Model-Predictive-Control-Based Reference Governor for Fuel Cells in Automotive Application Compared with Performance from a Real Vehicle

Abstract

1. Introduction

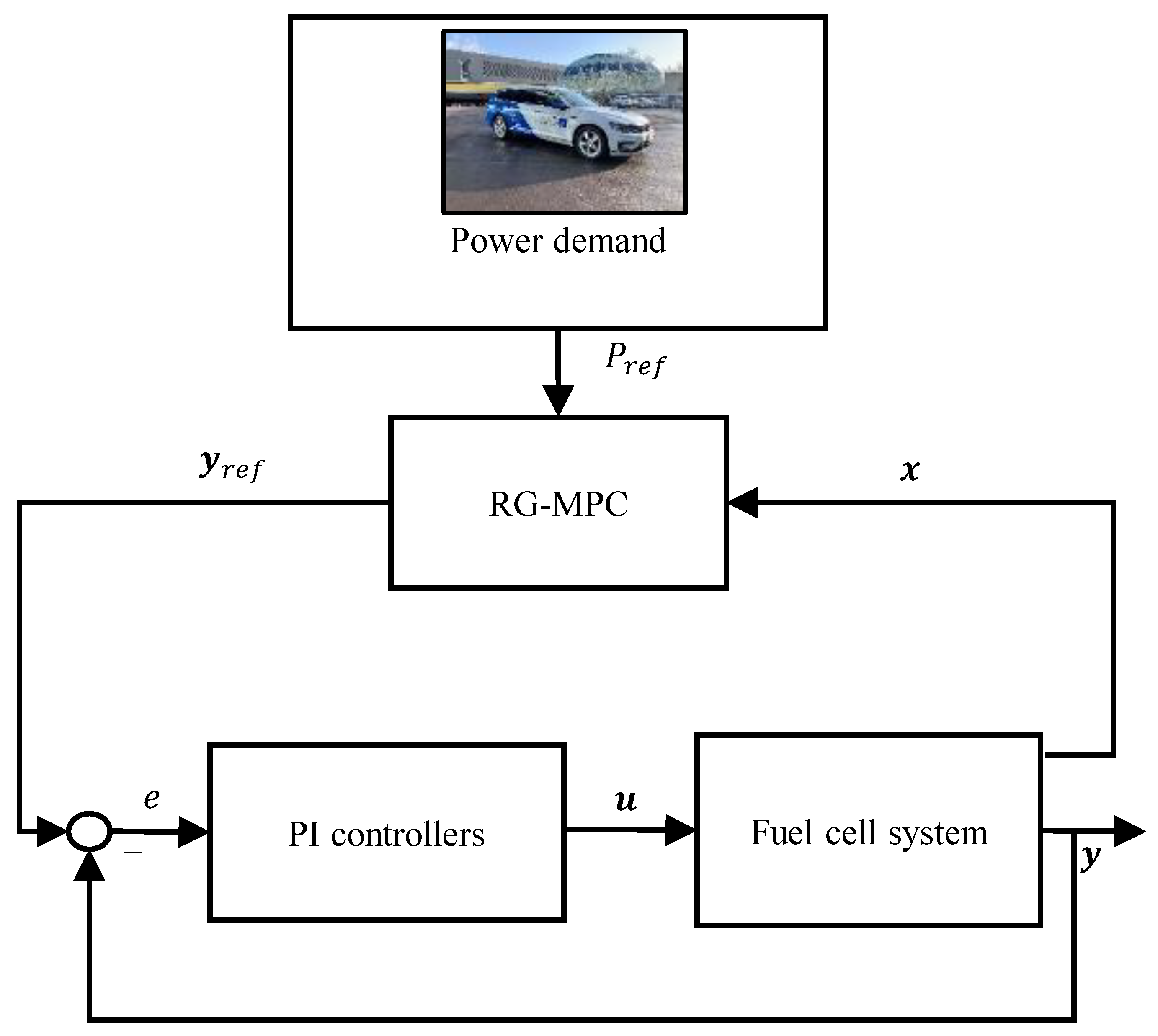

2. Vehicle as Validation Data Generator

Vehicle Control Strategy

- Tuning the controllers: it takes a lot of time, especially since decoupling has to be achieved and antiwindup schemes implemented. Further, the number of controllers to be tuned is high.

- Experimental work: to relate the requested power to the current, and then the current to all the other variables, the system has to be identified and a series of experiments with different levels of excitation at multiple operating points need to be conducted. This obviously includes a significant financial investment.

- Recalibration: in the case that a component is replaced (e.g., new compressor), the calibration process has to be repeated to some degree.

3. Methods

3.1. Plant Model

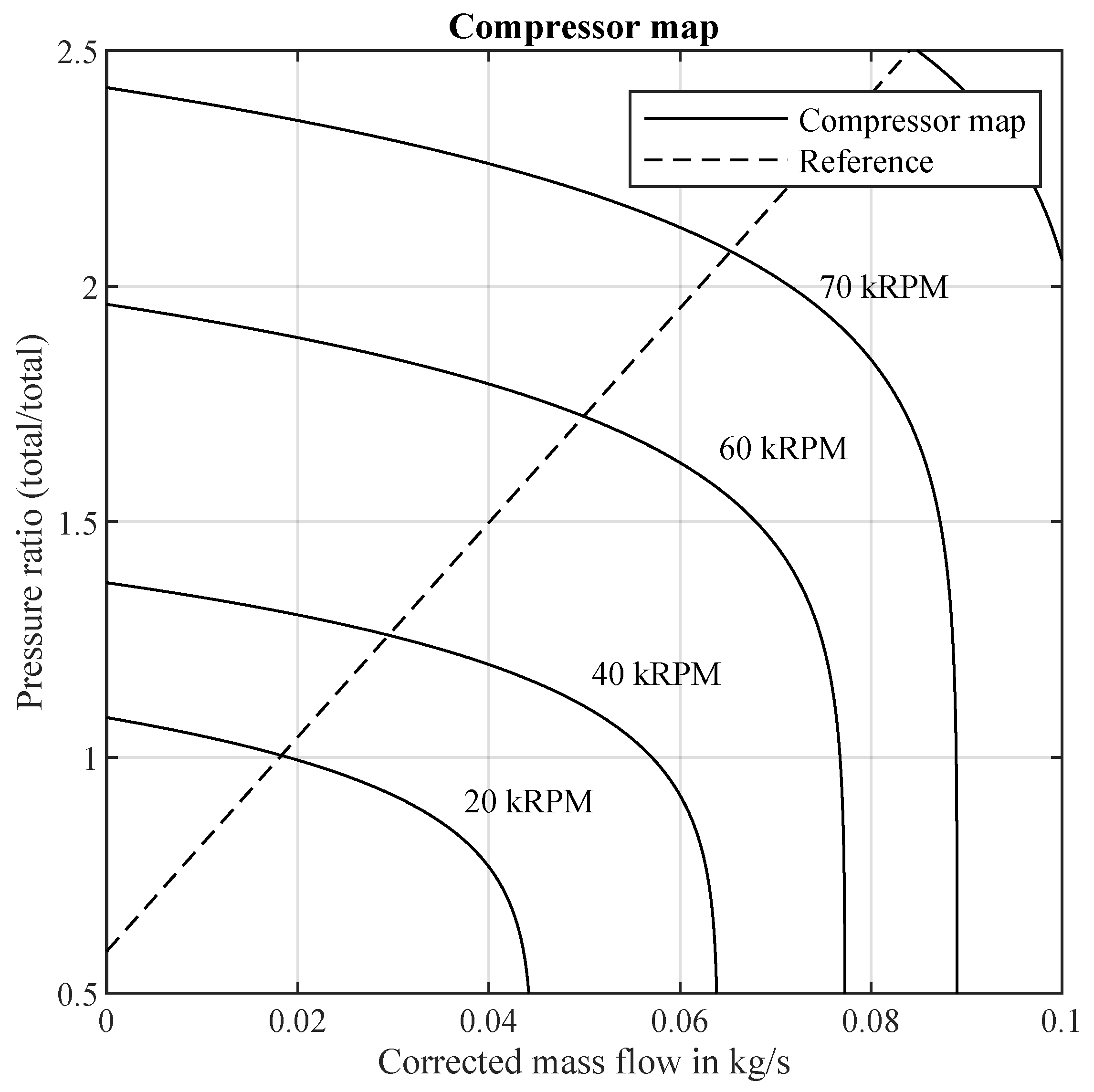

3.1.1. Cathode Submodel

3.1.2. Anode Submodel

3.1.3. GDL Submodel

3.1.4. Power and Efficiency

3.1.5. Surge and Choke Margin

3.1.6. Plant Model Summary

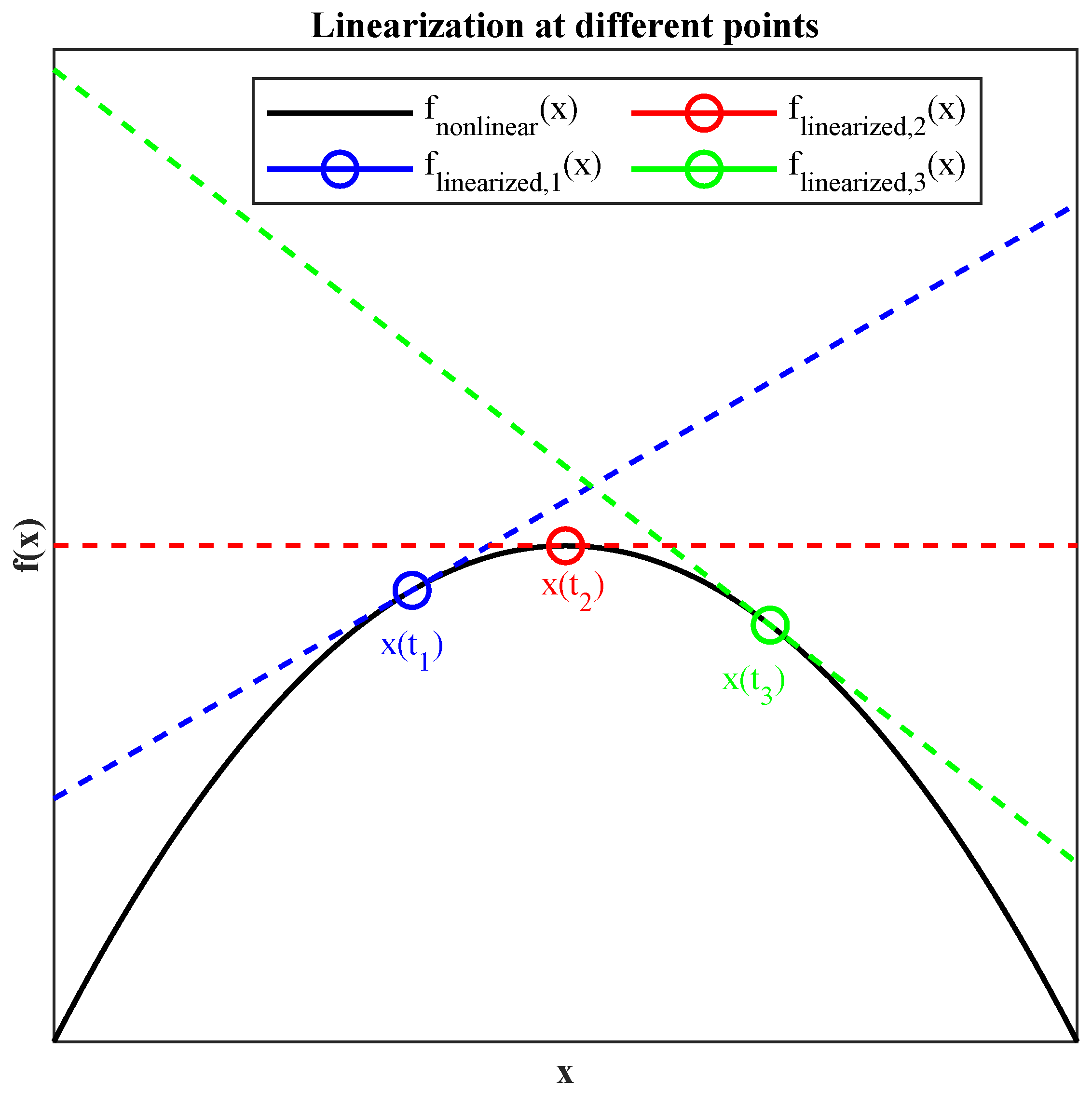

3.2. Prediction Model

3.3. Successive Linearization

3.4. MPC Formulation

3.5. Objective Formulation

- System net power—the reference is taken from the vehicle in Section 2.

- System efficiency—the reference value is 1.

- Pressure difference across the membrane—the reference value is 200 mbar.

- Distance from optimal line in the compressor map—the reference value is 0.

3.6. Constraints

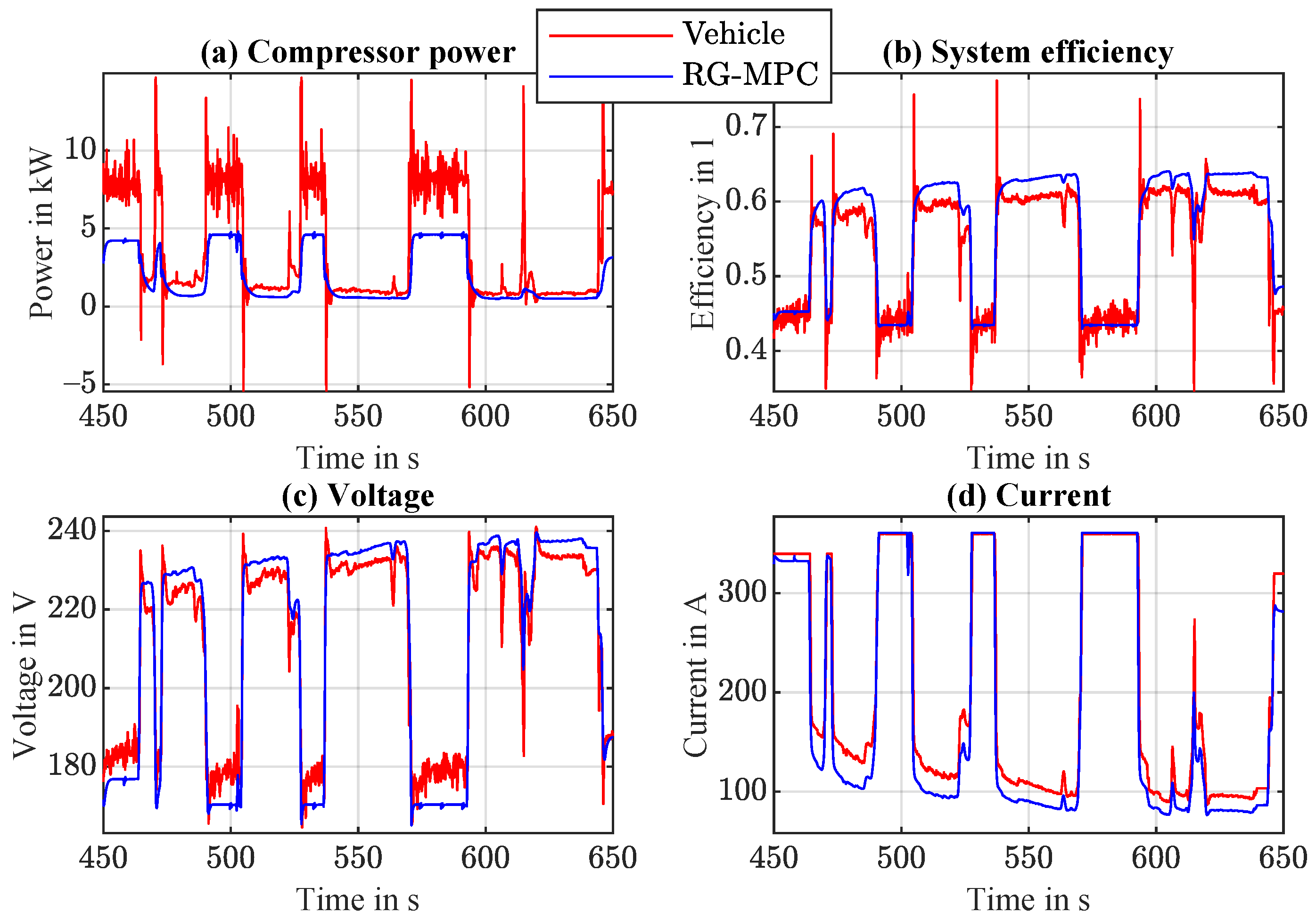

4. Results and Discussion

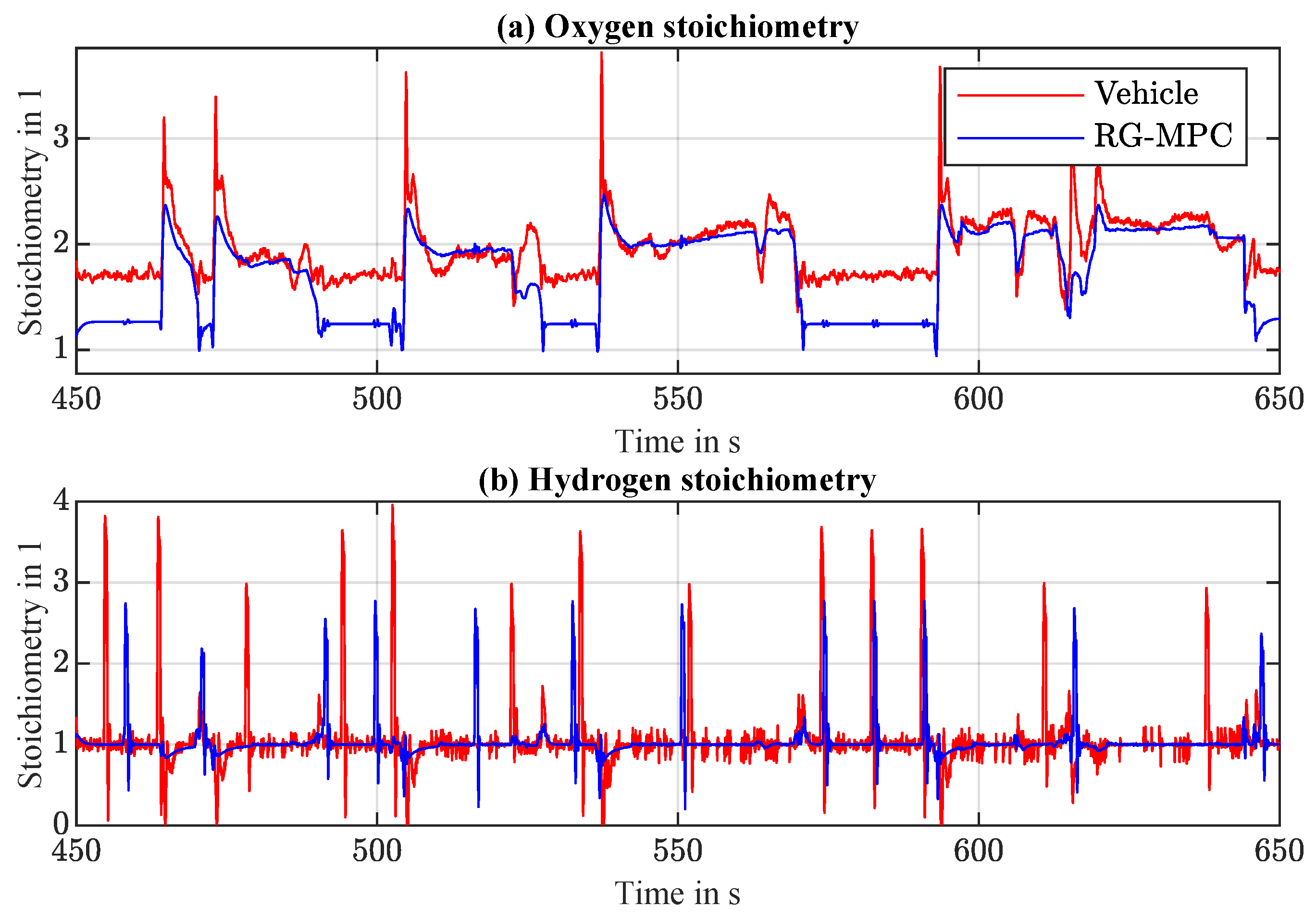

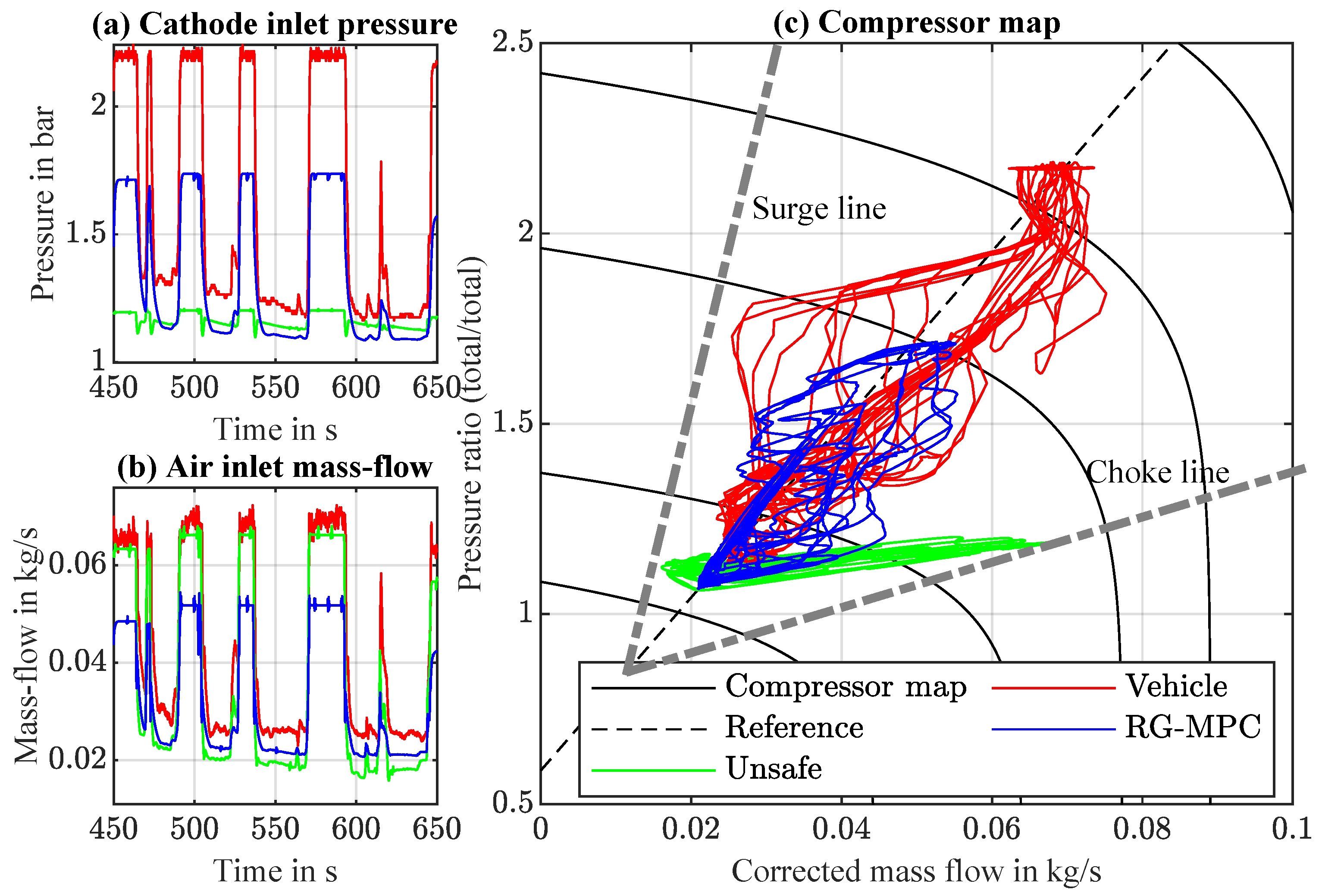

4.1. Simulation Results

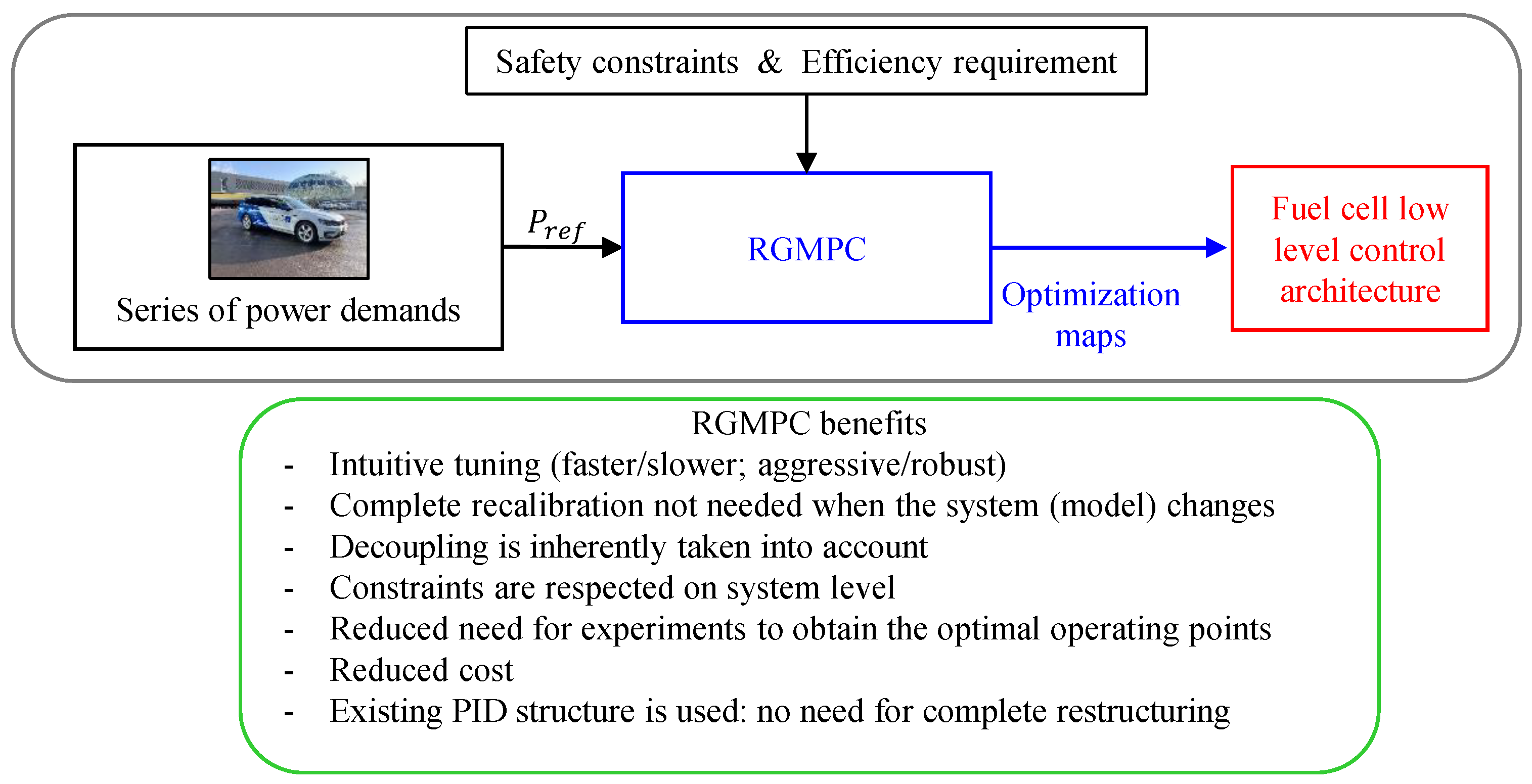

4.2. Benefits and Possible Applications of RG-MPC

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FC | Fuel cell |

| PEM | Polymer electrolyte membrane |

| MPC | Model predictive controller |

| RG-MPC | Reference governor model predictive controller |

| PI | Proportional-integral |

| PID | Proportional-integral-derivative |

References

- Liang, M.; Liu, Y.; Xiao, B.; Yang, S.; Wang, Z.; Han, H. An analytical model for the transverse permeability of gas diffusion layer with electrical double layer effects in proton exchange membrane fuel cells. Int. J. Hydrogen Energy 2018, 43, 17880–17888. [Google Scholar] [CrossRef]

- Liang, M.; Fu, C.; Xiao, B.; Luo, L.; Wang, Z. A fractal study for the effective electrolyte diffusion through charged porous media. Int. J. Heat Mass Transf. 2019, 137, 365–371. [Google Scholar] [CrossRef]

- Daud, W.R.; Rosli, R.E.; Majlan, E.H.; Hamid, S.A.; Mohamed, R.; Husaini, T. PEM fuel cell system control: A review. Renew. Energy 2017, 113, 620–638. [Google Scholar] [CrossRef]

- Woo, C.H.; Benziger, J.B. PEM fuel cell current regulation by fuel feed control. Chem. Eng. Sci. 2007, 62, 957–968. [Google Scholar] [CrossRef]

- Iqbal, M.T. Modeling and control of a wind fuel cell hybrid energy system. Renew. Energy 2003, 28, 223–237. [Google Scholar] [CrossRef]

- Garcia-Gabin, W.; Dorado, F.; Bordons, C. Real-time implementation of a sliding mode controller for air supply on a PEM fuel cell. J. Process Control 2010, 20, 325–336. [Google Scholar] [CrossRef]

- Dalvi, A.; Guay, M. Control and real-time optimization of an automotive hybrid fuel cell power system. Control Eng. Pract. 2009, 17, 924–938. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, G.; Yu, W.; Ouyang, M. Adaptive control of the airflow of a PEM fuel cell system. J. Power Sources 2008, 179, 649–659. [Google Scholar] [CrossRef]

- Almeida, P.E.; Simões, M.G. Neural optimal control of PEM fuel cells with parametric CMAC networks. IEEE Trans. Ind. Appl. 2005, 41, 237–245. [Google Scholar] [CrossRef]

- Hatti, M.; Tioursi, M. Dynamic neural network controller model of PEM fuel cell system. Int. J. Hydrogen Energy 2009, 34, 5015–5021. [Google Scholar] [CrossRef]

- Vahidi, A.; Stefanopoulou, A.; Peng, H. Current management in a hybrid fuel cell power system: A model-predictive control approach. IEEE Trans. Control Syst. Technol. 2006, 14, 1047–1057. [Google Scholar] [CrossRef]

- Vahidi, A.; Greenwell, W. A decentralized model predictive control approach to power management of a fuel cell-ultracapacitor hybrid. In Proceedings of the American Control Conference, New York, NY, USA, 9–13 July 2007; pp. 5431–5437. [Google Scholar] [CrossRef]

- Luna, J.; Jemei, S.; Yousfi-Steiner, N.; Husar, A.; Serra, M.; Hissel, D. Nonlinear predictive control for durability enhancement and efficiency improvement in a fuel cell power system. J. Power Sources 2016, 328, 250–261. [Google Scholar] [CrossRef]

- Danzer, M.A.; Wittmann, S.J.; Hofer, E.P. Prevention of fuel cell starvation by model predictive control of pressure, excess ratio, and current. J. Power Sources 2009, 190, 86–91. [Google Scholar] [CrossRef]

- Hähnel, C.; Aul, V.; Horn, J. Power Control for Efficient Operation of a PEM Fuel Cell System by Nonlinear Model Predictive Control. IFAC-PapersOnLine 2015, 48, 174–179. [Google Scholar] [CrossRef]

- Ebadighajari, A.; Homayouni, H.; Devaal, J.; Golnaraghi, F. Model Predictive Control of Polymer Electrolyte Membrane fuel cell with dead-end anode and periodic purging. In Proceedings of the 2016 IEEE Conference on Control Applications, CCA, Buenos Aires, Argentina, 19–22 September 2016; pp. 1500–1505. [Google Scholar] [CrossRef]

- Ziogou, C.; Pistikopoulos, E.N.; Georgiadis, M.C.; Voutetakis, S.; Papadopoulou, S. Empowering the performance of advanced NMPC by multiparametric programming—An application to a PEM fuel cell system. Ind. Eng. Chem. Res. 2013, 52, 4863–4873. [Google Scholar] [CrossRef]

- Ziogou, C.; Papadopoulou, S.; Georgiadis, M.C.; Voutetakis, S. On-line nonlinear model predictive control of a PEM fuel cell system. J. Process Control 2013, 23, 483–492. [Google Scholar] [CrossRef]

- Goshtasbi, A.; Ersal, T. Degradation-conscious control for enhanced lifetime of automotive polymer electrolyte membrane fuel cells. J. Power Sources 2020, 457, 227996. [Google Scholar] [CrossRef]

- Chen, H.; Chen, J.; Lu, H.; Yan, C.; Liu, Z. A Modified MPC-Based Optimal Strategy of Power Management for Fuel Cell Hybrid Vehicles. IEEE/ASME Trans. Mechatron. 2020, 25, 2009–2018. [Google Scholar] [CrossRef]

- Klaučo, M.; Kalúz, M.; Kvasnica, M. Real-time implementation of an explicit MPC-based reference governor for control of a magnetic levitation system. Control Eng. Pract. 2017, 60, 99–105. [Google Scholar] [CrossRef]

- Klaučo, M.; Kvasnica, M. Control of a boiler-turbine unit using MPC-based reference governors. Appl. Therm. Eng. 2017, 110, 1437–1447. [Google Scholar] [CrossRef]

- Garone, E.; Di Cairano, S.; Kolmanovsky, I. Reference and command governors for systems with constraints: A survey on theory and applications. Automatica 2017, 75, 306–328. [Google Scholar] [CrossRef]

- Klaučo, M.; Kvasnica, M. MPC-Based Reference Governors; Springer: Cham, Switzerland, 2019. [Google Scholar]

- Zhakatayev, A.; Rakhim, B.; Adiyatov, O.; Baimyshev, A.; Varol, H.A. Successive linearization based model predictive control of variable stiffness actuated robots. In Proceedings of the IEEE/ASME International Conference on Advanced Intelligent Mechatronics, AIM, Munich, Germany, 3–7 July 2017; pp. 1774–1779. [Google Scholar] [CrossRef]

- Ławryńczuk, M. Nonlinear predictive control of a boiler-turbine unit: A state-space approach with successive on-line model linearisation and quadratic optimisation. ISA Trans. 2017, 67, 476–495. [Google Scholar] [CrossRef] [PubMed]

- Goshtasbi, A.; Ersal, T. LQ-MPC design for degradation-conscious control of PEM fuel cells. In Proceedings of the American Control Conference, Philadelphia, PA, USA, 10–12 July 2019; pp. 1555–1560. [Google Scholar] [CrossRef]

- Bamimore, A.; Taiwo, O.; King, R. Comparison of two nonlinear model predictive control methods and implementation on a laboratory three tank system. In Proceedings of the IEEE Conference on Decision and Control, Orlando, FL, USA, 12–15 December 2011; pp. 5242–5247. [Google Scholar] [CrossRef]

- Ritzberger, D.; Hametner, C.; Jakubek, S. A real-time dynamic fuel cell system simulation for model-based diagnostics and control: Validation on real driving data. Energies 2020, 13, 3148. [Google Scholar] [CrossRef]

- Vrlic, M.; Ritzberger, D.; Jakubek, S. Fuel Cell Control Using Successive Linearization Vehicle Data. Energies 2020, 13, 5353. [Google Scholar] [CrossRef]

- Böhler, L.; Ritzberger, D.; Hametner, C.; Jakubek, S. Constrained Extended Kalman Filter Design and Application for On-Line State Estimation of High-Order Polymer Electrolyte Membrane Fuel Cell Systems. Int. J. Hydrogen Energy 2021. [Google Scholar] [CrossRef]

- KEYTECH4EV—Development and Demonstration of Key Technologies for Low-Cost Electric Vehicle Platforms. Available online: http://iesta.at/keytech4ev/ (accessed on 1 February 2021).

- Kravos, A.; Ritzberger, D.; Tavčar, G.; Hametner, C.; Jakubek, S.; Katrašnik, T. Thermodynamically consistent reduced dimensionality electrochemical model for proton exchange membrane fuel cell performance modelling and control. J. Power Sources 2020, 454, 227930. [Google Scholar] [CrossRef]

- Pukrushpan, T.; Peng, H. Dynamics of Low-Pressure and High-pressure Fuel Cell Air Supply Systems. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; pp. 2049–2054. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vrlić, M.; Ritzberger, D.; Jakubek, S. Model-Predictive-Control-Based Reference Governor for Fuel Cells in Automotive Application Compared with Performance from a Real Vehicle. Energies 2021, 14, 2206. https://doi.org/10.3390/en14082206

Vrlić M, Ritzberger D, Jakubek S. Model-Predictive-Control-Based Reference Governor for Fuel Cells in Automotive Application Compared with Performance from a Real Vehicle. Energies. 2021; 14(8):2206. https://doi.org/10.3390/en14082206

Chicago/Turabian StyleVrlić, Martin, Daniel Ritzberger, and Stefan Jakubek. 2021. "Model-Predictive-Control-Based Reference Governor for Fuel Cells in Automotive Application Compared with Performance from a Real Vehicle" Energies 14, no. 8: 2206. https://doi.org/10.3390/en14082206

APA StyleVrlić, M., Ritzberger, D., & Jakubek, S. (2021). Model-Predictive-Control-Based Reference Governor for Fuel Cells in Automotive Application Compared with Performance from a Real Vehicle. Energies, 14(8), 2206. https://doi.org/10.3390/en14082206