Innovative Construction of the AFPM-Type Electric Machine and the Method for Estimation of Its Performance Parameters on the Basis of the Induction Voltage Shape

Abstract

1. Introduction

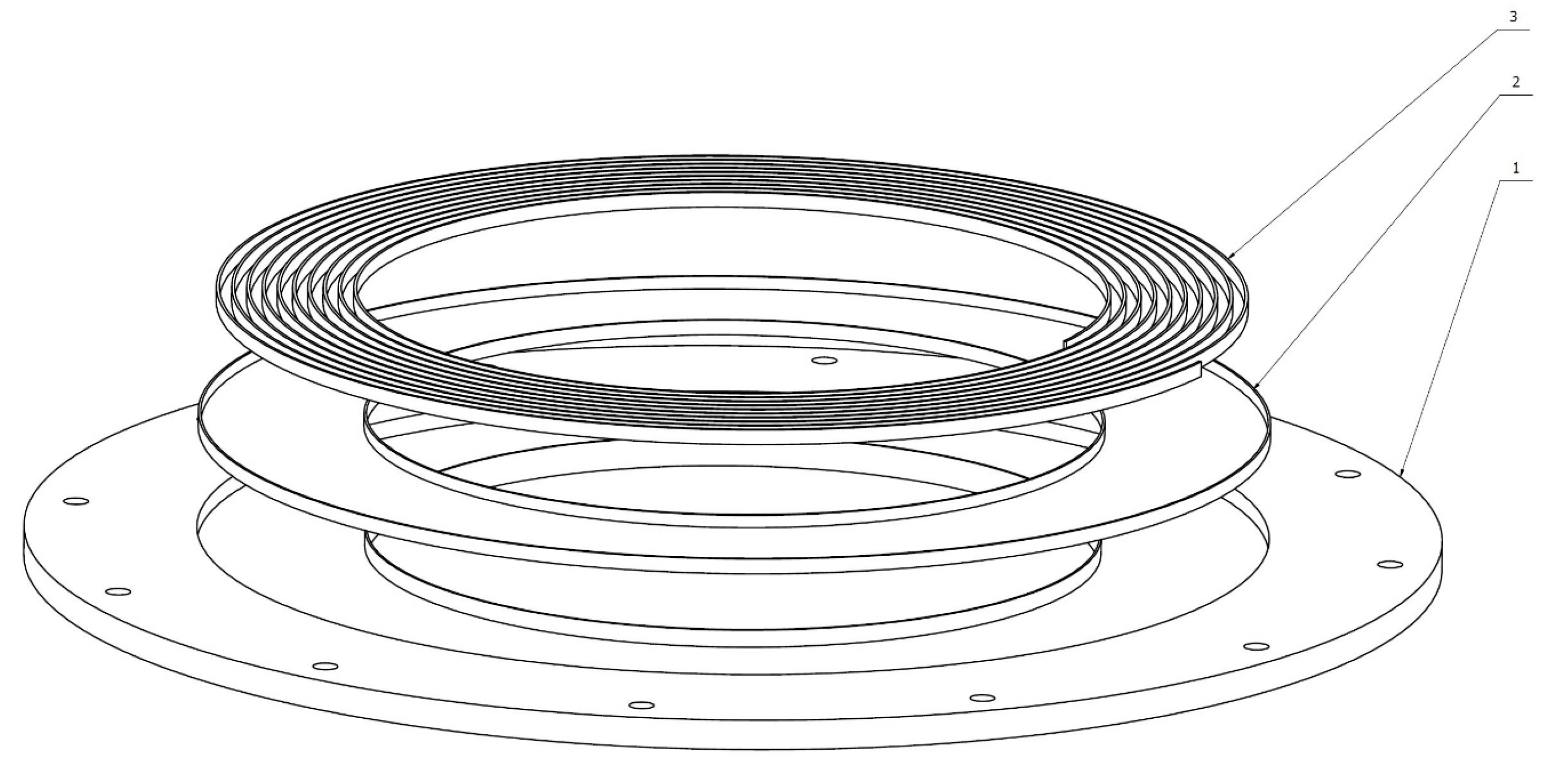

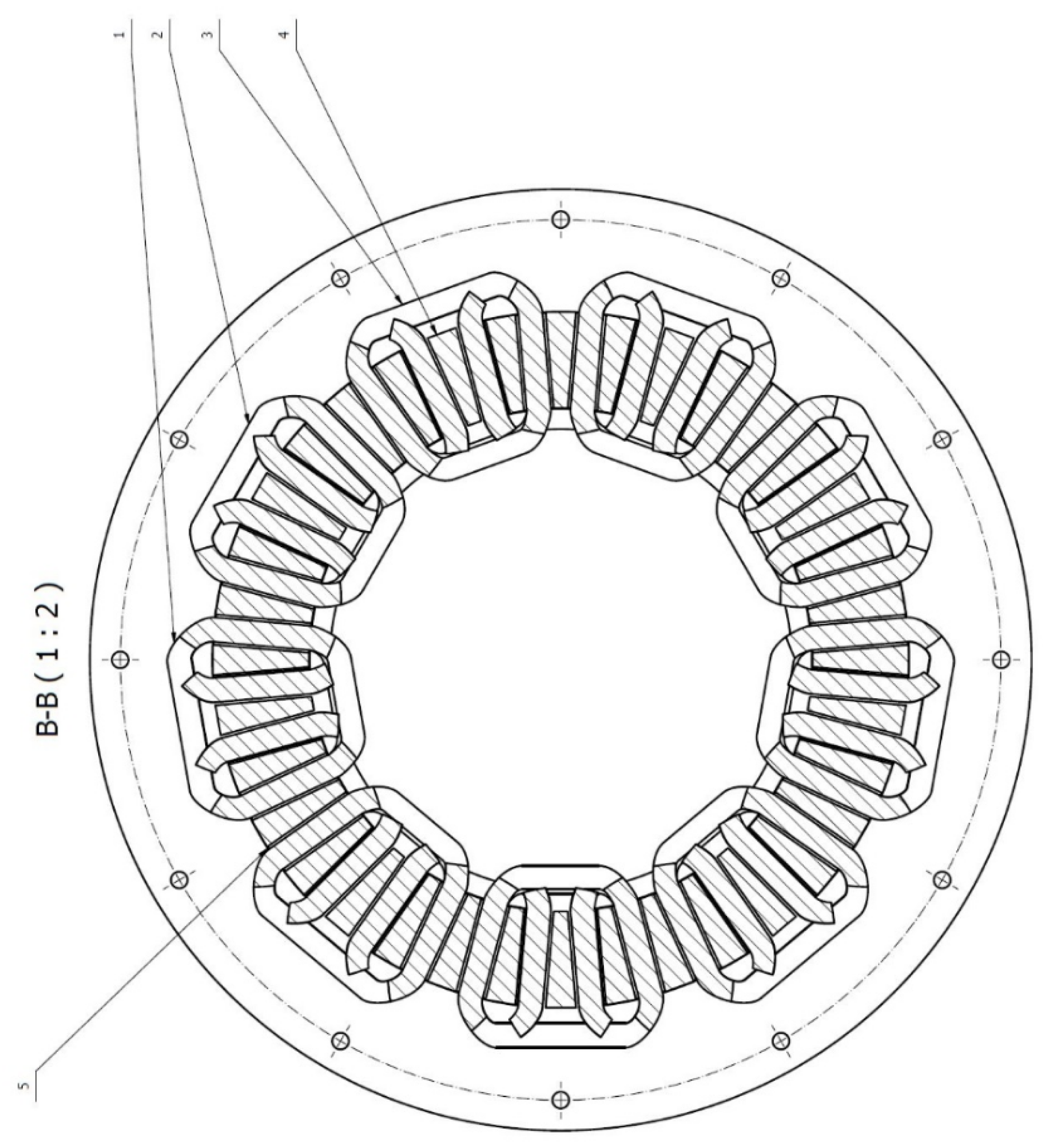

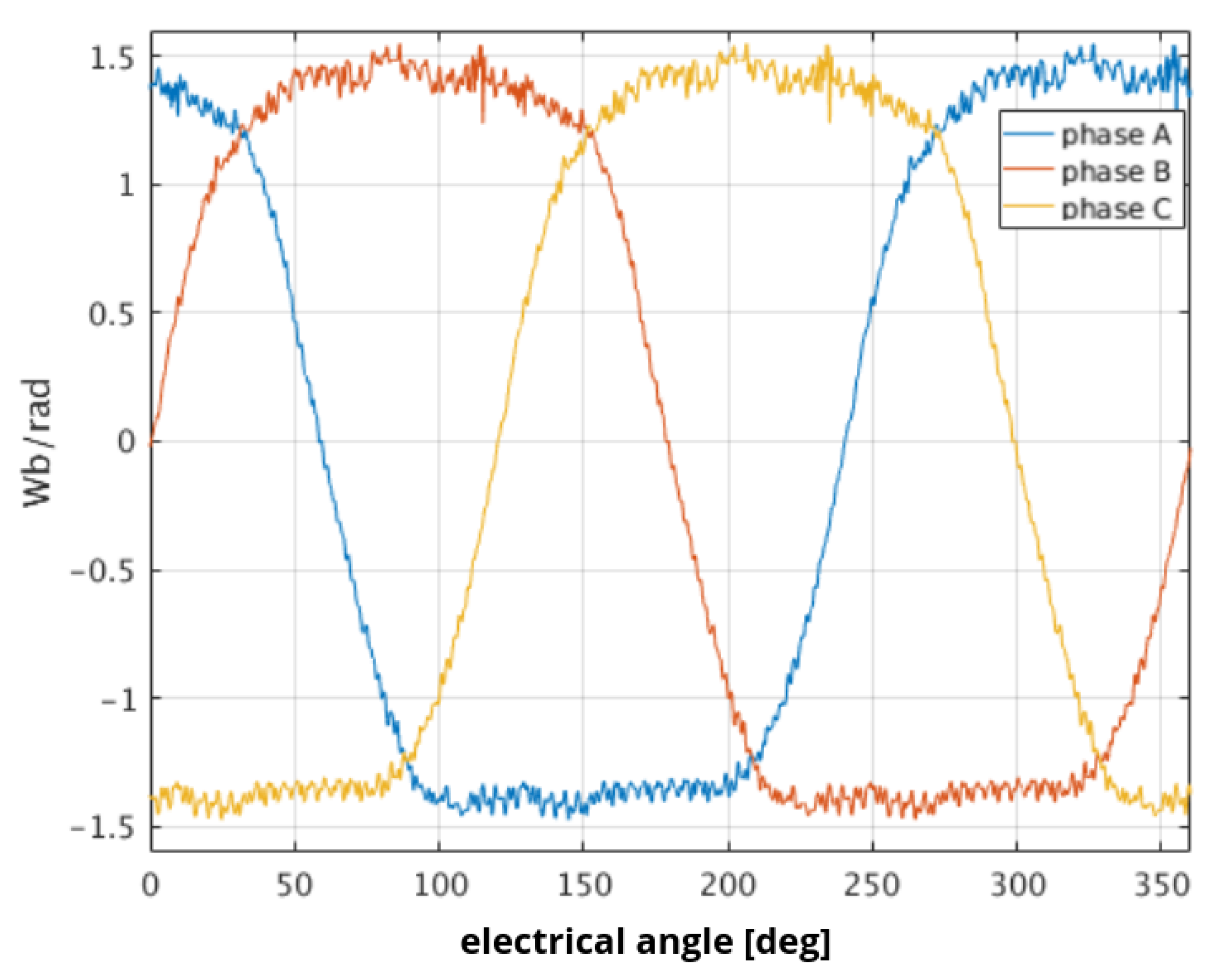

2. Proposed Machine Construction

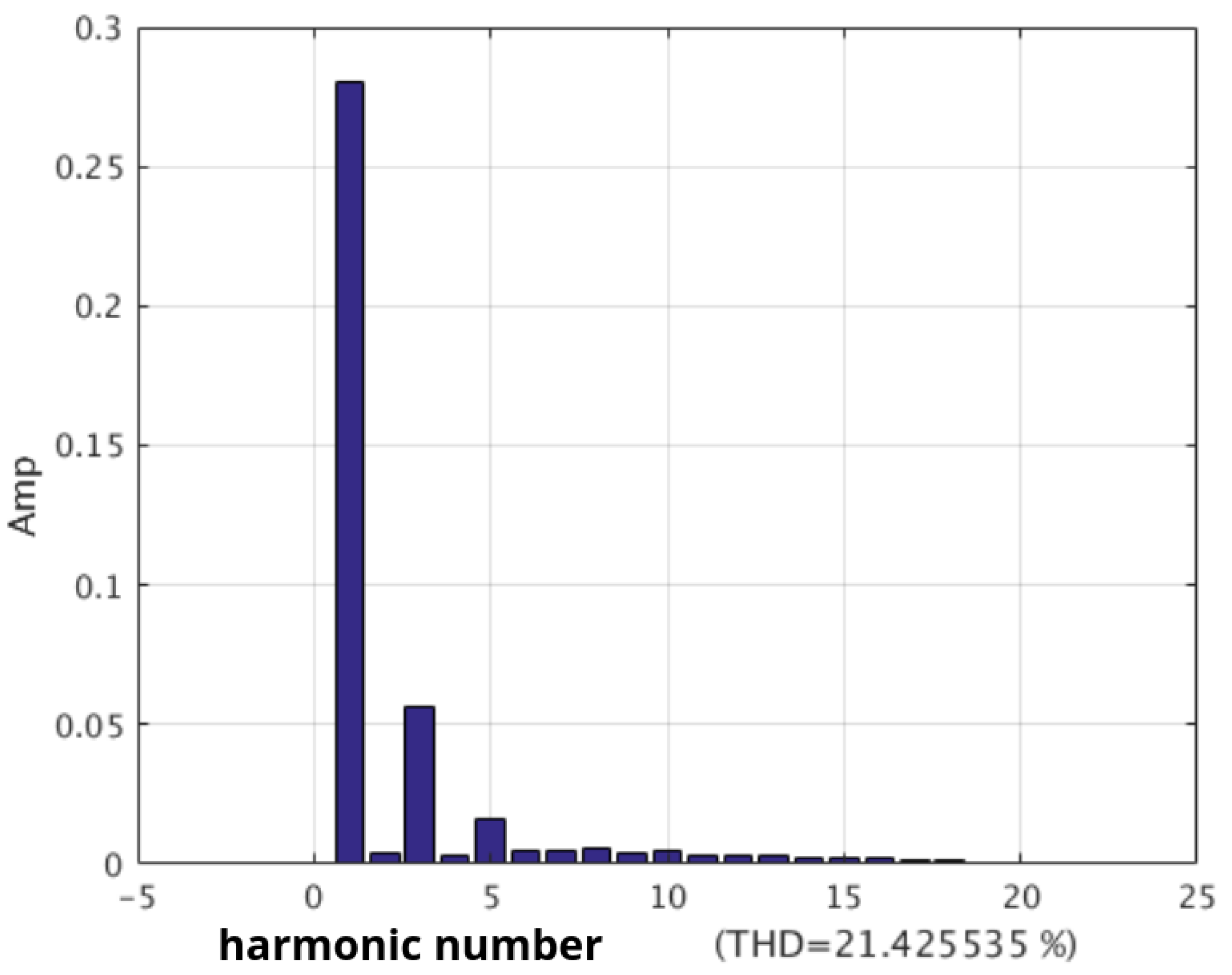

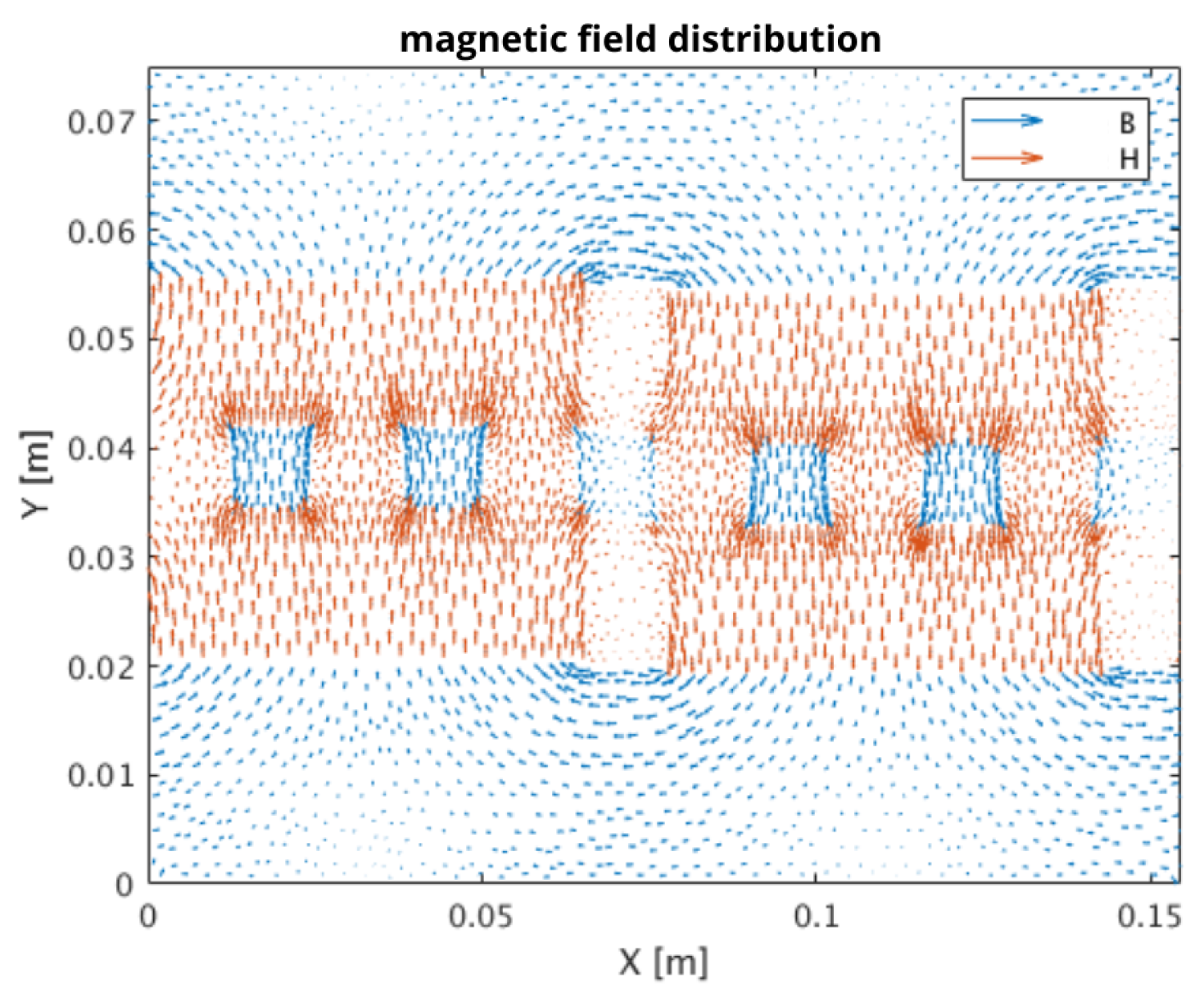

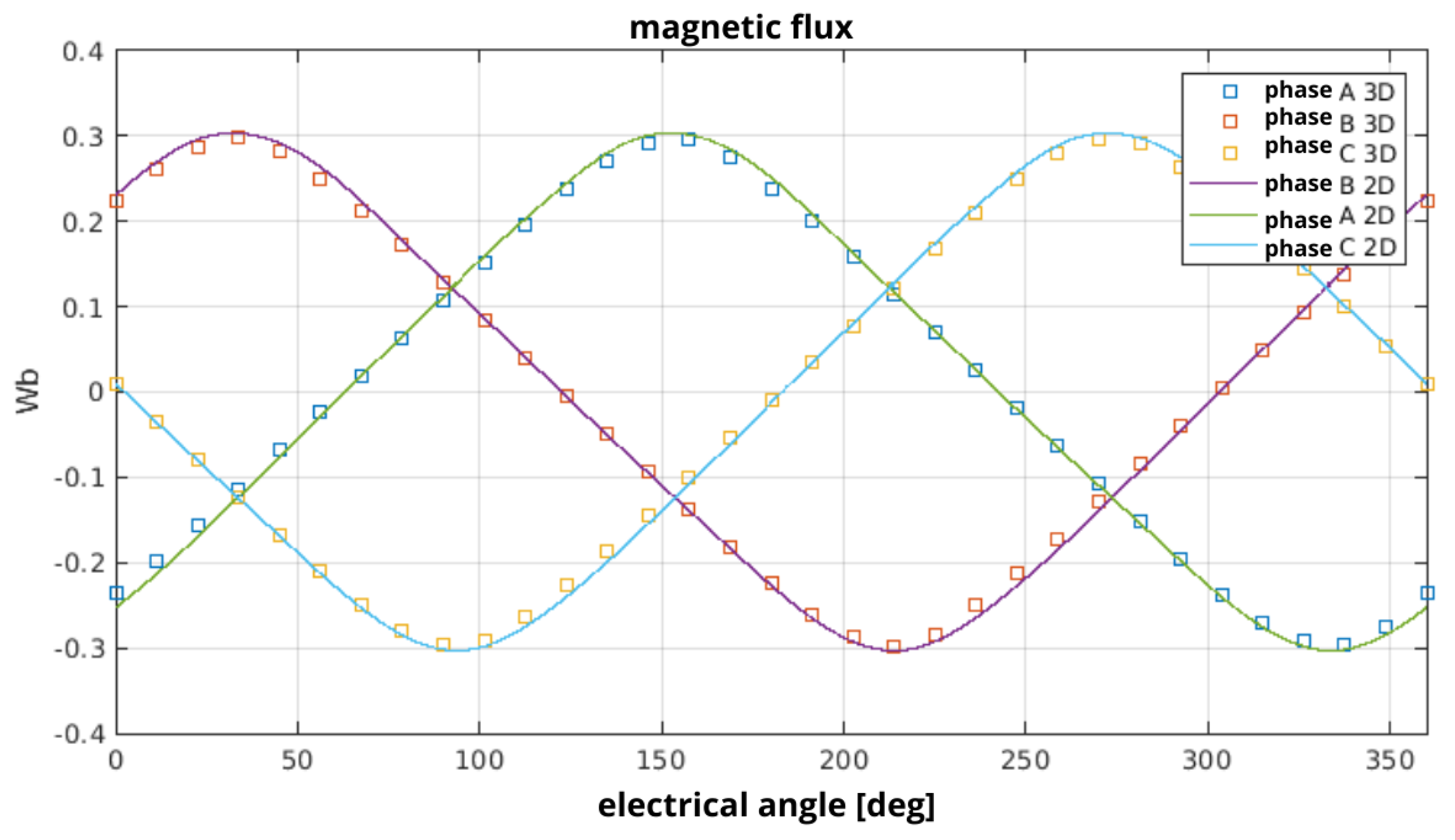

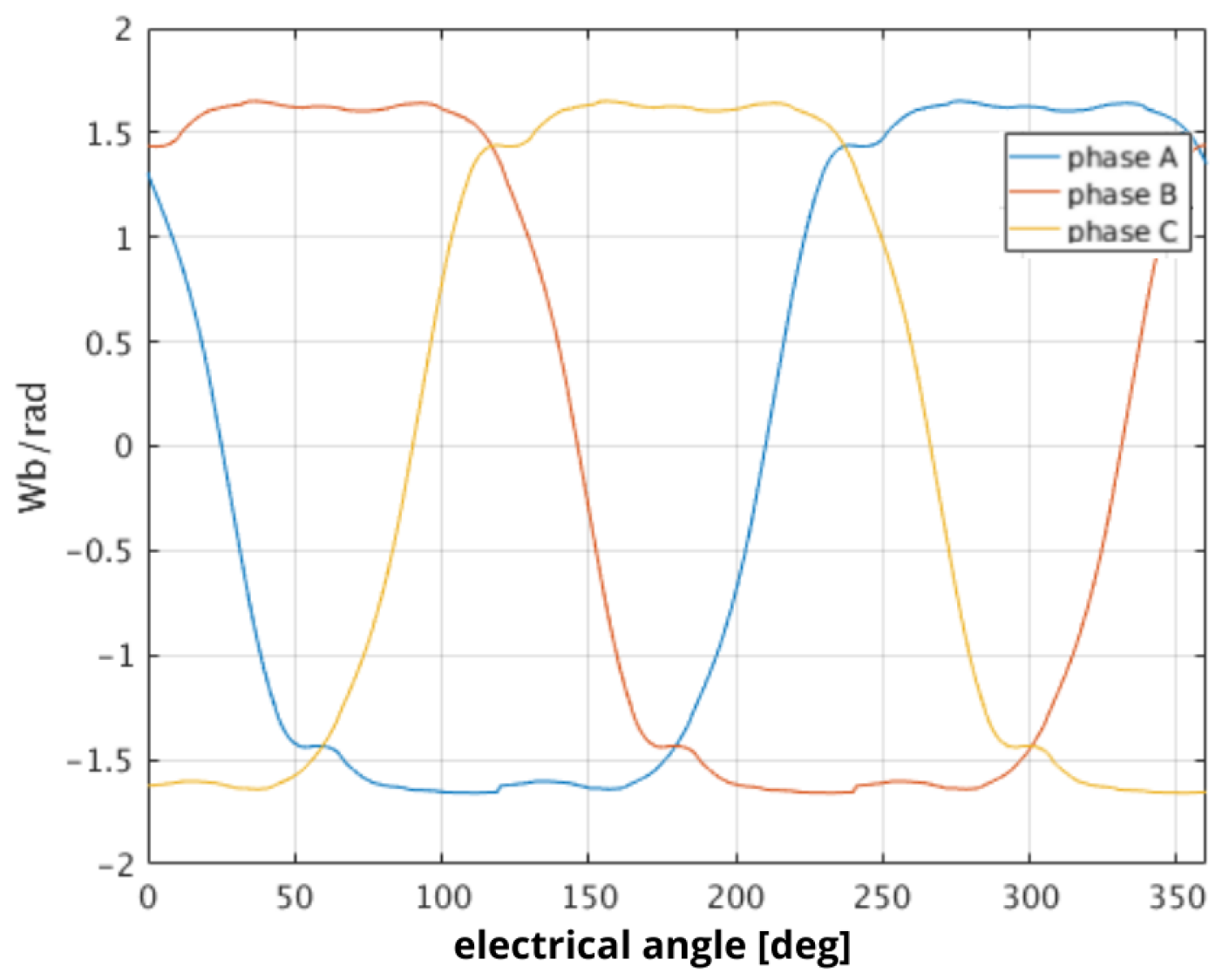

3. Selected Results of Magnetostatic MES3D Calculations

4. Validation of Results by Comparing with the Obtained Ones, Using Different Approaches

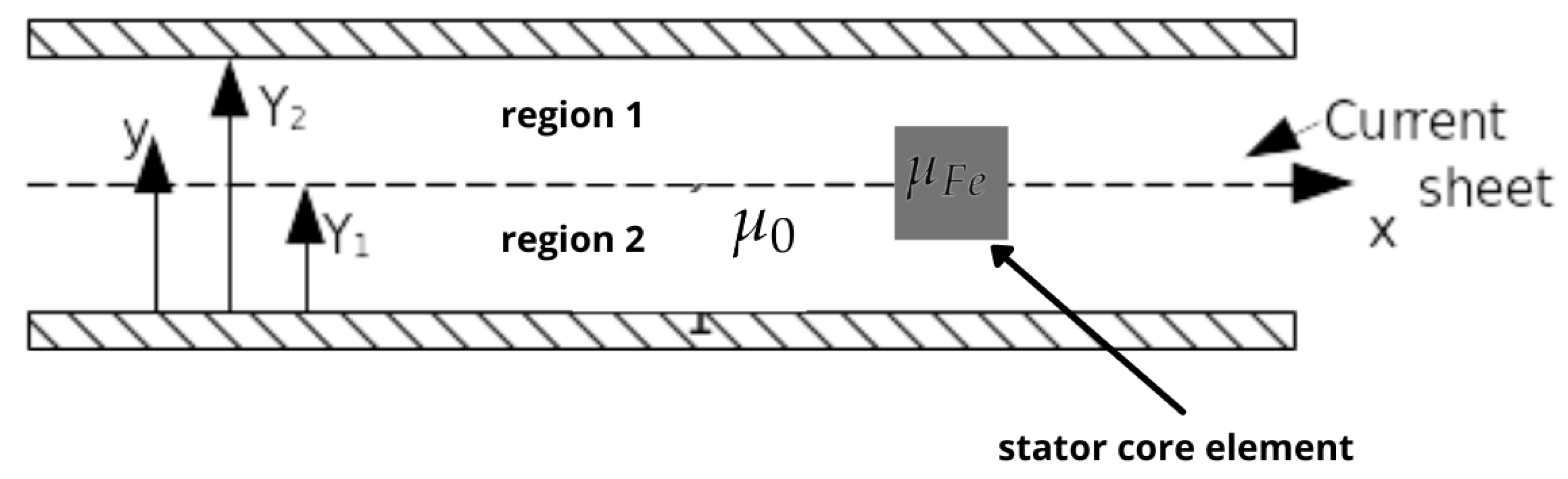

4.1. Determining Magnetic Field Distribution in the Proposed AFPM Machine with the Semi-Analytical Approach

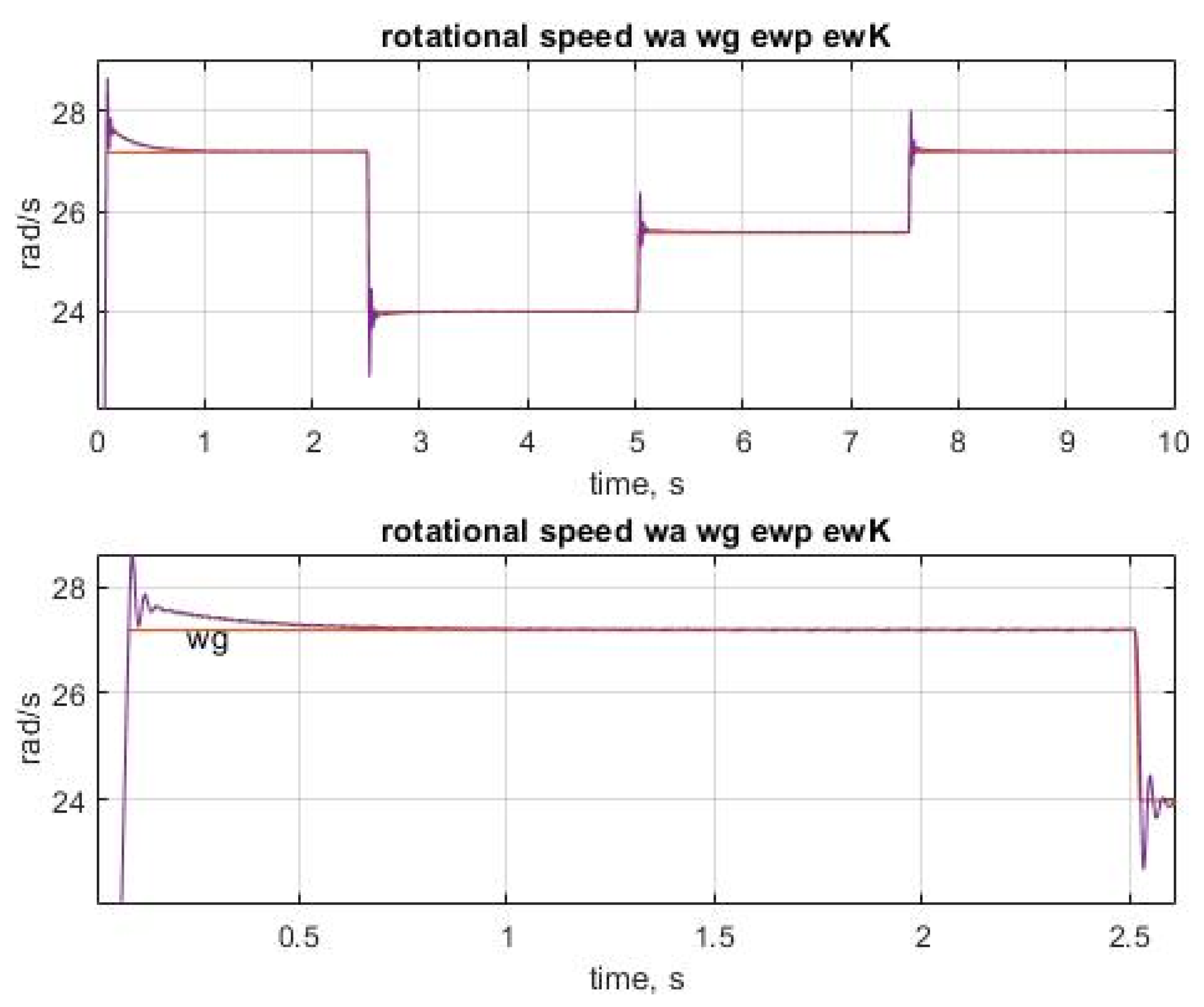

- Assume an infinitely big value of magnetic permeability for rotor plaids;

- Assume that the length at X dimension tends to infinity;

- Curvature was neglected in the model.

- denotes the location (on y dimension) of a boundary between two subdomains;

- represents the difference of magnitudes of the tangent component of the H field vector on both sites of the boundary.

4.2. Determining the Parameters of the Proposed Construction Using a Simplified 2D FEM Approach

- is a vector potential;

- is a magnetic remanence vector;

- is the phase winding current.

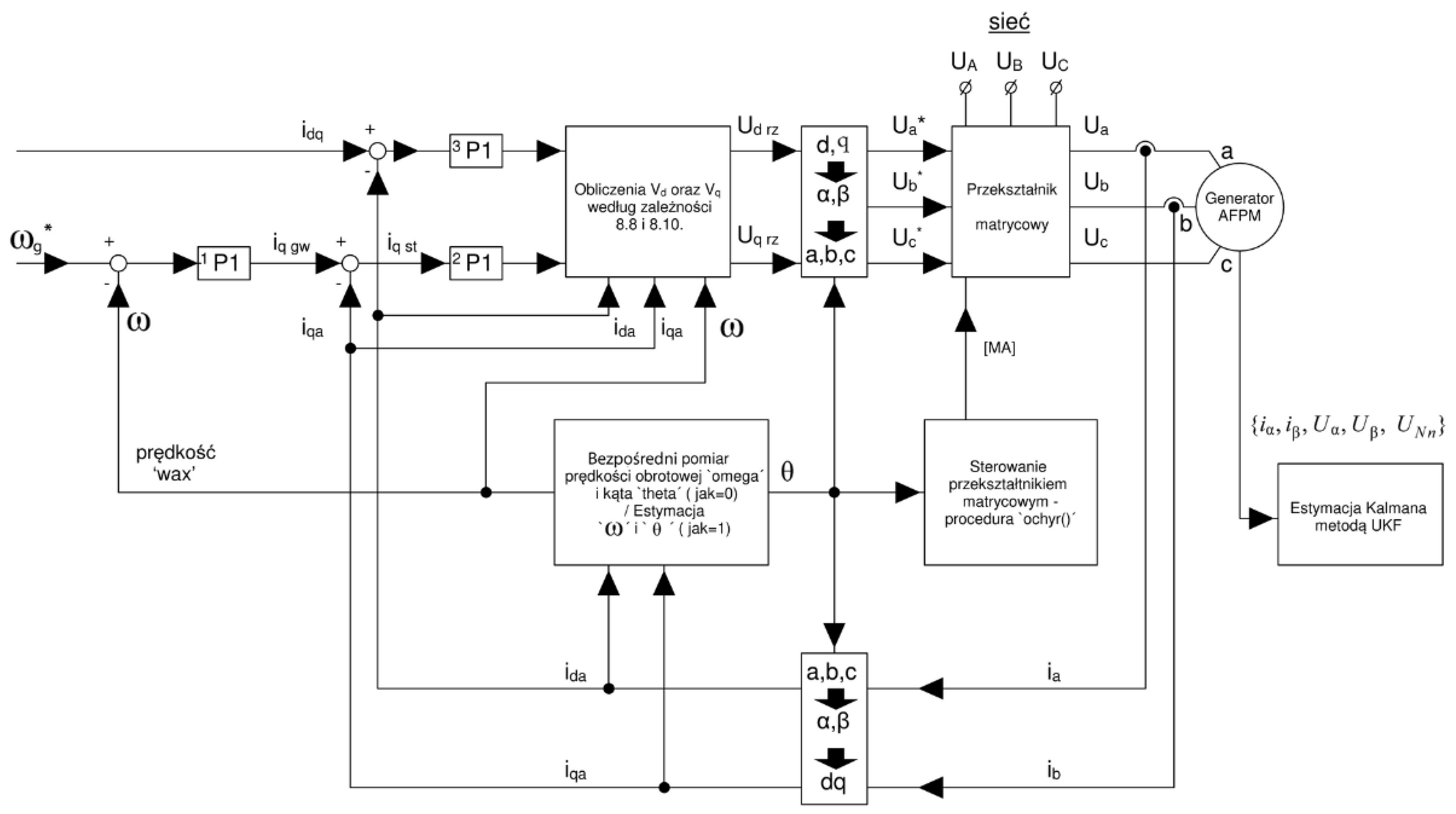

5. Brief Description of the Considered Control System

- —reference value for component d of stator current;

- —reference value for component q of stator current;

- and —proportionality coefficients;

- —instantaneous value of component d of stator current;

- —instantaneous value of component q of stator current.

6. The Proposed Method for Estimation of Rotor Rotation Angle and Speed of the Designed Machine on the Basis of the Output Voltage

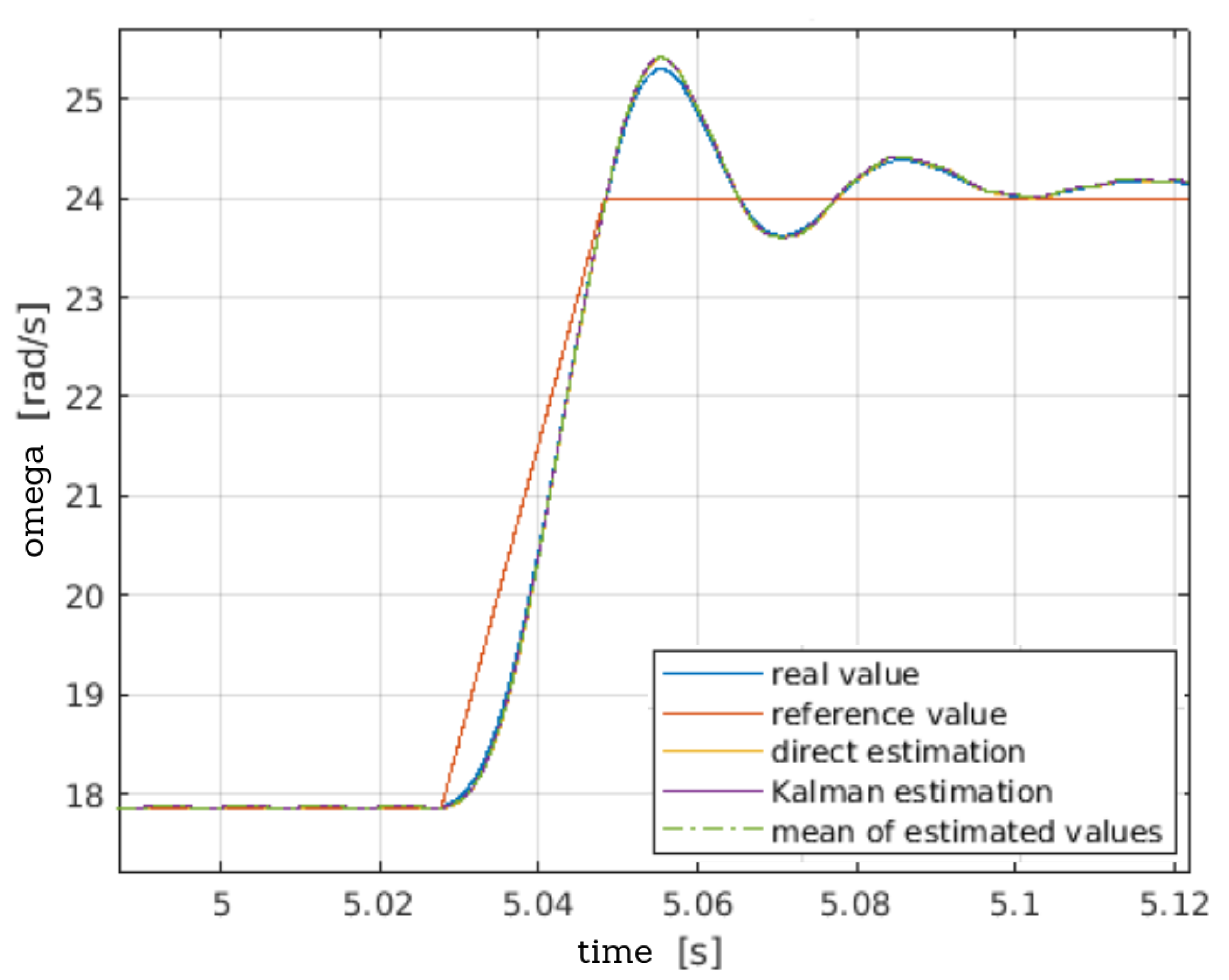

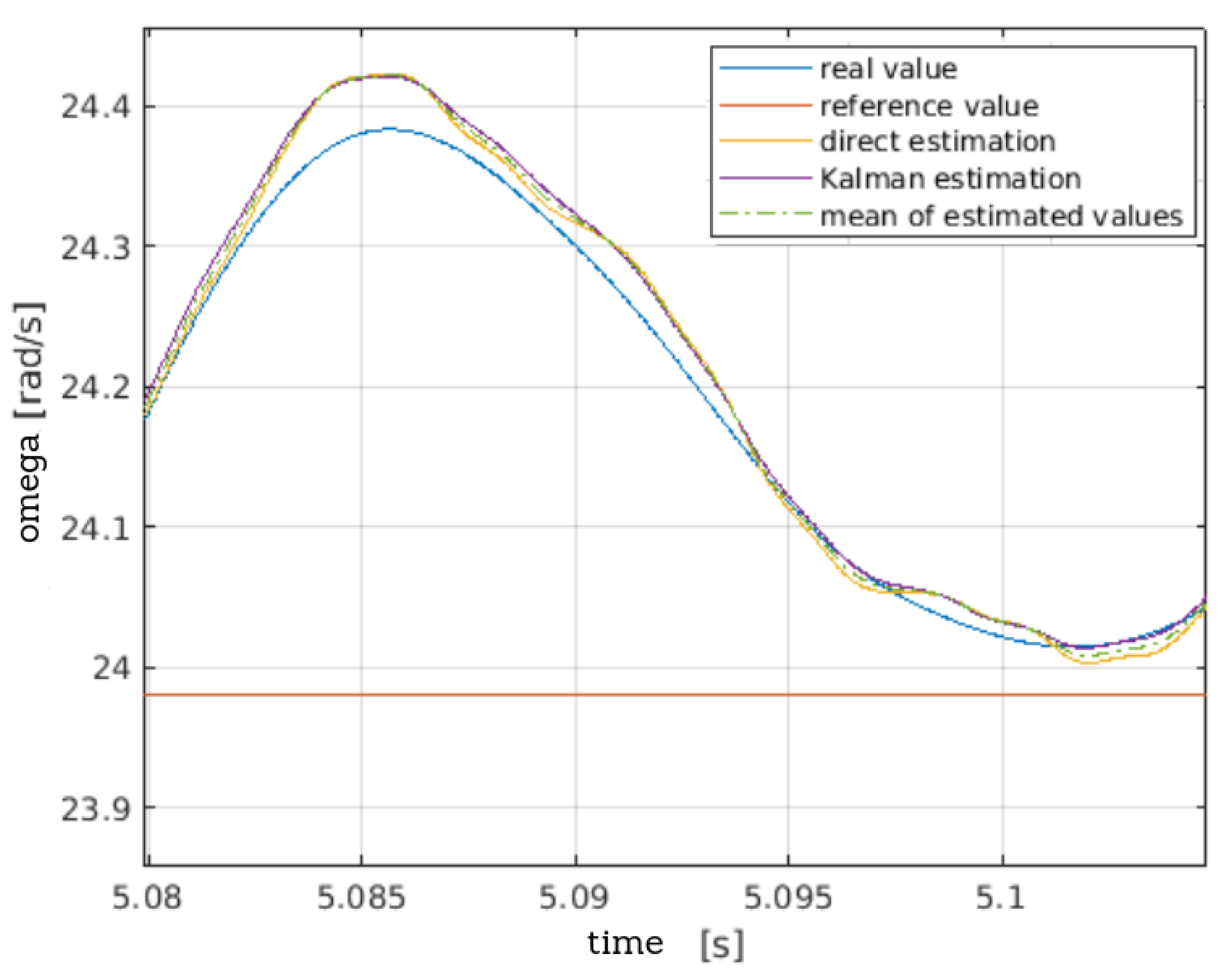

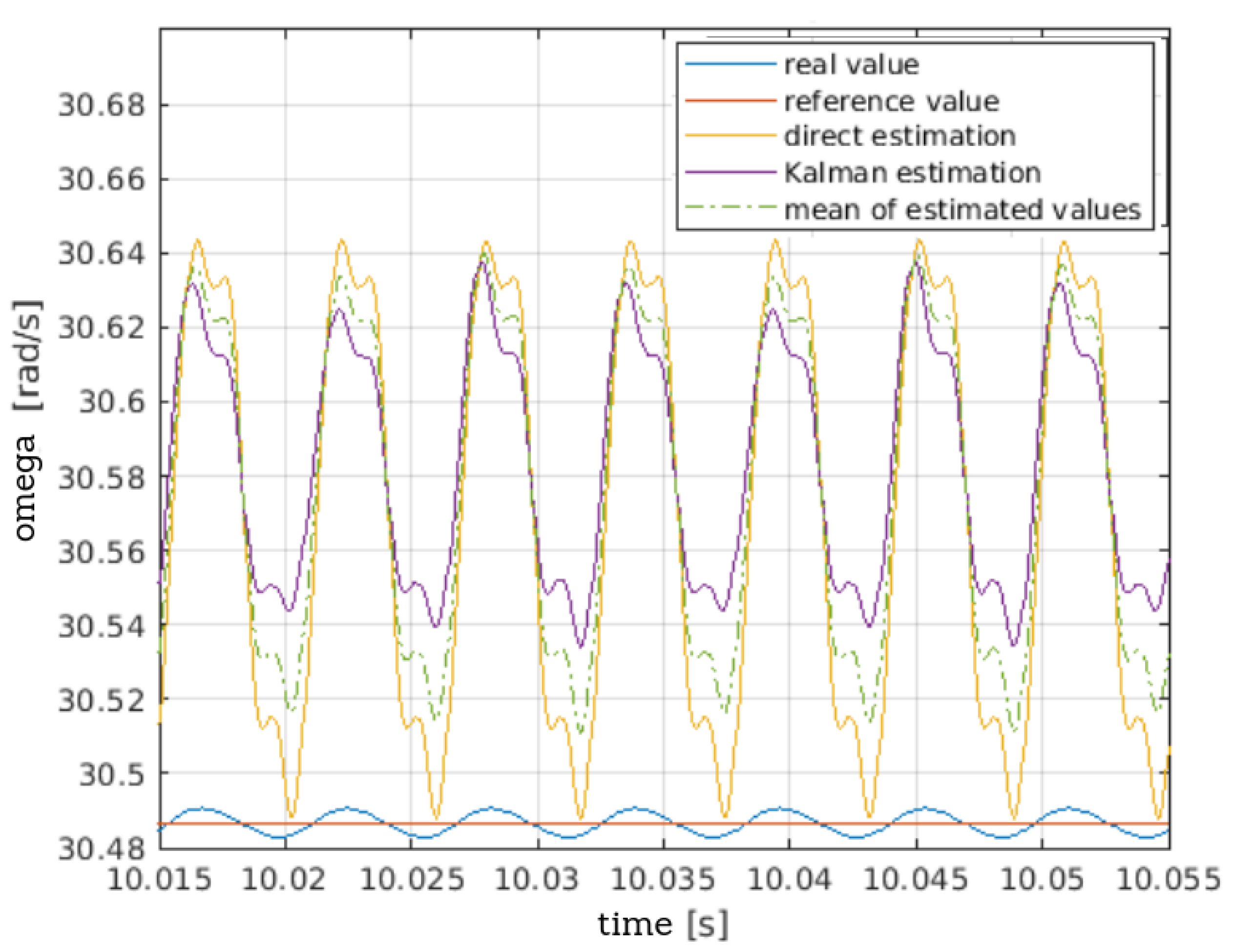

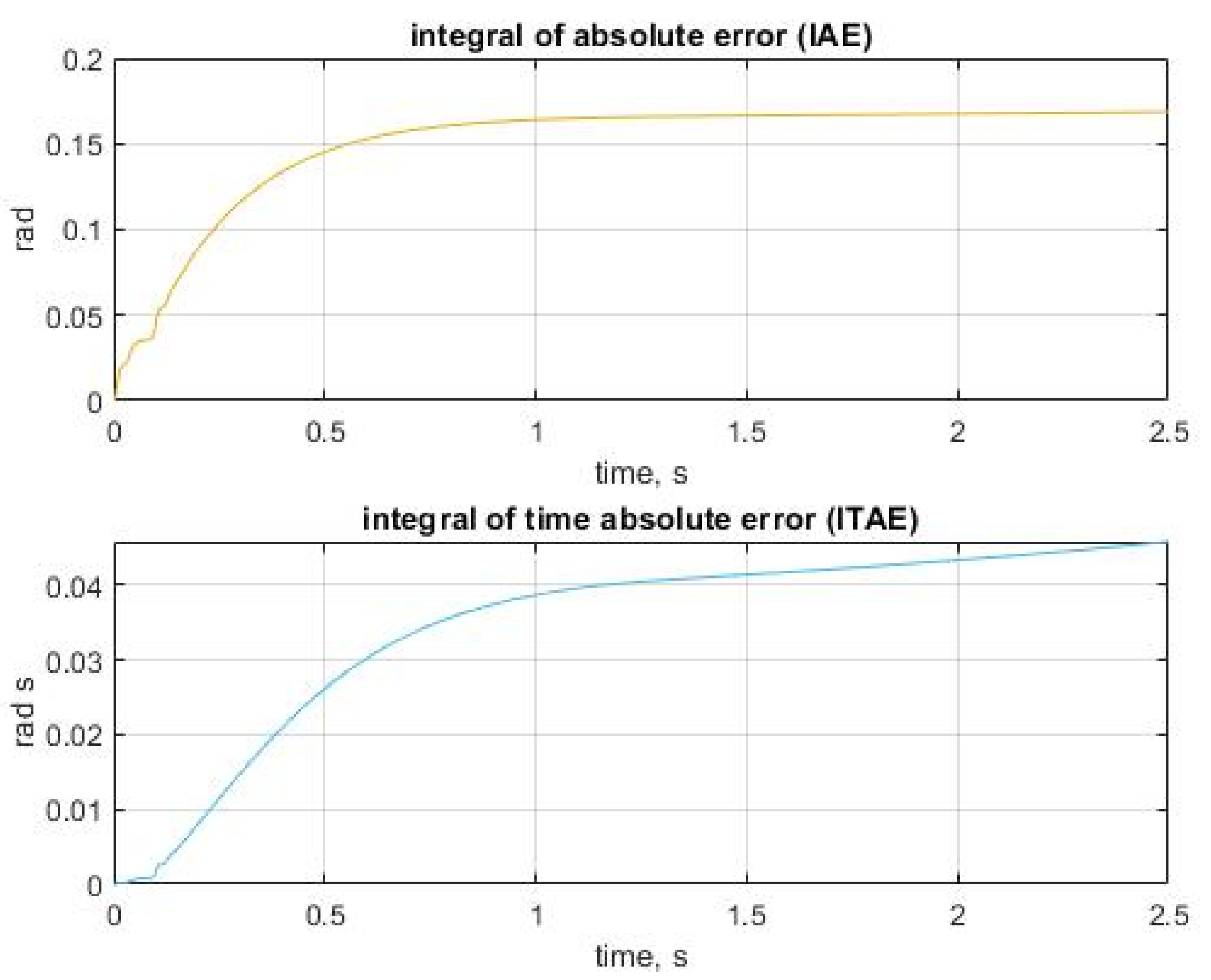

7. Results of Simulation Studies of Functioning of the Proposed Method of Generator Performance Parameter Estimation

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ferraro, L.; Caricchi, F.; Capponi, F.G.; Donato, G. Axial-flux PM starter/alternator machine with a novel mechanical device for extended flux weakening capabilities. In Proceedings of the Conference Record of the 2004 IEEE Industry Applications Conference, Seattle, WA, USA, 3–7 October 2004. [Google Scholar]

- Neveen, K.S.; Mobi, M.; Karthikeyan, N.; Hossain, J. Development of Permanent Magnet Axial Flux Generator for Small Wind Turbines. In Proceedings of the IEEE International Conference on Circuits and Systems ICCS, Thiruvananthapuram, India, 20–21 December 2017. [Google Scholar] [CrossRef]

- Yang, Y.-P.; Xing, X.-Y.; Liang, J.Y. Design and application of axial-flux permanent magnet wheel motors for an electric vehicle. In Proceedings of the IEEE International Conference Conference: AFRICON, AFRICON ’09, Nairobi, Kenya, 23–25 September 2009. [Google Scholar] [CrossRef]

- Yang, Y.P.; Lee, C.H.; Hung, P.C. Multi-objective optimal design of an axial-flux permanent-magnet wheel motor for electric scooters. IET Electr. Power Appl. 2014, 8, 1–12. [Google Scholar] [CrossRef]

- Zhao, J.; Han, Q.; Dai, Y.; Hua, M. Study on the Electromagnetic Design and Analysis of Axial Flux Permanent Magnet Synchronous Motors for Electric Vehicles. Energies 2019, 12, 3451. [Google Scholar] [CrossRef]

- Chan, T.F.; Lai, L.L. Axial Flux Permanent Magnet generator for a direct coupled wind turbine system. IEEE Trans. Energy Convers. 2007, 22, 86–94. [Google Scholar] [CrossRef]

- Rolak, M.; Kot, R.; Malinowski, M.; Goryca, Z.; Szuster, J.T. Generators with permanent magnets used in small wind power plants. In Proceedings of the 2015 Selected Problems of Electrical Engineering and Electronics (WZEE), Kielce, Poland, 17–19 September 2015. [Google Scholar] [CrossRef]

- Rolak, M.; Kot, R.; Malinowski, M.; Goryca, Z.; Szuster, J.T. Design of Small Wind Turbine with Maximum Power Point Tracking Algorithm. In Proceedings of the IEEE International Symposium on Industrial Electronics, Gdansk, Poland, 27–30 June 2011. [Google Scholar] [CrossRef]

- Pien, Y.; Shih, G.Y. Optimal Design of an Axial Flux Permanent Magnet Motor for an Electric Vehical Based on Driving Scenario. Energies 2016, 9, 285. [Google Scholar]

- Sabioni, C.L.; Riberio, M.; Vasconcelos, J.A. Robust Design of an Axial Flux Permanent Magnet Synchronous Generator Based on Many-Objective Optimization Approach. IEEE Trans. Magn. 2018, 54, 1–4. [Google Scholar] [CrossRef]

- Ojaghlu, P.; Vehedi, A. A New Axial Flux Permanet Magnet Machine. IEEE Trans. Magn. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Taran, N.; Rallabandi, V.; Ionel, D.M.; Heins, G. A Comparative Study of Coreless and Conventional Axial Flux Permanent Magnet Synchronous Machine for Low and High Speed Operation. In Proceedings of the IEEE Energy Conversion Congress and Expo (ECCE 2017), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Rahim, N.A.; Hew, W.P. Axial-flux permanent-magnet machine modeling, design, simulation and analysi. Sci. Res. Essays 2011, 6, 2525–2549. [Google Scholar]

- Gieras, F.J.; Wang, R.J.; Kampeer, M.J. Axial Flux Permanent Magnet Brushless Machines, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Huang, R.; Liu, C.; Song, Z.; Zhao, H. Design and Analysis of a Novel Axial-Radial Flux Permanent Magnet Machine with Halbach-Array Permanent Magnets. Energies 2021, 14, 3639. [Google Scholar] [CrossRef]

- Kutt, F.; Blecharz, K.; Karkosiński, D. Axial-Flux Permanent-Magnet Dual-Rotor Generator for a Counter-Rotating Wind Turbine. Energies 2020, 13, 2833. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Javadi, H.; Daghigh, A. Maximum power point tracking of a variable speed wind turbine with a coreless AFPM synchronous generator using OTC method. In Proceedings of the 8th Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Mashhad, Iran, 14–16 February 2017. [Google Scholar] [CrossRef]

- Caricchi, F.; Crescimbini, F.; Honorati, O.; Bianco, G.L.; Santini, E. Performance of coreless-winding axial-flux permanent-magnet generator with power output at 400 Hz, 3000 r/min. IEEE Trans. Ind. Appl. 1998, 34, 1263–1269. [Google Scholar] [CrossRef]

- Radwan-Pragłowska, N.; Węgiel, T.; Borkowski, D. Modeling of Axial Flux Permanent Magnet Generators. Energies 2020, 13, 5741. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, J.; Liu, T.; Hua, M. Adaptive Robust Control System for Axial Flux Permanent Magnet Synchronous Motor of Electric Medium Bus Based on Torque Optimal Distribution Method. Energies 2019, 12, 4681. [Google Scholar] [CrossRef]

- Pei, Y.; Wang, Q.; Bi, Y.; Chai, F. A Novel Structure of Axial Flux, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Tiegna, H.; Amara, Y.; Barakat, G. Study of Cogging Torque in Axial Flux Permanent Magnet Machines Using an Analytical Model. IEEE Trans. Magn. 2014, 50, 845–848. [Google Scholar] [CrossRef]

- Barmpatza, A.C.; Kappatou, J.C. Study of a Combined Demagnetization and Eccentricity Fault in an AFPM Synchronous Generator. Energies 2020, 13, 5609. [Google Scholar] [CrossRef]

- Sagar, S.V.; Joseph, K.D. Speed Estimation Algorithms for Sensorless Control of PMSM. In Proceedings of the International Mutli-Conference on Automation, Computing, Communication, Control and Compressed Sensing (iMac4s), Kottayam, Kerala, India, 22–23 February 2013. [Google Scholar] [CrossRef]

- Chen, G.; Yang, S.; Hsu, Y.; Li, K. Position and Speed Estimation of Permanent Magnet Machine Sensorless Drive at High Speed Using an Improved Phase-Locked Loop. Energies 2017, 10, 1571. [Google Scholar] [CrossRef]

- Yousfi, D.; Darkawi, A. Comparison of two Position and Speed Estimation Techniques used in PMSM Sensorless Vector Control. In Proceedings of the 4th IET Conference on Power Electronics, Machines and Drives, PEMD 2008, York, UK, 2–4 April 2008. [Google Scholar] [CrossRef]

- Badini, S.S.; Verma, V. MRAS-Based Speed and Parameter Estimation for a Vector Controlled PMSM Drive. Electrica 2020, 20, 28–40. [Google Scholar] [CrossRef]

- Liu, H.; Li, G. Rotor Position and Speed Estimation Method for Magnetically Suspended PMSM Based on Modified Sliding Mode Observer. In Proceedings of the International Conference on Mechatronics, Control and Automation Engineering (MCAE), Bangkok, Thailand, 24–25 July 2016. [Google Scholar] [CrossRef]

- Hijazi, A.; Sidhom, L.; Zgorski, A.; Shi, X.L. On speed estimation of permanent magnet synchronous motor using adaptive robust position observer and differentiator. In Proceedings of the 11th IFAC International Workshop on Adaptation and Learning in Control and Signal Processing (11 IFAC), Caen, France, 3–5 July 2013. [Google Scholar] [CrossRef]

- Sathans, O.M. Sliding-mode observer for estimating position and speed and minimizing ripples in rotor parameters of PMSM. In Proceedings of the 2nd International Conference on Inventive Systems and Control (ICISC), Coimbatore, India, 19–20 January 2018. [Google Scholar] [CrossRef]

- Białoń, T.; Niestrój, R.; Pasko, M.; Lewicki, A. Gains selection of non-proportional observers of an induction motor with dyadic methods. In Proceedings of the 13th Selected Issues of Electrical Engineering and Electronics (WZEE), Rzeszow, Poland, 4–8 May 2016. [Google Scholar] [CrossRef]

- Utrata, G.; Rolek, J.; Kapłon, A. Induction motor electromechanical quantities estimation based on the inductance frequency characteristic—Simulation studies. In Proceedings of the 16th International Conference on Computational Problems of Electrical Engineering, Lviv, Ukraine, 2–5 September 2015. [Google Scholar] [CrossRef]

- Gołębiowski, M.; Gołębiowski, L.; Smoleń, A.; Mazur, D. Direct Consideration of Eddy Current Losses in Laminated Magnetic Cores in Finite Element Method (FEM) Calculations Using the Laplace Transform. Energies 2020, 13, 1174. [Google Scholar] [CrossRef]

- Credo, A.; Tursini, M.; Villani, M.; Lodovico, C.D.; Orlando, M.; Frattari, F. Axial Flux PM In-Wheel Motor for Electric Vehicles: 3D Multiphysics Analysis. Energies 2021, 14, 2107. [Google Scholar] [CrossRef]

- Bumby, J.R.; Martin, R.; Mueller, M.A.; Spooner, E.; Brown, N.L.; Chalmers, B.J. Electromagnetic design of axial-flux permanent magnet machines. IEE Proc.-Electr. Power Appl. 2004, 151, 151–160. [Google Scholar] [CrossRef]

- Gołębiowski, L.; Gołębiowski, M.; Mazur, D.; Smoleń, A. Analysis of axial flux permanent magnet generator. COMPEL Int. J. Comput. Math. Electr. 2019, 38. [Google Scholar] [CrossRef]

- Smoleń, A.; Gołębiowski, M. Computationally efficient method for determining the most important electrical parameters of axial field permanent magnet machine. Biulletin Pol. Acad. Sci. Tech. Sci. 2018, 66, 947–959. [Google Scholar]

- Smoleń, A.; Gołębiowski, L.; Gołębiowski, M.; Mazur, D. Computationally Efficient Method of Co-Energy Calculation for Transverse Flux Machine Based on Poisson Equation in 2D. Energies 2019, 12, 4340. [Google Scholar] [CrossRef]

- Zbranek, P.; Vesely, L. Nonlinear state estimation using interval computation in PMSM state observer simulation. In Proceedings of the International Conference on Autonomous and Intelligent Systems, AIS, Povoa de Varzim, Portugal, 21–23 June 2010. [Google Scholar] [CrossRef]

- Li, X.; Li, S. Extended state observer based adaptive control scheme for PMSM system. In Proceedings of the Proceedings of the 33rd Chinese Control Conferences, Nanjing, China, 28–30 July 2014. [Google Scholar] [CrossRef]

- Drabek, T.; Matras, A.; Skwarczyński, J. Analytical calculation of simulation of permanent magnet synchronous machine. Przegląd Elektrotechniczny 2009, 85, 9–12. [Google Scholar]

- Li, H.; Wang, Z. Sensorless Control for PMSM Drives Using the Cubature Kalman Filter based Speed and Flux Observer. In Proceedings of the IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles and International Transportation Electrification Conference (ESARS-ITEC), Nottingham, UK, 7–9 November 2018. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, Y.; Fadel, M.; Xi, X. A Rotor Speed and Load Torque Observer for PMSM Based on Extended Kalman Filter. In Proceedings of the IEEE International Conference on Industrial Technology, Mumbai, India, 15–17 December 2006. [Google Scholar] [CrossRef]

- Chen, H.; Liu, B.; Qu, Y.; Zhou, X. Low speed control for PMSM based on reduced-order adaptive Kalman filter. In Proceedings of the 33rd Chinese Control Conference, Nanjing, China, 28–30 July 2014. [Google Scholar] [CrossRef]

- Gao, T.; Yang, Y.; Wang, J.; Zhou, Y.R.; Zhao, X.P. Rotor Position Estimation of Sensorless PMSM Based on Extented Kalman Filter. In Proceedings of the IEEE International Conference on Mechatronics, Robotics and Automation (ICMRA), Hefei, China, 18–21 May 2018. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Rotor disc | ||

| Disc outside diameter | 465 | mm |

| Bottom disc inside diameter | 240 | mm |

| Upper disc inside diameter | 71 | mm |

| Disc thickness | 10 | mm |

| Distance between the discs (axial) | 31 | mm |

| Material | steel s235 | [-] |

| Permanent magnets | ||

| Inside radius | 124 | mm |

| Outside radius | 172 | mm |

| Groove angle | mm | |

| Thickness | 10 | mm |

| Distance between magnets (axial) | 15 | mm |

| Distribution radius | 101 | mm |

| Induced remanence | 1.19 | T |

| Coercion intensity i | 1.19 | T |

| Relative magnetic permeability | 1.0922 | [-] |

| Stator coils | ||

| Length in the radial direction | 89.8 | mm |

| Distribution radius | 101.7 | mm |

| Number of windings | 64 | [-] |

| Coil wire cross section | 1.2 | mm |

| Estimated length of the coil wire | 12.33 | m |

| The length of coil active part | 47.6 | mm |

| Winding cross-section | ||

| Width | 12 | mm |

| Height | 8 | mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smoleń, A.; Gołębiowski, L.; Gołębiowski, M. Innovative Construction of the AFPM-Type Electric Machine and the Method for Estimation of Its Performance Parameters on the Basis of the Induction Voltage Shape. Energies 2022, 15, 236. https://doi.org/10.3390/en15010236

Smoleń A, Gołębiowski L, Gołębiowski M. Innovative Construction of the AFPM-Type Electric Machine and the Method for Estimation of Its Performance Parameters on the Basis of the Induction Voltage Shape. Energies. 2022; 15(1):236. https://doi.org/10.3390/en15010236

Chicago/Turabian StyleSmoleń, Andrzej, Lesław Gołębiowski, and Marek Gołębiowski. 2022. "Innovative Construction of the AFPM-Type Electric Machine and the Method for Estimation of Its Performance Parameters on the Basis of the Induction Voltage Shape" Energies 15, no. 1: 236. https://doi.org/10.3390/en15010236

APA StyleSmoleń, A., Gołębiowski, L., & Gołębiowski, M. (2022). Innovative Construction of the AFPM-Type Electric Machine and the Method for Estimation of Its Performance Parameters on the Basis of the Induction Voltage Shape. Energies, 15(1), 236. https://doi.org/10.3390/en15010236