The Cost of Photovoltaic Forecasting Errors in Microgrid Control with Peak Pricing

Abstract

1. Introduction

- Are state-of-the-art weather predictions already sufficient to reduce demand peaks?

- What is the correlation between prediction accuracy and resulting cost?

- What is the time horizon in which the prediction accuracy is relevant?

- Using solar irradiance forecasts from weather services as predictions for PV power generation can reduce peak costs;

- The cost reduction scales with the prediction error, specifically

- –

- If PV generation is known at the current time step, the costs increase linearly with the prediction error;

- –

- If only predictions are used for the current time step, the correlation resembles a piece-wise linear function, with a significantly higher slope for lower errors.

- Our results suggest that the prediction accuracy for PV generation is only relevant within a short period at the beginning of the prediction horizon.

2. Methodology and Simulation Setup

2.1. Microgrid Modeling

2.2. Economic MPC Approach

2.3. Simulation Framework

2.3.1. Data Sources

2.3.2. Artificial Errors

2.3.3. Treatment of Disturbances at Current Time Step

3. Results & Discussion

3.1. Potential Savings

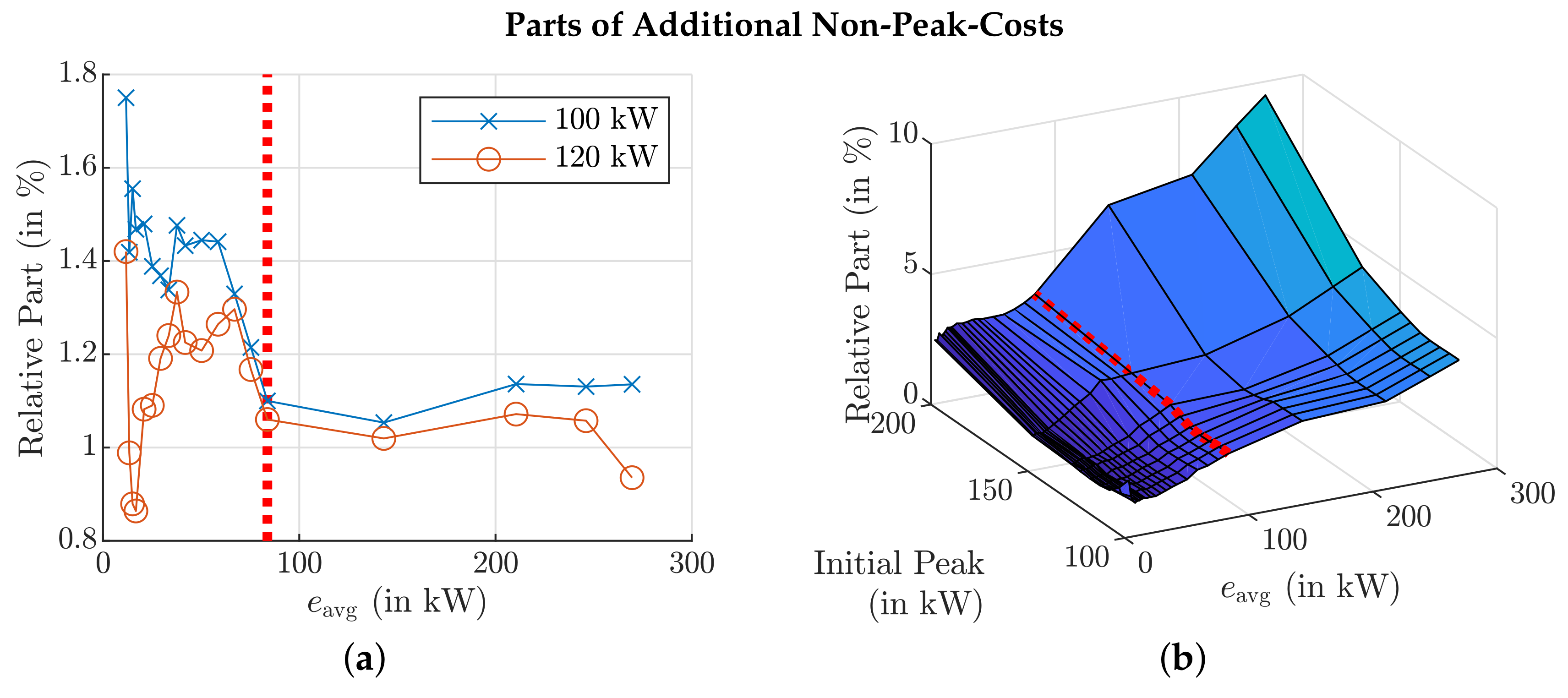

3.2. Correlation between Prediction Accuracy and Costs

3.3. Influence of Prediction Accuracy within the Time Horizon

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bayer, F.A.; Müller, M.A.; Allgöwer, F. Tube-based robust economic model predictive control. J. Process Control 2014, 24, 1237–1246. [Google Scholar] [CrossRef]

- Lucia, S.; Andersson, J.A.; Brandt, H.; Diehl, M.; Engell, S. I removed the ‘Informed Consent Statement’ since it does not apply: A comparative case study. J. Process Control 2014, 24, 1247–1259. [Google Scholar] [CrossRef]

- Mayne, D. Robust and Stochastic MPC: Are We Going In The Right Direction? In Proceedings of the 5th IFAC Conference on Nonlinear Model Predictive Control NMPC 2015, Seville, Spain, 17-20 Sep 2015. IFAC-PapersOnLine 2015, 48, 1–8. [Google Scholar] [CrossRef]

- Mesbah, A. Stochastic Model Predictive Control: An Overview and Perspectives for Future Research. IEEE Control Syst. Mag. 2016, 36, 30–44. [Google Scholar] [CrossRef]

- Heirung, T.A.N.; Paulson, J.A.; O’Leary, J.; Mesbah, A. Stochastic model predictive control—How does it work? Comput. Chem. Eng. 2018, 114, 158–170. [Google Scholar] [CrossRef]

- Cigler, J.; Prívara, S.; Váňa, Z.; Žáčeková, E.; Ferkl, L. Optimization of predicted mean vote index within model predictive control framework: Computationally tractable solution. Energy Build. 2012, 52, 39–49. [Google Scholar] [CrossRef]

- Zia, M.F.; Elbouchikhi, E.; Benbouzid, M. Microgrids energy management systems: A critical review on methods, solutions, and prospects. Appl. Energy 2018, 222, 1033–1055. [Google Scholar] [CrossRef]

- Zheng, Q.P.; Wang, J.; Liu, A.L. Stochastic Optimization for Unit Commitment—A Review. IEEE Trans. Power Syst. 2015, 30, 1913–1924. [Google Scholar] [CrossRef]

- Lazos, D.; Sproul, A.B.; Kay, M. Optimisation of energy management in commercial buildings with weather forecasting inputs: A review. Renew. Sustain. Energy Rev. 2014, 39, 587–603. [Google Scholar] [CrossRef]

- Agüera-Pérez, A.; Palomares-Salas, J.C.; González de la Rosa, J.J.; Florencias-Oliveros, O. Weather forecasts for microgrid energy management: Review, discussion and recommendations. Appl. Energy 2018, 228, 265–278. [Google Scholar] [CrossRef]

- Oldewurtel, F.; Parisio, A.; Jones, C.N.; Gyalistras, D.; Gwerder, M.; Stauch, V.; Lehmann, B.; Morari, M. Use of model predictive control and weather forecasts for energy efficient building climate control. Energy Build. 2012, 45, 15–27. [Google Scholar] [CrossRef]

- Lenzi, V.; Ulbig, A.; Andersson, G. Impacts of forecast accuracy on grid integration of renewable energy sources. In Proceedings of the 2013 IEEE Grenoble Conference, Grenoble, France, 16–20 June 2013; pp. 1–6. [Google Scholar] [CrossRef]

- Romero-Quete, D.; Cañizares, C.A. An Affine Arithmetic-Based Energy Management System for Isolated Microgrids. IEEE Trans. Smart Grid 2019, 10, 2989–2998. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, R.; Zhang, T.; Liu, Y.; Guo, B. Model predictive control-based operation management for a residential microgrid with considering forecast uncertainties and demand response strategies. IET Gener. Transm. Distrib. 2016, 10, 2367–2378. [Google Scholar] [CrossRef]

- Khodaei, A.; Bahramirad, S.; Shahidehpour, M. Microgrid Planning Under Uncertainty. IEEE Trans. Power Syst. 2015, 30, 2417–2425. [Google Scholar] [CrossRef]

- Mazzola, S.; Vergara, C.; Astolfi, M.; Li, V.; Perez-Arriaga, I.; Macchi, E. Assessing the value of forecast-based dispatch in the operation of off-grid rural microgrids. Renew. Energy 2017, 108, 116–125. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; Zhang, T.; Guo, B. An intelligent control strategy of battery energy storage system for microgrid energy management under forecast uncertainties. Int. J. Electrochem. Sci. 2014, 9, 4190–4204. [Google Scholar]

- Hosseinzadeh, M.; Salmasi, F.R. Robust Optimal Power Management System for a Hybrid AC/DC Micro-Grid. IEEE Trans. Sustain. Energy 2015, 6, 675–687. [Google Scholar] [CrossRef]

- Bertsimas, D.; Sim, M. The price of robustness. Oper. Res. 2004, 52, 35–53. [Google Scholar] [CrossRef]

- Zhang, Y.; Gatsis, N.; Giannakis, G.B. Robust Energy Management for Microgrids With High-Penetration Renewables. IEEE Trans. Sustain. Energy 2013, 4, 944–953. [Google Scholar] [CrossRef]

- Maasoumy, M.; Sangiovanni-Vincentelli, A. Optimal control of buildingHVAC systems in the presence of imperfect predictions. In Proceedings of the Dynamic Systems and Control Conference, Fort Lauderdale, FL, USA, 17–20 October 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 45301, pp. 257–266. [Google Scholar]

- Maasoumy, M.; Razmara, M.; Shahbakhti, M.; Vincentelli, A.S. Handling model uncertainty in model predictive control for energy efficient buildings. Energy Build. 2014, 77, 377–392. [Google Scholar] [CrossRef]

- Yang, S.; Wan, M.P.; Chen, W.; Ng, B.F.; Zhai, D. An adaptive robust model predictive control for indoor climate optimization and uncertainties handling in buildings. Build. Environ. 2019, 163, 106326. [Google Scholar] [CrossRef]

- Ma, Y.; Matuško, J.; Borrelli, F. Stochastic Model Predictive Control for Building HVAC Systems: Complexity and Conservatism. IEEE Trans. Control Syst. Technol. 2015, 23, 101–116. [Google Scholar] [CrossRef]

- Garifi, K.; Baker, K.; Touri, B.; Christensen, D. Stochastic Model Predictive Control for Demand Response in a Home Energy Management System. In Proceedings of the 2018 IEEE Power Energy Society General Meeting (PESGM), Portland, OR, USA, 5–10 August 2018; pp. 1–5. [Google Scholar] [CrossRef]

- Schmitt, T.; Rodemann, T.; Adamy, J. Multi-objective model predictive control for microgrids. at-Automatisierungstechnik 2020, 68, 687–702. [Google Scholar] [CrossRef]

- Schmitt, T.; Engel, J.; Rodemann, T.; Adamy, J. Application of Pareto Optimization in an Economic Model Predictive Controlled Microgrid. In Proceedings of the 28th Mediterranean Conference on Control and Automation, MED’20, Saint-Raphaël, France, 15–18 September 2020; Available online: https://tuprints.ulb.tu-darmstadt.de/11706/7/main_paper_pareto_FINAL%20VERSION_WITHLICENSEINFO.pdf (accessed on 9 May 2020).

- Skoplaki, E.; Palyvos, J. On the temperature dependence of photovoltaic module electrical performance: A review of efficiency/power correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- Schmitt, T.; Engel, J.; Hoffmann, M.; Rodemann, T. PARODIS: One MPC Framework to control them all. In Proceedings of the 2021 IEEE Conference on Control Technology and Applications (CCTA), San Diego, CA, USA, 8–11 August 2021. in press. [Google Scholar]

- Löfberg, J. YALMIP: A Toolbox for Modeling and Optimization in MATLAB. In Proceedings of the CACSD Conference, Taipei, Taiwan, 2–4 September 2004. [Google Scholar]

| Parameter | Description | Value |

|---|---|---|

| Sample time (step width) in h | 0.25, 0.5 or 1 | |

| Thermal capacity of the building in kWh/K | 1792.06 | |

| Heat transfer coefficient to outside air in kW/K | 341.94 | |

| Energy efficiency ratio cooling machine | ||

| Current constant CHP, i.e., | 0.677 |

| Variable | Limits | Unit |

|---|---|---|

| E | ||

| °C | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmitt, T.; Rodemann, T.; Adamy, J. The Cost of Photovoltaic Forecasting Errors in Microgrid Control with Peak Pricing. Energies 2021, 14, 2569. https://doi.org/10.3390/en14092569

Schmitt T, Rodemann T, Adamy J. The Cost of Photovoltaic Forecasting Errors in Microgrid Control with Peak Pricing. Energies. 2021; 14(9):2569. https://doi.org/10.3390/en14092569

Chicago/Turabian StyleSchmitt, Thomas, Tobias Rodemann, and Jürgen Adamy. 2021. "The Cost of Photovoltaic Forecasting Errors in Microgrid Control with Peak Pricing" Energies 14, no. 9: 2569. https://doi.org/10.3390/en14092569

APA StyleSchmitt, T., Rodemann, T., & Adamy, J. (2021). The Cost of Photovoltaic Forecasting Errors in Microgrid Control with Peak Pricing. Energies, 14(9), 2569. https://doi.org/10.3390/en14092569