Improved Self-Sensing Speed Control of IPMSM Drive Based on Cascaded Nonlinear Control

Abstract

1. Introduction

2. Nonlinear Modeling of IPMSM

2.1. IPMSM Dynamic Model

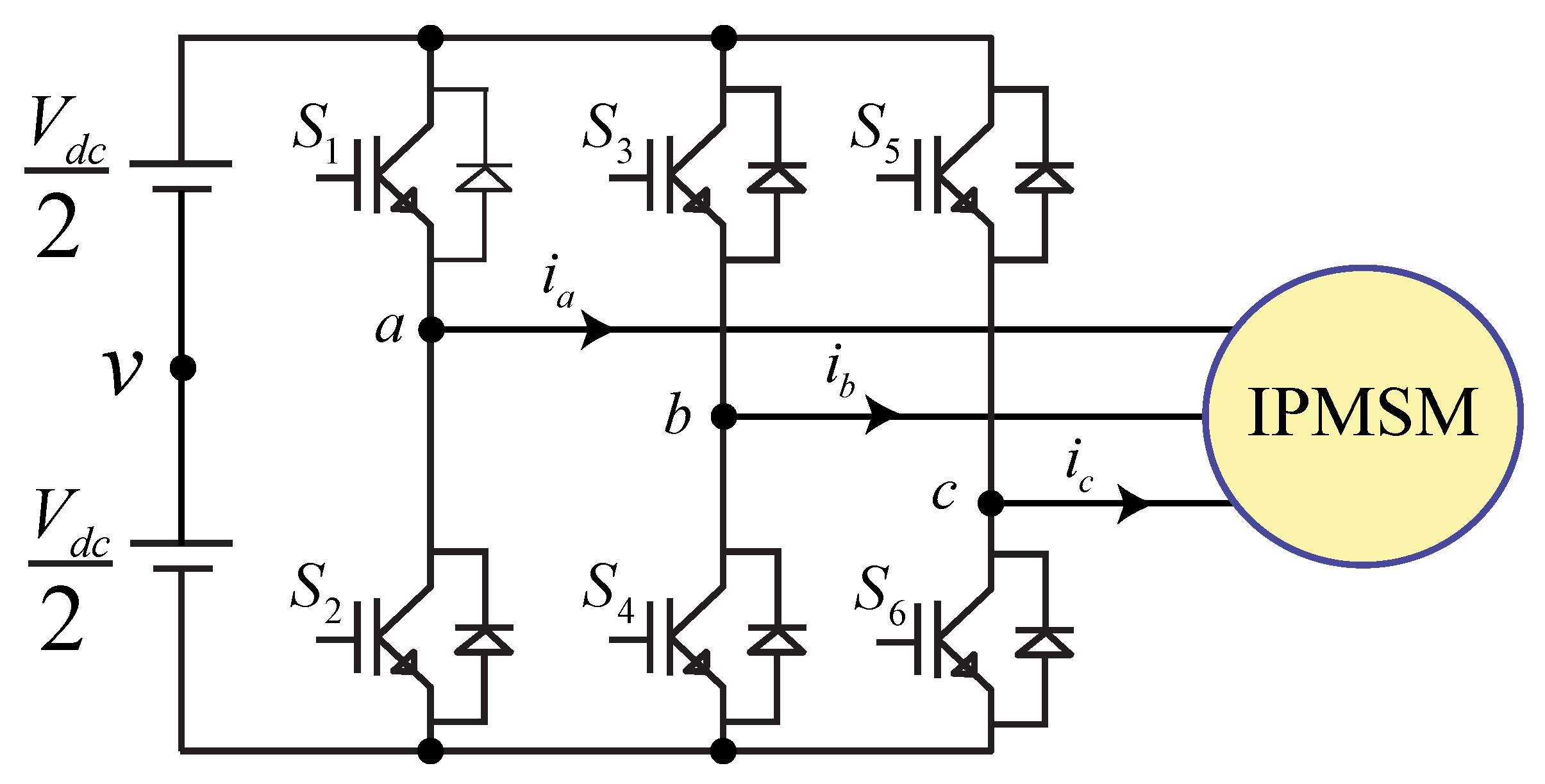

2.2. VSI Fed IPMSM

3. Control Strategies

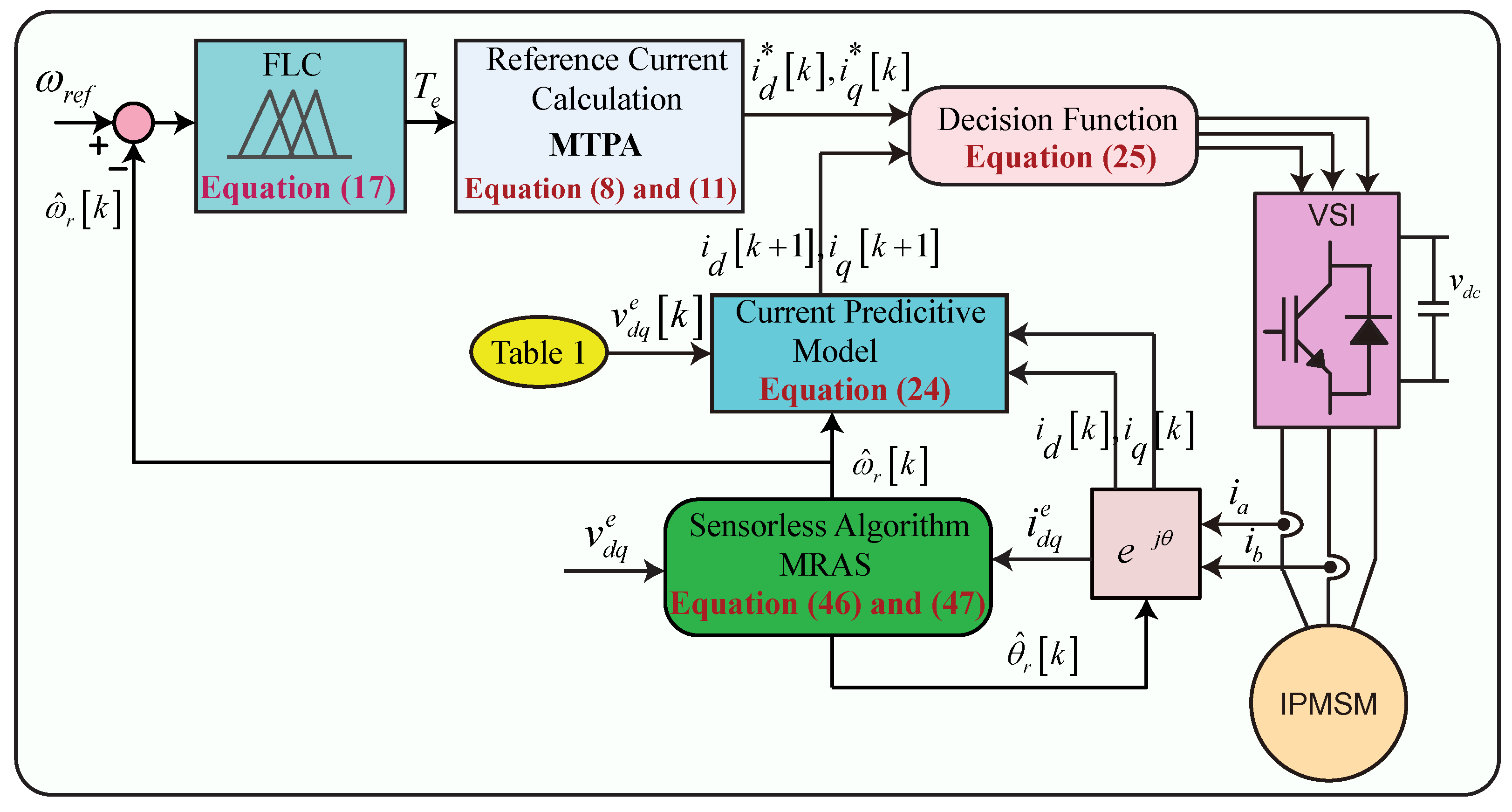

3.1. Nonlinear Cascaded Control Structure

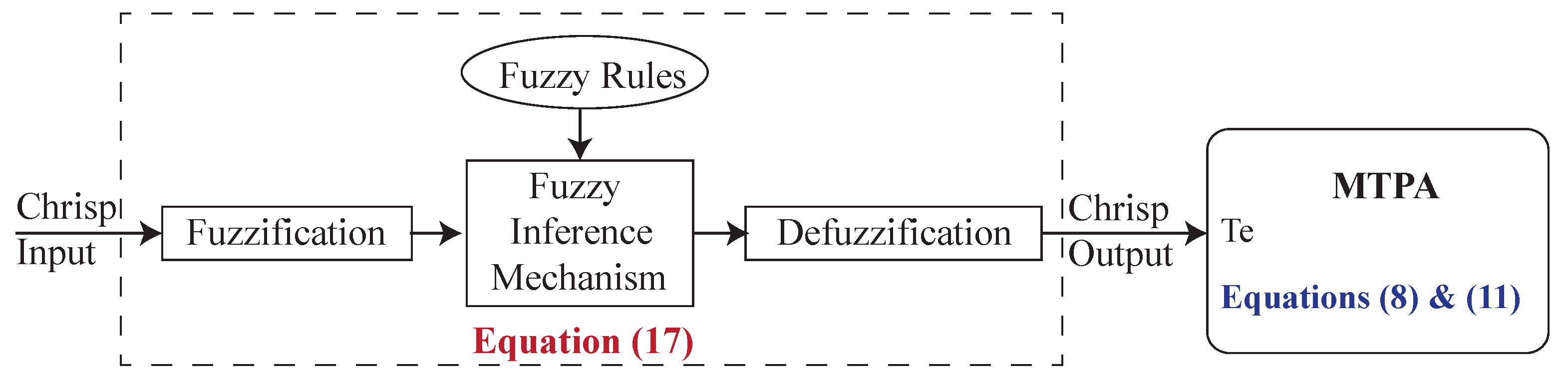

3.1.1. Intelligent Speed Control Loop

- a

- If and are NH, then the value across the output is NH.

- b

- If and are NH and PH, respectively, then the value across the output is ZE.

- c

- If and are PH and ZE, respectively, then the value across the output is PH.

- d

- If and are ZE and NH, respectively, then the value across the output is NH.

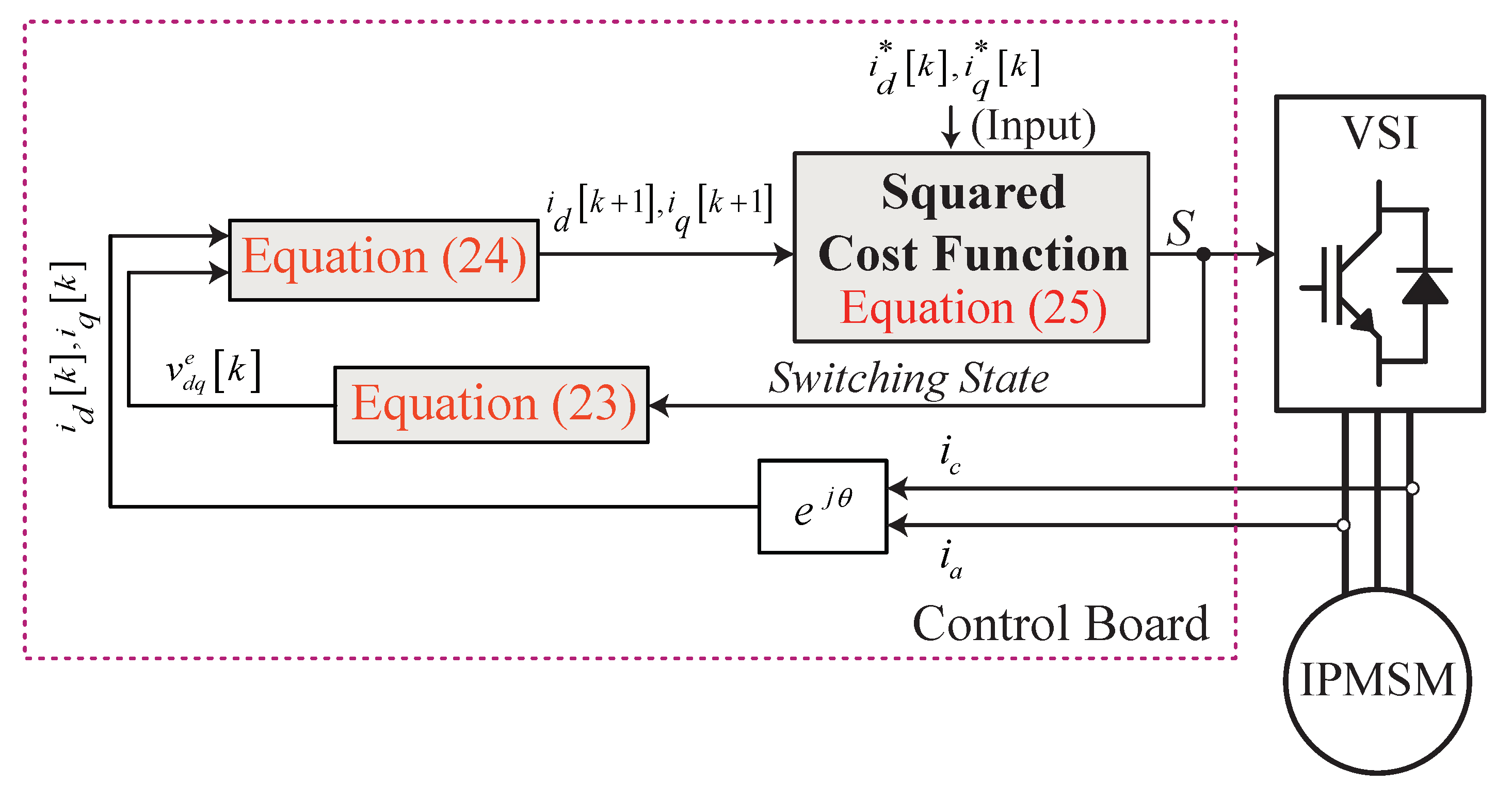

3.1.2. Finite Set Current Predictive Control of IPMSM

Convergence Analysis

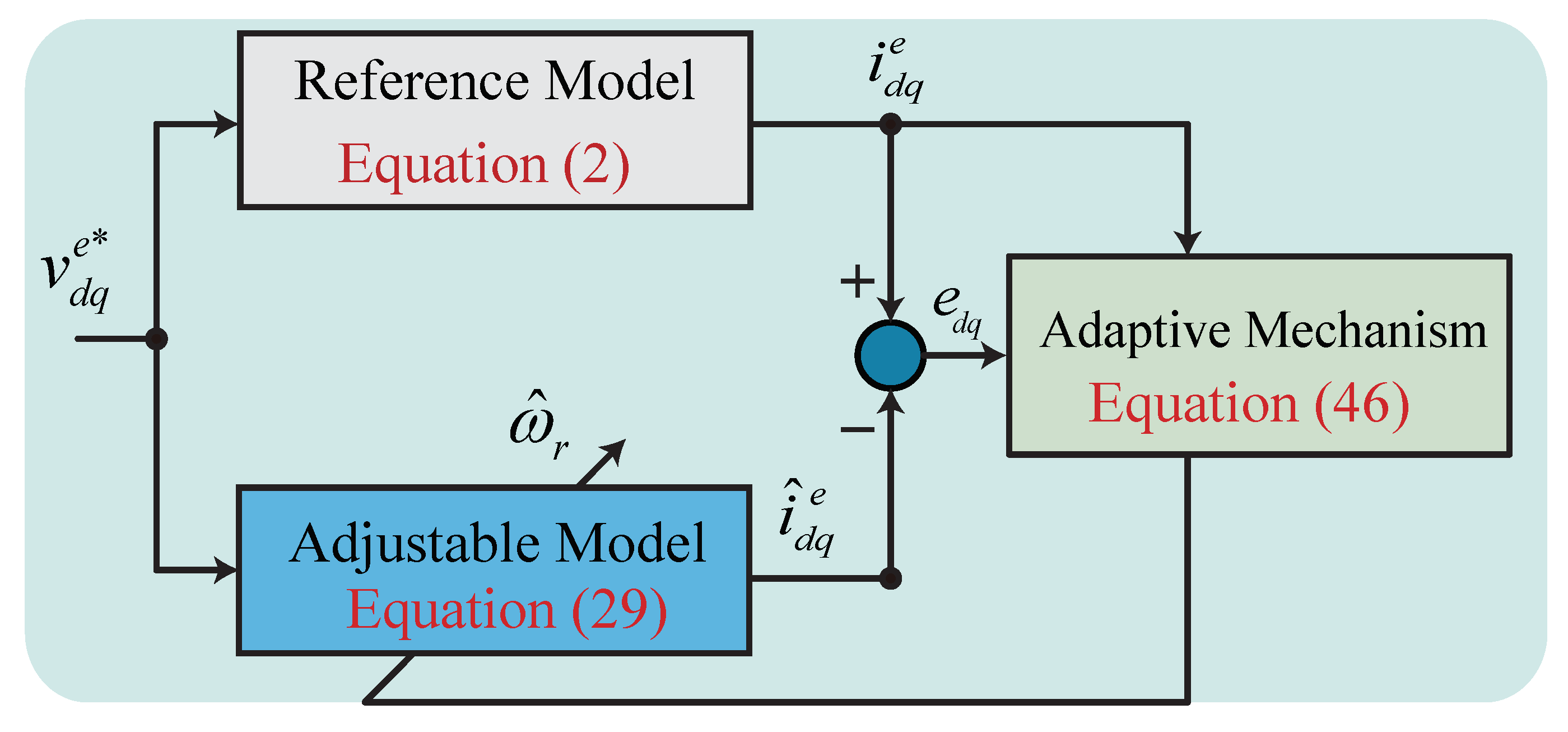

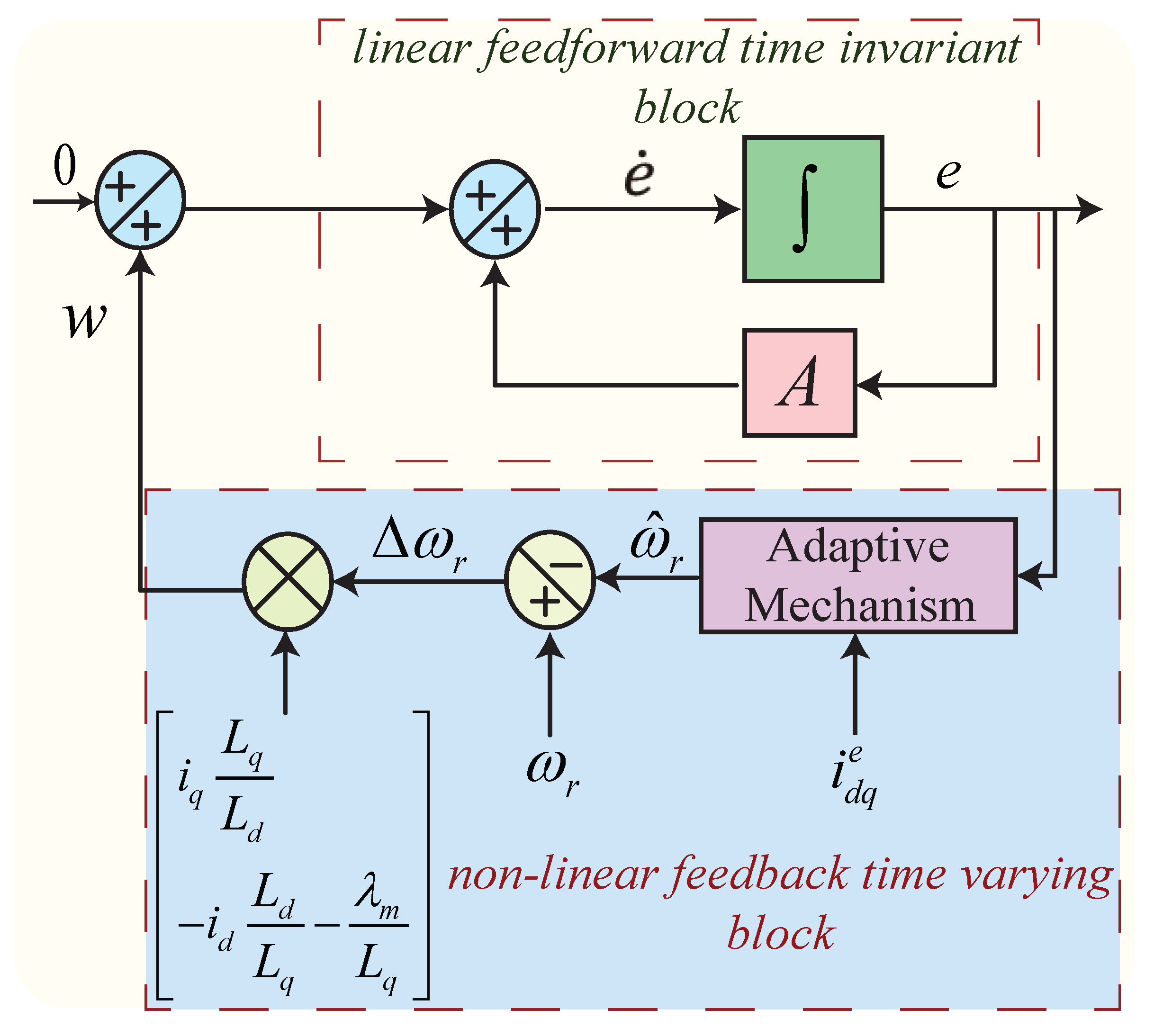

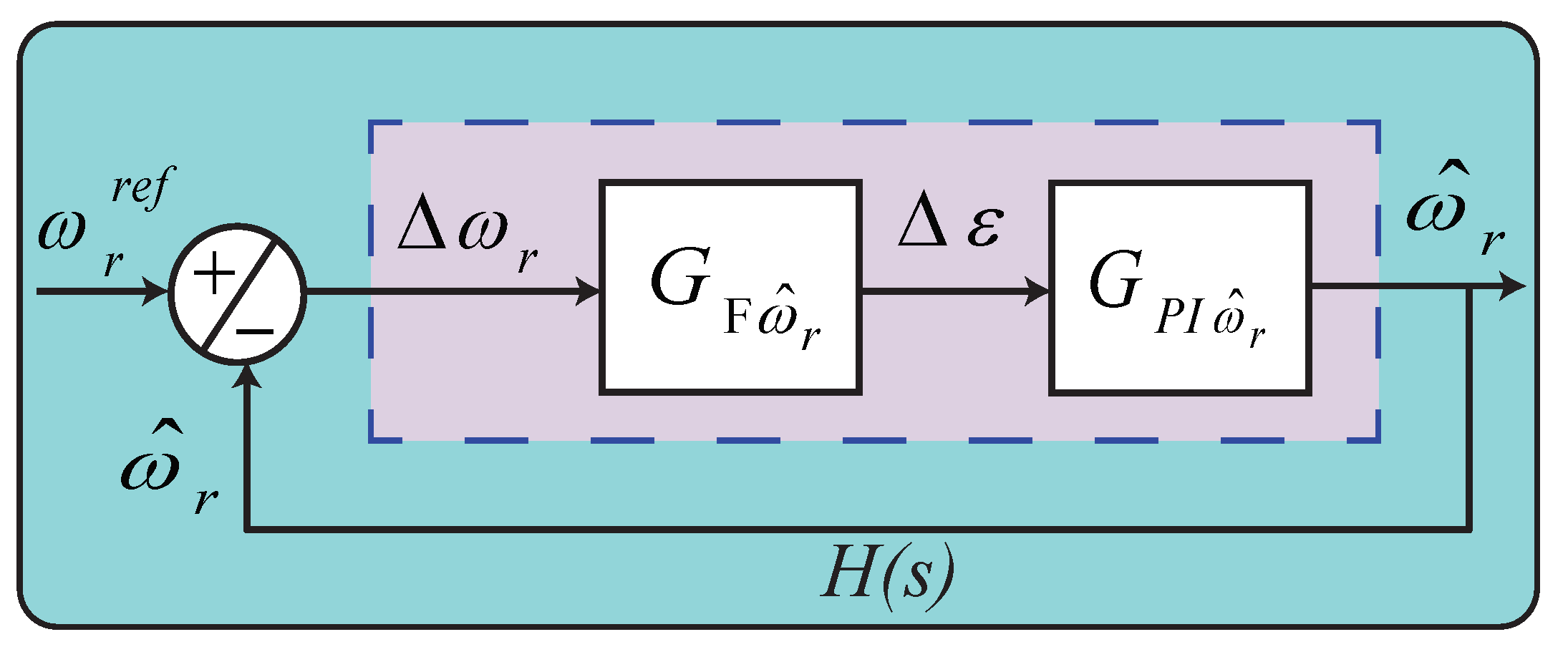

3.2. Self-Sensing Speed Mechanism

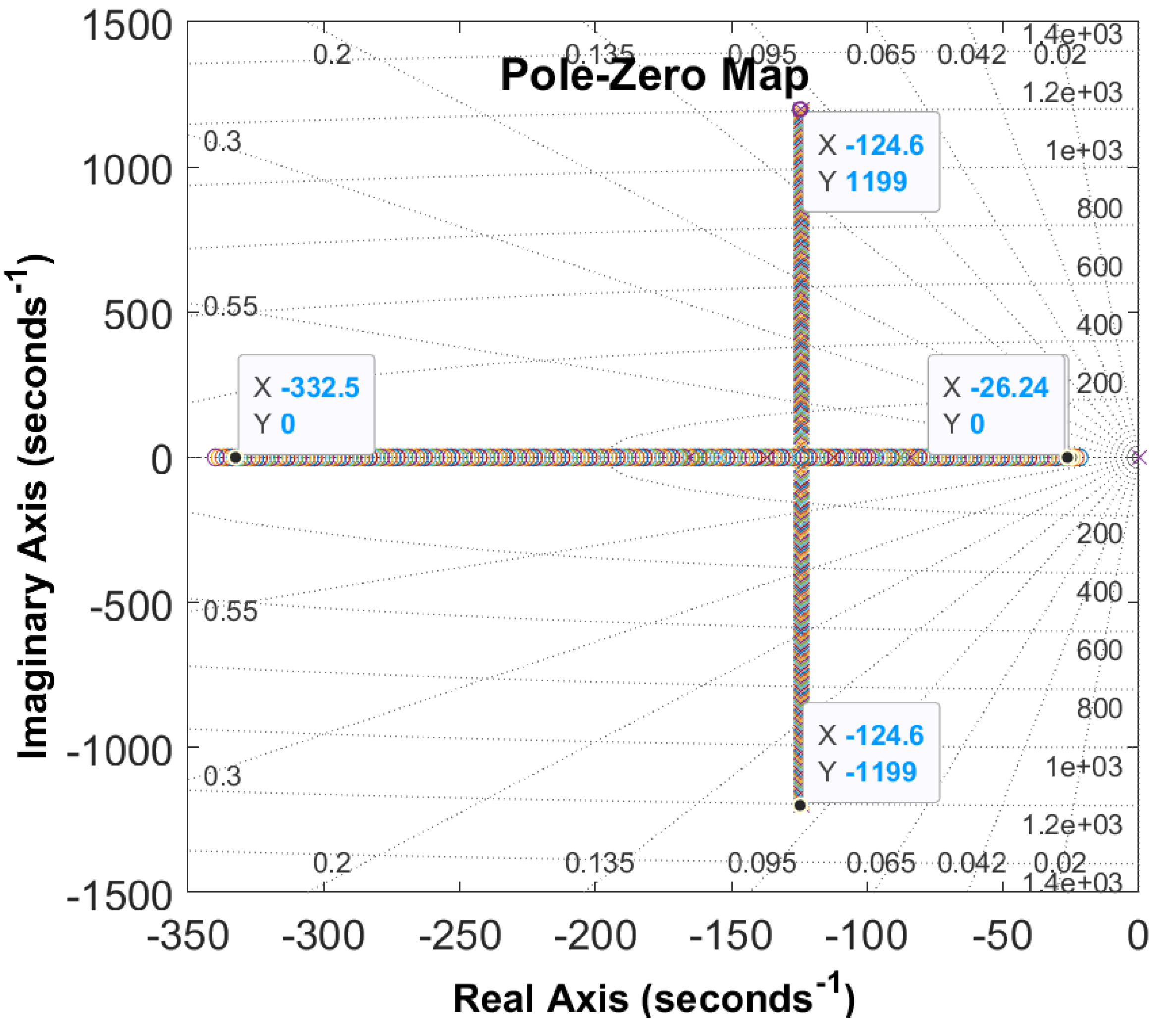

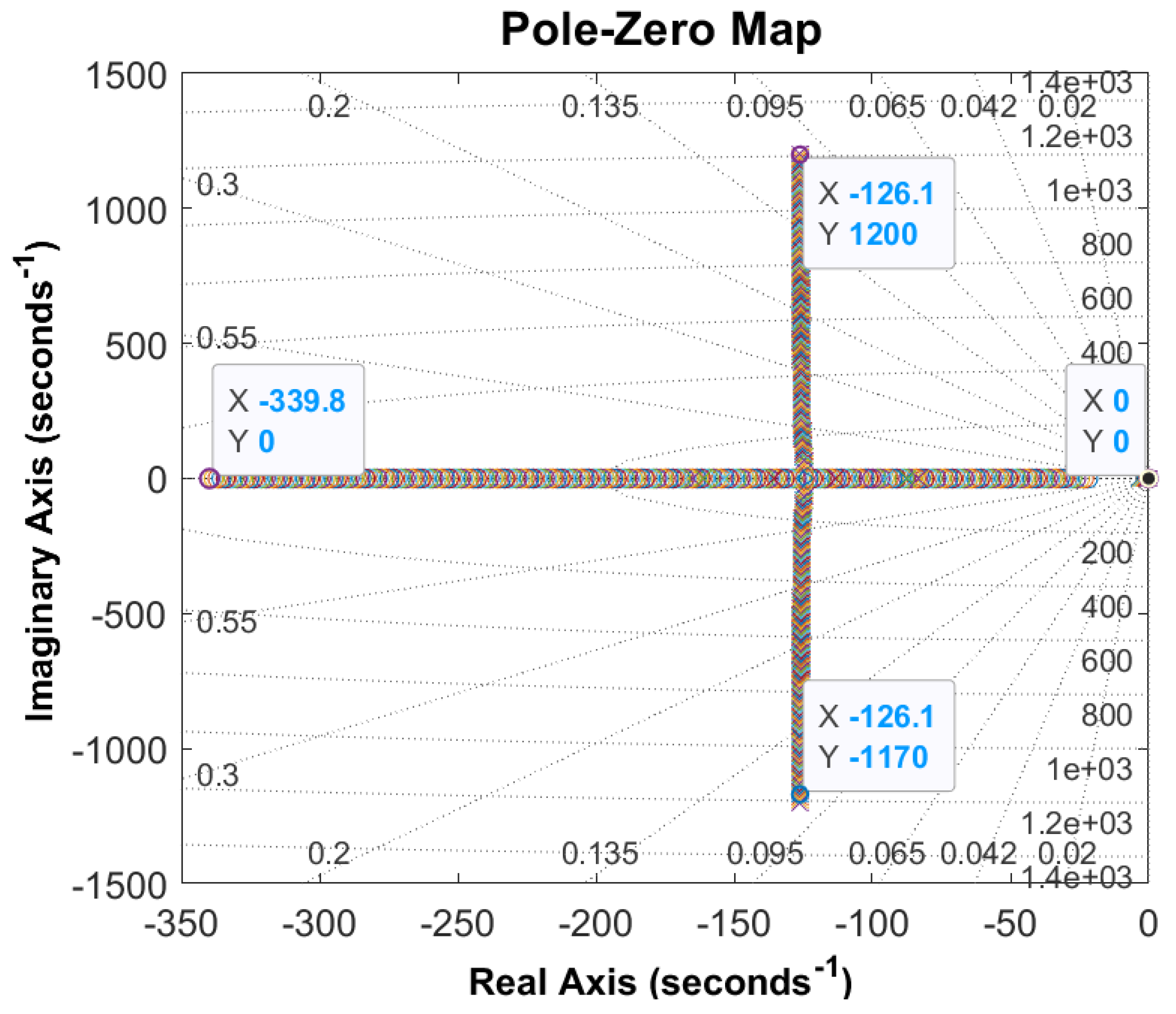

Stability Analysis

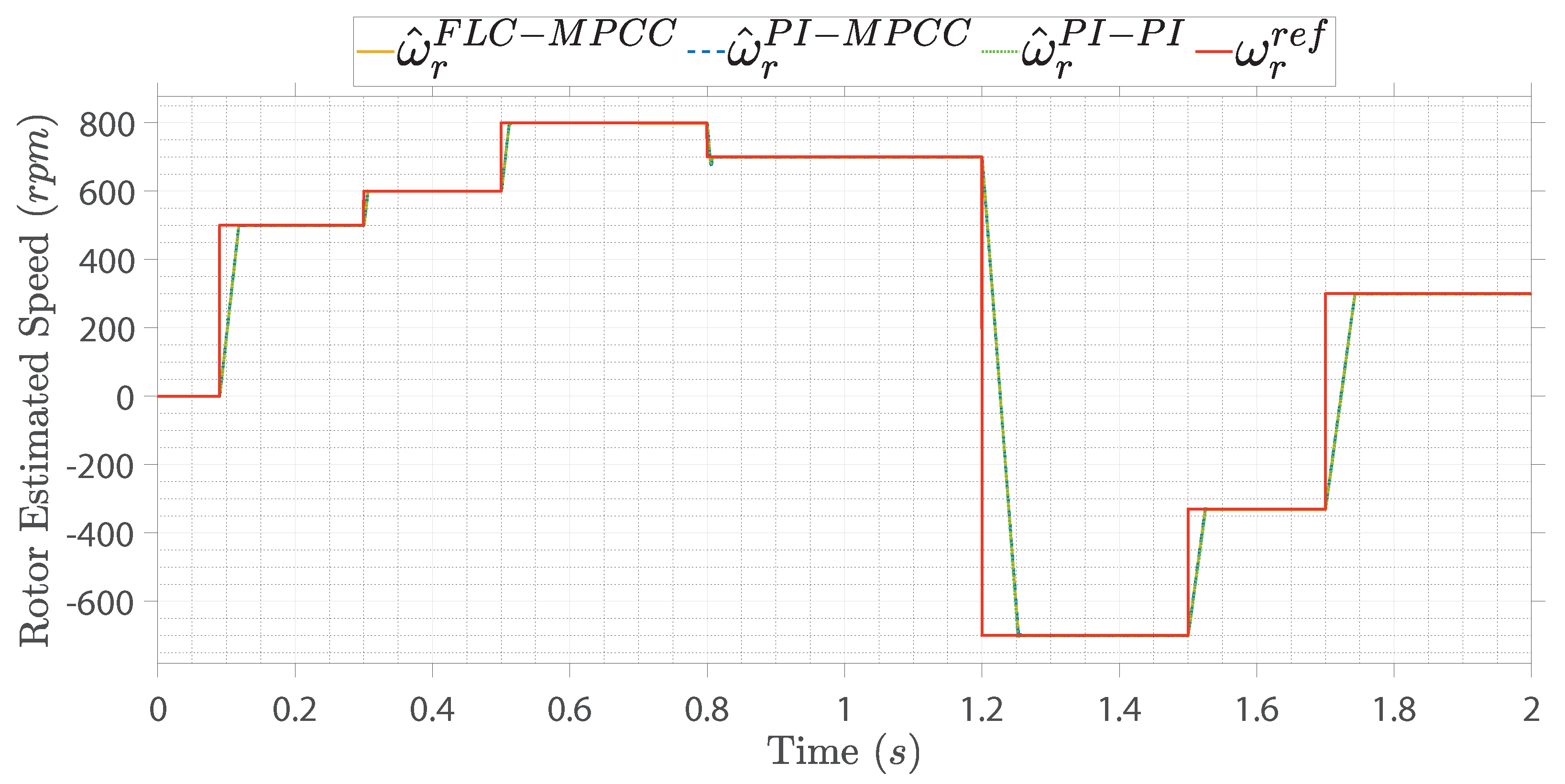

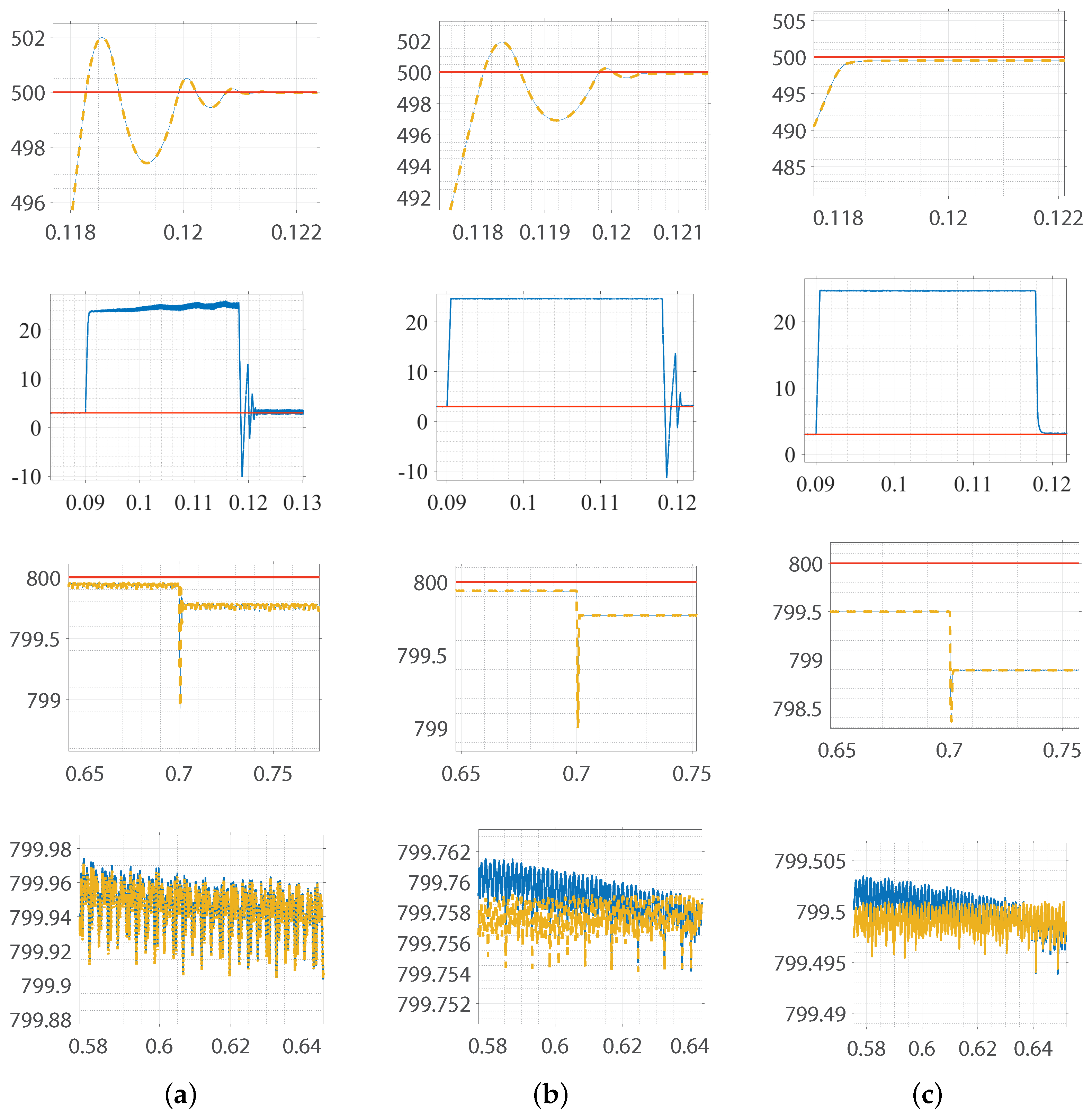

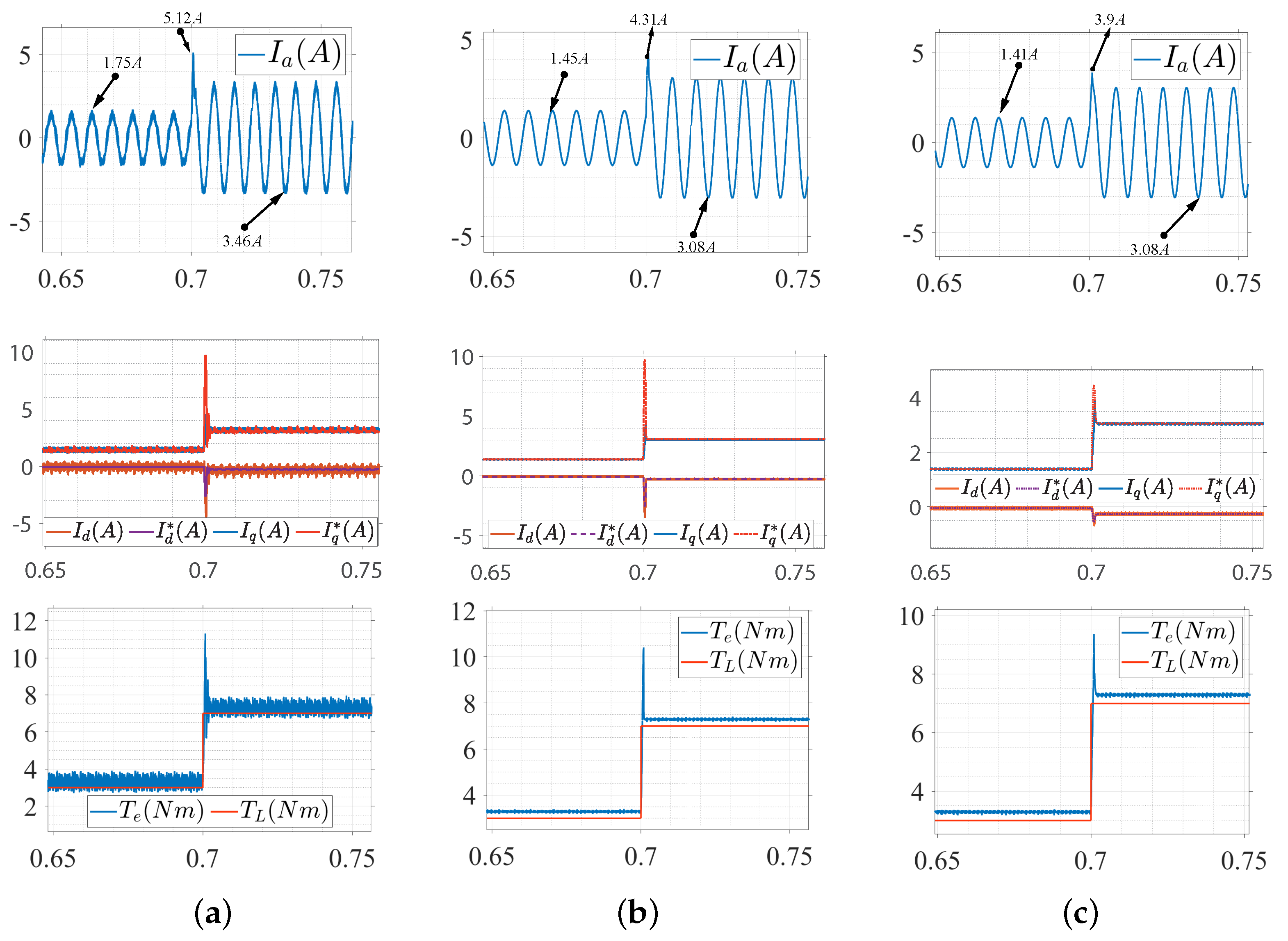

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Nam, K. Permanent Magnet AC Motors. In AC Motor Control and Electric Vehicle Applications; CRC Press: New York, NY, USA, 2010; Volume 1, pp. 133–158. [Google Scholar]

- Boldea, I. Control issues in adjustable speed drives. IEEE Ind. Electron. Mag. 2008, 2, 32–50. [Google Scholar] [CrossRef]

- Tursini, M.; Parasiliti, F.; Daqing, Z. Real-time gain tuning of PI controllers for high-performance PMSM drives. IEEE Trans. Ind. Appl. 2002, 38, 1018–1026. [Google Scholar] [CrossRef]

- Zhang, G.; Furusho, J. Speed control of two-inertia system by PI/PID control. In Proceedings of the IEEE International Conference on Power Electronics and Drive Systems, Hong Kong, China, 27–29 July 1999; Volume 1, pp. 567–572. [Google Scholar] [CrossRef]

- Yang, J.; Chen, W.; Li, S.; Guo, L.; Yan, Y. Disturbance/Uncertainty Estimation and Attenuation Techniques in PMSM Drives—A Survey. IEEE Trans. Ind. Electron. 2017, 64, 3273–3285. [Google Scholar] [CrossRef]

- Domínguez, J.R.; Navarrete, A.; Meza, M.A.; Loukianov, A.G.; Cañedo, J. Digital sliding-mode sensorless control for surface-mounted PMSM. IEEE Trans. Ind. Inform. 2014, 10, 137–151. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, L.; Zhao, K.; Sun, L. Nonlinear speed control for PMSM system using sliding-mode control and disturbance compensation techniques. IEEE Trans. Ind. Electron. 2013, 28, 1358–1365. [Google Scholar] [CrossRef]

- Underwood, S.J.; Husain, I. Online parameter estimation and adaptive control of permanent-magnet synchronous machines. IEEE Trans. Ind. Electron. 2010, 57, 2435–2443. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z. Adaptive speed control for permanent-magnet synchronous motor system with variations of load inertia. IEEE Trans. Ind. Electron. 2009, 56, 3050–3059. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M. Hybrid H∞-based wavelet-neural-network tracking control for permanent-magnet synchronous motor servo drives. IEEE Trans. Ind. Electron. 2010, 57, 3157–3166. [Google Scholar] [CrossRef]

- El-Sousy, F.F.M. Intelligent optimal recurrent wavelet elman neural network control system for permanent-magnet synchronous motor servo drive. IEEE Trans. Ind. Inform. 2013, 9, 1986–2003. [Google Scholar] [CrossRef]

- Camacho, E.F.; Bordons, C. Model Predictive Control; Springer: London, UK, 2007. [Google Scholar]

- Rawlings, J.B.; Mayne, D.Q. Model Predictive Control: Theory and Design; Nob Hill: Madison, WI, USA, 2009. [Google Scholar]

- Qin, S.J.; Badgwell, T.A. A survey of industrial model predictive control technology. Control Eng. Pract. 2003, 11, 733–764. [Google Scholar] [CrossRef]

- Cortes, P.; Kazmierkowski, M.P.; Kennel, R.M.; Quevedo, D.E.; Rodriguez, J. Predictive control in power electronics and drives. IEEE Trans. Ind. Electron. 2008, 55, 4312–4324. [Google Scholar] [CrossRef]

- Malesani, L.; Mattavelli, P.; Buso, S. Robust dead-beat current control for PWM rectifiers and active filters. IEEE Trans. Ind. Appl. 1999, 35, 613–620. [Google Scholar] [CrossRef]

- Usama, M.; Jaehong, K. Simplified model predicted current control method for speed control of non-silent permanent magnet synchronous motors. In Proceedings of the 2020 3rd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 29–30 January 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Fuentes, E.J.; Silva, C.A.; Yuz, J.I. Predictive speed control of a two-mass system driven by a permanent magnet synchronous motor. IEEE Trans. Ind. Electron. 2012, 59, 2840–2848. [Google Scholar] [CrossRef]

- Preindl, M.; Bolognani, S. Model predictive direct speed control with finite control set of PMSM drive systems. IEEE Trans. Ind. Electron. 2013, 28, 1007–1015. [Google Scholar] [CrossRef]

- Errouissi, R.; Ouhrouche, M.; Chen, W.; Trzynadlowski, A.M. Robust cascaded nonlinear predictive control of a permanent magnet synchronous motor with antiwindup compensator. IEEE Trans. Ind. Electron. 2012, 59, 3078–3088. [Google Scholar] [CrossRef]

- Lu, P. Optimal predictive control of continuous non-linear systems. Int. J. Control 1995, 62, 633–649. [Google Scholar] [CrossRef]

- Chen, W.-H.; Ballance, D.J.; Gawthrop, P.J. Optimal control of non-linear systems: A predictive control approach. Automatica 2003, 39, 633–641. [Google Scholar] [CrossRef]

- Chen, W.; Ballance, D.J.; Gawthrop, P.J.; Gribble, J.J.; O’Reilly, J. Non-linear PID predictive controller. Control Theory Appl. 1999, 146, 603–611. [Google Scholar] [CrossRef]

- Maiti, S.; Chakraborty, C.; Sengupta, S. Simulation studies on model reference adaptive controller based speed estimation technique for the vector controlled permanent magnet synchronous motor drive. Simul. Model. Pract. Theory 2009, 17, 585–596. [Google Scholar] [CrossRef]

- An, Q.; Sun, L. Online parameter identification for vector controlled PMSM drives using adaptive algorithm. In Proceedings of the IEEE Vehicle Power and Propulsion Conference, Harbin, China, 3–5 September 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Rashed, M.; MacConnell, P.F.A.; Stronach, A.F.; Acarnley, P. Sensorless indirect-rotor-field-orientation speed control of a permanent-magnet synchronous motor with stator-resistance estimation. IEEE Trans. Ind. Electron. 2007, 54, 1664–1675. [Google Scholar] [CrossRef]

- Usama, M.; Kim, J. Robust adaptive observer-based finite control set model predictive current control for sensorless speed control of surface permanent magnet synchronous motor. Trans. Inst. Meas. Control 2021. [Google Scholar] [CrossRef]

- Liang, Y.; Li, Y. Sensorless control of PM synchronous motors based on MRAS method and initial position estimation. In Proceedings of the Sixth International Conference on Electrical Machines and Systems, Beijing, China, 9–11 November 2003; Volume 1, pp. 96–99. [Google Scholar]

- Morimoto, S.; Sanada, M.; Takeda, Y. Wide-speed operation of interior permanent magnet synchronous motors with high-performance current regulator. IEEE Trans. Ind. Appl. 1994, 30, 920–926. [Google Scholar] [CrossRef]

- Sun, T.; Wang, J.; Chen, X. Maximum torque per ampere (MTPA) control for interior permanent magnet synchronous machine drives based on virtual signal injection. IEEE Trans. Power Electron. 2015, 30, 5036–5045. [Google Scholar] [CrossRef]

- Butt, C.B.; Hoque, M.A.; Rahman, M.A. Simplified fuzzy-logic-based MTPA speed control of IPMSM drive. IEEE Trans. Ind. Appl. 2004, 40, 1529–1535. [Google Scholar] [CrossRef]

- Rodriguez, J.; Pontt, J.; Silva, C.A.; Correa, P.; Lezana, P.; Cortes, P. Predictive current control of a voltage source inverter. IEEE Trans. Ind. Electron. 2007, 54, 495–503. [Google Scholar] [CrossRef]

- Hossain, M.J.; Hoque, M.A.; Islam, K.K. Simplified fuzzy control for flux-weakening speed control of IPMSM drive. Adv. Fuzzy Syst. 2011, 9. [Google Scholar] [CrossRef][Green Version]

- Emami, M.R.; Turksen, I.B.; Goldenberg, A.A. Development of a systematic methodology of fuzzy logic modeling. IEEE Trans. Fuzzy Syst. 1998, 6, 346–361. [Google Scholar] [CrossRef]

- Azam, M.H.; Hasan, M.H.; Hassan, S.; Abdulkadir, S.J. Fuzzy type-1 triangular membership function approximation using fuzzy C-means. In Proceedings of the 2020 International Conference on Computational Intelligence (ICCI), Bandar Seri Iskandar, Malaysia, 8–9 October 2020; pp. 115–120. [Google Scholar] [CrossRef]

- Uddin, N.N.; Rahman, M.A. High-speed control of IPMSM drives using improved fuzzy logic algorithms. IEEE Trans. Ind. Electron. 2007, 54, 190–199. [Google Scholar] [CrossRef]

- Usama, M.; Kim, J. Performance improvement speed control of IPMSM drive based on nonlinear current control. Turk. J. Electr. Eng. Comput. Sci. 2021, in press. [Google Scholar] [CrossRef]

- Astrom, K.; Wittenmark, B. Model Refernece Adaptive Systems in Adaptive Control; Dover Publications: Mineola, NY, USA, 2008; pp. 185–255. [Google Scholar]

- Khlaief, A.; Boussak, M.; Chaari, A. A MRAS-based stator resistance and speed estimation for sensorless vector controlled IPMSM drive. Electr. Power Syst. Res. 2014, 108, 1–15. [Google Scholar] [CrossRef]

- Landau, I. A hyperstability criterion for model reference adaptive control systems. IEEE Trans. Automat. Contr. 1969, 14, 552–555. [Google Scholar] [CrossRef]

| Parameters | Symbols | Values |

|---|---|---|

| Sampling Time | 1 μs | |

| DC-link | 500 V | |

| Stator resistance | 2.5 Ω | |

| Pole pairs | P | 3 |

| d-axis Inductance | 15.025 mH | |

| q-axis Inductance | 30.175 mH | |

| Moment of inertia | J | 0.00365 kgm2 |

| Flux | 0.5283 Wb | |

| Damping coefficient | B | 0.0011 Nm·s |

| Inverter on Legs | Voltage Vector | Switching States |

|---|---|---|

| = 0 | 0 0 0 | |

| = −− | 0 0 1 | |

| = −+ | 0 1 0 | |

| = − | 0 1 1 | |

| = | 1 0 0 | |

| = − | 1 0 1 | |

| = + | 1 1 0 | |

| = 0 | 1 1 1 |

| NH | NM | NL | ZE | PL | PM | PH | |

|---|---|---|---|---|---|---|---|

| NH | NH | NH | NH | NH | NM | NL | ZE |

| NM | NH | NH | NH | NM | NL | ZE | PL |

| NL | NH | NH | NM | NL | ZE | PL | PM |

| ZE | NH | NM | NL | ZE | PL | PM | PH |

| PL | NL | NL | ZE | PL | PM | PH | PH |

| PM | NL | ZE | PL | PM | PH | PH | PH |

| PH | ZE | PL | PM | PH | PH | PH | PH |

| Case | Representation | Details | Parameter Values |

|---|---|---|---|

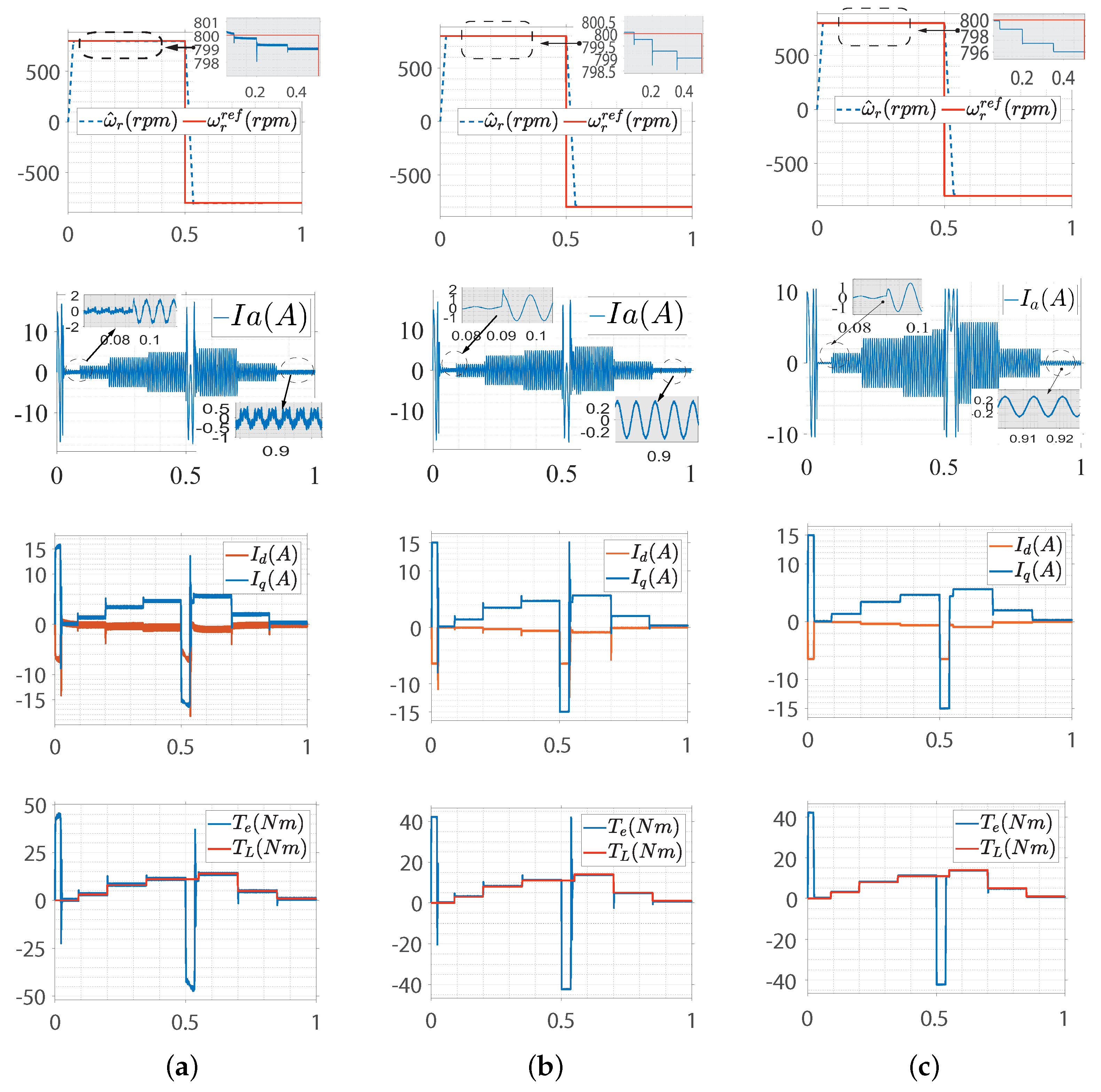

| 1 | Self-sensing speed convergence response with reference speed step variation | = [0, 500, 600, 800, 700, −700, −330, 300] rpm at [0 0.09, 0.3, 0.5, 0.8, 1.2, 1.5, 1.7] s → [3, 7] Nm at [0.7] s | Nominal |

| 2 | Self-sensing drive torque response with load step variation | = [0, 3, 8, 11, 14, 5, 1] Nm at [0, 0.09, 0.2, 0.35, 0.55, 0.7, 0.85] s = [800, −800] rpm at [0.5] s | Nominal |

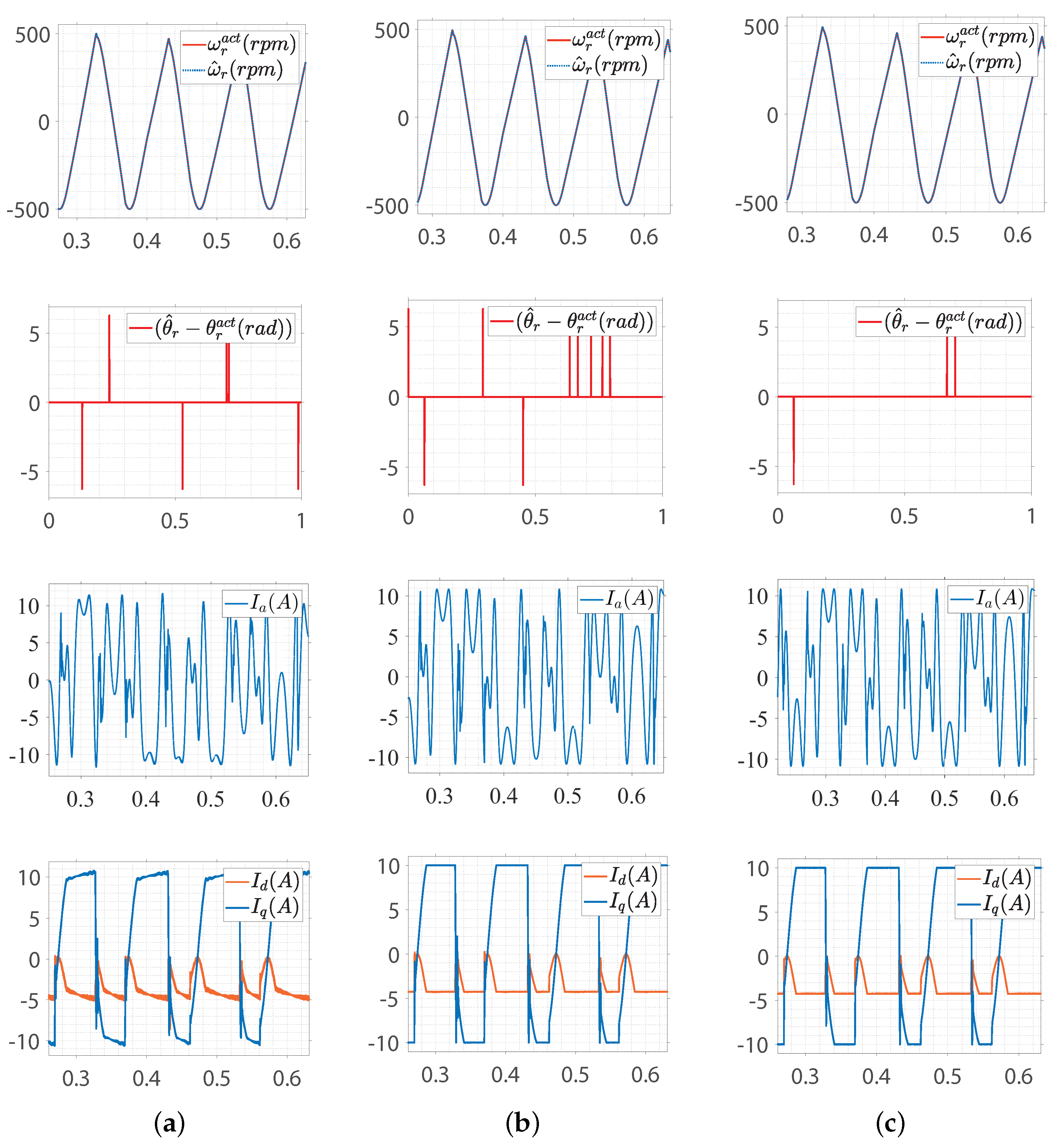

| 3 | Self-sensing sinusoidal speed convergence response | rpm | varied ↑ ↑ |

| Parameters | PI-PI | PI-MPCC | FLC-MPCC |

|---|---|---|---|

| Dynamics | Good | Good | Remarkable |

| Speed Steady-state Error | Minimum | Moderate | Moderate |

| Speed Ripples | Larger | Moderate | Small |

| Speed Overshoot(%) | 0.02 | 0.018 | 0.0 |

| Speed Settling time(s) | 0.1219 | 0.1205 | 0.118 |

| Torque Response | Slow | Medium | Fast |

| Torque Ripple | Larger | Moderate | Small |

| Switching Frequency | Fixed | Variable | Variable |

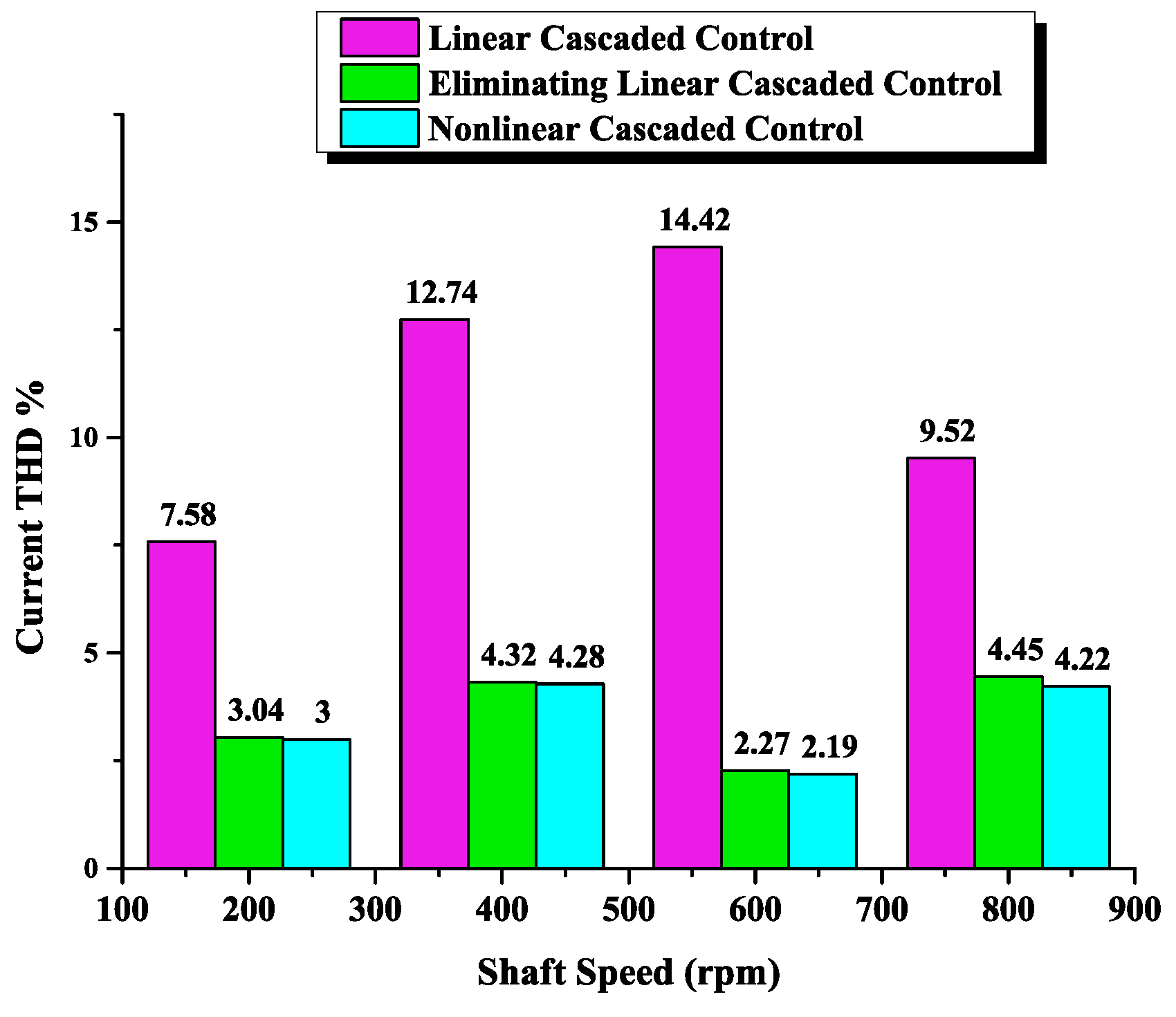

| Current Harmonics | Higher | Moderate | Lower |

| Control Efficiency | Average | Good | Remarkable |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Usama, M.; Kim, J. Improved Self-Sensing Speed Control of IPMSM Drive Based on Cascaded Nonlinear Control. Energies 2021, 14, 2205. https://doi.org/10.3390/en14082205

Usama M, Kim J. Improved Self-Sensing Speed Control of IPMSM Drive Based on Cascaded Nonlinear Control. Energies. 2021; 14(8):2205. https://doi.org/10.3390/en14082205

Chicago/Turabian StyleUsama, Muhammad, and Jaehong Kim. 2021. "Improved Self-Sensing Speed Control of IPMSM Drive Based on Cascaded Nonlinear Control" Energies 14, no. 8: 2205. https://doi.org/10.3390/en14082205

APA StyleUsama, M., & Kim, J. (2021). Improved Self-Sensing Speed Control of IPMSM Drive Based on Cascaded Nonlinear Control. Energies, 14(8), 2205. https://doi.org/10.3390/en14082205