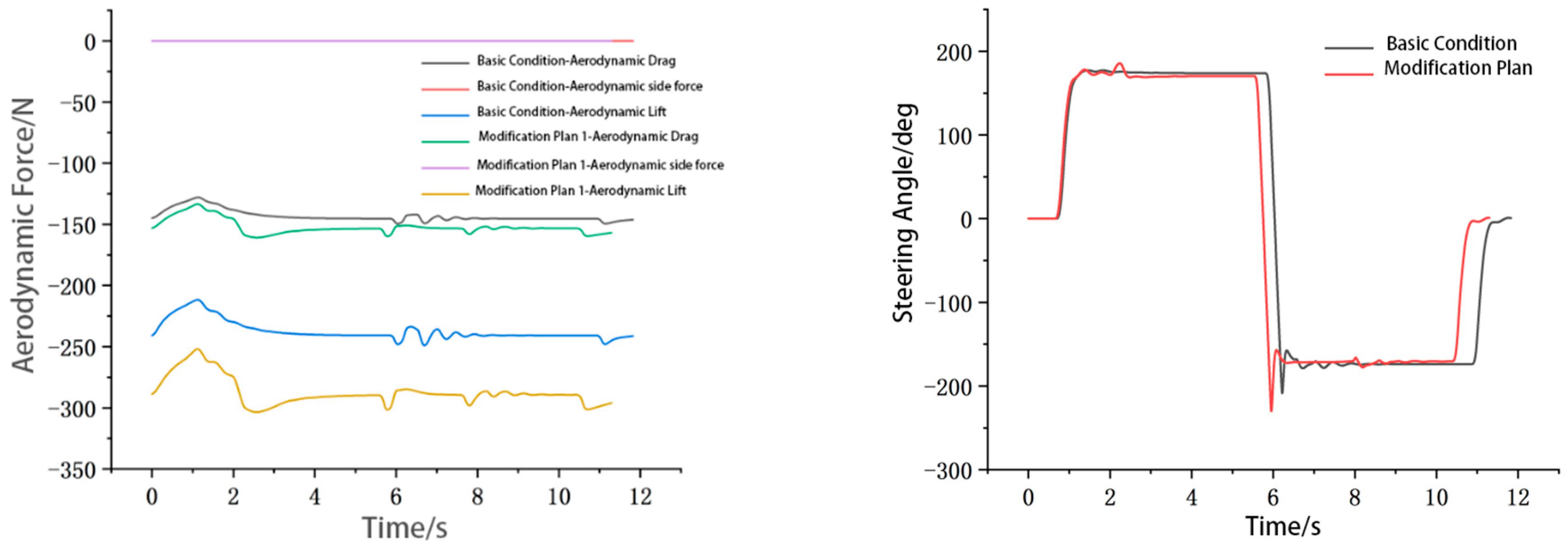

Figure 25.

Comparison curve of pitching moment and steering-wheel angle.

Figure 25.

Comparison curve of pitching moment and steering-wheel angle.

Figure 26.

Comparison curve of steering-wheel angle and difference of snaking test.

Figure 26.

Comparison curve of steering-wheel angle and difference of snaking test.

Figure 27.

Comparison curves of aerodynamic force and steering-wheel angle of figure-eight surround simulation with different aerodynamic parameters.

Figure 27.

Comparison curves of aerodynamic force and steering-wheel angle of figure-eight surround simulation with different aerodynamic parameters.

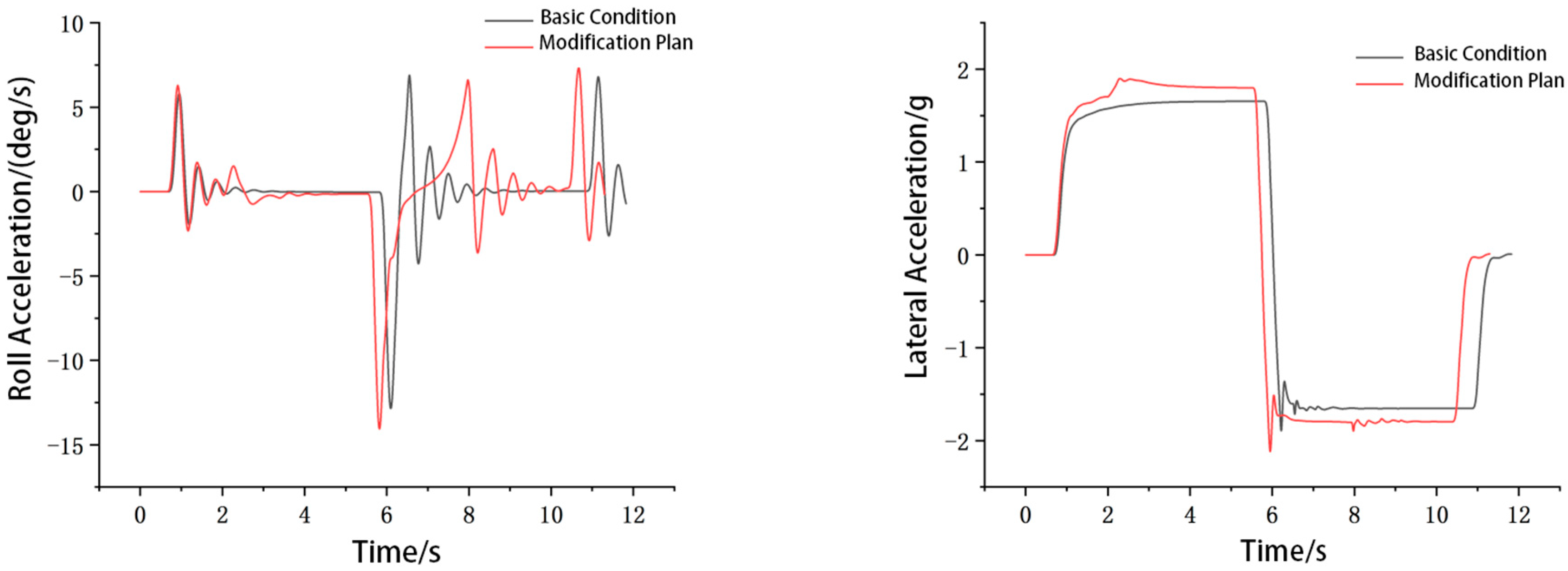

Figure 28.

Comparison curves of roll angle velocity and lateral acceleration of figure-eight surround simulation with different aerodynamic parameters.

Figure 28.

Comparison curves of roll angle velocity and lateral acceleration of figure-eight surround simulation with different aerodynamic parameters.

Table 1.

Final simulation strategy.

Table 1.

Final simulation strategy.

| Type | Related Parameter |

|---|

| Turbulence model | SST k-ω model |

| Boundary condition | Inlet velocity v = 15 m/s |

| Outlet pressure p = 0 Pa |

| Air density ρ = 1.18415 kg/m3 |

| Sliding surface |

| Ground slip |

| Type | Related Parameter |

| Boundary layer | Layer number 11 |

| Thickness 8 mm |

| Expansion ratio 1.2 |

| Grid base size | 0.512 m |

| Calculation domain | 11 length × 12 width × 5 height |

Table 2.

Comparison of lift coefficient and drag coefficient between numerical simulation and wind tunnel test.

Table 2.

Comparison of lift coefficient and drag coefficient between numerical simulation and wind tunnel test.

| | Numerical Simulation | Wind Tunnel Test | Relative Error |

|---|

| Lift coefficient | −2.089 | −1.968 | 6.14% |

| Drag coefficient | 1.254 | 1.195 | 4.94% |

Table 3.

Aerodynamic characteristics of FSAE racing car under the action of 10° crosswind angle.

Table 3.

Aerodynamic characteristics of FSAE racing car under the action of 10° crosswind angle.

| | Lift/N | Drag/N | Lateral Force/N |

|---|

| Wind-tunnel-test data | −280.389 | 182.319 | −87.743 |

| Yaw-model-method simulation | −292.389 | 194.784 | −85.709 |

Table 4.

Lift data and drag data of racing components in pitching conditions of −1.0°, 0° and 0.5°.

Table 4.

Lift data and drag data of racing components in pitching conditions of −1.0°, 0° and 0.5°.

| Component Name | Pitch −1.0° (Lift/N) | Pitch 0° (Lift/N) | Pitch 0.5° (Lift/N) | Pitch −1.0° (Drag/N) | Pitch 0° (Drag/N) | Pitch 0.5° (Drag/N) |

|---|

| Body | −110.806 | −97.763 | −95.096 | 76.603 | 81.689 | 81.517 |

| Front wheel | 10.198 | 10.660 | 13.797 | 9.023 | 10.651 | 12.136 |

| Front wing | −114.849 | −94.890 | −93.482 | 24.117 | 21.990 | 22.133 |

| Rear wheel | 10.527 | 12.746 | 10.834 | 11.428 | 12.068 | 10.953 |

| Tail | −148.934 | −145.772 | −140.723 | 66.254 | 64.890 | 65.166 |

| Total | −353.866 | −315.027 | −304.670 | 187.425 | 191.299 | 191.904 |

Table 5.

Variation conditions of crosswind angle of vehicle attitude stability.

Table 5.

Variation conditions of crosswind angle of vehicle attitude stability.

| Vehicle Attitude | Level of Stability |

|---|

| Crosswind angle/° | 0, ±10, ±20, ±90, ±160, 180 |

Table 6.

Data of downflow velocity, vehicle velocity and crosswind velocity at crosswind angle in crosswind simulation part.

Table 6.

Data of downflow velocity, vehicle velocity and crosswind velocity at crosswind angle in crosswind simulation part.

| Crosswind angle β | ±10° | ±0° | ±0° | ±160° | 180° |

| Wind velocity V (m/s) | 15 | 15 | 15 | 15 | 15 |

| Vehicle velocity VA (m/s) | 14.772 | 14.095 | 0 | −14.095 | −15 |

| Crosswind velocity VW (m/s) | ±2.605 | ±5.130 | 15 | ±5.130 | 0 |

Table 7.

Parameters of dynamic simulation model.

Table 7.

Parameters of dynamic simulation model.

| Component/System | Parameter Name | Unit | Numerical |

|---|

| Body assembly | Total weight | kg | 260.000 |

| Height of the center of mass | mm | 280.000 |

| Moment of inertia about the X axis | kg.m2 | 304.763 |

| Moment of inertia about the Y axis | kg.m2 | 109.800 |

| Moment of inertia about the Z axis | kg.m2 | 122.875 |

| Longitudinal position of center of mass from front axis | mm | 866.250 |

| Center of mass to the longitudinal plane in a transverse position | mm | 0 |

| Steering system | Kingpin inclination angle | ° | 7.000 |

| Kingpin rake angle | ° | 25.000 |

| Steering force ratio | | 1/3.800 |

| Suspension system | Front overhang | Unsprung mass | kg | 18 |

| Front-wheel camber | | −0.500 |

| Front-wheel beam Angle | | −0.700 |

| Stiffness of suspension spring | | 30.000 |

| Shock absorber damping | N/(mm/s) | 3.600 |

| Rear overhang | Unsprung mass | kg | 22.000 |

| Stiffness of suspension spring | N/mm | 45.000 |

| Shock absorber damping | N/(mm/s) | 2.400 |

| Tyre | Outer diameter | inch | 18.300 |

| Tread width | inch | 7.500 |

| Applicable rim width | inch | 7.000–8.000 |

| Weight | kg | 4.540 |

| Aerodynamics | Aerodynamics reference point XYZ | mm | (−866.250,0,46.100) |

| Orthographic area | A/m² | 1.145 |

| Wheelbase | L/mm | 1575.000 |

| Air density D | kg/m³ | 1.184 |

Table 8.

Performance indexes of snaking test at 65, 70 and 75 km/h without crosswind.

Table 8.

Performance indexes of snaking test at 65, 70 and 75 km/h without crosswind.

| Average Velocity/(km/h) | Transit Time/s | Average Peak Lateral Acceleration/(m.s−2) | Peak of Average Crosswind Angle Velocity/(deg.s−1) | Peak of Average Steering-Wheel Angle/deg. |

|---|

| 64.805 | 11.7 | 5.834 | 18.497 | 39.087 |

| 69.772 | 10.875 | 6.804 | 20.020 | 40.833 |

| 74.734 | 10.150 | 7.845 | 21.538 | 42.572 |

Table 9.

Performance index scores of 65, 70 and 75 km/h serpentine tests without crosswind.

Table 9.

Performance index scores of 65, 70 and 75 km/h serpentine tests without crosswind.

| Working Condition | | | |

|---|

| 65 km/h | 77.341 | 100 (106.971) | 84.894 |

| 70 km/h | 73.280 | 100 (106.389) | 82.187 |

| 75 km/h | 69.891 | 100 (105.809) | 79.927 |

Table 10.

Performance index score of snaking test with and without crosswind effect.

Table 10.

Performance index score of snaking test with and without crosswind effect.

| Working Condition | | | |

|---|

| No crosswind 65 km/h | 77.341 | 100 | 84.894 |

| Crosswind 65 km/h | 74.876 | 100 | 83.251 |

Table 11.

Comparison of performance parameters of figure-eight surround simulation before and after adjusting aerodynamic parameters under pitching condition.

Table 11.

Comparison of performance parameters of figure-eight surround simulation before and after adjusting aerodynamic parameters under pitching condition.

| | Aerodynamic Lift /N | Lateral Acceleration/g | Simulation Time/s |

|---|

| Base car | −249.782 | 1.654 | 11.825 |

| Modification plan | −303.475 | 1.904 | 11.3 |

| Parameter difference | −53.693 | 0.25 | −0.525 |

| Differential ratio | 21.50% | 15.11% | −4.40% |