Efficiency of Energy Consumption between Reinforced Concrete Structure and Cross-Laminated Timber Based Hybrid Structure in East Asian Cities

Abstract

1. Introduction

2. Methodology

2.1. Assessment of Energy Consumption

2.2. Assessment of Carbon Dioxide Emission

- (A)

- Electricity consumption is converted into carbon emissions by using the following formula:

= electricity carbon dioxide emissions (kg)

- (B)

- Fuel consumption is converted into carbon emissions by using the following equation:

= fuel carbon dioxide emissions (kg),

- (C)

- The carbon emission of total energy consumption is calculated as follows:

= electricity carbon dioxide emissions (kg)+ fuel carbon dioxide emissions (kg)

3. Simulation Modeling

- According to the descriptions on the official website of Autodesk, the data on weather stations were obtained from the World Meteorological Organization.

- For the electromechanical system and indoor load, detailed data were required from the DOE-2.2 analysis core to the electromechanical system for the operation. However, the building envelope and electromechanical system parameters were preset in GBS according to the ASHRAE standards. Different air-conditioning systems are used in different countries. The preset parameters were used for the mechanical system and indoor load in this study. The preset parameters of heating, ventilation, and air-conditioning (HVAC) systems were a central variable air volume system, hot-water heating, a performance coefficient of 5.96 for the freezer, and a boiler efficiency of 84.5.

- The window positions remained the same when switching from an RC structure to a CLT structure; thus, the illumination demands remained the same.

- Except for the balcony, the indoor temperatures of all the rooms were controlled between 18 and 26 °C.

- No heating or cooling was conducted in the stair areas.

- Electricity was used for the air-conditioning system and illumination, and fuel was used for heating.

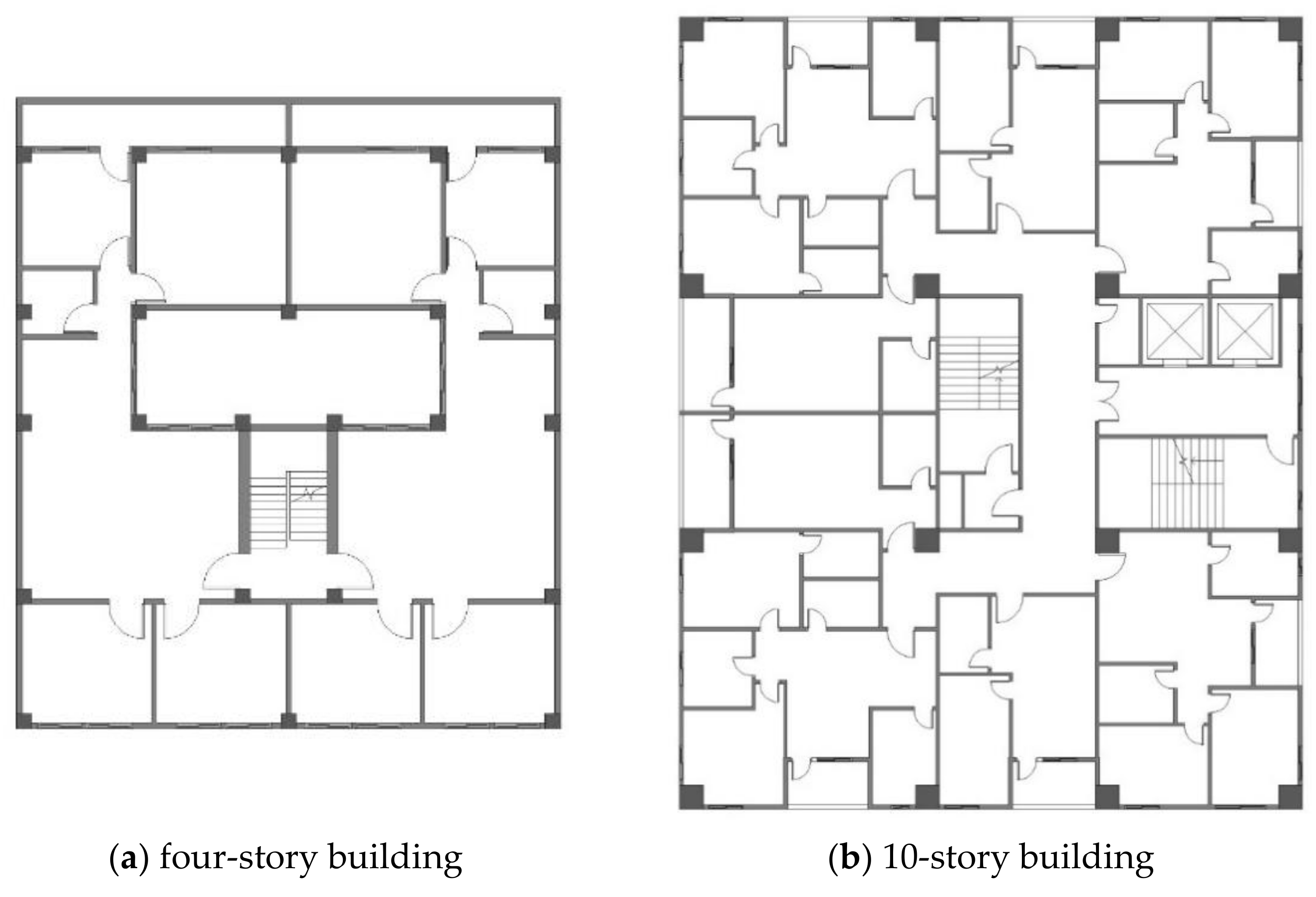

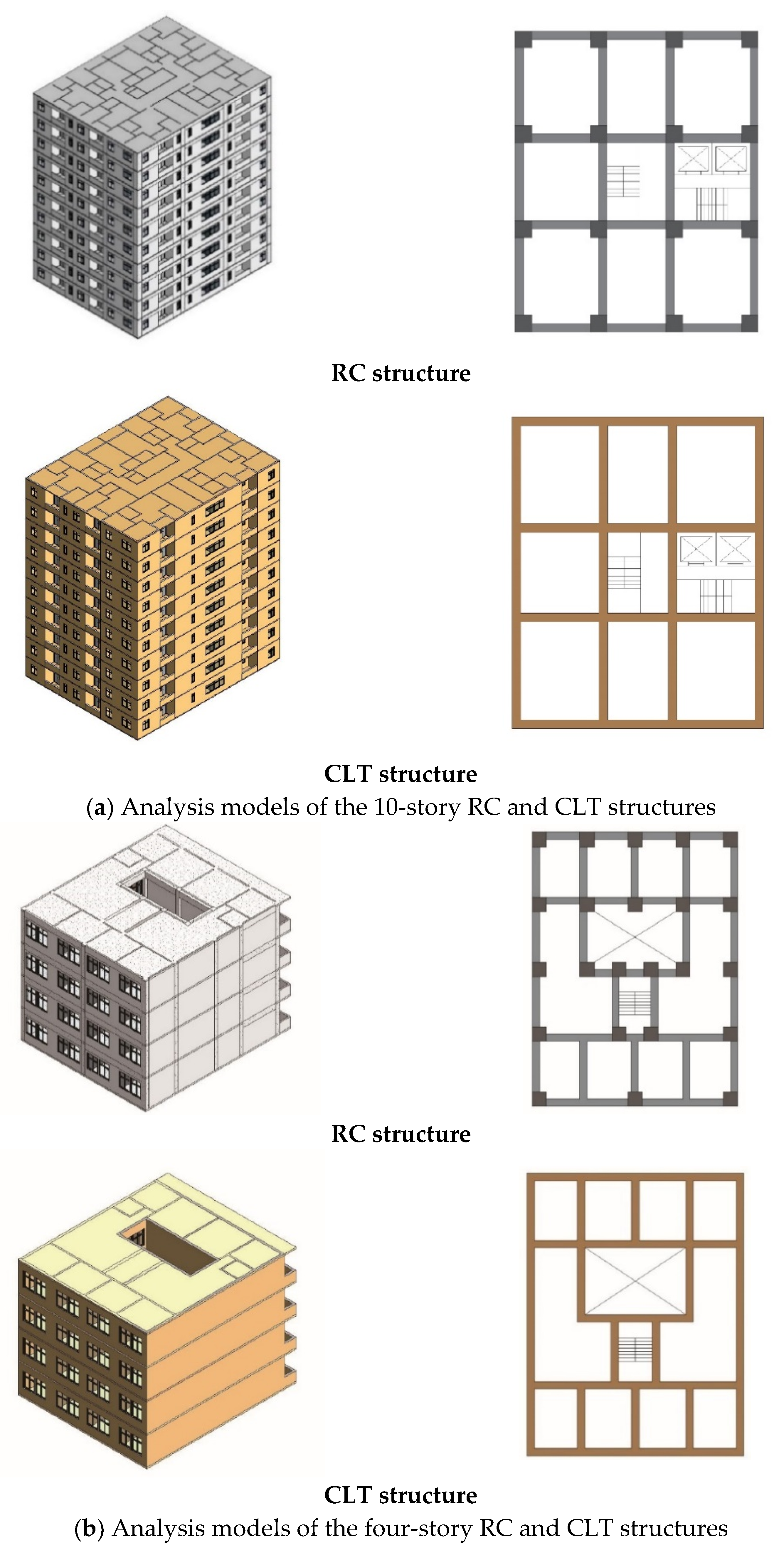

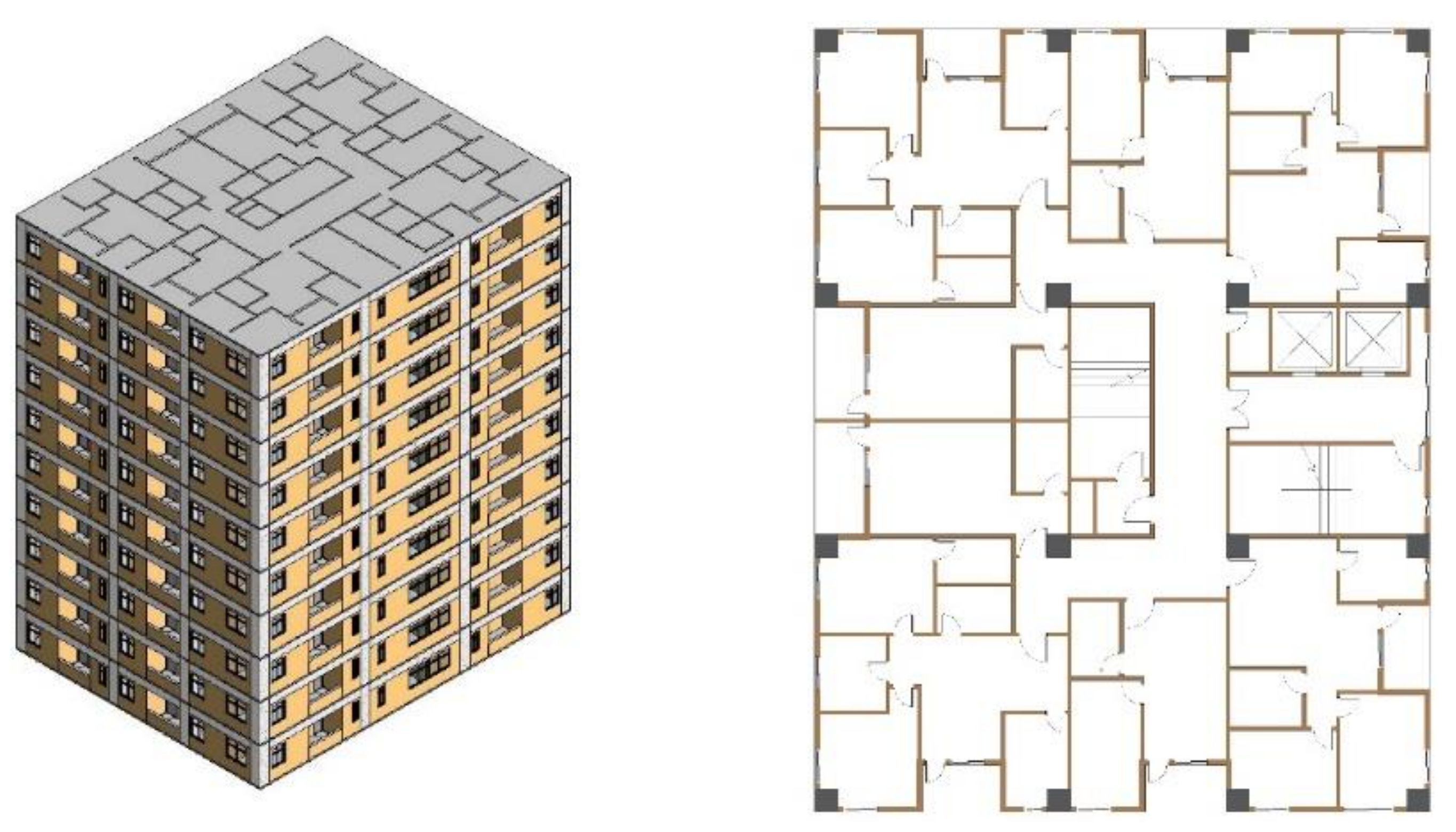

3.1. Target Building

3.2. Building Materials

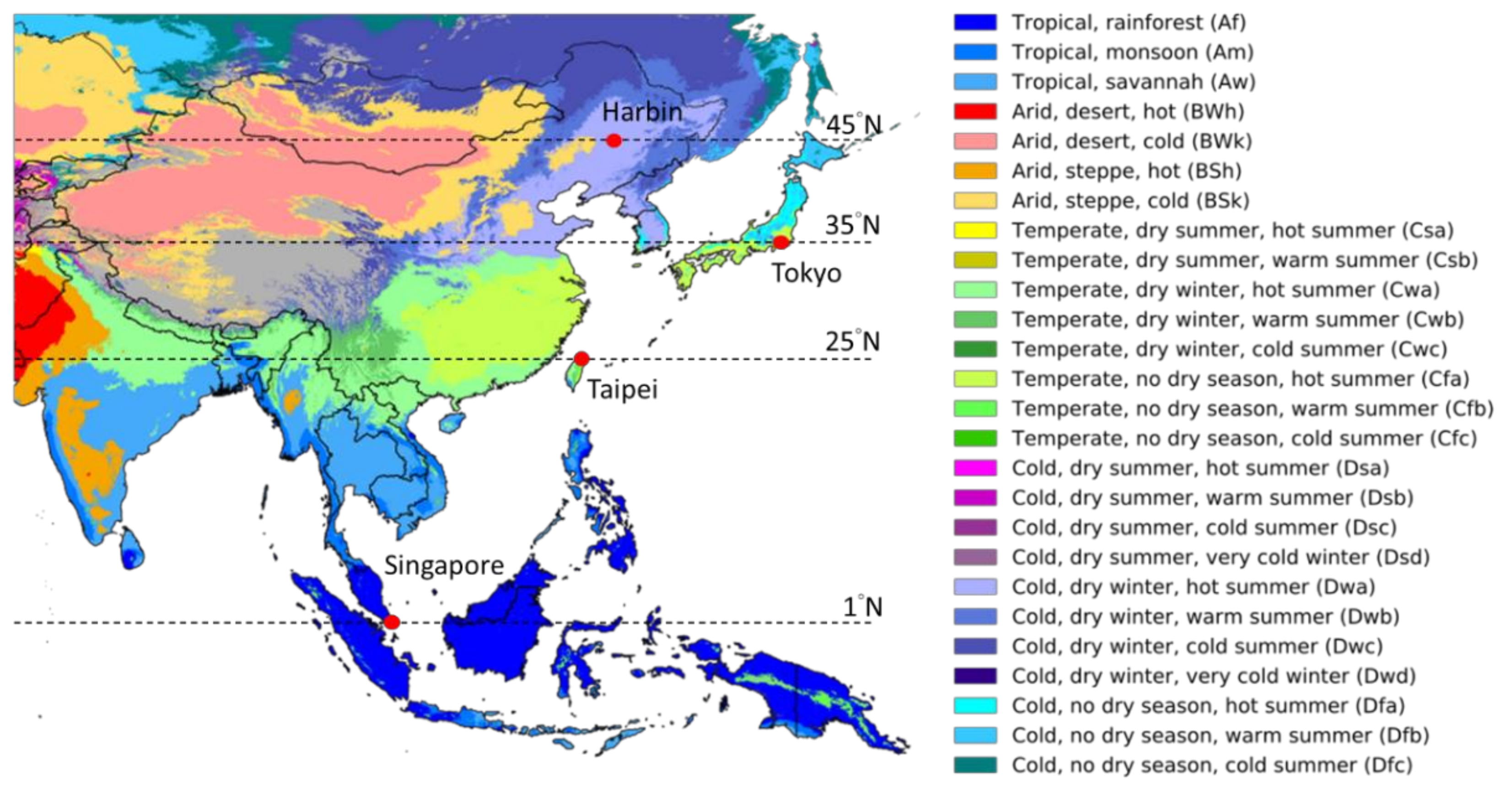

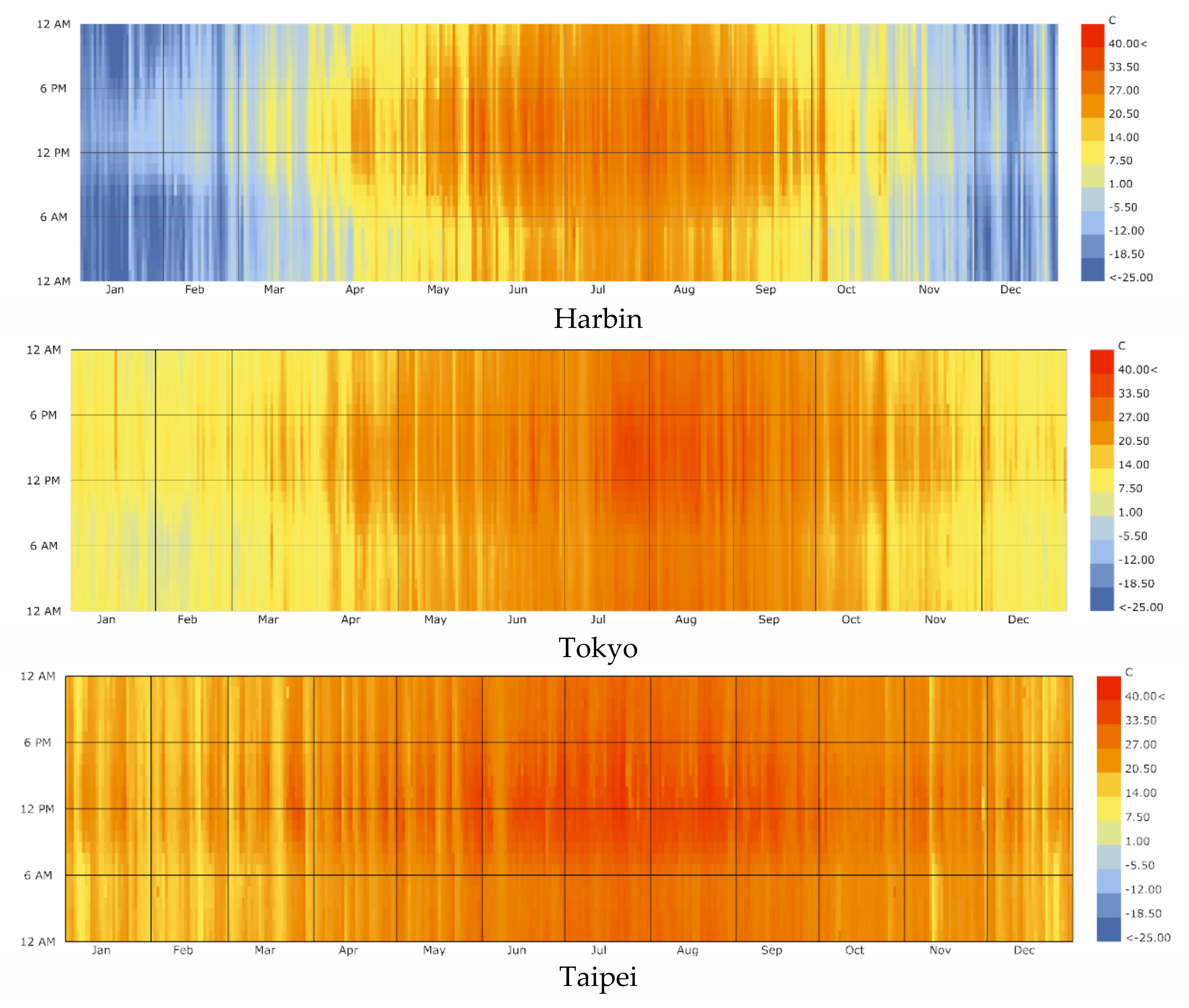

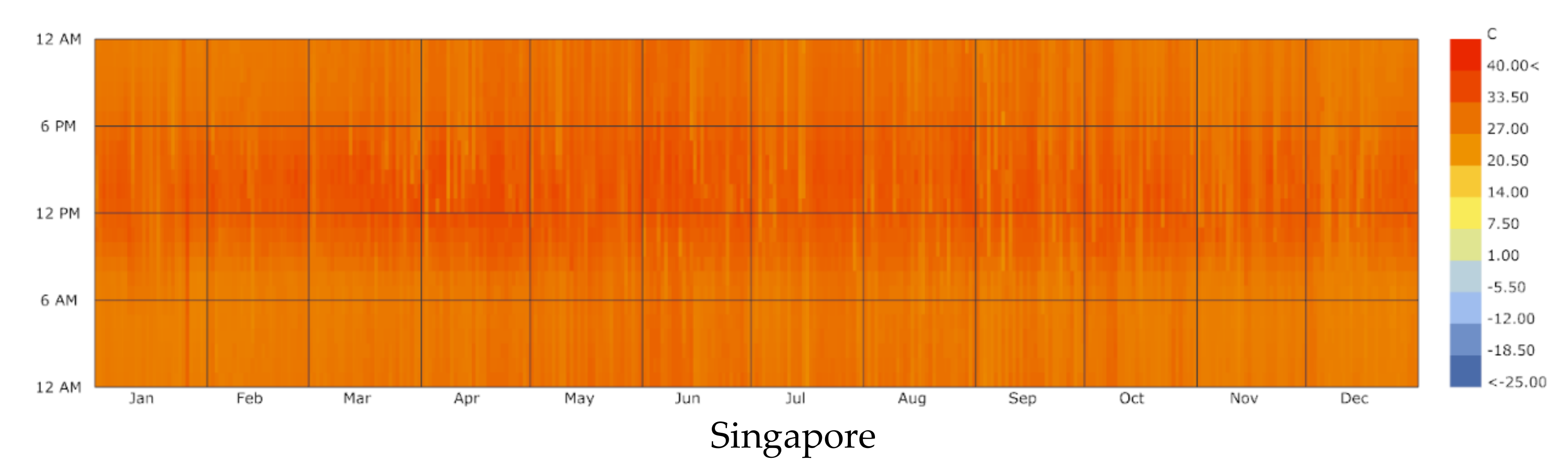

3.3. Cities in Different Latitude

4. Results and Discussion

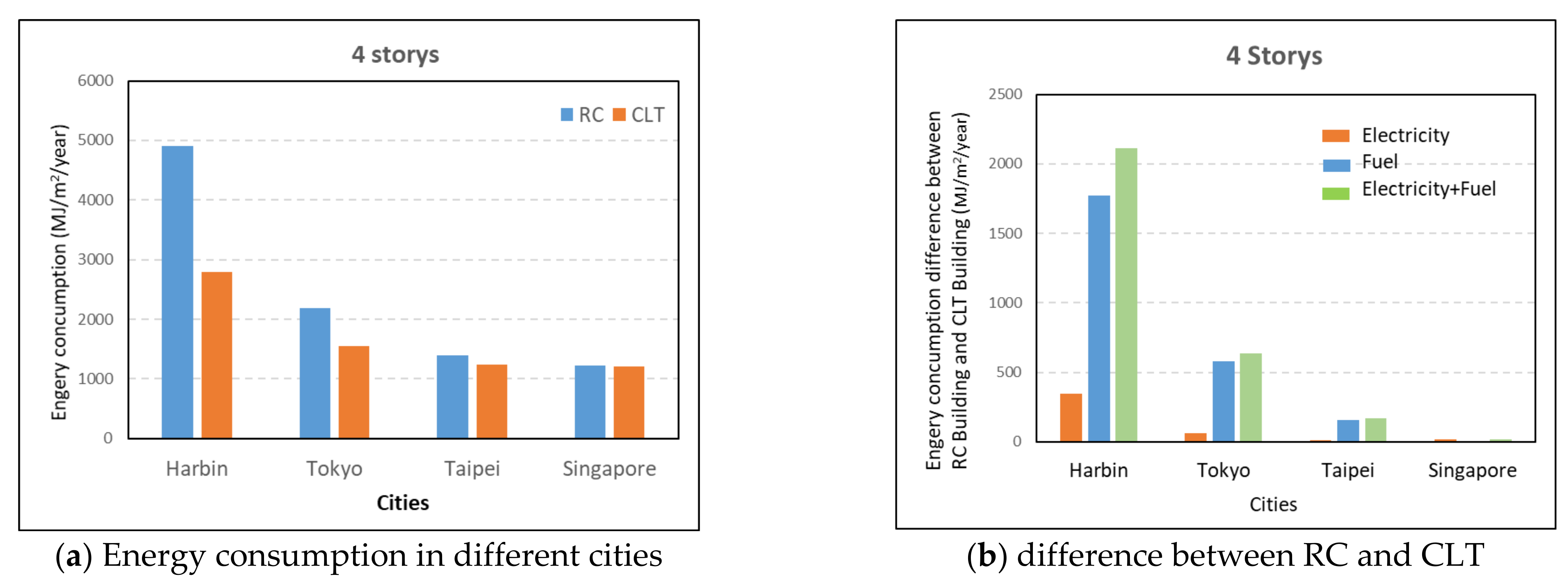

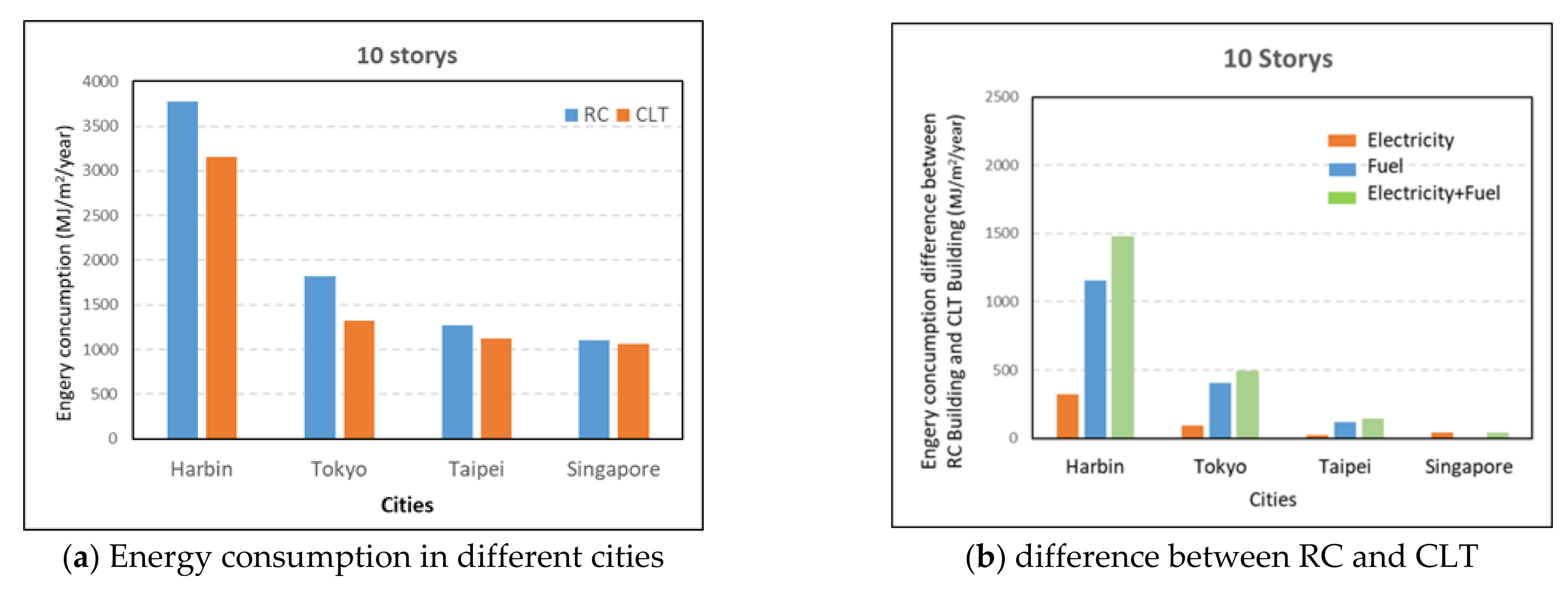

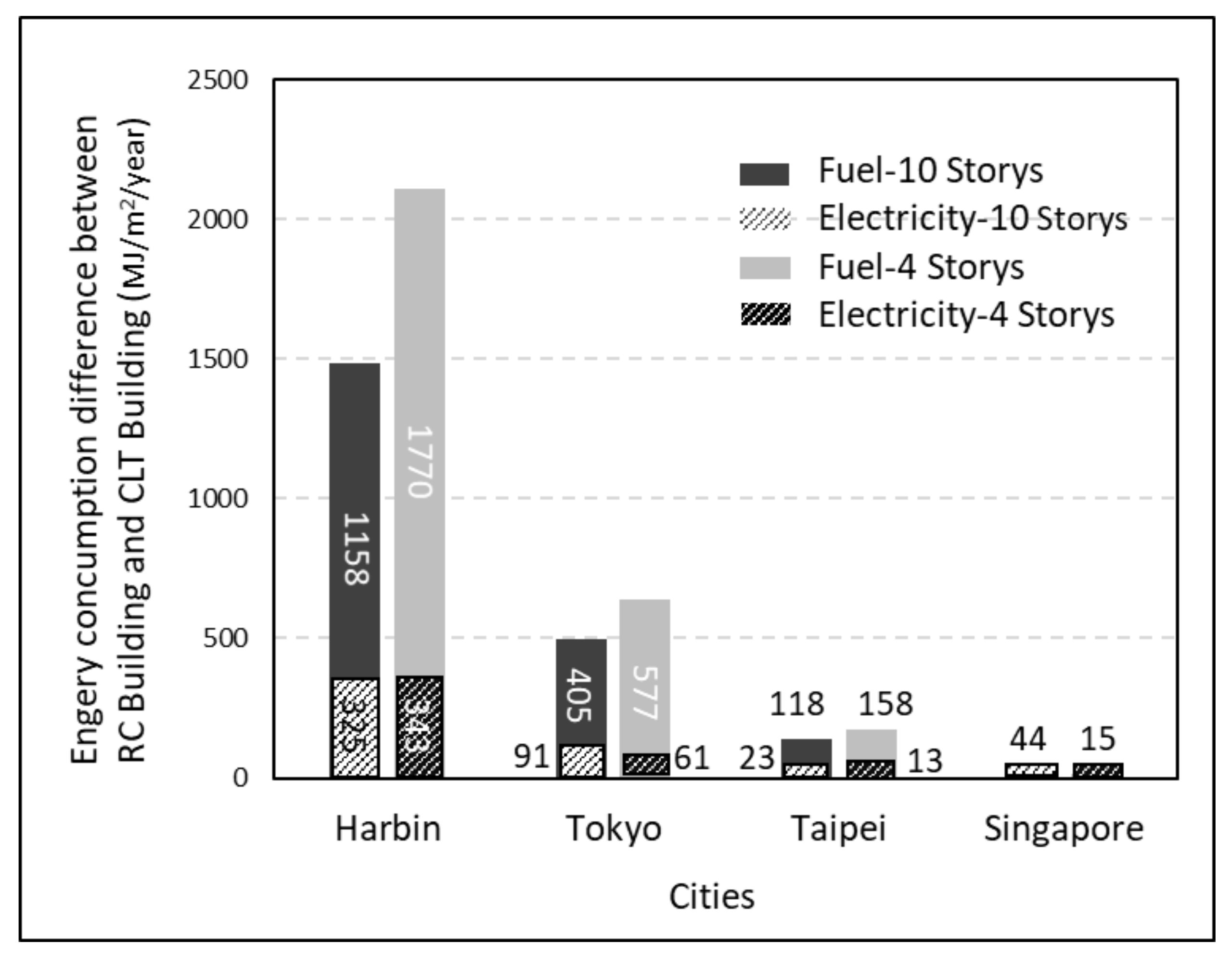

4.1. Energy Consumption

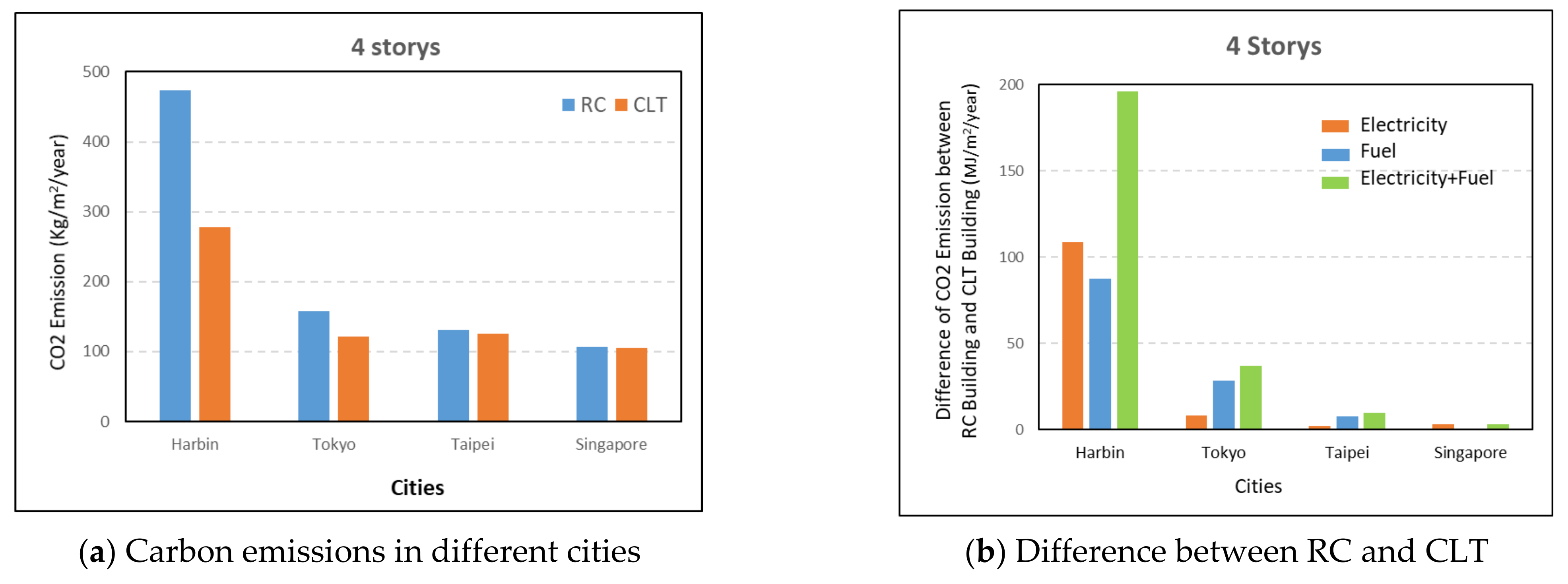

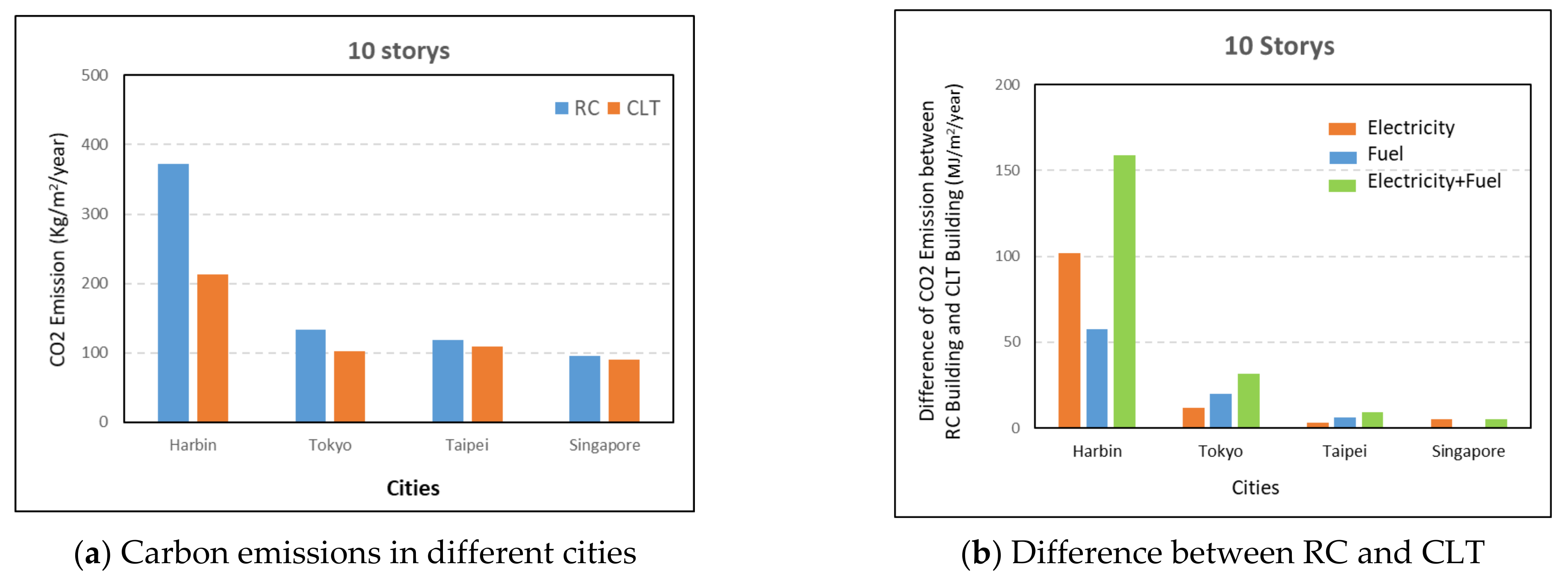

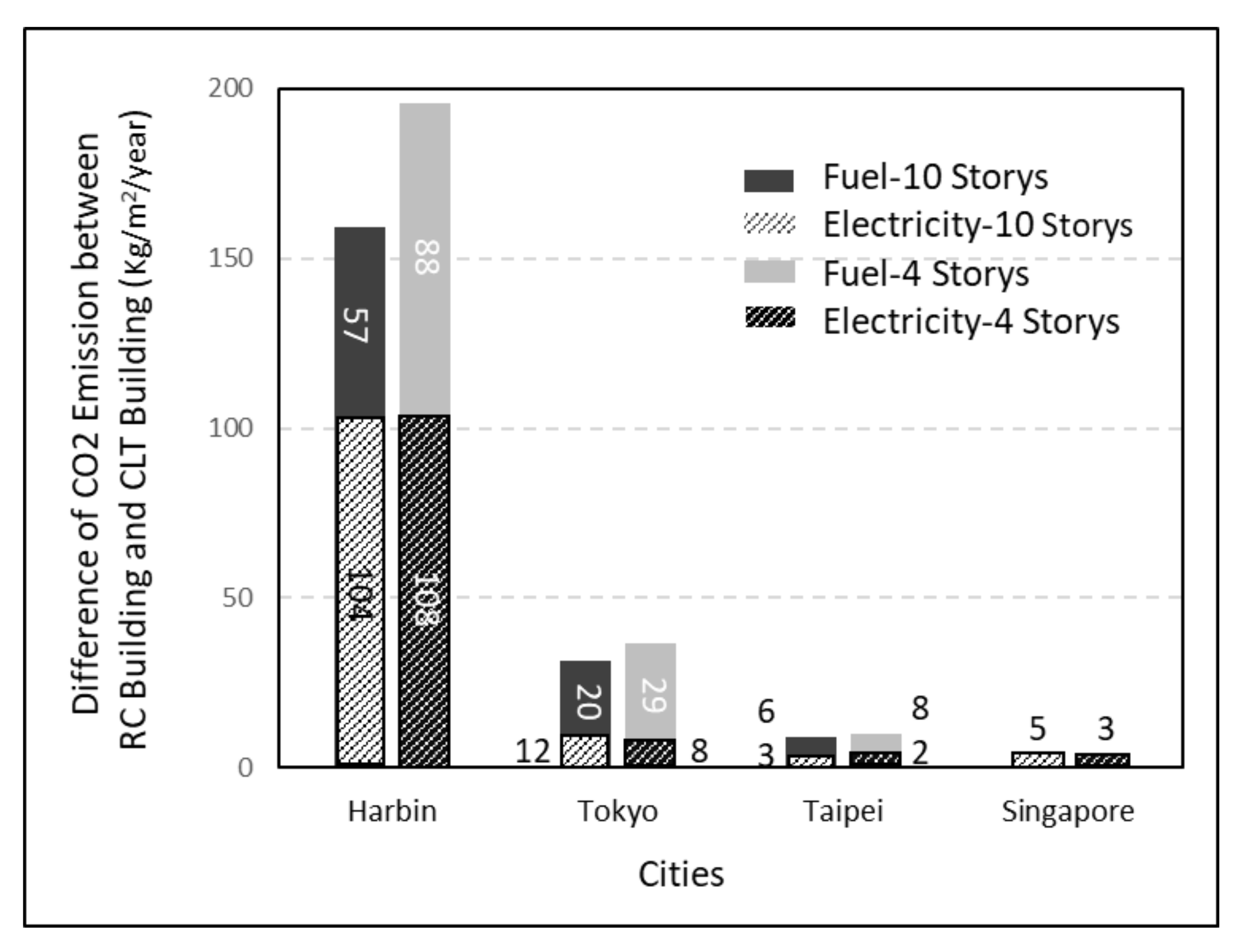

4.2. CO2 Emission

4.3. Potential Hybrid Structure System for Renovation in Asian Cities

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pierrehumbert, R. There Is No Plan B for Dealing with the Climate Crisis. Bull. At. Sci. 2019, 75, 1–7. [Google Scholar] [CrossRef]

- Guidelines on Green Houses of Worship, UN Environment Programme, July. 2020. Available online: https://www.unenvironment.org/resources/publication/guidelines-green-houses-worship (accessed on 5 October 2020).

- Green, M.; Taggart, J. Tall Wood Buildings: Design, Construction and Performance, 2nd ed.; Birkhäuser: Basel, Switzerland, 2020. [Google Scholar]

- Popovski, M.; Mohammad, M.; Ni, C.; Rezai, M.; Below, K.; Malczyk, R.; Sherstobitoff, J. Design and Construction of Tall Wood Buildings: Input Data, Testing and Advanced Analysis. In Proceedings of the 13th World Conference on Timber Engineering (13WCTE), Quebec City, QC, Canada, 10–14 August 2014. [Google Scholar]

- Connolly, T.; Loss, C.; Iqbal, A.; Tannert, T. Feasibility Study of Mass-Timber Cores for the UBC Tall Wood Building. Buildings 2018, 8, 98. [Google Scholar] [CrossRef]

- Connolly, T.; Moudgil, M.; Loss, C.; Iqbal, A. Feasibility of Cross-Laminated Timber Cores for the UBC Tall Wood Building. In Proceedings of the 15th World Conference on Timber Engineering (15WCTE), Seoul, Korea, 20–23 August 2018. [Google Scholar]

- Švajlenka, J.; Kozlovská, M. Evaluation of the Efficiency and Sustainability of Timber-Based Construction. J. Clean. Prod. 2020, 259, 120835. [Google Scholar] [CrossRef]

- C. P. CLT Handbook: Cross-Laminated Timber; Gagnon, S., Ed.; FPInnovations: Vancouver, BC, Canada, 2011. [Google Scholar]

- Alsayegh, G.; Mukhopadhyaya, P.; Wang, J.; Zalok, E.; van Reenen, D. Preliminary Characterization of Physical Properties of Cross-Laminated-Timber (CLT) Panels for Hygrothermal Modelling. Adv. Civ. Eng. Mater. 2013, 2, 472. [Google Scholar] [CrossRef]

- Laguarda Mallo, M.F.; Espinoza, O. Outlook for Cross-Laminated Timber in the United States. BioResources 2014, 9, 7427–7443. [Google Scholar] [CrossRef]

- Weissensteiner, J.; Barbu, M.C. Cross Laminated Timber—European Experiences. Pro Ligno 2013, 9, 69–72. [Google Scholar]

- Balasbaneh, A.T.; Sher, W. Comparative Sustainability Evaluation of Two Engineered Wood-Based Construction Materials: Life Cycle Analysis of CLT versus GLT. Build. Environ. 2021, 204, 108112. [Google Scholar] [CrossRef]

- Nässén, J.; Hedenus, F.; Karlsson, S.; Holmberg, J. Concrete vs. Wood in Buildings—An Energy System Approach. Build. Environ. 2012, 51, 361–369. [Google Scholar] [CrossRef]

- Haibo, G.; Ying, L.; Yiping, M.; Haoyu, H.; Cheng, S.; Yu, S. A Comparison of the Energy Saving and Carbon Reduction Performance between Reinforced Concrete and Cross-Laminated Timber Structures in Residential Buildings in the Severe Cold Region of China. Sustainability 2017, 9, 1. [Google Scholar]

- Haibo, G.; Ying, L.; Wen-Shao, C.; Yu, S.; Cheng, S. Energy Saving and Carbon Reduction in the Operation Stage of Cross Laminated Timber Residential Buildings in China. Sustainability 2017, 9, 292. [Google Scholar] [CrossRef]

- Khavari, A.M.; Pei, S.; Tabares-Velasco, P.C. Energy Consumption Analysis of Multistory Cross-Laminated Timber Residential Buildings: A comparative study. J. Archit. Eng. 2016, 22, 04016002. [Google Scholar] [CrossRef]

- Ying, L.; Haibo, G.; Cheng, S.; Wen-Shao, C. Assessing Cross Laminated Timber (CLT) as an Alternative Material for Mid-Rise Residential Buildings in Cold Regions in China—A Life-Cycle Assessment Approach. Sustainability 2016, 8, 1047. [Google Scholar] [CrossRef]

- Dong, Y.; Cui, X.; Yin, X.; Chen, Y.; Guo, H. Assessment of Energy Saving Potential by Replacing Conventional Materials by cross Laminated Timber (CLT)—A Case Study of Office Buildings in China. Appl. Sci. 2019, 9, 858. [Google Scholar] [CrossRef]

- Švajlenka, J.; Kozlovská, M.; Badida, M.; Moravec, M.; Dzuro, T.; Vranay, F. Analysis of the Characteristics of External Walls of Wooden Prefab Cross Laminated Timber. Energies 2020, 13, 5974. [Google Scholar] [CrossRef]

- Adekunle, T.O. Occupants’ Comfort and Stress Indices in a Structural Timber School Building in the Northeast US in Different Seasons. Build. Res. Inform. 2020, 48, 331–348. [Google Scholar] [CrossRef]

- Adekunle, T.O. A Field Survey on Thermal Comfort of Occupants and Cold Stress in CLT School Buildings. In Smart and Sustainable Cities and Buildings; Roggema, R., Roggema, A., Eds.; Springer: Cham, Switzerland, 2020. [Google Scholar]

- Amitha, J.; Satheeskumar, N.; Tuan, D.; Priyan, M.; Nick, H.; Lu, A. Life Cycle Performance of Cross Laminated Timber Mid-rise Residential Buildings in Australia. Energy Build. 2020, 223, 110091. [Google Scholar] [CrossRef]

- Laleman, R.; Albrecht, J. Estimations of the Reserve Margin during the Nuclear Phase-out. Int. J. Electr. Power Energy Syst. 2016, 81, 416–426. [Google Scholar] [CrossRef]

- Gülen, G.; Bellman, D.K. Scenarios of Resource Adequacy in ERCOT: Mandated Reserve Margin, Impact of Environmental Regulations and Integration of Renewables. Electr. J. 2015, 28, 89–100. [Google Scholar] [CrossRef]

- Lindner, B.; Brits, R.; van Vuuren, J.; Bekker, J. Tradeoffs between Levelling the Reserve Margin and Minimising Production Cost in Generator Maintenance Scheduling for Regulated Power Systems. Int. J. Electr. Power Energy Syst. 2018, 101, 458–471. [Google Scholar] [CrossRef]

- National Statistics (Taiwan). Housing Conditions of 2010 Statistical Tables. Population and Housing Census. 2010. Available online: https://census.dgbas.gov.tw/PHC2010/english/rehome.htm (accessed on 25 September 2020).

- Margani, G.; Evola, G.; Tardo, C.; Marino, E.M. Energy, Seismic, and Architectural Renovation of RC Framed Buildings with Prefabricated Timber Panels. Sustainability 2020, 12, 4845. [Google Scholar] [CrossRef]

- Barbagallo, F.; Margani, G.; Marino, E.M.; Moretti, A.; Tardo, C. Impact of Retrofit of RC Frames by CLT Panels and Friction Dampers. In Proceedings of the 8th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, CompDyn 2021, Streamed from Athens, Athens, Greece, 28–30 June 2021. [Google Scholar]

- Pelaz, B.; Blanco, J.M.; Cuadrado, J.; Egiluz, Z.; Buruaga, A. Analysis of the Influence of Wood Cladding on the Thermal Behavior of Building Façades; Characterization through Simulation by Using Different Tools and Comparative Testing Validation. Energy Build. 2017, 141, 349–360. [Google Scholar] [CrossRef]

- Cambiaso, F.; Pietrasanta, M.V. Innovative Timber Construction: Sustainability and High Performance Building Skin. Int. J. Eng. Technol. 2014, 6, 47–54. [Google Scholar] [CrossRef]

- Haba, R.; Kitamori, A.; Mori, T.; Fukuhara, T.; Fukuhara, T.; Isoda, H. Development of CLT Panels Bond-in Method for Seismic Retrofitting of RC Frame Structure. J. Struct. Constr. Eng. (Trans. AIJ) 2016, 81, 1299–1308. [Google Scholar] [CrossRef][Green Version]

- Khajehpour, M.; Pan, Y.; Tannert, T. Seismic Analysis of Hybrid Steel Moment Frame CLT Shear Walls Structures. J. Perform. Constr. Facil. 2021, 35, 04021059. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Faria, J.; Jalali, S. Embodied Energy versus Operational Energy. Showing the Shortcomings of the Energy Performance Building Directive (EPBD). Mater. Sci. Forum 2013, 730, 587–591. [Google Scholar] [CrossRef]

- Taipower Company Sustainabilty Report. 2008. Available online: https://www.taipower.com.tw/upload/85/2018010916401984784.pdf (accessed on 16 January 2021).

- CO2 Emissions, CO2 Emissions Intensity and Electricity Sales. 2020. Available online: https://www.tepco.co.jp/en/corpinfo/illustrated/environment/emissions-co2-e.html (accessed on 22 January 2021).

- Bureau of Energy, Ministry of Economic Affairs, Taiwan. 2019. Available online: https://www.moeaboe.gov.tw/ECW/populace/news/Board.aspx?kind=3&menu_id=57&news_id=17638 (accessed on 16 January 2021).

- EMA: Singapore Energy Statistics|Energy Transformation. 2020. Available online: https://www.ema.gov.sg/Singapore-Energy-Statistics-2019/Ch02/index2 (accessed on 18 January 2021).

- Ministry of Economic Affairs, Taiwan. 2017. Available online: https://reurl.cc/pd3oj8 (accessed on 16 January 2021).

- Peng, C. Calculation of a Building’s Life Cycle Carbon Emissions Based on Ecotect and Building Information Modeling. J. Clean. Prod. 2016, 112, 453–465. [Google Scholar] [CrossRef]

- The Technical Characteristics of KLH Cross-Laminated Timber Panels. Available online: http://www.klhuk.com/media/29233/technical%20characteristics.pdf (accessed on 5 May 2020).

- Stora Enso. CLT. Technical Brochure. Available online: https://www.storaenso.com/-/media/documents/download-center/documents/product-brochures/wood-products/clt-by-stora-enso-technical-brochure-en.pdf (accessed on 11 May 2020).

| Country | Electricity Carbon Emission Coefficient (kg CO2e/kWh) |

|---|---|

| China (Harbin) | 1.13 [34] |

| Japan (Tokyo) | 0.47 [35] |

| Taiwan (Taipei and Kaohsiung) | 0.53 [36] |

| Singapore | 0.41 [37] |

| Item | Carbon Emission Coefficient (CO2e/m³) |

|---|---|

| Natural gas | 1.88 [38] |

| Building Type | 4F | 10F | |

|---|---|---|---|

| Single-story floor area | 192.8 m2 | 702.6 m2 | |

| Total floor area | 771.2 m2 | 7026.0 m2 | |

| floor-to-ceiling height | others | 3.0 m | 3.2 m |

| Ground level | 3.2 m | 3.6 m | |

| Total surface area | 1161.2 m2 | 3906.6 m2 | |

| Exterior window ratio | 16.4% | 19.9% | |

| User number per unit area | 3 people/100 m2 | 3 people/100 m2 | |

| Total user number | 23 people | 211 people | |

| Average illumination power | 6.6 W/ m2 | 6.6 W/ m2 | |

| Wall Material | Wall Purpose | Total Thickness (mm) | Heat Transfer Coefficient W/(m2·K) | Thermal Resistance (m2·K)/W | Thermal Mass kJ/K |

|---|---|---|---|---|---|

| RC | Exterior wall | 150 | 3.87 | 0.25 | 60.98 |

| Interior wall | 120 | 3.46 | 0.29 | 22.59 | |

| CLT | Exterior wall (10F) | 300 | 0.30 | 3.3 | 4.66 |

| Exterior wall (4F) | 215 | 0.38 | 2.59 | 3.91 | |

| Interior wall | 150 | 0.59 | 1.67 | 2.48 |

| Wall Material | Wall Purpose | Total Thickness (mm) | Wall Schematic | Interior Material | Thickness (mm) |

|---|---|---|---|---|---|

| RC | Exterior wall | 150 |  | Ceramic tile | 10 |

| Cement mortar | 10 | ||||

| Concrete | 120 | ||||

| Cement mortar | 10 | ||||

| Interior wall | 120 |  | Cement mortar | 10 | |

| Concrete | 100 | ||||

| Cement mortar | 10 | ||||

| CLT | Exterior wall (10F) | 300 |  | Plasterboard | 15 |

| Rigid insulation wall | 50 | ||||

| CLT | 220 | ||||

| Plasterboard | 15 | ||||

| Exterior wall (4F) | 215 |  | Plasterboard | 15 | |

| Rigid insulation wall | 50 | ||||

| CLT | 135 | ||||

| Plasterboard | 15 | ||||

| Interior wall | 150 |  | Plywood | 10 | |

| Rigid insulation wall | 20 | ||||

| CLT | 110 | ||||

| Plywood | 10 |

| City | Temperature (°C) | Relative Humidity (%) | Wind Speed (m/s) | Radiation (Wh/m2) | ||||

|---|---|---|---|---|---|---|---|---|

| Hottest | Coldest | Highest | Lowest | Highest | Lowest | Highest | Lowest | |

| Harbin | 33 | −30 | 81 | 45 | 4.2 | 1.9 | 209 | 106 |

| Tokyo | 34 | −1 | 77 | 52 | 3.9 | 2.6 | 198 | 132 |

| Taipei | 35 | 7 | 84 | 76 | 4.6 | 2.2 | 166 | 44 |

| Singapore | 34 | 24 | 88 | 82 | 3.9 | 1.2 | 96 | 49 |

| Harbin | Tokyo | Taipei | Singapore | ||||||

|---|---|---|---|---|---|---|---|---|---|

| RC | CLT | RC | CLT | RC | CLT | RC | CLT | ||

| (A) Electricity (kWh/m²/yr) | 4 storys | 244 | 148 | 165 | 148 | 175 | 179 | 232 | 227 |

| 10 storys | 195 | 105 | 143 | 119 | 157 | 151 | 202 | 190 | |

| (B) Electricity (MJ/m²/yr) | 4 storys | 877 | 534 | 594 | 533 | 644 | 631 | 833 | 818 |

| 10 storys | 702 | 377 | 517 | 426 | 566 | 543 | 726 | 682 | |

| (C) Fuel (MJ/m²/yr) | 4 storys | 4021 | 2251 | 1597 | 1020 | 761 | 603 | 390 | 389 |

| 10 storys | 3075 | 1917 | 1304 | 899 | 701 | 583 | 382 | 382 | |

| Sum (B) + (C) (MJ/m²/yr) | 4 storys | 4898 | 2785 | 2191 | 1553 | 1392 | 1247 | 1223 | 1207 |

| 10 storys | 3777 | 2294 | 1821 | 1325 | 1267 | 1126 | 1108 | 1064 | |

| Harbin | Tokyo | Taipei | Singapore | ||

|---|---|---|---|---|---|

| Electricity (Ratio of CLT/RC) | 4 storys | 0.61 | 0.90 | 0.98 | 0.98 |

| 10 storys | 0.54 | 0.82 | 0.96 | 0.94 | |

| Fuel (Ratio of CLT/RC) | 4 storys | 0.56 | 0.64 | 0.79 | 1.00 |

| 10 storys | 0.62 | 0.69 | 0.83 | 1.00 | |

| Total Consumption (Ratio of CLT/RC) | 4 storys | 0.57 | 0.71 | 0.88 | 0.99 |

| 10 storys | 0.61 | 0.73 | 0.89 | 0.96 | |

| Harbin | Tokyo | Taipei | Singapore | ||||||

|---|---|---|---|---|---|---|---|---|---|

| RC | CLT | RC | CLT | RC | CLT | RC | CLT | ||

| (A)Electricity (kg/m²/yr) | 4 storys | 276 | 167 | 79 | 71 | 95 | 93 | 96 | 93 |

| 10 storys | 220 | 119 | 69 | 57 | 84 | 81 | 83 | 78 | |

| (C)Fuel (Kg/m²/yr) | 4 storys | 199 | 111 | 79 | 50 | 38 | 30 | 12 | 12 |

| 10 storys | 152 | 95 | 69 | 65 | 35 | 29 | 12 | 12 | |

| Sum (A)+(B) (Kg/m²/yr) | 4 storys | 474 | 278 | 158 | 121 | 133 | 123 | 108 | 105 |

| 10 storys | 372 | 213 | 133 | 102 | 118 | 109 | 95 | 90 | |

| Harbin | Tokyo | Taipei | Singapore | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RC | CLT | Hybrid | RC | CLT | Hybrid | RC | CLT | Hybrid | RC | CLT | Hybrid | |

| (A) Electricity (MJ/m2/yr) | 702 | 377 | 389 | 517 | 426 | 436 | 566 | 543 | 549 | 726 | 682 | 692 |

| (B) Fuel (MJ/m2/yr) | 3075 | 1917 | 1874 | 1304 | 899 | 882 | 701 | 583 | 570 | 382 | 382 | 382 |

| Sum (A) + (B) (MJ/m2/yr) | 3777 | 2294 | 2263 | 1821 | 1325 | 1318 | 1267 | 1126 | 1119 | 1108 | 1064 | 1074 |

| City | RC Structure Ratio (RC/RC) | Hybrid Structure Ratio (Hybrid/RC) | CLT Structure Ratio (CLT/RC) |

|---|---|---|---|

| Harbin |  |  |  |

| Tokyo |  |  |  |

| Taipei |  |  |  |

| Singapore |  |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsai, M.-T.; Lin, W.-T. Efficiency of Energy Consumption between Reinforced Concrete Structure and Cross-Laminated Timber Based Hybrid Structure in East Asian Cities. Energies 2022, 15, 165. https://doi.org/10.3390/en15010165

Tsai M-T, Lin W-T. Efficiency of Energy Consumption between Reinforced Concrete Structure and Cross-Laminated Timber Based Hybrid Structure in East Asian Cities. Energies. 2022; 15(1):165. https://doi.org/10.3390/en15010165

Chicago/Turabian StyleTsai, Meng-Ting, and Wei-Ting Lin. 2022. "Efficiency of Energy Consumption between Reinforced Concrete Structure and Cross-Laminated Timber Based Hybrid Structure in East Asian Cities" Energies 15, no. 1: 165. https://doi.org/10.3390/en15010165

APA StyleTsai, M.-T., & Lin, W.-T. (2022). Efficiency of Energy Consumption between Reinforced Concrete Structure and Cross-Laminated Timber Based Hybrid Structure in East Asian Cities. Energies, 15(1), 165. https://doi.org/10.3390/en15010165