Energetic Performances Booster for Electric Vehicle Applications Using Transient Power Control and Supercapacitors-Batteries/Fuel Cell

Abstract

1. Introduction

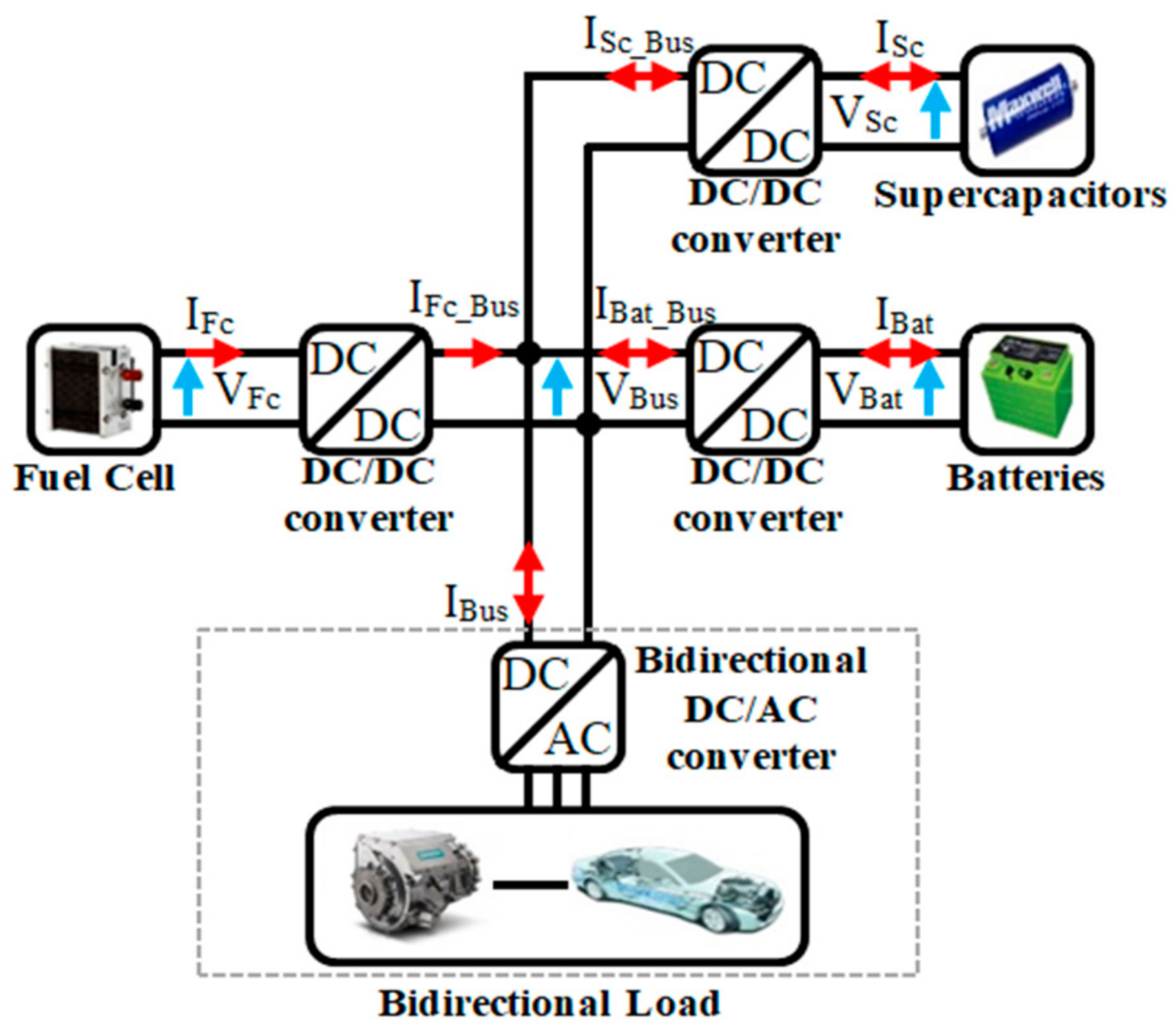

2. Model of the Sources

2.1. Model of Proton-Exchange Membrane Fuel Cells

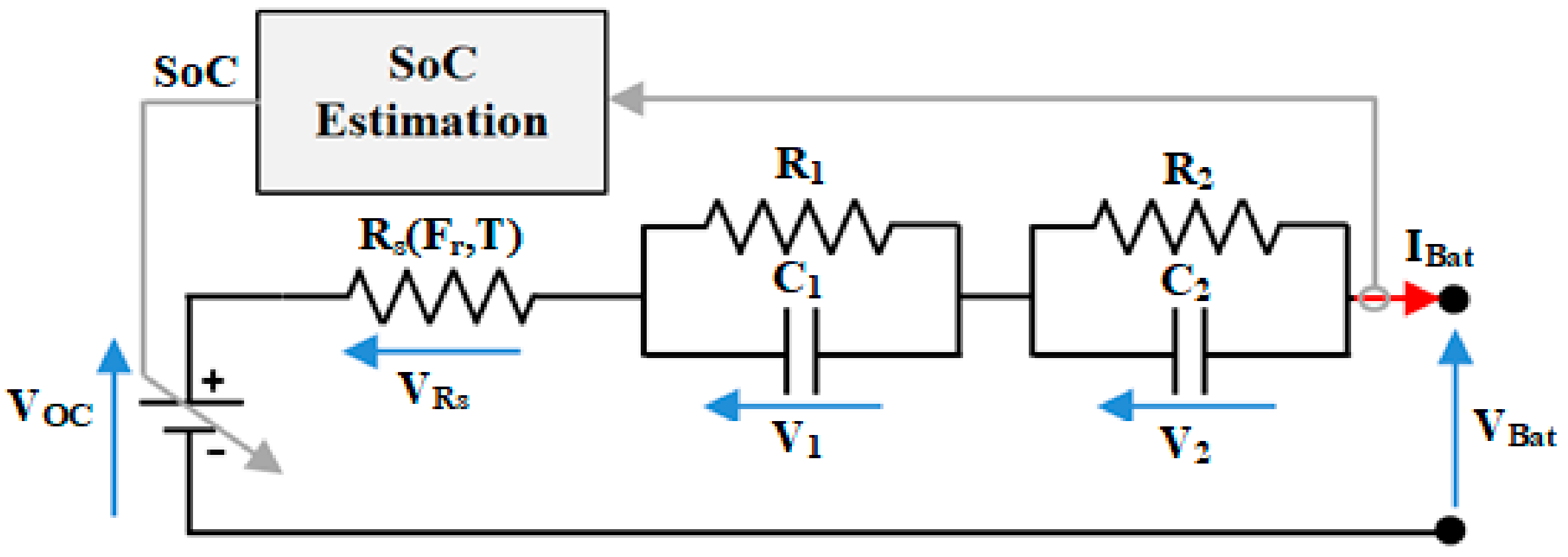

2.2. Model of LiFePO4 Batteries

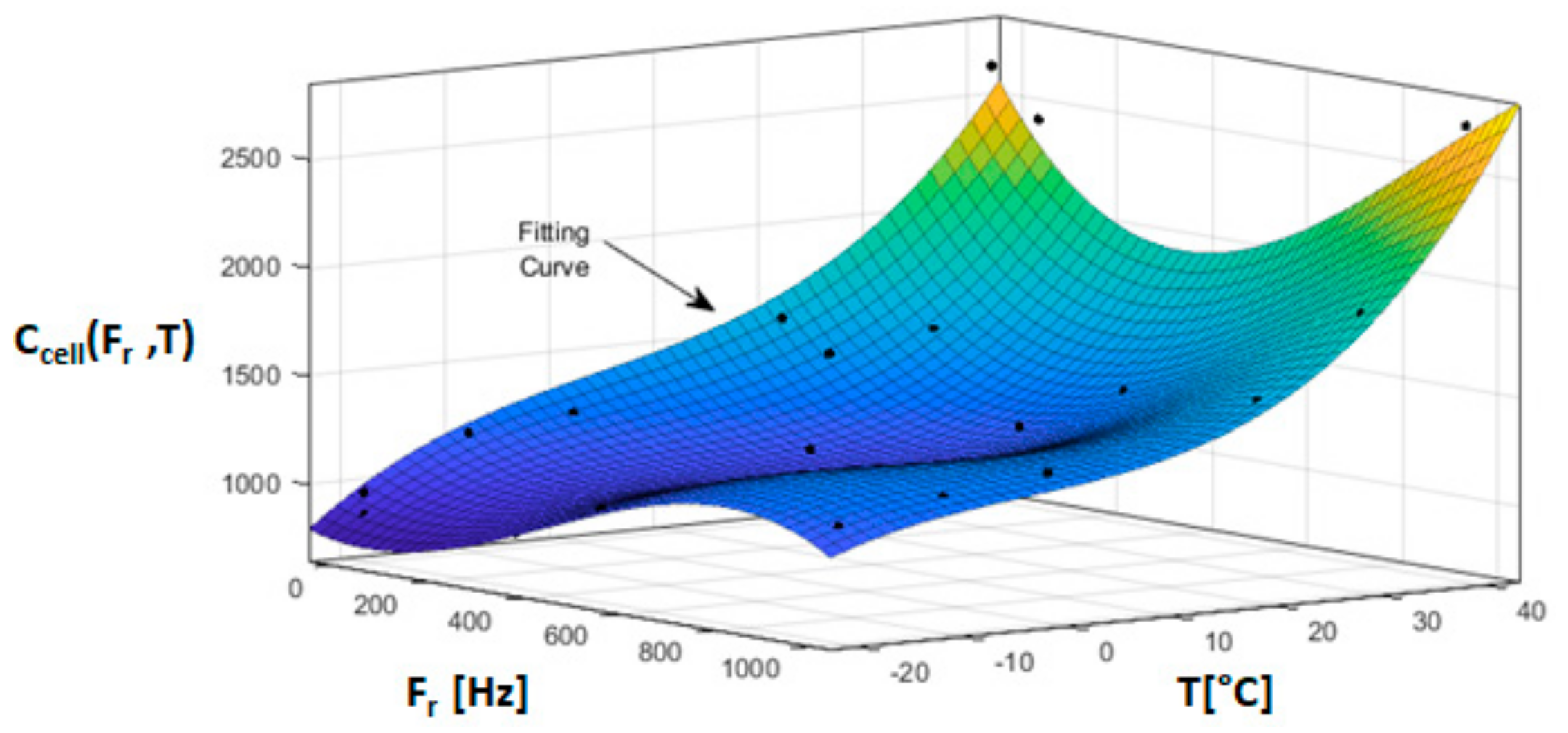

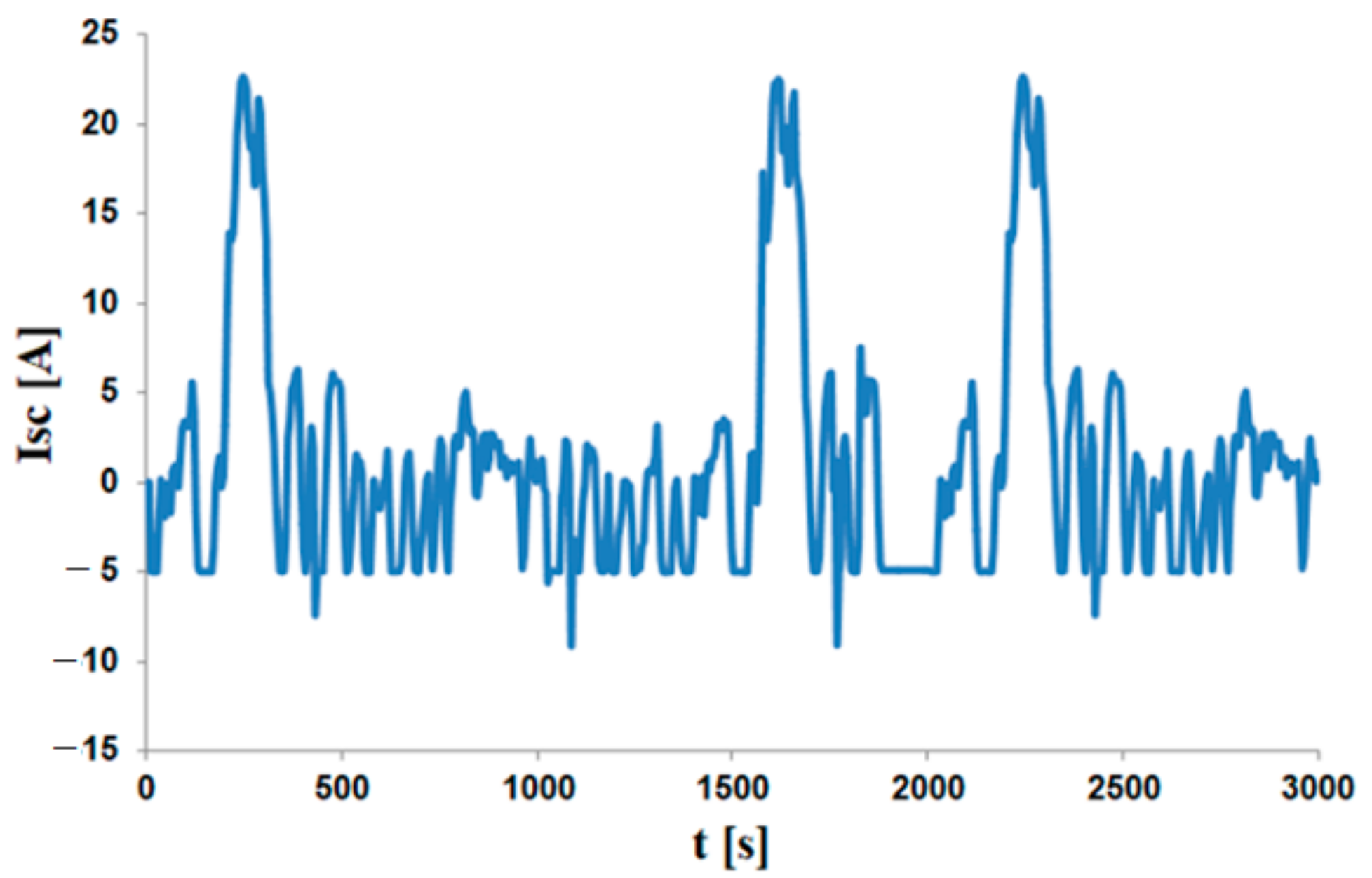

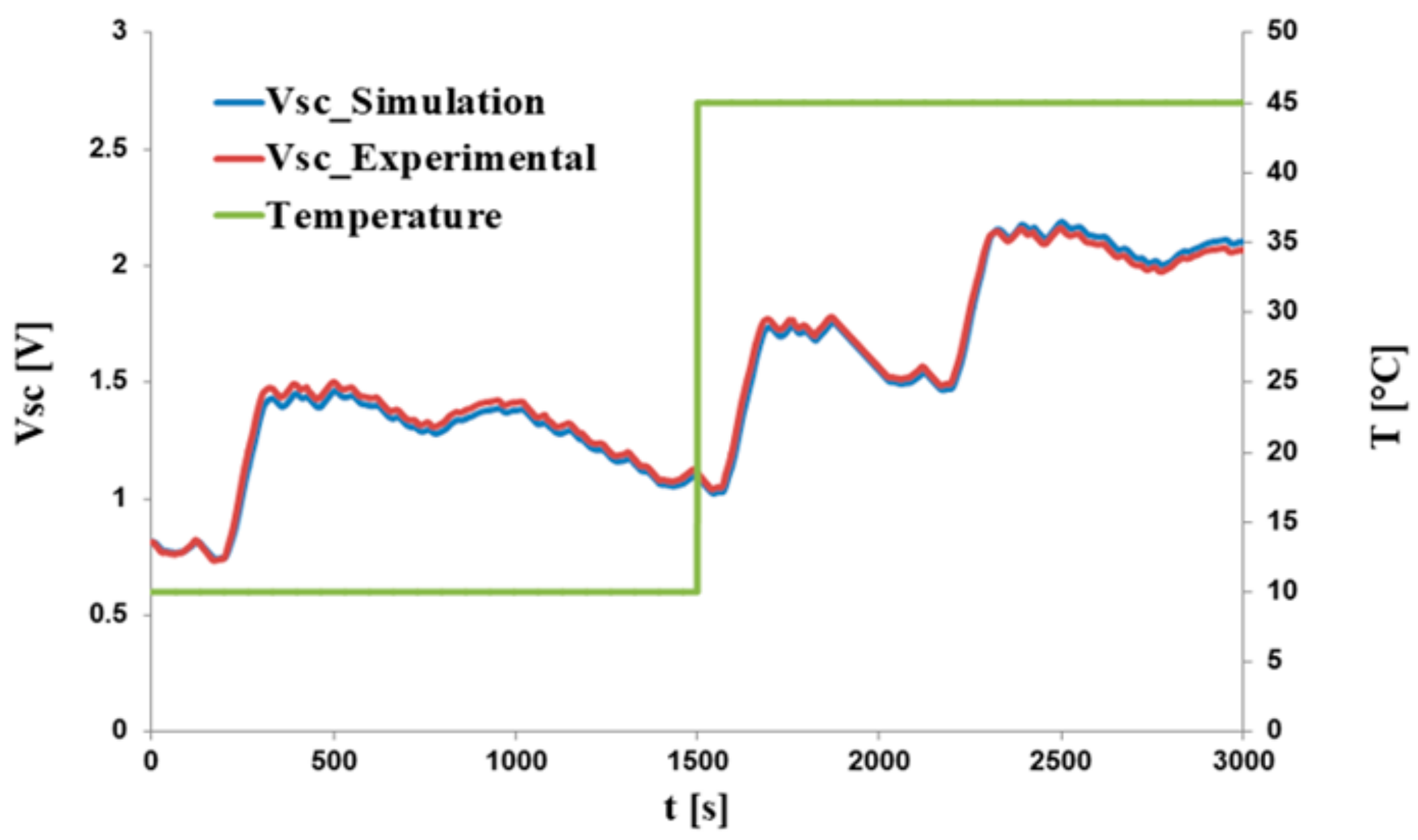

2.3. Supercapacitors Characterization and Modeling

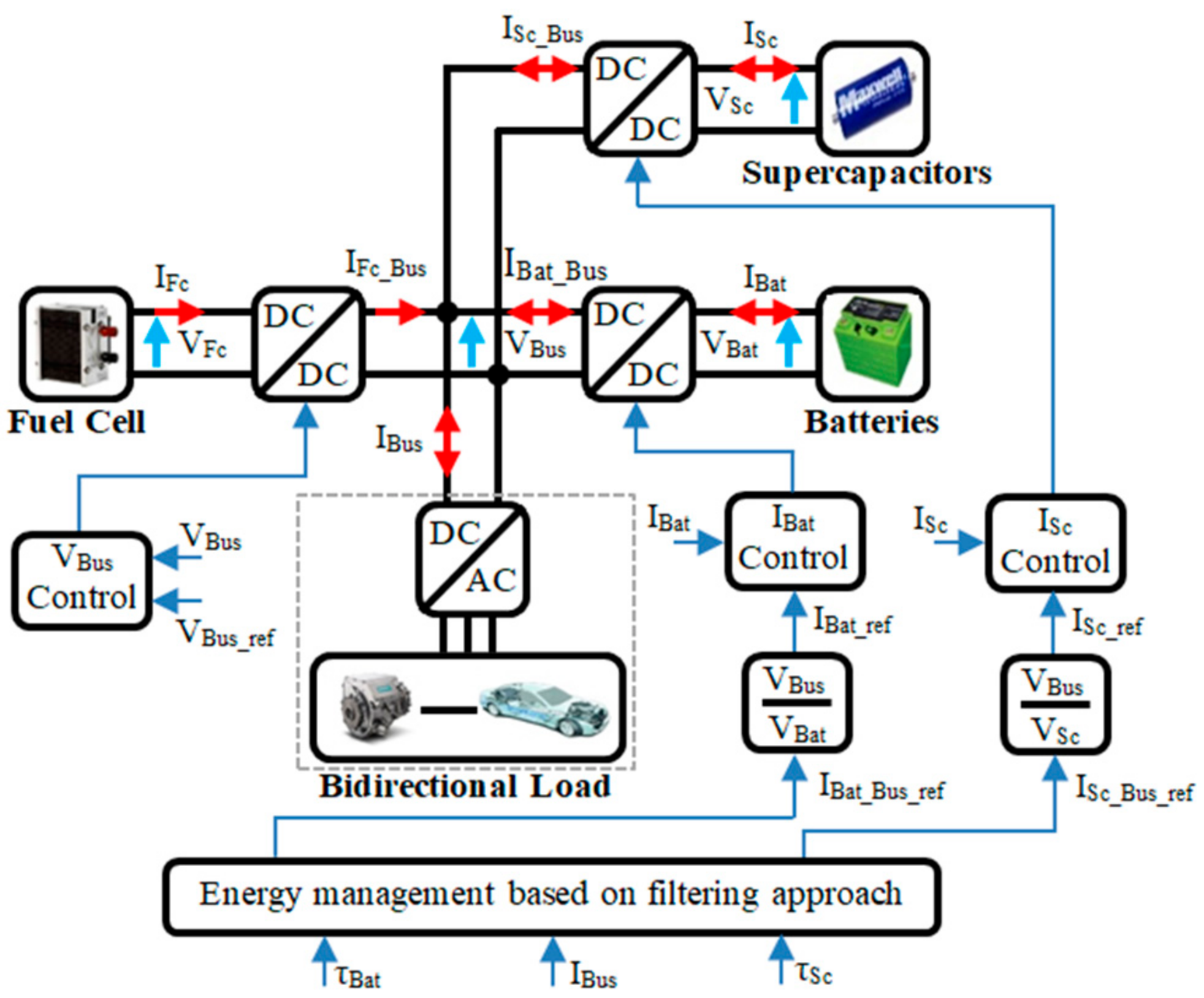

3. Electric Vehicle Energy Management Strategy (EMS)

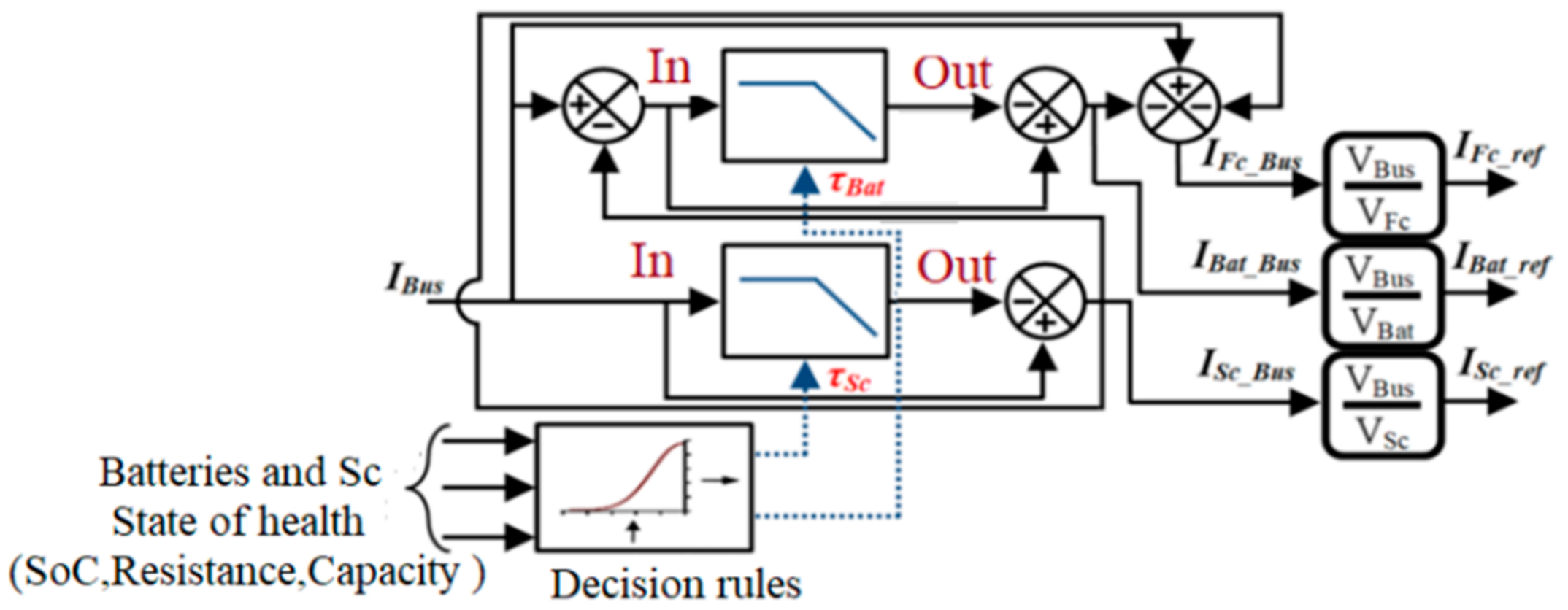

3.1. Filtering Approach for High and Average Frequency Components Extraction from Load’s Current

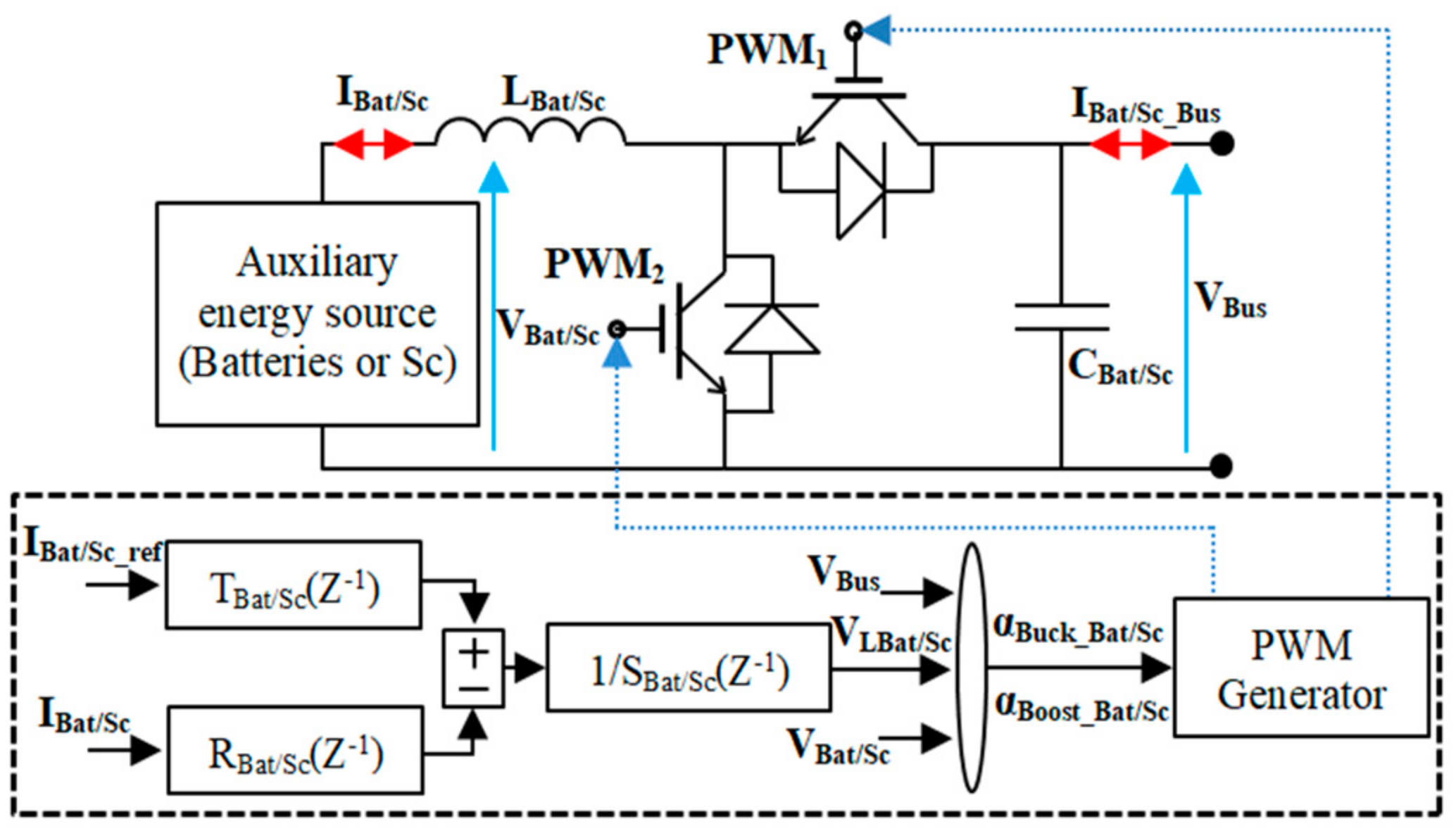

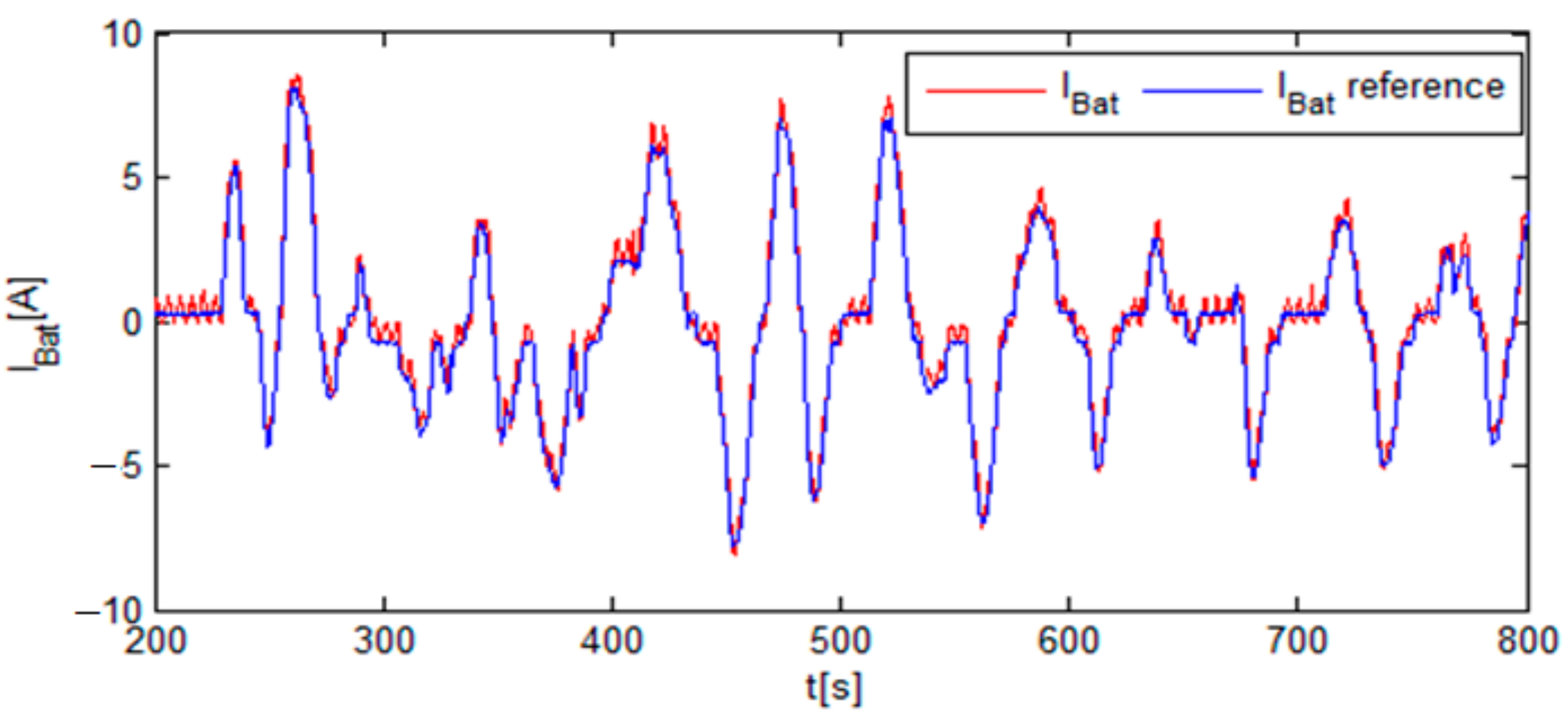

3.2. Supercapacitors and Batteries Current Control

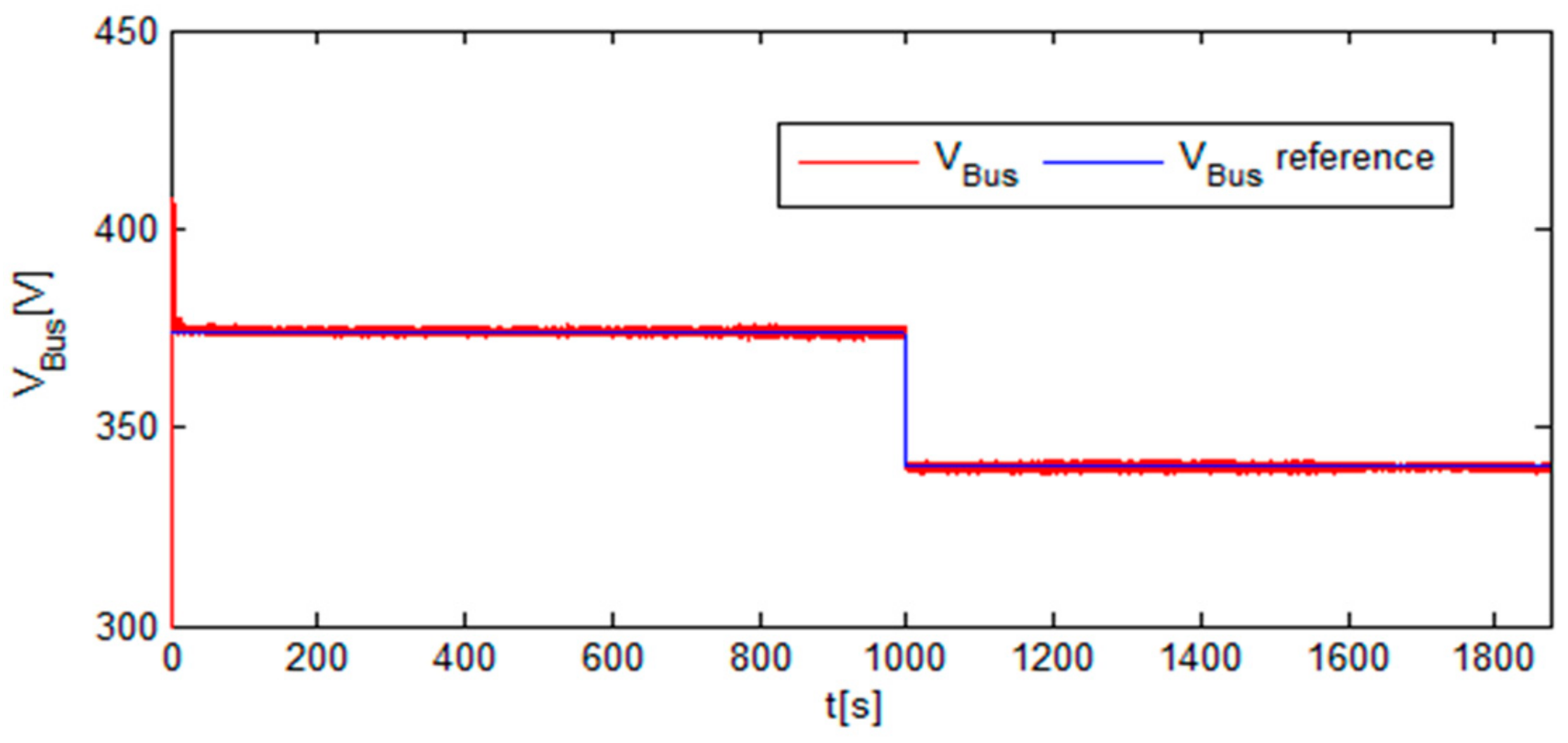

3.3. DC-Link Voltage Management

4. Simulations and Experimental Verifications

4.1. Simulation Conditions

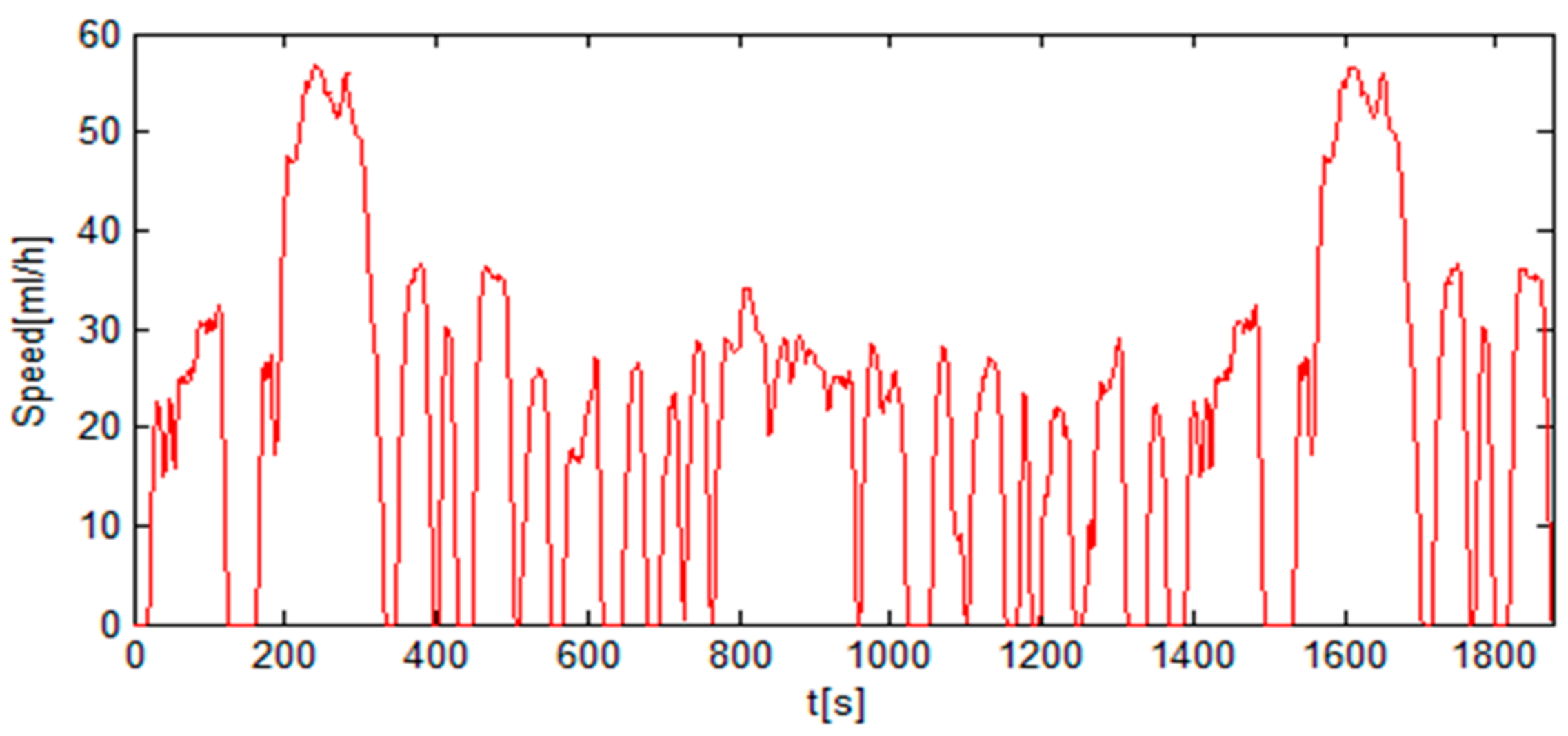

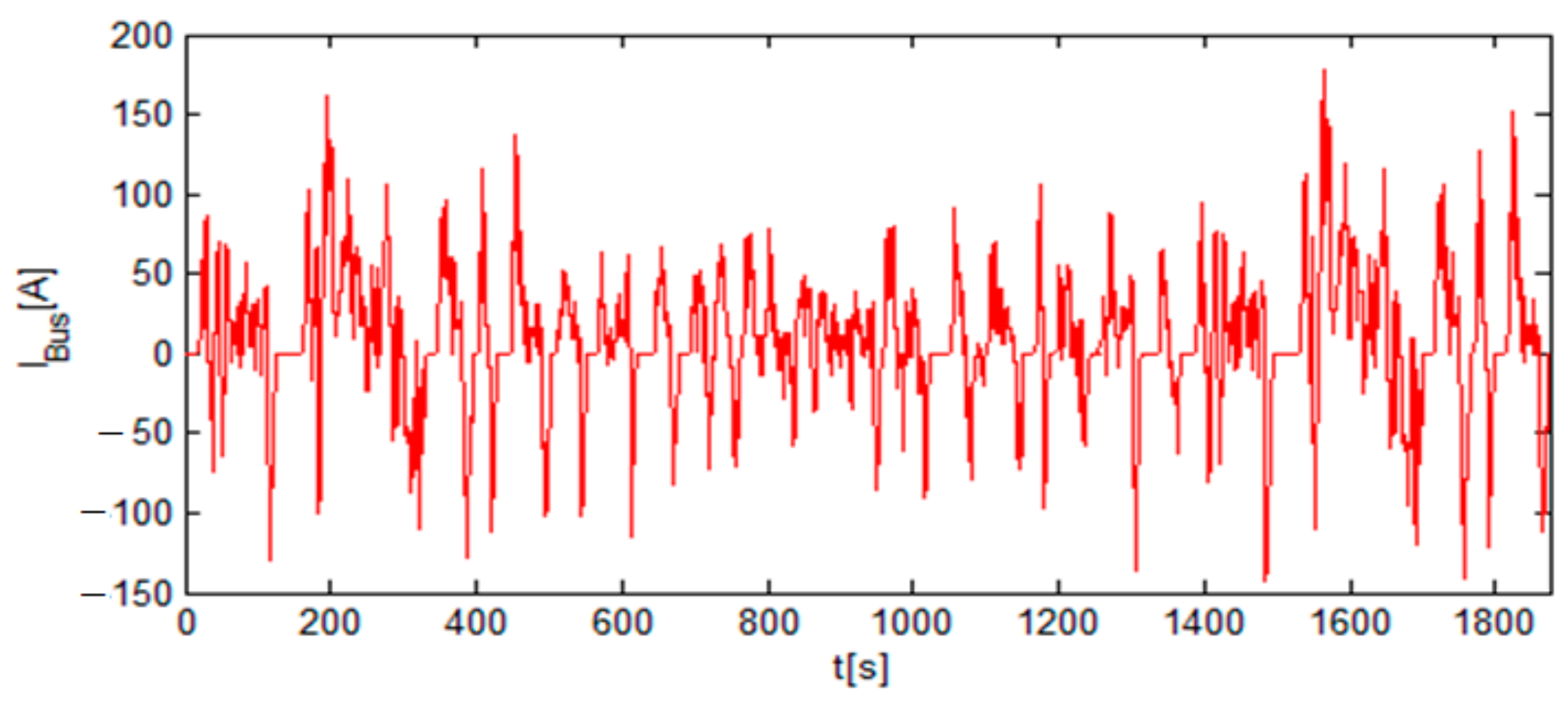

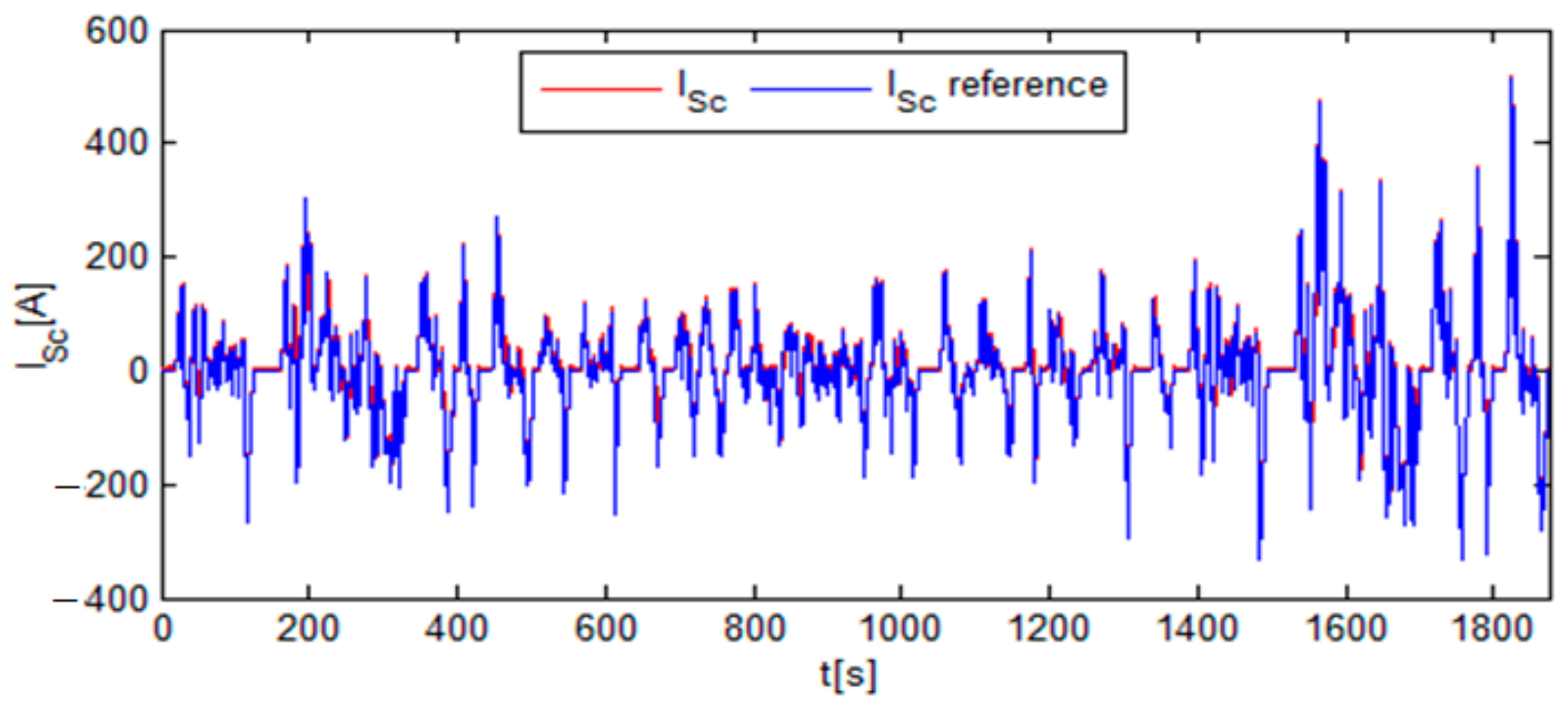

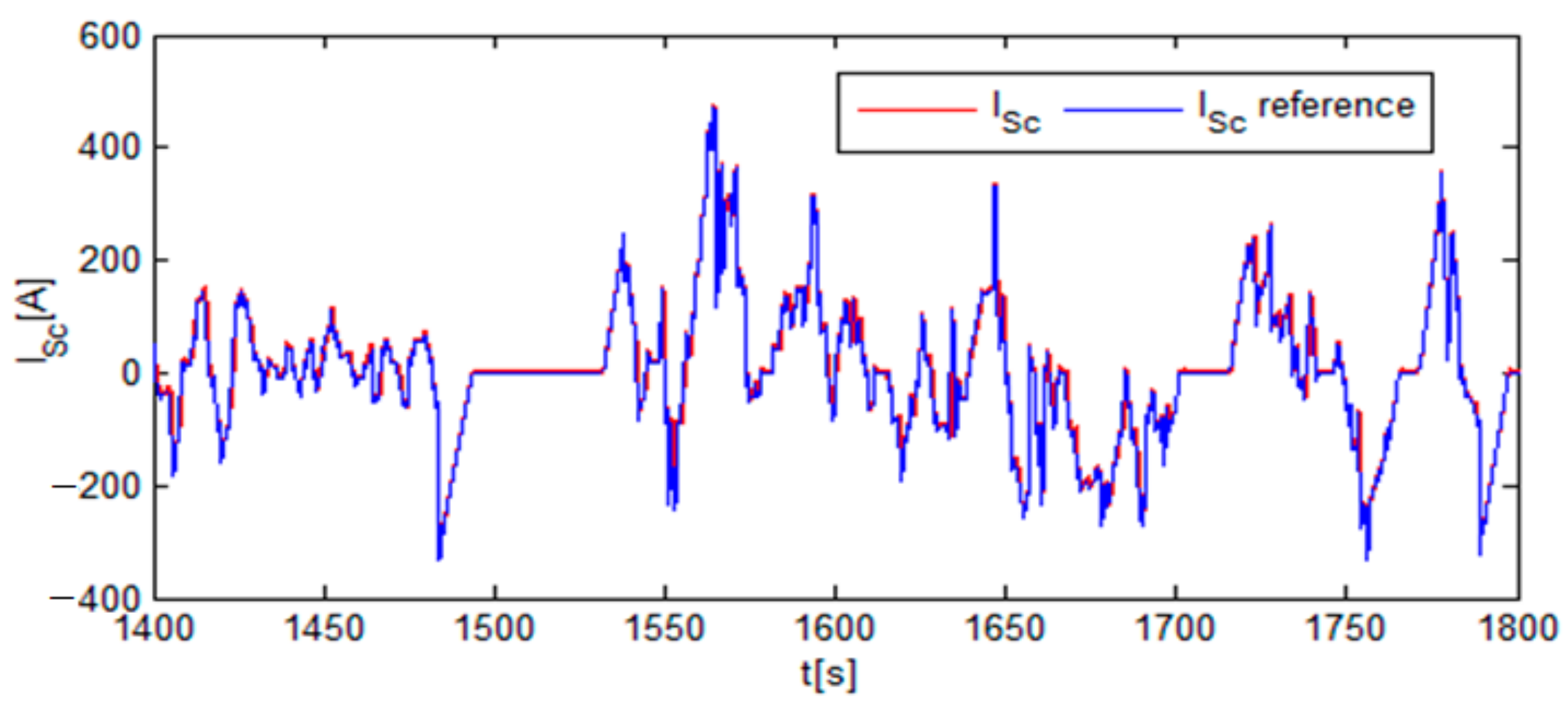

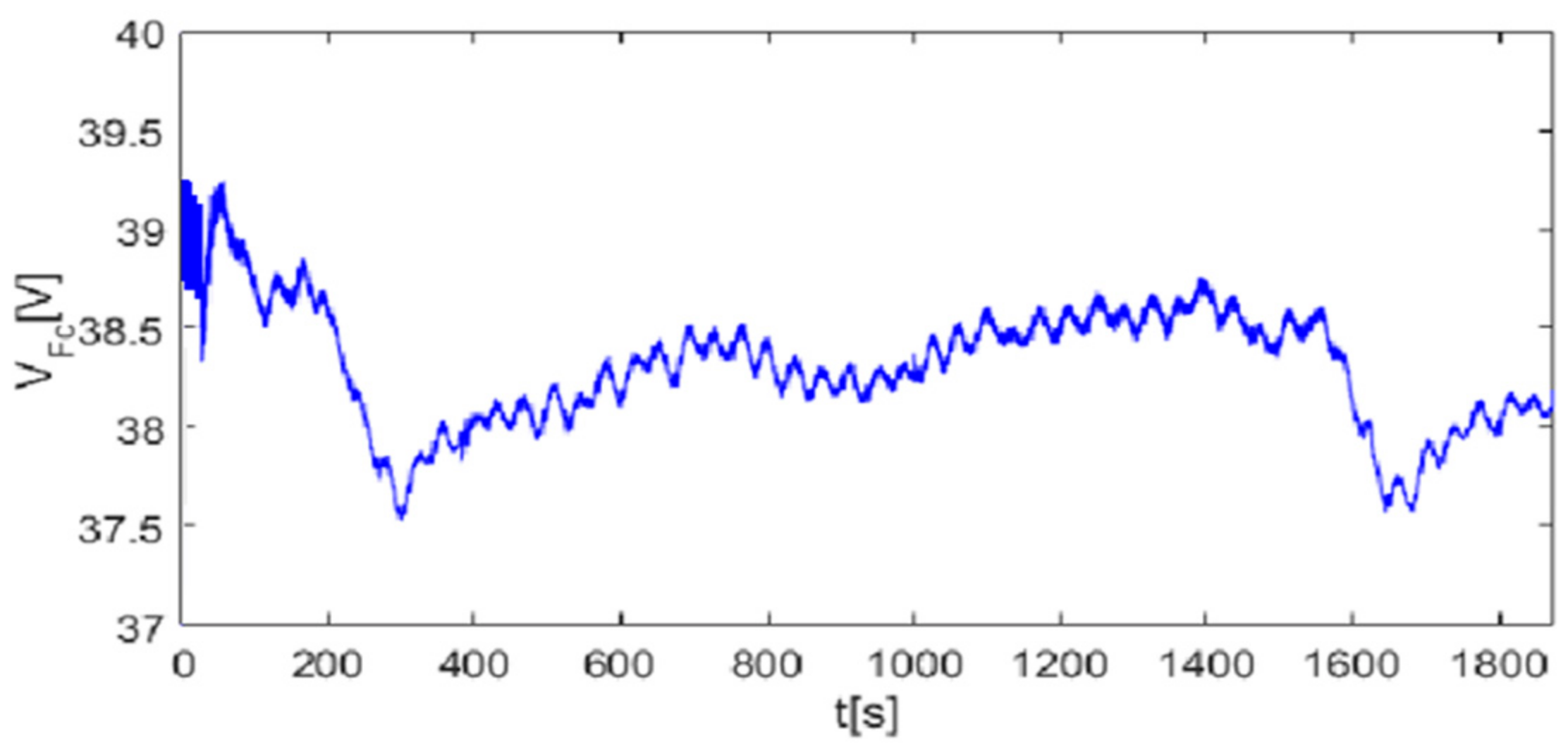

4.2. Simulation Results

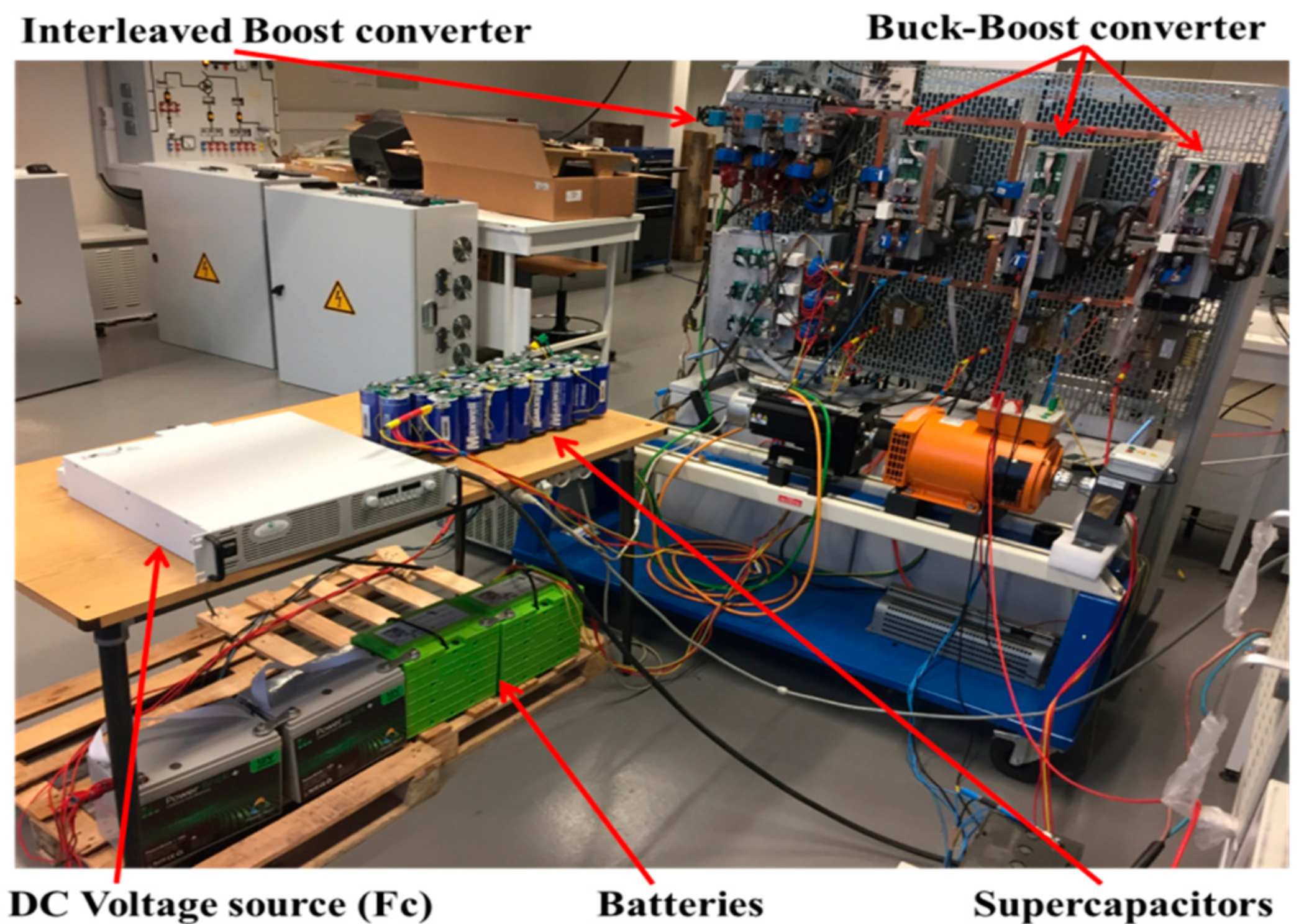

4.3. Experimental Tests Conditions

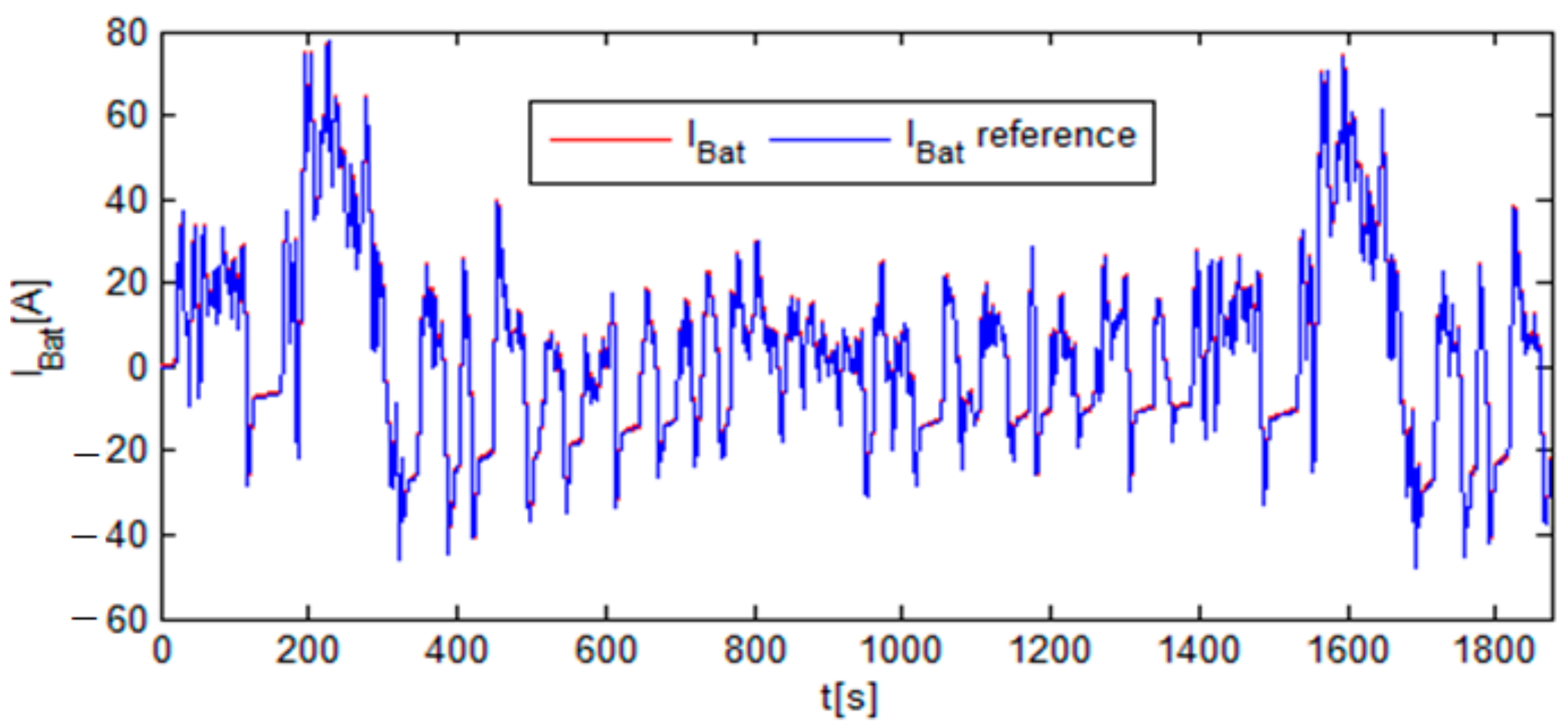

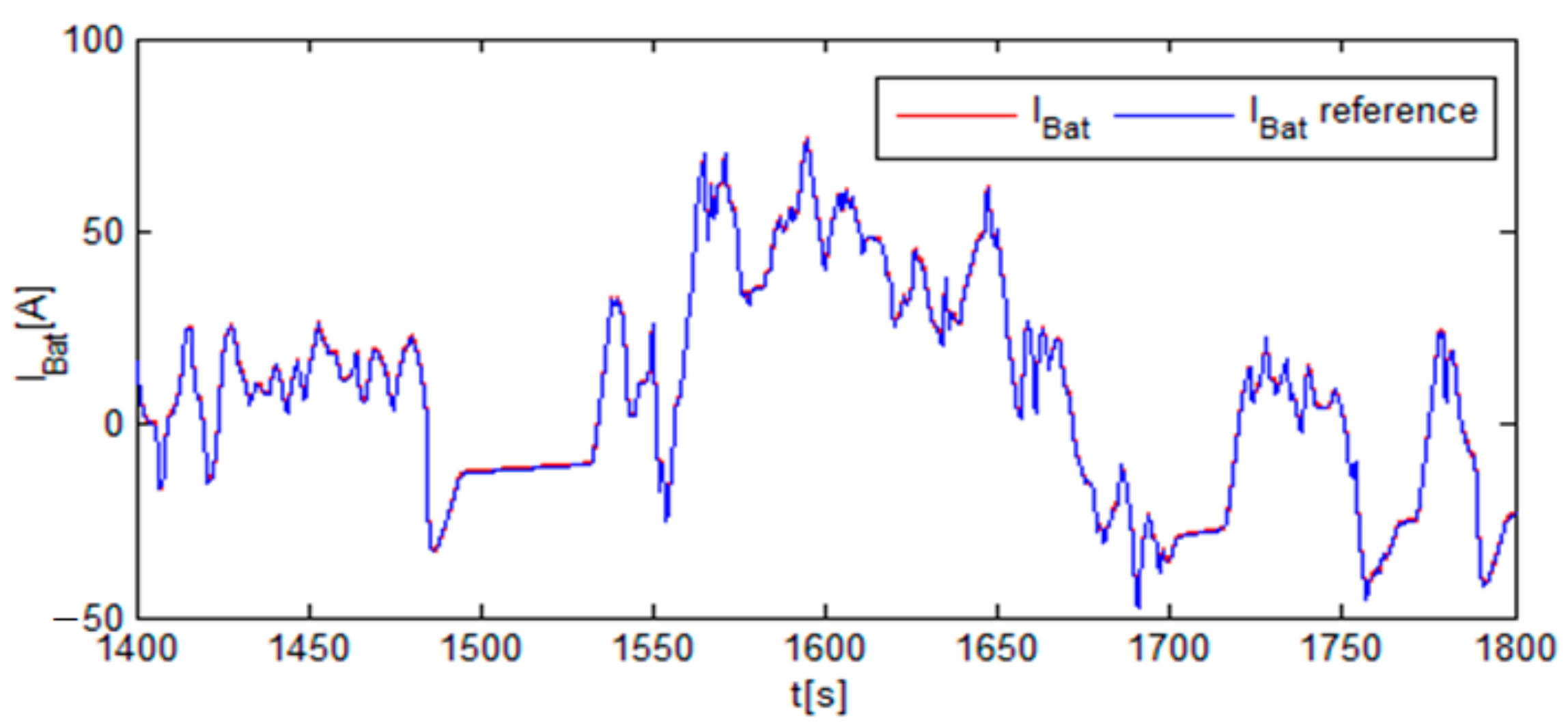

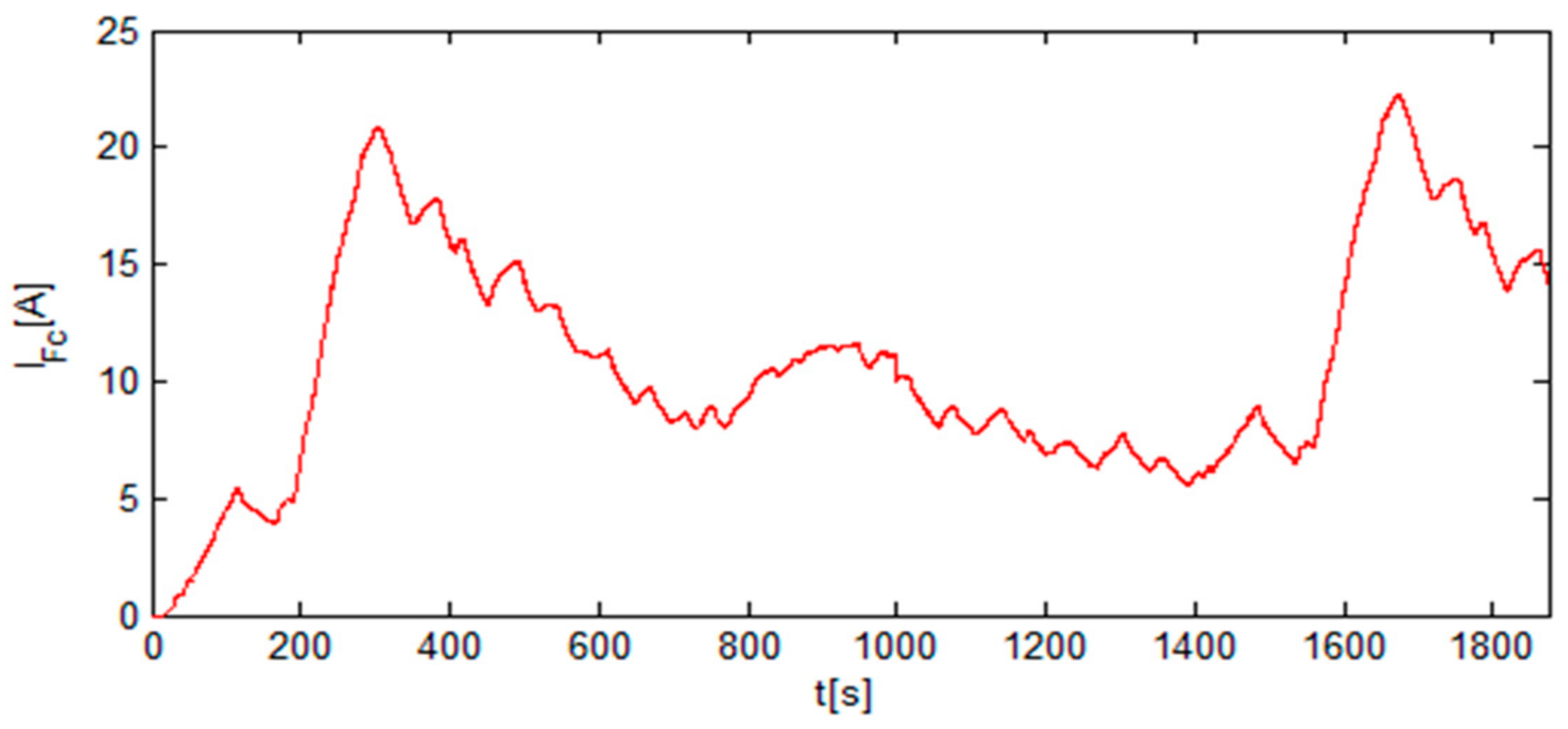

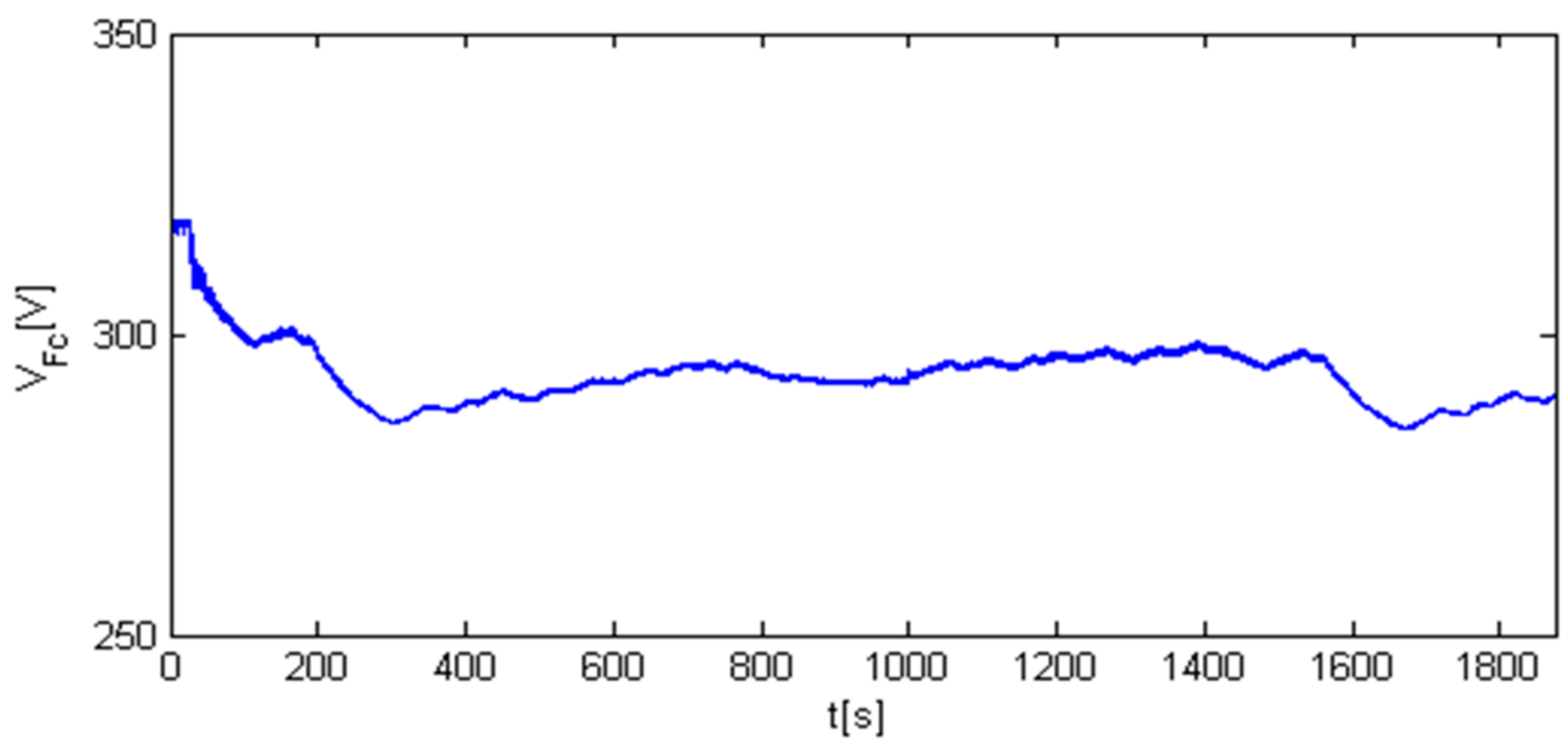

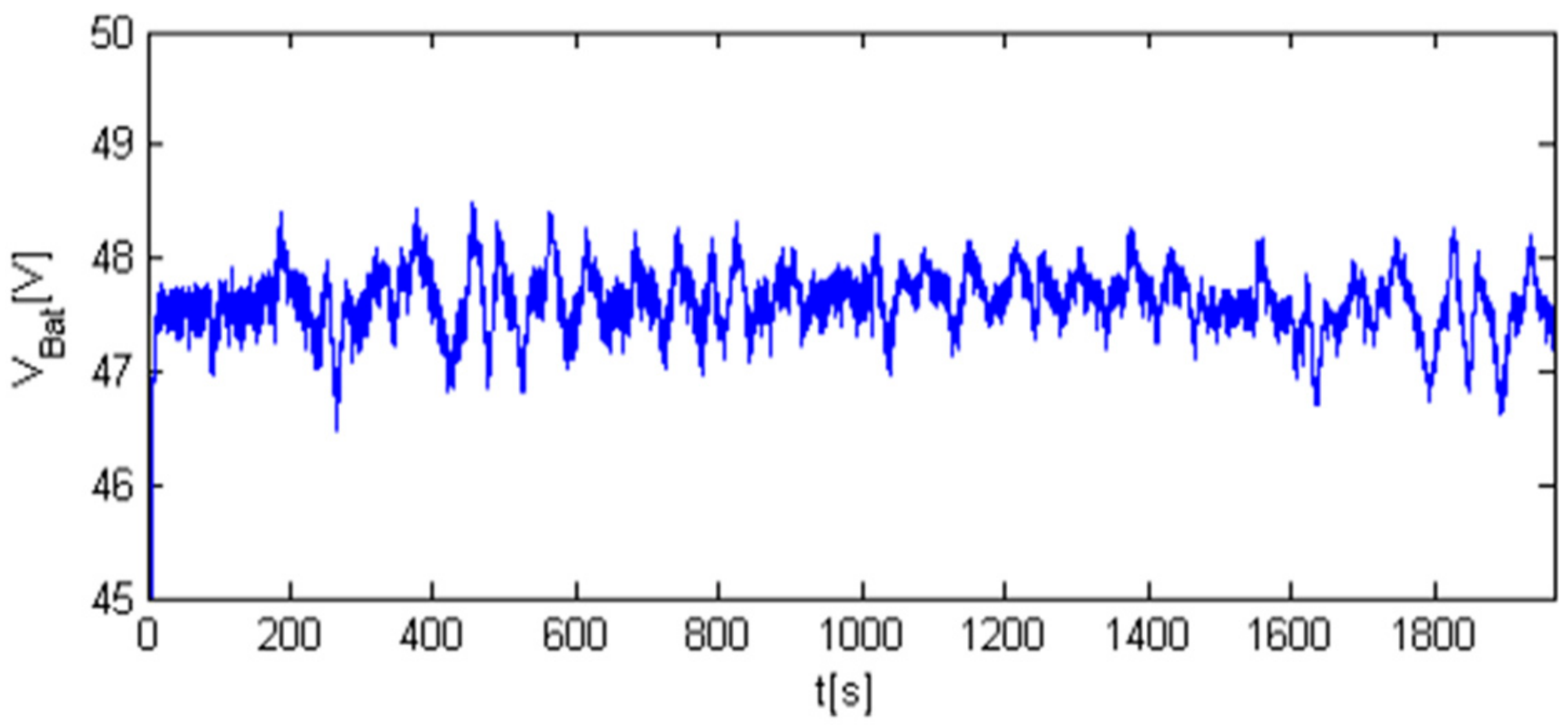

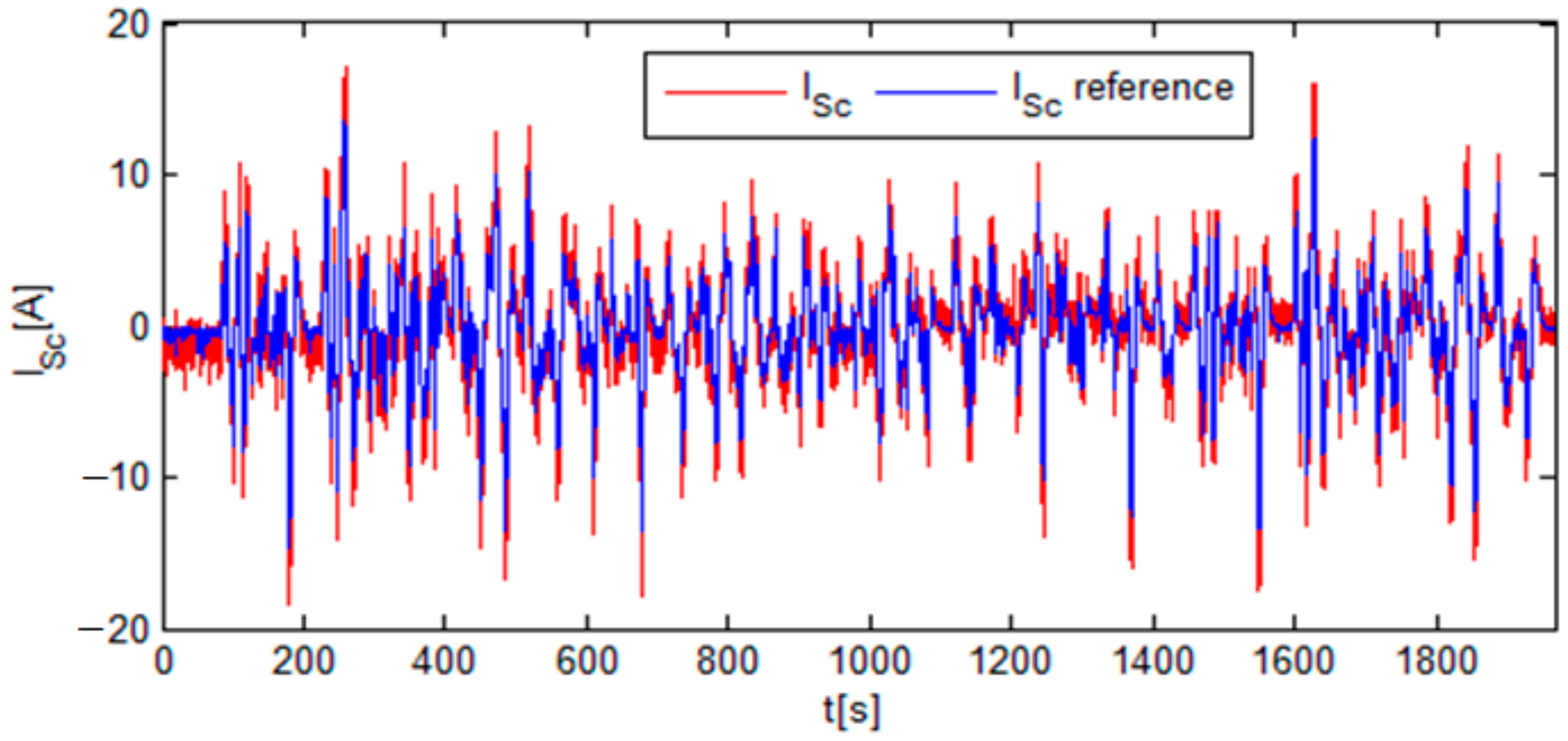

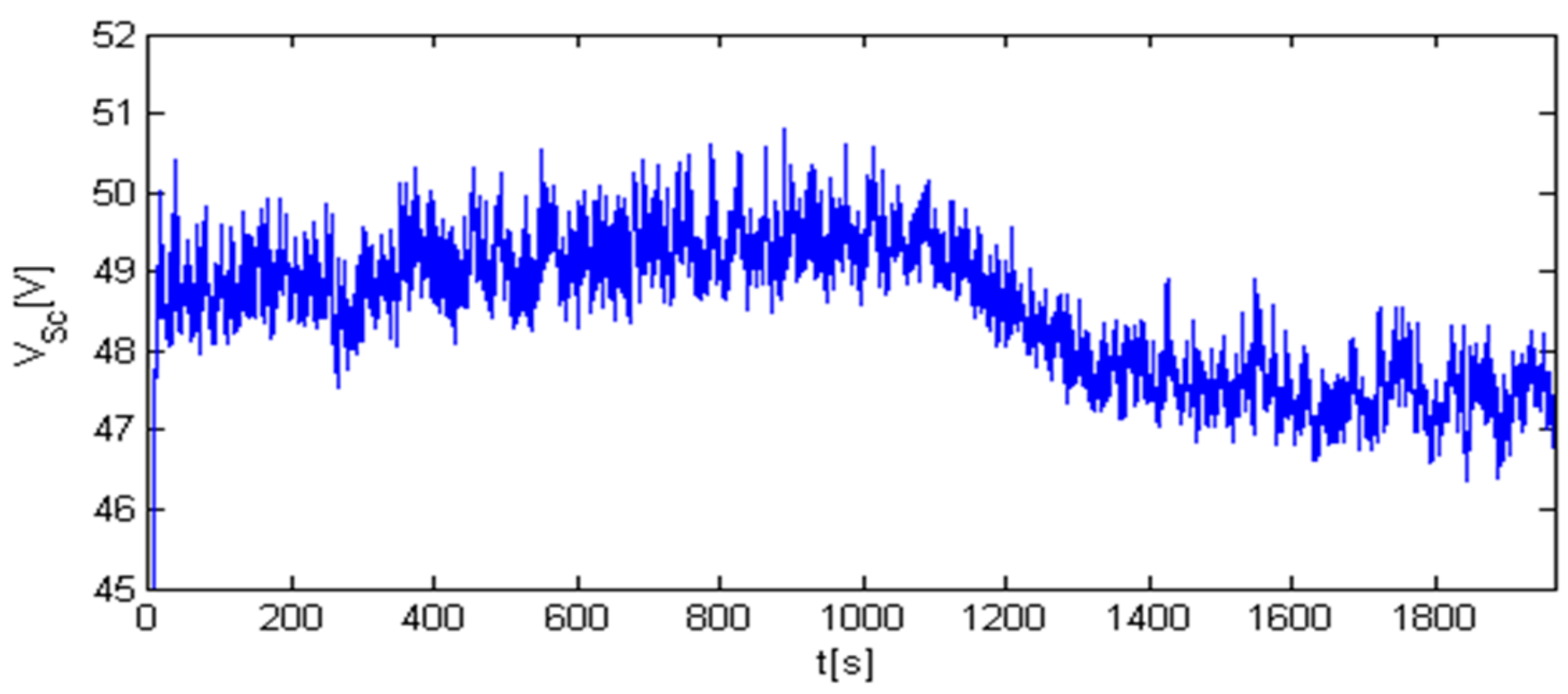

4.4. Experimental Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EV | Electric Vehicle |

| HEV | Hybrid Electric Vehicle |

| ESS | Energy Storage System |

| PEMFC | Proton Exchange Membrane Fuel Cell |

| Fc | Fuel cell |

| Sc | Supercapacitors |

| VBus | DC-link voltage in [V] |

| VBat | Batteries module terminal voltage in [V] |

| IBat | Batteries module current in [A] |

| VSc | Sc pack terminal voltage in [V] |

| ISc | Sc pack current in [A] |

| VFc | Fc stack terminal voltage in [V] |

| IFc | Fc stack current in [A] |

| IBus | Load’s current in the DC-link in [A] |

| IBat_Bus | Batteries contribution in the DC-link in [A] |

| ISc_Bus | Sc contribution in the DC-link in [A] |

| IFc_Bus | Fc contribution in the DC-link in [A] |

| SoCBat | Batteries State of Charge |

| SoH | State of Health |

| VOC | Battery cell open circuit voltage in [V] |

| LiFePO4 | Lithium iron Phosphate |

| τSc | Time constant of the first filter in [s] |

| τBat | Time constant of the second filter in [s] |

| ICE | Internal Combustion Engine |

| IGBT | Insulated Gate Bipolar Transistor |

| PWM | Pulse Width Modulation |

| EMS | Energy Management Strategy |

| eSC; eBat | Sc and Battery energy density (specific energy) in [Wh/kg] |

| pSC; pBat | Sc and Battery Power density (specific power) in [W/kg] |

References

- Abdelrahmana, S.; Attiaa, Y.; Woronowiczb, K.; Youssef, M.Z. Hybrid Fuel Cell/Battery Rail Car: A Feasibility Study. IEEE Trans Transp. Electrif. 2016, 2, 493–503. [Google Scholar] [CrossRef]

- Yin, H.; Zhou, W.; Li, M.; Ma, C.; Zhao, C. An Adaptive Fuzzy Logic-Based Energy Management Strategy on Battery/Ultracapacitor Hybrid Electric Vehicles. IEEE Trans. Transp. Electrif. 2016, 2, 300–311. [Google Scholar] [CrossRef]

- Shen, J.; Khaligh, A. A Supervisory Energy Management Control Strategy in a Battery/Ultracapacitor Hybrid Energy Storage System. IEEE Trans Transp. Electrif. 2015, 1, 223–231. [Google Scholar] [CrossRef]

- Itani, K.; De Bernardinis, A.; Jammal, A.; Oueidat, M. Extreme conditions regenerative braking modeling, control and simulation of a hybrid energy storage system for an electric vehicle. IEEE Trans Transp. Electrif. 2016, 2, 465–479. [Google Scholar] [CrossRef]

- Snoussi, J.; Ben Elghali, S.; Benbouzid, M.; Mimouni, M.F. Optimal Sizing of Energy Storage Systems Using Frequency-Separation-Based Energy Management for Fuel Cell Hybrid Electric Vehicles. IEEE Trans. Veh. Technol. 2018, 67, 9337–9346. [Google Scholar] [CrossRef]

- Han, Y.; Li, Q.; Wang, T.; Chen, W.; Ma, L. Multisource Coordination Energy Management Strategy Based on SOC Consensus for a PEMFC–Battery–Supercapacitor Hybrid Tramway. IEEE Trans. Veh. Technol. 2017, 67, 296–305. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, H.; Khajepour, A.; Li, B.; Ji, J.; Zhao, K.; Hu, C. A review of power management strategies and component sizing methods for hybrid vehicles. Renew. Sustain. Energy Rev. 2018, 96, 132–144. [Google Scholar] [CrossRef]

- Hossain, M.; Rahim, N.; Selvaraj, J.A. Recent progress and development on power DC-DC converter topology, control, design and applications: A review. Renew. Sustain. Energy Rev. 2018, 81, 205–230. [Google Scholar] [CrossRef]

- Sorlei, I.-S.; Bizon, N.; Thounthong, P.; Varlam, M.; Carcadea, E.; Culcer, M.; Iliescu, M.; Raceanu, M. Fuel Cell Electric Vehicles—A Brief Review of Current Topologies and Energy Management Strategies. Energies 2021, 14, 252. [Google Scholar] [CrossRef]

- Odeim, F.; Roes, J.; Heinzel, A. Power Management Optimization of an Experimental Fuel Cell/Battery/Supercapacitor Hybrid System. Energies 2015, 8, 6302–6327. [Google Scholar] [CrossRef]

- Sampietro, J.L.; Puig, V.; Costa-Castelló, R. Optimal Sizing of Storage Elements for a Vehicle Based on Fuel Cells, Supercapacitors, and Batteries. Energies 2019, 12, 925. [Google Scholar] [CrossRef]

- Gherairi, S. Hybrid Electric Vehicle: Design and Control of a Hybrid System (Fuel Cell/Battery/Ultra-Capacitor) Supplied by Hydrogen. Energies 2019, 12, 1272. [Google Scholar] [CrossRef]

- Nassef, A.M.; Fathy, A.; Rezk, H. An Effective Energy Management Strategy Based on Mine-Blast Optimization Technique Applied to Hybrid PEMFC/Supercapacitor/Batteries System. Energies 2019, 12, 3796. [Google Scholar] [CrossRef]

- Do, T.C.; Truong, H.V.A.; Dao, H.V.; Ho, C.M.; To, X.D.; Dang, T.D.; Ahn, K.K. Energy Management Strategy of a PEM Fuel Cell Excavator with a Supercapacitor/Battery Hybrid Power Source. Energies 2019, 12, 4362. [Google Scholar] [CrossRef]

- Hussain, S.; Ali, M.U.; Park, G.-S.; Nengroo, S.H.; Khan, M.A.; Kim, H.-J. A Real-Time Bi-Adaptive Controller-Based Energy Management System for Battery–Supercapacitor Hybrid Electric Vehicles. Energies 2019, 12, 4662. [Google Scholar] [CrossRef]

- Nazir, M.S.; Ahmad, I.; Khan, M.J.; Ayaz, Y.; Armghan, H. Adaptive Control of Fuel Cell and Supercapacitor Based Hybrid Electric Vehicles. Energies 2020, 13, 5587. [Google Scholar] [CrossRef]

- Han, J.; Charpentier, J.-F.; Tang, T. An Energy Management System of a Fuel Cell/Battery Hybrid Boat. Energies 2014, 7, 2799–2820. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Chen, W.; Yan, Y.; Wang, X. A Fast Fault Diagnosis Method of the PEMFC System Based on Extreme Learning Machine and Dempster–Shafer Evidence Theory. IEEE Trans. Transp. Electrif. 2019, 5, 271–284. [Google Scholar] [CrossRef]

- Liang, M.; Liu, Y.; Xiao, B.; Yang, S.; Wang, Z.; Han, H. An analytical model for the transverse permeability of gas diffusion layer with electrical double layer effects in proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2018, 43, 17880–17888. [Google Scholar] [CrossRef]

- Wang, Y.X.; Ou, K.; Kim, Y.B. Modeling and experimental validation of hybrid proton exchange membrane fuel cell/battery system for power management control. Int. J. Hydrogen Energy 2015, 40, 11713–11721. [Google Scholar] [CrossRef]

- Cao, Y.; Kroeze, R.C.; Krein, P.T. Multi-timescale Parametric Electrical Battery Model for Use in Dynamic Electric Vehicle Simulations. IEEE Trans. Transp. Electrif. 2016, 2, 432–442. [Google Scholar] [CrossRef]

- Bellache, K.; Camara, M.B.; Dakyo, B.; Sridhar, R. Aging characterization of lithium iron phosphate batteries considering temperature and direct current undulations as degrading factors. IEEE Trans. Ind. Electron. 2020, 1. [Google Scholar] [CrossRef]

- El Mejdoubi, A.; Chaoui, H.; Gualous, H.; Sabor, J. Online Parameter Identification for Supercapacitor State-of-Health Diagnosis for Vehicular Applications. IEEE Trans. Power Electron. 2017, 32, 9355–9363. [Google Scholar] [CrossRef]

- Ahmad, H.; Wan, W.Y.; Isa, D. Modeling the Ageing Effect of Cycling Using a Supercapacitor-Module Under High Temperature with Electrochemical Impedance Spectroscopy Test. IEEE Trans. Reliab. 2018, 68, 109–121. [Google Scholar] [CrossRef]

- Liu, W.; Song, Y.; Liao, H.; Li, H.; Zhang, X.; Jiao, Y.; Peng, J.; Huang, Z. Distributed Voltage Equalization Design for Supercapacitors Using State Observer. IEEE Trans. Ind. Appl. 2018, 55, 620–630. [Google Scholar] [CrossRef]

- Murray, D.B.; Hayes, J.G. Cycle Testing of Supercapacitors for Long-Life Robust Applications. IEEE Trans. Power Electron. 2015, 30, 2505–2516. [Google Scholar] [CrossRef]

- Bellache, K.; Camara, M.B.; Dakyo, B.; Brayima, D. Supercapacitors Characterization and Modeling Using Combined Electro-Thermal Stress Approach Batteries. IEEE Trans. Ind. Appl. 2018, 55, 1817–1827. [Google Scholar] [CrossRef]

- Camara, M.B.; Gualous, H.; Gustin, F.; Berthon, A.; Dakyo, B. DC/DC Converter Design for Supercapacitor and Battery Power Management in Hybrid Vehicle Applications—Polynomial Control Strategy. IEEE Trans. Ind. Electron. 2010, 57, 587–597. [Google Scholar] [CrossRef]

- Snoussi, J.; Ben Elghali, S.; Benbouzid, M.; Mimouni, M.F. Auto-Adaptive Filtering-Based Energy Management Strategy for Fuel Cell Hybrid Electric Vehicles. Energies 2018, 11, 2118. [Google Scholar] [CrossRef]

- Datasheet Maxwell Technologies, K2 Ultracapacitors-2.7V Series. Available online: https://www.maxwell.com/images/documents/k2series_ds_10153704.pdf (accessed on 15 April 2021).

- GWL Power, Technical specification, Winston-LFP100AHA TALL Cell. Available online: https://files.gwl.eu/inc/_doc/attach/StoItem/7705/ThunderSky-Winston-LIFEPO4-100Ah-TALL-Datasheet.pdf (accessed on 15 April 2021).

- Oukkacha, I.; Camara, M.B.; Dakyo, B. Energy Management in Electric Vehicle based on Frequency sharing approach, using Fuel cells, Lithium batteries and Supercapacitors. In Proceedings of the 2018 7th International Conference on Renewable Energy Research and Applications (ICRERA), Paris, France, 14–17 October 2018; pp. 986–992. [Google Scholar] [CrossRef]

- Khanchoul, M.; Hilairet, M. Design and comparison of different RST controllers for PMSM control. In Proceedings of the IECON 2011–37th Annual Conference of the IEEE Industrial Electronics Society, Melbourne, VIC, Australia, 7–10 November 2011; pp. 1795–1800. [Google Scholar] [CrossRef]

- Technical Specifications for the e-Up Volkswagen Electric Car, 2017 Model. Available online: https://ev-database.org/car/1081/Volkswagen-e-Up (accessed on 15 April 2021).

| Description | Symbol | Parameters |

|---|---|---|

| Parametric coefficients | λ1; λ2 λ3; λ4 | −0.984; 0.00312 7.22 × 10−5; −1.061 × 10−4 |

| Electron flow resistance | Rel | 3 × 10−4 Ω |

| Pressures of O2 and H2 | PO2; PH2 | 0.209 atm; 1.476 atm |

| Polymer membrane thickness | L | 25 × 10−4 cm |

| Fc active area | Ar | 67 cm2 |

| Maximum current density | Jmax | 0.672 A/cm2 |

| Constant parameter | β1 | 0.15 |

| Cells number in series | NS_Fc | 288 |

| Description | Symbol | Parameters |

|---|---|---|

| Operating voltage range for battery cell | VBatmin~VBatmax | 2.8 V~3.8 V |

| Resistance of the first parallel RC | R1 | 0.033 Ω |

| Capacitance of the first parallel RC | C1 | 92 F |

| Resistance of the second parallel RC | R2 | 0.375 Ω |

| Capacitance of the second parallel RC | C2 | 499 F |

| Specific power | PBat | 310 W/Kg |

| Specific energy | EBat | 102 Wh/Kg |

| Battery State of Charge (SoC) initial value | SoC(t0) | 97% |

| Number of elements in series | Ns_Bat | 59 |

| Number of elements in parallel | NP_Bat | 1 |

| Resistance due to electric wiring for one battery | Rbwi | 4.5 m Ω |

| Description | Symbol | Parameters |

|---|---|---|

| Operating voltage range for Sc cell | VScmin~VScmax | 0.7 V~2.7 V |

| Specific power | PSc | 5900 W/kg |

| Specific energy | ESc | 6 Wh/kg |

| Initial value of SoC | SoC(t0) | 70% |

| Number of cells in series | Ns_Sc | 70 |

| Number of cells in parallel | NP_Sc | 1 |

| Resistance due to electric wiring for one cell | Rwi | 4.47 m Ω |

| Description | Symbol | Parameters |

|---|---|---|

| DC-link capacitance ISc and IBat smoothing inductances Sc current control parameters | CSc = CBat = CFc = CBus LSc = LBat t0Sc; t1Sc | 3.3 mF 12 mH 110.27; 59.60 |

| Battery’s current control parameters | t0Bat; t1Bat | 85.84; 55.13 |

| DC-link voltage control parameters | t0Fc; t1Fc | 3.27; 3.23 |

| PWM frequency | fd | 2 kHz |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oukkacha, I.; Sarr, C.T.; Camara, M.B.; Dakyo, B.; Parédé, J.Y. Energetic Performances Booster for Electric Vehicle Applications Using Transient Power Control and Supercapacitors-Batteries/Fuel Cell. Energies 2021, 14, 2251. https://doi.org/10.3390/en14082251

Oukkacha I, Sarr CT, Camara MB, Dakyo B, Parédé JY. Energetic Performances Booster for Electric Vehicle Applications Using Transient Power Control and Supercapacitors-Batteries/Fuel Cell. Energies. 2021; 14(8):2251. https://doi.org/10.3390/en14082251

Chicago/Turabian StyleOukkacha, Ismail, Cheikh Tidiane Sarr, Mamadou Baïlo Camara, Brayima Dakyo, and Jean Yves Parédé. 2021. "Energetic Performances Booster for Electric Vehicle Applications Using Transient Power Control and Supercapacitors-Batteries/Fuel Cell" Energies 14, no. 8: 2251. https://doi.org/10.3390/en14082251

APA StyleOukkacha, I., Sarr, C. T., Camara, M. B., Dakyo, B., & Parédé, J. Y. (2021). Energetic Performances Booster for Electric Vehicle Applications Using Transient Power Control and Supercapacitors-Batteries/Fuel Cell. Energies, 14(8), 2251. https://doi.org/10.3390/en14082251