Potential Use of Constructed Wetland Systems for Rural Sanitation and Wastewater Reuse in Agriculture in the Moroccan Context

Abstract

:1. Introduction

2. Materials and Methods

3. Constructed Wetlands Definition and Classification

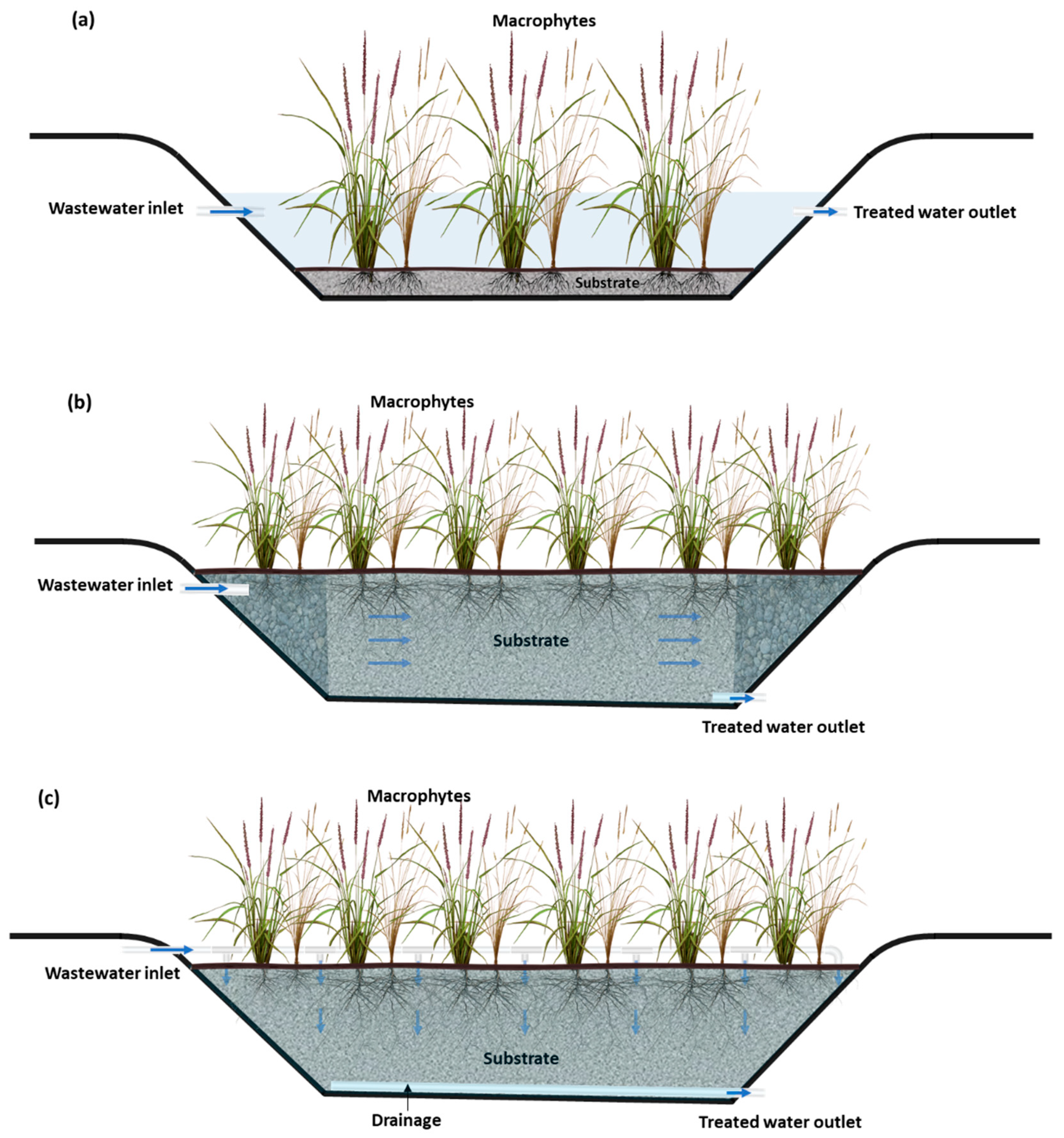

3.1. Free Water Surface Constructed Wetlands (FWS CWs)

3.2. Horizontal Subsurface Constructed Wetlands (HSSF CWs)

3.3. Vertical Subsurface Constructed Wetlands (VSSF CWs)

3.4. Hybrid Constructed Wetlands

4. Constructed Wetlands Components

4.1. Substrate

4.2. Vegetation

4.3. Microorganisms

5. Discussion on CWs Performances under Different Design and Operational Parameters

6. Wastewater Reuse and Potential of Constructed Wetlands in the Moroccan Context

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Santos Pereira, L.; Cordery, I.; Iacovides, I. Coping with Water Scarcity: Addressing the Challenges; Springer: Dordrecht, The Netherlands, 2009; pp. 1–382. [Google Scholar] [CrossRef]

- Ofori, S.; Puškáčová, A.; Růžičková, I.; Wanner, J. Treated wastewater reuse for irrigation: Pros and cons. Sci. Total Environ. 2021, 760, 144026. [Google Scholar] [CrossRef]

- Elgallal, M.; Fletcher, L.; Evans, B. Assessment of potential risks associated with chemicals in wastewater used for irrigation in arid and semiarid zones: A review. Agric. Water Manag. 2016, 177, 419–431. [Google Scholar] [CrossRef]

- FAO. The Water-Energy-Food Nexus; FAO: Rome, Italy, 2014; pp. 215–243. [Google Scholar] [CrossRef]

- Singh, A. A review of wastewater irrigation: Environmental implications. Resour. Conserv. Recycl. 2021, 168, 105454. [Google Scholar] [CrossRef]

- UNESCO. Valuing Water; UNESCO: Paris, France, 2021; Volume 191, ISBN 9789231004346. [Google Scholar]

- UNESCO; WSSM. Water Reuse within a Circular Economy Context; UNESCO: Paris, France; i-WSSM: Daejeon, Korea, 2020; ISBN 978-92-3-100413-1. [Google Scholar]

- Helmecke, M.; Fries, E.; Schulte, C. Regulating water reuse for agricultural irrigation: Risks related to organic micro-contaminants. Environ. Sci. Eur. 2020, 32, 10. [Google Scholar] [CrossRef] [Green Version]

- Nan, X.; Lavrnić, S.; Toscano, A. Potential of constructed wetland treatment systems for agricultural wastewater reuse under the EU framework. J. Environ. Manag. 2020, 275, 111219. [Google Scholar] [CrossRef]

- Salgot, M. ScienceDirect Wastewater treatment and water reuse. Curr. Opin. Environ. Sci. Health 2018, 2, 64–74. [Google Scholar] [CrossRef]

- Almuktar, S.A.A.A.N.; Abed, S.N.; Scholz, M. Wetlands for wastewater treatment and subsequent recycling of treated effluent: A review. Environ. Sci. Pollut. Res. 2018, 25, 23595–23623. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chojnacka, K.; Witek-krowiak, A.; Moustakas, K.; Skrzypczak, D.; Mikula, K.; Loizidou, M. A transition from conventional irrigation to fertigation with reclaimed wastewater: Prospects and challenges. Renew. Sustain. Energy Rev. 2020, 130, 109959. [Google Scholar] [CrossRef]

- Rizzo, L.; Gernjak, W.; Krzeminski, P.; Malato, S.; McArdell, C.S.; Perez, J.A.S.; Schaar, H.; Fatta-Kassinos, D. Best available technologies and treatment trains to address current challenges in urban wastewater reuse for irrigation of crops in EU countries. Sci. Total Environ. 2020, 710, 136312. [Google Scholar] [CrossRef]

- Alhamed, H.; Biad, M.; Saad, S.; Masaki, M. Business Opportunities Report for Reuse of Wastewater in Morocco; Netherlands Enterprise Agency: The Hague, The Netherlands, 2018; p. 96. [Google Scholar]

- World-Bank Gestion de la Rareté de l’ Eau en Milieu Urbain au Maroc; World Bank: Washington, DC, USA, 2017; pp. 1–38.

- Jaramillo, M.F.; Restrepo, I. Wastewater reuse in agriculture: A review about its limitations and benefits. Sustainability 2017, 9, 1734. [Google Scholar] [CrossRef] [Green Version]

- McFarland, M.J.; Sanderson, M.A.; McFarland, A.M.S. Wastewater and Reclaimed Water; The American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 1990; pp. 754–789. [Google Scholar]

- Kaushal, M.; Patil, M.D.; Wani, S.P. Potency of constructed wetlands for deportation of pathogens index from rural, urban and industrial wastewater. Int. J. Environ. Sci. Technol. 2018, 15, 637–648. [Google Scholar] [CrossRef] [Green Version]

- Skaiki, S. Réutilisation des eaux Usées Traitées (Reut) en Méditerranée. Rapport REUT—Version Finale. 2020. Available online: https://www.pseau.org/ (accessed on 17 December 2021).

- Rajasulochana, P. Comparison on efficiency of various techniques in treatment of waste and sewage water—A comprehensive review. Resour. Technol. 2016, 2, 175–184. [Google Scholar] [CrossRef] [Green Version]

- Rodias, E.; Aivazidou, E.; Achillas, C.; Aidonis, D.; Bochtis, D. Water-energy-nutrients synergies in the agrifood sector: A circular economy framework. Energies 2021, 14, 159. [Google Scholar] [CrossRef]

- Moreira, F.D.; Dias, E.H.O. Constructed wetlands applied in rural sanitation: A review. Environ. Res. 2020, 190, 110016. [Google Scholar] [CrossRef] [PubMed]

- Maiga, Y.; von Sperling, M.; Mihelcic, J.R. Constructed Wetlands. 2017. Available online: https://www.waterpathogens.org/book/constructed-wetlands (accessed on 17 December 2021).

- Masi, F.; Rizzo, A.; Regelsberger, M. The role of constructed wetlands in a new circular economy, resource oriented, and ecosystem services paradigm. J. Environ. Manag. 2018, 216, 275–284. [Google Scholar] [CrossRef]

- Cohen-Shacham, E.; Walters, G.; Janzen, C.; Maginnis, S. Nature-based Solutions to address global societal challenges; IUCN: Gland, Switzerland, 2016; ISBN 9782831718125. [Google Scholar]

- European Commission. Towards an EU Research and Innovation Policy Agenda for Nature-Based Solutions & Re-Naturing Cities: Final Report of the Horizon 2020 Expert Group on “Nature-Based Solutions and Re-Naturing Cities”; European Commission: Brussels, Belgium, 2015; ISBN 9789279460517. [Google Scholar]

- Stefanakis, A.; Akratos, C.S.; Tsihrintzis, V.A. Vertical Flow Constructed Wetlands: Eco-engineering Systems for Wastewater and Sludge Treatment; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed wetlands for treatment of industrial wastewaters: A review. Ecol. Eng. 2014, 73, 724–751. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed wetlands for wastewater treatment. Encycl. Ecol. 2011, 45, 14–21. [Google Scholar] [CrossRef] [Green Version]

- Vymazal, J. The use of hybrid constructed wetlands for wastewater treatment with special attention to nitrogen removal: A review of a recent development. Water Res. 2013, 47, 4795–4811. [Google Scholar] [CrossRef]

- Vymazal, J. Constructed Wetlands for Wastewater Treatment, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780444641304. [Google Scholar]

- US EPA. Manual Constructed Wetlands Treatment of Municipal Wastewaters; EPA/625/R-99/010; US EPA: Washington, DC, USA, 2000; p. 166. [Google Scholar]

- Parde, D.; Patwa, A.; Shukla, A.; Vijay, R.; Killedar, D.J.; Kumar, R. A review of constructed wetland on type, treatment and technology of wastewater. Environ. Technol. Innov. 2021, 21, 101261. [Google Scholar] [CrossRef]

- Kadlec, R.H.; Wallace, S. Treatment Wetlands; CRC Press: Boca Raton, FL, USA, 2008; ISBN 9781566705264. [Google Scholar]

- Gunes, K.; Tuncsiper, B.; Ayaz, S.; Drizo, A. The ability of free water surface constructed wetland system to treat high strength domestic wastewater: A case study for the Mediterranean. Ecol. Eng. 2012, 44, 278–284. [Google Scholar] [CrossRef]

- Ezzat, S.M.; Moustafa, M.T. Treating wastewater under zero waste principle using wetland mesocosms. Front. Environ. Sci. Eng. 2021, 15, 59. [Google Scholar] [CrossRef]

- Vymazal, J. Is removal of organics and suspended solids in horizontal sub-surface flow constructed wetlands sustainable for twenty and more years? Chem. Eng. J. 2019, 378, 122117. [Google Scholar] [CrossRef]

- Dotro, G.; Molle, P.; Nivala, J.; Puigagut, J.; Stein, O. BIOLOGICAL WASTE WATER TREATMENT SERIES: Treatment Wetlands; IWA Publishing: London, UK, 2017; Volume 7, ISBN 9781780408767. [Google Scholar]

- Toscano, A.; Marzo, A.; Milani, M.; Cirelli, G.L.; Barbagallo, S. Comparison of removal efficiencies in Mediterranean pilot constructed wetlands vegetated with different plant species. Ecol. Eng. 2015, 75, 155–160. [Google Scholar] [CrossRef]

- Tuttolomondo, T.; Leto, C.; La Bella, S.; Leone, R.; Virga, G.; Licata, M. Water balance and pollutant removal efficiency when considering evapotranspiration in a pilot-scale horizontal subsurface flow constructed wetland in Western Sicily (Italy). Ecol. Eng. 2016, 87, 295–304. [Google Scholar] [CrossRef]

- Witthayaphirom, C.; Chiemchaisri, C.; Chiemchaisri, W.; Ogata, Y.; Ebie, Y.; Ishigaki, T. Long-term removals of organic micro-pollutants in reactive media of horizontal subsurface flow constructed wetland treating landfill leachate. Bioresour. Technol. 2020, 312, 123611. [Google Scholar] [CrossRef] [PubMed]

- Witthayaphirom, C.; Chiemchaisri, C.; Chiemchaisri, W. Optimization of reactive media for removing organic micro-pollutants in constructed wetland treating municipal landfill leachate. Environ. Sci. Pollut. Res. 2020, 27, 24627–24638. [Google Scholar] [CrossRef] [PubMed]

- Andreo-Martínez, P.; García-Martínez, N.; Quesada-Medina, J.; Almela, L. Domestic wastewaters reuse reclaimed by an improved horizontal subsurface-flow constructed wetland: A case study in the southeast of Spain. Bioresour. Technol. 2017, 233, 236–246. [Google Scholar] [CrossRef]

- Verma, R.; Suthar, S. Performance assessment of horizontal and vertical surface flow constructed wetland system in wastewater treatment using multivariate principal component analysis. Ecol. Eng. 2018, 116, 121–126. [Google Scholar] [CrossRef]

- Zeng, L.; Tao, R.; Tam, N.F.; Huang, W.; Zhang, L.; Man, Y.; Xu, X.; Dai, Y.; Yang, Y. Differences in bacterial N, P, and COD removal in pilot-scale constructed wetlands with varying flow types. Bioresour. Technol. 2020, 318, 124061. [Google Scholar] [CrossRef]

- Nakamura, K.; Hatakeyama, R.; Tanaka, N.; Takisawa, K.; Tada, C.; Nakano, K. A novel design for a compact constructed wetland introducing multi-filtration layers coupled with subsurface superficial space. Ecol. Eng. 2017, 100, 99–106. [Google Scholar] [CrossRef]

- Abdelhakeem, S.G.; Aboulroos, S.A.; Kamel, M.M. Performance of a vertical subsurface flow constructed wetland under different operational conditions. J. Adv. Res. 2016, 7, 803–814. [Google Scholar] [CrossRef] [Green Version]

- El fanssi, S.; Ouazzani, N.; Mandi, L. Effectiveness of domestic wastewater treatment using a constructed wetlands and reuse tests of treated wastewater in rural area of Morocco. Geo Eco Trop. 2019, 43, 385–393. [Google Scholar]

- Liang, M.Y.; Han, Y.C.; Easa, S.M.; Chu, P.P.; Wang, Y.L.; Zhou, X.Y. New solution to build constructed wetland in cold climatic region. Sci. Total Environ. 2020, 719, 137124. [Google Scholar] [CrossRef] [PubMed]

- Ávila, C.; Bayona, J.M.; Martín, I.; Salas, J.J.; García, J. Emerging organic contaminant removal in a full-scale hybrid constructed wetland system for wastewater treatment and reuse. Ecol. Eng. 2015, 80, 108–116. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, X.C.; Nguyen, D.D.; Tran, Q.B.; Nguyen, T.T.H.; Tran, T.K.A.; Tran, T.C.P.; Nguyen, T.H.G.; Tran, T.N.T.; La, D.D.; Chang, S.W.; et al. Two-step system consisting of novel vertical flow and free water surface constructed wetland for effective sewage treatment and reuse. Bioresour. Technol. 2020, 306, 123095. [Google Scholar] [CrossRef]

- Torrens, A.; de la Varga, D.; Ndiaye, A.K.; Folch, M.; Coly, A. Innovative multistage constructed wetland for municipal wastewater treatment and reuse for agriculture in Senegal. Water 2020, 12, 3139. [Google Scholar] [CrossRef]

- Morvannou, A.; Forquet, N.; Michel, S.; Troesch, S.; Molle, P. Treatment performances of French constructed wetlands: Results from a database collected over the last 30 years. Water Sci. Technol. 2015, 71, 1333–1339. [Google Scholar] [CrossRef] [Green Version]

- Zamora, S.; Marín-Muñíz, J.L.; Nakase-Rodríguez, C.; Fernández-Lambert, G.; Sandoval, L. Wastewater treatment by constructed wetland eco-technology: Influence of mineral and plastic materials as filter media and tropical ornamental plants. Water 2019, 11, 2344. [Google Scholar] [CrossRef] [Green Version]

- Yuan, Y.; Yang, B.; Wang, H.; Lai, X.; Li, F.; Salam, M.M.A.; Pan, F.; Zhao, Y. The simultaneous antibiotics and nitrogen removal in vertical flow constructed wetlands: Effects of substrates and responses of microbial functions. Bioresour. Technol. 2020, 310, 123419. [Google Scholar] [CrossRef]

- Xu, G.; Li, Y.; Hou, W.; Wang, S.; Kong, F. Effects of substrate type on enhancing pollutant removal performance and reducing greenhouse gas emission in vertical subsurface flow constructed wetland. J. Environ. Manag. 2021, 280, 111674. [Google Scholar] [CrossRef]

- Dordio, A.V.; Carvalho, A.J.P. Organic xenobiotics removal in constructed wetlands, with emphasis on the importance of the support matrix. J. Hazard. Mater. 2013, 252–253, 272–292. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, H.; Zhang, J.; Ngo, H.H.; Guo, W.; Hu, Z.; Liang, S.; Fan, J.; Liu, H. A review on the sustainability of constructed wetlands for wastewater treatment: Design and operation. Bioresour. Technol. 2015, 175, 594–601. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Cai, Z.; Sheng, S.; Pan, F.; Chen, F.; Fu, J. Comprehensive evaluation of substrate materials for contaminants removal in constructed wetlands. Sci. Total Environ. 2020, 701, 134736. [Google Scholar] [CrossRef]

- Yang, Y.; Zhao, Y.; Liu, R.; Morgan, D. Global development of various emerged substrates utilized in constructed wetlands. Bioresour. Technol. 2018, 261, 441–452. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Xu, D.; He, F.; He, J.; Wu, Z. Comprehensive evaluation of substrates in vertical-flow constructed wetlands for domestic wastewater treatment. Water Pract. Technol. 2015, 10, 625–632. [Google Scholar] [CrossRef]

- Wang, H.X.; Xu, J.L.; Sheng, L.X.; Liu, X.J. A review of research on substrate materials for constructed wetlands. Mater. Sci. Forum 2018, 913, 917–929. [Google Scholar] [CrossRef]

- Mateus, D.M.R.; Pinho, H.J.O. Evaluation of solid waste stratified mixtures as constructed wetland fillers under different operation modes. J. Clean. Prod. 2020, 253, 119986. [Google Scholar] [CrossRef]

- Madeła, M.; Skuza, M. Towards a circular economy: Analysis of the use of biowaste as biosorbent for the removal of heavy metals. Energies 2021, 14, 5427. [Google Scholar] [CrossRef]

- Mateus, D.M.R.; Pinho, H.J.O. Screening of Solid Waste as Filler Material for Constructed Wetlands. IOP Conf. Ser. Earth Environ. Sci. 2018, 182, 012001. [Google Scholar] [CrossRef] [Green Version]

- Bianchi, E.; Coppi, A.; Nucci, S.; Antal, A.; Berardi, C.; Coppini, E.; Fibbi, D.; Del Bubba, M.; Gonnelli, C.; Colzi, I. Closing the loop in a constructed wetland for the improvement of metal removal: The use of Phragmites australis biomass harvested from the system as biosorbent. Environ. Sci. Pollut. Res. 2021, 28, 11444–11453. [Google Scholar] [CrossRef]

- Wang, H.; Sheng, L.; Xu, J. Clogging mechanisms of constructed wetlands: A critical review. J. Clean. Prod. 2021, 295, 126455. [Google Scholar] [CrossRef]

- Miranda, S.T.; de Matos, A.T.; de Matos, M.P.; Saraiva, C.B.; Teixeira, D.L. Influence of the substrate type and position of plant species on clogging and the hydrodynamics of constructed wetland systems. J. Water Process Eng. 2019, 31, 100871. [Google Scholar] [CrossRef]

- Vymazal, J. Emergent plants used in free water surface constructed wetlands: A review. Ecol. Eng. 2013, 61, 582–592. [Google Scholar] [CrossRef]

- Shelef, O.; Gross, A.; Rachmilevitch, S. Role of plants in a constructed Wetland: Current and new perspectives. Water 2013, 5, 405–419. [Google Scholar] [CrossRef]

- Vymazal, J.; Březinová, T. Accumulation of heavy metals in aboveground biomass of Phragmites australis in horizontal flow constructed wetlands for wastewater treatment: A review. Chem. Eng. J. 2016, 290, 232–242. [Google Scholar] [CrossRef]

- Wang, J.; Wang, W.; Xiong, J.; Li, L.; Zhao, B.; Sohail, I.; He, Z. A constructed wetland system with aquatic macrophytes for cleaning contaminated runoff/storm water from urban area in Florida. J. Environ. Manag. 2021, 280, 111794. [Google Scholar] [CrossRef]

- Leto, C.; Tuttolomondo, T.; La Bella, S.; Leone, R.; Licata, M. Effects of plant species in a horizontal subsurface flow constructed wetland—Phytoremediation of treated urban wastewater with Cyperus alternifolius L. and Typha latifolia L. in the West of Sicily (Italy). Ecol. Eng. 2013, 61, 282–291. [Google Scholar] [CrossRef]

- Maucieri, C.; Salvato, M.; Borin, M. Vegetation contribution on phosphorus removal in constructed wetlands. Ecol. Eng. 2020, 152, 105853. [Google Scholar] [CrossRef]

- Meng, P.; Pei, H.; Hu, W.; Shao, Y.; Li, Z. How to increase microbial degradation in constructed wetlands: Influencing factors and improvement measures. Bioresour. Technol. 2014, 157, 316–326. [Google Scholar] [CrossRef]

- Fu, G.; Wu, J.; Han, J.; Zhao, L.; Chan, G.; Leong, K. Effects of substrate type on denitrification efficiency and microbial community structure in constructed wetlands. Bioresour. Technol. 2020, 307, 123222. [Google Scholar] [CrossRef]

- Yu, G.; Li, P.; Wang, G.; Wang, J.; Zhang, Y.; Wang, S.; Yang, K. A review on the removal of heavy metals and metalloids by constructed wetlands: Bibliometric, removal pathways, and key factors. World J. Microbiol. Biotechnol. 2021, 37, 1–12. [Google Scholar] [CrossRef]

- Shingare, R.P.; Thawale, P.R.; Raghunathan, K.; Mishra, A.; Kumar, S. Constructed wetland for wastewater reuse: Role and efficiency in removing enteric pathogens. J. Environ. Manag. 2019, 246, 444–461. [Google Scholar] [CrossRef]

- Wu, S.; Carvalho, P.N.; Müller, J.A.; Manoj, V.R.; Dong, R. Sanitation in constructed wetlands: A review on the removal of human pathogens and fecal indicators. Sci. Total Environ. 2016, 541, 8–22. [Google Scholar] [CrossRef] [PubMed]

- Elfanssi, S.; Ouazzani, N.; Latrach, L.; Hejjaj, A.; Mandi, L. Phytoremediation of domestic wastewater using a hybrid constructed wetland in mountainous rural area. Int. J. Phytoremediation 2018, 20, 75–87. [Google Scholar] [CrossRef] [PubMed]

- Soudi, B. Appui a La Promotion De La Reutilisation Des Eaux Usees Par Le Renforcement Des Aspects Institutionnels, Reglementaires Et Financieres, Ainsi Que Des Démarches Participatives, Des Mesures Incitatives Et La Sensibilisation (Activité n° EFS-MO-2). 2018. Available online: https://www.swim-h2020.eu/wp-content/uploads/2018/09/SWIM-H2020-EFS-MO-2-Global-Report.pdf. (accessed on 17 December 2021).

- Malki, M.; Bouchaou, L.; Mansir, I.; Benlouali, H.; Nghira, A.; Choukr-Allah, R. Wastewater treatment and reuse for irrigation as alternative resource for water safeguarding in Souss-Massa region, Morocco. Eur. Water 2017, 59, 365–371. [Google Scholar]

- Shoushtarian, F.; Negahban-Azar, M. World wide regulations and guidelines for agriculturalwater reuse: A critical review. Water 2020, 12, 971. [Google Scholar] [CrossRef] [Green Version]

- Jeong, H.; Kim, H.; Jang, T. Irrigation water quality standards for indirect wastewater reuse in agriculture: A contribution toward sustainablewastewater reuse in South korea. Water 2016, 8, 169. [Google Scholar] [CrossRef] [Green Version]

- SEEE. Arrêté conjoint du ministre de l’équipement et du ministre chargé de l’aménagement du territoire, de l’urbanisme, de l’habitat et de l’environnement n° 1276-01 Définissant la Grille de Qualité des eaux Destinées à L’irrigation 2002. Available online: http://www.eau-tensift.net/fileadmin/user_files/pdf/reglementation/ControleQualiteEau/Arrete1276_01NormeQualitepourIrrigation.pdf (accessed on 17 December 2021).

- Saidi, A.; Elamrani, B.; Amraoui, F. Mise en place d’un filtre planté pour le traitement des eaux usées d’un Hammam et leur réutilisation dans l’irrigation d’une ferme solidaire dans le périurbain Casablancais. J. Mater. Environ. Sci. 2014, 5, 2184–2190. [Google Scholar]

- El Hamouri, B.; Nazih, J.; Lahjouj, J. Subsurface-horizontal flow constructed wetland for sewage treatment under Moroccan climate conditions B. Desalination 2007, 248, 123–130. [Google Scholar] [CrossRef]

| Type of CW | Location | Experimental Scale | Type of Wastewater | Pre-Treatment | Surface (m²) | Experimental Period (Months) | Plant Species | Substrate | HLR (m/d) | HRT (day) | OLR (g/m²d) | Reference | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| COD | BOD5 | ||||||||||||

| Multistage FWS CW | Turkey | Full-scale | High-strength domestic wastewater | Septic system | 2840 | 12 | 2nd stage: Algae + Macrophyte 3rd stage: Typha latifolia L. | - | 0.163 | 29.1 | 100.21 | 47.50 | [35] |

| FWS CW | Egypt | Mesocosms | Domestic wastewater | Dynamic roughing filter | 0.975 | - | Cyperus papyrus | M1: Soil M2: Soil amended with zeolite | 0.15 | 2.93 | - | 5.8 | [36] |

| HSSF CW | Spain | Full-scale | Artificially aerated domestic wastewater | Decanter tank | 8 | 12 | Phragmites australis | Blast furnace slags (BFS) Construction sand | 0.0262 | 8.70 | - | - | [43] |

| HSSF CW | Italy | Pilot-scale | Treated wastewater | - | 4.5 | - | Vetiveria zizanoides Miscanthus x giganteus Arundo donax Phragmites australis | Volcanic gravel | 0.36 | 0.54 | 40 | - | [39] |

| HSSF CW | Mexico | Microcosms | Domestic wastewater | - | 0.495 | 6 | Canna indica Cyperus papyrus Hedychium coronarium | S-A: Porous stone + tepezil + soil S-B: Porous stone + Plastic residues+ tepezil + soil | 0.08 | 3 | - | [54] | |

| HSSF CW | Thailand | Pilot-scale | Landfill leachate | - | 2 | 36 | Typha sp. | Mixture: sand-clay-iron powder | 0.04 | 5.9–6.8 | - | - | [41] |

| HSSF CW | Italy | Pilot-scale | Secondary treated wastewater | Secondary treated wastewater | 33 | 6 | Cyperus alternifolius L.

Typha latifolia L. | Silica quartz river gravel | 0.12 | - | 6.54 | 3.216 | [40] |

| Four-layer VSSF CW | Japan | Full scale | Anaerobic digestate | - | 100 | Ornamental flowers | Granular calcium silicate Recycled granular glass sand Granular zeolite | 0.01 | - | 135.4 | - | [46] | |

| Multistage VSSF CWs | China | Lab-scale | Synthetic wastewater | - | 0.2 | 4 | Phragmites communis | CW-Z: Cobblestone + Zeolite + Quartz sand + soil CW-M: Cobblestone + Mn ore + Quartz sand + soil CW-C: Cobblestone + Biochar + Quartz sand + soil | 0.05 | 3 | 153.965 | - | [55] |

| VSSF CW | China | Lab-scale | Synthetic sewage | - | 4 | Iris pseudacorus | GG-CW: Gravel + Gravel+ sand WS-CW: Gravel+ Walnut shell group + sand MO-CW: Gravel+ Mn ore group + sand AA-CW: Gravel+ Activated alumina group + sand | - | 3 | - | - | [56] | |

| VSSF CW | Egypt | Pilot-scale | Domestic wastewater | - | - | 8 | Phragmites australis | Gravel Vermiculite | 0.15 | 0.5 | - | - | [47] |

| Hybrid CW (VF-HF-HF Cws) | China | Pilot-scale | Domestic wastewater | - | 16 | 3 | - | Gravel Zeolite Volcanic rock Steel slag | 0.2–0.3 | 06–10 | - | - | [49] |

| Hybrid CW (VSSF-HSSF-FWS CWs) | Spain | Pilot-scale | Urban wastewater | Screening + sand and grease removal + Imhoff tank | 786 | 1 | SSF: Phragmites australis FWS: Typha spp. + Scirpus spp.+ Iris pseudacorus + Carex flacca. +Cyperus rutundus. +Juncus spp. | Sand Siliceous gravel Siliceous gravel Stones | 0.044 | >7.4 | - | 6 | [50] |

| Hybrid CW (VSSF-HSSF CWs) | Morocco | Full-scale | Domestic wastewater | Screening + decanter tank | 218 | 24 | Phragmites australis | VSSF: Pebble + coarse gravel + fine gravel HSSF: Mixture of sand and gravel | 0.17 | - | - | [48] | |

| Hybrid CW (Novel VSSF-FWS CWs) | Vietnam | Lab-scale | Domestic wastewater | - | - | - | Colocasia esculenta (Tree) Dracaena sanderiana (Lucky bamboo) | NVF: Expanded clay + sand+ gravel + sandy soil FWS: Sandy soil layer | I: 0.02 II: 0.04 III: 0.06 IV: 0.12 | - | - | 1.022 3.136 4.614 8.952 | [51] |

| Hybrid CW (VSSF-VSSF-HSSF CWs) | Senegal | Full-scale | Municipal wastewater | Settler tank with bar racks | 192 | 6 | Phragmites and Typha | FV1a: Silex FV1b: Granite FV1c: River gravel + Silex FV2a: River sand FV2b: River sand FHa: Silex FHb: Silex | 0.026 | - | 66–199 | 30–92 | [52] |

| VSSF CWs FWS CWs HSSF CWs | China | Pilot-scale | Domestic wastewater | - | 0.48 | 6 | Thalia dealbata | Gravel | 0.25 | - | 55 | - | [45] |

| Canna indica | |||||||||||||

| HSSF CW VSSF CW | India | Pilot-scale | Dairy wastewater effluent | - | 9 | Typha. angustifolia | Sand + gravel + boulders | 0.288–0.345 | 1 | - | - | [44] | |

| Reference | Specification | Removal Efficiency (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Organic Matter | Suspended Solids | Nutrients | Pathogens Indicators | |||||||||

| COD | BOD5 | TSS | NH4+-N | NO3−-N | TN | TP | PO4-P | FC | E. coli | TC | ||

| [35] | Multistage FWS CW | 91.6 | 91.5 | 86 | 57.1 | 43.4 | ||||||

| [36] | FWS CW Soil amended with zeolite | 84.3 | 76.3 | 98.8 (NH3) | 99.4 | 98.8 | 99.7 | |||||

| [43] | HSSF CW | 92.7 | 97.8 | 97.5 | 91.5 | 96.9 | Absence | |||||

| With artificial aeration | ||||||||||||

| [39] | Unplanted HSSF CW | 53 | 83 | 43 | 43 | 19 | 99.36 | |||||

| Planted HSSF CW | ||||||||||||

| Vetiveria zizanoides | 62 | 86 | 51 | 59 | 25 | 99.84 | ||||||

| Miscanthus x giganteus | 61 | 86 | 52 | 57 | 20 | 99.84 | ||||||

| Arundo donax | 59 | 89 | 53 | 56 | 28 | 99.84 | ||||||

| Phragmites australis | 63 | 88 | 57 | 61 | 29 | 99.92 | ||||||

| [54] | HSSF CW (PRR + tepezil + soil) | |||||||||||

| Canna indica | 91.4 | 76.7 | 62.7 | 44 | 45.1 | |||||||

| Cyperus papyrus | 91.9 | 74.2 | 50.9 | 41.7 | 57.2 | |||||||

| Hedychium coronarium | 90.9 | 57.4 | 39.1 | 40.3 | 55 | |||||||

| Unplanted | 76.5 | 34.2 | 17.5 | 20.8 | 38.5 | |||||||

| HSSF CW (PRR +PET+ tepezil + soil) | ||||||||||||

| Canna indica | 90.9 | 76.2 | 68.6 | 41 | 49.5 | |||||||

| Cyperus papyrus | 91.2 | 73.8 | 54.8 | 38.2 | 53.9 | |||||||

| Hedychium coronarium | 91.4 | 52.5 | 31.2 | 37.5 | 57.2 | |||||||

| Unplanted | 77.7 | 35.1 | 20.2 | 17.4 | 35.2 | |||||||

| [41] | HSSF CW | 64.3–91.9 | 69.6–93.2 | 68.3–85.5 | ||||||||

| [40] | Planted HSSF CW | |||||||||||

| Cyperus | 63.6 | 60.5 | ||||||||||

| Typha latifolia L. | 69.3 | 65.5 | ||||||||||

| Unplanted HSSF CW | 48.7 | 35.3 | ||||||||||

| [46] | VSSF CW | |||||||||||

| Unsaturated | 98.7 | 99.96 | 62.4 | 97.3 | ||||||||

| Saturated | 98.9 | 99.77 | 76.5 | 96.1 | ||||||||

| [55] | VSSF CW | |||||||||||

| Zeolite | 80.89 | 85.98 | 87.21 | 58.23 | ||||||||

| Manganese | 83.84 | 94.87 | 94.68 | 71.71 | ||||||||

| Biochar | 86.64 | 93.93 | 93.28 | 62.98 | ||||||||

| [56] | VSSF CW | |||||||||||

| Gravel group | 71.6 | 31 | 22.3 | 8 | ||||||||

| Walnut shell group | 69.7 | 38.1 | 11.1 | |||||||||

| Mn ore group | 90.1 | 84.1 | 65.1 | 97.1 | ||||||||

| Activated alumina group | 83.4 | 21.1 | 99 | |||||||||

| [47] | VSSF CW | |||||||||||

| Gravel/Continuous | 70 | 83 | 61 | 19 | −18 | 19 | ||||||

| Gravel/Batch | 76 | 85 | 80 | 36 | −22 | 16 | ||||||

| Vermiculite/Continuous | 76 | 83 | 78 | 26 | −27 | 31 | ||||||

| Vermiculite/Batch | 78 | 87 | 81 | 48 | −31 | 24 | ||||||

| [49] | Hybrid CW | - | - | - | 44.5 | 54.8 | 77.7 | - | - | - | ||

| [50] | Hybrid CW | 89 | 99 | 98 | 98 | 94 | 47 | 99.99 | ||||

| [48] | Hybrid CW | 91.4 | 93.47 | 94.83 | 67 | 62 | 99.994 | 99.995 | ||||

| [51] | Hybrid CW | |||||||||||

| Phase I: HLR = 0.02 m/d | 75 | 88 | 84 | 59 | ||||||||

| Phase II: HLR = 0.04 m/d | 82 | 85 | 92 | 74 | ||||||||

| Phase III: HLR = 0.06 m/d | 80 | 80 | 91 | 80 | ||||||||

| Phase IV: HLR = 0.12 m/d | 59 | 56 | 89 | 77 | ||||||||

| Overall | 74 | 76 | 90 | 84 | ||||||||

| [52] | Hybrid CW | 90.7 | 99.5 | 95.6 | −304.2 | 80.9 | 90.7 | 99.999 | ||||

| [45] | VSSF CW | |||||||||||

| Unplanted | 75 | 73 | Ns | 14 | 24 | |||||||

| T. dealbata | 76 | 81 | Ns | 18 | 37 | |||||||

| C. indica | 77 | 76 | Ns | 27 | 47 | |||||||

| FWS CW | ||||||||||||

| Unplanted | 46 | −2 | 68 | 6 | 11 | |||||||

| T. dealbata | 58 | 1 | 53 | 14 | 17 | |||||||

| C. indica | 50 | −1 | 44 | 8 | 15 | |||||||

| HSSF CW | ||||||||||||

| Unplanted | 50 | 3 | 36 | 3 | 13 | |||||||

| T. dealbata | 57 | 7 | 37 | 6 | 18 | |||||||

| C. indica | 59 | 7 | 42 | 6 | 22 | |||||||

| [44] | HSSF CW | 73.9 | 73 | 72.6 | 53.1 | 62.9 | 49.4 | |||||

| VSSF CW | 82.8 | 83.2 | 55 | 66.2 | 47.5 | 59.7 | ||||||

| Parameters | Legal Limits | Control Frequency |

|---|---|---|

| Biological Parameters | ||

| Faecal coliform (CFU/100 mL) | 1000 | Fortnightly |

| Salmonella (U/51 mL) | Absence | Fortnightly |

| Choleric Vibrio (CFU/450 mL) | Absence | Fortnightly |

| Pathogenic parasites | Absence | Fortnightly |

| Intestinal nematode eggs | Absence | Fortnightly |

| Ankylostome larvae | Absence | Fortnightly |

| Metals and Metalloids | ||

| Mercury (mg/L) | 0.001 | Quarterly |

| Cadmium (mg/L) | 0.01 | Quarterly |

| Arsenic (mg/L) | 0.1 | Quarterly |

| Chromium (mg/L) | 0.1 | Quarterly |

| Lead (mg/L) | 5 | Quarterly |

| Copper (mg/L) | 0.2 | Quarterly |

| Zinc (mg/L) | 2 | Quarterly |

| Selenium (mg/L) | 0.02 | Quarterly |

| Fluoride (mg/L) | 1 | Quarterly |

| Cyanide (mg/L) | 1 | Quarterly |

| Phenol (mg/L) | 3 | Quarterly |

| Aluminium (mg/L) | 5 | Quarterly |

| Beryllium (mg/L) | 0.1 | Quarterly |

| Cobalt (mg/L) | 0.05 | Quarterly |

| Iron (mg/L) | 5 | Quarterly |

| Lithium (mg/L) | 2.5 | Quarterly |

| Manganese (mg/L) | 0.2 | Quarterly |

| Molybdenum (mg/L) | 0.01 | Quarterly |

| Nickel (mg/L) | 0.2 | Quarterly |

| Vanadium (mg/L) | 0.1 | Quarterly |

| Physico-Chemical Parameters | ||

| Total salinity (mg/L) | 7680 | fortnightly |

| Electrical conductivity (mS/cm) | 12 | Fortnightly |

| Sodium (mg/L) | 9 (Surface irrigation) | Fortnightly |

| 69 (Sprinkler irrigation) | Fortnightly | |

| Chloride (mg/L) | 350 (Surface irrigation) | Fortnightly |

| 105 (Sprinkler irrigation) | Fortnightly | |

| Boron (mg/L) | 3 | Fortnightly |

| pH | 6.5–8.4 | Fortnightly |

| TSS (mg/L) | 100 | Fortnightly |

| Nitrate(mg/L) | 30 | Fortnightly |

| Carbonate (mg/L) | 518 | Fortnightly |

| Sulphates (mg/L) | 250 | Fortnightly |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hdidou, M.; Necibi, M.C.; Labille, J.; El Hajjaji, S.; Dhiba, D.; Chehbouni, A.; Roche, N. Potential Use of Constructed Wetland Systems for Rural Sanitation and Wastewater Reuse in Agriculture in the Moroccan Context. Energies 2022, 15, 156. https://doi.org/10.3390/en15010156

Hdidou M, Necibi MC, Labille J, El Hajjaji S, Dhiba D, Chehbouni A, Roche N. Potential Use of Constructed Wetland Systems for Rural Sanitation and Wastewater Reuse in Agriculture in the Moroccan Context. Energies. 2022; 15(1):156. https://doi.org/10.3390/en15010156

Chicago/Turabian StyleHdidou, Meryem, Mohamed Chaker Necibi, Jérôme Labille, Souad El Hajjaji, Driss Dhiba, Abdelghani Chehbouni, and Nicolas Roche. 2022. "Potential Use of Constructed Wetland Systems for Rural Sanitation and Wastewater Reuse in Agriculture in the Moroccan Context" Energies 15, no. 1: 156. https://doi.org/10.3390/en15010156

APA StyleHdidou, M., Necibi, M. C., Labille, J., El Hajjaji, S., Dhiba, D., Chehbouni, A., & Roche, N. (2022). Potential Use of Constructed Wetland Systems for Rural Sanitation and Wastewater Reuse in Agriculture in the Moroccan Context. Energies, 15(1), 156. https://doi.org/10.3390/en15010156