A MCDM Methodology to Determine the Most Critical Variables in the Pressure Drop and Heat Transfer in Minichannels

Abstract

1. Introduction

2. Materials and Methods

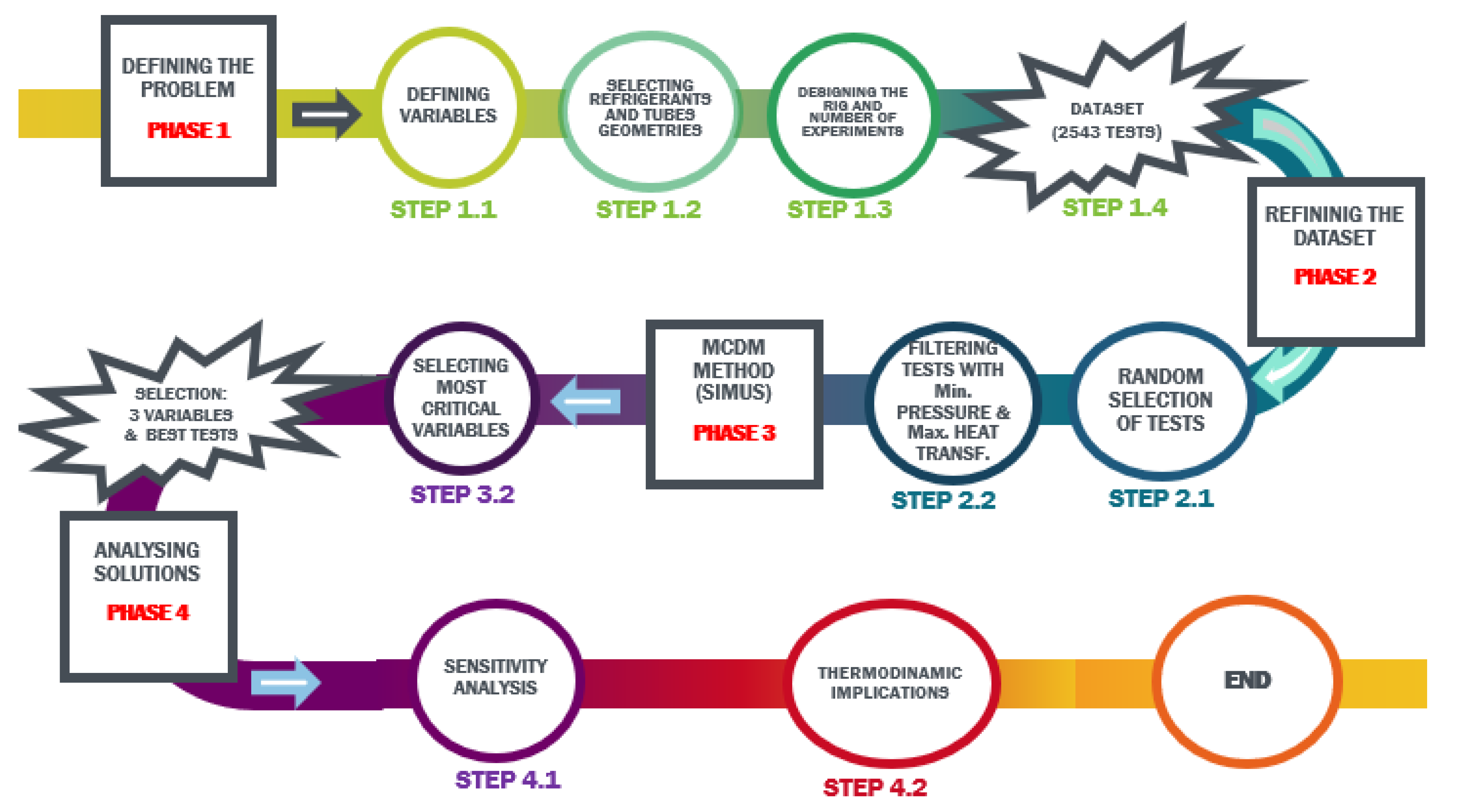

2.1. Methodology

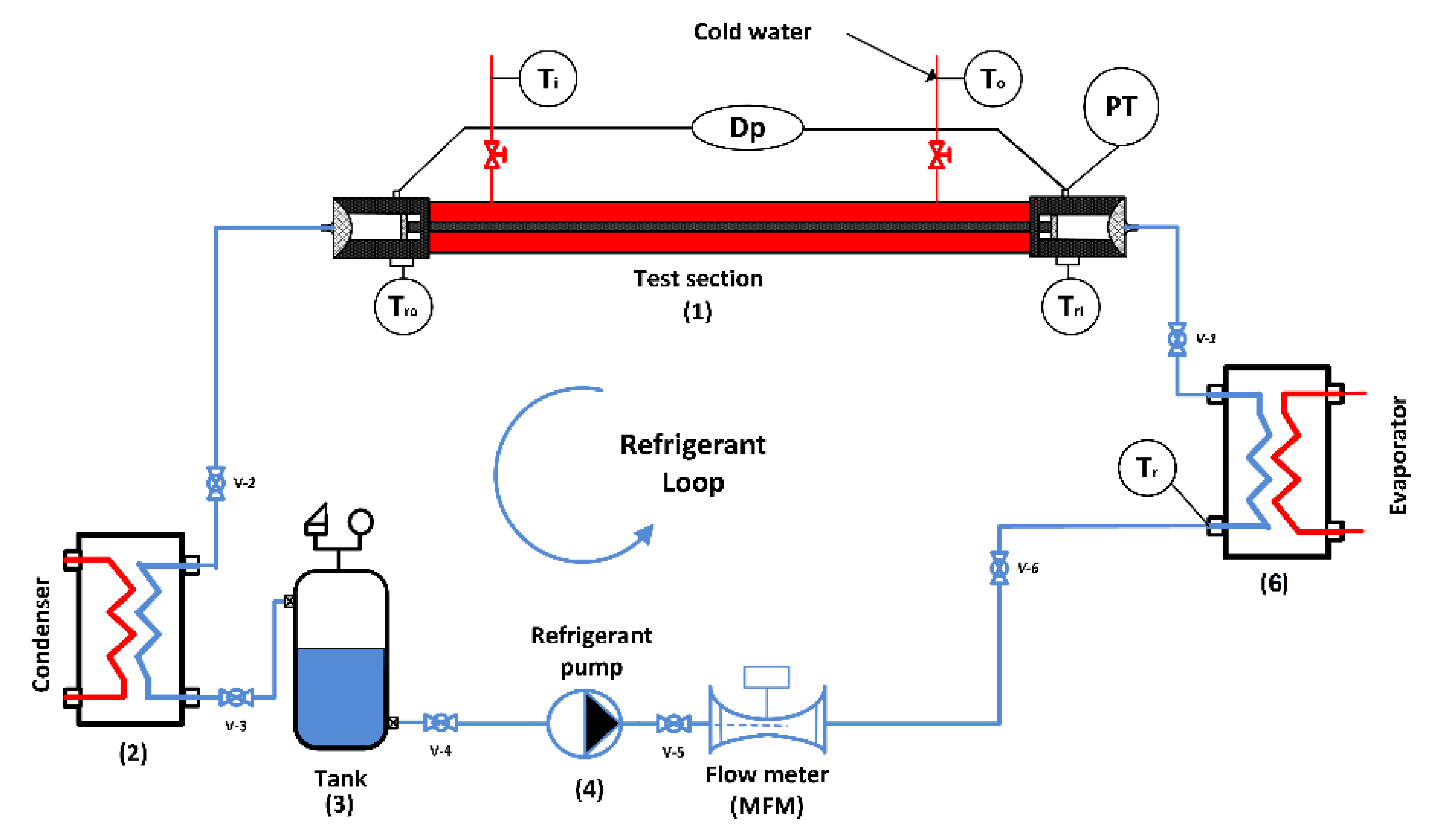

2.2. Description of the Lab Experiment

2.3. Input Variables

2.4. Data Collection

Refining Data Collection

2.5. SIMUS: A MCDM Method

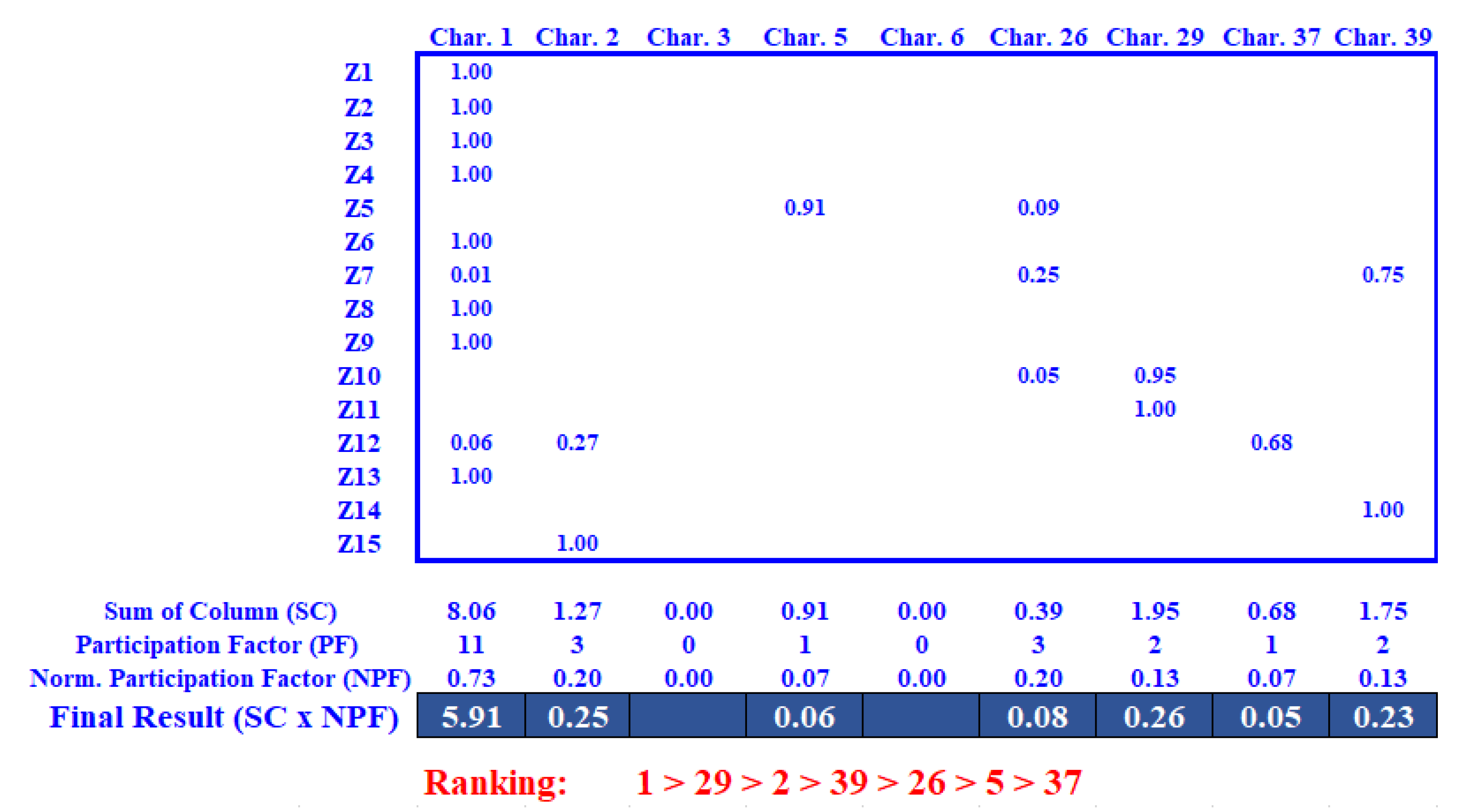

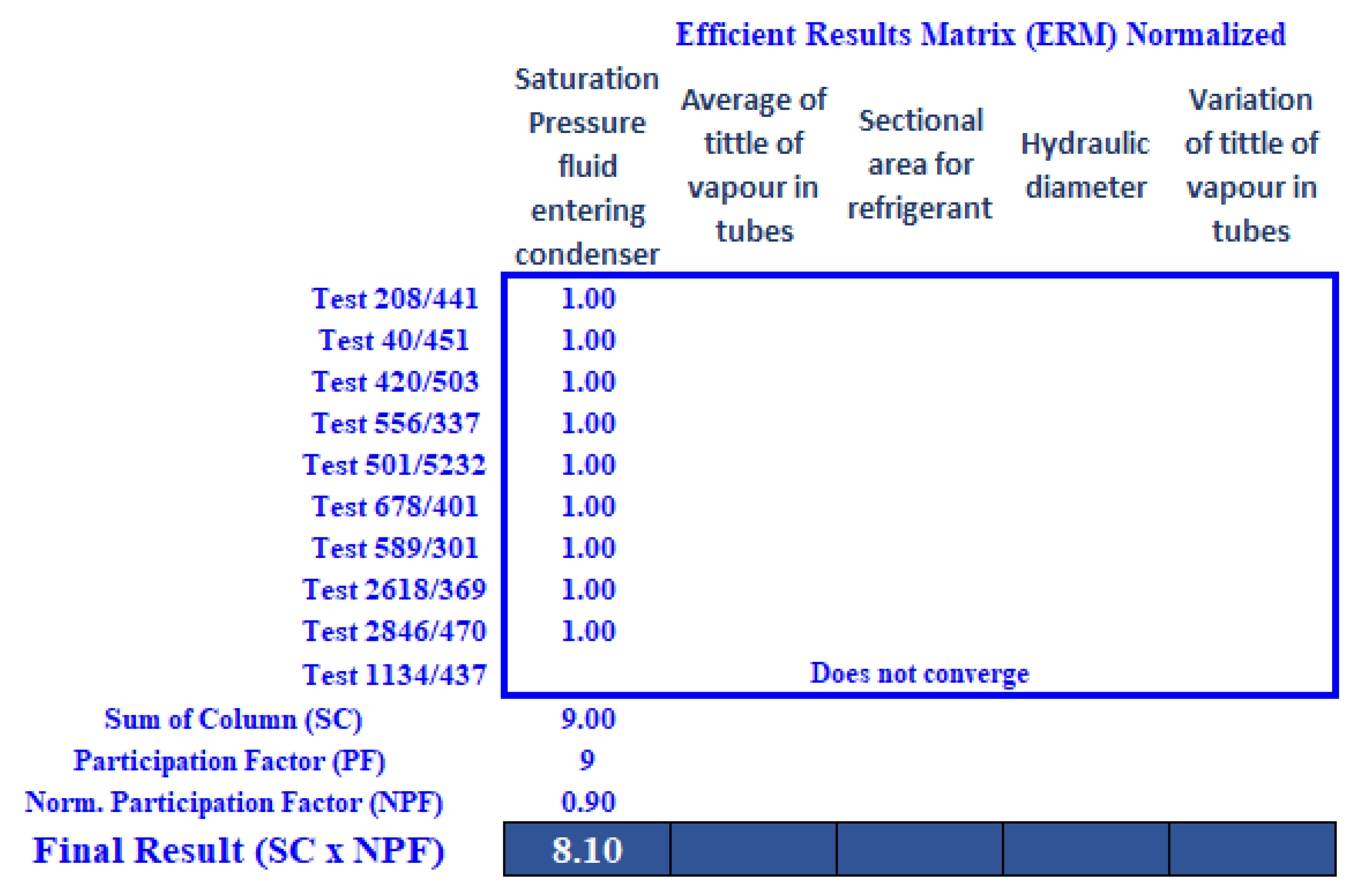

Application of SIMUS to the Dataset

3. Results

Sensitivity Analysis

4. Discussion

5. Conclusions

- The authors present a case in which MCDM methods are applied to a phase change thermofluid dynamic problem, obtaining similar results to the experimental tests and align with the physical theory of the problem.

- SIMUS can allow the user to obtain interesting conclusions, decreasing the effort needed to make experimental tests and even to optimize the experimental measuring campaign. This is possible because it allows users to identify the most influencing variables in the problem analyzed. In this case, the method offers interesting information regarding the optimal operating point in heat exchangers working with different refrigerant fluids. This optimal point involves the minimization of energy consumption and, therefore, the minimization of greenhouse gas emissions.

- Additionally, the SIMUS results match with other experimental studies about phase change, heat transfer and pressure drop problems. SIMUS points out the same influencing variables as in experimental studies dealing with frictional pressure drop and heat transfer coefficient estimation. This fact is very important since this technique allows us to reduce the number of thermofluid-dynamic variables that must be considered in predicting correlations and it can even improve existing predicting models discarding low influencing variables.

- The variable “saturation pressure of superheated vapour entering the condenser” is the variable with the highest influence out of the 37 variables analysed. This result is consistent with what is expected from a thermodynamic point of view because saturation pressure is the only one that simultaneously affects both pressure drop and heat transfer coefficient. Consequently, a good adjustment of the saturation pressure in phase change heat exchangers leads to a reduction in the pressure drop and to optimized heat transfer in both processes, evaporation and condensation.An important conclusion to be drawn from this numerical study is the low influence of the type of refrigerant used. Surely, this fact is due to the refrigerants used for these tests campaign and for the comparison between them, all of them are refrigerant proposed for the replacement of the currently used HFCs by other HFOs or Natural HC as propane. Therefore, it follows that these new refrigerants are valid for replacement, from a thermodynamic point of view.

- With the new refrigerants as R1234yf, R290, R32 and R410a, it is possible to optimize and even characterize their working in refrigeration equipment in the same way as it has been done up to now with current refrigerants as R134a. Furthermore, considering that these new refrigerants have much lower GWP and ODP values, their use will have benefits on this matter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings. Off. J. Eur. Union 2010. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2010:153:0013:0035:en:PDF (accessed on 7 April 2021).

- Laustsen, M.J. Energy Efficiency Requirements in Building Codes, Energy Efficiency Policies for New Buildings. IEA Information Paper; International Energy Agency: Paris, France, 2008. [Google Scholar]

- Hepbasli, A. LOW Exergy (LowEx) Heating and Cooling Systems for Sustainable Buildings and Societies. Renew. Sustain. Energy Rev. 2012, 16, 73–104. [Google Scholar] [CrossRef]

- Kharseh, M.; Altorkmany, L.; Al-Khawaj, M.; Hassani, F. Warming Impact on Energy Use of HVAC System in Buildings of Different Thermal Qualities and in Different Climates. Energy Convers. Manag. 2014, 81, 106–111. [Google Scholar] [CrossRef]

- Poggi, F.; Macchi-Tejeda, H.; Leducq, D.; Bontemps, A. Refrigerant Charge in Refrigerating Systems and Strategies of Charge Reduction. Int. J. Refrig. 2008, 31, 353–370. [Google Scholar] [CrossRef]

- Asadi, M.; Xie, G.; Sunden, B. A Review of Heat Transfer and Pressure Drop Characteristics of Single and Two-phase Microchannels. Int. J. Heat Mass Transf. 2014, 79, 34–53. [Google Scholar] [CrossRef]

- Dalkılıç, A.S.; Çebi, A.; Celen, A.; Awad, M.M.; Wongwises, S. Evaluation of the Performance of the Empirical Correlations Used to Predict R134a’s Boiling Frictional Pressure Drop Inside Smooth and Corrugated Tubes. Int. Commun. Heat Mass Transf. 2017, 81, 8–18. [Google Scholar] [CrossRef]

- Kaew-On, J.; Wongwises, S. New Proposed Two-phase Multiplier and Evaporation Heat Transfer Coefficient Correlations for R134a Flowing at Low Mass Flux in a Multiport Minichannel. Int. Commun. Heat Mass Transf. 2012, 39, 853–860. [Google Scholar] [CrossRef]

- Wang, G.; Cheng, P. An Experimental Study of Flow Boiling Instability in a Single Microchannel. Int. Commun. Heat Mass Transf. 2008, 35, 1229–1234. [Google Scholar] [CrossRef]

- Li, S.; Zhao, Z.; Zhang, Y.; Xu, H.; Zeng, W. Experimental and Numerical Analysis of Condensation Heat Transfer and Pressure Drop of Refrigerant R22 in Minichannels of a Printed Circuit Heat Exchanger. Energies 2020, 13, 6589. [Google Scholar] [CrossRef]

- Piasecka, M.; Maciejewska, B.; Łabędzki, P. Heat Transfer Coefficient Determination during FC-72 Flow in a Minichannel Heat Sink Using the Trefftz Functions and ADINA Software. Energies 2020, 13, 6647. [Google Scholar] [CrossRef]

- Grabowski, M.; Hożejowska, S.; Maciejewska, B.; Płaczkowski, K.; Poniewski, M.E. Application of the 2-D Trefftz Method for Identification of Flow Boiling Heat Transfer Coefficient in a Rectangular MiniChannel. Energies 2020, 13, 3973. [Google Scholar] [CrossRef]

- Kandlikar, S.G.; Grande, W.J. Evolution of Microchannel Flow Passages-thermohydraulic Performance and Fabrication Technology. Heat Transf. Eng. 2003, 24, 3–17. [Google Scholar] [CrossRef]

- Fernando, P.; Palm, B.; Lundqvist, P.; Granryd, E. Propane Heat Pump with Low Refrigerant Charge: Design and Laboratory tests. Int. J. Refrig. 2004, 27, 761–773. [Google Scholar] [CrossRef]

- The Science of Climate Change: Summary for Policymakers. In Climate Change 1995, Technical Summary of the Working Group I Report; Cambridge University Press: Cambridge, UK, 1995; p. 22.

- Hu, J.; Wan, D.; Li, C.; Zhang, J.; Yi, X. Forecast of Consumption and Emission of HFC-134a Used in the Mobile Air-conditioner Sector in China. Adv. Clim. Chang. Res. 2010, 1, 20–26. [Google Scholar] [CrossRef]

- Munier, N. A Strategy for Using Multicriteria Analysis in Decision Making: A Guide for Simple and Complex Environmental Projects; Springer: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- López-Belchí, A.; Illán-Gómez, F.; Cano-Izquierdo, J.M.; García-Cascales, J.R. GMDH ANN to Optimise Model Development: Prediction of the Pressure Drop and the Heat Transfer Coefficient during Condensation within Mini-channels. Appl. Therm. Eng. 2018, 144, 321–330. [Google Scholar] [CrossRef]

- García-Cascales, J.R.; Vera-García, F.; Corberán-Salvador, J.M.; Gonzálvez-Maciá, J.; Fuentes-Díaz, D. Assessment of Boiling Heat Transfer Correlations in the Modelling of Fin and Tube Heat Exchangers. Int. J. Refrig. 2007, 30, 1004–1017. [Google Scholar] [CrossRef]

- López-Belchí, A.; Illán-Gómez, F.; García-Cascales, J.R.; Vera-García, F. Heat Transfer Coefficient during Condensation Inside a Minichannel Multiport Tube with R32 and R410A as Working Fluids. Sci. Technol. Built Environ. 2015, 21, 535–544. [Google Scholar] [CrossRef]

- López-Belchí, A.; Illán-Gómez, F.; Vera-García, F.; García-Cascales, J.R. Experimental Condensing Two-phase Frictional Pressure Drop Inside Mini-channels. Comparisons and New Model Development. Int. J. Heat Mass Transf. 2014, 75, 581–591. [Google Scholar] [CrossRef]

- Ramírez-Rivera, F.; López-Belchí, A.; Vera-García, F.; García-Cascales, J.R.; Illán-Gómez, F. Two Phase Flow Pressure Drop in Multiport Mini-channel Tubes Using R134a and R32 as Working Fluids. Int. J. Therm. Sci. 2015, 92, 17–33. [Google Scholar] [CrossRef]

- López-Belchí, A.; Illán-Gómez, F.; García-Cascales, J.R.; Vera-García, F. R32 and R410A Condensation Heat Transfer Coefficient and Pressure Drop within Minichannel Multiport Tube. Experimental Technique and Measurements. Ap. Therm. Eng. 2016, 105, 118–131. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018. [Google Scholar]

- Munier, N.; Hontoria, E.; Jiménez-Sáez, F. Strategic Approach in Multi-Criteria Decision Making: A Practical Guide for Complex Scenarios; Springer International Publishing: Chem, Switzerland, 2019. [Google Scholar] [CrossRef]

- Stoilova, S.; Munier, N.; Kendra, M.; Skrúcaný, T. Multi-criteria Evaluation of Railway Network Performance in Countries of the TEN-T Orient-east Med Corridor. Sustainability 2020, 12, 1482. [Google Scholar] [CrossRef]

- Garcia-Cascales, M.S.; Molina-Garcia, A.; Sanchez-Lozano, J.M.; Rubio-Aliaga, A.; Munier, N. Assessment of Groundwater Pumping Alternatives for Irrigation Purposes based on the SIMUS Method. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe, EEEIC / I and CPS Europe, Madrid, Spain, 9–12 June 2020. [Google Scholar]

- Munier, N. Methodology to Select a Set of Urban Sustainability Indicators to Measure the State of the City, and Performance Assessment. Ecol. Indic. 2011, 11, 1020–1026. [Google Scholar] [CrossRef]

- Friedel, L. Improved Friction Pressure Drop Correlation for Horizontal and Vertical Two- phase Pipe Flow. Proc. Eur. Two-Phase Flow Group Meet. 1979, E2. [Google Scholar]

| Characteristics | R134a | R1234yf | R290 | R32 | R410A |

|---|---|---|---|---|---|

| Type | HFC | HFO | Natural | HFC | HFC |

| Composition | Pure | Pure | Pure | Pure | R32/R125 |

| ODP | 0 | 0 | 0 | 0 | 0 |

| GWP | 1430 | 4 | 3 | 675 | 2088 |

| ASHRAE Safety Class | A1 | A2 | A3 | A2 | A1 |

| Critical Temperature (°C) | 101 | 95 | 97 | 78 | 71 |

| Critical Pressure (bar) | 41 | 34 | 43 | 58 | 49 |

| Device | Type | Measuring Range | Accuracy |

|---|---|---|---|

| Absolute pressure transmitter | Piezoelectric | 1–4000 kPa | 0.04% |

| Differential pressure transmitter | Piezoelectric | 1–100 kPa | 0.065% |

| Resistive temperature detector | 1/10 DIN | −50 to 350 °C | 0.03 ± 5 × 10−4 T (°C) |

| Thermocouple | T Class 1 | −30 to 125 °C | ±0.5 (°C) |

| Mass flow meter | Coriolis | 0–0.03 kg/s | 0.05% |

| Tube Geometry | Flow Area (mm2) | Outer Perimeter (mm) | Inner Perimeter (mm) | Ports | Dh (mm) | Ra (μm) | Relative Roughness (-) |

|---|---|---|---|---|---|---|---|

| Triangular | 10.16 | 40.17 | 57.04 | 17 | 0.71 | 0.262 | 7.35 × 10−4 |

| Square | 12.54 | 40.17 | 43.22 | 10 | 1.16 | 0.226 | 3.89 × 10−4 |

| Characteristic ID | Name | Unit |

|---|---|---|

| 1 | Saturation pressure entering the tube | Pa |

| 2 | Pressure drop due to friction with the tube | Pa/m |

| 3 | Flow mass | kg/s |

| 4 | Section area for refrigerant | m2 |

| 5 | Flow speed | kg/m2s |

| 6 | Hydraulic diameter | m |

| 7 | Tube roughness | |

| 8 | Tube geometry | |

| 9 | Refrigerant type | |

| 10 | Title of vapor measured in tube | |

| 11 | Dynamic viscosity liquid phase | Pa-s |

| 12 | Dynamic viscosity vapor phase | Pa-s |

| 13 | Average density liquid phase | kg/m3 |

| 14 | Average density vapor phase | kg/m3 |

| 15 | Title of vapor at entrance | |

| 16 | Title of vapor at exit | |

| 17 | Dynamic viscosity of liquid phase at entrance | Pa-s |

| 18 | Dynamic viscosity of liquid phase at exit | Pa-s |

| 19 | Dynamic viscosity of vapor phase at entrance | Pa-s |

| 20 | Dynamic viscosity of liquid phase at exit | Pa-s |

| 21 | Density of liquid phase at entrance | kg/m3 |

| 22 | Density of liquid phase at exist | kg/m3 |

| 23 | Density of vapor phase at entrance | kg/m3 |

| 24 | Density of liquid phase at exit | kg/m3 |

| Characteristic ID | Name | Unit |

|---|---|---|

| 25 | Average saturation pressure in tune | Pa |

| 26 | Mass flow | kg/s |

| 27 | Section area for refrigerant | m2 |

| 28 | Flow speed | kg/s |

| 29 | Hydraulic diameter. | M |

| 30 | Average title of vapor in tube | |

| 31 | Tube roughness | |

| 32 | Tube geometry | |

| 33 | Refrigerant type | |

| 34 | Average viscosity of liquid phase | Pa-s |

| 35 | Average saturation pressure in tube | Pa |

| 36 | Average density of liquid phase | kg/m3 |

| 37 | Average density of vapor phase | kg/m3 |

| 38 | Heat transfer coefficient | W/m2 |

| 39 | Title variation of vapor in tube |

| Variable Name | |||||||

|---|---|---|---|---|---|---|---|

| Test Number | Saturation Pressure | Pressure Drop | Mass Flow | Tube Section | Flow Velocity | Hydraulic Diameter | Tube Roughness |

| 647 | 1.02E + 06 | 4.68E + 04 | 5.93E − 03 | 1.25E − 05 | 4.73E + 02 | 1.16E − 03 | 3.89E − 04 |

| 1167 | 1.15E + 06 | 2.61E + 04 | 3.60E − 03 | 1.02E − 05 | 3.54E + 02 | 7.15E − 04 | 7.33E − 04 |

| 40 | 2.14E + 06 | 3.06E + 04 | 1.04E − 02 | 1.25E − 05 | 8.27E + 02 | 1.16E − 03 | 3.89E − 04 |

| Variable | Name |

|---|---|

| 1 | Saturation pressure entering the tube |

| 29 | Hydraulic diameter |

| 2 | Pressure drop due to friction in the tube |

| 39 | Title variation of vapor in tube |

| 26 | Mass flow |

| 5 | Hydraulic diameter |

| 37 | Average density of vapor phase |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hontoria, E.; López-Belchí, A.; Munier, N.; Vera-García, F. A MCDM Methodology to Determine the Most Critical Variables in the Pressure Drop and Heat Transfer in Minichannels. Energies 2021, 14, 2069. https://doi.org/10.3390/en14082069

Hontoria E, López-Belchí A, Munier N, Vera-García F. A MCDM Methodology to Determine the Most Critical Variables in the Pressure Drop and Heat Transfer in Minichannels. Energies. 2021; 14(8):2069. https://doi.org/10.3390/en14082069

Chicago/Turabian StyleHontoria, Eloy, Alejandro López-Belchí, Nolberto Munier, and Francisco Vera-García. 2021. "A MCDM Methodology to Determine the Most Critical Variables in the Pressure Drop and Heat Transfer in Minichannels" Energies 14, no. 8: 2069. https://doi.org/10.3390/en14082069

APA StyleHontoria, E., López-Belchí, A., Munier, N., & Vera-García, F. (2021). A MCDM Methodology to Determine the Most Critical Variables in the Pressure Drop and Heat Transfer in Minichannels. Energies, 14(8), 2069. https://doi.org/10.3390/en14082069