Effect of Permeability on Hydrate-Bearing Sediment Productivity and Stability in Ulleung Basin, East Sea, South Korea

Abstract

:1. Introduction

2. Site of Interest

2.1. Gas Hydrates in Ulleung Basin

2.2. UBGH2-6

3. Experimental Tests for Permeability Measurement

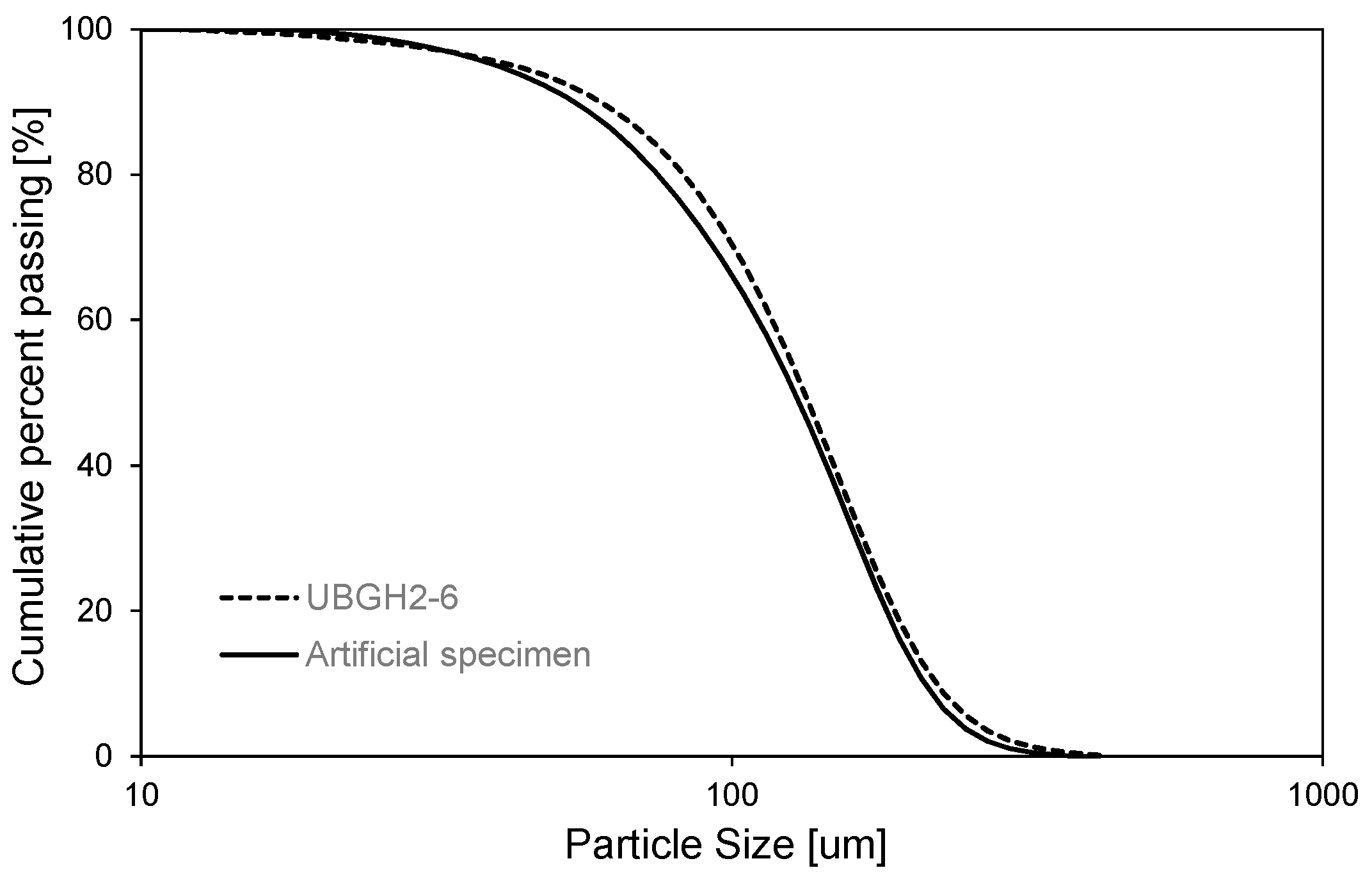

3.1. Soil

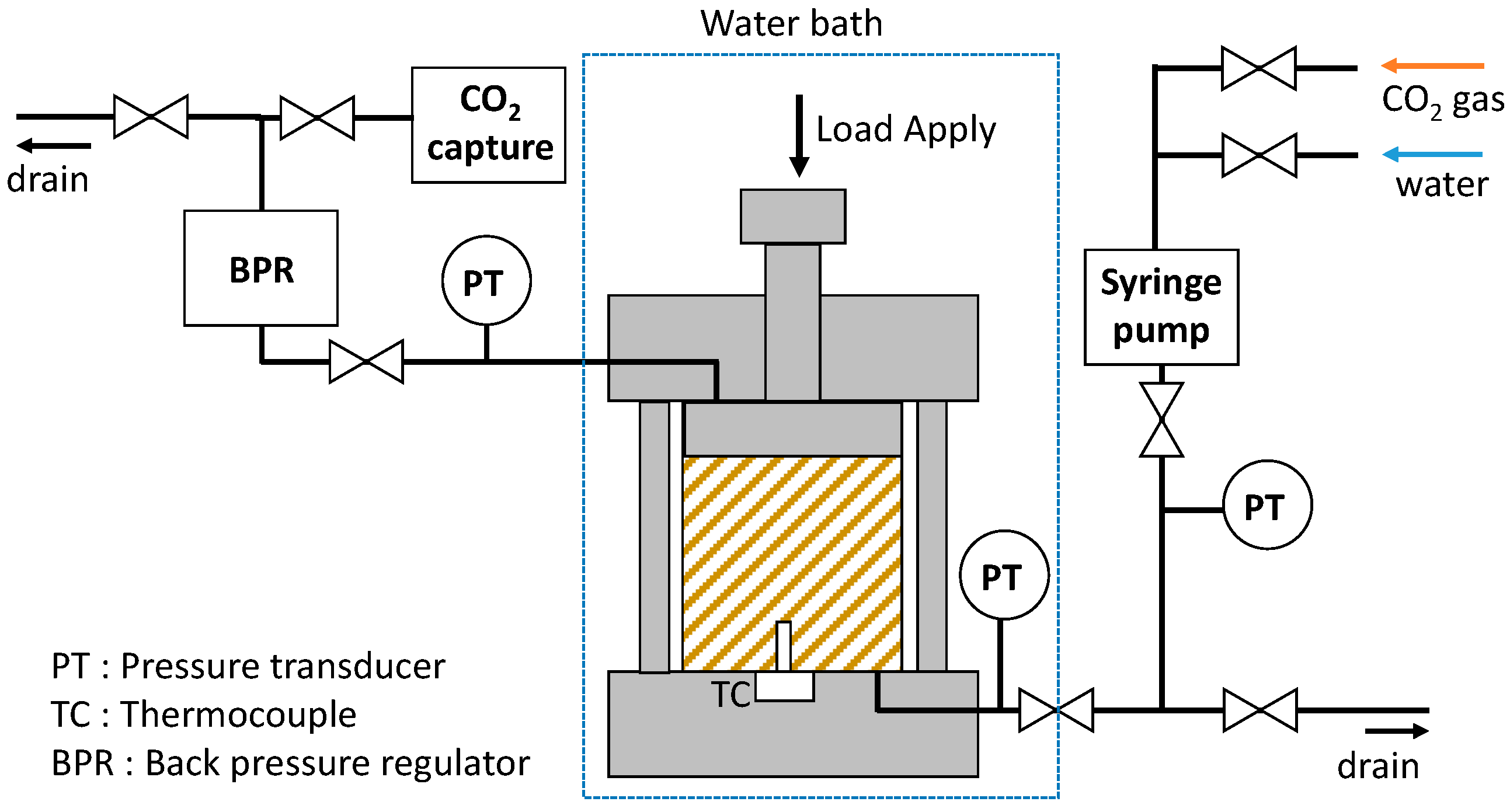

3.2. Experimental Setup

3.3. Experimental Procedure

3.3.1. Hydrate Formation

3.3.2. Permeability Measurement

3.3.3. Hydrate Dissociation

3.4. Experimental Results and Discussion

3.5. Permeability Model Derivation

4. Numerical Analysis for Gas Productivity and Stability

4.1. Numerical Simulator

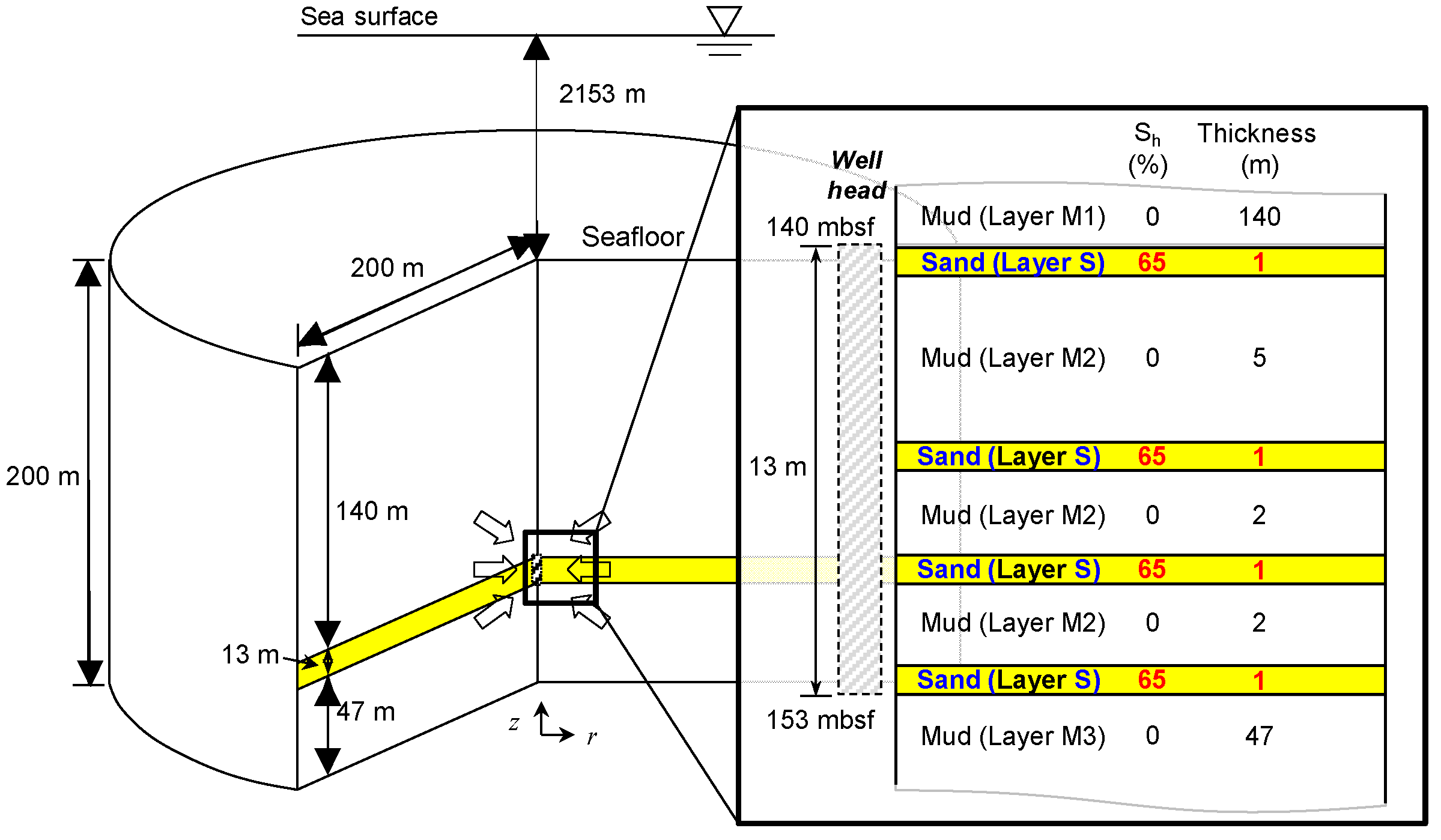

4.2. Model Conditions

4.3. Numerical Analysis Results and Discussion

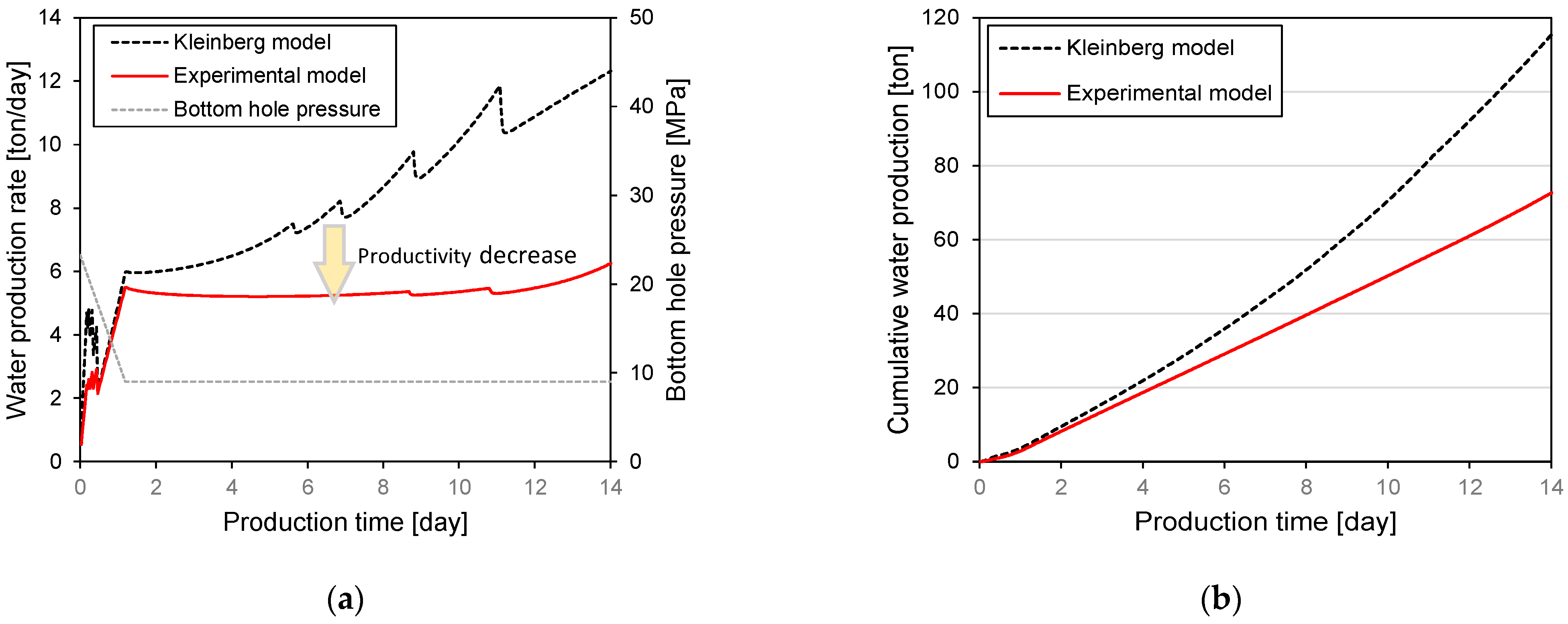

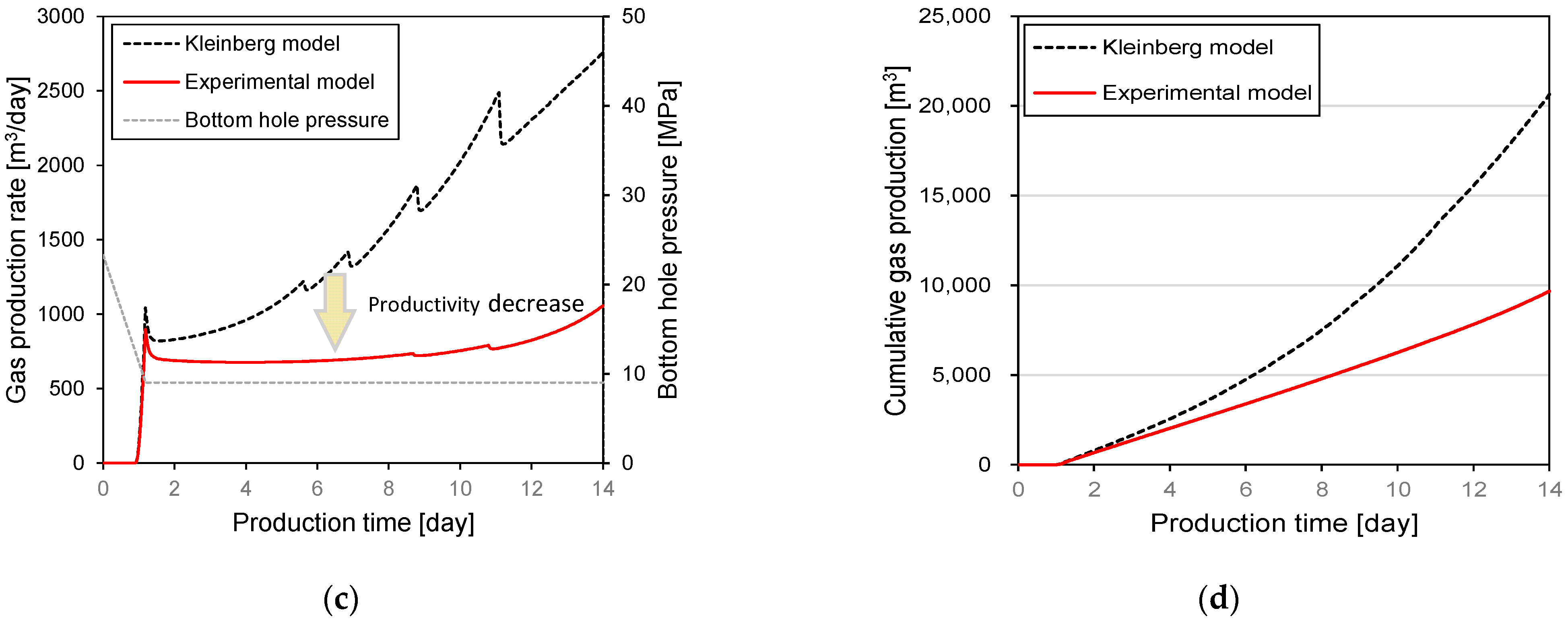

4.3.1. Effects of Permeability Models on Water and Gas Productivity

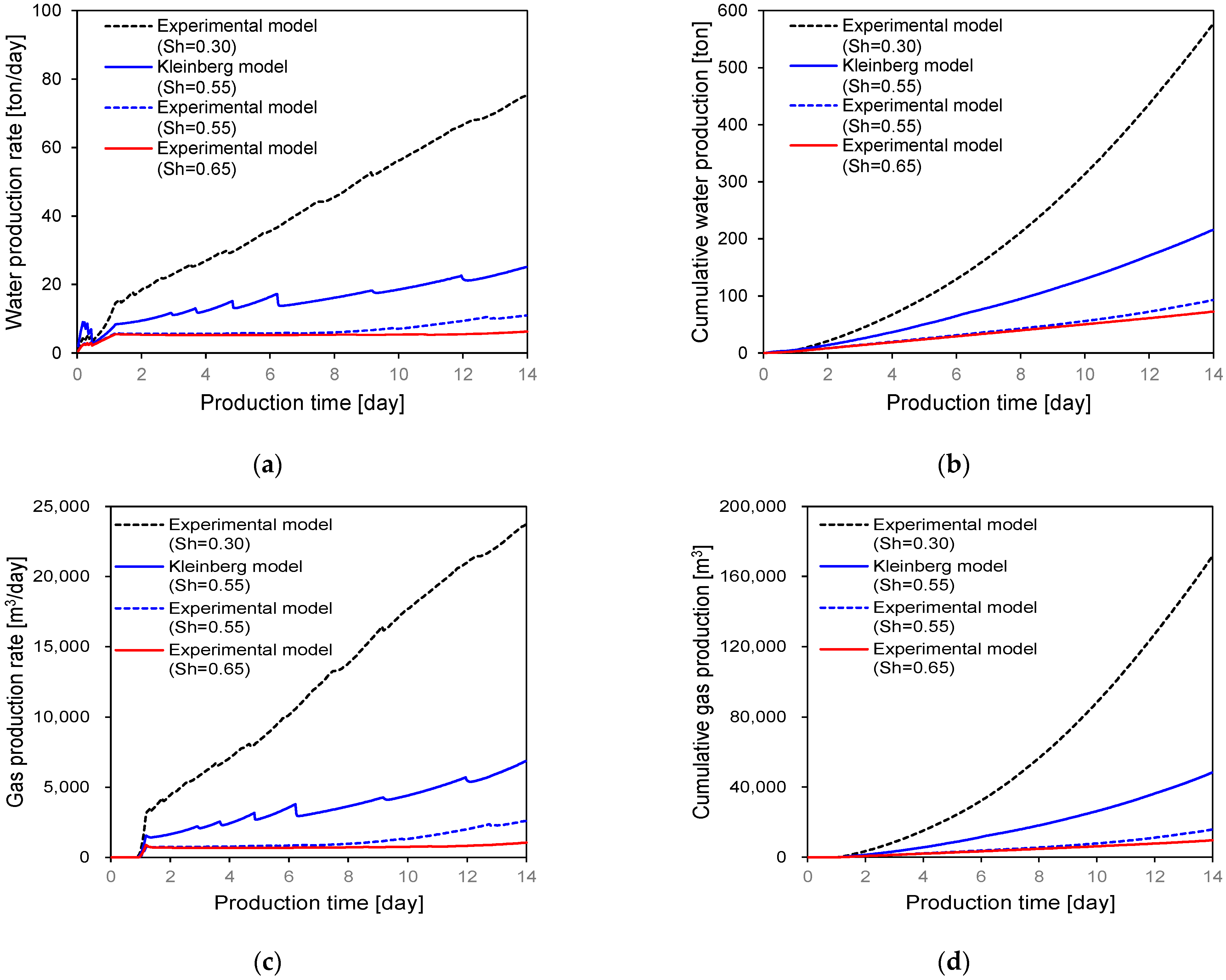

4.3.2. Effects of Initial Hydrate Saturation on Productivity

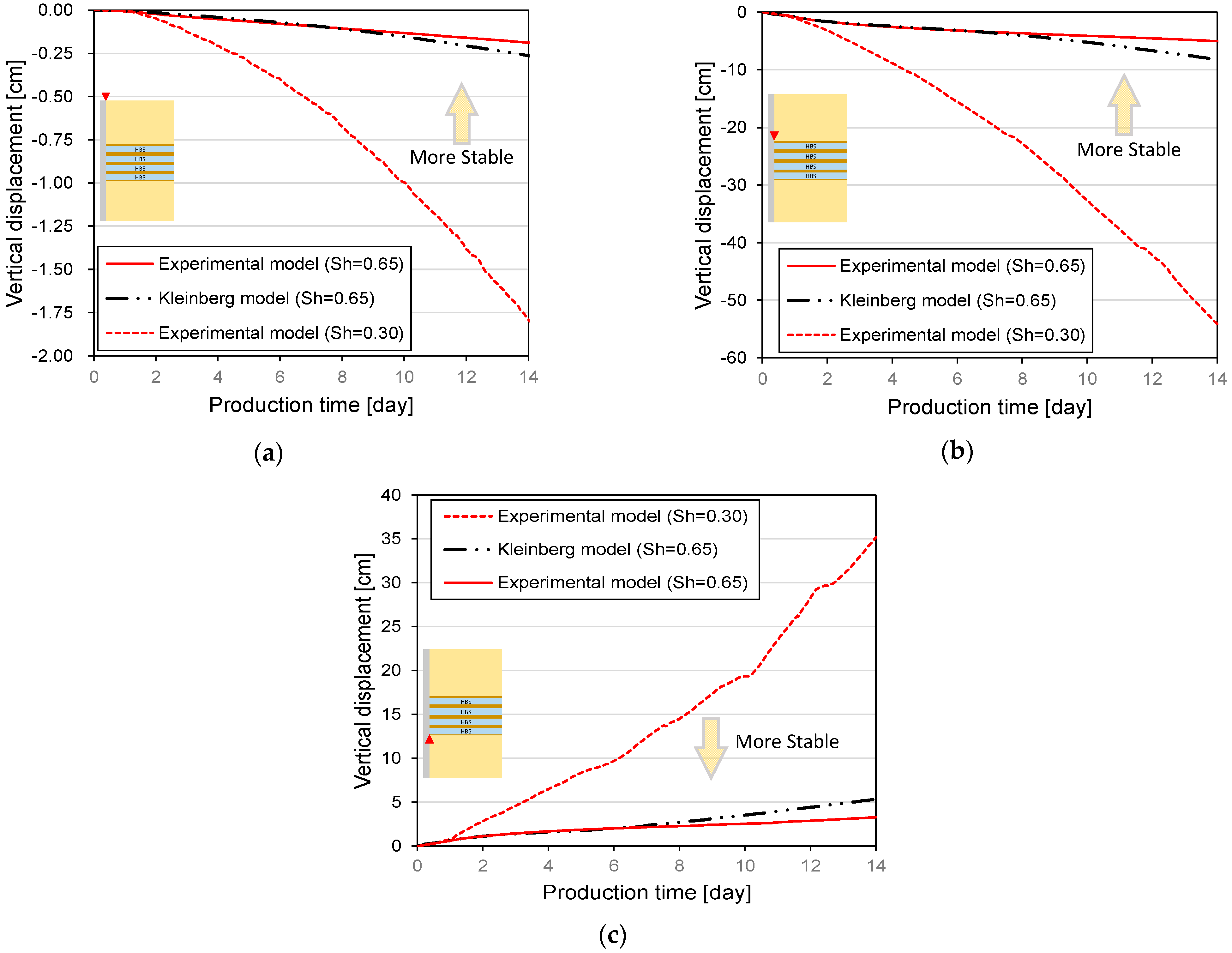

4.3.3. Stability of Hydrate-Bearing Sediments

5. Limitations and Further Work

6. Conclusions

- The measured permeability using the artificial specimen of the Ulleung Basin has significant differences compared to that of theoretical models. The measured permeability exhibited differences of up to 75 times in the Masuda model (N = 10) and approximately 15 times in the Kleinberg model (grain coating), at 60% hydrate saturation.

- The experimental model showed the convergence in permeability as the hydrate saturation increase, reflecting the impervious permeability of silty sand, whereas the existing theoretical models did not reflect the hydraulic characteristics of the sediments, and showed a continuous decrease in permeability as the hydrate saturation increases.

- In the numerical estimation that applied the experimental model, the maximum water and gas production were approximately 50% and 60% smaller than those of the Kleinberg model. The cumulative water and gas production for the experimental model predicted the total water and gas production as approximately 37% and 53% less, respectively, than those of the Kleinberg model.

- The initial hydrate saturation significantly affects the productivity. This is due to the initial permeability and the tendencies of permeability change due to the hydrate saturation. This means that in long-term production, the productivity might increase as the hydrate dissociates from the high initial hydrate saturation, which in certain production periods can show inverse productivity tendencies in regards to the initial hydrate saturation.

- The hydrate-bearing sediment stability was similar to the production estimates. The ground displacement tended to be proportional to the permeability and inversely proportional to the initial hydrate saturation.

- Ground heave occurs at the bottom of the production well, the interaction between the ground heave, and subsidence might induce tensile or compressive stresses on the production well.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sloan, E.D. Fundamental principles and applications of natural gas hydrates. Nature 2003, 426, 353. [Google Scholar] [CrossRef]

- Makogon, Y.F.; Holditch, S.; Makogon, T.Y. Natural gas-hydrates—A potential energy source for the 21st Century. J. Pet. Sci. Eng. 2007, 56, 14–31. [Google Scholar] [CrossRef]

- Rossi, F.; Gambelli, A.M.; Sharma, D.K.; Castellani, B.; Nicolini, A.; Castaldi, M.J. Experiments on methane hydrates formation in seabed deposits and gas recovery adopting carbon dioxide replacement strategies. Appl. Therm. Eng. 2019, 148, 371–381. [Google Scholar] [CrossRef]

- Holder, G.; Kamath, V.; Godbole, S. The potential of natural gas hydrates as an energy resource. Annu. Rev. Energy 1984, 9, 427–445. [Google Scholar] [CrossRef]

- Collett, T.; Bahk, J.-J.; Baker, R.; Boswell, R.; Divins, D.; Frye, M.; Goldberg, D.; Husebø, J.; Koh, C.; Malone, M. Methane Hydrates in Nature Current Knowledge and Challenges. J. Chem. Eng. Data 2014, 60, 319–329. [Google Scholar] [CrossRef]

- Park, K.-P.; Bahk, J.-J.; Kwon, Y.; Kim, G.Y.; Riedel, M.; Holland, M.; Schultheiss, P.; Rose, K. Korean national Program expedition confirms rich gas hydrate deposit in the Ulleung Basin, East Sea. Fire Ice Methane Hydrate Newsl. 2008, 8, 6–9. [Google Scholar]

- Kim, G.Y.; Yi, B.Y.; Yoo, D.G.; Ryu, B.J.; Riedel, M. Evidence of gas hydrate from downhole logging data in the Ulleung Basin, East Sea. Mar. Pet. Geol. 2011, 28, 1979–1985. [Google Scholar] [CrossRef]

- Ryu, B.-J.; Collett, T.S.; Riedel, M.; Kim, G.Y.; Chun, J.-H.; Bahk, J.-J.; Lee, J.Y.; Kim, J.-H.; Yoo, D.-G. Scientific results of the second gas hydrate drilling expedition in the Ulleung basin (UBGH2). Mar. Pet. Geol. 2013, 47, 1–20. [Google Scholar] [CrossRef]

- Lee, G.H.; Bo, Y.Y.; Yoo, D.G.; Ryu, B.J.; Kim, H.J. Estimation of the gas-hydrate resource volume in a small area of the Ulleung Basin, East Sea using seismic inversion and multi-attribute transform techniques. Mar. Pet. Geol. 2013, 47, 291–302. [Google Scholar] [CrossRef]

- Kurihara, M.; Sato, A.; Funatsu, K.; Ouchi, H.; Yamamoto, K.; Numasawa, M.; Ebinuma, T.; Narita, H.; Masuda, Y.; Dallimore, S.R. Analysis of production data for 2007/2008 Mallik gas hydrate production tests in Canada. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010; Society of Petroleum Engineers: Richardson, TX, USA, 2010. [Google Scholar]

- Yamamoto, K.; Dallimore, S. Aurora-JOGMEC-NRCan Mallik 2006–2008 gas hydrate research project progress. Nat. Gas Oil 2008, 304, 285–4541. [Google Scholar]

- Sun, Z.; Xin, Y.; Sun, Q.; Ma, R.; Zhang, J.; Lv, S.; Cai, M.; Wang, H. Numerical simulation of the depressurization process of a natural gas hydrate reservoir: An attempt at optimization of field operational factors with multiple wells in a real 3D geological model. Energies 2016, 9, 714. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.-C.; Li, X.-S.; Zhang, Y.; Li, G. Evaluation of gas production from marine hydrate deposits at the GMGS2-Site 8, Pearl river Mouth Basin, South China Sea. Energies 2016, 9, 222. [Google Scholar] [CrossRef] [Green Version]

- Feng, Y.; Chen, L.; Suzuki, A.; Kogawa, T.; Okajima, J.; Komiya, A.; Maruyama, S. Numerical analysis of gas production from layered methane hydrate reservoirs by depressurization. Energy 2019, 166, 1106–1119. [Google Scholar] [CrossRef]

- Li, G.; Li, C.; Li, X.; Wei, N. Permeability experiments on the methane hydrate in quartz sands and its model verification. Nat. Gas Ind. B 2018, 5, 298–305. [Google Scholar] [CrossRef]

- Corey, A.T. The interrelation between gas and oil relative permeabilities. Prod. Mon. 1954, 19, 38–41. [Google Scholar]

- Van Genuchten, M.T. A closed-form equation for predicting the hydraulic conductivity of unsaturated soils 1. Soil Sci. Soc. Am. J. 1980, 44, 892–898. [Google Scholar] [CrossRef] [Green Version]

- Brooks, R.H.; Corey, A.T. Properties of porous media affecting fluid flow. J. Irrig. Drain. Div. 1966, 92, 61–90. [Google Scholar] [CrossRef]

- Xue, K.; Yang, L.; Zhao, J.; Li, Y.; Song, Y.; Yao, S. The study of flow characteristics during the decomposition process in hydrate-bearing porous media using magnetic resonance imaging. Energies 2019, 12, 1736. [Google Scholar] [CrossRef] [Green Version]

- Spangenberg, E. Modeling of the influence of gas hydrate content on the electrical properties of porous sediments. J. Geophys. Res. Solid Earth 2001, 106, 6535–6548. [Google Scholar] [CrossRef]

- Kleinberg, R.; Flaum, C.; Griffin, D.; Brewer, P.; Malby, G.; Peltzer, E.; Yesinowski, J. Deep sea NMR: Methane hydrate growth habit in porous media and its relationship to hydraulic permeability, deposit accumulation, and submarine slope stability. J. Geophys. Res. Solid Earth 2003, 108, 2508. [Google Scholar] [CrossRef]

- Masuda, Y. Modeling and experimental studies on dissociation of methane gas hydrates in Berea sandstone cores. In Proceedings of the Third International Gas Hydrate Conference, Salt Lake City, UT, USA, 18–22 July 1999. [Google Scholar]

- Gardner, J.; Shor, A.; Jung, W. Acoustic imagery evidence for methane hydrates in the Ulleung Basin. Mar. Geophys. Res. 1998, 20, 495–503. [Google Scholar] [CrossRef]

- Bahk, J.-J.; Um, I.-K.; Holland, M. Core lithologies and their constraints on gas-hydrate occurrence in the East Sea, offshore Korea: Results from the site UBGH1-9. Mar. Pet. Geol. 2011, 28, 1943–1952. [Google Scholar] [CrossRef]

- Tak, H.; Byun, J.; Seol, S.J.; Yoo, D.G. Zero-offset vertical seismic profiling survey and estimation of gas hydrate concentration from borehole data from the Ulleung Basin, Korea. Mar. Pet. Geol. 2013, 47, 204–213. [Google Scholar] [CrossRef]

- Bahk, J.-J.; Kim, J.-H.; Kong, G.-S.; Park, Y.; Lee, H.; Park, Y.; Park, K.P. Occurrence of near-seafloor gas hydrates and associated cold vents in the Ulleung Basin, East Sea. Geosci. J. 2009, 13, 371–385. [Google Scholar] [CrossRef]

- Choi, J.; Kim, J.-H.; Bahk, J.-J.; Ryu, B.-J. Gas geochemistry for gas hydrate in the Ulleung Basin, East Sea. In Proceedings of the 7th International Conference on Gas Hydrates (ICGH2011), Edinburgh, UK, 17–21 July 2011; p. 105. [Google Scholar]

- Bahk, J.-J.; Kim, D.-H.; Chun, J.-H.; Son, B.-K.; Kim, J.-H.; Ryu, B.-J.; Torres, M.; Riedel, M.; Schultheiss, P. Gas hydrate occurrences and their relation to host sediment properties: Results from Second Ulleung Basin gas hydrate drilling expedition, East Sea. Mar. Pet. Geol. 2013, 47, 21–29. [Google Scholar] [CrossRef]

- Jung, J.; Espinoza, D.N.; Santamarina, J.C. Properties and phenomena relevant to CH4-CO2 replacement in hydrate-bearing sediments. J. Geophys. Res. Solid Earth 2010, 115, B10102. [Google Scholar] [CrossRef]

- Delli, M.L.; Grozic, J.L. Experimental determination of permeability of porous media in the presence of gas hydrates. J. Pet. Sci. Eng. 2014, 120, 1–9. [Google Scholar] [CrossRef]

- Darcy, H.P.G. Les Fontaines Publiques de la ville de Dijon. Exposition et Application des Principes à Suivre et des Formules à Employer dans les Questions de Distribution d’eau, etc; V. Dalamont: Paris, France, 1856. [Google Scholar]

- Servio, P.; Englezos, P. Effect of temperature and pressure on the solubility of carbon dioxide in water in the presence of gas hydrate. Fluid Phase Equilibria 2001, 190, 127–134. [Google Scholar] [CrossRef]

- Minagawa, H.; Ohmura, R.; Kamata, Y.; Ebinuma, T.; Narita, H.; Masuda, Y. Water permeability measurements of gas hydrate-bearing sediments. In Proceedings of the Fifth International Conference on Gas Hydrates (ICGH 5), Trondheim, Norway, 12–16 June 2005. [Google Scholar]

- Bear, J. Dynamics of Fluids in Porous Media; Courier Corporation: Chelmsford, MA, USA, 2013. [Google Scholar]

- Kim, A.-R.; Kim, J.-T.; Cho, G.-C.; Lee, J.Y. Methane Production from Marine Gas Hydrate Deposits in Korea: Thermal-Hydraulic-Mechanical Simulation on Production Wellbore Stability. J. Geophys. Res. Solid Earth 2018, 123, 9555–9569. [Google Scholar] [CrossRef]

- Kim, A. THM Coupled Numerical Analysis of Gas Production from Methane Hydrate Deposits in the Ulleung Basin in Korea. Ph.D. Thesis, Korea Advanced Institute of Science and Technology (KAIST), Daejeon, Korea, 2016. [Google Scholar]

- Manual, I.F.D. Fast Lagrangian Analysis Continua–Version 7.0 User Manual; Itasca Consulting Group: Minneapolis, MN, USA, 2015. [Google Scholar]

- Kim, H.; Cho, G.; Lee, J. Geotechnical and geophysical properties of deep oceanic sediments recovered from UBGH2 sites in the Ulleung Basin, East Sea, Offshore Korea. Mar. Pet. Geol. 2013, 47, 56–65. [Google Scholar] [CrossRef]

- Uchida, S.; Soga, K.; Yamamoto, K. Critical state soil constitutive model for methane hydrate soil. J. Geophys. Res. Solid Earth 2012, 117, B03209. [Google Scholar] [CrossRef]

- Kim, J.-T.; Kim, A.-R.; Cho, G.-C.; Kang, C.-W.; Lee, J.Y. The Effects of Coupling Stiffness and Slippage of Interface between the Wellbore and Unconsolidated Sediment on the Stability Analysis of the Wellbore Under Gas Hydrate Production. Energies 2019, 12, 4177. [Google Scholar] [CrossRef] [Green Version]

- Sloan, E. Clathrate Hydrates of Natural Gases; Marcel Decker. Inc.: New York, NY, USA, 1998. [Google Scholar]

- Klar, A.; Uchida, S.; Soga, K.; Yamamoto, K. Explicitly coupled thermal flow mechanical formulation for gas-hydrate sediments. SPE J. 2013, 18, 196–206. [Google Scholar] [CrossRef]

- Lu, J.; Li, D.; He, Y.; Shi, L.; Liang, D.; Xiong, Y. Experimental Study of Sand Production during Depressurization Exploitation in Hydrate Silty-Clay Sediments. Energies 2019, 12, 4268. [Google Scholar] [CrossRef] [Green Version]

| Theoretical Model | Parameter | Remark | Reference |

|---|---|---|---|

| n = 1.5 | Grain coating | Kleinberg [20,21] | |

| n = 0.7Sh + 0.3 | Pore filling | ||

| Capillary tube | Masuda [22] |

| Hydrate saturation [-] | 0.00 | 0.05 | 0.10 | 0.15 | 0.22 | 0.28 | 0.35 | 0.44 | 0.52 | 0.61 |

| Permeability [mD] | 209.92 | 134.31 | 67.65 | 33.83 | 9.95 | 5.07 | 2.39 | 1.59 | 1.49 | 1.29 |

| Uncertainty of Permeability 1 [mD] |

| Parameter | Value | Parameter | Value | ||

|---|---|---|---|---|---|

| Geologic conditions | Hydrostatic pressure at sea floor (MPa) | 21.9 | Mechanical properties | Bulk density of sand (Layer S, kg/m3) | 1700 |

| Temperature at sea floor (°C) | 0.482 | Bulk density of mud (Layer M1, kg/m3) | 1500 | ||

| Geothermal gradient (°C/km) | 112 | Bulk density of mud (Layer M2, kg/m3) | 1610 | ||

| Hydrate occurrence zone (mbsf) | 140–153 | Bulk density of mud (Layer M3, kg/m3) | 1640 | ||

| Initial hydrate saturation (Sh) in sand (Layer S, %) | 65 | Methane hydrate density (kg/m3) | 910 | ||

| Initial hydrate saturation in mud (%) | 0.0 | Young modulus of sand (Layer S, MPa) | 40 | ||

| Thermal properties | Thermal conductivity of sand (W/m K) | 1.45 | Young modulus of mud (Layer M2, MPa) | 18 | |

| Thermal conductivity of mud (W/m K) | 1.00 | Young modulus of mud (Layer M3, MPa) | 20 | ||

| Hydraulic properties | Intrinsic permeability of mud (mD) | 0.21 | Poisson ratio of sand (Layer S, -) | 0.25 | |

| Intrinsic permeability of sand (mD) | 209 | Poisson ratio of mud (Layer M1, M2, and M3, -) | 0.35 | ||

| Porosity of sand (Layer S, -) | 0.48 | Friction angle of sand (Layer S, °) | 25 | ||

| Porosity of mud (Layer M1, -) | 0.69 | Friction angle of mud (Layer M1, M2, and M3, °) | 22 | ||

| Porosity of mud (Layer M2, -) | 0.67 | Cohesion of sand (Layer S, kPa) | 35 | ||

| Porosity of mud (Layer M3, -) | 0.63 | Cohesion of mud (Layer M1 and M2, kPa) | 30 | ||

| Residual water saturation ( [–]) | 0.1 | Cohesion of mud (Layer M3, kPa) | 40 | ||

| Residual gas saturation ( [–]) | 0.01 | Hydrate dissociation properties | Molecular mass of gas (Mg, g/mol) | 16.042 | |

| Permeability models | (this study) | Molecular mass of water (Mw, g/mol) | 18.016 | ||

| [21] | Molecular mass of hydrate (Mh, g/mol) | 124.133 | |||

| Van Genuchten parameters | P0 (kPa) | 2.2 | Hydration number (Nh) [41,42] | 6 | |

| α | 0.6 | Phase equilibrium model parameters (α and β) | 42.047, −9332 | ||

| n | 0.5 | Stiffness model | |||

| m | 0.5 | Ehyd is the Young’s modulus at a certain hydrate saturation, E0 is the Young’s modulus without hydrate | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.-T.; Kang, C.-W.; Kim, A.-R.; Lee, J.Y.; Cho, G.-C. Effect of Permeability on Hydrate-Bearing Sediment Productivity and Stability in Ulleung Basin, East Sea, South Korea. Energies 2021, 14, 1752. https://doi.org/10.3390/en14061752

Kim J-T, Kang C-W, Kim A-R, Lee JY, Cho G-C. Effect of Permeability on Hydrate-Bearing Sediment Productivity and Stability in Ulleung Basin, East Sea, South Korea. Energies. 2021; 14(6):1752. https://doi.org/10.3390/en14061752

Chicago/Turabian StyleKim, Jung-Tae, Chul-Whan Kang, Ah-Ram Kim, Joo Yong Lee, and Gye-Chun Cho. 2021. "Effect of Permeability on Hydrate-Bearing Sediment Productivity and Stability in Ulleung Basin, East Sea, South Korea" Energies 14, no. 6: 1752. https://doi.org/10.3390/en14061752