1. Introduction

Engine misfire is a phenomenon of no-burning in cylinder which may be caused by insufficient fuel injection, bad fuel quality, insufficient ignition energy, or mechanical failure, etc. Since misfire fault will cause abnormal engine running condition and air pollution, many researchers have been trying to put forward effective methods to achieve accurate and real-time misfire detection.

The techniques for engine misfire detection can be categorized according to the utilized sensor signals, which includes the method using engine body vibration signal [

1], the method using acoustic signal [

2], the method analyzing exhaust gas temperature [

3], the method monitoring in-cylinder iron current [

4], and the method using crank speed [

5]. The method using engine body vibration signal could sample much information, since the vibration signal is sampled with high resolution and is related to in-cylinder combustion. However, a large amount of computation is required for processing vibration data. The method using acoustic signal has not solved the problem of noise interference in practical implementation. The method analyzing the temperature of exhaust gas is limited by the sensor’s response time. The method monitoring in-cylinder iron current needs to modify the engine body. The method using crank speed has been adopted by many researchers, since the crank speed can be sampled relatively easily and cannot be easily contaminated by uncorrelated noise.

The misfire detection methods based on crank speed can be categorized into physical model-based algorithms and data-driven diagnosis algorithms.

The model-based method is used to diagnose engine misfire by building the relationship between crank speed and in-cylinder pressure based on the engine dynamic model. Zheng et al. [

5] designed a Luenberger sliding mode observer to estimate engine combustion torque based on experimental crank speed of a four-cylinder engine. Rizvi et al. [

6] proposed a hybrid model for simulating the relationship between engine power and crank speed fluctuations. Misfire was detected by using Markov chain. Helm et al. [

7] estimated engine torque based on a parametric Kalman filter. Misfire was detected by employing the estimated torque and an interacting multiple model algorithm. Hmida et al. [

8] proposed the torsional model of crankshaft. The Lagrange method and Newmark algorithm were employed to derive the equations of motion. The appearance of sidebands around the acyclic frequency was adopted to detect misfire.

The model-based algorithm can lead to very accurate results if properly executed. Nevertheless, the method needs precise engine model parameters which is hard to gauge accurately. The damping is an example that cannot even be measured. Meanwhile, the complexity of model-based algorithm may not permit the real time implementation of the algorithm [

9]. Therefore, this method has not been widely used in industrial application.

The data-driven diagnosis algorithms provide another way of misfire detection, in which the misfire related characteristics are extracted directly from crank speed instead of deriving the excitation torque or in-cylinder pressure. Misfire is detected by distinguishing the misfire related characteristics from fault free. The representative data-driven method is the engine roughness method which is proposed by Plapp et al. [

10] and is still used in modern vehicles. However, this method is limited on high-speed low-load conditions when the number of engine cylinders is not less than six.

Another data-driven method is conducted by analyzing the typical frequencies of crank speed. Taraza et al. [

11] utilized the lowest three harmonic orders of crank speed as an indicator for one-cylinder misfire detection. Geveci et al. [

12] analyzed the first and the second harmonic components of crank speed under normal and cylinder 1# misfire conditions at various speeds and loads. This method is limited as well, since the speed spectrum of two-cylinder misfire fault may be confused with one-cylinder misfire patterns.

Over the past about twenty years, machine learning algorithms developed rapidly and have been exploited in misfire detection research field [

13]. Compared with the algorithms that one or some human-designed indicators are calculated for misfire detection, the machine learning algorithm could extract more fault features from one signal or could process many signals at the same time. Not only the crank speed, but also the engine vibration and in-cylinder pressure have been used in the machine learning algorithm as reported in the literature.

Li et al. [

14] utilized the crank speed and the techniques including the empirical mode decomposition, kernel independent component analysis, Wigner bispectrum and support vector machine (SVM) for detecting misfire of a marine diesel engine. Chen and Randall [

15] designed a misfire detection method which consists of three stages: fault detection, fault localization and fault severity identification. This method was achieved by using the lowest four harmonic orders of crank speed and a fully connected artificial neural network (ANN). Jung et al. [

16] distinguish misfire and fault-free conditions using crank speed and Kullback–Leibler divergence. SVM was utilized as the automatic classification tool. Gani and Manzie [

17] also employed the SVM technique and crank speed for classifying normal condition, intermittent misfire and continuous misfire in cylinder 6# of engine. The accuracy approached 100% in test dataset. In the work of Sharma et al. [

18], the statistic features of vibration signals, like standard deviation, kurtosis, median and so on, were selected as fault features for misfire detection. The decision tree algorithm was employed for fault classification. As reported by Moosavian et al. [

19], wavelet denoising technique, ANN, least square support vector machine, and D–S evidence theory were applied for misfire detection. The final classification accuracy of 98.56% was achieved by using acoustic and vibration signal under idle condition. Gu et al. [

20] utilized multivariate empirical mode decomposition and SVM techniques for a twelve-cylinder diesel engine misfire detection. Qin et al. [

1] designed a deep twin convolutional neural network with multi-domain inputs for misfire detection. Since the vibration signal was employed, the authors also studied the algorithm’s performance when there was strong environmental noise on the vibration. Jafarian et al. [

21] employed vibration signals from four sensors placed on the engine for misfire detection. The fast Fourier transform (FFT) was used for feature extraction; the ANN, SVM, and k-nearest neighbor (kNN) algorithms were used for classification. Liu et al. [

22] took many signals, including engine speed, exhaust temperature, and fuel consumption, as the inputs of ANN for misfire detection. Bahri et al. [

23] detected misfire of a homogeneous charge compression ignition engine by using in-cylinder pressure and ANN model.

It can be seen that the mentioned data-driven diagnosis algorithms mainly focused on the classical feature extraction methods, such as human-designed threshold, FFT, wavelet transform and empirical mode decomposition, and traditional pattern recognition methods, such as fully connected ANN and SVM. Thus, the algorithm performance often depends on the proper selected features and the domain expertise in engine misfire. In addition, the mentioned algorithms based on machine learning either mainly considered a few engine speed and load conditions, or only considered a few one-cylinder misfire types. In practice, the fault features would change with the engine running conditions or different misfire types, and for a data-driven algorithm especially a machine learning algorithm, the sample size is an important factor for the algorithm training. Therefore, there is still some research work needs to do for applying the machine learning based algorithms into actual industrial scenario.

Recurrent neural network (RNN) is a type of neural network which is good at processing sequence data. Sequences may be of finite or countably infinite length, and may be temporal or non-temporal. Examples of time-indexed data include the audio recordings which are sampled at fixed intervals. In fact, RNNs are frequently applied to sequences whose meaning are directly related to the data order but no explicit notion of time [

24]. Engine crank speed is a type of sequence that the prior motion will affect the later motion. For example, assuming the firing order of a six-cylinder engine is 1-5-3-6-2-4, if misfire occurs in the first cylinder, not only the instantaneous speed variation of the first cylinder changes, but also the fourth cylinder. Therefore, RNN is hopeful for misfire detection. For the earlier RNN, it was difficult to handle the problems of vanishing and exploding gradient that occurred when training RNN across many steps [

25]. Therefore, in this paper, the RNN with long short-term memory (LSTM) [

26] which overcomes the training difficulties is utilized.

Compared with misfire detection studies in literature, the main contribution of this paper is as follows.

A new misfire detection method that is based on LSTM RNN is proposed.

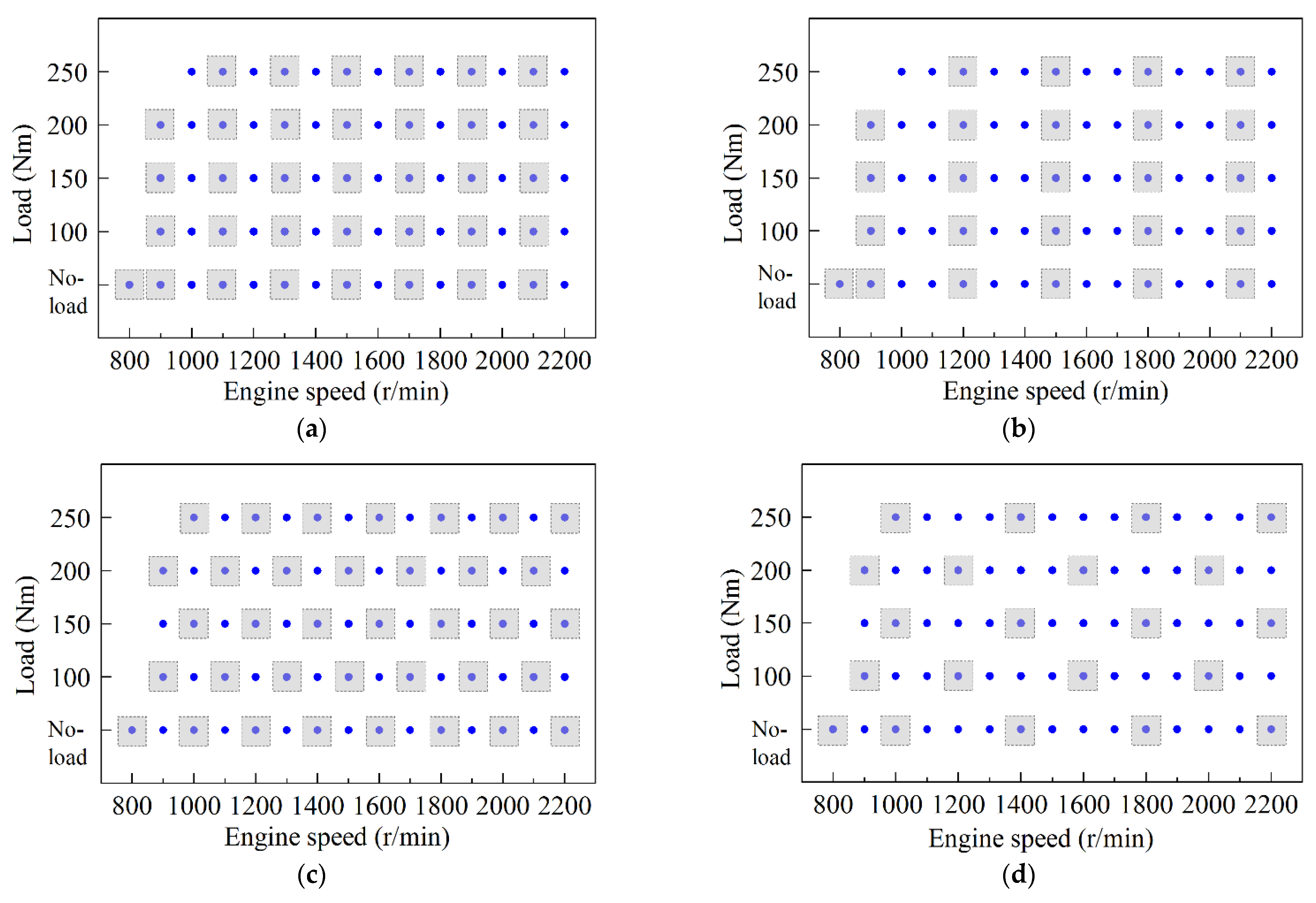

Datasets for network training and testing are acquired in wide range of speed and load conditions of the tested diesel engine, which ensures the diversity of datasets and makes the network more applicable.

For a six-cylinder engine, limited studies [

12,

16,

22,

27] have considered the detection of two-cylinder misfire faults which include more misfire types and may disturb the detection of one-cylinder misfire and even cause misdiagnosis. In this paper, besides the one-cylinder misfire faults, all the fifteen two-cylinder misfire faults are considered as well.

The rest of the paper is organized as follows. In

Section 2, the experiment setup and diesel engine rig tests are introduced. The speed characteristics under misfire and the limitation of traditional misfire detection method are described in

Section 3. The scheme of misfire diagnosis and the LSTM algorithm are introduced in

Section 4. In

Section 5, the experimental results are analyzed and discussed. Finally, conclusions are given in

Section 6.

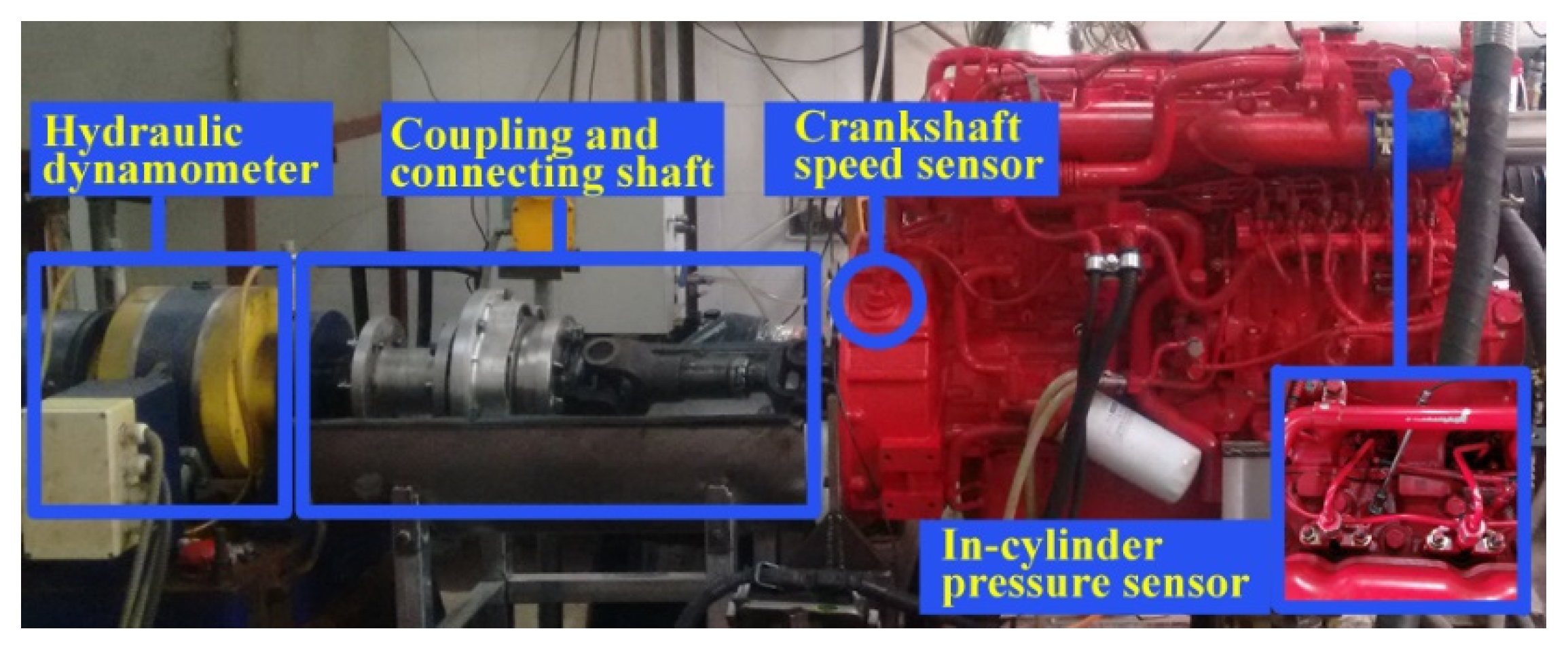

3. The Speed Characteristics under Misfire and the Limitation of Traditional Misfire Detection Method

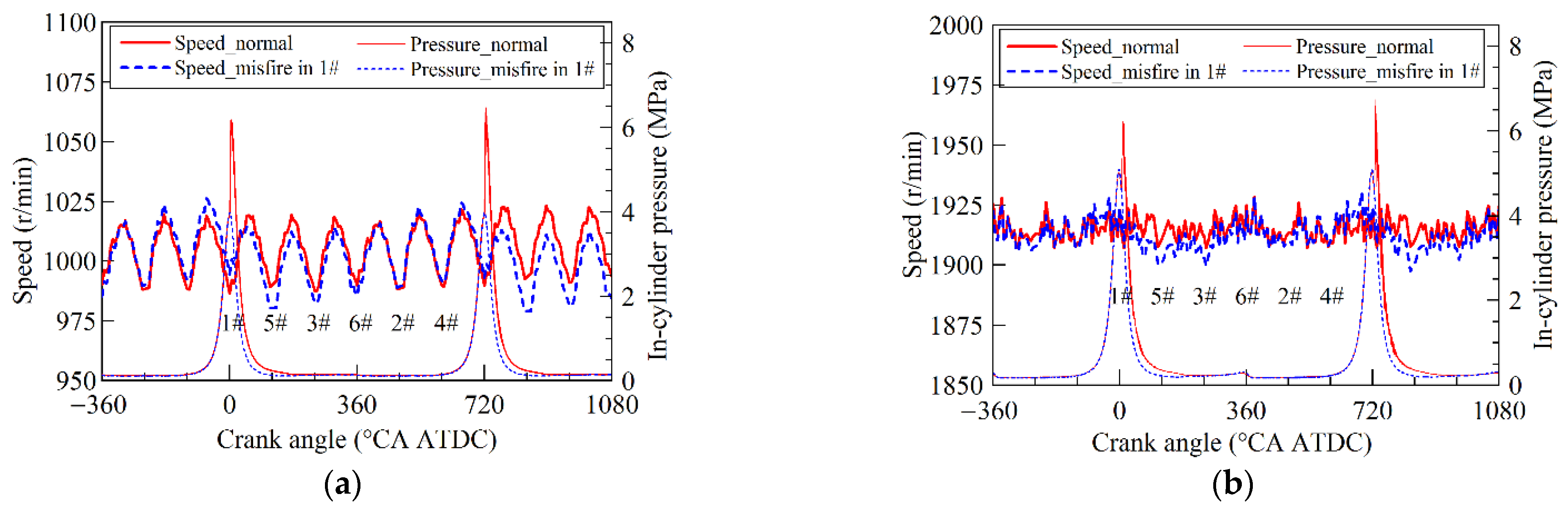

When misfire occurs, the instantaneous engine crankshaft speed will drop and the subsequent speed will rise up compared with the normal conditions. The variation of the whole speed curve will be larger. An example is shown in

Figure 3a, under the running condition of 1000 r/min and 100 Nm, when a misfire occurs in cylinder 1#, as the dash curve indicates, the speed becomes different from the normal condition. When the engine speed is high and the load is low, as shown in

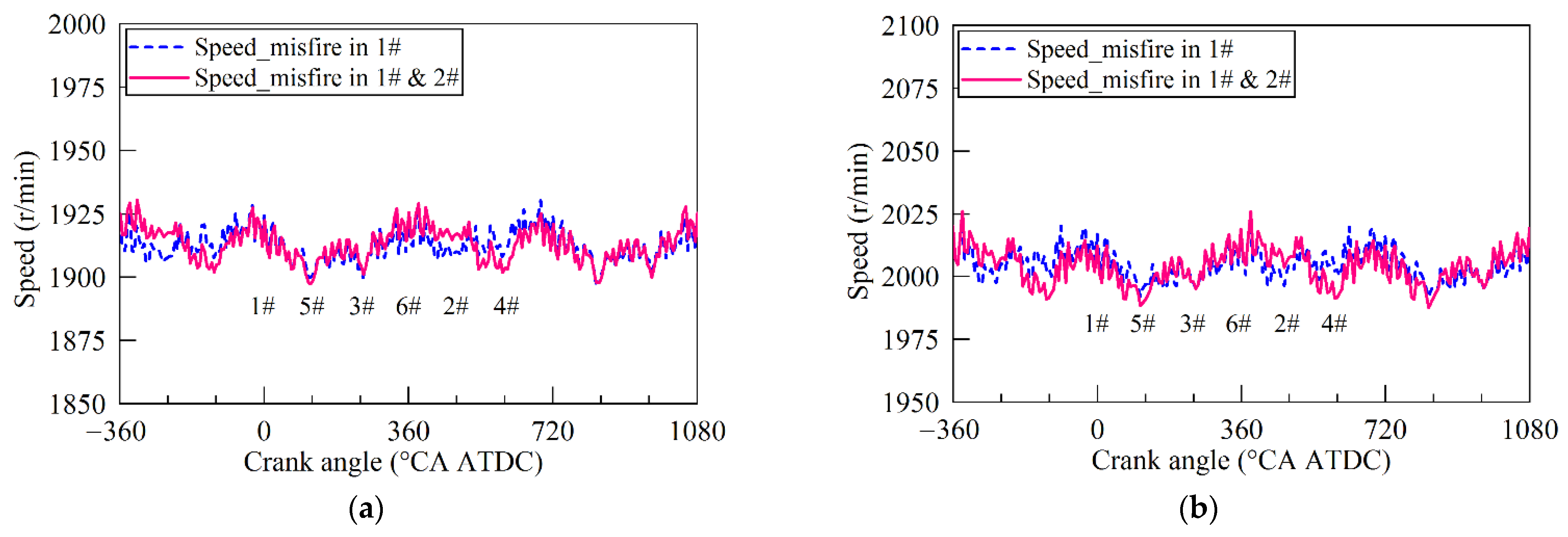

Figure 3b, the variation rule of instantaneous crankshaft speed becomes unclear, and the difference between normal and misfire condition also becomes indistinguishable. Moreover, when two-cylinder misfire occurs, the fault features expressed from engine speed curve is easily confused with that of one-cylinder misfire condition, especially under the high-speed and low-load conditions.

Figure 4a,b show the comparison between speed curves of one-cylinder misfire and two-cylinder misfire.

Therefore, for detecting misfire accurately, the fault features that can reduce or eliminate the interference from engine speed and load should be found. One way to eliminate the impact of engine running range is to divide it into small blocks and then find fault features for each block [

27]. However, this will increase workload when the engine running range is large. The better way is to find or design an algorithm that can extract useful feature or can learn more features for the whole engine running conditions.

An example of the traditional methods which is called engine roughness method is introduced as below. This method calculates a misfire indicator that is based on the difference of two consecutive angular accelerations. Equation (1) presents the calculation of the indicator [

10].

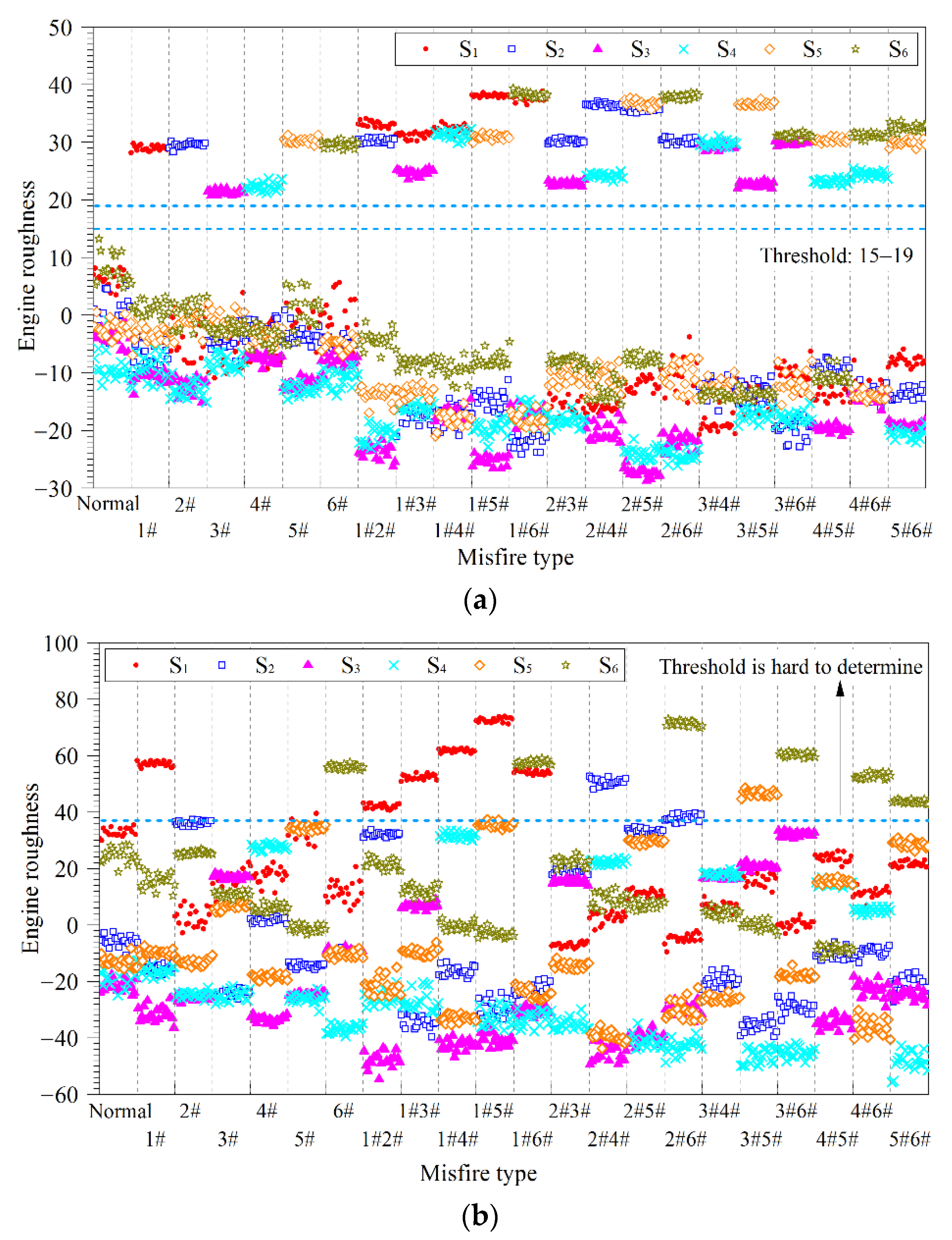

where S

i is engine roughness of the

ith cylinder.

Ti is the time period from ignition of the

ith cylinder to ignition of the next cylinder in firing order.

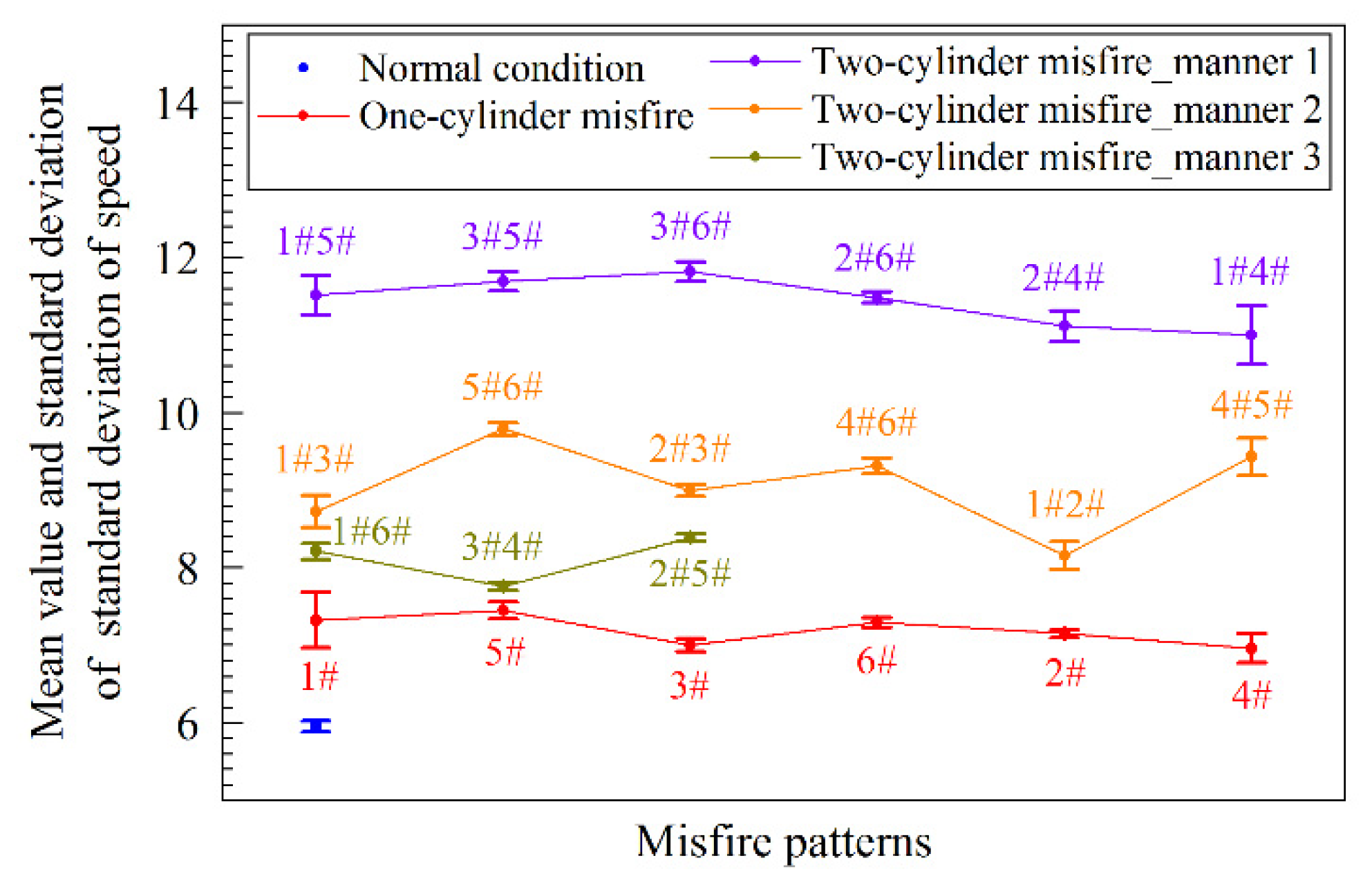

Figure 5 shows the results of indicator S under different engine speeds and different misfire patterns. When misfire occurs in cylinder

i, the corresponding S

i will become larger than the predefined threshold. An example is shown in

Figure 5a, the threshold can be defined in range 15–19, and when S

i is detected larger than the threshold, it is thought the misfire happened in the cylinder

i. This method is limited at the high-speed low-load conditions. As shown in

Figure 5b, under 1900 r/min and no-load condition, it is hard to determine the threshold, and the two-cylinder misfire modes are easily confused with one-cylinder misfire modes.

The unsatisfied results appeared at high-speed and low-load conditions are caused by the background noise which has approximately the same order of magnitude with the value related to the misfire presence. The reasons for relatively higher background noise are mainly from the different burning behaviors caused by the systematic nonuniformity. In addition, with the speed increasing and load decreasing, the signal to noise ratio will decrease since the useful features caused by misfire will decrease.

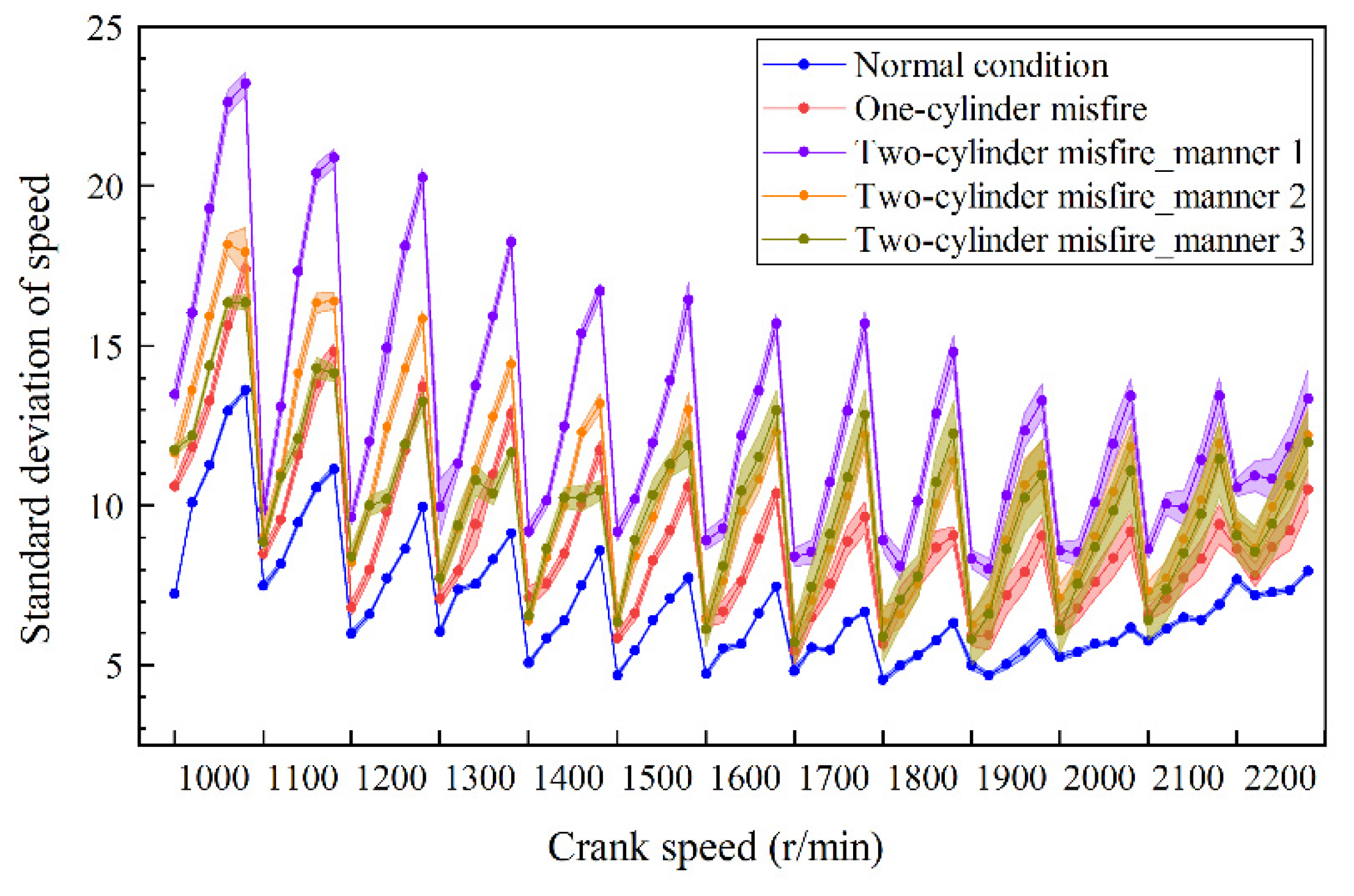

Figure 6 presents the standard deviation of crankshaft speed under 800 r/min and no-load conditions. The standard deviation is calculated once per cycle, the points in

Figure 6 which are shown in the form of mean value and standard deviation are calculated from 200 cycles of data. The results clearly show that when misfire occurs, the amplitude of speed variation will increase, and this is helpful for extracting misfire features. However, when engine speed becomes higher and load becomes lower, the amplitude of speed variation decreases, and the amplitude difference between normal and misfire patterns also decreases, as shown in

Figure 7. Then, the signal to noise ratio decreases. The limitation of the engine roughness method proves that it is hard to use too few features to achieve a perfect fault detection result.

Since LSTM RNN is good at learning features of sequences, the LSTM RNN is utilized in this paper to detect misfire and to overcome the limitation of traditional algorithm.

4. The LSTM RNN

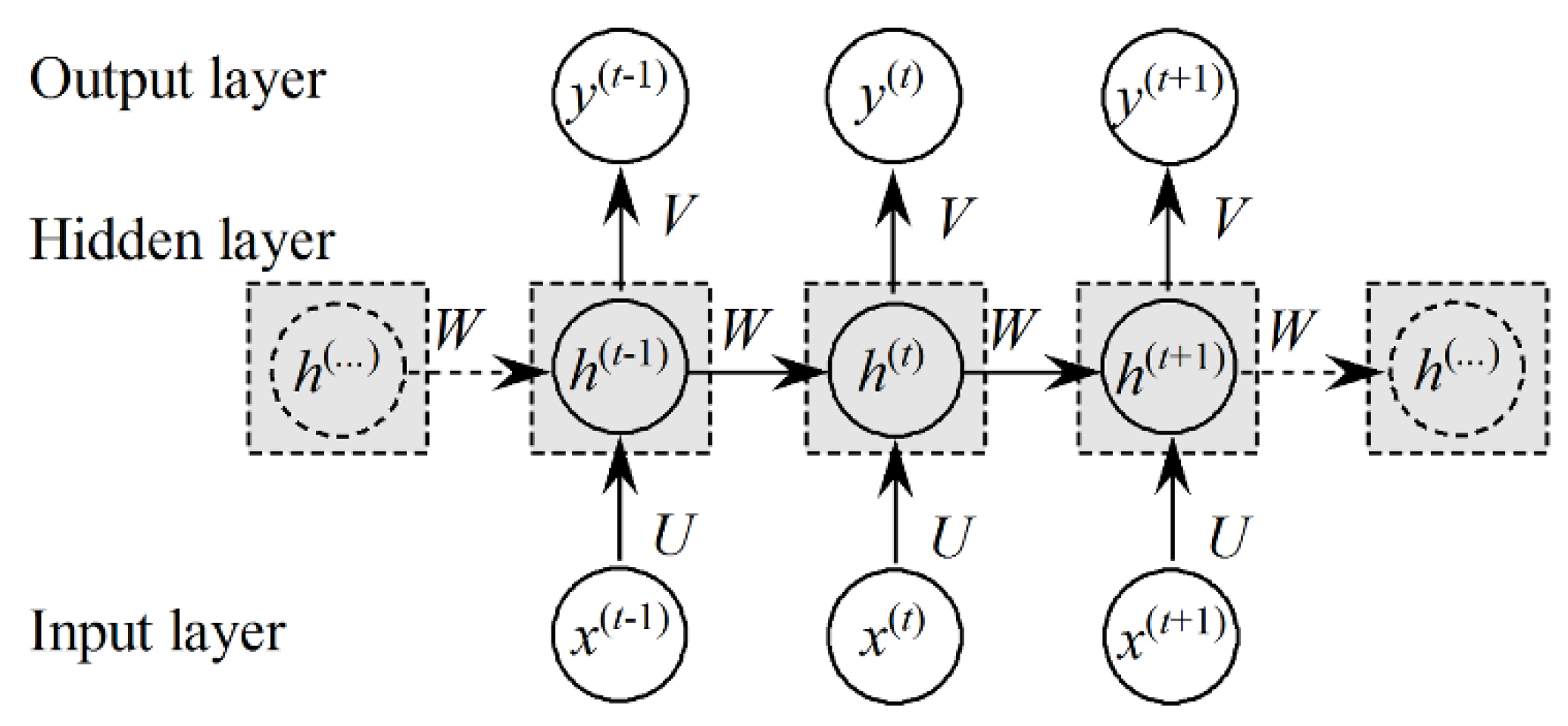

The classical artificial neural networks are design to extract features from datasets whose sub-samples are independent with each other. In some application scenarios, like natural language processing, the meaning of a whole sentence is dependent on the meaning and order of the previous and later words. RNNs are designed to be applied in this kind of research field. RNNs are connectionist models that capture the meaning of sequences via cycles in the network. Basic architecture of an RNN is shown in

Figure 8, which is an unfold architecture.

As presented in

Figure 8, the forward pass of an RNN module looks the same as that of a multi-layer perceptron which has a single hidden layer. The main difference is that the activations of the hidden layer are from both the current input layer and the hidden layer activations from the previous step, as described in Equation (2) [

29]. Equation (3) calculates the output value or vector. Thus, an RNN will map the input sequences into output.

where

W,

U and

V are the weight matrices.

b,

x,

h,

f, and

y donate the bias vector, input vector, hidden layer vector, activation function and the output vector, respectively.

The classic RNN has the problem of a vanishing gradient [

30]. In addition, sometimes gradient explosion will also occur. This is because the error surface is either very flat or very deep after updating weights in many time steps. This problem is also called the long-term dependency problem. One effective way to solve this problem is using gating mechanism to control the information passing path, such as LSTM.

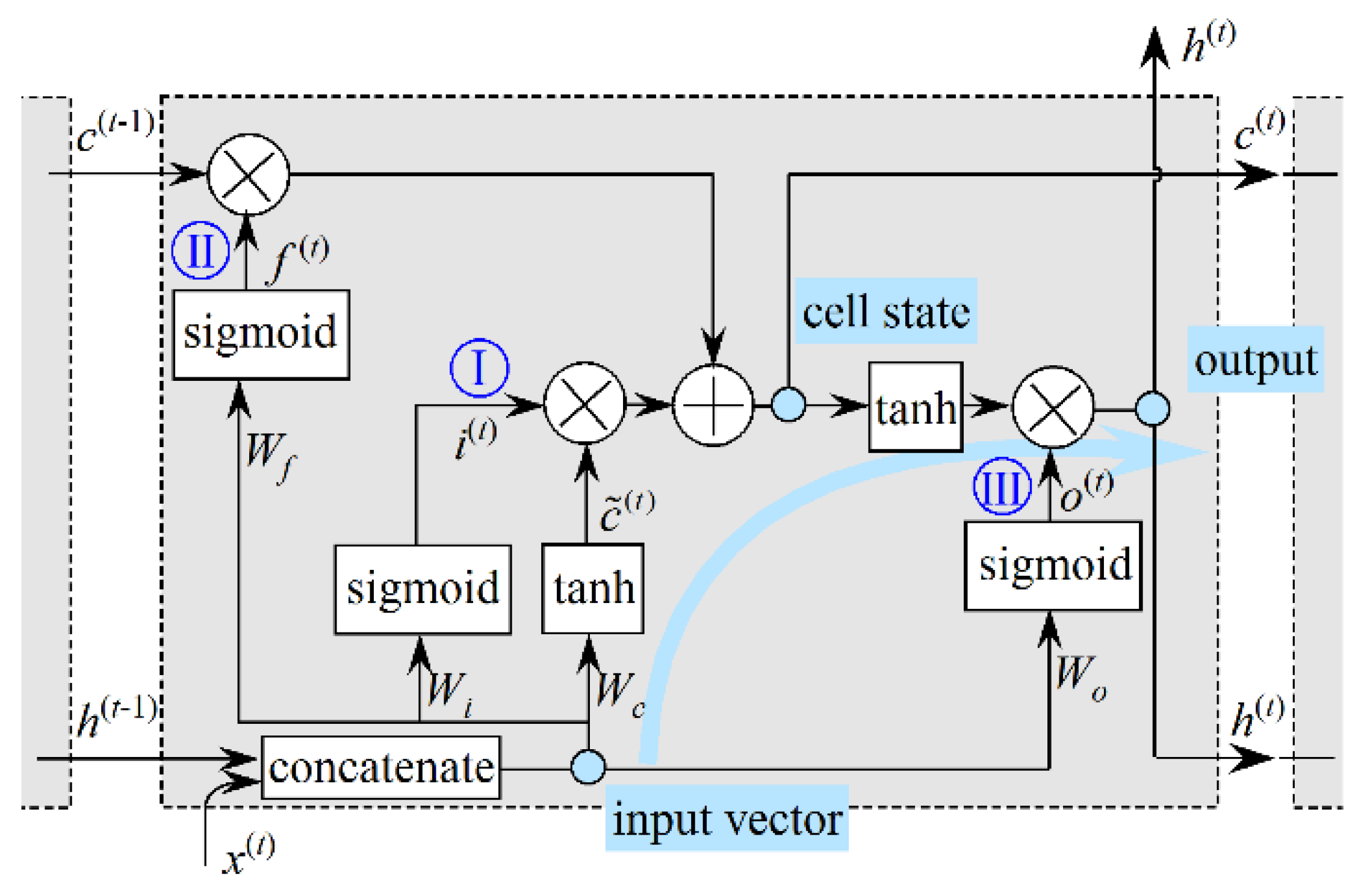

LSTM RNN has the basic structure of RNN, which is a chain of repeating modules. The main difference of an LSTM RNN from other RNNs is the structure of the module, which is marked with shadow area in

Figure 8 and

Figure 9. In a module of LSTM RNN, three gates are designed to control the output.

The main line of an LSTM module is the calculations of input vector, cell state and output, as indicated by the blue dot and arrow in

Figure 9. First of all, the input vector of LSTM module is acquired by concatenating the outputs of the previous module and the current inputs. Secondly, two gates are designed to adjust the cell state. As shown in

Figure 9, the input gate is applied to decide whether the current inputs will be used to update the cell state. By the same principle, the forget gate is applied to adjust the proportion of previous cell state in the current one. This makes an LSTM module have the memory function. Then the cell state will be updated and stored for the LSTM module of next step. Next, an output gate is designed to adjust the output of the updated cell which has been rescaled by a tanh activation function firstly. Finally, the output will be transported to the next layer and the next module.

Equations (4) and (5) show the calculation of new candidate vector

and input gate vector

; Equation (6) calculates the forget gate vector

; the cell state

can be updated by Equation (7); the output gate vector

is calculated by Equation (8); and the final output

will be acquired by Equation (9) [

24]. The output vectors of these three gates are all the values between 1 and 0, which will make the outputs of corresponding layer change from original value to 0.

where sigmoid and tanh are activation functions.

is the input vector from training or testing dataset.

and

are the current and previous outputs of LSTM module, respectively.

means concatenating

and

.

,

,

, and

are biases.

,

,

, and

are weight matrices.

means Hadamard product. When the network is trained,

,

,

, and

are initialized with ones. For

,

,

, and

, each weight matrix is the concatenation of two matrices which are corresponding to

and

, respectively; accordingly, the two parts of a weight matrix are initialized, respectively. In this work, both the two parts of each weight are initialized as uniform distribution which is shown in Equation (10) [

31].

where

and

is the element number layer

j and

j + 1, respectively.

This is the key mechanism of LSTM RNN. The network training is also based on back propagation through time (BPTT) strategy and gradient descent algorithm. Up to now, there have been many types of variants on the LSTM, such as adding peephole connections, using coupled forget and input gates, gated recurrent unit, depth gated RNNs and so on. As reported in Greff’s work [

32], the result of comparing these popular LSTM variants shown that there were not significant differences among them. Therefore, the standard LSTM RNN is adopted in this paper.

6. Conclusions

In this paper, an LSTM RNN based approach for engine misfire detection is proposed.

The traditional misfire detection method has limitations on the high-speed and low-load engine operating conditions. Hence, the traditional misfire detection method is conducted on the datasets to verify its feasibility first; and the reason of the limitation, that one threshold is insufficient to extract the fault feature when the background noise is high, is concluded. In order to extract the fault features extensively and effectively, unlike previous works, the LSTM RNN is a powerful technique on sequence signal processing is utilized to detect misfire. In addition, for the sake of ensuring the feasibility of proposed algorithm, two-cylinder misfire faults are tested beside one-cylinder faults, and a wide range of engine working speed and load conditions which including the high-speed and low-load conditions are tested.

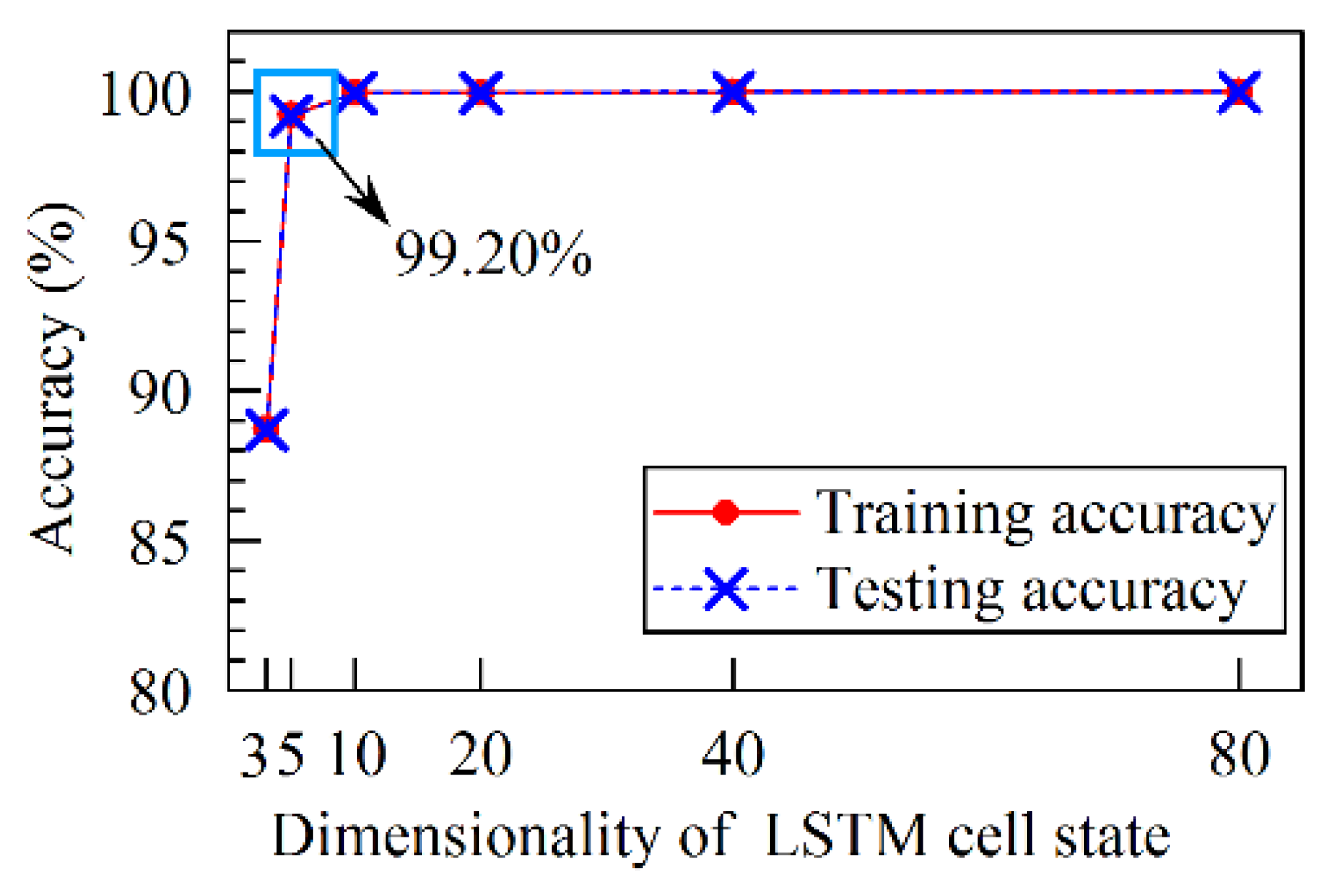

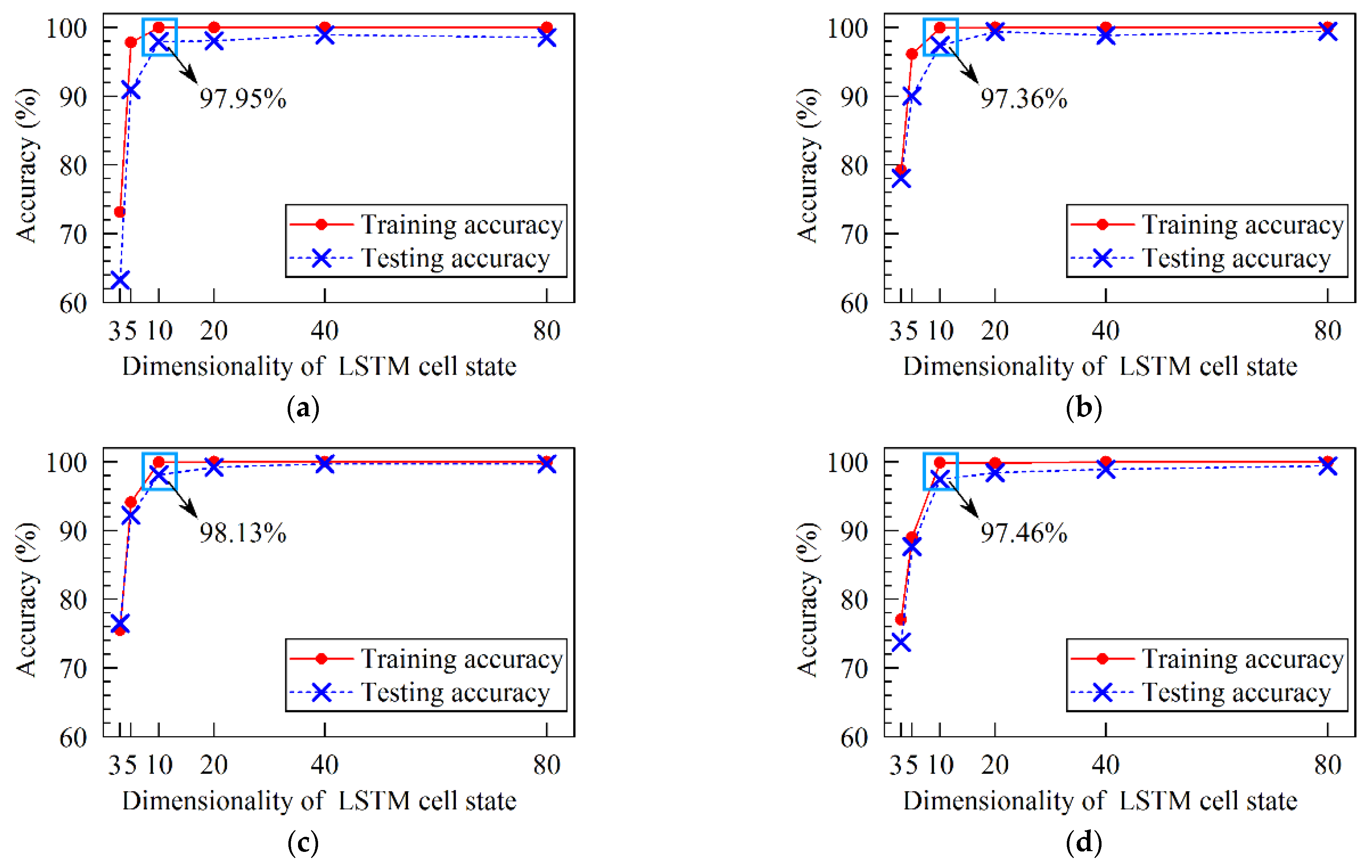

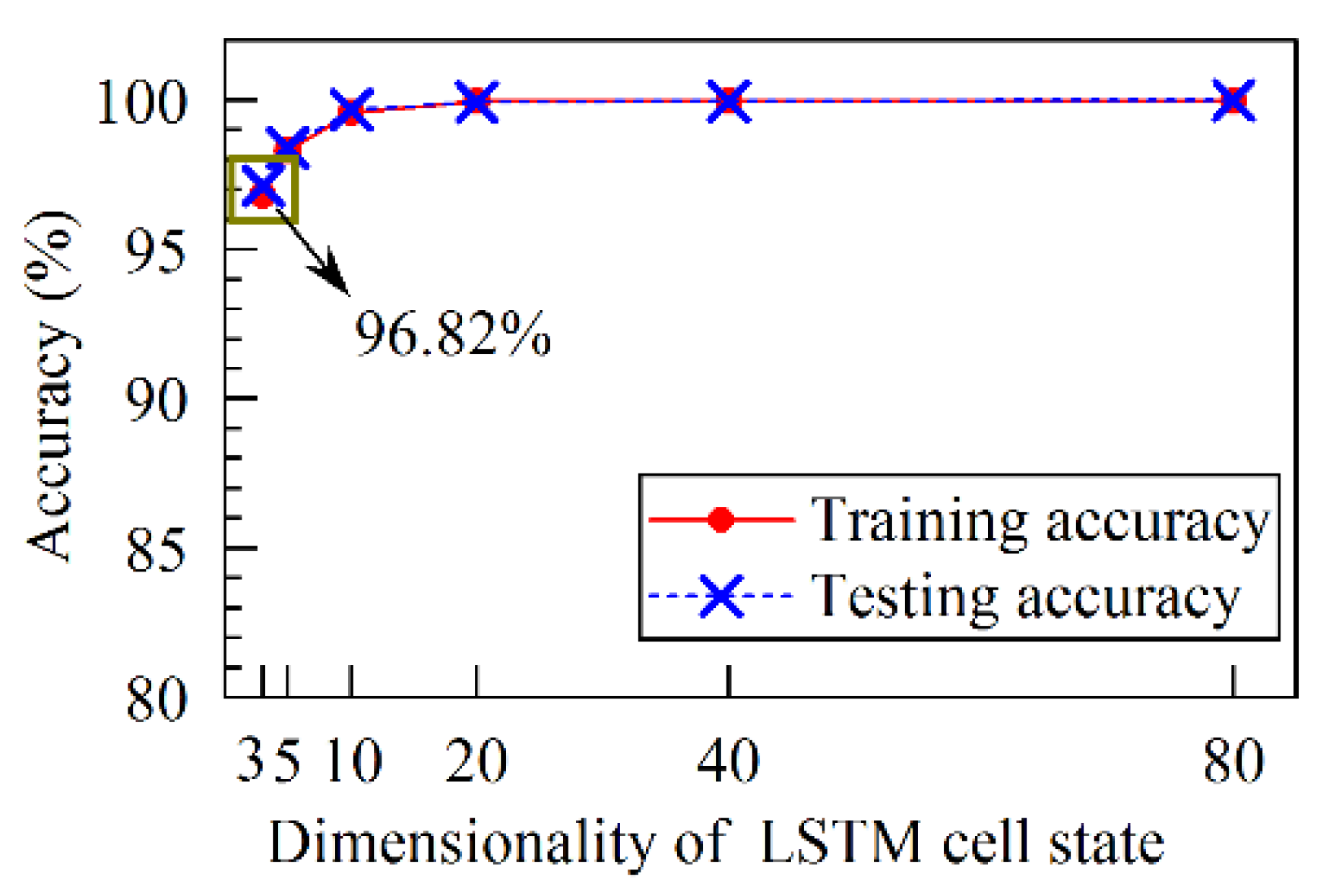

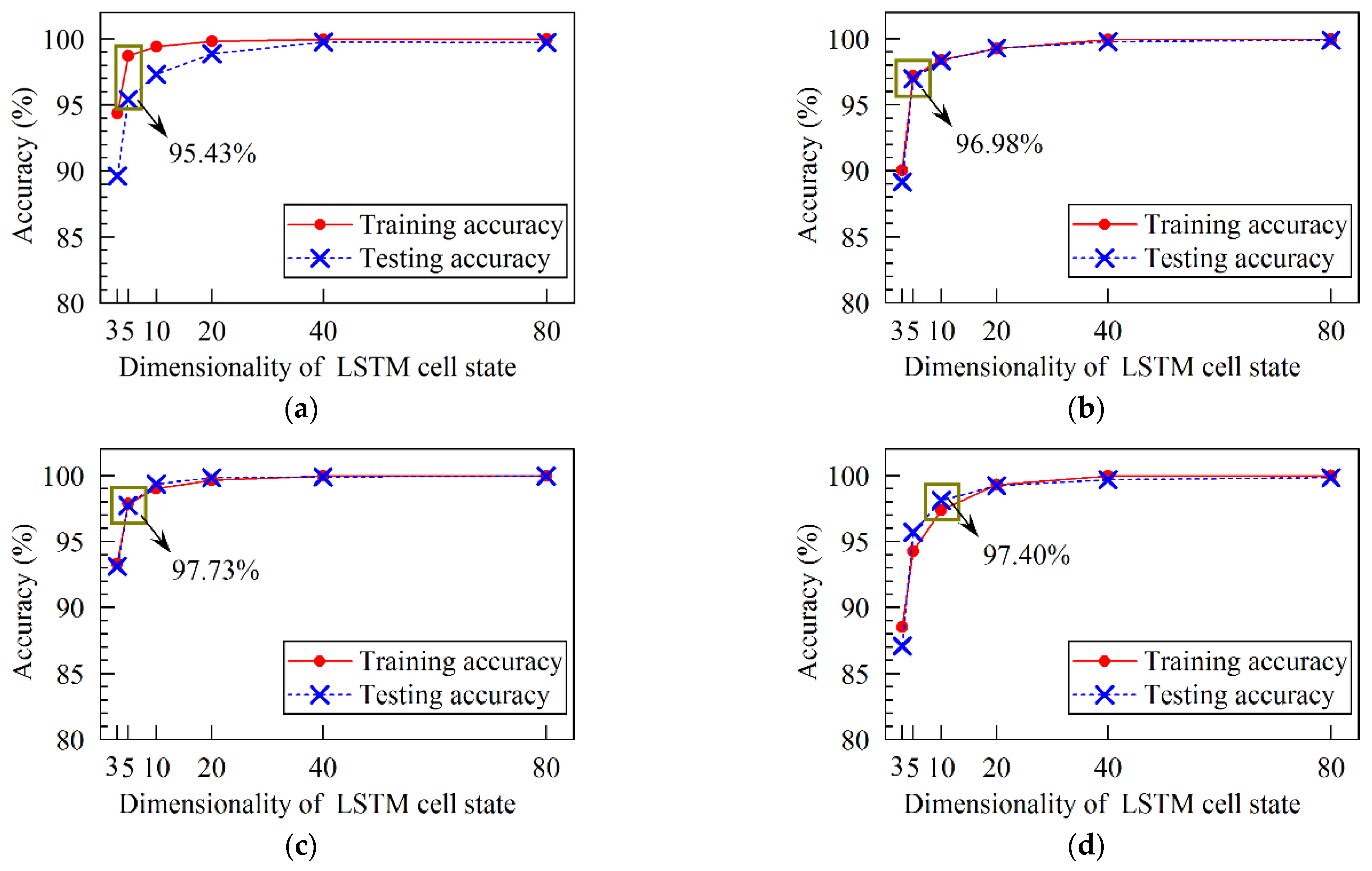

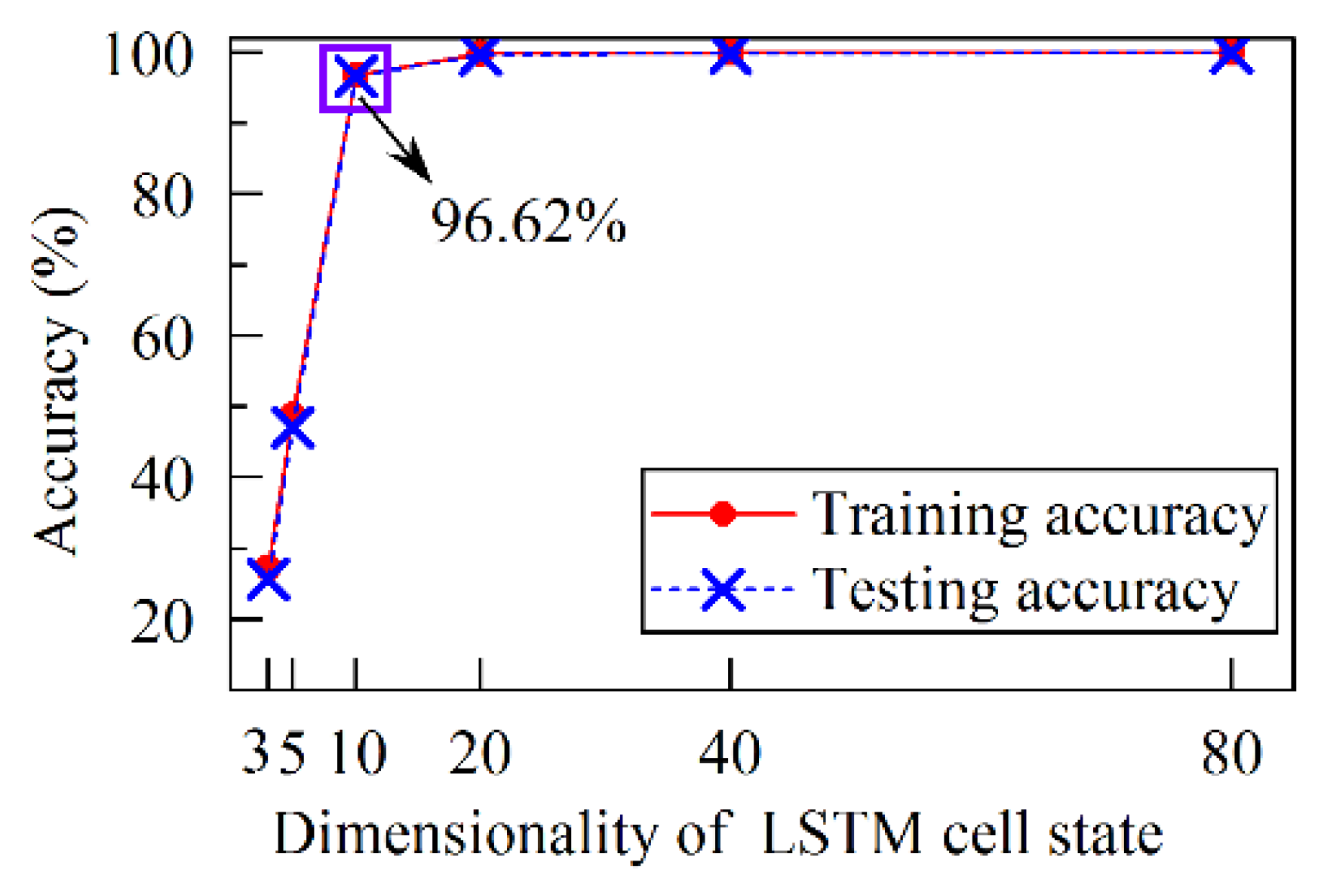

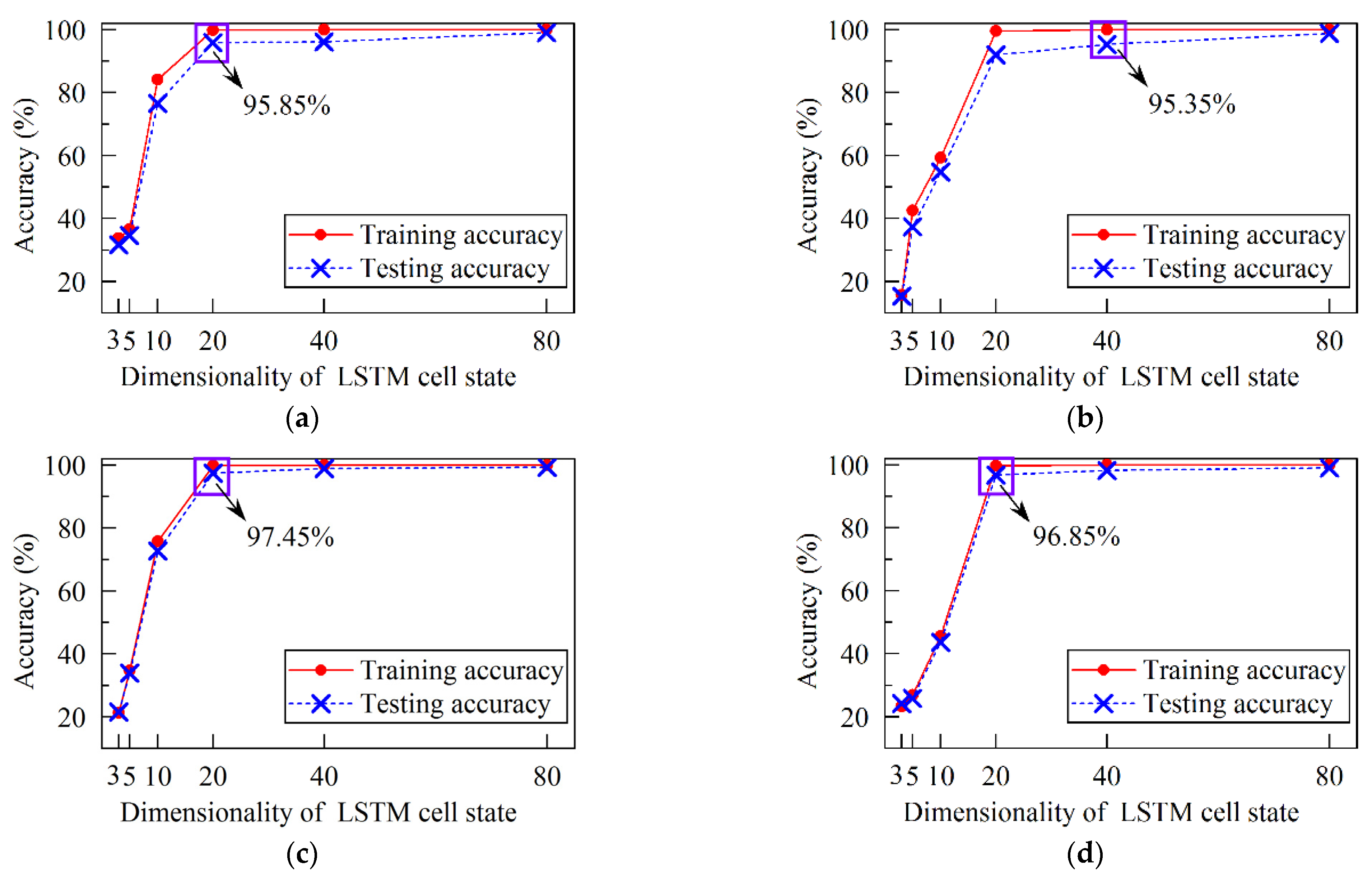

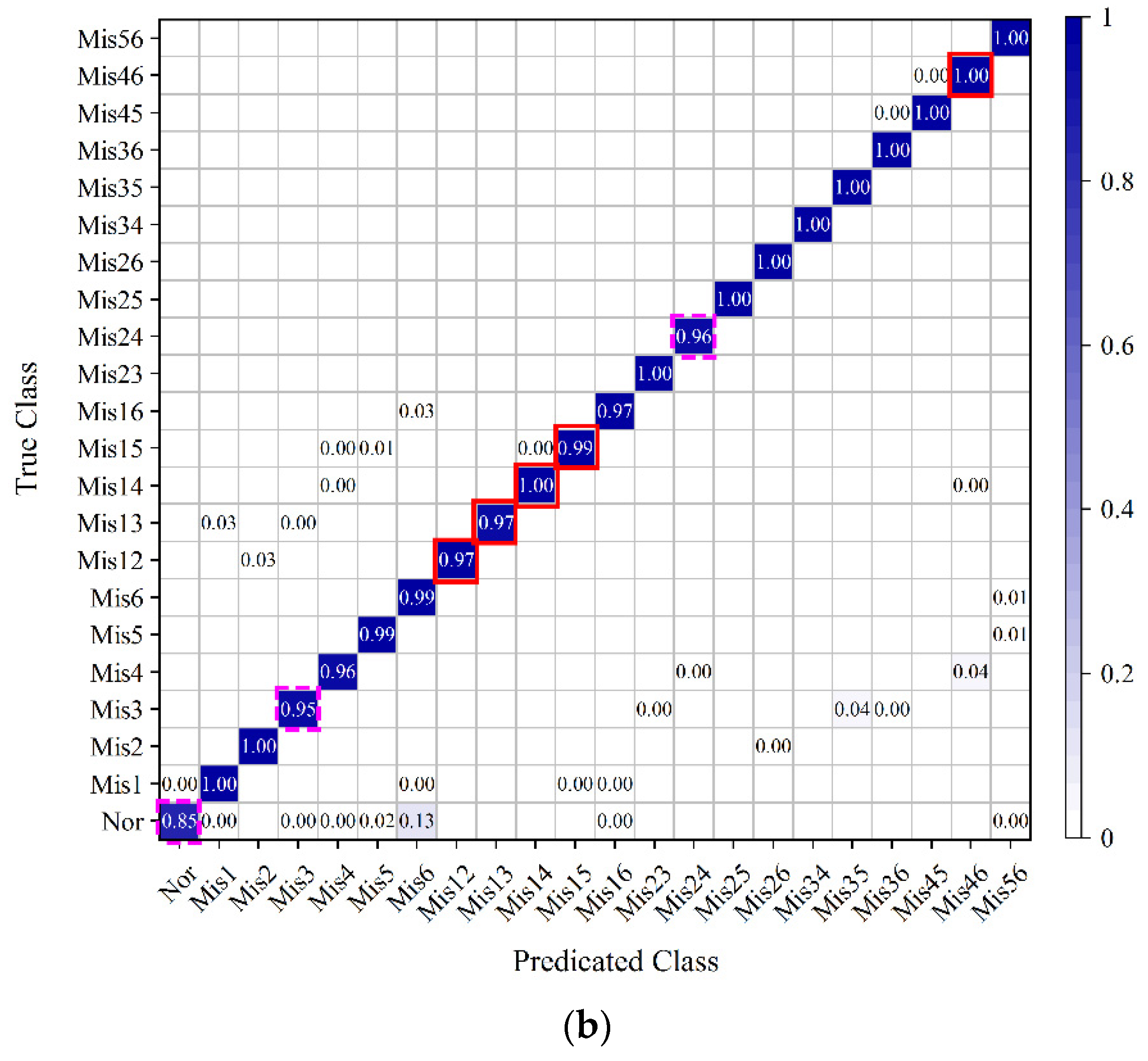

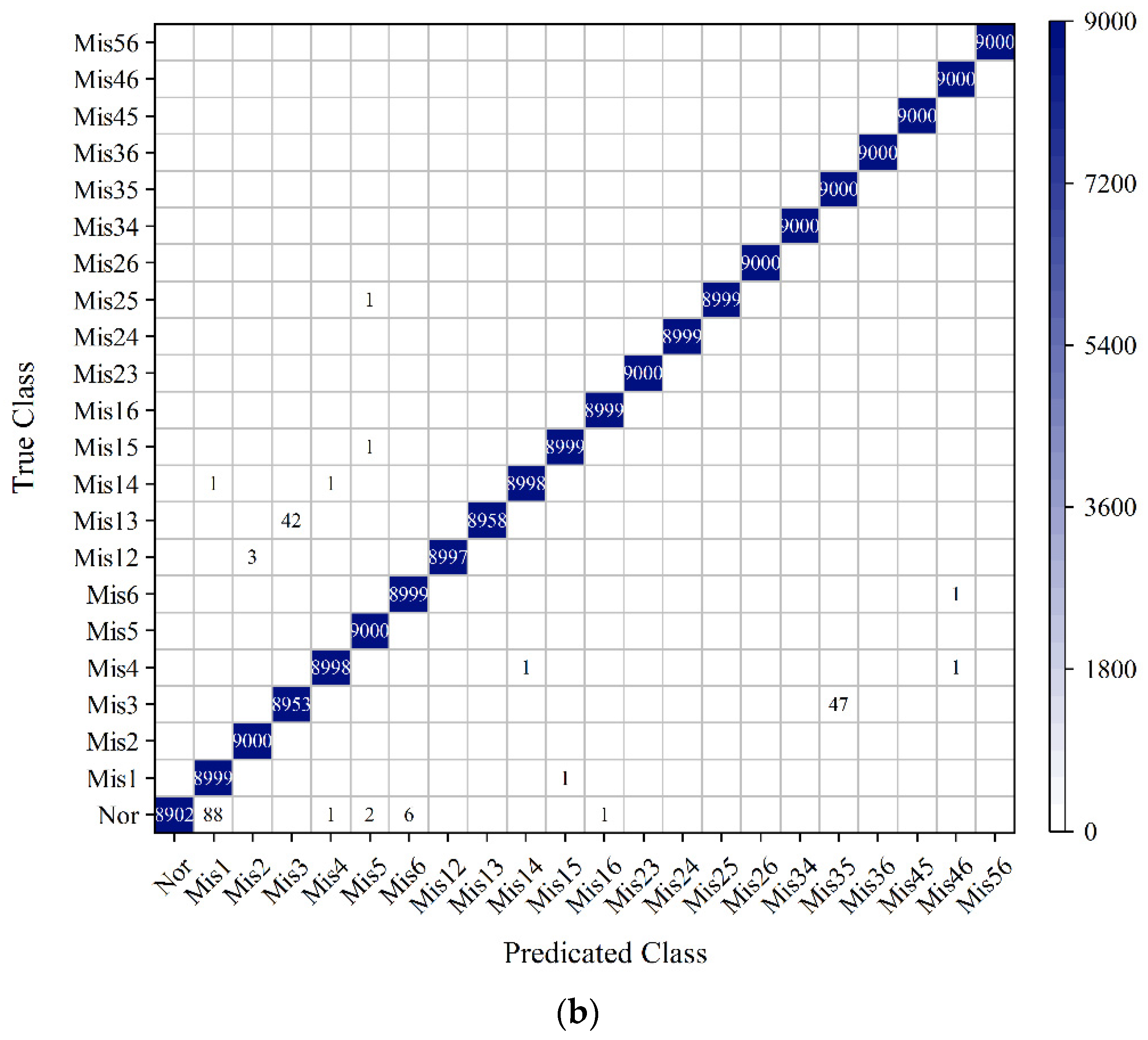

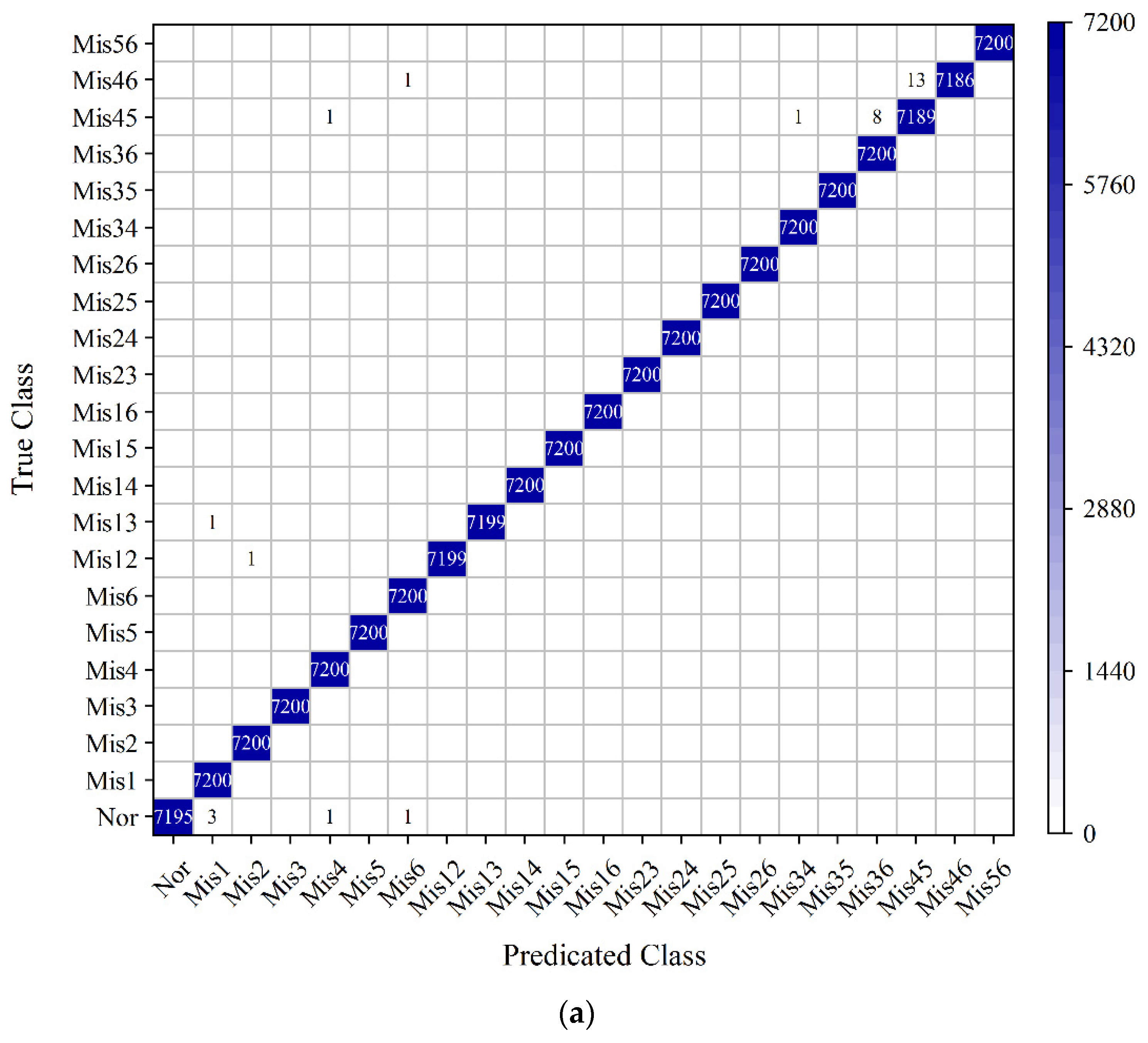

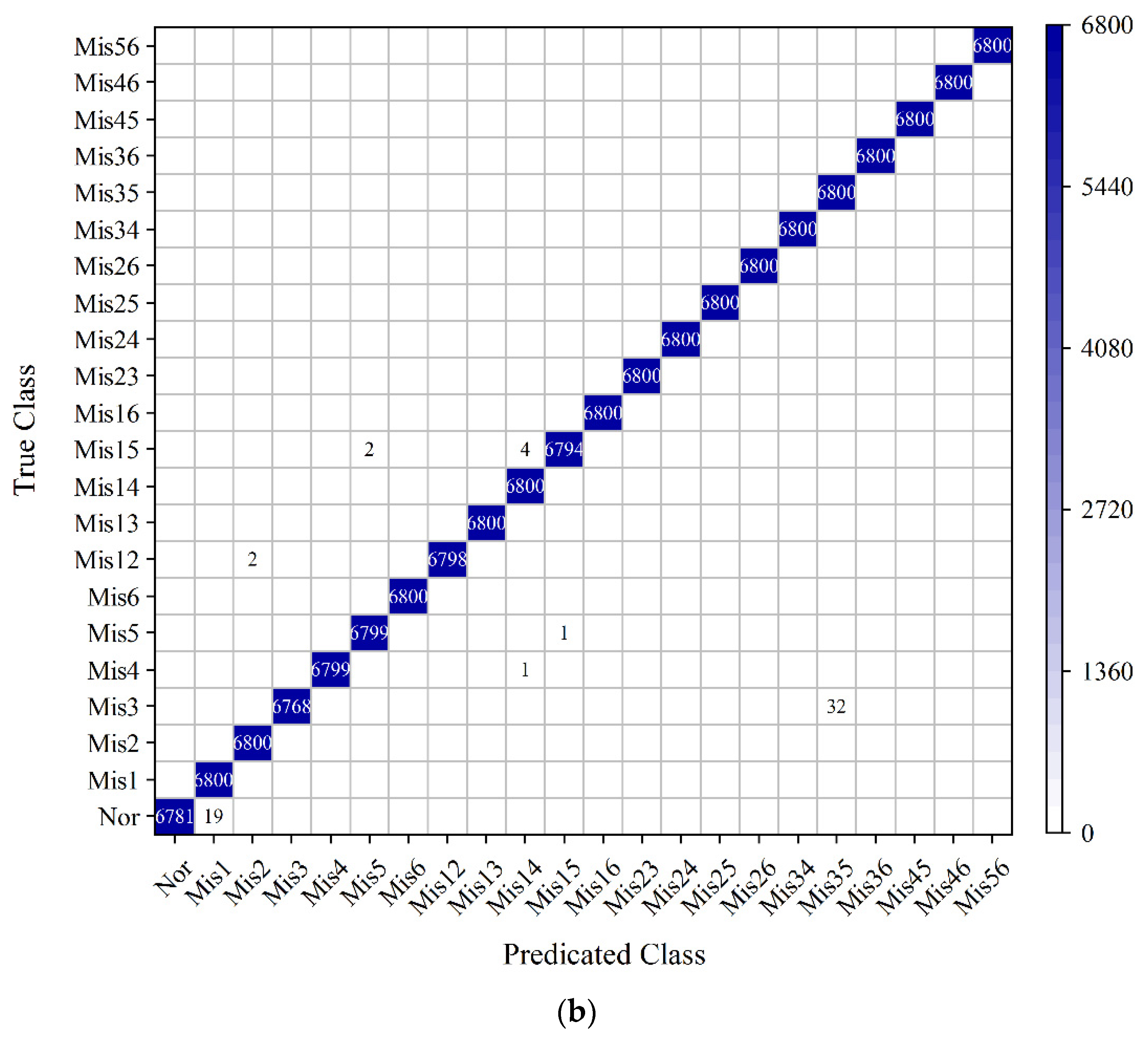

The LSTM RNNs are designed according to the characteristic of speed signal. Four kinds of input layer structures are designed. These inputs contain instantaneous raw speed signal, a fixed segment of raw speed signal, and the extracted real and imaginary parts of speed signal. Moreover, five data division modes are attempted to explore the optimal training data size. These training datasets can be categorized into two parts: the training data that has running condition intersection with the testing data, and the training data that has no running condition intersection with the testing data. The testing results show that the sequence-input-sequence-output LSTM RNN which utilizes raw speed data could not achieve acceptable detecting accuracy. The second, third and fourth LSTM RNNs could achieve accuracies more than 98%. The best performance is achieved by the third LSTM RNN with data division mode 2_c, and the testing accuracy is 99.96%. Meanwhile, the third LSTM RNN with data division mode 2_b is also recommended, because it has the relatively high testing accuracy 99.90% and small training data size as well.

In this study, misfire detection is conducted on complete misfire conditions. It is also significant that misfire fault could be detected when it is not severe. Therefore, in further research, the slight misfire fault including partial misfire will be utilized to improve the detection sensitivity of the proposed algorithm. In addition, future work will include developing hardware for misfire detection of this engine as well. The LSTM RNN models developed in this study will then be written into the hardware to provide misfire information.