Robust Inverse Optimal Control for a Boost Converter

Abstract

1. Introduction

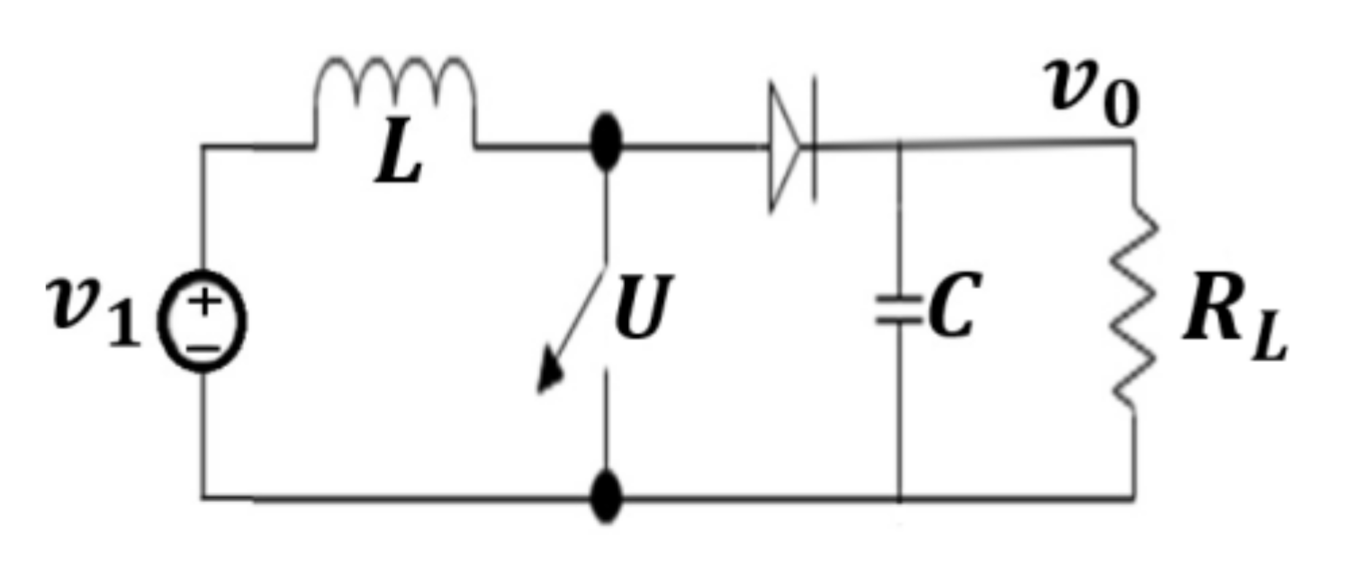

2. State Equations Model of the Boost Converter

3. Trajectory Tracking Inverse Optimal control

- i.

- Tracking Inverse: It achieves (global) asymptotic stability of for system Equations (1) and (2) along with reference ;

- ii.

- Second is a (radially unbounded) positive definite function such that inequalityis satisfied.

4. The Proposed Methodology

- To find the values of and that cause the system to converge to a target value, there are heuristic search methods.

- Give values to the input variables, and the parameters of the system and analyze which are the ranges of those variables that generate an error greater than tolerance .

- Find a value for each desired input variable or target in the ranges or values of the previous point that fit the model to the desired reference.

- Implement different found in the simulation for the different values of the input variables.

- Fit the coefficients found to an equation that depends on the input variable or the parameter that destabilized the system.

- In the case that an appropriate value of is not found, which adjusts the desired model for a value of the input variable or the desired objective, once again tune the model looking for appropriate and .

5. Inverse Optimal Control Applied for a Boost Converter

6. Results of the Implementation of the New Methodology

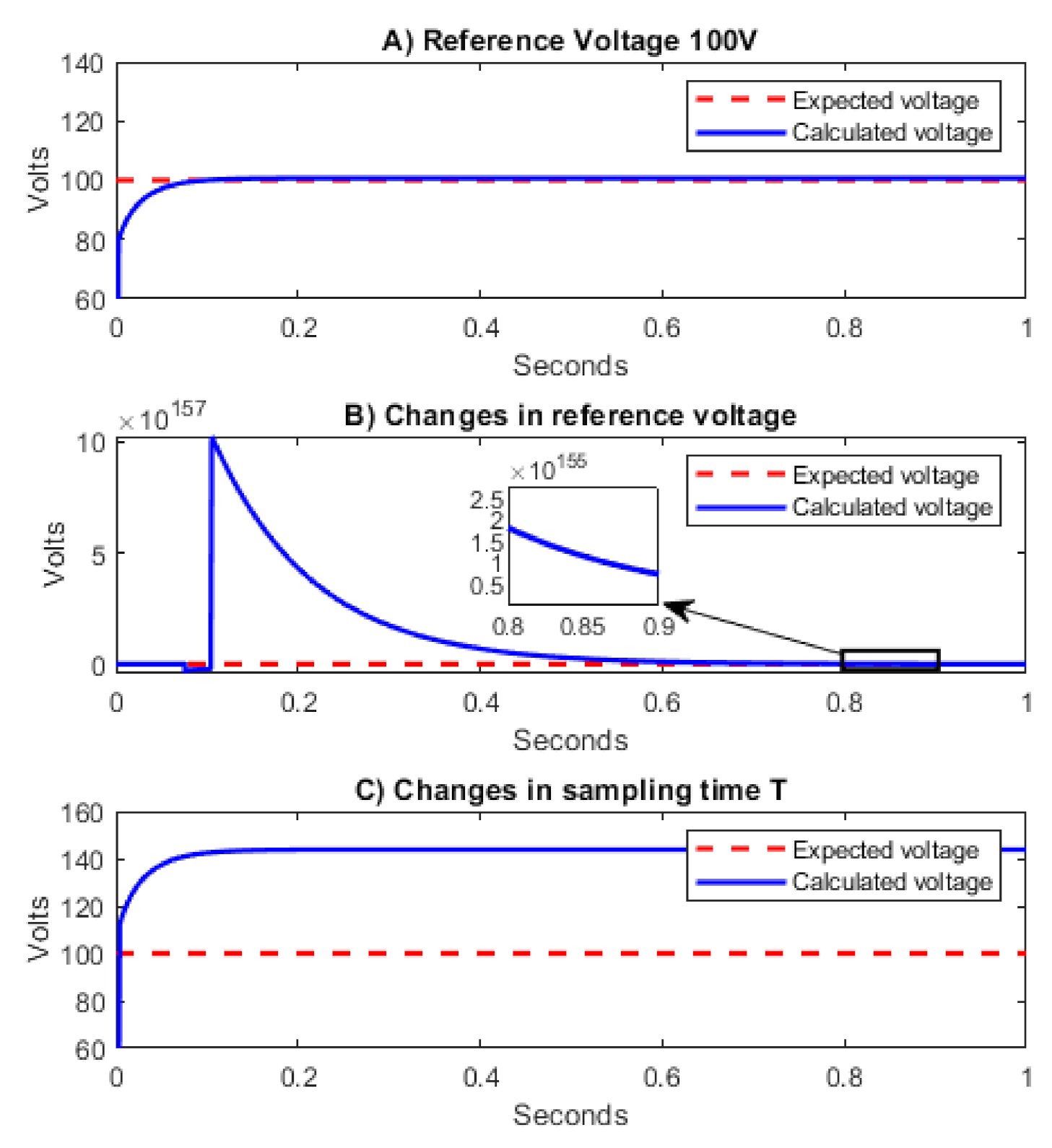

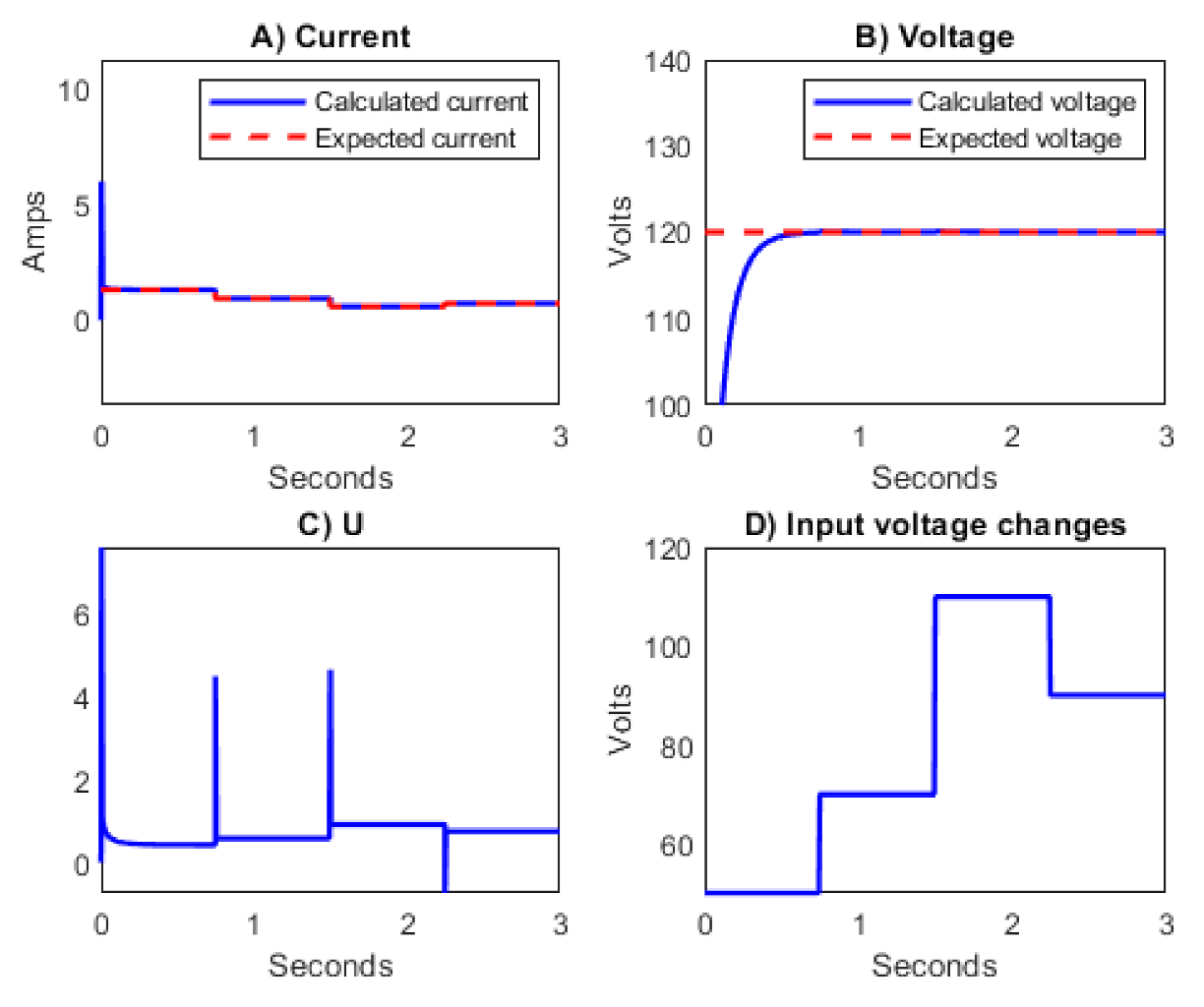

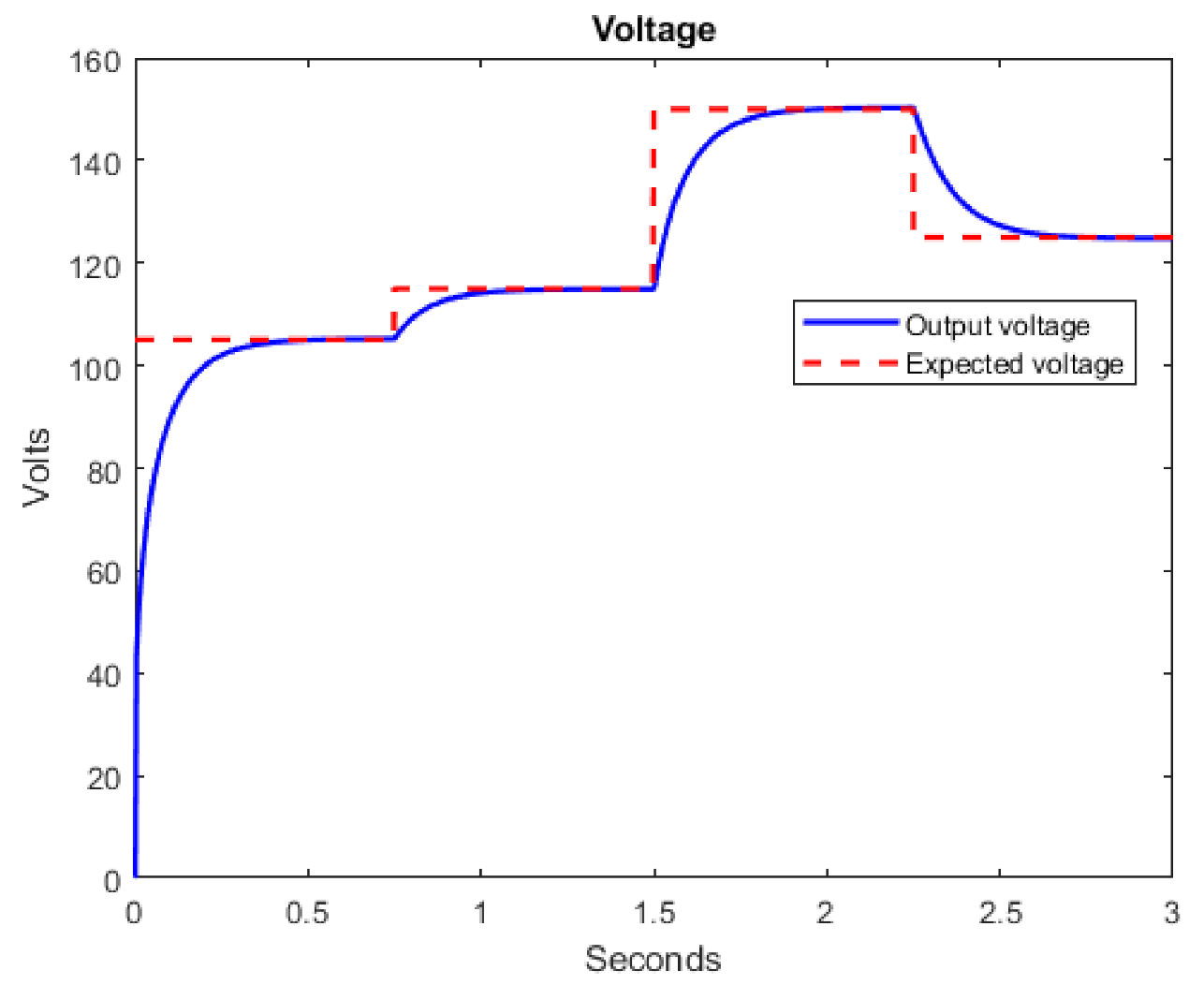

6.1. Changes in Reference, Sampling Time, and Input Variables

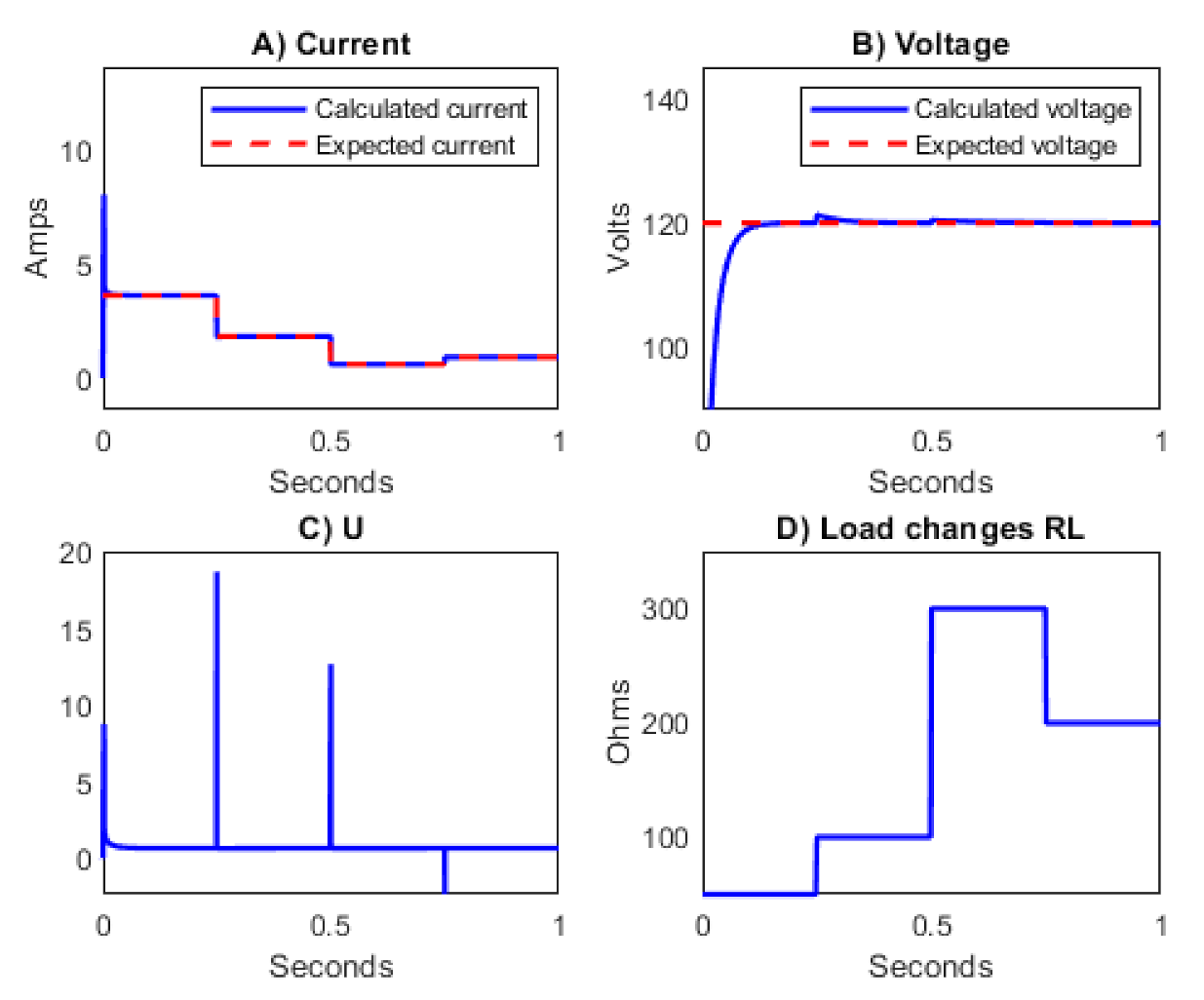

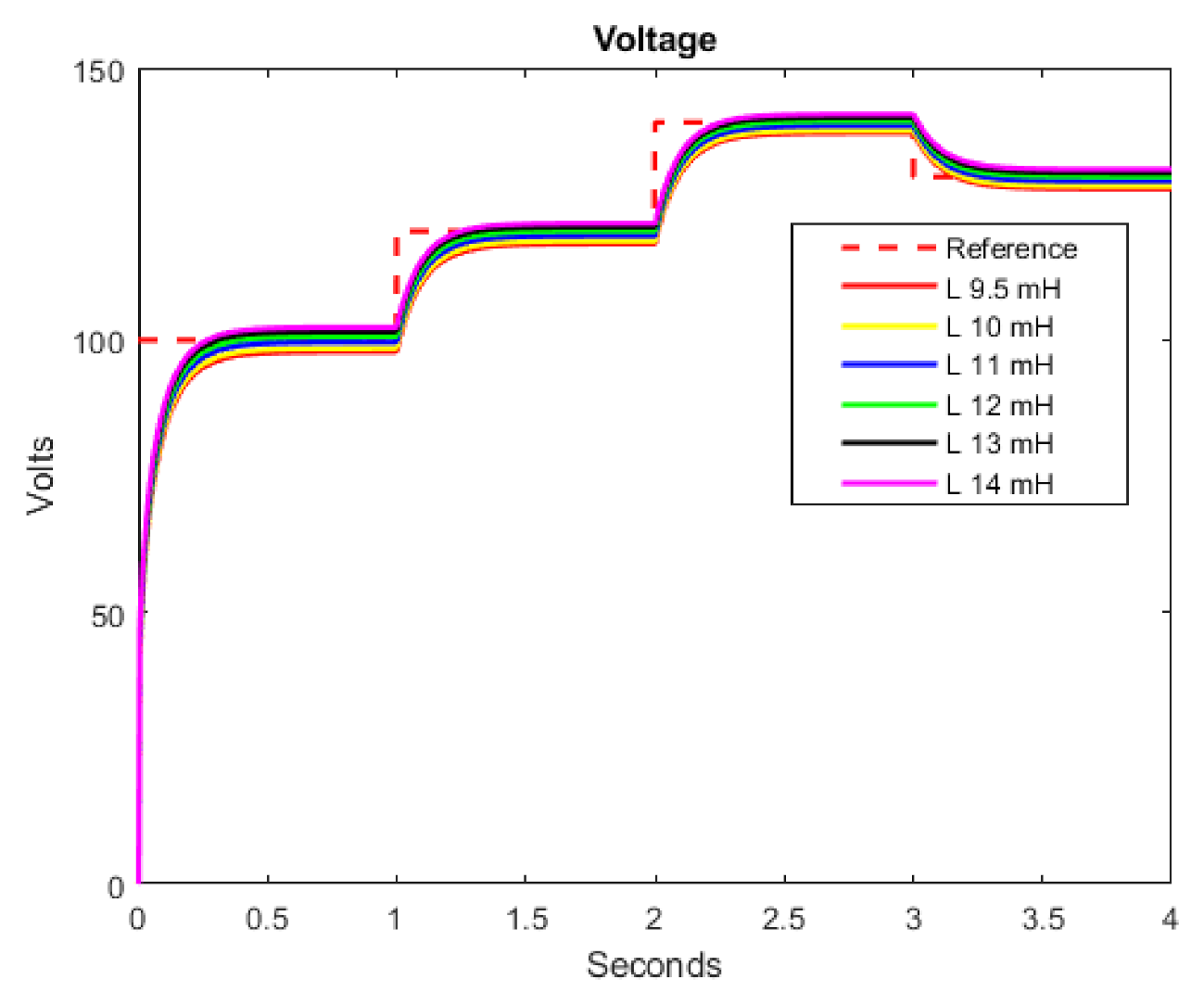

6.2. Robustness Analysis

6.3. Analysis for Different Voltage Reference Changes

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CLF | Control Lyapunov Function |

| PWM | Pulse Width Modulated Signal |

| HJB | Hamilton–Jacobi–Bellman |

| PSO | Particle Swarm Optimization |

| GA | Genetic Algorithm |

| PI | Proportional–Integral Control |

| PID | Proportional–Integral–Derivative Control |

Nomenclature

| Capacitor voltage | |

| Inductor current | |

| Input voltage | |

| Inductance of the inductor | |

| Capacitance of the capacitor | |

| A resistance | |

| Is the signal control () | |

| Is the duty cycle | |

| Time | |

| State of the system at time | |

| State of the system at time | |

| Is the input corresponding to the control signals at time | |

| It is a function of the state of the system | |

| It is a function of the state of the system | |

| Cost functional | |

| Tracking error | |

| Is a positive semidefinite function | |

| Is a real symmetric positive definite weighting matrix | |

| Is positive definite | |

| The desired trajectory for | |

| Lyapunov function | |

| Lyapunov function | |

| Discrete-time Hamiltonian | |

| The optimal control law to achieve trajectory tracking | |

| Control setting constant | |

| Percentage error | |

| Tolerance error | |

| Reference voltage | |

| Output current at time | |

| Output voltage at time |

References

- Güler, N.; Irmak, E. Design, Implementation and Model Predictive Based Control of a Mode-Changeable DC/DC Converter for Hybrid Renewable Energy Systems. ISA Trans. 2020. [Google Scholar] [CrossRef]

- Palomba, V.; Borri, E.; Charalampidis, A.; Frazzica, A.; Cabeza, L.F.; Karellas, S. Implementation of a Solar-Biomass System for Multi-Family Houses: Towards 100% Renewable Energy Utilization. Renew. Energy 2020, 166, 190–209. [Google Scholar] [CrossRef]

- Antwi, S.H.; Ley, D. Renewable Energy Project Implementation in Africa: Ensuring Sustainability through Community Acceptability. Sci. Afr. 2021, 11, e00679. [Google Scholar] [CrossRef]

- Upadhyay, P.; Kumar, R. A High Gain Cascaded Boost Converter with Reduced Voltage Stress for PV Application. Sol. Energy 2019, 183, 829–841. [Google Scholar] [CrossRef]

- Fathabadi, H. Novel High Efficiency DC/DC Boost Converter for Using in Photovoltaic Systems. Sol. Energy 2016, 125, 22–31. [Google Scholar] [CrossRef]

- Cucuzzella, M.; Lazzari, R.; Trip, S.; Rosti, S.; Sandroni, C.; Ferrara, A. Control Engineering Practice Sliding Mode Voltage Control of Boost Converters in DC Microgrids. Control Eng. Pract. 2018, 73, 161–170. [Google Scholar] [CrossRef]

- Rahimi, M. Modeling, Control and Stability Analysis of Grid Connected PMSG Based Wind Turbine Assisted with Diode Rectifier and Boost Converter. Int. J. Electr. Power Energy Syst. 2017, 93, 84–96. [Google Scholar] [CrossRef]

- Slah, F.; Mansour, A.; Hajer, M.; Faouzi, B. Analysis, Modeling and Implementation of an Interleaved Boost DC-DC Converter for Fuel Cell Used in Electric Vehicle. Int. J. Hydrog. Energy 2017, 42, 28852–28864. [Google Scholar] [CrossRef]

- Wen, H.; Su, B. Hybrid-Mode Interleaved Boost Converter Design for Fuel Cell Electric Vehicles. Energy Convers. Manag. 2016, 122, 477–487. [Google Scholar] [CrossRef]

- Xu, L.; Hong, P.; Fang, C.; Li, J.; Ouyang, M.; Lehnert, W. Interactions between a Polymer Electrolyte Membrane Fuel Cell and Boost Converter Utilizing a Multiscale Model. J. Power Sources 2018, 395, 237–250. [Google Scholar] [CrossRef]

- Sobrino-Manzanares, F.; Garrig, A. ScienceDirect Multi-Switch Synchronous Boost Converter for Fuel Cell Applications. Int. J. Hydrog. Energy 2015. [Google Scholar] [CrossRef]

- Forouzesh, M.; Siwakoti, Y.P.; Gorji, S.A.; Blaabjerg, F.; Lehman, B. Overview Step-Up DC. DC Converters: A Comprehensive Review of Voltage-Boosting Techniques. IEEE Trans. Power Electron. 2017, 32, 9143–9178. [Google Scholar] [CrossRef]

- Dash, S.S.; Nayak, B. Control Analysis and Experimental Verification of a Practical Dc–Dc Boost Converter. J. Electr. Syst. Inf. Technol. 2015, 2, 378–390. [Google Scholar] [CrossRef]

- Nouri, A.; Salhi, I.; Elwarraki, E.; El Beid, S.; Essounbouli, N. DSP-Based Implementation of a Self-Tuning Fuzzy Controller for Three-Level Boost Converter. Electr. Power Syst. Res. 2017, 146, 286–297. [Google Scholar] [CrossRef]

- Abdelmalek, S.; Dali, A.; Bakdi, A.; Bettayeb, M. Design and Experimental Implementation of a New Robust Observer-Based Nonlinear Controller for DC-DC Buck Converters. Energy 2020, 213, 118816. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, Z.; Li, S.; Gao, J.; Si, J.; Das, H.S.; Dong, W. A Novel Cascaded Control to Improve Stability and Inertia of Parallel Buck-Boost Converters in DC Microgrid. Int. J. Electr. Power Energy Syst. 2020, 119, 105950. [Google Scholar] [CrossRef]

- Qingfeng, L.; Zhaoxia, L.; Jinkun, S.; Huamin, W. A Composite PWM Control Strategy for Boost Converter. Phys. Procedia 2012, 24, 2053–2058. [Google Scholar] [CrossRef]

- Siddhartha, V.; Hote, Y.V.; Saxena, S. Non-Ideal Modelling and IMC Based PID Controller Design of PWM DC-DC Buck Converter. IFAC-PapersOnLine 2018, 51, 639–644. [Google Scholar] [CrossRef]

- Dinniyah, F.S.; Wahab, W.; Alif, M. Simulation of Buck-Boost Converter for Solar Panels Using PID Controller. Energy Procedia 2017, 115, 102–113. [Google Scholar] [CrossRef]

- Repecho, V.; Biel, D.; Olm, J.M.; Fossas, E. Robust Sliding Mode Control of a DC/DC Boost Converter with Switching Frequency Regulation. J. Frankl. Inst. 2018, 355, 5367–5383. [Google Scholar] [CrossRef]

- Coronado-Mendoza, A.; Gurubel-Tun, K.J.; Zúñiga-Grajeda, V.; Domínguez-Navarro, J.A.; Artal-Sevil, J.S. Variable Frequency Control of a Photovoltaic Boost Converter System with Power Quality Indexes Based on Dynamic Phasors. IFAC-PapersOnLine 2018, 51, 180–185. [Google Scholar] [CrossRef]

- Dancholvichit, N.; Kapoor, S.G.; Salapaka, S.M. Temperature Regulation for Thermoplastic Micro-Forming of Bulk Metallic Glass: Robust Control Design Using Buck Converter. J. Manuf. Process. 2020, 56, 1294–1303. [Google Scholar] [CrossRef]

- Seguel, J.L.; Seleme, S.I. Robust Digital Control Strategy Based on Fuzzy Logic for a Solar Charger of VRLA Batteries. Energies 2021, 14, 1001. [Google Scholar] [CrossRef]

- Vega Pérez, C.J.; Alzate Castaño, R. Control Óptimo Inverso Como Alternativa Para La Regulación de Un Convertidor DC-DC Elevador. Rev. Tecnura 2015, 19, 65. [Google Scholar] [CrossRef][Green Version]

- Vega, C.; Alzate, R. Inverse Optimal Control on Electric Power Conversion. In Proceedings of the 2014 IEEE International Autumn Meeting on Power, Electronics and Computing (ROPEC), Ixtapa, Mexico, 5–7 November 2014. [Google Scholar] [CrossRef]

- Sanchez, E.N.; Ornelas-Tellez, F. Discrete-Time Inverse Optimal Control for Nonlinear Systems; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781466580886. [Google Scholar]

- Alsmadi, Y.M.; Utkin, V.; Haj-ahmed, M.A.; Xu, L. Sliding Mode Control of Power Converters: DC/DC Converters. Int. J. Control 2018, 91, 2472–2493. [Google Scholar] [CrossRef]

- Yang, T.; Liao, Y. Discrete Sliding Mode Control Strategy for Start-up and Steady-State of Boost Converter. Energies 2019, 14, 2990. [Google Scholar] [CrossRef]

- Vega Pérez, C.; Alzate Castaño, R. Control Óptimo Inverso Para Sistemas No Lineales En Tiempo Continuo. Respuestas 2014, 19, 13–18. [Google Scholar] [CrossRef]

- Do, K.D. Inverse Optimal Control of Stochastic Systems Driven by Lévy Processes. Automatica 2019, 107, 539–550. [Google Scholar] [CrossRef]

- Ornelas, F.; Sanchez, E.N.; Loukianov, A.G. Discrete-Time Inverse Optimal Control for Nonlinear Systems Trajectory Tracking. Proc. IEEE Conf. Decis. Control 2010, 4813–4818. [Google Scholar] [CrossRef]

- Sakly, M.; Sakly, A.; M’Sahli, F. Inverse Optimal Control of Switched Discrete Non Linear Systems Based on Control Lyapunov Function and Genetic Algorithm. In Proceedings of the 16th International Conference on Sciences and Techniques of Automatic Control and Computer Engineering (STA 2015), Monastir, Tunisia, 21–23 December 2015. [Google Scholar] [CrossRef]

- Ornelas-Tellez, F.; Sanchez, E.N.; Loukianov, A.G.; Rico, J.J. Robust Inverse Optimal Control for Discrete-Time Nonlinear System Stabilization. Eur. J. Control 2014, 20, 38–44. [Google Scholar] [CrossRef]

- El-Hussieny, H.; Abouelsoud, A.A.; Assal, S.F.M.; Megahed, S.M. Adaptive Learning of Human Motor Behaviors: An Evolving Inverse Optimal Control Approach. Eng. Appl. Artif. Intell. 2016, 50, 115–124. [Google Scholar] [CrossRef]

- Lastire, E.A.; Sanchez, E.N.; Alanis, A.Y.; Ornelas-Tellez, F. Passivity Analysis of Discrete-Time Inverse Optimal Control for Trajectory Tracking. J. Frankl. Inst. 2016, 353, 3192–3206. [Google Scholar] [CrossRef]

- Zhang, Y.; Mohammadpour Shotorbani, A.; Wang, L.; Mohammadi-Ivatloo, B. Enhanced PI Control and Adaptive Gain Tuning Schemes for Distributed Secondary Control of an Islanded Microgrid. IET Renew. Power Gener. 2021, 1–11. [Google Scholar] [CrossRef]

- Lhachemi, H.; Saussié, D.; Zhu, B. Hidden Coupling Terms Inclusion in Gain-Scheduling Control Design: Extension of an Eigenstructure Assignment-Based Technique. IFAC-PapersOnLine 2016, 49, 403–408. [Google Scholar]

- Kersten, J.; Rauh, A.; Aschemann, H. Interval Methods for Robust Gain Scheduling Controllers. Granul. Comput. 2020, 5, 203–216. [Google Scholar] [CrossRef]

- Awad, O.A.; Salim, I.L. Fuzzy PID Gain Scheduling Controller for Networked Control System. Iraqi J. Sci. 2021, 210–216. [Google Scholar] [CrossRef]

- Bhukya, L.; Annamraju, A.; Srikanth, N. Robust Frequency Control in a Wind-Diesel Autonomous Microgrid: A Novel Two-Level Control Approach. Renew. Energy Focus 2021, 36, 21–30. [Google Scholar] [CrossRef]

| Reference Voltage | 100 V | 120 V | 140 V | 130 V |

|---|---|---|---|---|

| 0.25 | 0.11 | 0.02 | 0.06 |

| Reference Voltage | ||||

|---|---|---|---|---|

| Capacitance (Microfarads) | 100 | 120 | 140 | 130 |

| 250 | 0.6206 | 0.0061 | 0.1339 | 0.0029 |

| 500 | 0.6174 | 0.0054 | 0.1327 | 0.0035 |

| 750 | 0.5797 | 0.0140 | 0.1128 | 0.0154 |

| 1000 | 0.4045 | 0.0990 | 0.0296 | 0.0647 |

| Reference Voltage | ||||

|---|---|---|---|---|

| Inductance (Millihenries) | 100 | 120 | 140 | 130 |

| 10 | 1.5155 | 1.4942 | 1.0358 | 1.3005 |

| 11 | 0.3851 | 0.7005 | 0.4189 | 0.611 |

| 12 | 0.6174 | 0.0054 | 0.1327 | 0.0035 |

| 13 | 1.5211 | 0.6435 | 0.6338 | 0.5602 |

| 14 | 2.3463 | 1.228 | 1.0949 | 1.071 |

| Reference Voltage | ||||

|---|---|---|---|---|

| Inductance (Millihenries) | 100 | 120 | 140 | 130 |

| 10 | 0.10473 | 0.18533 | 0.73934 | 0.12719 |

| 11 | 0.18514 | 0.19462 | 0.18906 | 0.08304 |

| 12 | 0.44703 | 0.14109 | 0.03092 | 0.14510 |

| 13 | 0.68133 | 0.06205 | 0.11666 | 0.14156 |

| 14 | 0.89051 | 0.02586 | 0.13987 | 0.10738 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Villegas-Ruvalcaba, M.; Gurubel-Tun, K.J.; Coronado-Mendoza, A. Robust Inverse Optimal Control for a Boost Converter. Energies 2021, 14, 2507. https://doi.org/10.3390/en14092507

Villegas-Ruvalcaba M, Gurubel-Tun KJ, Coronado-Mendoza A. Robust Inverse Optimal Control for a Boost Converter. Energies. 2021; 14(9):2507. https://doi.org/10.3390/en14092507

Chicago/Turabian StyleVillegas-Ruvalcaba, Mario, Kelly Joel Gurubel-Tun, and Alberto Coronado-Mendoza. 2021. "Robust Inverse Optimal Control for a Boost Converter" Energies 14, no. 9: 2507. https://doi.org/10.3390/en14092507

APA StyleVillegas-Ruvalcaba, M., Gurubel-Tun, K. J., & Coronado-Mendoza, A. (2021). Robust Inverse Optimal Control for a Boost Converter. Energies, 14(9), 2507. https://doi.org/10.3390/en14092507