Direct-Contact Air, Gravel, Ground Heat Exchanger in Air Treatment Systems for Cowshed Air Conditioning

Abstract

:1. Introduction

1.1. Reasons for Raising the Issue

1.2. The Air Direct-Contact, Gravel, Ground Heat Exchanger (GAHE)

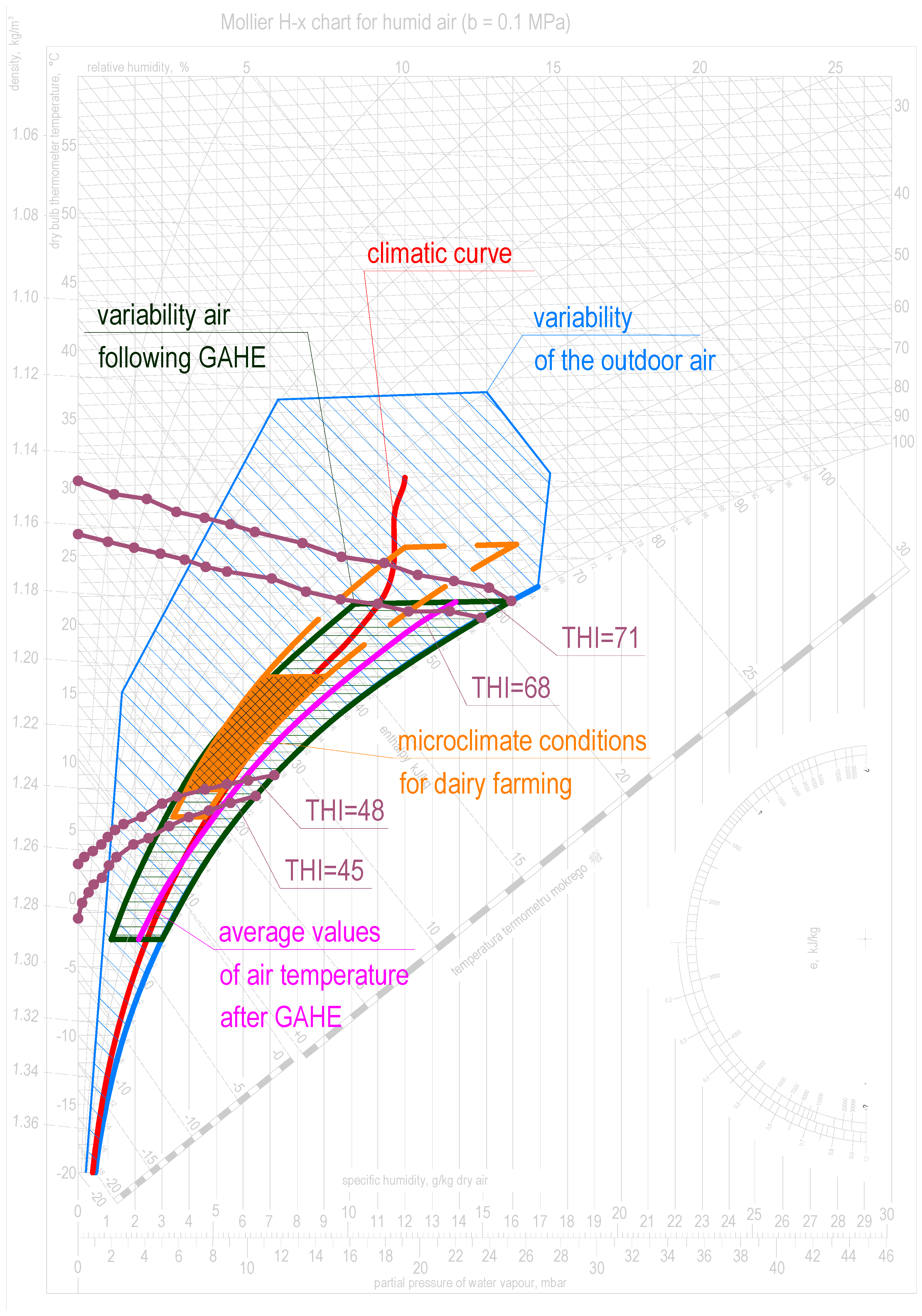

1.3. Required Air Parameters for Cowshed

1.4. Temperature Stress on Dairy Cows

- panting with an increased respiration score (open-mouthed breathing),

- reduced feed intake,

- lethargy,

- increased sweating,

- rise in rectal temperature,

- reduced heart rate,

- decreased feed intake,

- increase water intake,

- drop in daily milk production,

- restlessness.

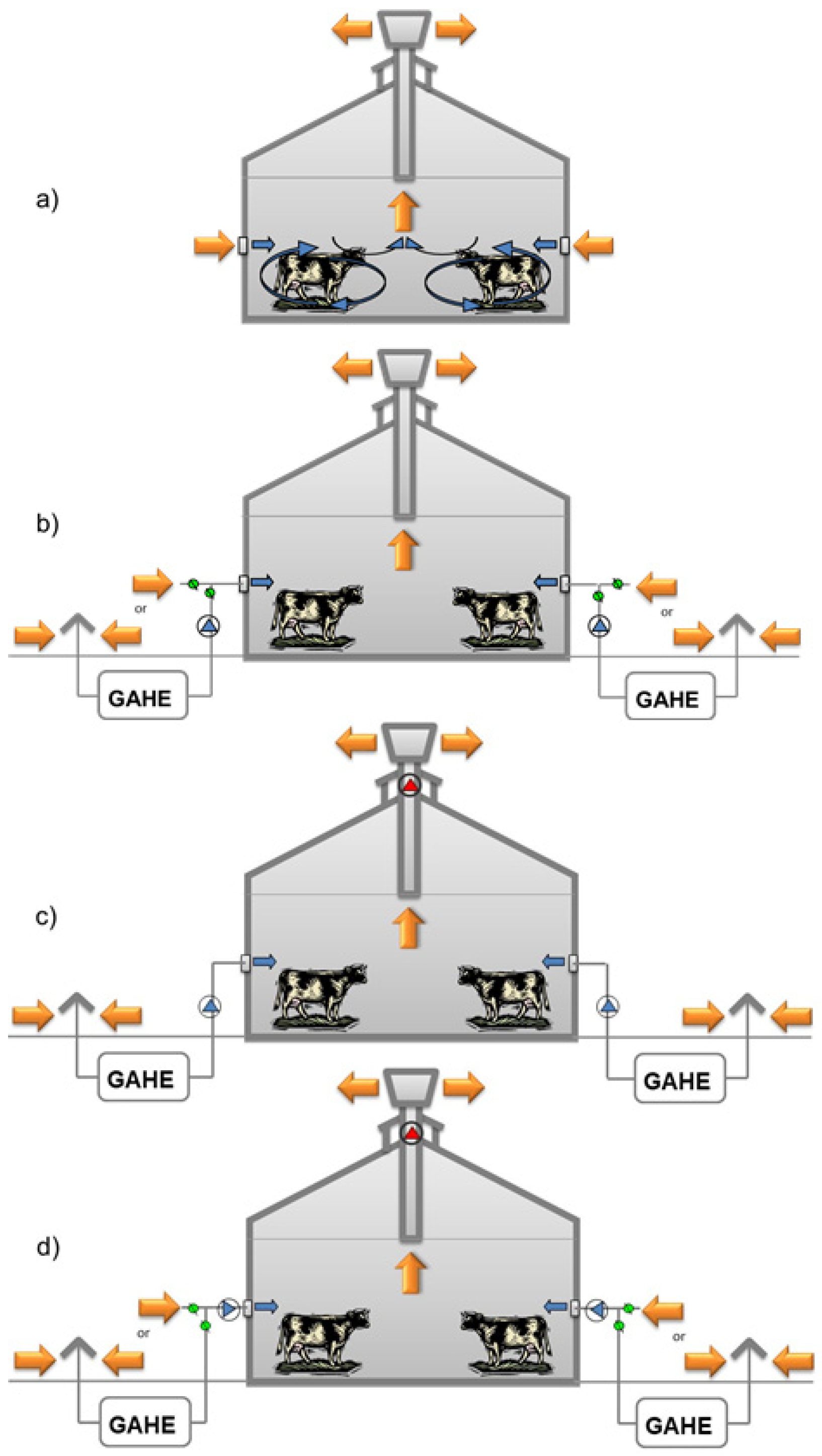

1.5. Solution Idea

1.6. Research Gap and the Aims of the Paper

- determining the possibility of using a ground heat exchanger to provide microclimate parameters in a cowshed;

- determination of the influence of the type of ventilation and assumed air flows on microclimate;

- determining the areas of reasonable application of the analyzed solution.

1.7. Novelty of the Work

- application in a barn of modern design,

- application for shaping the microclimate of a cowshed,

- supported ventilation performance compared to an installation without GAHE,

- supported ventilation-control-regiments proposal for the cowsheds.

2. Materials and Methods

2.1. Analysis

2.2. Assumptions

2.2.1. Total Dairy-Cow Heat Production

2.2.2. Sensible Dairy-Cow Heat Production

2.2.3. Creation of EDSL TAS “Internal Condition” for GAHE

2.3. Options Considered and Research Route

- External conditions—the cows are kept outside, Polish second climate zone.

- Typical case—ventilation air volume at external air temperatures lower than 0 °C set at 90 m3/cow/h, ventilation air volume at external air temperatures higher than 0 °C set at 350 m3/cow/h.

- Typical case with GAHE—air supplied through GAHE, ventilation air volume at external air temperatures lower than 0 °C set to 90 m3/cow/h, and ventilation air volume at external air temperatures higher than 0 °C set to 350 m3/cow/h.

- GAHE, daily average, 0 °C—air supplied through GAHE, ventilation air volume at daily average external air temperatures lower than 0 °C set at 90 m3/cow/h, and ventilation air volume at daily average external air temperatures higher than 0 °C set at 350 m3/cow/h, setting the mode of operation for the next 24 h at 6 a.m.—after morning milking.

- GAHE, daily average, 6/8 °C—air supplied through GAHE, ventilation air volume at daily average external air temperatures lower than 6 °C, throughout the year, 90 m3/cow/h, and ventilation air volume at daily average external air temperatures higher than 8 °C set at 350 m3/cow/h, setting the mode of operation for the next 24 h at 6 a.m.—after morning milking.

- GAHE, throughout the year, 90 m3/cow/h—air supplied through the GAHE, and ventilation air volume set to a constant value of 90 m3/cow/h throughout the year.

- GAHE, throughout the year, 350 m3/cow/h—air supplied through GAHE, and ventilation air volume set to constant value of 350 m3/cow/h throughout the year.

- GAHE, throughout the year, 180 m3/cow/h—air supplied through the GAHE, and ventilation air volume set to a constant value of 180 m3/cow/h throughout the year.

- GAHE, throughout the year, 270 m3/cow/h—air supplied through the GAHE, and ventilation air volume set to constant value of 270 m3/cow/h throughout the year.

- GAHE, daily average, 6/8 °C, 180/270 m3/cow/h—air supplied through GAHE, ventilation air volume at daily average external air temperatures lower than 6 °C set to 180 m3/cow/h, and ventilation air volume at daily average external air temperatures higher than 8 °C set to 270 m3/cow/h, setting the mode of operation for the next 24 h at 6 a.m.—after morning milking.

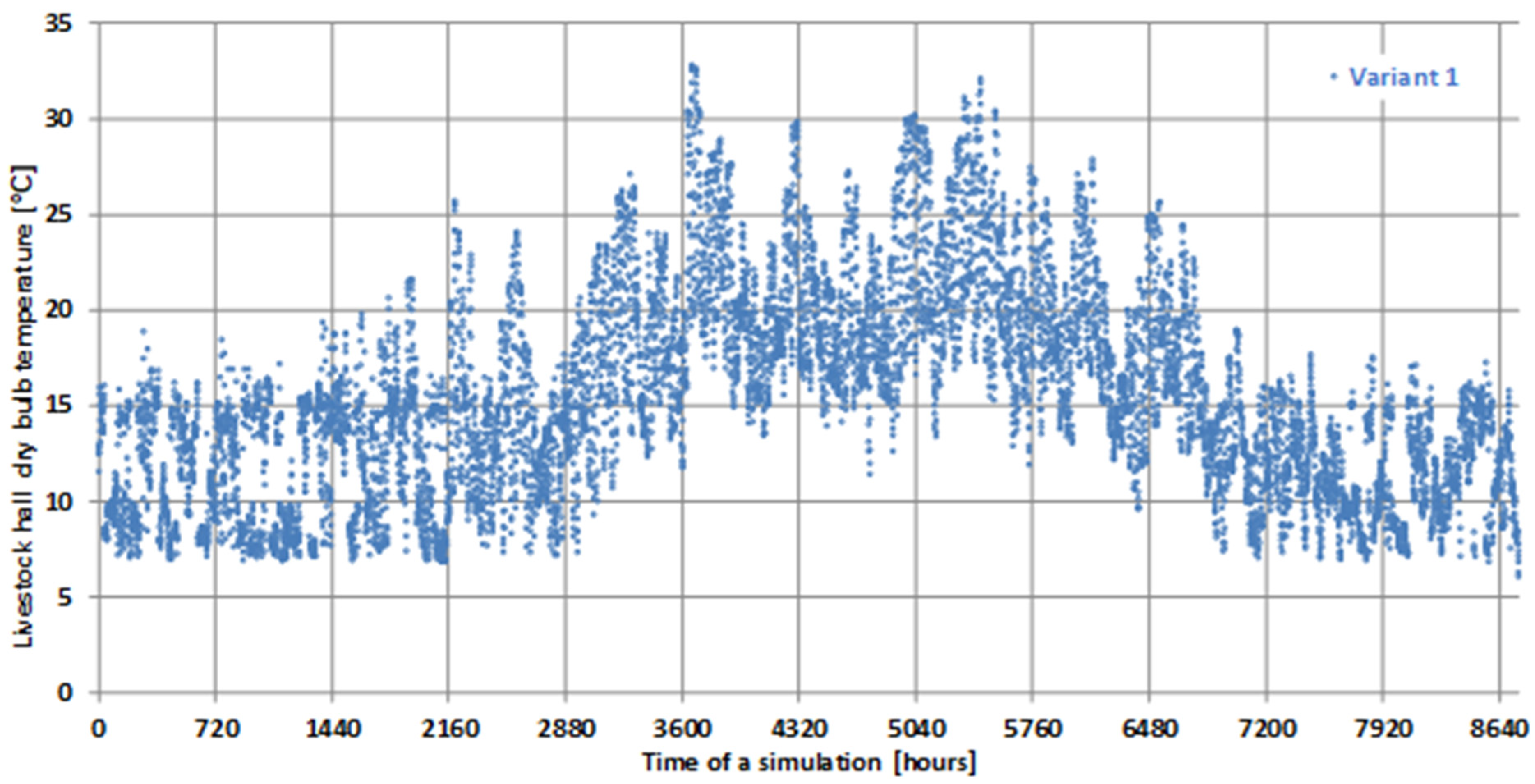

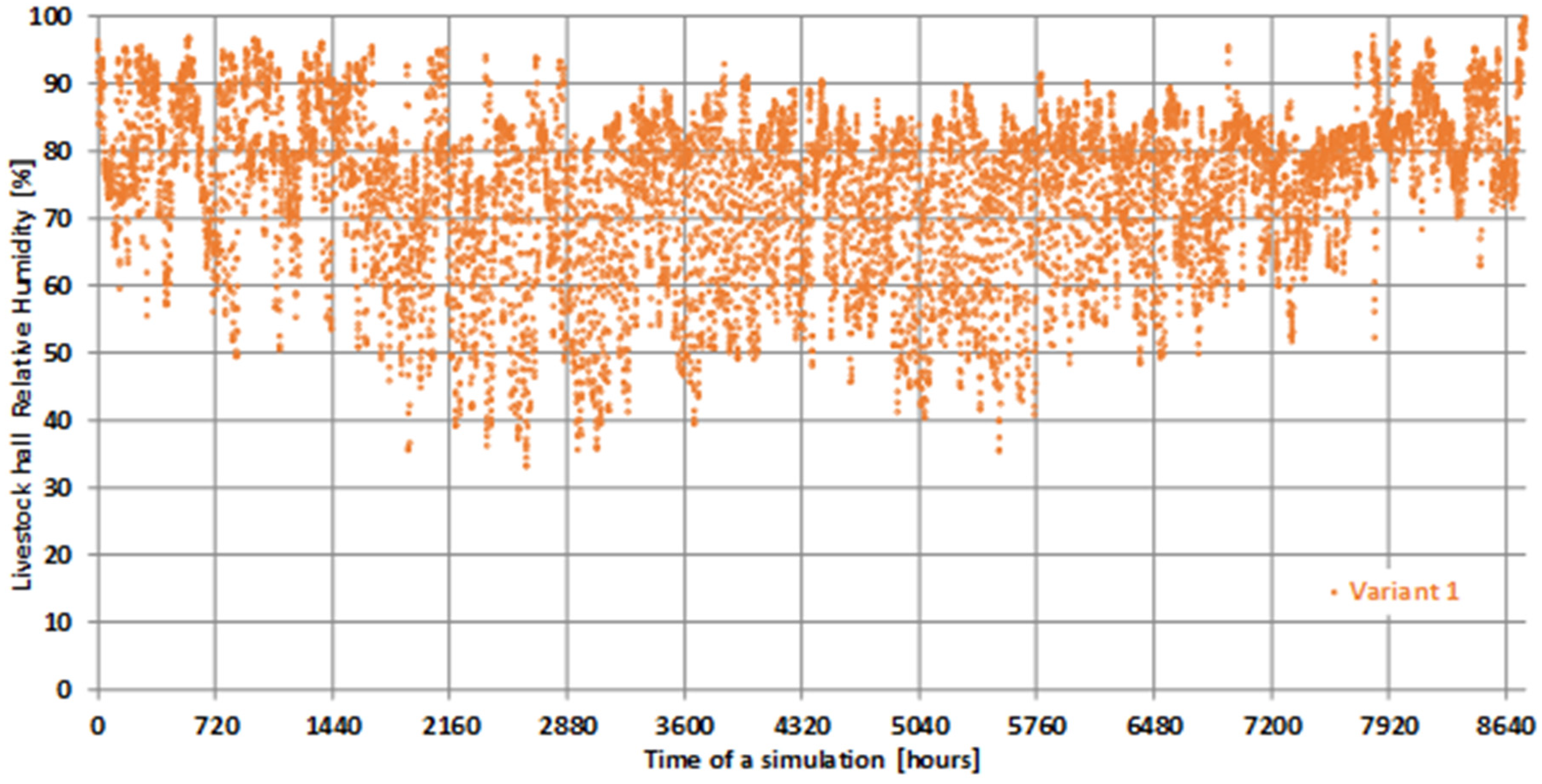

3. Results and Discussion

3.1. Results of Calculations and Analysis

3.1.1. Application of GAHE

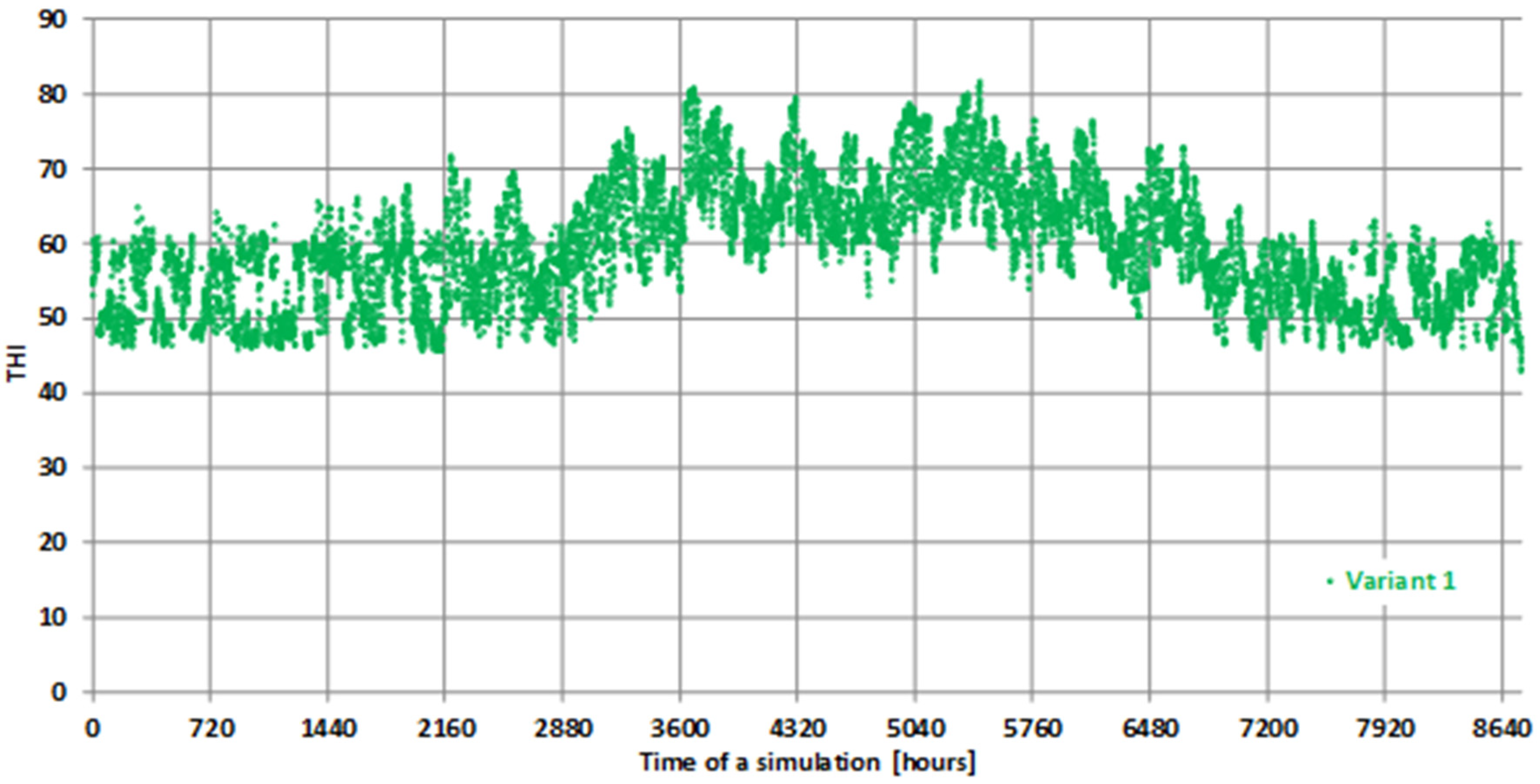

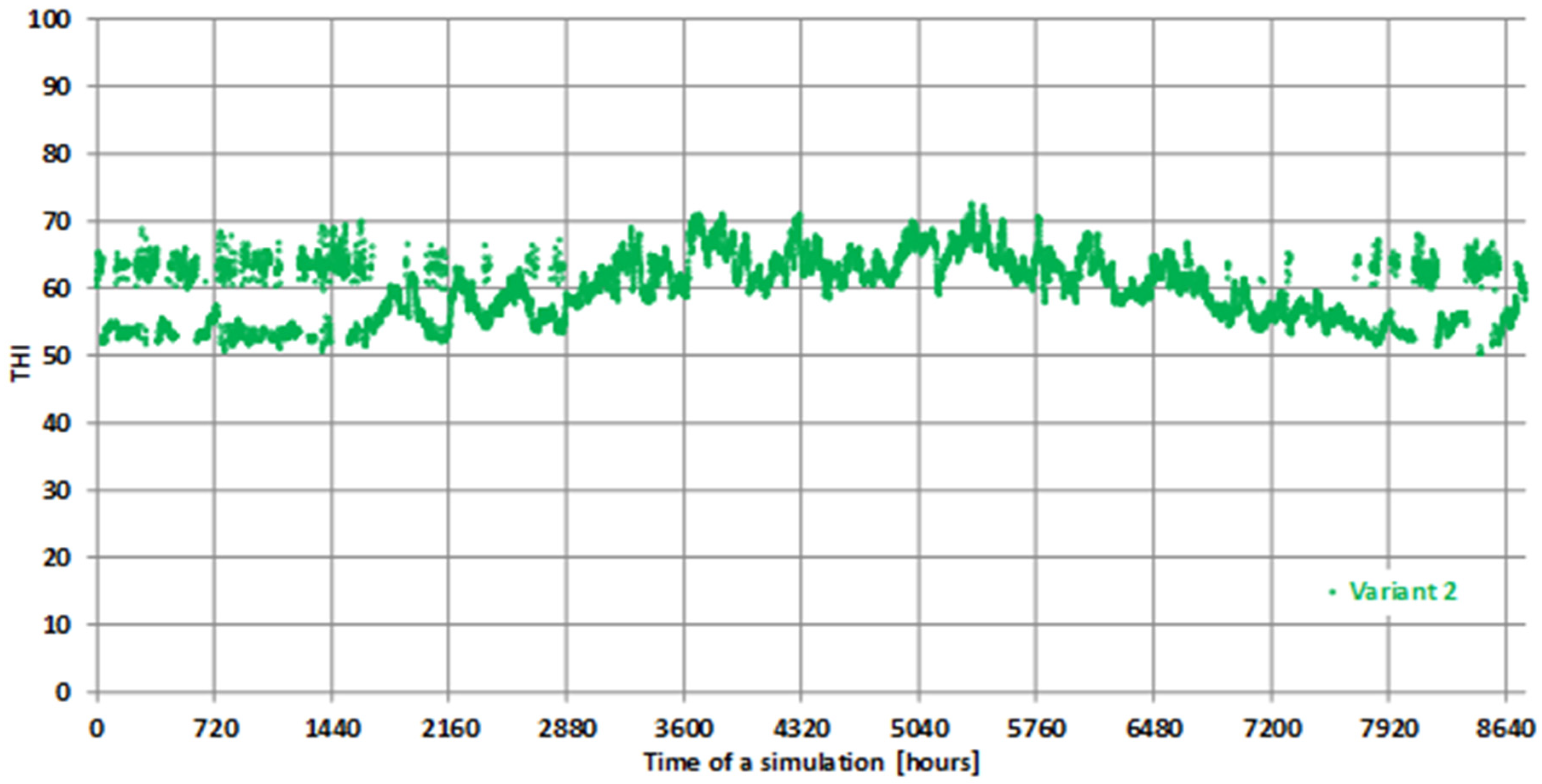

3.1.2. Limitation of the Minimum and Maximum Values of Air Temperature and Humidity in the Barn—Variants 3 and 4—Change in Ventilation-Control Method

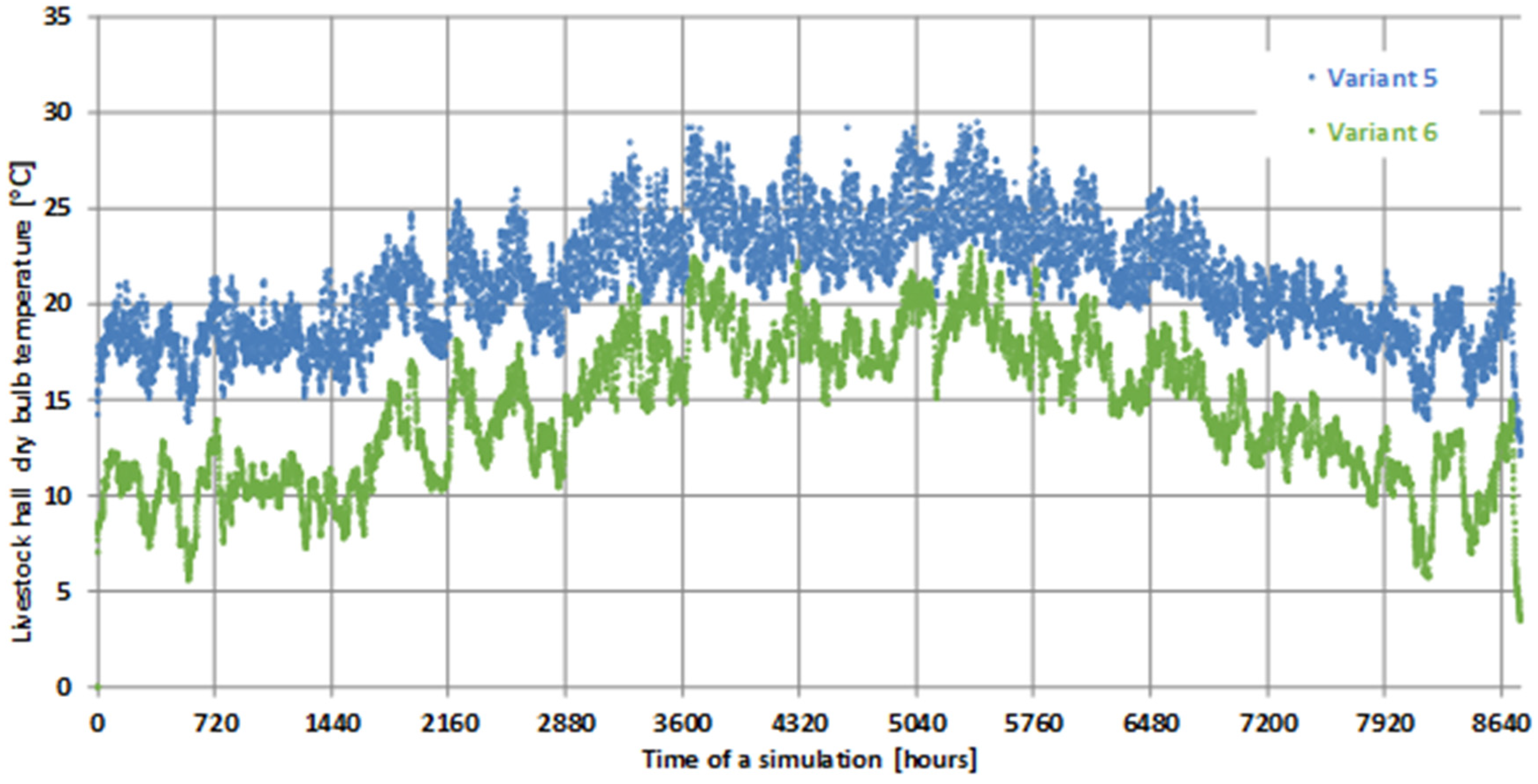

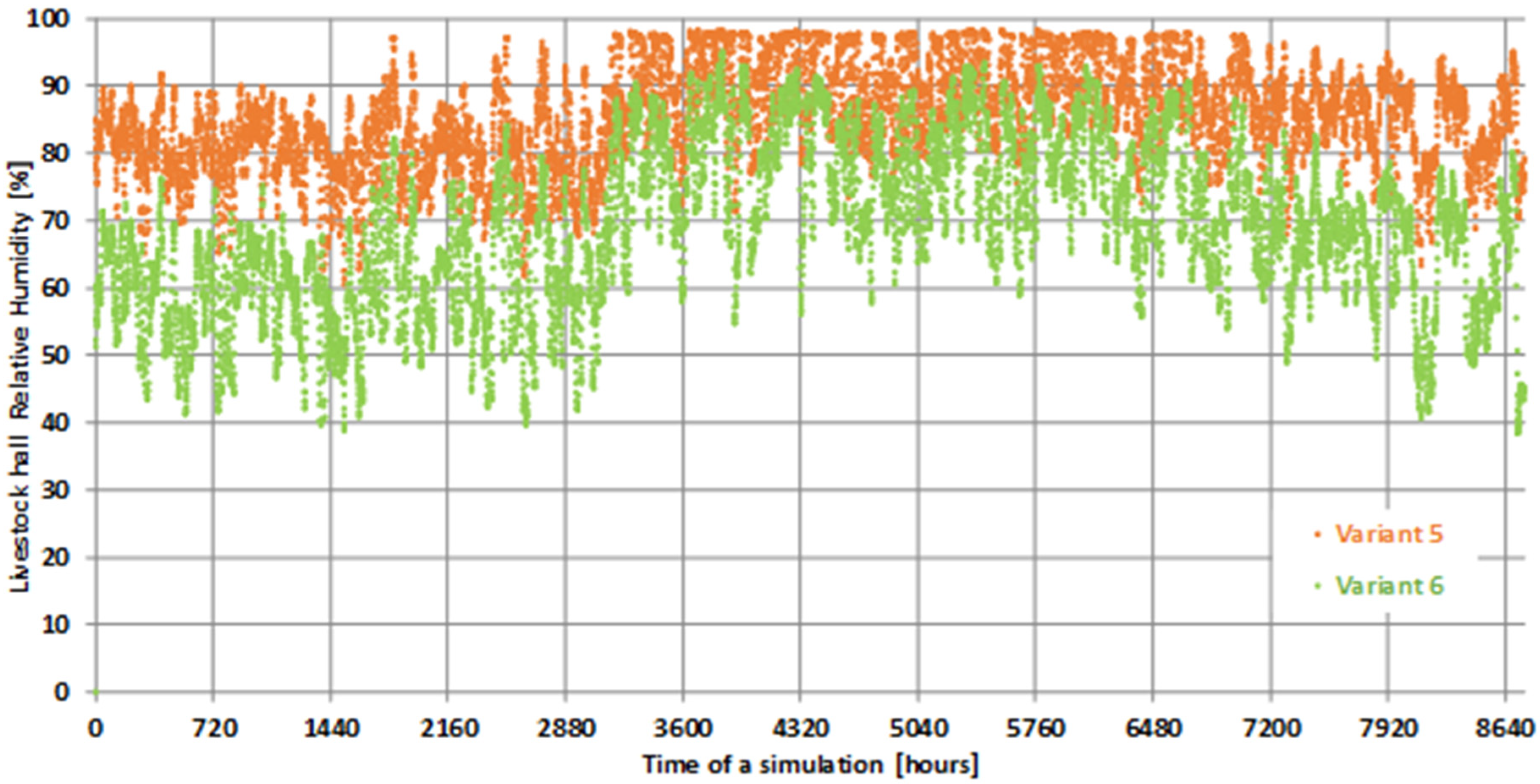

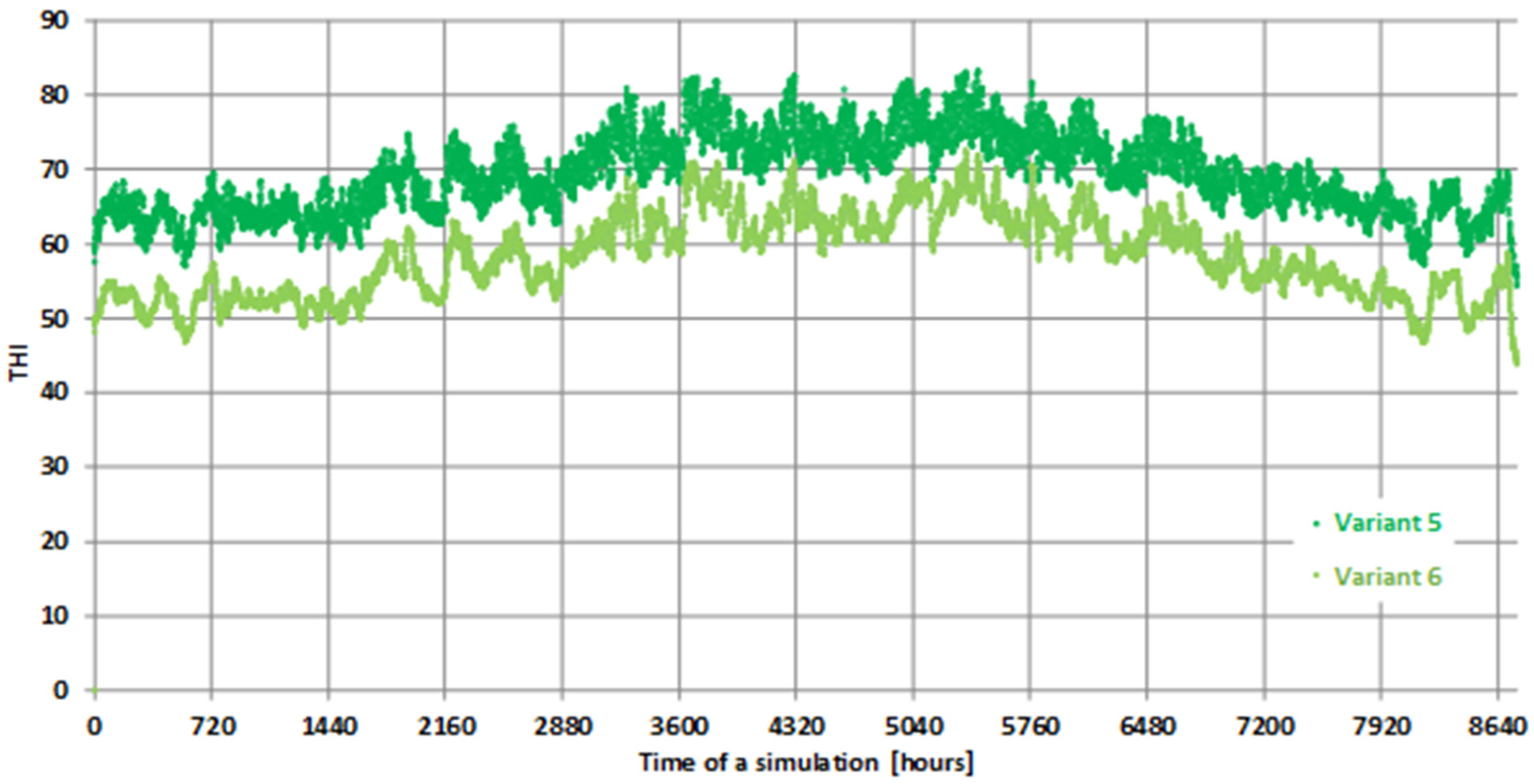

3.1.3. Limitation of the Minimum and Maximum Values of Air Temperature and Humidity in the Barn—Variant 5–8—Change in Ventilation Air Volumes

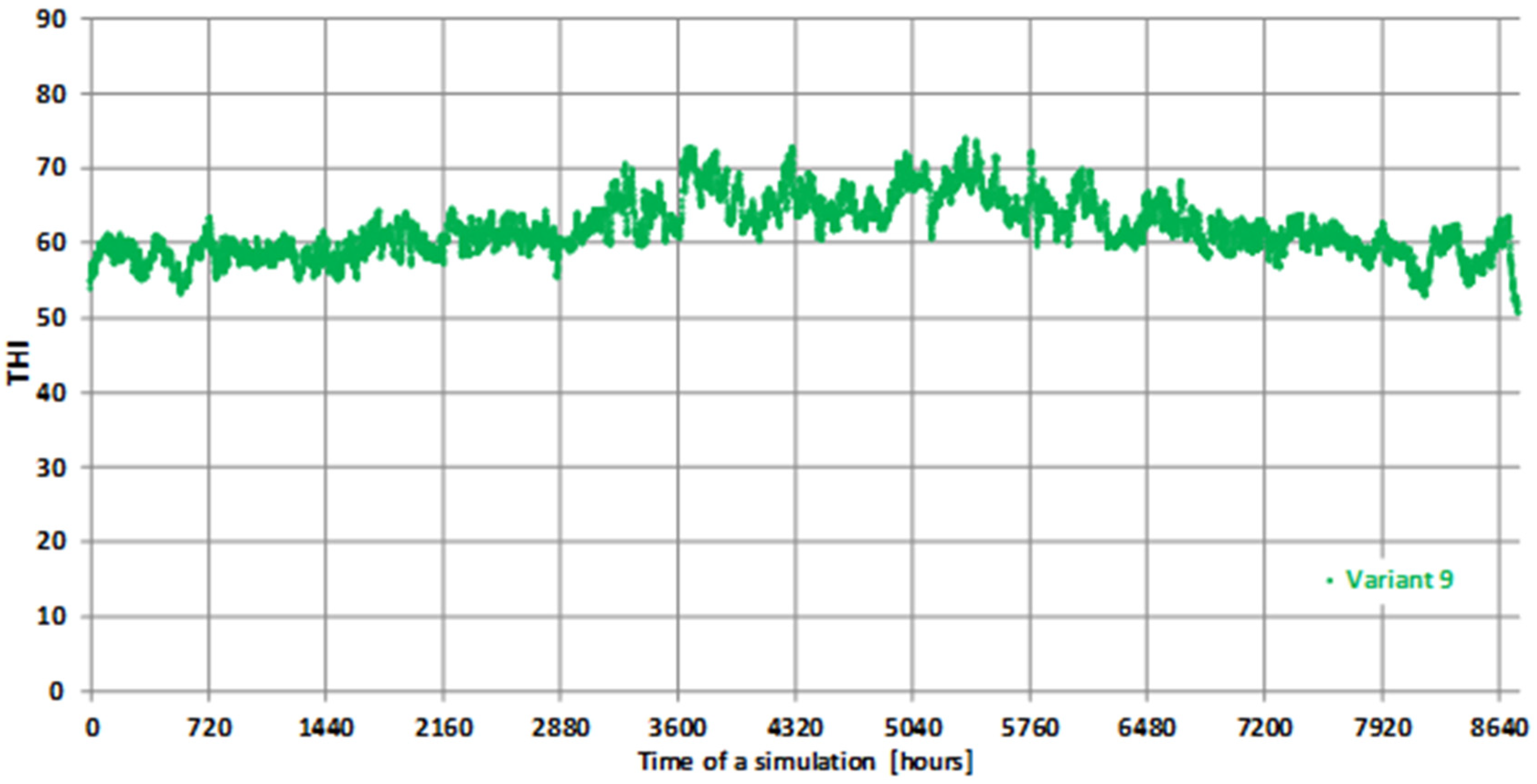

3.1.4. Final Variant for the Adopted Assumptions

3.2. Comparison of Variants

4. Conclusions

- Much more favorable microclimate conditions in the cowshed during the year.

- The reduction of the average air temperature and summer heat peaks in the barn during the warm season.

- The air temperature increases the possibility in winter with the same air stream as in classic solutions.

- Reduction in daily and monthly fluctuations in indoor air temperature and relative humidity, as well as a significant reduction in the occurrence of unfavorable parameters, which all translate into a higher possible milk production.

- Significant reduction in the occurrence of heat-stress conditions.

- Reduction in THI index values during summer season.

- Possibility of scaling down the amount of ventilation air in the summer season, which enables design of a system with smaller components, and the reduction in fans which drive electricity consumption.

- By passively heating the air, it allows an increase in ventilation air volume during the winter season without overcooling the animal residence zone, which also increases indoor air quality and cleanliness.

- The use of the considered solution is particularly advantageous:

- in new livestock buildings,

- in existing, modernized, or renovated livestock buildings.

- Variable ventilation airflow controlled hourly throughout the year, customized to meet current external or internal conditions.

- System control based on the THI index values or other indicators.

- Mixing of GAHE air supply with outdoor air (Figure 2b,d).

- Active use of the GAHE bypass.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cepiński, W.; Besler, M. Industrial applications of the air direct-contact, gravel, ground heat exchanger. In Proceedings of the E3S Web of Conferences, Wrocław, Poland, 7 November 2017; Volume 22. [Google Scholar] [CrossRef] [Green Version]

- Deutsches Institut Für Normung, e.V. DIN 18910-1–2004-11 Wärmeschutz geschlossener Stelle—Wärmedämmung und Lüftung—Teil 1: Planungs- und Berechnungsgrundlagen für geschlossene zwangsbelüftete Ställe.4. Available online: https://www.beuth.de/en/standard/din-18910-1/74837170 (accessed on 22 November 2021).

- Wolski, L. Mikroklimat w Budynkach Inwentarskich; PWN: Warszawa, Poland, 1988. [Google Scholar]

- Fiedorowicz, G.; Mazur, K. Microclimate inside the buildings of free-stall cattle barns during spring-summer season. Part I. Probl. Inz. Rol. 2011, 19, 123–134. [Google Scholar]

- Belizgys, R.; Bagdoniene, I. Control of ammonia air pollution through the management of thermal processes in cowsheds. Sci. Total Environ. 2016, 568, 990–997. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Hoff, S.; Cai, L.; Koziel, J.; Zelle, B. Evaluation of Wood Chip-Based Biofilters to Reduce Odor, Hydrogen Sulfide, and Ammonia from Swine Barn Ventilation Air. J. Air Waste Manag. Assoc. 2009, 59, 520–530. [Google Scholar] [CrossRef] [PubMed]

- Zou, B.; Shi, Z.; Du, S. Gases emissions estimation and analysis by using carbon dioxide balance method in natural-ventilated dairy cow barns. Int. J. Agric. Biol. Eng. 2020, 13, 41–47. [Google Scholar] [CrossRef]

- Lees, A.M.; Sejian, V.; Wallage, A.L.; Steel, C.C.; Mader, T.L.; Lees, J.C.; Gaughan, J.B. The Impact of Heat Load on Cattle. Animals 2019, 9, 322. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sprinkle, E.; Sagers, J.K.; Hall, J.B.; Ellison, M.J.; Yelich, J.V.; Brennan, J.R.; Taylor, J.B.; Lamb, J.B. Protein Supplementation and Grazing Behavior for Cows on Differing Late-Season Rangeland Grazing Systems James. Animals 2021, 11, 3219. [Google Scholar] [CrossRef]

- Thom, E.C. The discomfort index. Weatherwise 1959, 12, 57–60. [Google Scholar] [CrossRef]

- National Research Council. A Guide to Environmental Research on Animals; National Academy of Science: Washington, DC, USA, 1971. [Google Scholar]

- Yian, G.; Li, H.; Shi, Z. Evaluation of Thermal Indices as the Indicators of Heat Stress in Dairy Cows in a Temperate Climate. Animals 2021, 11, 2459. [Google Scholar] [CrossRef]

- West, J.W. Effect of heat stress on production in dairy cattle. J. Dairy Sci. 2003, 86, 2131–2214. [Google Scholar] [CrossRef]

- McDowell, R.E.; Hooven, N.W.; Camoens, J.K. Effects of climate on performance of Holsteins in first lactation. J. Dairy Sci. 1976, 59, 965–973. [Google Scholar] [CrossRef]

- Negri, R.; Aguilar, I.; Feltes, G.L.; Cobuci, J.A. Selection for Test-Day Milk Yield and Thermotolerance in Brazilian Holstein Cattle. Animals 2001, 11, 128. [Google Scholar] [CrossRef]

- Duru, S. Determination of starting level of heat stress on daily milk yield in Holstein cows in Bursa city of Turkey. Vet. Fakültesi Derg. 2018, 65, 93–198. [Google Scholar]

- Kadzere, C.T.; Murphy, M.R.; Silanikove, N.; Maltz, E. Heat stress in lactating dairy cows: A review. Livest. Prod. Sci. 2002, 77, 59–91. [Google Scholar] [CrossRef]

- Hansen, P.J. Exploitation of genetic and physiological determinants of embrionic resistance to elevated temperature to improve embryonic survival in dairy cattle during heat stress. Theriogenology 2007, 68, S242–S249. [Google Scholar] [CrossRef]

- Hristov, S.; Stankowić, B.; Joksimović—Todorowić, M.; Bojkowski, J.; Davidović, V. Uticaj toplotnog stresa na proizvodnju mlečnih krava. Zb. Naučnih Rad. 2007, 13, 3–4. [Google Scholar]

- Pinto, S.; Hoffmann, G.; Ammon, C.; Heuwieser, W.; Levit, H.; Halachmi, I.; Amon, T. Effect of two cooling frequencies on respiration rate in lactating dairy cows under hot and humid climate conditions. Ann. Anim. Sci. 2019, 19, 821–834. [Google Scholar] [CrossRef] [Green Version]

- Almuhanna, E.A.; Gamea, G.R.; Osman, O.E.; Almahdi, F.M. Performance of roof-mounted misting fans to regulate heat stress in dairy cows. J. Therm. Biol. 2021, 99, 102984. [Google Scholar] [CrossRef]

- Bang, N.N.; Gaughan, J.B.; Hayes, B.J.; Lyons, R.E.; Chanh, N.V.; Trach, N.X.; Khang, D.N.; McNeill, D.M. Characteristics of Cowsheds in Vietnamese Smallholder Dairy Farms and Their Associations with Microclimate—A Preliminary Study. Animals 2021, 11, 351. [Google Scholar] [CrossRef] [PubMed]

- Sarentonglaga, B.; Sugiyama, T.; Fukumori, R.; Nagao, Y. Effects of a tunnel ventilation system within the tie-stall barn environment upon the productivity of dairy cattle during the winter season. Asian-Australas. J. Anim. Sci. 2019, 32, 748–756. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Doumbia, E.M.; Janke, D.; Yi, Q.; Prinz, A.; Amon, T.; Kriegel, M.; Hempel, S. A Parametric Model for Local Air Exchange Rate of Naturally Ventilated Barns. Agronomy 2021, 11, 1585. [Google Scholar] [CrossRef]

- Doumbia, E.M.; Janke, D.; Yi, Q.; Amon, T.; Kriegel, M.; Hempel, S. CFD modelling of an animal occupied zone using an anisotropic porous medium model with velocity depended resistance parameters. Comput. Electron. Agric. 2021, 181, 105950. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Comparison of different mechanical ventilation systems for dairy cow barns: CFD simulations and field measurements. Comput. Electron. Agric. 2021, 186, 106207. [Google Scholar] [CrossRef]

- Tomasello, N.; Valenti, F.; Cascone, G.; Porto, S.M.C. Development of a CFD Model to Simulate Natural Ventilation in a Semi-Open Free-Stall Barn for Dairy Cows. Buildings 2019, 9, 183. [Google Scholar] [CrossRef] [Green Version]

- Pustovaya, O.; Pustovoy, E. Optimization of energy spending with accelerated ventilation. Web Conf. 2020, 178, 1022. [Google Scholar] [CrossRef]

- Kowalczyk, W. Model Matematyczny Ciepła i Masy w Bezprzeponowym Gruntowym Wymienniku w Systemie Wentylacyjnym, Praca Doktorska; Wydział Inżynierii Środowiska Politechniki Wrocławskiej: Wrocław, Poland, 1988. [Google Scholar]

- Official EnergyPlus Website, Weather Data (March 2018r). Available online: https://energyplus.net/weather-download/europe_wmo_region_6/POL//POL_Wroclaw.124240_IMGW/all (accessed on 22 November 2021).

- Kic, P. Effect of construction shape and materials on indoor microclimatic conditions inside the cowsheds in dairy farms. Agron. Res. 2017, 15, 426–434. [Google Scholar]

- Kavolelis, B.; Sateikis, I. Effective cowshed insulating and ventilation system parameters. Energy Build. 2004, 36, 969–973. [Google Scholar] [CrossRef]

- Nowak, D. Warunki Utrzymywania Bydła w Świetle Obowiązujących Przepisów; Centrum Doradztwa Rolniczego w Brwinowie Oddział w Poznaniu: Poznań, Poland, 2013; ISBN 978 83-60232-49-1. Available online: https://www.cdr.gov.pl/images/wydawnictwa/2013/2013-WARUNKI-UTRZYMYWANIA-BYDLA-W-SWIETLE-OBOWIAZUJACYCH-PRZEPISOW.pdf (accessed on 22 November 2021).

- Pedersen, S.; Sällvik, K. Climatization of Animal Houses Heat and Moisture Production at Animal and House Levels; Section II; International Commission of Agricultural Engineering: Chicago, IL, USA, 2002. [Google Scholar]

- Głuski, T. Parametry Stada w Procesie Projektowania Mikroklimatu w Budynkach dla Bydła. Inżynieria Rol. 2009, 13, 95–101. [Google Scholar]

- Official Website of Ministerstwo Infrasturktury i Budownictwa, Weather Data (March 2018). Available online: http://mib.gov.pl/2-wskazniki_emisji_wartosci_opalowe_paliwa.htm (accessed on 22 November 2021).

- Bagdoniene, I.; Belizgys, R. The problems of microclimate in lithuanian cowsheds. In Proceedings of the International Scientific Conference “Rural Development 2019”, Kaunas, Lithuania, 26–28 September 2019. [Google Scholar]

- Wójcik, A.; Mituniewicz, T.; Dzik, S.; Kostrubiec, Ł.; Wolska, A.; Dzięgiel, D. Environmental indicators for assessing the welfare of dairy cattle housed indoors. Sci. Ann. Pol. Soc. Anim. Prod. 2017, 13, 71–82. [Google Scholar] [CrossRef]

| Animals | Temperature, °C | Relative Humidity, % | Airflow Rate, m/s | Air Exchange, m3/h | |||||

|---|---|---|---|---|---|---|---|---|---|

| - | Min. | Opt. | Max | Opt. | Max | Winter | Summer | Winter | Summer |

| Dairy cows | 6 | 8–16 | 25 | 60–80 | 85 | 0.1–0.3 | 0.5 | 90 | 350–400 |

| Cows in the delivery room | 16 | 16–20 | 25 | 60–80 | 85 | 0.1–0.2 | 0.4 | 90 | 350–400 |

| Calves in a preventive treatment | 12 | 16–20 | 30 | 60–80 | 85 | 0.1–0.2 | 0.3 | 20 | 80 |

| Calves up to 6 months old maintained in the system: | 30 | 90–120 | |||||||

| - bedding | 8 | 12–16 | 25 | 60–80 | 85 | 0.1–0.3 | 0.3 | 30 | 90–120 |

| - bedding free | 12 | 12–20 | 25 | 60–80 | 85 | 0.1–0.3 | 0.3 | 30 | 90–120 |

| Heifers under 6 months in the room for the period of treatment | 16 | 17–20 | 25 | 60–80 | 85 | 0.1–0.3 | 0.5 | 60 | 250 |

| Cattle over 6 months | 6 | 10–18 | 25 | 60–80 | 85 | 0.1–0.3 | 0.5 | 70 | 280–300 |

| Permissible concentration of admixtures in the air: | |||||||||

| Carbon dioxide (CO2) | 0.25000% | ||||||||

| Ammonia (NH3) | 0.00260% | ||||||||

| Hydrogen sulfide (H2S) | 0.00100% | ||||||||

| Calculation Parameter | Value |

|---|---|

| Time steps per hour | one step |

| Simulation period | from 01.01 to 12.31 of typical calc. year |

| Temperature control | air temperature |

| General solution algorithm | conduction transfer function |

| Number of model warm-up days | 30 days |

| Location of the site | Poland/Wroclaw/N 51.10° E 17.03° |

| Weather data | WMO Region 6/POL/Station no. 124240 |

| Terrain type | open |

| Parameter | Value |

|---|---|

| External dimensions of the building | 36.05 × 16.65 m |

| Total floor area | 597.60 m2 |

| Total building volume | 2728.90 m3 |

| Livestock hall area | 236.50 m2 |

| Livestock hall volume | 709.50 m3 |

| Roof type | open gable, 20 degrees |

| Gates | quantity: five gates, total area: 37.50 m2 |

| Roof glazing area | 68.00 m2 |

| Wall glazing area | 13.80 m2 |

| Construction | Manufacturer/Type | Total Thickness, mm | U-Value, W/(m2K) |

|---|---|---|---|

| External wall | ALFAPANEL/wall panel PU with mounting | 50 | 0.42 |

| Gable roof | ALFAPANEL/roof panel PU ARGO | 50 | 0.34 |

| Ground floor | /cast concrete | 200 | 2.27 |

| Glazing | ALFAPANEL/multichamber polycarbonate plates | 35 | 1.11 |

| Parameter | Value |

|---|---|

| Heating and cooling installation | none used |

| Ventilation type | mechanical with or without GAHE |

| Ventilation air volume at external air temperatures lower than 0.0 °C (“winter season”) | 3600 m3/h (90 m3/cow) |

| Ventilation air volume at external air temperatures greater than 0.0 °C (“summer season”) | 14.000 m3/h (350 m3/cow) |

| Roof zone fluorescent lighting heat gains | 4.0 W/m2 |

| Total cow heat production calculated at 20.0 °C | 1270 W/cow |

| Sensible and latent heat-production ratio | depending on the livestock hall indoor temperature |

| Sensible and latent heat-production localization | animal residence zone only |

| Sensible heat-production range MIN/AVERAGE/MAX | 140.4 W/m2/149.1 W/m2/156.4 W/m2 |

| Latent heat-production range MIN/AVERAGE/MAX | 60.7 W/m2/62.4 W/m2/64.4 W/m2 |

| Variant | Temperature | Relative Humidity | Both | Both | Max Δ t | Avg Δ t | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| - | t < 8 °C | t > 16 °C | t > 20 °C | t < 6 °C | t > 25 °C | φ < 60% | φ > 80% | φ > 85% | 16 < t < 8 °C & 80 < φ < 60% | 20 < t < 8 °C & 80 < φ < 60% | K | K |

| 0 | 4332 | 1617 | 699 | 3706 | 175 | 1154 | 4957 | 3779 | 4274 | 3832 | 19.0 | 8.0 |

| 1 | 481 | 3529 | 1706 | 0 | 462 | 1293 | 3221 | 1420 | 1933 | 1077 | 15.5 | 7.3 |

| 2 | 0 | 4735 | 598 | 0 | 0 | 976 | 2089 | 1032 | 2051 | 357 | 13.0 | 3.3 |

| 3 | 0 | 4627 | 685 | 0 | 0 | 1116 | 2027 | 1007 | 1979 | 356 | 11.7 | 2.6 |

| 4 | 0 | 7335 | 1648 | 0 | 0 | 410 | 3797 | 1933 | 3760 | 837 | 10.2 | 2.6 |

| 5 | 0 | 8487 | 5292 | 0 | 1043 | 0 | 6747 | 4718 | 6701 | 4467 | 7.8 | 3.5 |

| 6 | 296 | 3357 | 540 | 57 | 0 | 2144 | 1807 | 1005 | 2049 | 647 | 6.3 | 1.8 |

| 7 | 5 | 5550 | 2444 | 0 | 34 | 1157 | 1846 | 878 | 2138 | 1278 | 5.8 | 2.4 |

| 8 | 87 | 4151 | 1015 | 13 | 0 | 1925 | 1675 | 821 | 1924 | 704 | 5.9 | 1.9 |

| 9 | 0 | 5336 | 1014 | 0 | 0 | 1617 | 1672 | 820 | 2071 | 611 | 5.2 | 2.1 |

| Variant | THI | |||||||

|---|---|---|---|---|---|---|---|---|

| - | THI < 45 | THI > 68 | 68 > THI > 72 | 72 > THI > 75 | 75 > THI > 79 | 79 > THI > 84 | THI > 84 | Avg Value |

| 0 | 3866 | 476 | 306 | 125 | 45 | 0 | 0 | 47.3 |

| 1 | 4 | 1283 | 710 | 329 | 212 | 32 | 0 | 59.2 |

| 2 | 0 | 318 | 314 | 4 | 0 | 0 | 0 | 60.3 |

| 3 | 0 | 351 | 348 | 3 | 0 | 0 | 0 | 60.3 |

| 4 | 0 | 934 | 931 | 3 | 0 | 0 | 0 | 64.0 |

| 5 | 0 | 4859 | 2046 | 1424 | 1094 | 295 | 0 | 69.2 |

| 6 | 9 | 298 | 295 | 3 | 0 | 0 | 0 | 58.3 |

| 7 | 0 | 1818 | 1422 | 351 | 45 | 0 | 0 | 63.1 |

| 8 | 0 | 694 | 660 | 34 | 0 | 0 | 0 | 60.0 |

| 9 | 0 | 692 | 652 | 40 | 0 | 0 | 0 | 61.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Besler, M.; Cepiński, W.; Kęskiewicz, P. Direct-Contact Air, Gravel, Ground Heat Exchanger in Air Treatment Systems for Cowshed Air Conditioning. Energies 2022, 15, 234. https://doi.org/10.3390/en15010234

Besler M, Cepiński W, Kęskiewicz P. Direct-Contact Air, Gravel, Ground Heat Exchanger in Air Treatment Systems for Cowshed Air Conditioning. Energies. 2022; 15(1):234. https://doi.org/10.3390/en15010234

Chicago/Turabian StyleBesler, Maciej, Wojciech Cepiński, and Piotr Kęskiewicz. 2022. "Direct-Contact Air, Gravel, Ground Heat Exchanger in Air Treatment Systems for Cowshed Air Conditioning" Energies 15, no. 1: 234. https://doi.org/10.3390/en15010234

APA StyleBesler, M., Cepiński, W., & Kęskiewicz, P. (2022). Direct-Contact Air, Gravel, Ground Heat Exchanger in Air Treatment Systems for Cowshed Air Conditioning. Energies, 15(1), 234. https://doi.org/10.3390/en15010234