Thermal Management of Bone Drilling Based on Rotating Heat Pipe

Abstract

:1. Introduction

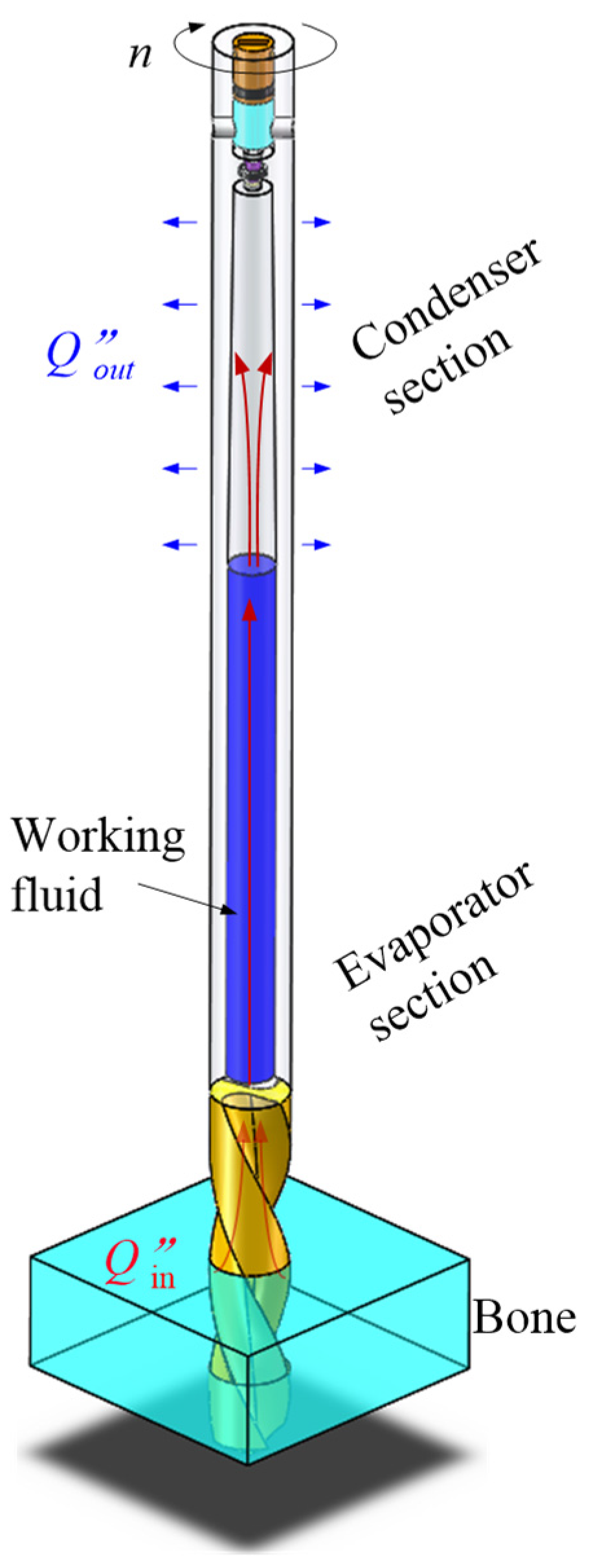

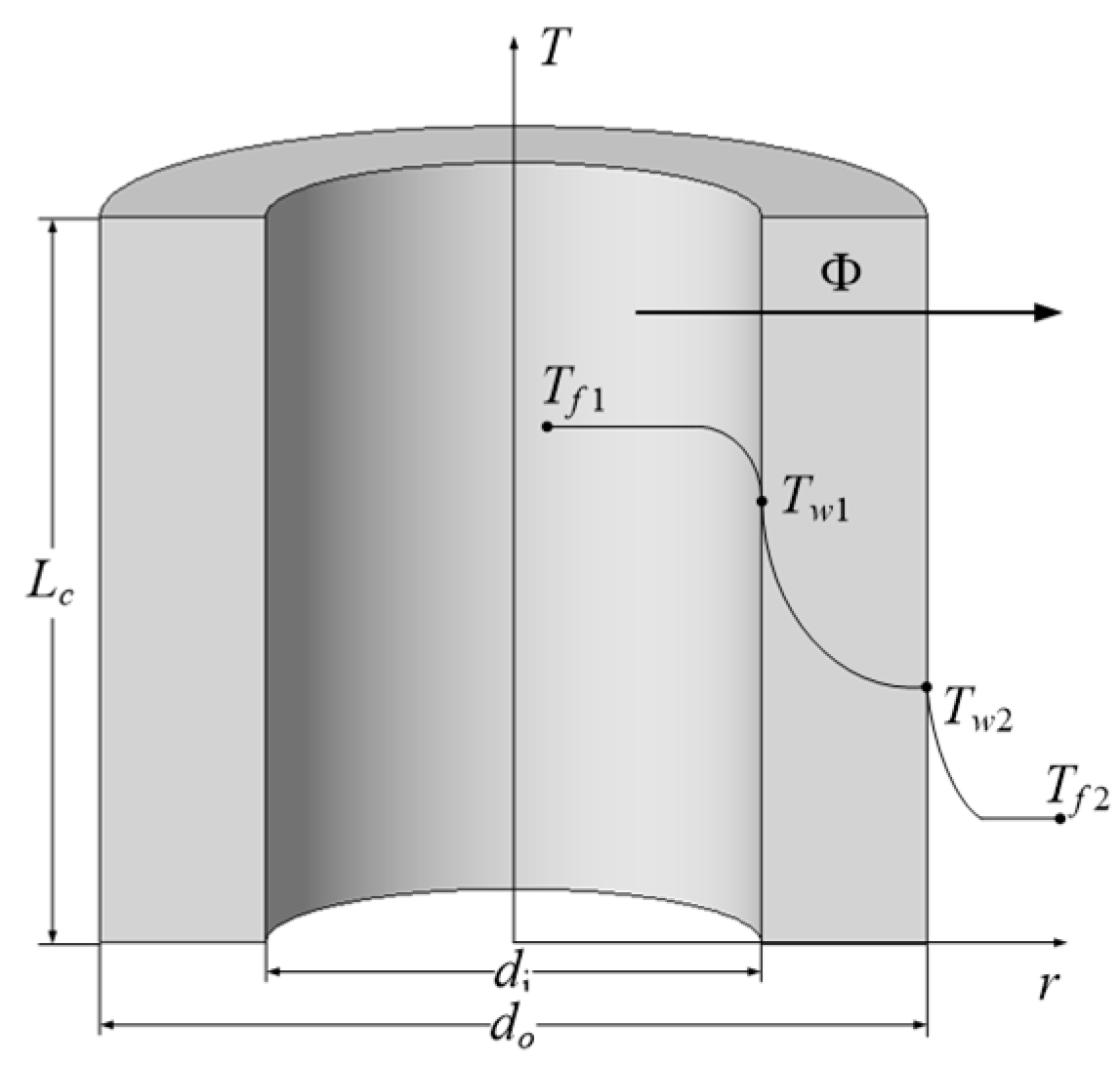

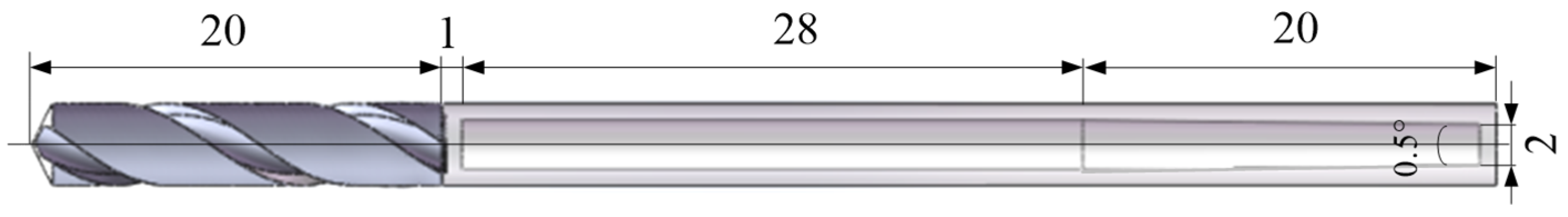

2. Design of Rotating Heat Pipe Drill

2.1. Heat Transfer Principle of Rotating Heat Pipe Drill

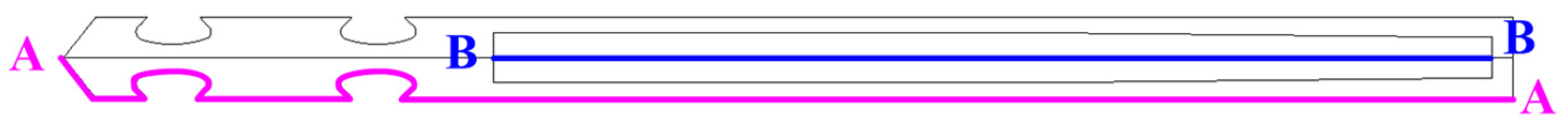

2.2. Design of Rotating Heat Pipe Drill

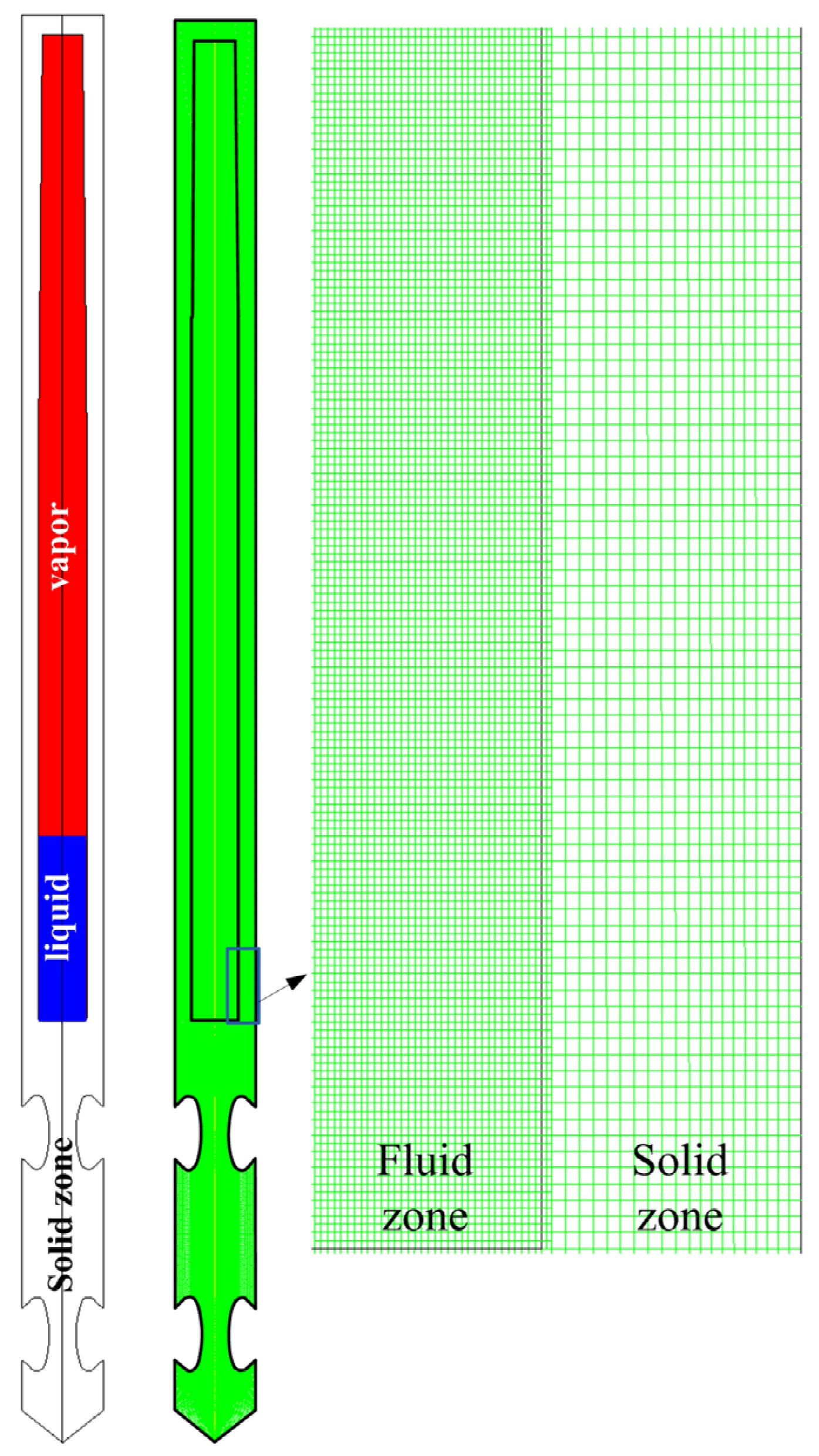

3. Simulation Details

3.1. Solution Methods

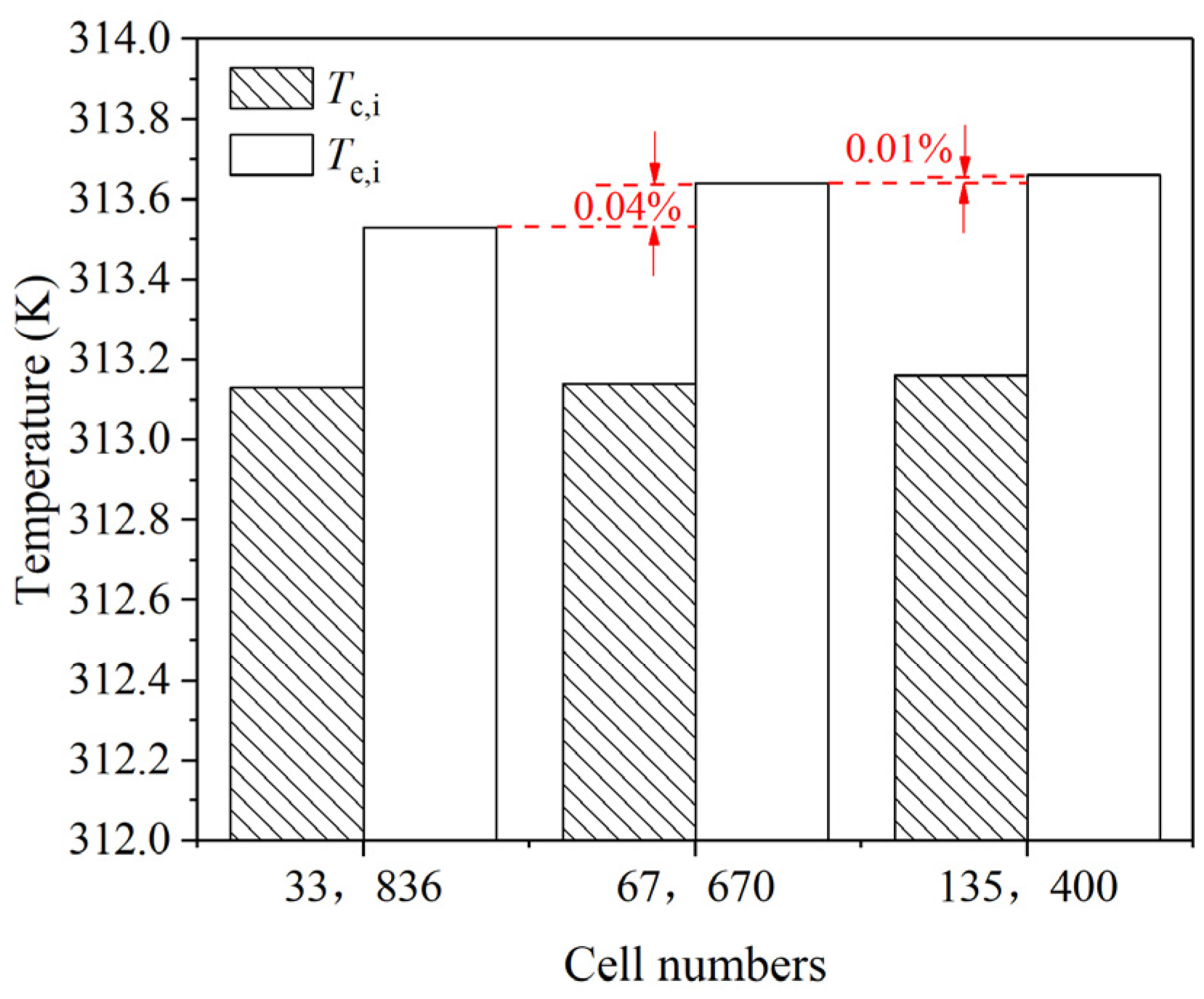

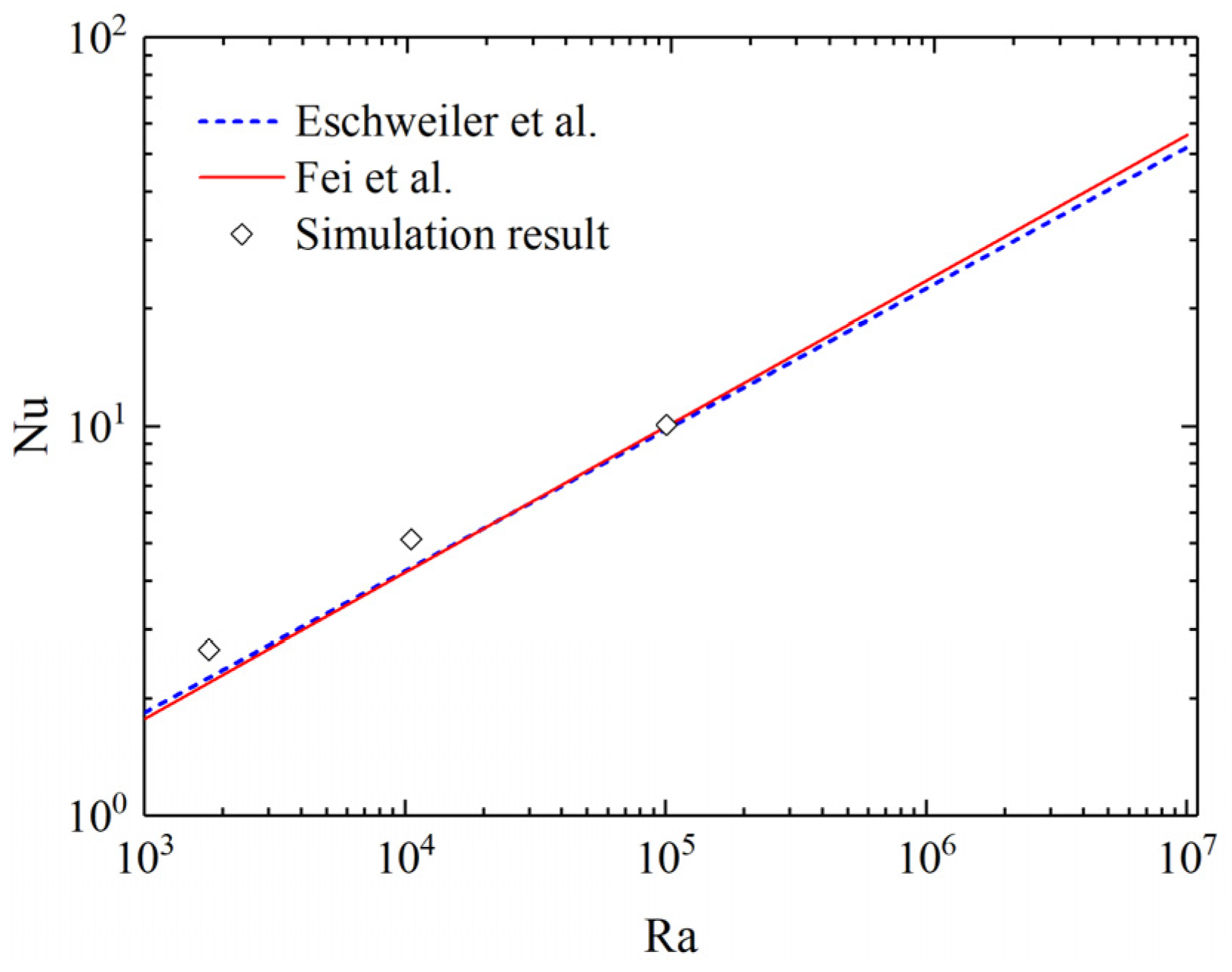

3.2. Simulation Model for RHPD

4. Results and Discussion

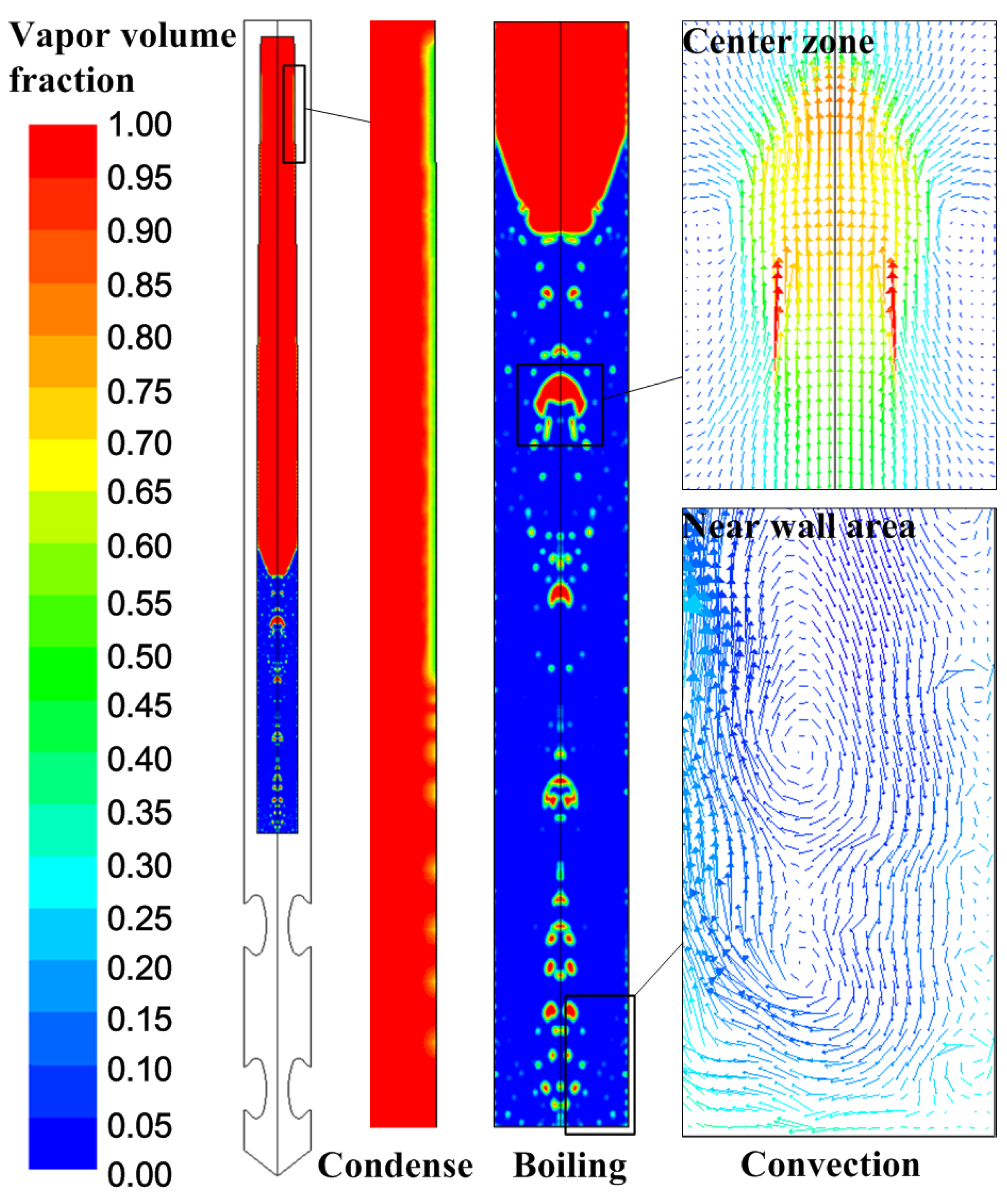

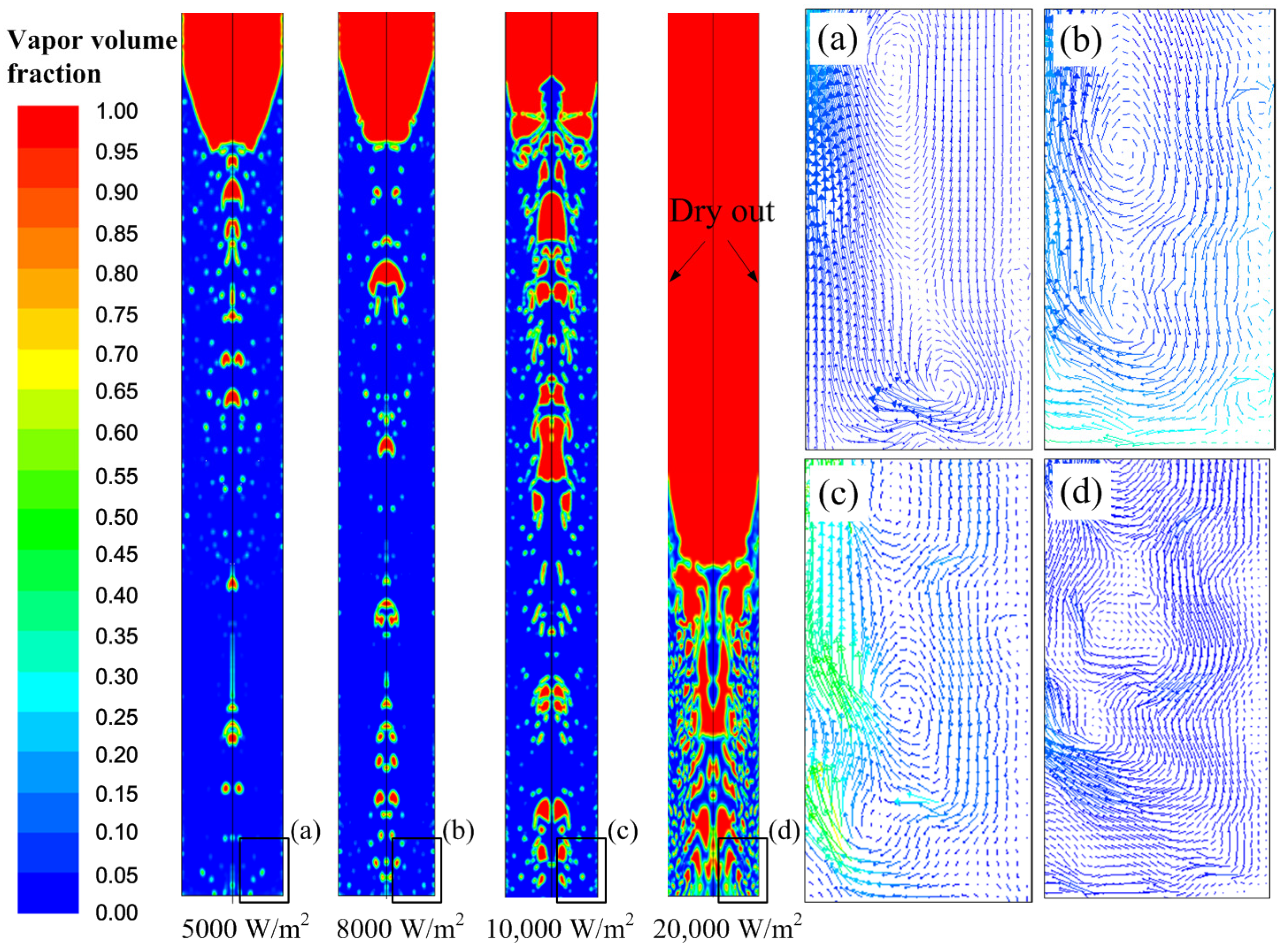

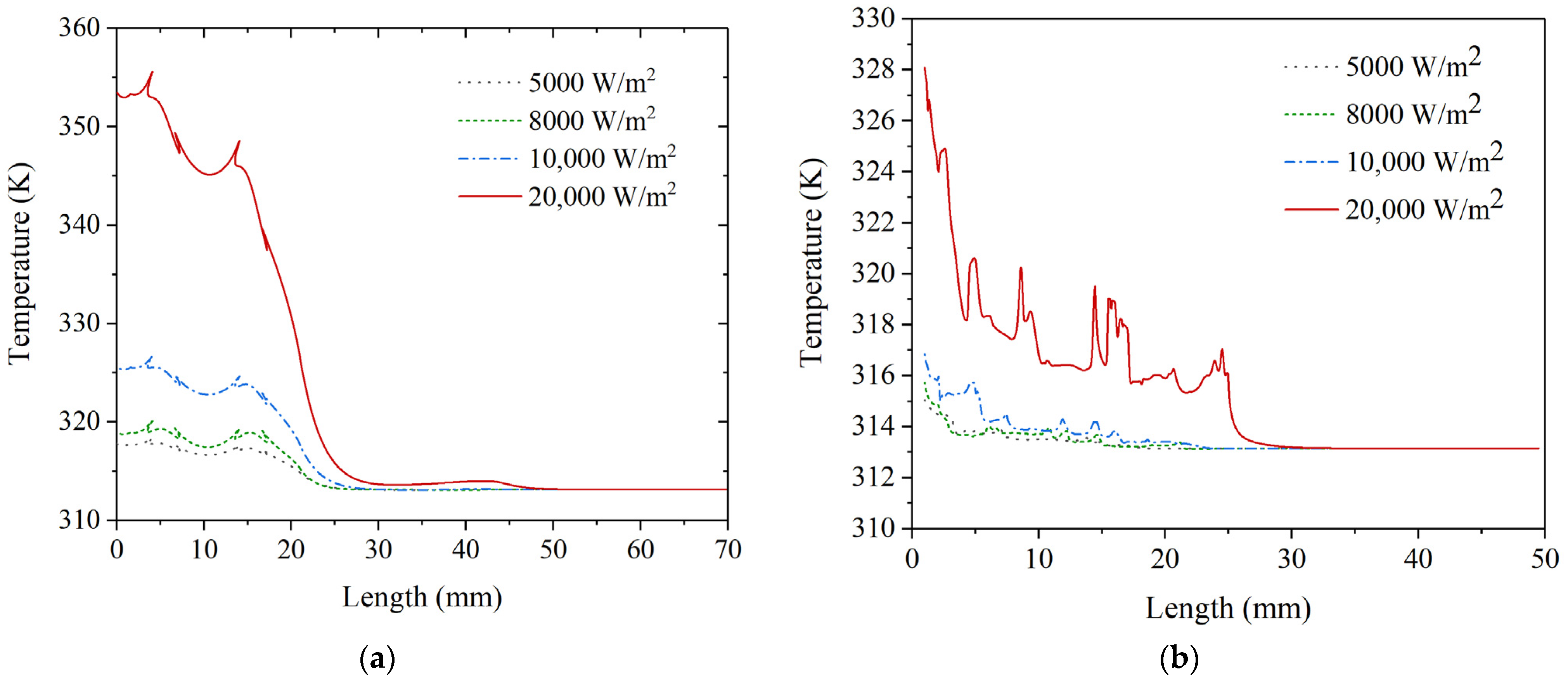

4.1. Heat Transfer Process in the RHPD

4.2. Heat Trasnfer Capacity of the RHPD

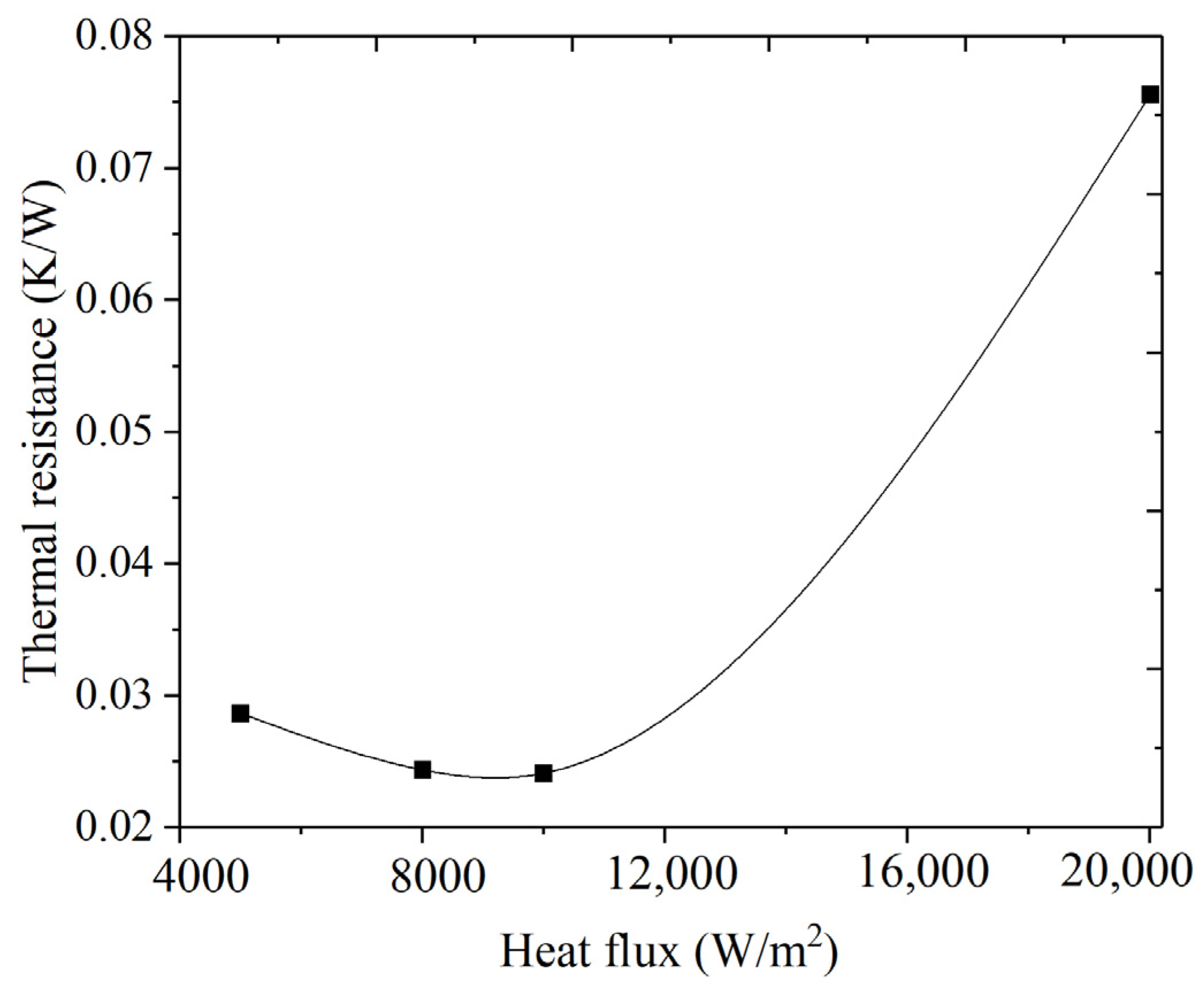

4.2.1. Effect of Input Heat Flux

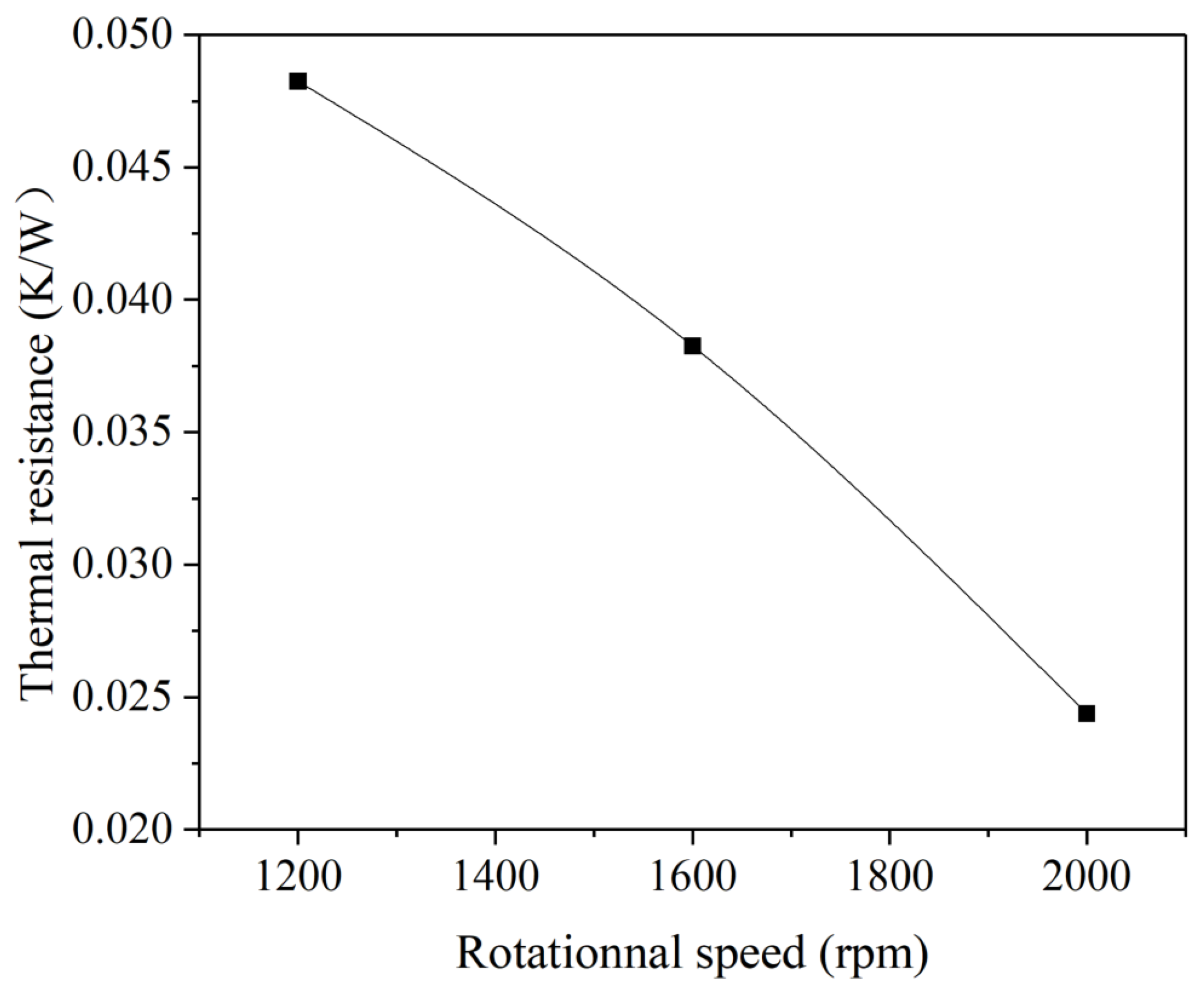

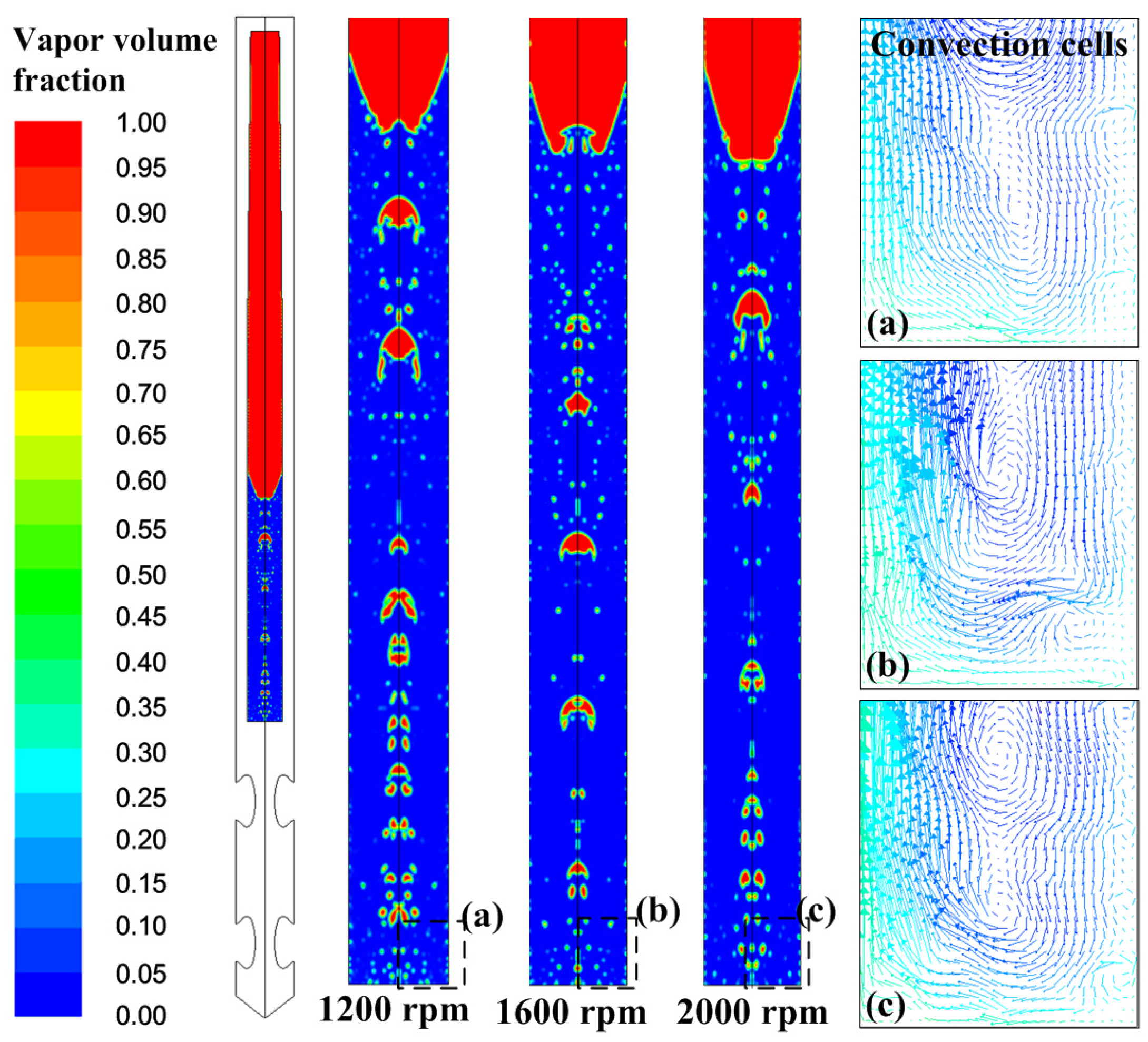

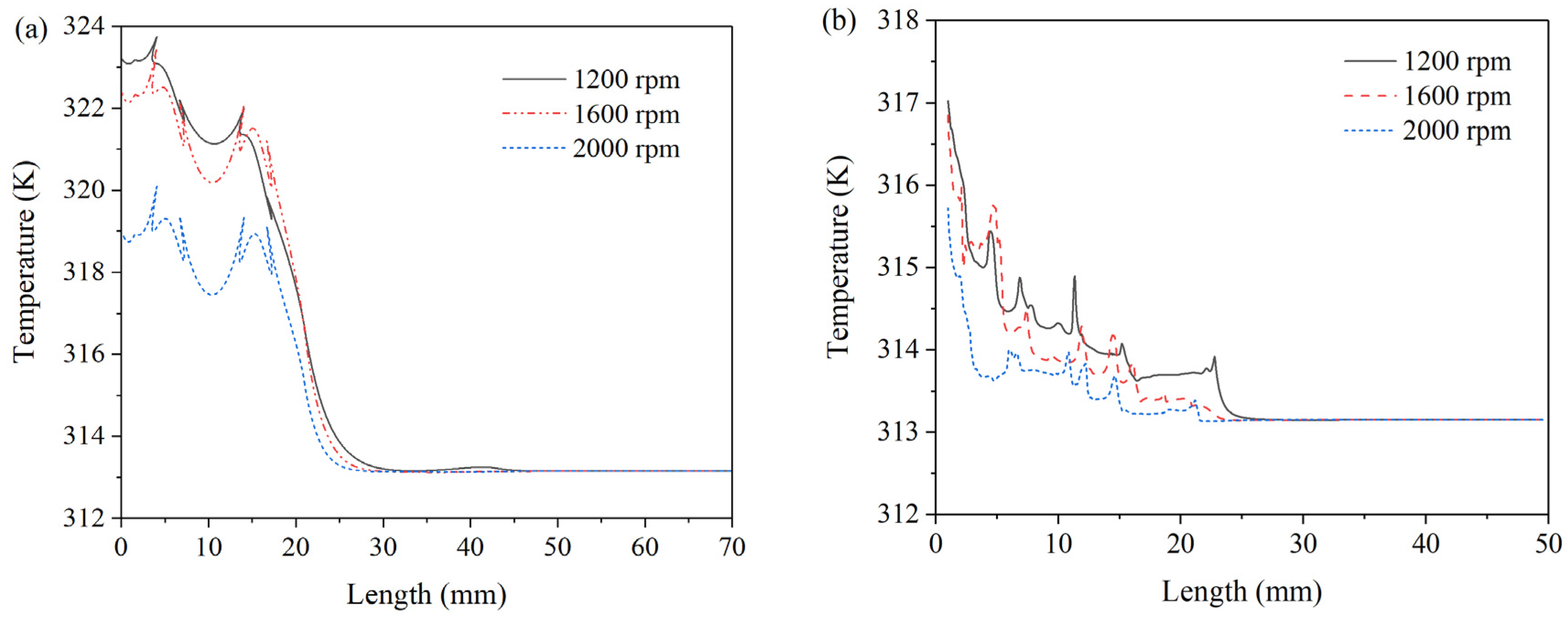

4.2.2. Effect of Rotational Speed

5. Conclusions

- (1)

- Boiling and convection heat transfer was found to be the main heat transfer mechanism in the evaporator. Film condensation turned out to be the heat transfer regime in the condenser.

- (2)

- An ideal bone drilling temperature of 46.9 °C and a thermal resistance of 0.0244 K/W was found with an input flux of 8000 W/m2 and a rotational speed of 2000 rpm.

- (3)

- The thermal resistance decreased with the increase of the rotational speed at the range from 1200 to 2000 rpm because of more intense convection heat transfer.

- (4)

- The thermal resistance decreased as the input heat flux rose from 5000 to 10,000 W/m2 due to more intense boiling and convection heat transfer, while it increased at 20,000 W/m2 because of the appearance of dry-out of the working fluid.

- (5)

- The phase change heat transfer in the rotating heat pipe turned out to be much faster and better than the heat conduction in the solid drill matrix. RHPD is of great prospect to realize the thermal management in bone drilling.

6. Patents

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| A | area of the rotating heat pipe, mm2 |

| C | constant of vapor |

| d | diameter, mm |

| e | internal energy, J |

| h | heat transfer coefficient, W/(m2∙K) |

| k | specific heat ratio |

| L | length, mm |

| LH | latent heat of working fluid, KJ/kg |

| n | rotational speed, rpm |

| P | local pressure, Pa |

| Q | heat power, W |

| q” | heat flux, W/m2 |

| R | thermal resistance, K/W |

| r | radius, mm |

| S | source term |

| T | temperature, °C |

| ΔT | temperature difference |

| u | vapor velocity, m/s |

| Greek | |

| ρ | density, kg/m3 |

| α | volume fraction of liquid phase |

| σ | allowable stress, N/m2 |

| δ | wall thickness, mm |

| θ | condenser taper angle, ° |

| λ | thermal conductivity, W/m−1·K−1 |

| μ | kinematic viscosity, Pa·s |

| ω | angular speed, rad/s |

| Փ | heat power transferred through the cylinder, W |

| Subscripts | |

| in | input |

| c | condenser |

| ci | inside the condenser |

| ei | inside the evaporator |

| EC | heat transfer of condensation |

| EE | heat transfer of evaporation |

| f1 | fluid in the cylinder |

| f2 | fluid out of the cylinder |

| fg | phase change from liquid to vapor |

| L | liquid phase |

| LV | phase change from liquid to vapor |

| m | momentum |

| mix | mixture of liquid and vapor |

| max | maximum |

| min | minimum |

| ML | mass transfer of liquid |

| MV | mass transfer of vapor |

| o | outer of the rotating heat pipe |

| out | output |

| sat | saturate |

| I | inside the rotating heat pipe |

| w1 | inner wall of the cylinder |

| w2 | outer wall of the cylinder |

| V | vapor phase |

References

- Akhbar, M.F.A.; Yusoff, A.R. Fast & Injurious: Reducing thermal osteonecrosis regions in the drilling of human bone with multi-objective optimization. Measurement 2019, 152, 107385. [Google Scholar] [CrossRef]

- Augustin, G.; Davila, S.; Udilljak, T.; Staroveski, T.; Brezak, D.; Babic, S. Temperature changes during cortical bone drilling with a newly designed step drill and an internally cooled drill. Int. Orthop. 2012, 36, 1449–1456. [Google Scholar] [CrossRef] [Green Version]

- Feldmann, A.; Wandel, J.; Zysset, P. Reducing temperature elevation of robotic bone drilling. Med. Eng. Phys. 2016, 38, 1495–1504. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Szalma, J.; Lovasz, B.V.; Vajta, L.; Soos, B.; Lempel, E.; Mohlhenrich, S.C. The influence of the chosen in vitro bone simu-lation model on intraosseous temperatures and drilling times. Sci. Rep. 2019, 9, 11817. [Google Scholar] [CrossRef] [PubMed]

- Biyikli, S.; Modest, M.F.; Tarr, R. Measurements of thermal properties for human femora. J. Biomed. Mater. Res. 1986, 20, 1335–1345. [Google Scholar] [CrossRef] [PubMed]

- Davidson, S.R.; James, D.F. Measurement of thermal conductivity of bovine cortical bone. Med. Eng. Phys. 2000, 22, 741–747. [Google Scholar] [CrossRef]

- Feldmann, A.; Wili, P.; Maquer, G.; Zysset, P. The thermal conductivity of cortical and cancellous bone. eCM 2018, 35, 25–33. [Google Scholar] [CrossRef]

- Akhbar, M.F.A.; Sulong, A.W. Surgical Drill Bit Design and Thermomechanical Damage in Bone Drilling: A Review. Ann. Biomed. Eng. 2020, 49, 29–56. [Google Scholar] [CrossRef] [PubMed]

- Allan, W.; Williams, E.D.; Kerawala, C.J. Effects of repeated drill use on temperature of bone during preparation for osteo-synthesis self-tapping screws. Br. J. Oral Maxillofac. Surg. 2005, 43, 314–319. [Google Scholar] [CrossRef]

- Soriano, J.; Garay, A.; Iriarte, L.M.; Eguren, J.A.; Aristimuño, P.; Arrazola, P.J. Influence of Cutting Conditions on Temperature Rise, Feed Force and Cutting Torque when Drilling Bone. Adv. Mater. Res. 2012, 498, 145–150. [Google Scholar] [CrossRef]

- Bachus, K.N.; Rondina, M.; Hutchinson, D.T. The effects of drilling force on cortical temperatures and their duration: An in vitro study. Med. Eng. Phys. 2000, 22, 685–691. [Google Scholar] [CrossRef]

- Shakouri, E.; Nezhad, M.G.; Ghorbani, P.; Khosravi-Nejad, F. Investigation of thermal aspects of high-speed drilling of bone by theoretical and experimental approaches. Phys. Eng. Sci. Med. 2020, 43, 959–972. [Google Scholar] [CrossRef] [PubMed]

- Crowninshield, R.D.; Pope, M.H. The response of compact bone in tension at various strain rates. Ann. Biomed. Eng. 1974, 2, 217–225. [Google Scholar] [CrossRef]

- Bogovič, V.; Svete, A.; Rupnik, K.; Bajsić, I. Experimental analysis of the temperature rise during the simulation of an implant drilling process using experimental designs. Measurement 2015, 63, 221–231. [Google Scholar] [CrossRef]

- Augustin, G.; Davila, S.; Mihoci, K.; Udiljak, T.; Vedrina, D.S.; Antabak, A. Thermal osteonecrosis and bone drilling parameters revisited. Arch. Orthop. Trauma Surg. 2007, 128, 71–77. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bogovič, V.; Svete, A.; Bajsić, I. Effects of a drill diameter on the temperature rise in a bone during implant site preparation under clinical conditions. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2016, 230, 907–917. [Google Scholar] [CrossRef] [PubMed]

- Alam, K.; Hassan, E.; Bahadur, I. Experimental measurements of temperatures in ultrasonically assisted drilling of cortical bone. Biotechnol. Biotechnol. Equip. 2015, 29, 753–757. [Google Scholar] [CrossRef]

- Sun, Z.; Wang, Y.; Xu, K.; Zhou, G.; Liang, C.; Qu, J. Experimental investigations of drilling temperature of high-energy ultrasonically assisted bone drilling. Med. Eng. Phys. 2019, 65, 1–7. [Google Scholar] [CrossRef]

- Gok, K.; Buluc, L.; Muezzinoglu, U.S.; Kisioglu, Y. Development of a new driller system to prevent the osteonecrosis in orthopedic surgery applications. J. Braz. Soc. Mech. Sci. Eng. 2014, 37, 549–558. [Google Scholar] [CrossRef]

- Gok, K.; Gok, A.; Kisioglu, Y. Optimization of processing parameters of a developed new driller system for orthopedic surgery applications using Taguchi method. Int. J. Adv. Manuf. Technol. 2014, 76, 1437–1448. [Google Scholar] [CrossRef]

- Shakouri, E.; Hassanalideh, H.H.; Gholampour, S. Experimental investigation of temperature rise in bone drilling with cooling: A comparison between modes of without cooling, internal gas cooling, and external liquid cooling. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2017, 232, 45–53. [Google Scholar] [CrossRef] [Green Version]

- Maani, N.; Farhang, K.; Hodaei, M. A Model for the Prediction of Thermal Response of Bone in Surgical Drilling. J. Therm. Sci. Eng. Appl. 2014, 6, 041005. [Google Scholar] [CrossRef]

- Tu, Y.K.; Hong, Y.Y.; Chen, Y.C. Finite element modeling of kirschner pin and bone thermal contact during drilling. Life Sci. J. 2009, 6, 23–27. [Google Scholar]

- Lee, J.; Rabin, Y.; Ozdoganlar, B. A new thermal model for bone drilling with applications to orthopaedic surgery. Med. Eng. Phys. 2011, 33, 1234–1244. [Google Scholar] [CrossRef] [PubMed]

- Legierski, J.; Wiecek, B. Steady state analysis of cooling electronic circuits using heat pipes. IEEE Trans. Components Packag. Technol. 2001, 24, 549–553. [Google Scholar] [CrossRef]

- Cao, Y.; Reding, B.; Gao, M. ROTATING MINIATURE AND SECTOR HEAT PIPES FOR COOLING GAS TURBINE ROTOR BLADES AND DISKS. Heat Transf. Res. 2013, 44, 101–114. [Google Scholar] [CrossRef]

- Chen, J.; Fu, Y.; Qian, N.; Ching, C.Y.; Ewing, D.; He, Q. A study on thermal performance of revolving heat pipe grinding wheel. Appl. Therm. Eng. 2020, 182, 116065. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, H.; Fu, Y.; Qian, N. Heat Transfer Performance of an Axially Rotating Heat Pipe for Cooling of Grinding. Energies 2020, 13, 5745. [Google Scholar] [CrossRef]

- Zhuang, J.; Zhang, H. Heat Pipe Technology and Its Engineering Application; Chemical Industry Press: Beijing, China, 2000; pp. 31–66. [Google Scholar]

- Jen, T.C.; Jadhav, R. Thermal management of a heat-pipe drill: A new simulation model for heat pipe. In Proceedings of the of the ASME Summer Heat Transfer Conference, San Francisco, CA, USA, 17–22 July 2005; Volume 3, pp. 355–360. [Google Scholar]

- Trent, E.; Wright, P. Metal Cutting; Butterworth/Heinemann: Oxford, UK, 2000. [Google Scholar]

- Yang, S.M.; Tao, W.X. Heat Transfer, 4th ed.; Higher Education Press: Beijing, China, 2006. [Google Scholar]

- Ma, Z.; Zhang, J.; Sun, D. New experimental method for inundation effect of film condensation on horizontal tube bundle. Sci. China Ser. E Technol. Sci. 2012, 55, 2856–2863. [Google Scholar] [CrossRef]

- Fadhl, B.; Wrobel, L.C.; Jouhara, H. Numerical modeling of the temperature distribution in a two-phase closed ther-mosyphon. Appl. Therm. Eng. 2013, 60, 122–131. [Google Scholar] [CrossRef] [Green Version]

- De Schepper, S.C.; Heynderickx, G.J.; Marin, G.B. Modeling the evaporation of a hydrocarbon feedstock in the convection section of a steam cracker. Comput. Chem. Eng. 2009, 33, 122–132. [Google Scholar] [CrossRef]

- Brackbill, J.U.; Kothe, D.B.; Zemach, C. A continuum method for modeling surface tension. J. Comput. Phys. 1992, 100, 335–354. [Google Scholar] [CrossRef]

- Song, F. Investigation on the fluid and heat transport characteristics of moderate and high-speed rotating heat pipe. Ph.D. Thesis, Mcmaster University, Burlington, ON, Canada, 2005. [Google Scholar]

- Eschweiler, J.C.; Benton, A.M.; Prechshot, G.W. Boiling and convective heat transfer at high accelerations. Chem. Eng. Prog. Symp. Ser. 1967, 63, 66–72. [Google Scholar]

- Xie, M.; Xue, Z.; Qu, W.; Li, W. Experimental Investigation of Heat Transfer Performance of Rotating Heat Pipe. Procedia Eng. 2015, 99, 746–751. [Google Scholar] [CrossRef] [Green Version]

- Wang, C. Condensation film on an inclined rotating disk. Appl. Math. Model. 2007, 31, 1582–1593. [Google Scholar] [CrossRef]

- Song, F.; Ewing, D.; Ching, C. Experimental investigation on the heat transfer characteristics of axial rotating heat pipes. Int. J. Heat Mass Transf. 2004, 47, 4721–4731. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Yuan, D.; Jiang, H.; Zhang, L.; Yang, Y.; Fu, Y.; Qian, N.; Jiang, F. Thermal Management of Bone Drilling Based on Rotating Heat Pipe. Energies 2022, 15, 35. https://doi.org/10.3390/en15010035

Chen J, Yuan D, Jiang H, Zhang L, Yang Y, Fu Y, Qian N, Jiang F. Thermal Management of Bone Drilling Based on Rotating Heat Pipe. Energies. 2022; 15(1):35. https://doi.org/10.3390/en15010035

Chicago/Turabian StyleChen, Jiajia, Dongdong Yuan, Huafei Jiang, Liyong Zhang, Yong Yang, Yucan Fu, Ning Qian, and Fan Jiang. 2022. "Thermal Management of Bone Drilling Based on Rotating Heat Pipe" Energies 15, no. 1: 35. https://doi.org/10.3390/en15010035

APA StyleChen, J., Yuan, D., Jiang, H., Zhang, L., Yang, Y., Fu, Y., Qian, N., & Jiang, F. (2022). Thermal Management of Bone Drilling Based on Rotating Heat Pipe. Energies, 15(1), 35. https://doi.org/10.3390/en15010035