Environmental Life-Cycle Assessment of an Innovative Multifunctional Toilet

Abstract

1. Introduction

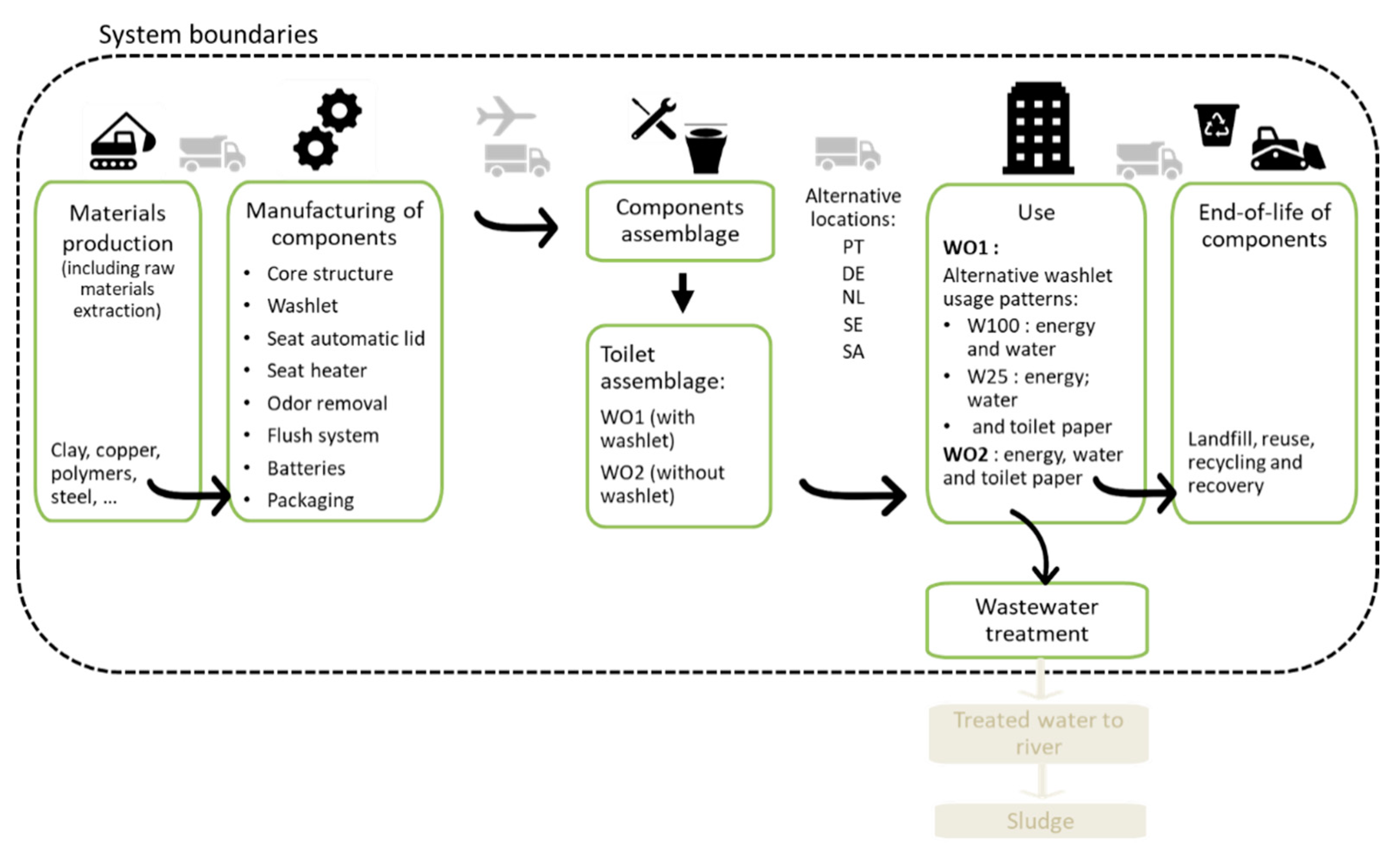

2. Materials and Methods

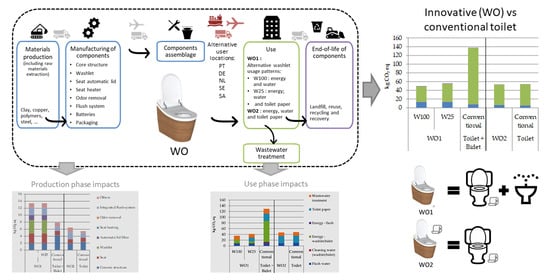

2.1. Goal and Scope Definition

2.2. Life-Cycle Inventory Analysis

2.2.1. Production and Distribution

2.2.2. Use Phase and End-of-Life

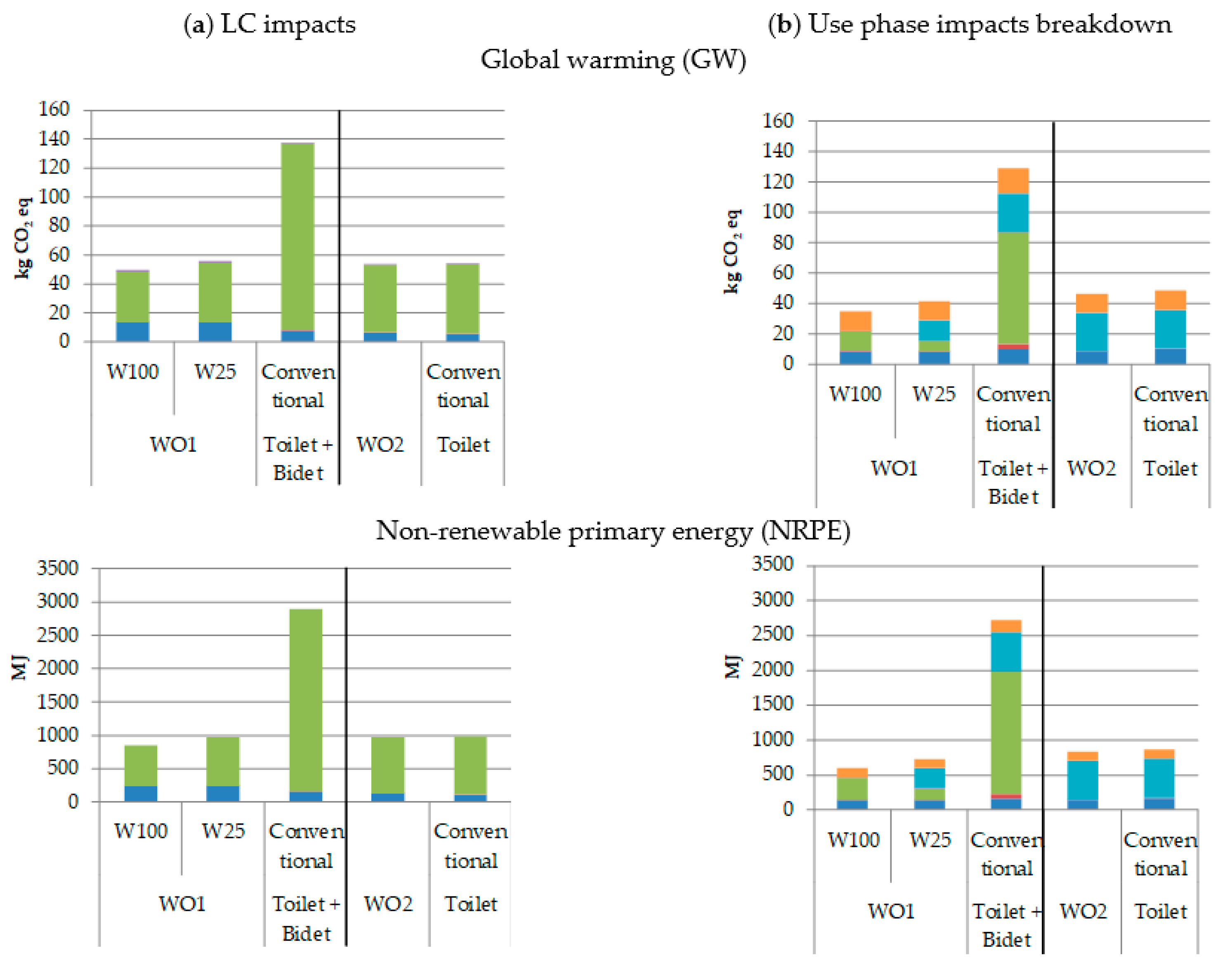

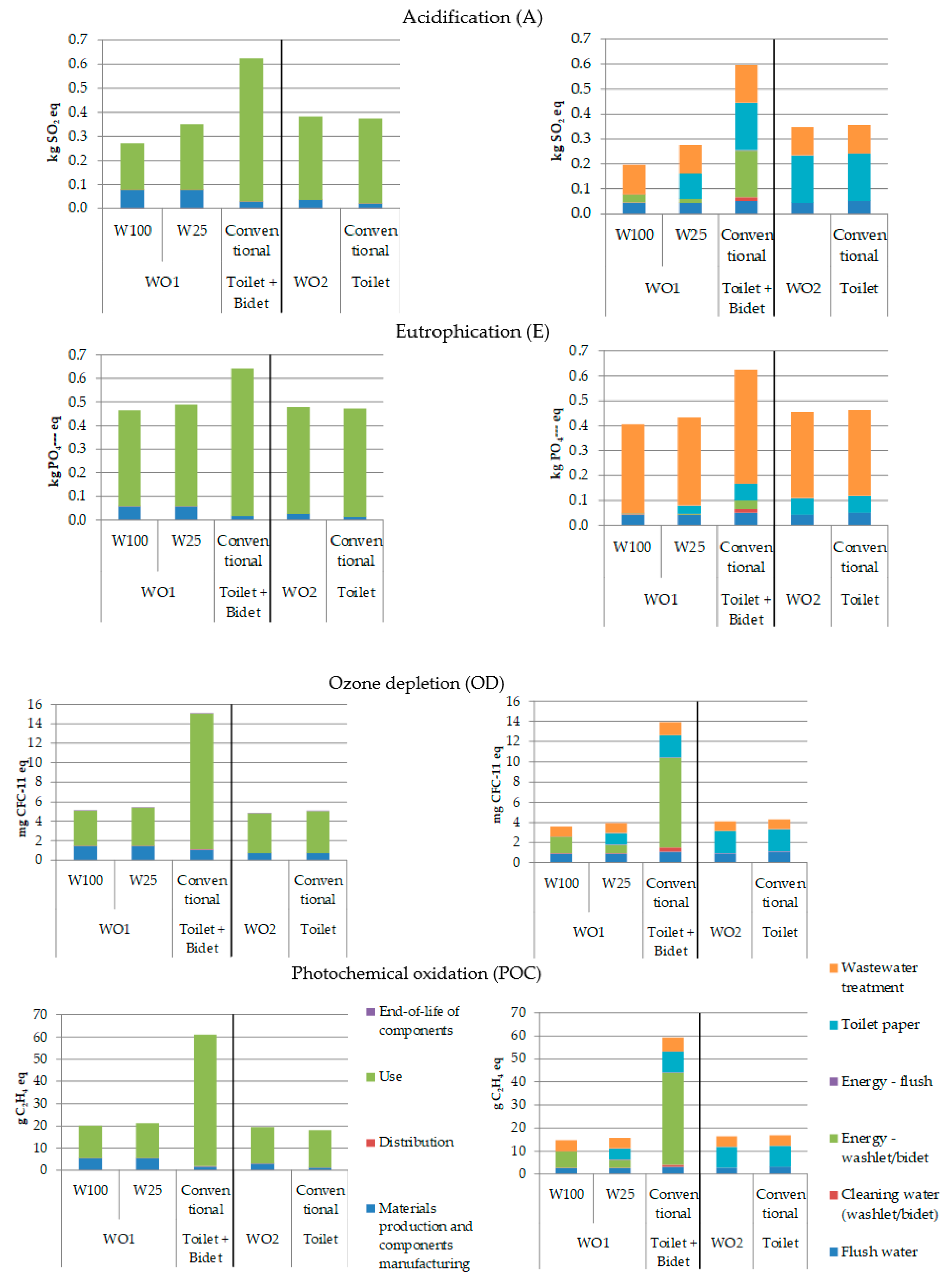

3. Results

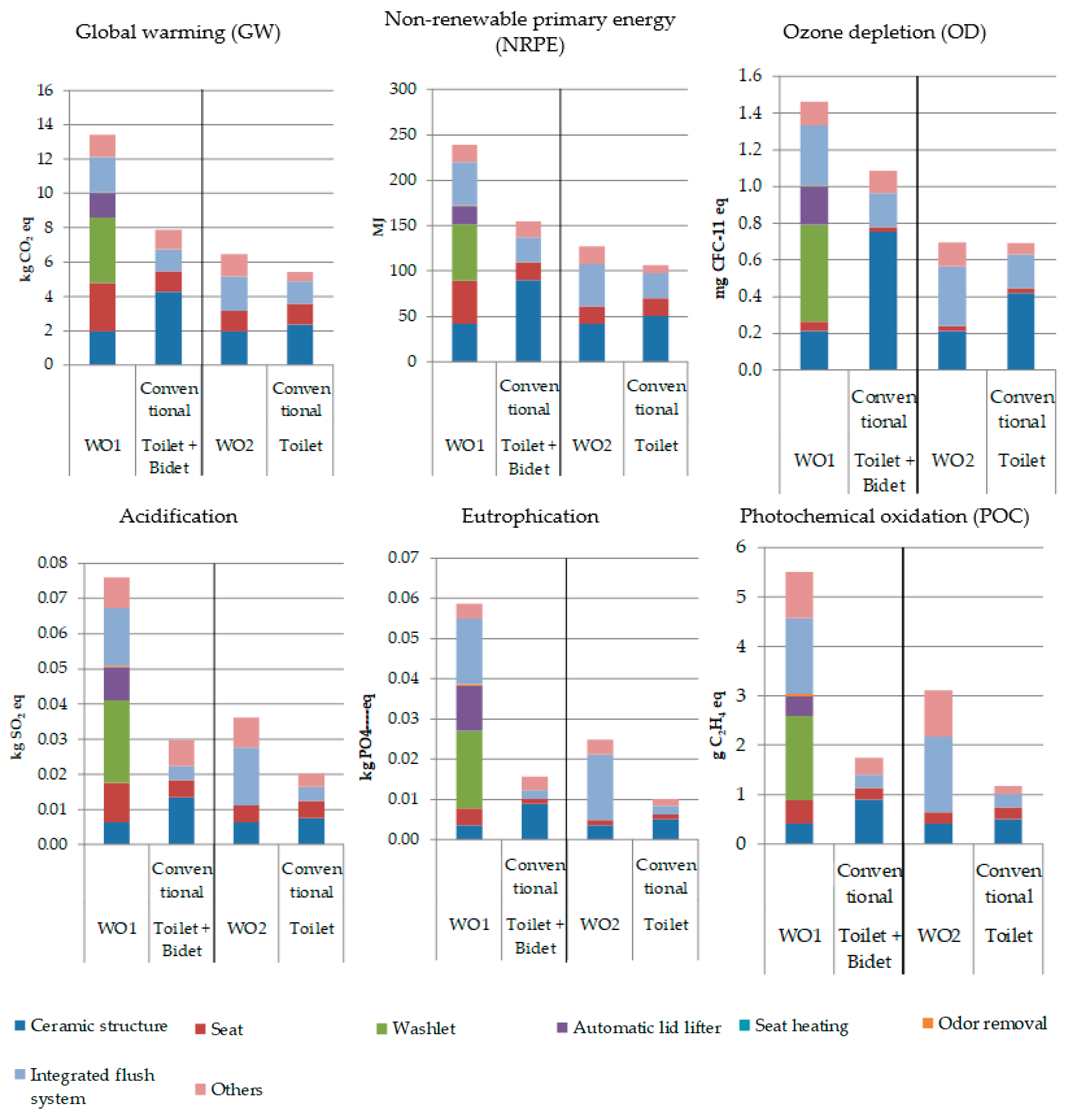

3.1. Comparative Assessment and User Behavior Analysis

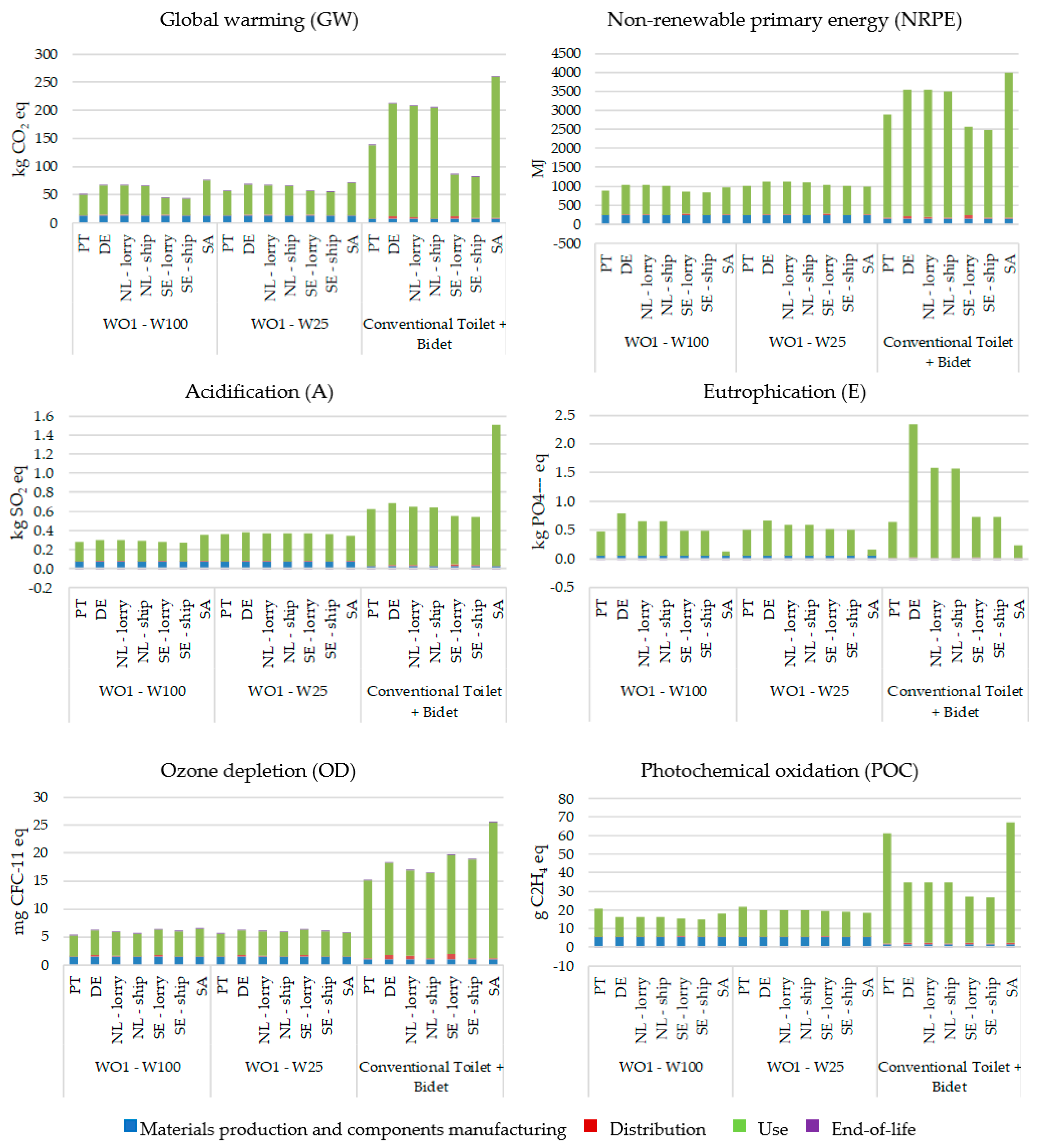

3.2. User Location Scenario Analysis

4. Conclusions and Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mannan, M.; Al-Ghamdi, S.G. Environmental impact of water-use in buildings: Latest developments from a life-cycle assessment perspective. J. Environ. Manag. 2020, 261, 110198. [Google Scholar] [CrossRef]

- European Commission Energy Use in Buildings. Available online: https://ec.europa.eu/energy/eu-buildings-factsheets-topics-tree/energy-use-buildings_en (accessed on 1 February 2021).

- BIO Intelligence Service. Water Performance of Buildings, Final Report for European Commision; BIO Intelligence Service: Paris, France, 2012. [Google Scholar]

- Weyand, S.; Wittich, C.; Schebek, L. Environmental performance of emerging photovoltaic technologies: Assessment of the status quo and future prospects based on a meta-analysis of life-cycle assessment studies. Energies 2019, 12, 4228. [Google Scholar] [CrossRef]

- Battisti, A.; Persiani, S.G.L.; Crespi, M. Review and mapping of parameters for the early stage design of adaptive building technologies through life cycle assessment tools. Energies 2019, 12, 1729. [Google Scholar] [CrossRef]

- Gasia, J.; Fabiani, C.; Chàfer, M.; Pisello, A.L.; Manni, A.; Ascani, M.; Cabeza, L.F. Life cycle assessment and life cycle costing of an innovative component for refrigeration units. J. Clean. Prod. 2021, 295, 126442. [Google Scholar] [CrossRef]

- Cornaro, C.; Zanella, V.; Robazza, P.; Belloni, E.; Buratti, C. An innovative straw bale wall package for sustainable buildings: Experimental characterization, energy and environmental performance assessment. Energy Build. 2020, 208, 109636. [Google Scholar] [CrossRef]

- Casas-Ledón, Y.; Daza Salgado, K.; Cea, J.; Arteaga-Pérez, L.E.; Fuentealba, C. Life cycle assessment of innovative insulation panels based on eucalyptus bark fibers. J. Clean. Prod. 2020, 249, 119356. [Google Scholar] [CrossRef]

- Göswein, V.; Rodrigues, C.; Silvestre, J.D.; Freire, F.; Habert, G.; König, J. Using anticipatory life cycle assessment to enable future sustainable construction. J. Ind. Ecol. 2020, 24, 178–192. [Google Scholar] [CrossRef]

- Lv, J.; Gu, F.; Zhang, W.; Guo, J. Life cycle assessment and life cycle costing of sanitary ware manufacturing: A case study in China. J. Clean. Prod. 2019, 238, 117938. [Google Scholar] [CrossRef]

- Silvestri, L.; Forcina, A.; Silvestri, C.; Ioppolo, G. Life cycle assessment of sanitaryware production: A case study in Italy. J. Clean. Prod. 2020, 251, 119708. [Google Scholar] [CrossRef]

- Lam, L.; Kurisu, K.; Hanaki, K. Comparative environmental impacts of source-separation systems for domestic wastewater management in rural China. J. Clean. Prod. 2015, 104, 185–198. [Google Scholar] [CrossRef]

- Ishii, S.K.L.; Boyer, T.H. Life cycle comparison of centralized wastewater treatment and urine source separation with struvite precipitation: Focus on urine nutrient management. Water Res. 2015, 79, 88–103. [Google Scholar] [CrossRef]

- Benetto, E.; Nguyen, D.; Lohmann, T.; Schmitt, B.; Schosseler, P. Life cycle assessment of ecological sanitation system for small-scale wastewater treatment. Sci. Total Environ. 2009, 407, 1506–1516. [Google Scholar] [CrossRef]

- Remy, C.; Ruhland, A.; Jekel, M. Ecological Assessment of Alternative Sanitation Concepts with Life Cycle Assessment-Final Report for Subtask 5 of the Demonstration Project “Sanitation Concepts for Separate Treatment of Urine, Faeces and Greywater” (SCST); Technische Universität Berlin: Berlin, Germany, 2006. [Google Scholar]

- Devkota, J.; Schlachter, H.; Anand, C.; Phillips, R.; Apul, D. Development and application of EEAST: A life cycle based model foruse of harvested rainwater and composting toilets in buildings. J. Environ. Manag. 2013, 130, 397–404. [Google Scholar] [CrossRef] [PubMed]

- Anand, C.; Apul, D.S. Economic and environmental analysis of standard, high efficiency, rainwater flushed, and composting toilets. J. Environ. Manag. 2011, 92, 419–428. [Google Scholar] [CrossRef] [PubMed]

- Shi, Y.; Zhou, L.; Xu, Y.; Zhou, H.; Shi, L. Life cycle cost and environmental assessment for resource-oriented toilet systems. J. Clean. Prod. 2018, 196, 1188–1197. [Google Scholar] [CrossRef]

- Liu, X.; Dai, J.; Ng, T.L.; Chen, G. Evaluation of potential environmental benefits from seawater toilet flushing. Water Res. 2019, 162, 505–515. [Google Scholar] [CrossRef]

- IPCC. IPCC, 2013: Climate Change 2013: The Physical Science Basis. Contribution of Working Group I to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013. [Google Scholar]

- Yoonus, H.; Al-Ghamdi, S.G. Environmental performance of building integrated grey water reuse systems based on Life-Cycle Assessment: A systematic and bibliographic analysis. Sci. Total Environ. 2020, 712, 136535. [Google Scholar] [CrossRef]

- Leong, J.Y.C.; Balan, P.; Chong, M.N.; Poh, P.E. Life-cycle assessment and life-cycle cost analysis of decentralised rainwater harvesting, greywater recycling and hybrid rainwater-greywater systems. J. Clean. Prod. 2019, 229, 1211–1224. [Google Scholar] [CrossRef]

- Remy, C.; Jekel, M. Energy analysis of conventional and source-separation systems for urban wastewater management using Life Cycle Assessment. Water Sci. Technol. 2012, 65, 22–29. [Google Scholar] [CrossRef]

- Lam, C.M.; Leng, L.; Chen, P.C.; Lee, P.H.; Hsu, S.C. Eco-efficiency analysis of non-potable water systems in domestic buildings. Appl. Energy 2017, 202, 293–307. [Google Scholar] [CrossRef]

- Gnoatto, E.L.; Kalbusch, A.; Henning, E. Evaluation of the environmental and economic impacts on the life cycle of different solutions for toilet flush systems. Sustainability 2019, 11, 4742. [Google Scholar] [CrossRef]

- Cruz, P.; Costa, A.; Costa, V.; Pereira, M.; Rodrigues, L.; Pimentel-Rodrigues, C.; Lopes, A.; Rodrigues, C.; Freire, F.; Almeida, J.; et al. Innovative toilet integrating water storage and flushing system, electronic bidet and urine separation. (in PT: Sanita inovadora integrando sistemas de armazenamento e descarga de água, bidé eletrónico e separação de urinas.). Indústria e Ambient. 2018, 108, 29–31. [Google Scholar]

- Kellenberger, D.; Althaus, H.; Künniger, T.; Lehmann, M.; Jungbluth, N. Life Cycle Inventories of Building Products. Ecoinvent Report; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Hischier, R. Life Cycle Inventories of Packaging and Graphical Papers (Part I). Ecoinvent Report No 11; Swiss Center for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Hischier, R. Life Cycle Inventories of Packaging and Graphical Papers (Part II: Plastics). Ecoinvent Report No 11; Swiss Center for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Hischier, R.; Classen, M.; Lehmann, M.; Scharnhorst, W. Ecoinvent Report No 18: Life Cycle Inventories of Electric and Electronic Equipment: Production, Use and Disposal (Part I); Swiss Center for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Spielmann, M.; Bauer, C.; Dones, R.; Tuchschmin, M. Life Cycle Inventories of Transport Services. Ecoinvent Rep. No 14, v2.0; Swiss Center for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Garcia, R.; Marques, P.; Freire, F. Life-cycle assessment of electricity in Portugal. Appl. Energy 2014, 134, 563–572. [Google Scholar] [CrossRef]

- Kabayo, J.; Marques, P.; Garcia, R.; Freire, F. Life-cycle sustainability assessment of key electricity generation systems in Portugal. Energy 2019, 176, 131–142. [Google Scholar] [CrossRef]

- Dones, R.; Bauer, C.; Bolliger, R.; Burger, B.; Heck, T.; Röder, A.; Institut, P.S.; Emmenegger, M.F.; Frischknecht, R.; Jungbluth, N.; et al. Life Cycle Inventories of Energy Systems: Results for Current Systems in Switzerland and Other UCTE Countries. Ecoinvent Rep. No 5; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007. [Google Scholar]

- Ruiz, M. Documentation of changes implemented in ecoinvent. In Ecoinvent Report; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2013. [Google Scholar]

- Doka, G. Life Cycle Inventories of Waste Treatment Services. Ecoinvent Rep. No. 13; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2003; p. 111. [Google Scholar]

- JRC-IES. ILCD Handbook. International Reference Life Cycle Data System. General Guide for Life Cycle Assessment; Joint Research Center: Ispra, Italy, 2010. [Google Scholar]

- Fazio, S.; Biganzioli, F.; De Laurentiis, V.; Zampori, L.; Sala, S.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods, Version 2, from ILCD to EF 3.0, EUR 29600 EN; European Commission: Ispra, Italy, 2018; ISBN 978-92-79-98584-3. [Google Scholar] [CrossRef]

- Rocha, C.; Almeida, M.; Duarte, P. Regras de Categoria de Produto–Louça Sanitária; DAP Habitat: Aveiro, Portugal, 2015. [Google Scholar]

- Dias, A.C.; Dias, A.B.; Rocha, C.; Freire, F.; Gervásio, H.; Silvestre, J.; Arroja, L.; Almeida, M.; Duarte, P.; Mateus, R.; et al. Regras para a Categoria de Produto (RCP)–Modelo Base–Produtos e Serviços de Construção. Versão 2.0; DAP Habitat: Aveiro, Portugal, 2015. [Google Scholar]

| Materials/Components | WO1 | WO2 | Toilet | Bidet |

|---|---|---|---|---|

| (kg) | ||||

| Acrylonitrile Butadiene Styrene (ABS) | 4.14 | 2.76 | - | - |

| Aluminum | 0.05 | 0.00 | - | - |

| Battery | 0.10 | 0.00 | - | - |

| Cardboard | 8.50 | 8.50 | 5 | 5 |

| Ceramic (vitreous china) | 17.0 | 17.0 | 50.4 | 27.6 |

| Control unit | 0.30 | 0.00 | - | - |

| Copper | 0.04 | 0.00 | - | - |

| Duroplast | 3.60 | 3.88 | 2 | - |

| Fans | 0.07 | 0.05 | - | - |

| Motors 12 V | 0.57 | 0.37 | - | - |

| Polypropylene (PP) | 0.10 | 1.98 | - | - |

| Polystyrene (PS) | 0.50 | 0.50 | 1 | - |

| Polycarbonate (PC) | 0.01 | 0.01 | - | - |

| Pumps 40 W | 3.00 | 3.42 | - | - |

| Rubber | 0.06 | 0.06 | - | - |

| Electronics (sensors) | 0.02 | 0.02 | - | - |

| Steel | 0.91 | 0.66 | - | - |

| Water heater | 0.14 | 0.00 | - | - |

| Total weight | 41 | 39 | 58 | 33 |

| User Location | Mode of Transportation | Distance | WO1 (41 kg) | Conventional Toilet and Bidet (91 kg) |

|---|---|---|---|---|

| (km) | (tkm 1) | |||

| Portugal (PT) | Lorry 16 ton—EURO5 | 200 | 8 | 18 |

| Germany (DE) | Lorry 16 ton—EURO5 | 2700 | 111 | 246 |

| The Netherlands (NL) | Lorry 16 ton—EURO5 | 2100 | 86 | 191 |

| Boat (+lorry 16 ton—EURO5) | 1800 (+130) | 74 (+5) | 164 (+12) | |

| Sweden (SE) | Lorry 16 ton—EURO5 | 3500 | 144 | 319 |

| Barco (+lorry 16 ton—EURO5) | 3500 (+150) | 144 (+6) | 319 (+14) | |

| Middle East (Saudi Arabia—SA) | Boat (+lorry 16 ton—EURO5) | 10,000 (+230) | 410 (+10) | 910 (+21) |

| Function | Components | Power (W) | Time of Use (s) | Consumption Per Use (kWh) |

|---|---|---|---|---|

| Automatic lid lifter | Motor | 36 | 3 | 6.0 × 10−5 |

| Seat heating | Electrical resistance | 60 | 300 | 5.0 × 10−3 |

| Washlet nozzle cleaning | Pump | 12 | 4 | 1 × 10−5 |

| User’s cleaning | Pump | 12 | * | * |

| * | * | |||

| Motor | 2 | 8 | 4.4 × 10−6 | |

| Water heater | 1444 | * | * | |

| * | * | |||

| Washlet nozzle oscillation | Motor | 2 | 60 | 3.3 × 10−5 |

| Drying | Fan | 5 | 30 | 4.2 × 10−5 |

| Electrical resistance | 122 | 30 | 1.02 × 10−3 | |

| Odor removal | Fan | 5 | 300 | 4.2 × 10−4 |

| Full flush (major visits) | Pump | 108 | 5 | 1.5 × 10−4 |

| Half flush (minor visits) | Pump | 108 | 2.92 | 8.8 × 10−5 |

| Washlet and Toilet Use Parameters | Type of Visit | |

|---|---|---|

| Major | Minor | |

| Washlet | (rear position) | (feminine/front position) |

| Water usage duration 1 (s) | 45 | 20 |

| Water flow rate (L/min) | 0.65 | |

| Used water volume (L) | 0.49 | 0.22 |

| Water heater efficiency 1 | 0.95 | |

| Water temperature difference ΔT 1 (K) | 30 (40–10 °C) | |

| Water heating energy 2 (Wh) | 18.06 | 8.03 |

| Air dryer usage duration 1 (s) | 30 | |

| Air flow rate (L/s) | 3.33 | |

| Air heater efficiency 1 | 0.98 | |

| Air temperature difference ΔT 1 (K) | 30 (45–15 °C) | |

| Air heating energy 3 (Wh) | 1.02 | |

| Total energy consumption (Wh) | 19.08 | 9.05 |

| Toilet | ||

| Flush water usage (L) | 6.0 (full flush) | 4.5 (half flush) 4 |

| Flush flow rate (L/s) | 1.20 | |

| Flush duration (s) | 5.00 | 2.92 |

| Pump motor power (W) | 108.0 | |

| Energy consumption (Wh) | 0.150 | 0.088 |

| Bidet System’s Infrastructure | |

| Water heater’s efficiency | 0.8 |

| Piping length 1 (m) | 8 |

| Water flow (L/min) | 6.4 |

| Water temperature difference 2—∆T (K) | 30 |

| Hot water quantity (L) | 4 |

| Bidet Use Per Visit | |

| Energy use (kWh) | 0.2 |

| Water use (L) | 8 |

| Toilet Water Use Per Visit | |

| Flush water use (L) | |

| Half flush (minor visits) | 4.5 |

| Full flush (major visits) | 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodrigues, C.; Almeida, J.; Santos, M.I.; Costa, A.; Além, S.; Rufo, E.; Tadeu, A.; Freire, F. Environmental Life-Cycle Assessment of an Innovative Multifunctional Toilet. Energies 2021, 14, 2307. https://doi.org/10.3390/en14082307

Rodrigues C, Almeida J, Santos MI, Costa A, Além S, Rufo E, Tadeu A, Freire F. Environmental Life-Cycle Assessment of an Innovative Multifunctional Toilet. Energies. 2021; 14(8):2307. https://doi.org/10.3390/en14082307

Chicago/Turabian StyleRodrigues, Carla, João Almeida, Maria Inês Santos, Andreia Costa, Sandra Além, Emanuel Rufo, António Tadeu, and Fausto Freire. 2021. "Environmental Life-Cycle Assessment of an Innovative Multifunctional Toilet" Energies 14, no. 8: 2307. https://doi.org/10.3390/en14082307

APA StyleRodrigues, C., Almeida, J., Santos, M. I., Costa, A., Além, S., Rufo, E., Tadeu, A., & Freire, F. (2021). Environmental Life-Cycle Assessment of an Innovative Multifunctional Toilet. Energies, 14(8), 2307. https://doi.org/10.3390/en14082307