Research on the Fault Feature Extraction of Rolling Bearings Based on SGMD-CS and the AdaBoost Framework

Abstract

1. Introduction

- (1)

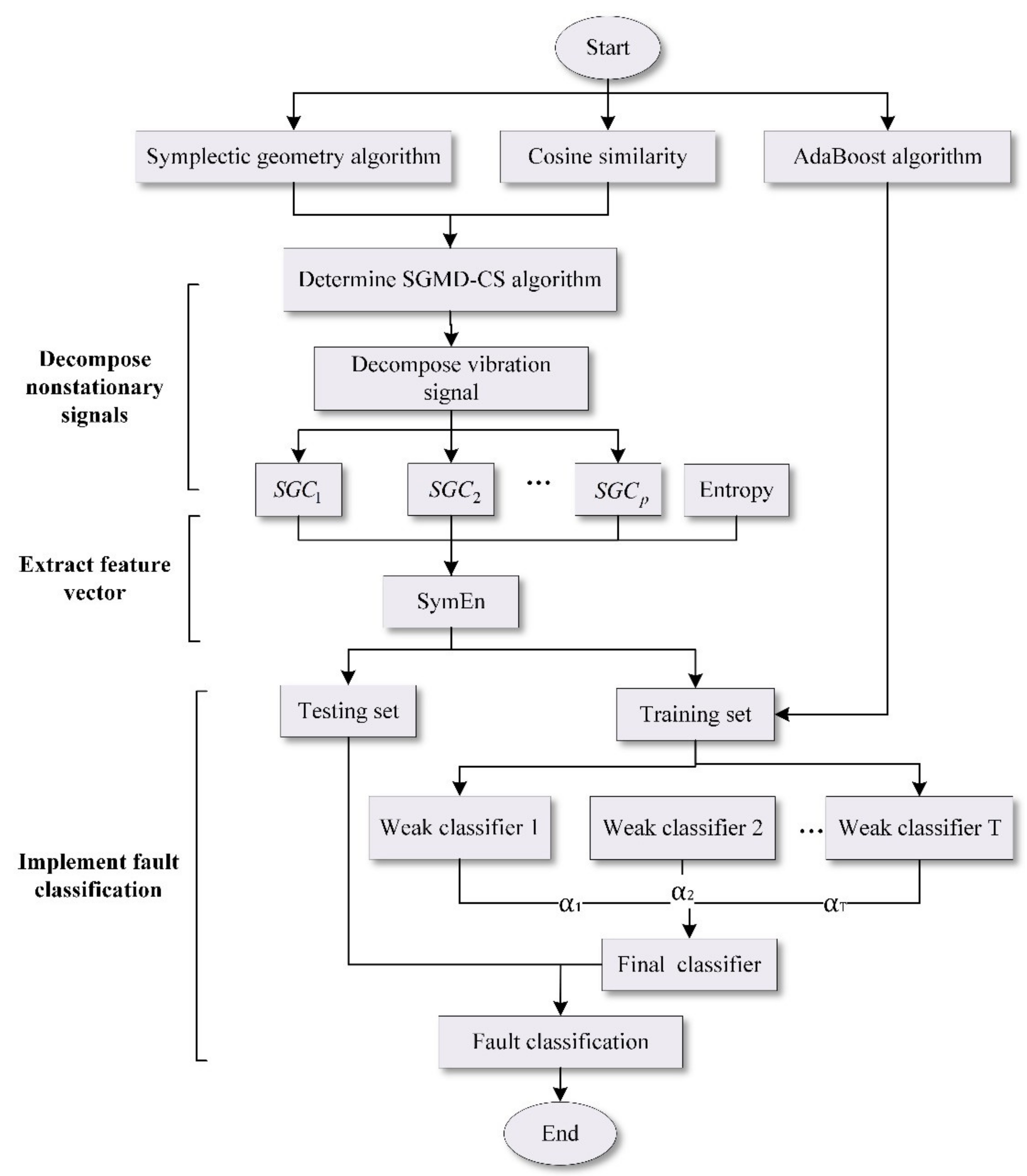

- Aiming at the problem of recombination of similar components obtained by using the SGMD algorithm, the cosine similarity is introduced into the SGMD algorithm to obtain the SGMD-CS algorithm. The effectiveness of the method is verified by simulation signals and actual rolling bearing fault signals.

- (2)

- Based on the SGMD-CS algorithm, SymEn is constructed as the extracted fault feature vector.

- (3)

- Using Adaboost algorithm to realize automatic identification of bearing failure modes.

- (4)

- A complete fault diagnosis flowchart of rolling bearings is given, and experimental research and comparative analysis are carried out.

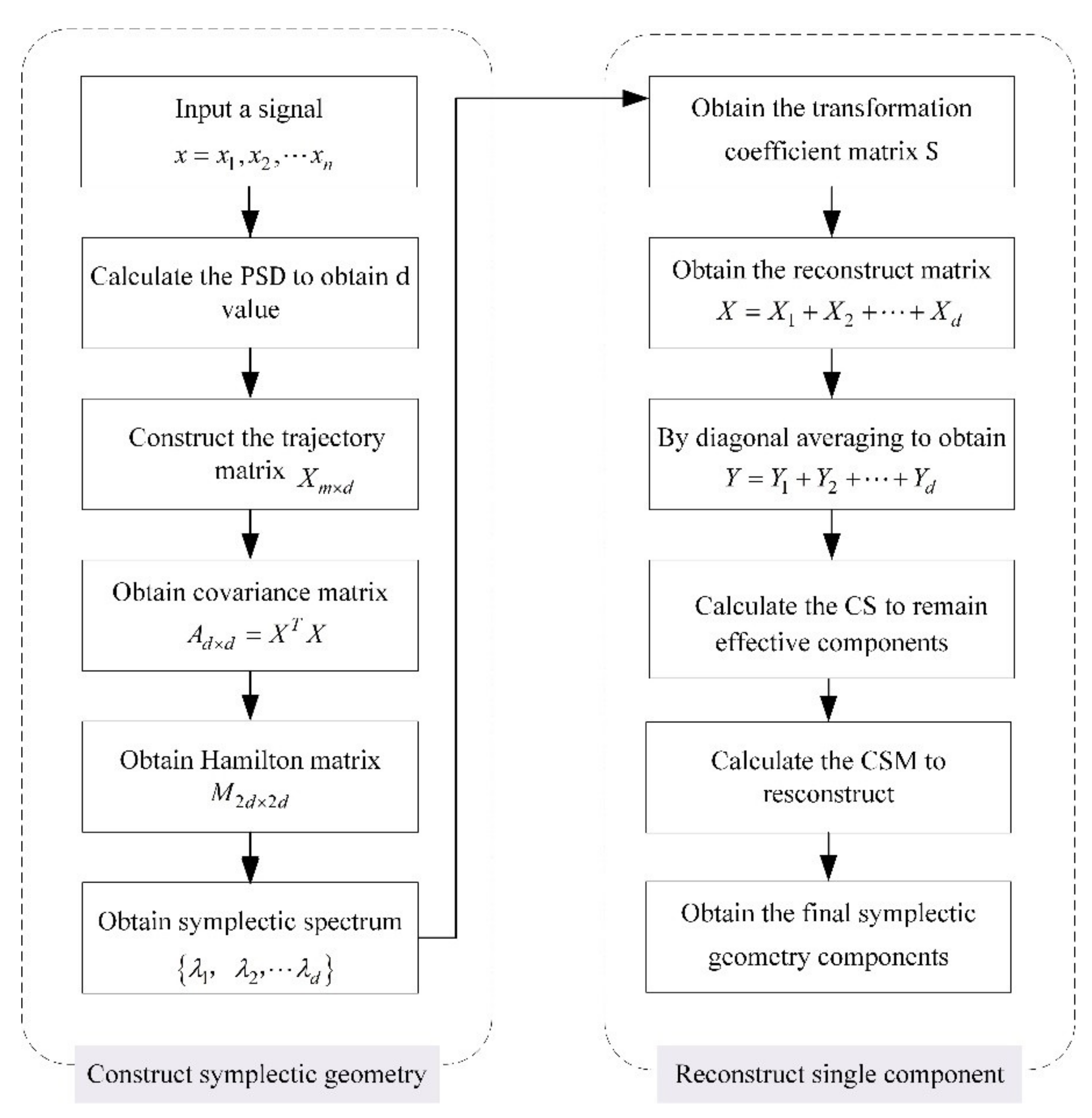

2. Symplectic Geometry Algorithm

2.1. Symplectic Theory

- (1)

- Phase space reconstruction

- (2)

- Symplectic QR decomposition

- (3)

- Diagonal averaging transformation

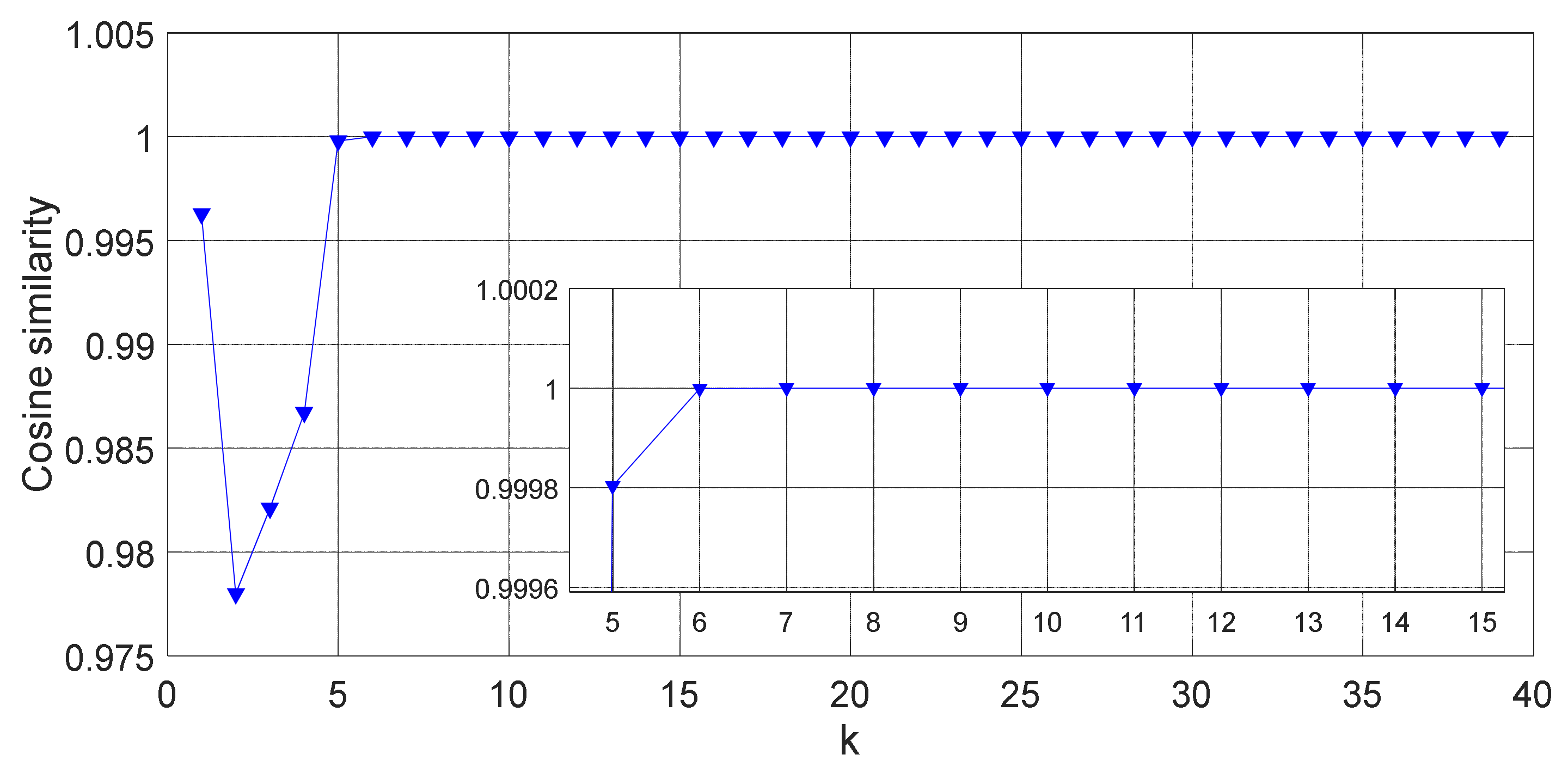

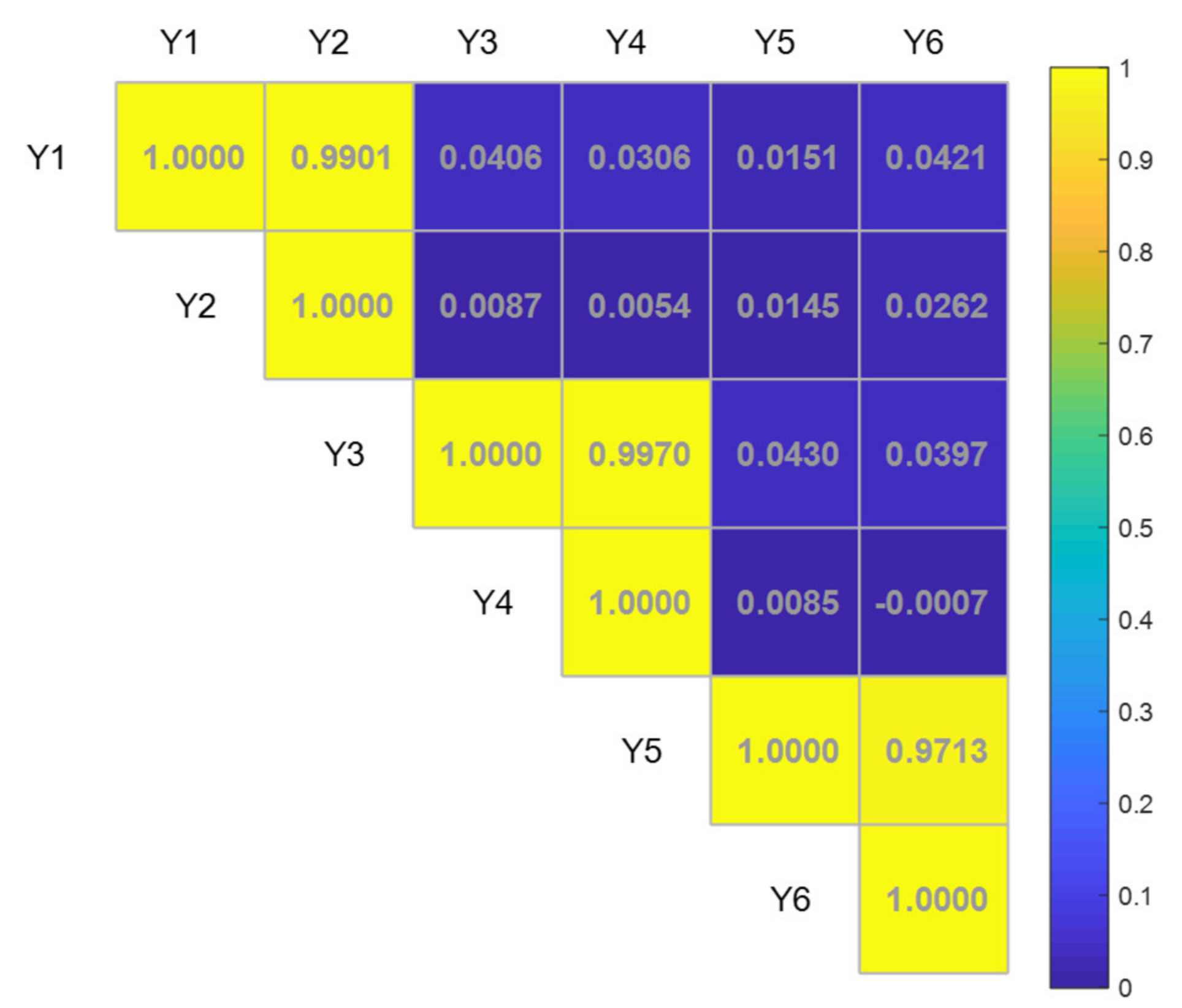

2.2. SGMD-CS Algorithm

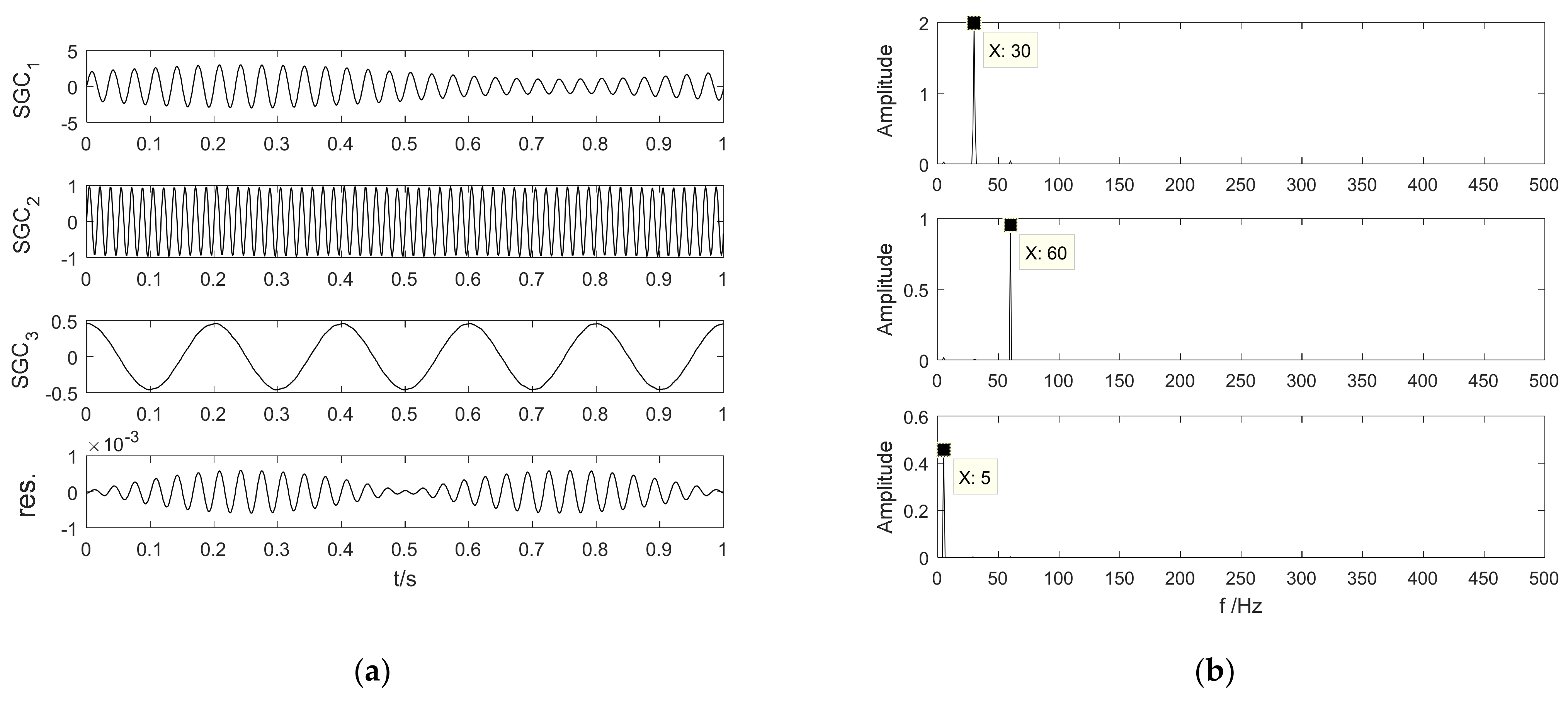

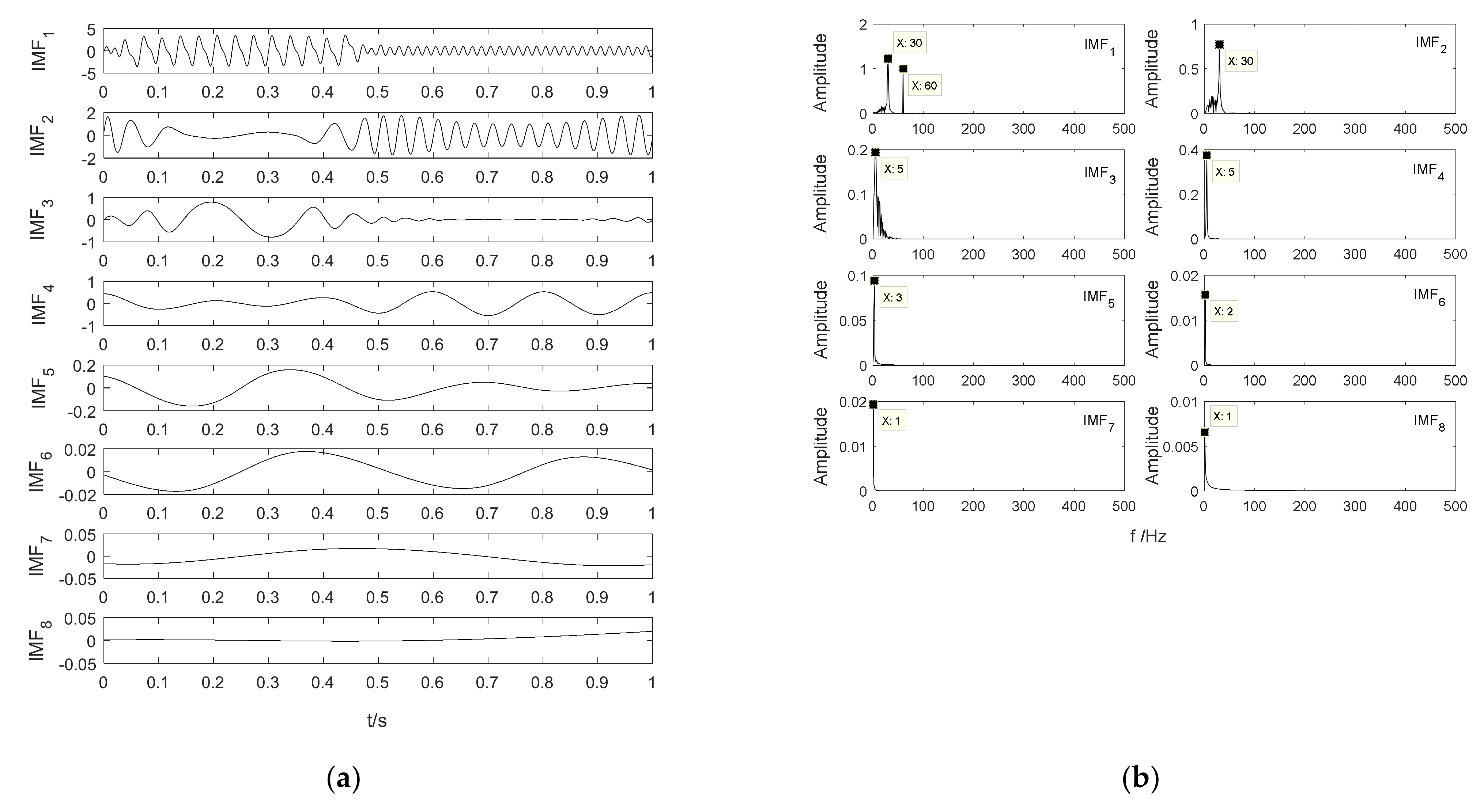

3. Simulation Analysis

4. Feature Classification

4.1. AdaBoost Theory

- Step 1: Calculate the input.

- (1)

- Given training set , where .

- (2)

- Weak learning algorithm.

- Step 2: Calculate the output .

- (1)

- Initial weight distribution of training data.

- (2)

- For , using the training data set with weight distribution to learn, we obtain a weak classifier.

- (3)

- Calculate the classification error rate on the training data set .

- (4)

- Calculate the coefficient of .It is worth noting that .

- (5)

- Update the weight distribution of the training data set.where is the normalization factor.

- (6)

- Construct a linear combination of basic classifiers to obtain the final classifier.

4.2. Feature Vector Selection

5. Experimental Analysis

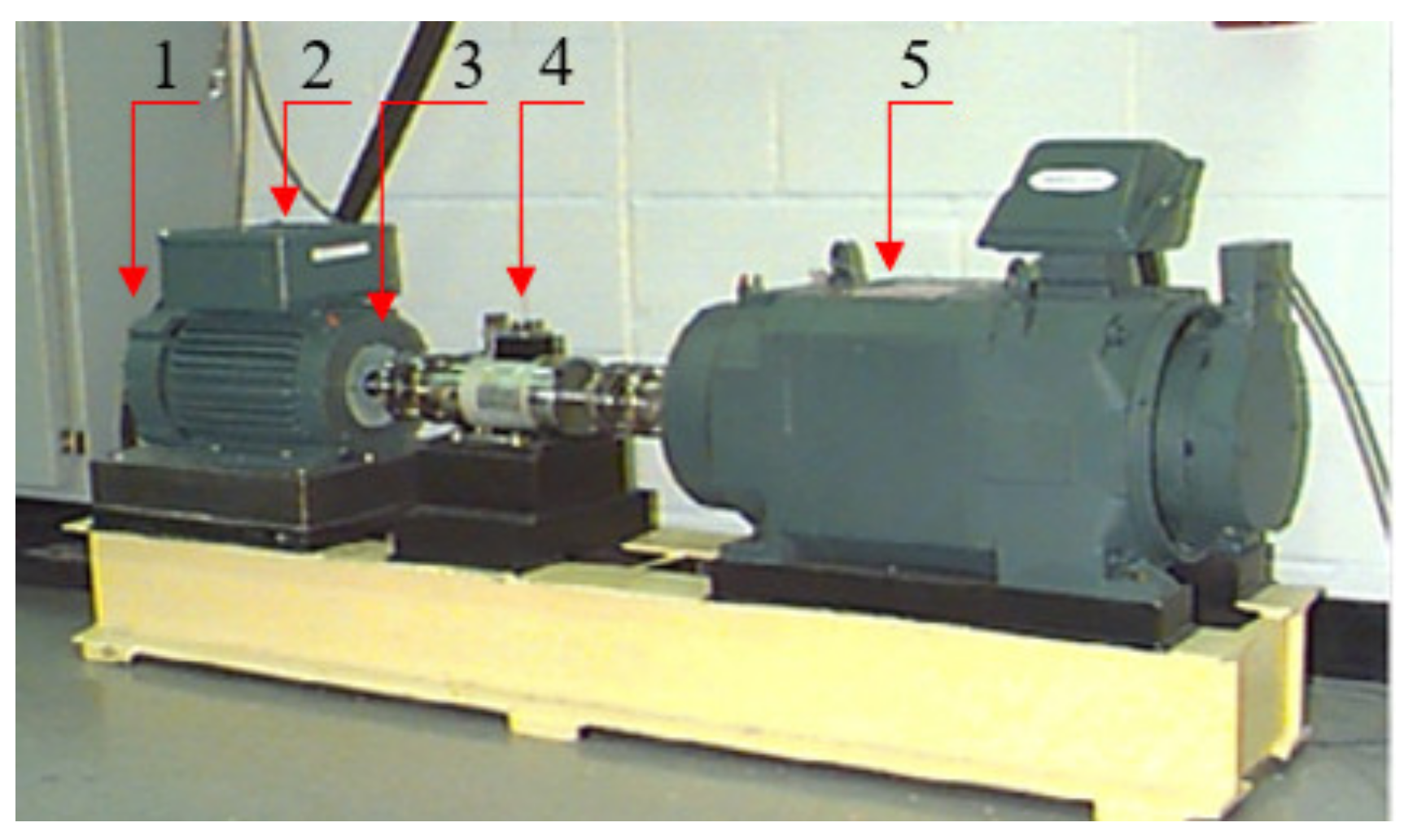

5.1. Experimental Arrangement and Data Description

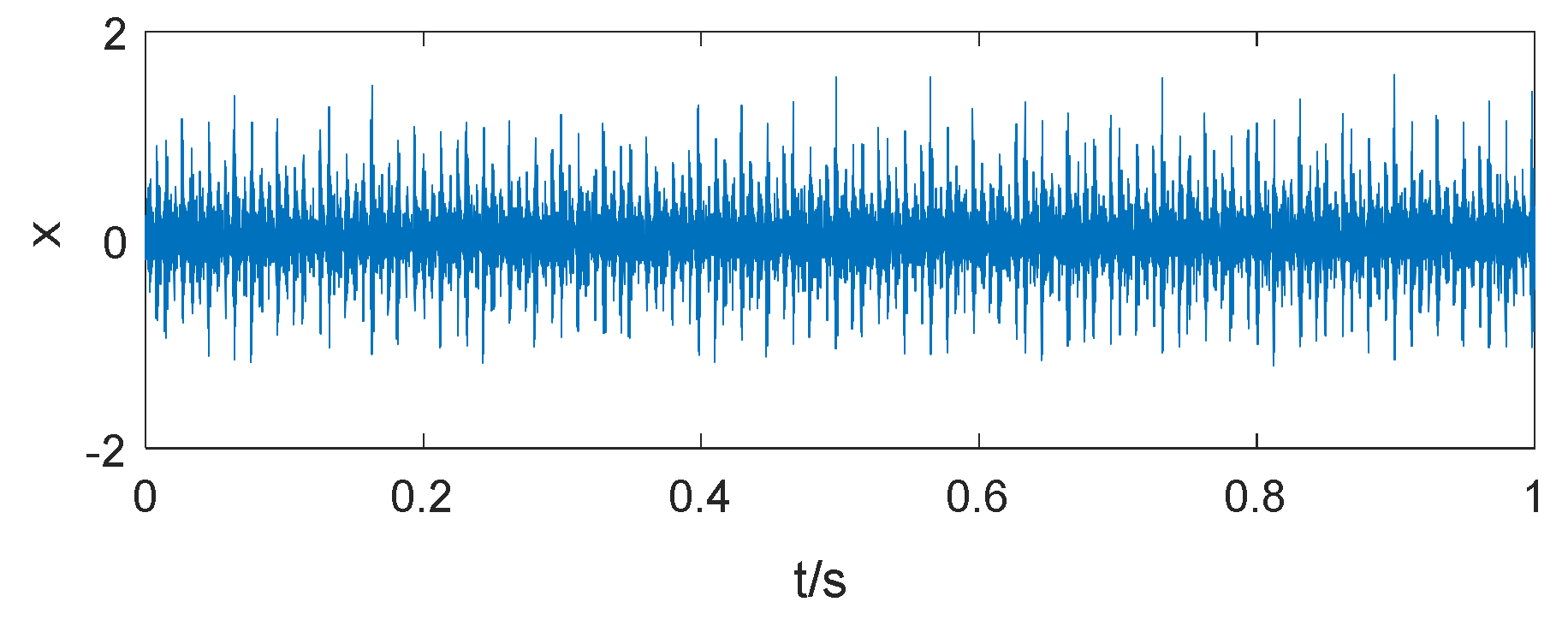

5.2. Signal Preprocessing

5.3. Classification of Different Fault Types

6. Conclusions

- To address the problem of similar component recombination in the symplectic geometric decomposition process, the cosine similarity is introduced into this method, the SGMD-CS method is proposed, and a block diagram of the method is given. The effectiveness of this method is verified by constructing a complex AM-FM signal and comparing it with the decomposition results of the LMD and EMD methods. The results show that the decomposition error of this method is small, and the trend components of the original signal can be better stripped, so this method is suitable for the analysis of nonlinear time series. In addition, the characteristics of this method have also been compared and verified on actual rolling bearing fault signals.

- When addressing the problem of using high-dimensional feature vectors when extracting fault feature information, there will be data redundancy, and the diagnosis accuracy will be reduced. In this paper, based on the SGMD-CS method, the symplectic geometric entropy is calculated as a low-dimensional feature vector and sent to the AdaBoost classification framework based on decision trees. According to the given fault diagnosis flow chart, taking the rolling bearing vibration data of Case Western Reserve University’s Electrical Engineering Laboratory as an example, a high classification accuracy rate is obtained by discriminating and classifying the fault type. At the same time, compared with sample entropy, approximate entropy, and fuzzy entropy, symplectic geometric entropy is highlighted as a measure that can effectively extract fault information, thereby making the diagnosis more accurate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Z.; Zhang, L. A review of failure modes, condition monitoring and fault diagnosis methods for large-scale wind turbine bearings. Measurement 2020, 149, 107002. [Google Scholar] [CrossRef]

- Ehsan, M.; David, W.; Qiao, S. Indicative Fault Diagnosis of Wind Turbine Generator Bearings Using Tower Sound and Vi-bration. Energies 2017, 10, 1853. [Google Scholar]

- Francesco, C.; Luigi, G.; Alessandro, P.D.; Davide, A.; Francesco, N. Diagnosis of Faulty Wind Turbine Bearings Using Tower Vibration Measurements. Energies 2020, 13, 1474. [Google Scholar]

- Daniel, S.; Pär, M.; Kim, B.; Per-Erik, L. Bearing monitoring in the wind turbine drivetrain: A comparative study of the FFT and wavelet transforms. Wind Energy 2020, 23, 1381–1393. [Google Scholar]

- Huang, N.E.; Shen, Z.; Long, S.R.; Wu, M.C.; Shih, H.H.; Zheng, Q.; Yen, N.-C.; Tung, C.C.; Liu, H.H. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis. Proc. R. Soc. A 1998, 454, 903–995. [Google Scholar] [CrossRef]

- Wu, Z.; Huang, N.E. Ensemble Empirical Mode Decomposition: A Noise-Assisted Data Analysis Method. Adv. Adapt. Data Anal. 2009, 1, 1–41. [Google Scholar] [CrossRef]

- Liu, B.; Zheng, P.; Dai, Q.; Zhou, Z. The Measurement and Elimination of Mode Splitting: From the Perspective of the Partly Ensemble Empirical Mode Decomposition. Complexity 2018, 2018, 4230649. [Google Scholar] [CrossRef]

- Guo, T.; Deng, Z. An improved EMD method based on the multi-objective optimization and its application to fault feature extraction of rolling bearing. Appl. Acoust. 2017, 127, 46–62. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Z.; Hu, C.; Chen, S.; Wang, J.; Zhang, X. An optimized ensemble local mean decomposition method for fault detection of mechanical components. Meas. Sci. Technol. 2017, 28, 035102. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, J.; Cai, W.; Zhou, J.; Du, W.; Wang, J.; He, G.; He, H. Application of an Improved Ensemble Local Mean Decomposition Method for Gearbox Composite Fault Diagnosis. Complexity 2019, 2019, 1564243. [Google Scholar] [CrossRef]

- Xie, H.; Wang, Z.; Huang, H. Identification determinism in time series based on symplectic geometry spectra. Phys. Lett. A 2005, 342, 156–161. [Google Scholar] [CrossRef]

- Fassbender, H.; Kressner, D. Structured Eigenvalue Problems. GAMM Mitt. 2006, 29, 297–318. [Google Scholar] [CrossRef]

- Lei, M.; Wang, Z.; Feng, Z. A method of embedding dimension estimation based on symplectic geometry. Phys. Lett. A 2002, 303, 179–189. [Google Scholar] [CrossRef]

- Lei, M.; Meng, G. Symplectic Principal Component Analysis: A New Method for Time Series Analysis. Math. Probl. Eng. 2011, 2011, 1–14. [Google Scholar] [CrossRef]

- Xie, H.-B.; Dokos, S.; Sivakumar, B.; Mengersen, K. Symplectic geometry spectrum regression for prediction of noisy time series. Phys. Rev. E 2016, 93, 93. [Google Scholar] [CrossRef]

- Xie, H.-B.; Dokos, S. A symplectic geometry-based method for nonlinear time series decomposition and prediction. Appl. Phys. Lett. 2013, 103, 054103. [Google Scholar] [CrossRef]

- Xie, H.-B.; Guo, T.; Sivakumar, B.; Liew, A.W.-C.; Dokos, S. Symplectic geometry spectrum analysis of nonlinear time series. Proc. R. Soc. A Math. Phys. Eng. Sci. 2014, 470, 20140409. [Google Scholar] [CrossRef]

- Lei, M.; Meng, G.; Dong, G. Fault Detection for Vibration Signals on Rolling Bearings Based on the Symplectic Entropy Method. Entropy 2017, 19, 607. [Google Scholar] [CrossRef]

- Zheng, Z.; Xin, G. Fault Feature Extraction of Hydraulic Pumps Based on Symplectic Geometry Mode Decomposition and Power Spectral Entropy. Entropy 2019, 21, 476. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.; Lin, J.; Chen, X.; Yi, C. Modal Parameters Identification Method Based on Symplectic Geometry Model Decomposition. Shock. Vib. 2019, 2019, 1–26. [Google Scholar] [CrossRef]

- Li, X.; Li, D. Structural damage identification based on symplectic geometric spectrum analysis method under the influence of environmental factors. J. Water Resour. Archit. Eng. 2016, 14, 154–160, 176. [Google Scholar]

- Niu, X.; Qu, F.; Wang, N. Analysis and Evaluation of Surface EMG Signals of Athletes Based on EMD and Symplectic Geometry. J. Ocean Univ. China Nat. Sci. Ed. 2005, 1, 125–129. [Google Scholar]

- Pan, H.; Yang, Y.; Li, X.; Zheng, J.; Cheng, J. Symplectic geometry mode decomposition and its application to rotating machinery compound fault diagnosis. Mech. Syst. Signal Process. 2019, 114, 189–211. [Google Scholar] [CrossRef]

- Kalhori, H.; Alamdari, M.M.; Ye, L. Automated algorithm for impact force identification using cosine similarity searching. Measurement 2018, 122, 648–657. [Google Scholar] [CrossRef]

- Al-Anzi, F.S.; AbuZeina, D. Toward an enhanced Arabic text classification using cosine similarity and Latent Semantic Indexing. J. King Saud Univ. Comput. Inf. Sci. 2016, 29, 189–195. [Google Scholar] [CrossRef]

- Liu, R.; Yang, B.; Zio, E.; Chen, X. Artificial intelligence for fault diagnosis of rotating machinery: A review. Mech. Syst. Signal Process. 2018, 108, 33–47. [Google Scholar] [CrossRef]

- Lei, M.; Meng, G.; Zhang, W.; Wade, J.; Sarkar, N. Symplectic Entropy as a Novel Measure for Complex Systems. Entropy 2016, 18, 412. [Google Scholar] [CrossRef]

- Takens, F. Detecting strange attractors in turbulence. In Dynamical Systems and Turbulence, Warwick 1980; Springer: Berlin/Heidelberg, Germany, 1981; pp. 366–381. [Google Scholar]

- Bonizzi, P.; Karel, J.M.; Meste, O.; Peeters, R.L. Singular spectrum decomposition: A new time series decomposition. Adv. Adapt. Data Anal. 2014, 6, 107–109. [Google Scholar] [CrossRef]

- Van Loan, C. A symplectic method for approximating all the eigenvalues of a Hamiltonian matrix. Linear Algebra Appl. 1984, 61, 233–251. [Google Scholar] [CrossRef]

- Freund, Y.; Schapire, R.E. Experiments with a new boosting algorithm. In Proceedings of the International Conference on International Conference on Machine Learning (ICML), Bari, Italy, 3–6 July 1996; Morgan Kaufmann Publishers Inc.: Bari, Italy, 1996; Volume 96, pp. 148–156. [Google Scholar]

- Baig, M.M.; Awais, M.M.; El-Alfy, E.S.M. AdaBoost-based artificial neural network learning. Neurocomputing 2017, 248, 120–126. [Google Scholar] [CrossRef]

- Lee, W.; Jun, C.-H.; Lee, J.-S. Instance categorization by support vector machines to adjust weights in AdaBoost for imbalanced data classification. Inf. Sci. 2017, 381, 92–103. [Google Scholar] [CrossRef]

- Schapire, R.E.; Freund, Y. Boosting: Foundations and Algorithms; MIT Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Li, H.; Fan, B.; Jia, R.; Zhai, F.; Bai, L.; Luo, X. Research on Multi-Domain Fault Diagnosis of Gearbox of Wind Turbine Based on Adaptive Variational Mode Decomposition and Extreme Learning Machine Algorithms. Energies 2020, 13, 1375. [Google Scholar] [CrossRef]

- Gao, X.; Yan, X.; Gao, P.; Gao, X.; Zhang, S. Automatic detection of epileptic seizure based on approximate entropy, recurrence quantification analysis and convolutional neural networks. Artif. Intell. Med. 2020, 102, 101711. [Google Scholar] [CrossRef]

- Wu, H.; Zhou, J.; Xie, C.; Zhang, J.; Huang, Y. Two-dimensional time series sample entropy algorithm: Applications to rotor axis orbit feature identification. Mech. Syst. Signal Process. 2021, 147, 107123. [Google Scholar]

- Harezlak, K.; Kasprowski, P. Application of Time-Scale Decomposition of Entropy for Eye Movement Analysis. Entropy 2020, 22, 168. [Google Scholar] [CrossRef]

| Class | Deep Groove Ball Bearing |

|---|---|

| Type | 6205-2RS JEM SKF |

| Position | Drive end |

| Sampling frequency fs (Hz) | 12,000 |

| Inside diameter (inches) | 0.9843 |

| Outside diameter (inches) | 2.0472 |

| Thickness (inches) | 0.5906 |

| Ball diameter (inches) | 0.3126 |

| Pitch diameter (inches) | 1.537 |

| Rotation frequency (Hz) | |

| Inner ring defect frequency (Hz) | 5.4152 × fr |

| Outer ring defect frequency (Hz) | 3.5848 |

| Rolling element frequency (Hz) | 4.7135 |

| Number of rolling elements | 9 |

| Parameters | Value |

|---|---|

| Data | 105.mat |

| Fault diameter | 0.007″ |

| Approximate motor speed | 1797 rpm |

| Rotation frequency | 29.95 Hz |

| Inner ring defect frequency | 162.19 Hz |

| Motor load | 0 hp |

| Fault Type | Data | Fault Diameter (Inches) | Motor Load (HP) | Rotation Frequency (r/min) | Class Label |

|---|---|---|---|---|---|

| Inner ring fault (IRF) | 171.mat | 0.014 | 2 | 1750 | 1 |

| Outer ring fault (ORF) | 199.mat | 0.014 | 2 | 1750 | 2 |

| Ball element fault (BF) | 187.mat | 0.014 | 2 | 1750 | 3 |

| Normal (NOR) | 099.mat | 0.014 | 2 | 1750 | 4 |

| SymEn | ApEn | SampEn | FuzzyEn | ||

|---|---|---|---|---|---|

| Accuracy | 97.50 | 95.00 | 90.00 | 70.00 | |

| Precision | 100.00 | 100.00 | 91.67 | 63.64 | |

| Inner ring | Recall | 100.00 | 100.00 | 100.00 | 63.64 |

| F1-score | 100.00 | 100.00 | 95.65 | 63.64 | |

| Precision | 100.00 | 100.00 | 100.00 | 61.54 | |

| Outer ring | Recall | 100.00 | 100.00 | 100.00 | 100.00 |

| F1-score | 100.00 | 100.00 | 100.00 | 76.19 | |

| Precision | 100.00 | 88.89 | 100.00 | 33.33 | |

| Ball element | Recall | 88.89 | 88.89 | 66.67 | 11.11 |

| F1-score | 94.12 | 88.89 | 80.00 | 16.67 | |

| Precision | 92.31 | 91.67 | 78.57 | 92.31 | |

| Normal | Recall | 100.00 | 91.67 | 91.67 | 100.00 |

| F1-score | 96.00 | 91.67 | 84.62 | 96.00 |

| SymEn | ApEn | SampEn | FuzzyEn | ||

|---|---|---|---|---|---|

| Accuracy | 93.00 ± 5.12 | 91.00 ± 4.54 | 88.50 ± 7.83 | 67.50 ± 3.95 | |

| Precision | 89.67 ± 10.83 | 88.14 ± 11.39 | 88.14 ± 11.39 | 51.90 ± 21.18 | |

| Inner ring | Recall | 100.00 ± 0.00 | 97.78 ± 4.97 | 97.78 ± 4.97 | 49.83 ± 14.68 |

| F1-score | 94.27 ± 6.13 | 92.32 ± 7.08 | 92.32 ± 7.08 | 49.21 ± 13.09 | |

| Precision | 96.00 ± 8.94 | 96.57 ± 4.80 | 93.70 ± 8.80 | 69.31 ± 13.17 | |

| Outer ring | Recall | 92.35 ± 8.39 | 92.57 ± 12.99 | 96.57 ± 4.80 | 88.70 ± 7.29 |

| F1-score | 94.08 ± 8.27 | 93.99 ± 7.24 | 94.88 ± 5.09 | 76.88 ± 7.74 | |

| Precision | 88.95 ± 12.08 | 85.99 ± 14.17 | 86.48 ± 16.34 | 50.33 ± 17.89 | |

| Ball element | Recall | 88.82 ± 10.58 | 77.10 ± 15.24 | 67.84 ± 25.46 | 36.72 ± 21.71 |

| F1-score | 88.71 ± 10.31 | 80.52 ± 12.79 | 74.57 ± 21.12 | 41.10 ± 20.40 | |

| Precision | 98.46 ± 3.44 | 94.40 ± 5.48 | 85.48 ± 11.12 | 98.46 ± 3.44 | |

| Normal | Recall | 89.27 ± 6.67 | 95.83 ± 5.89 | 90.00 ± 10.87 | 92.35 ± 7.48 |

| F1-score | 93.43 ± 2.20 | 95.09 ± 5.45 | 87.44 ± 9.99 | 95.10 ± 3.37 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Li, F.; Jia, R.; Zhai, F.; Bai, L.; Luo, X. Research on the Fault Feature Extraction of Rolling Bearings Based on SGMD-CS and the AdaBoost Framework. Energies 2021, 14, 1555. https://doi.org/10.3390/en14061555

Li H, Li F, Jia R, Zhai F, Bai L, Luo X. Research on the Fault Feature Extraction of Rolling Bearings Based on SGMD-CS and the AdaBoost Framework. Energies. 2021; 14(6):1555. https://doi.org/10.3390/en14061555

Chicago/Turabian StyleLi, Hui, Fan Li, Rong Jia, Fang Zhai, Liang Bai, and Xingqi Luo. 2021. "Research on the Fault Feature Extraction of Rolling Bearings Based on SGMD-CS and the AdaBoost Framework" Energies 14, no. 6: 1555. https://doi.org/10.3390/en14061555

APA StyleLi, H., Li, F., Jia, R., Zhai, F., Bai, L., & Luo, X. (2021). Research on the Fault Feature Extraction of Rolling Bearings Based on SGMD-CS and the AdaBoost Framework. Energies, 14(6), 1555. https://doi.org/10.3390/en14061555