Influence of Silica Nano-Additives on Performance and Emission Characteristics of Soybean Biodiesel Fuelled Diesel Engine

Abstract

:1. Introduction

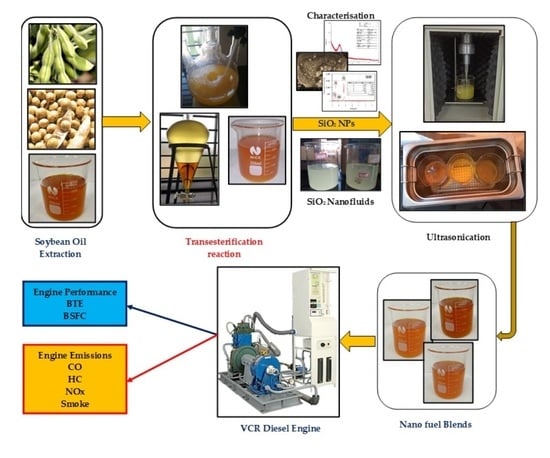

2. Materials and Methodology

2.1. Materials

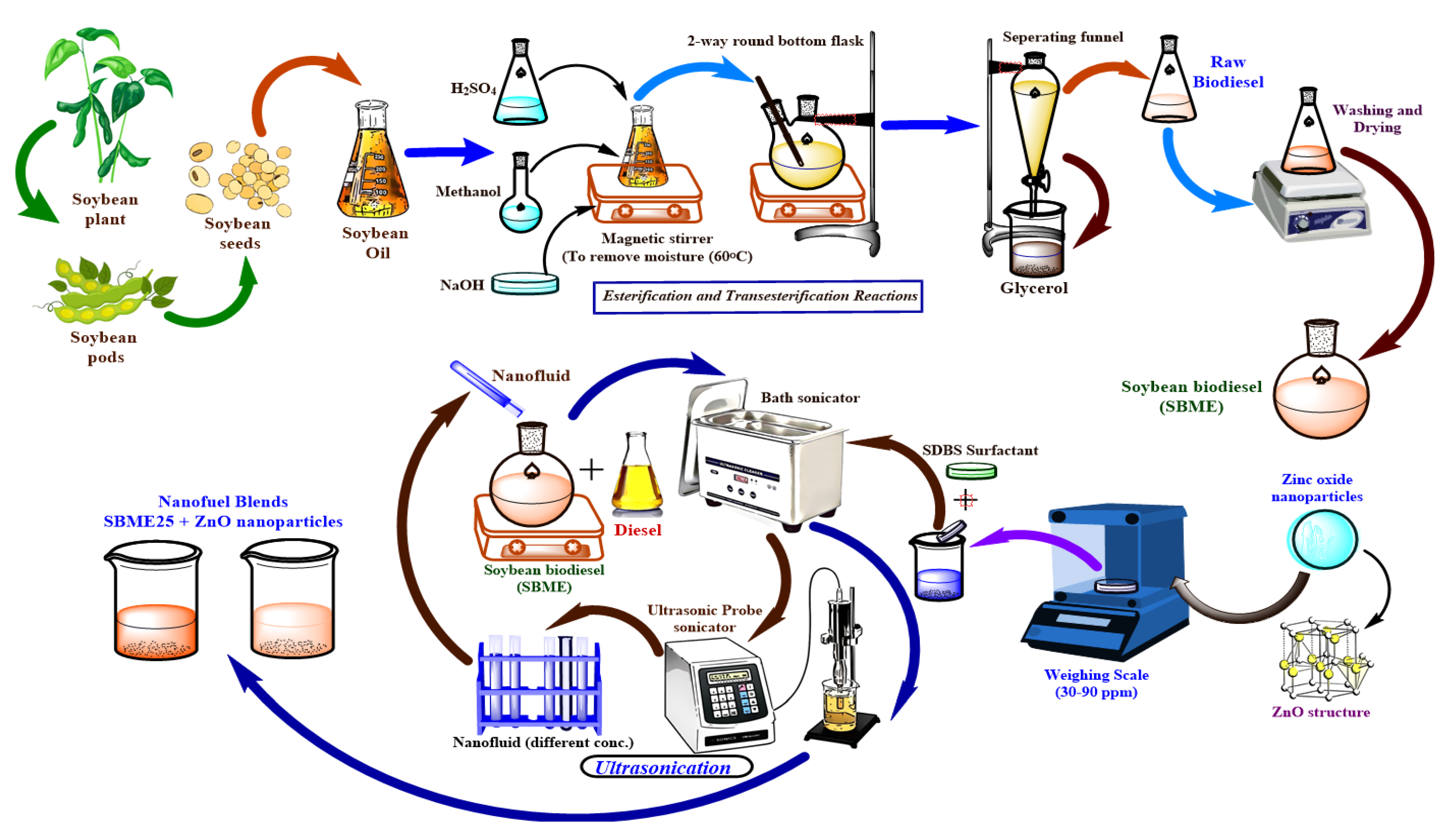

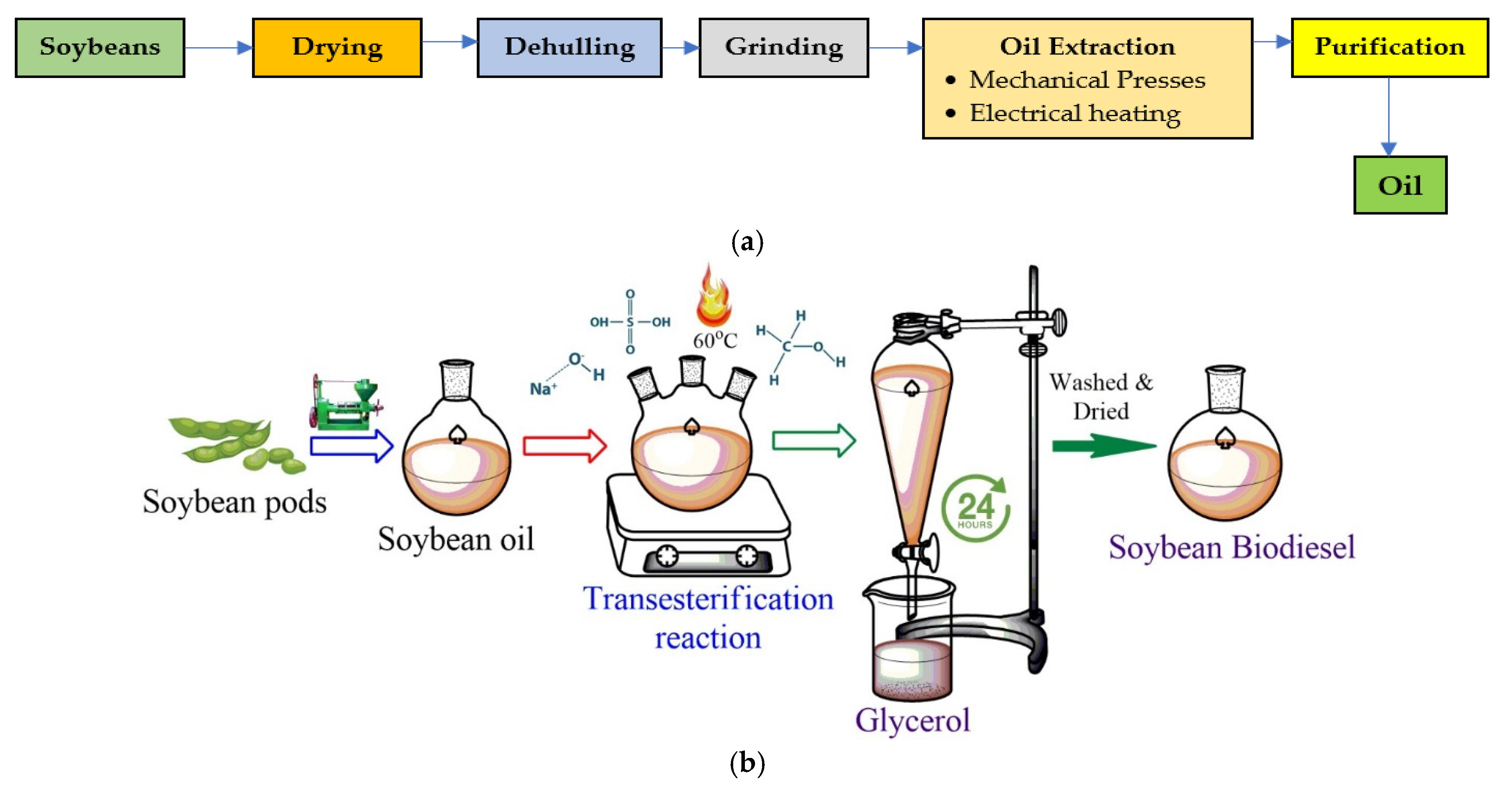

2.2. Preparation of Soybean Biodiesel by Transesterification Process

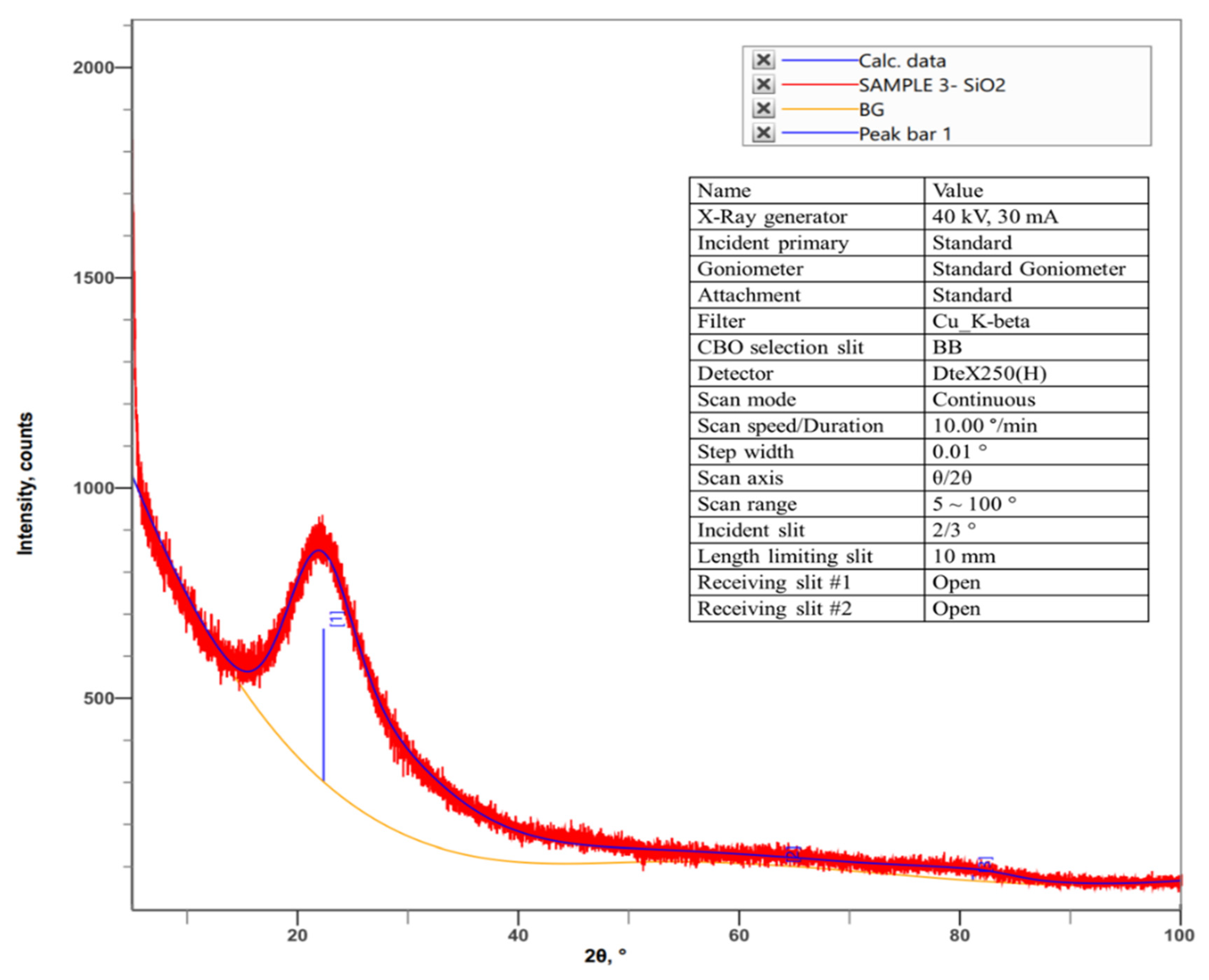

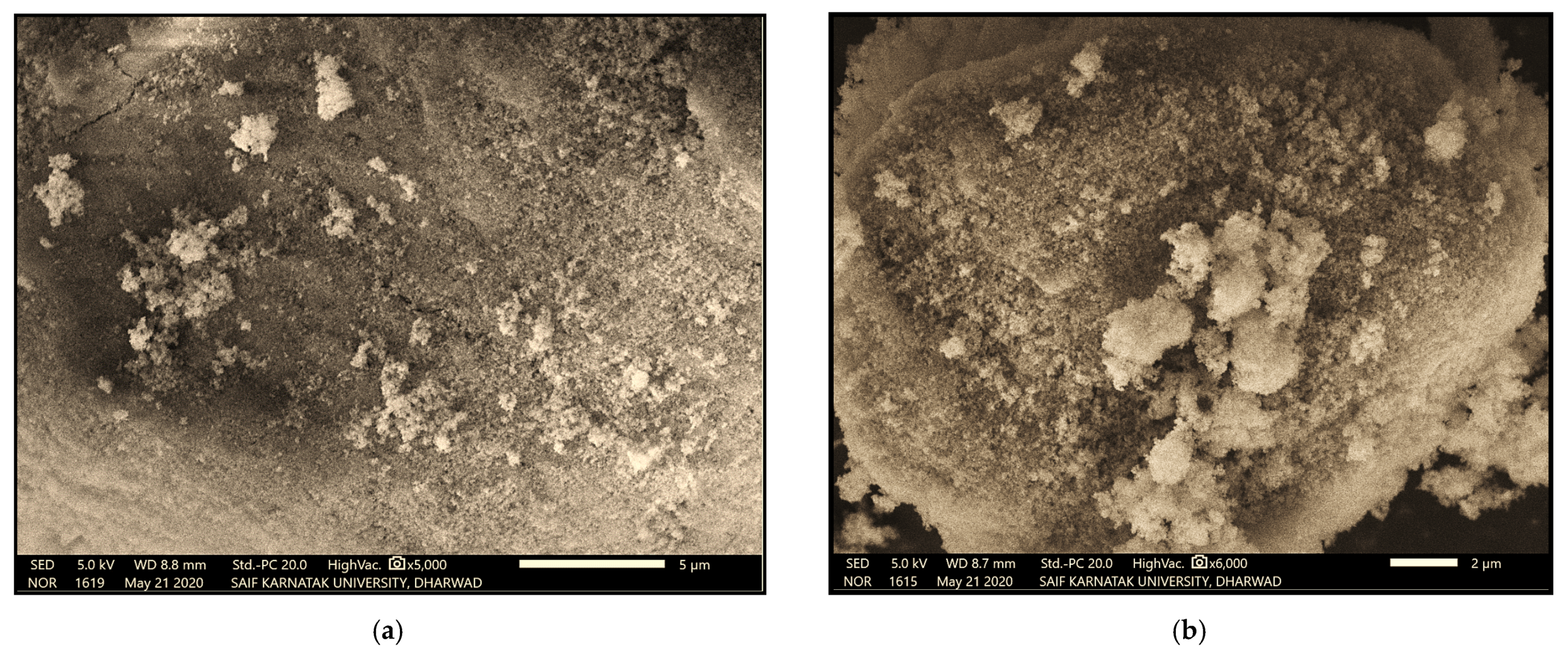

2.3. Characterisation of Silica Nano-Additive

2.4. Preparation and Physicochemical Properties of Nano Fuel Blends

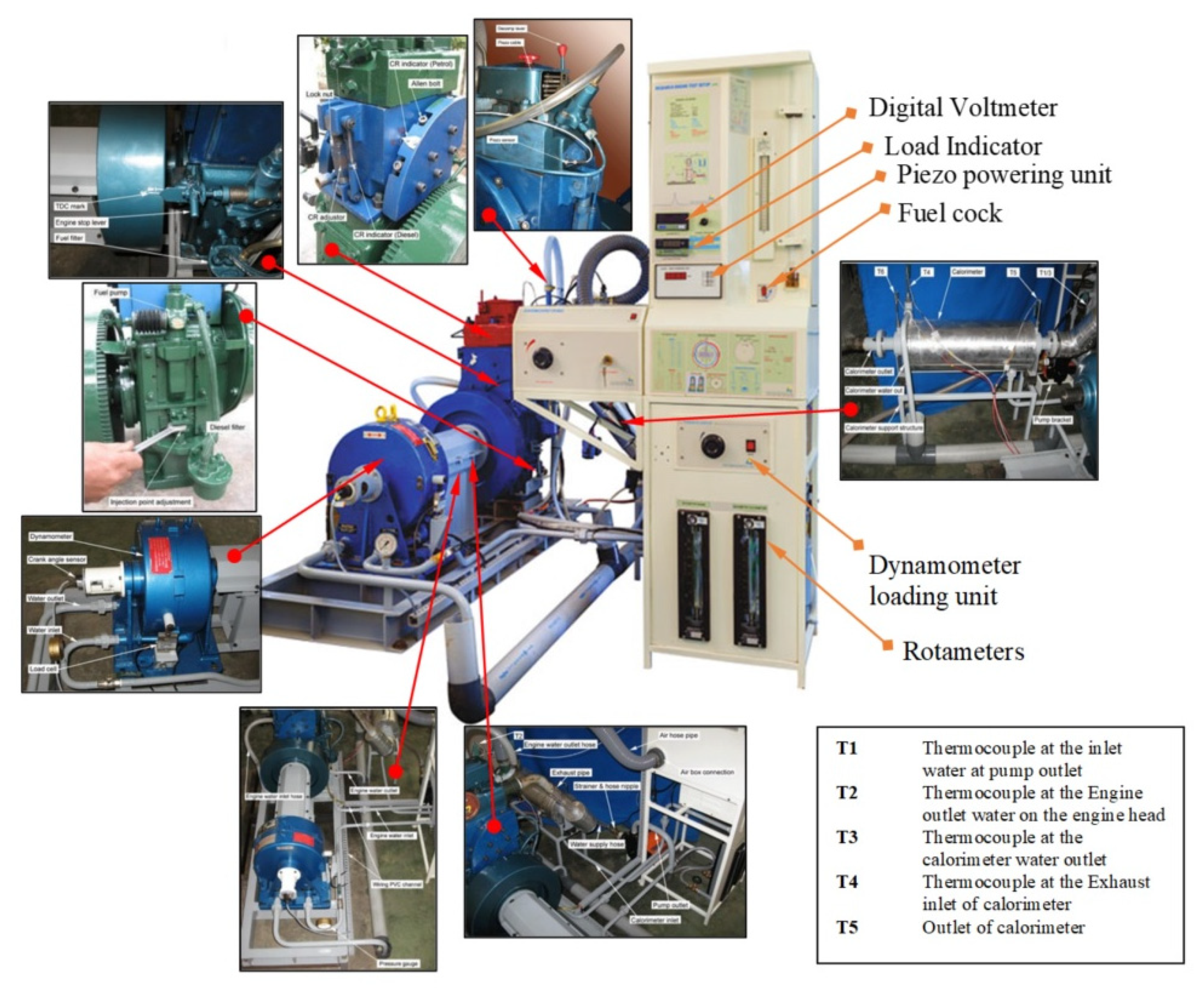

2.5. Test Setup

2.6. Uncertainty Analysis

3. Results and Discussion

3.1. Effect of Nano-Additive on the Performance Parameters

3.1.1. Effect on BTE at Varying Load Condition

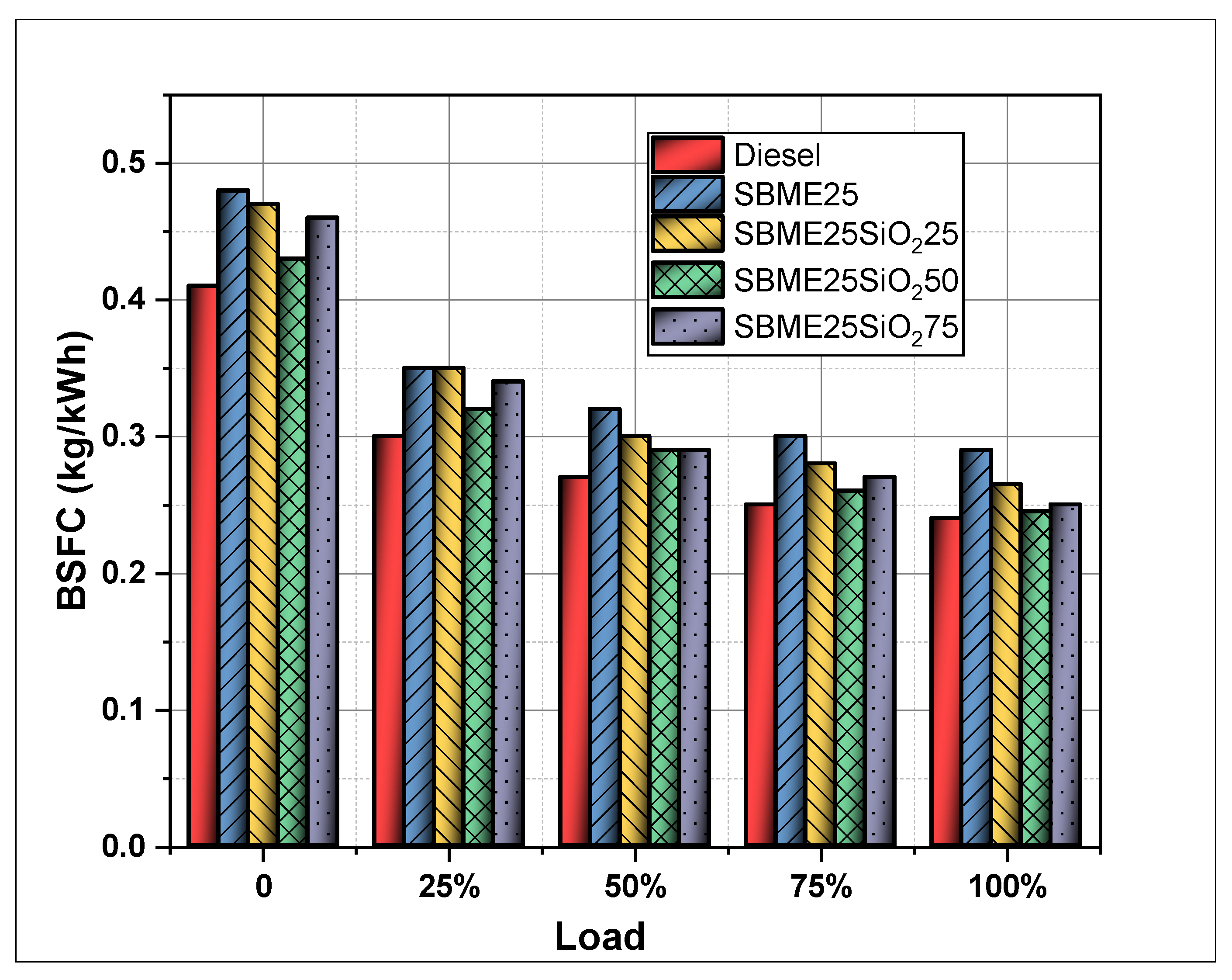

3.1.2. Effect on BSFC at Varying Load Condition

3.2. Effect of Nano-Additive on the Engine Emission Parameters

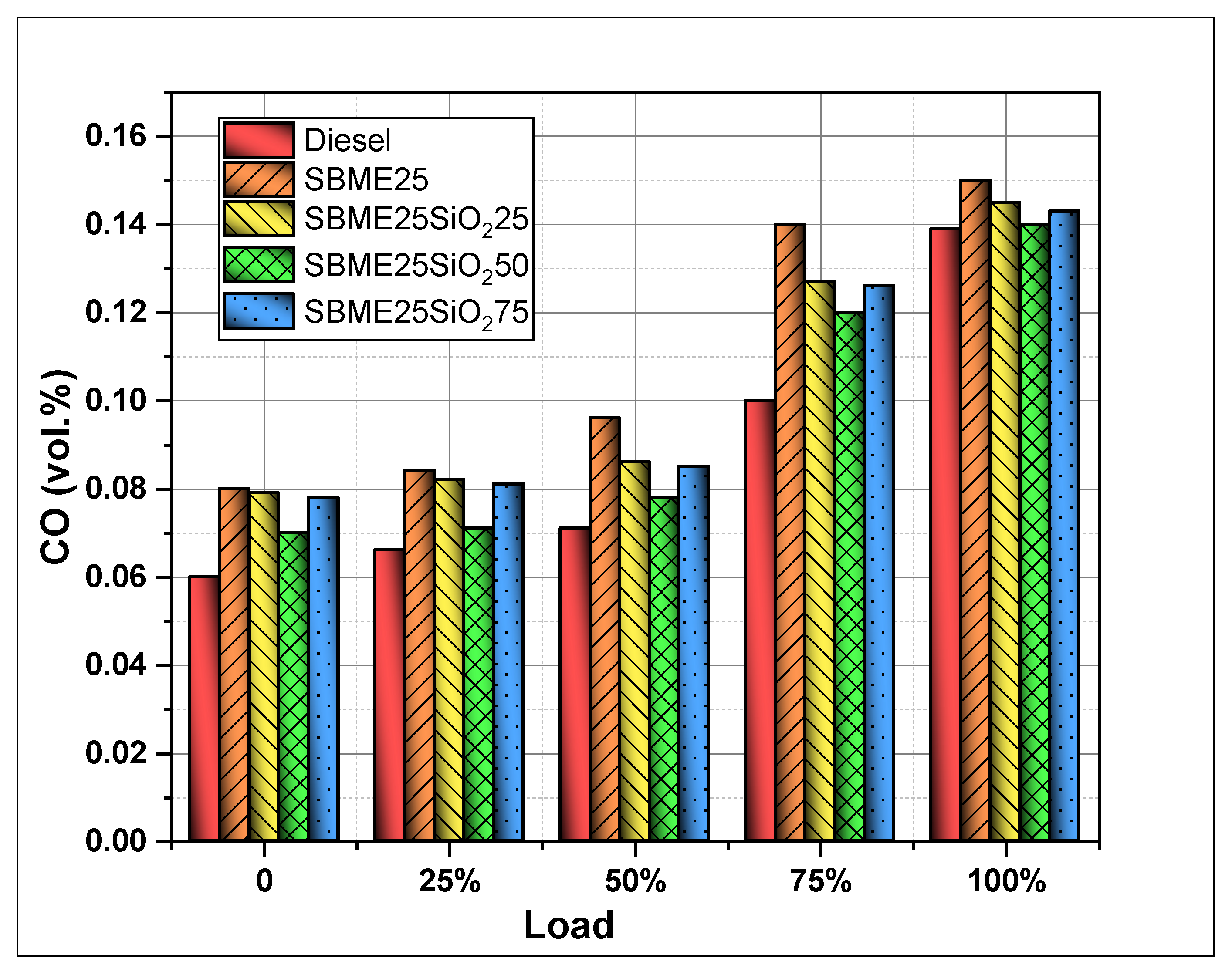

3.2.1. Effect on CO Emission at Varying Load Condition

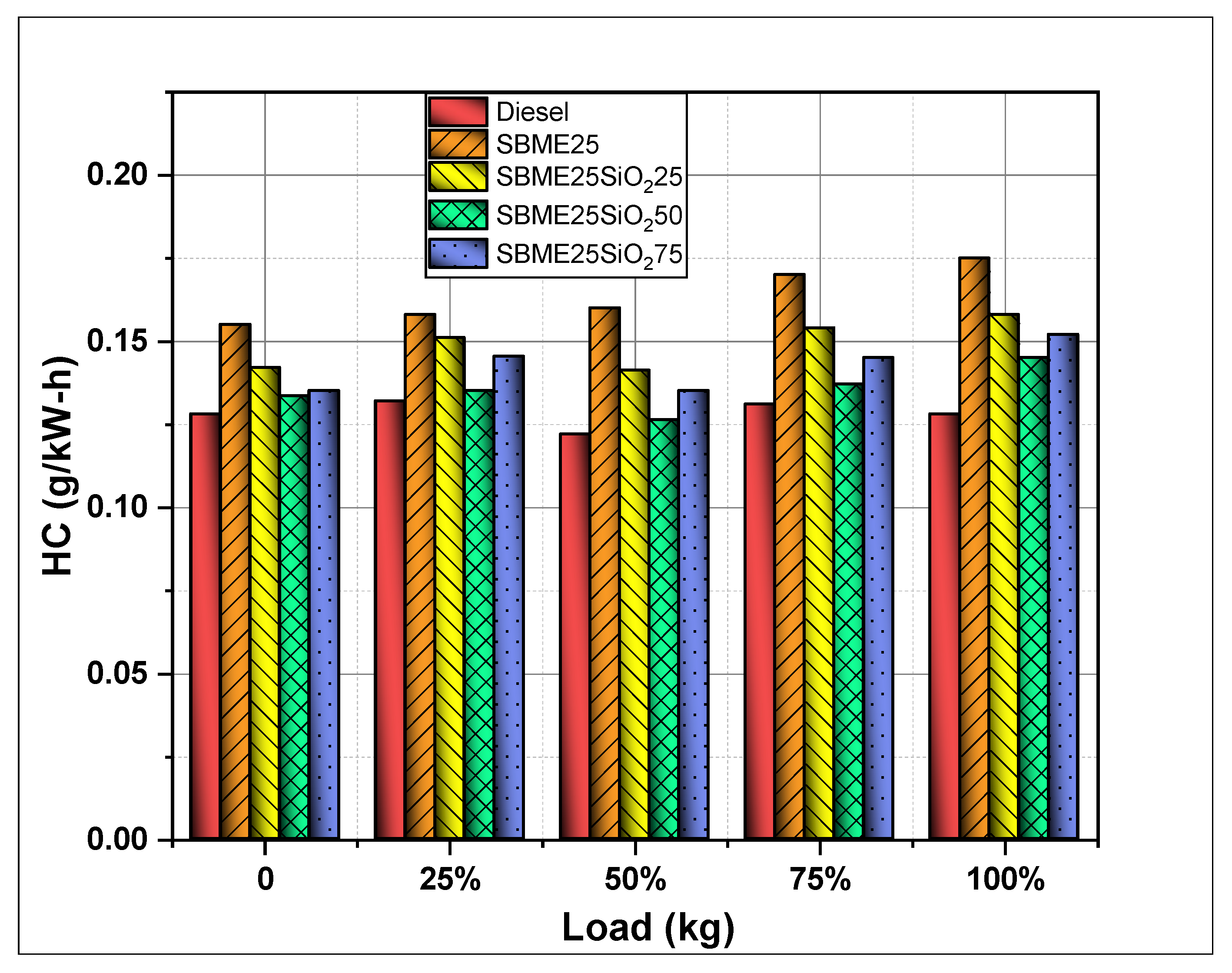

3.2.2. Effect on HC Emission at Varying Load Condition

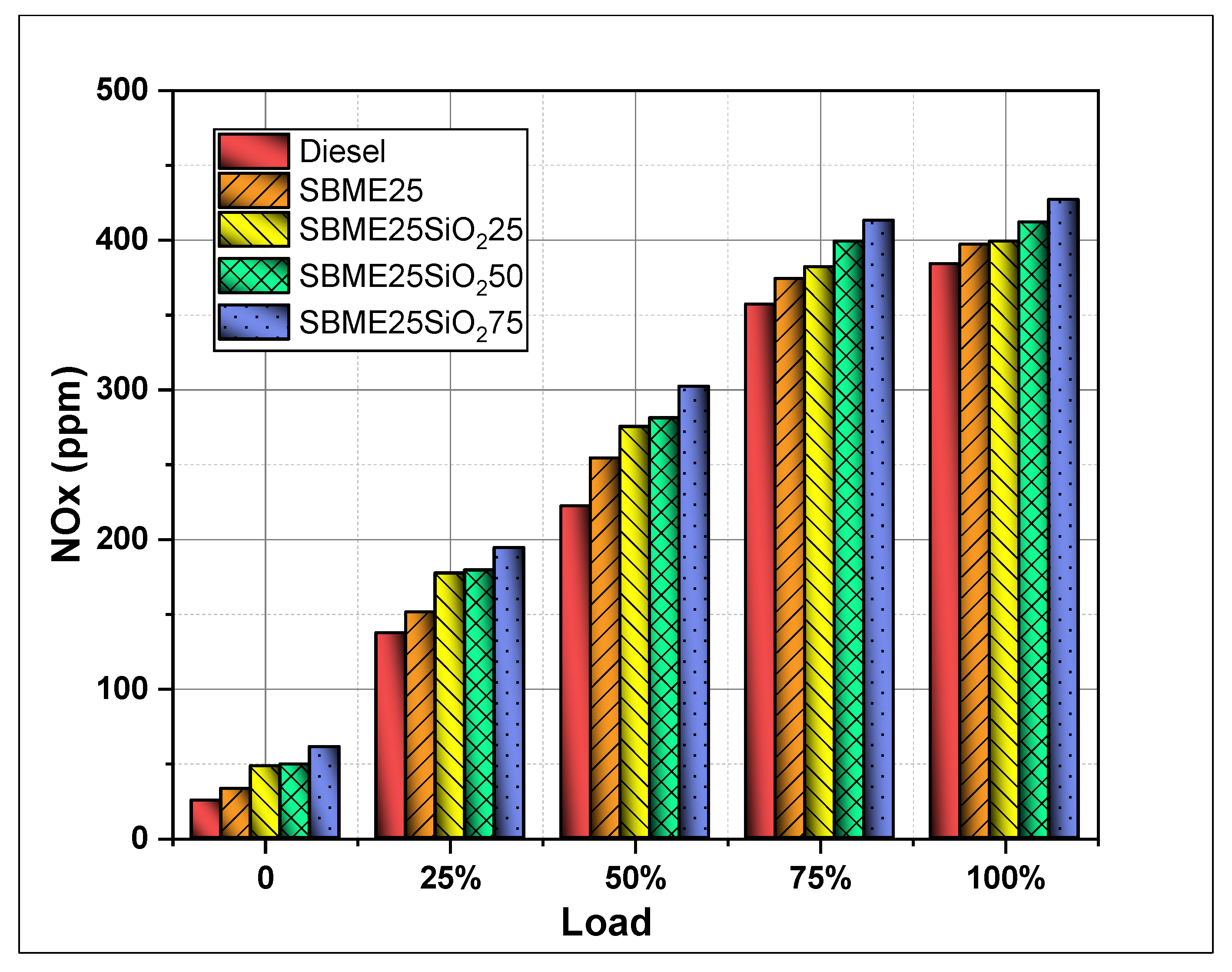

3.2.3. Effect on NOx Emission at Varying Load Condition

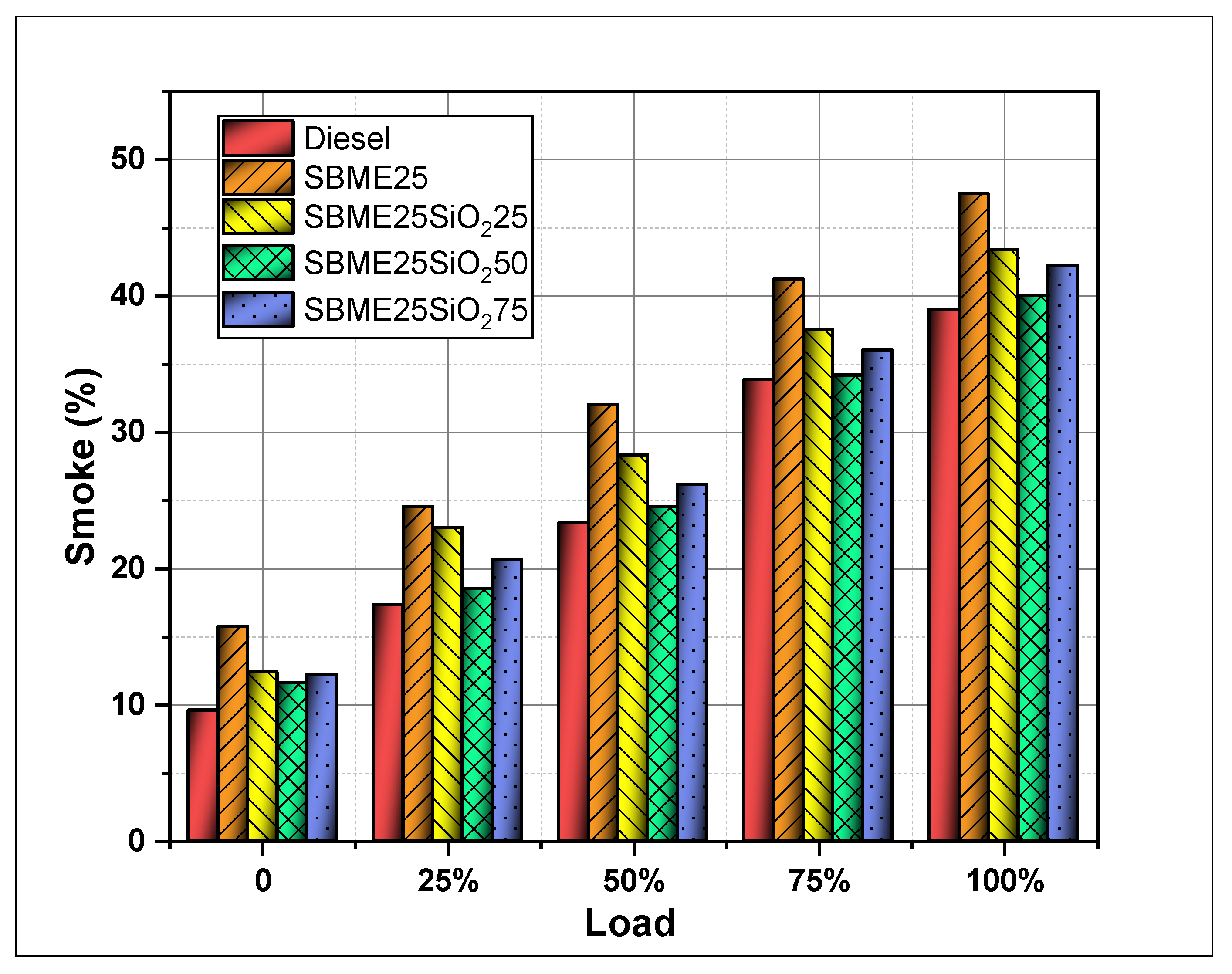

3.2.4. Effect on Smoke Emission at Varying Load Condition

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| NPs | Nanoparticles |

| VCR | Variable Compression Ratio |

| CO2 | Carbon dioxide |

| NOX | Oxides of nitrogen |

| HC | Hydrocarbon |

| BTE | Brake thermal efficiency |

| nm | Nanometre |

| g/kWh | Grams per kilowatt hour |

| ATDC | After top dead centre |

| Sr@ZnO | Strontium coated Zinc oxide |

| SBME25 | 25% Soybean methyl ester |

| blended with diesel | |

| SBME25SiO250 | SBME25 and 50 ppm SiO2 NPs |

| XRD | X-ray diffraction |

| ULSD | Ultra-low sulphur diesel |

| SEM | Scanning electron microscopy |

| SiO2 | Silicon dioxide |

| SDS | Sodium dodecyl sulphate |

| CO | Carbon monoxide |

| PM | Particulate matter |

| °CA | Crank angle (degrees) |

| BSFC | Brake specific fuel consumption |

| ppm | Parts per million |

| MWCNT | Multi-walled Carbon nanotubes |

| BTDC | Before top dead centre |

| SBME | Soybean methyl ester |

| SBME25SiO225 | SBME25 and 25 ppm SiO2 NPs |

| SBME25SiO275 | SBME25 and 75 ppm SiO2 NPs |

| DAQ | Data Acquisition |

| GO | Graphene oxide |

| EDS | Energy Dispersive Spectroscopy |

References

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.A.; Badruddin, I.; Banapurmath, N.; Akram, N. The effect of nano-additives in diesel-biodiesel fuel blends: A comprehensive review on stability, engine performance and emission characteristics. Energy Convers. Manag. 2018, 178, 146–177. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Banapurmath, N.; Afzal, A.; Hossain, N.; Abbas, M.M.; Haniffa, M.A.C.M.; Naik, B.; Ahmed, W.; Nizamuddin, S.; Mubarak, N. Study of diesel engine characteristics by adding nano-sized zinc oxide and diethyl ether additives in Mahua biodiesel–diesel fuel blend. Sci. Rep. 2020, 10, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Soudagar, M.E.M.; Nik-Ghazali, N.-N.; Kalam, M.; Badruddin, I.A.; Banapurmath, N.; Ali, M.A.B.; Kamangar, S.; Cho, H.M.; Akram, N. An investigation on the influence of aluminium oxide nano-additive and honge oil methyl ester on engine performance, combustion and emission characteristics. Renew. Energy 2020, 146, 2291–2307. [Google Scholar] [CrossRef]

- Shahir, S.; Masjuki, H.; Kalam, M.; Imran, A.; Fattah, I.R.; Sanjid, A. Feasibility of diesel–biodiesel–ethanol/bioethanol blend as existing CI engine fuel: An assessment of properties, material compatibility, safety and combustion. Renew. Sustain. Energy Rev. 2014, 32, 379–395. [Google Scholar] [CrossRef]

- Imtenan, S.; Varman, M.; Masjuki, H.; Kalam, M.; Sajjad, H.; Arbab, M.; Fattah, I.R. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

- Fattah, I.R.; Masjuki, H.; Kalam, M.; Hazrat, M.; Masum, B.; Imtenan, S.; Ashraful, A. Effect of antioxidants on oxidation stability of biodiesel derived from vegetable and animal based feedstocks. Renew. Sustain. Energy Rev. 2014, 30, 356–370. [Google Scholar] [CrossRef]

- Khan, H.; Soudagar, M.E.M.; Kumar, R.H.; Safaei, M.R.; Farooq, M.; Khidmatgar, A.; Banapurmath, N.R.; Farade, R.A.; Abbas, M.M.; Afzal, A. Effect of Nano-Graphene Oxide and n-Butanol Fuel Additives Blended with Diesel—Nigella sativa Biodiesel Fuel Emulsion on Diesel Engine Characteristics. Symmetry 2020, 12, 961. [Google Scholar] [CrossRef]

- Rahman, S.M.A.; Fattah, I.M.R.; Maitra, S.; Mahlia, T.M.I. A ranking scheme for biodiesel underpinned by critical physicochemical properties. Energy Convers. Manag. 2021, 229, 113742. [Google Scholar] [CrossRef]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Rizwanul Fattah, I.M.; Mobarak, H.M. Comparative evaluation of performance and emission characteristics of Moringa oleifera and Palm oil based biodiesel in a diesel engine. Ind. Crops Prod. 2014, 53, 78–84. [Google Scholar] [CrossRef]

- Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A.; Mofijur, M.; Abedin, M.J. Effect of antioxidant on the performance and emission characteristics of a diesel engine fueled with palm biodiesel blends. Energy Convers. Manag. 2014, 79, 265–272. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Pawar, A.; Soudagar, M.E.M.; Fayaz, H. Effect of Soybean biodiesel and Copper coated Zinc oxide Nanoparticles on Enhancement of Diesel Engine Characteristics. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–19. [Google Scholar] [CrossRef]

- Palash, S.M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E.; Rizwanul Fattah, I.M.; Sanjid, A. Biodiesel production, characterisation, diesel engine performance, and emission characteristics of methyl esters from Aphanamixis polystachya oil of Bangladesh. Energy Convers. Manag. 2015, 91, 149–157. [Google Scholar] [CrossRef] [Green Version]

- Özener, O.; Yüksek, L.; Ergenç, A.T.; Özkan, M. Effects of soybean biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 2014, 115, 875–883. [Google Scholar] [CrossRef]

- Seraç, M.R.; Aydın, S.; Yılmaz, A.; Şevik, S. Evaluation of comparative combustion, performance, and emission of soybean-based alternative biodiesel fuel blends in a CI engine. Renew. Energy 2020, 148, 1065–1073. [Google Scholar] [CrossRef]

- Fayaz, H.; Mujtaba, M.A.; Soudagar, M.E.M.; Razzaq, L.; Nawaz, S.; Nawaz, M.A.; Farooq, M.; Afzal, A.; Ahmed, W.; Khan, T.M.Y.; et al. Collective effect of ternary nano fuel blends on the diesel engine performance and emissions characteristics. Fuel 2021, 293, 120420. [Google Scholar] [CrossRef]

- Ong, H.C.; Tiong, Y.W.; Goh, B.H.H.; Gan, Y.Y.; Mofijur, M.; Fattah, I.M.R.; Chong, C.T.; Alam, M.A.; Lee, H.V.; Silitonga, A.S.; et al. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energy Convers. Manag. 2020, 113647. [Google Scholar] [CrossRef]

- Razzaq, L.; Mujtaba, M.A.; Soudagar, M.E.M.; Ahmed, W.; Fayaz, H.; Bashir, S.; Fattah, I.M.R.; Ong, H.C.; Shahapurkar, K.; Afzal, A.; et al. Engine performance and emission characteristics of palm biodiesel blends with graphene oxide nanoplatelets and dimethyl carbonate additives. J. Environ. Manag. 2021, 282, 111917. [Google Scholar] [CrossRef] [PubMed]

- Hussain, F.; Soudagar, M.E.M.; Afzal, A.; Mujtaba, M.; Fattah, I.M.R.; Naik, B.; Mulla, M.H.; Badruddin, I.A.; Khan, T.M.Y.; Raju, V.D.; et al. Enhancement in Combustion, Performance, and Emission Characteristics of a Diesel Engine Fueled with Ce-ZnO Nanoparticle Additive Added to Soybean Biodiesel Blends. Energies 2020, 13, 4578. [Google Scholar] [CrossRef]

- Mujtaba, M.; Kalam, M.; Masjuki, H.; Gul, M.; Soudagar, M.E.M.; Ong, H.C.; Ahmed, W.; Atabani, A.; Razzaq, L.; Yusoff, M. Comparative study of nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for performance and emission improvements. Fuel 2020, 279, 118434. [Google Scholar] [CrossRef]

- Gavhane, R.S.; Kate, A.M.; Pawar, A.; Safaei, M.R.; Soudagar, M.E.M.; Abbas, M.M.; Ali, H.M.; Banapurmath, N.R.; Goodarzi, M.; Badruddin, I.A.; et al. Effect of Zinc Oxide Nano-Additives and Soybean Biodiesel at Varying Loads and Compression Ratios on VCR Diesel Engine Characteristics. Symmetry 2020, 12, 1042. [Google Scholar] [CrossRef]

- Najafi, G. Diesel engine combustion characteristics using nanoparticles in biodiesel-diesel blends. Fuel 2018, 212, 668–678. [Google Scholar] [CrossRef]

- Mujtaba, M.; Masjuki, H.; Kalam, M.; Noor, F.; Farooq, M.; Ong, H.C.; Gul, M.; Soudagar, M.E.M.; Bashir, S.; Rizwanul Fattah, I. Effect of Additivized Biodiesel Blends on Diesel Engine Performance, Emission, Tribological Characteristics, and Lubricant Tribology. Energies 2020, 13, 3375. [Google Scholar] [CrossRef]

- Ghanbari, M.; Najafi, G.; Ghobadian, B.; Yusaf, T.; Carlucci, A.; Kiani, M.K.D. Performance and emission characteristics of a CI engine using nano particles additives in biodiesel-diesel blends and modeling with GP approach. Fuel 2017, 202, 699–716. [Google Scholar] [CrossRef]

- Adzmi, M.A.; Abdullah, A.; Abdullah, Z.; Mrwan, A.G. Effect of Al2O3 and SiO2 Metal Oxide Nanoparticles Blended with POME on Combustion, Performance and Emissions Characteristics of a Diesel Engine. Int. J. Automot. Mech. Eng. 2019, 16, 6859–6873. [Google Scholar] [CrossRef] [Green Version]

- Saravankumar, P.T.; Suresh, V.; Vijayan, V.; Godwin Antony, A. Ecological effect of corn oil biofuel with SiO2 nano-additives. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2845–2852. [Google Scholar] [CrossRef]

- Özgür, T.; Özcanli, M.; Aydin, K. Investigation of Nanoparticle Additives to Biodiesel for Improvement of the Performance and Exhaust Emissions in a Compression Ignition Engine. Int. J. Green Energy 2015, 12, 51–56. [Google Scholar] [CrossRef]

- Habibullah, M.; Masjuki, H.H.; Kalam, M.A.; Rizwanul Fattah, I.M.; Ashraful, A.M.; Mobarak, H.M. Biodiesel production and performance evaluation of coconut, palm and their combined blend with diesel in a single-cylinder diesel engine. Energy Convers. Manag. 2014, 87, 250–257. [Google Scholar] [CrossRef]

- Her, Y.-S.; Lee, S.-H.; Matijević, E. Continuous precipitation of monodispersed colloidal particles. II. SiO2, Al(OH)3, and BaTiO3. J. Mater. Res. 1996, 11, 156–161. [Google Scholar] [CrossRef]

- Bajpai, N.; Tiwari, A.; Khan, S.; Kher, R.; Bramhe, N.; Dhoble, S. Effects of rare earth ions (Tb, Ce, Eu, Dy) on the thermoluminescence characteristics of sol–gel derived and γ-irradiated SiO2 nanoparticles. Luminescence 2014, 29, 669–673. [Google Scholar] [CrossRef]

- Tabatabaei, S.; Shukohfar, A.; Aghababazadeh, R.; Mirhabibi, A. Experimental study of the synthesis and characterisation of silica nanoparticles via the sol-gel method. In Proceedings of Journal of Physics: Conference Series; IOP Publishing Ltd.: Bristol, UK, 2006; p. 371. [Google Scholar]

- Musić, S.; Filipović-Vinceković, N.; Sekovanić, L. Precipitation of amorphous SiO2 particles and their properties. Braz. J. Chem. Eng. 2011, 28, 89–94. [Google Scholar] [CrossRef]

- Soudagar, M.E.M.; Mujtaba, M.; Safaei, M.R.; Afzal, A.; Ahmed, W.; Banapurmath, N.; Hossain, N.; Bashir, S.; Badruddin, I.A.; Goodarzi, M. Effect of Sr@ ZnO nanoparticles and Ricinus communis biodiesel-diesel fuel blends on modified CRDI diesel engine characteristics. Energy 2020, 215, 119094. [Google Scholar] [CrossRef]

- Hoseini, S.; Najafi, G.; Ghobadian, B.; Ebadi, M.; Mamat, R.; Yusaf, T. Performance and emission characteristics of a CI engine using graphene oxide (GO) nano-particles additives in biodiesel-diesel blends. Renew. Energy 2020, 145, 458–465. [Google Scholar] [CrossRef]

- Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A.; Wakil, M.A.; Ashraful, A.M.; Shahir, S.A. Experimental investigation of performance and regulated emissions of a diesel engine with Calophyllum inophyllum biodiesel blends accompanied by oxidation inhibitors. Energy Convers. Manag. 2014, 83, 232–240. [Google Scholar] [CrossRef]

- Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A.; Wakil, M.A.; Rashedul, H.K.; Abedin, M.J. Performance and emission characteristics of a CI engine fueled with Cocos nucifera and Jatropha curcas B20 blends accompanying antioxidants. Ind. Crops Prod. 2014, 57, 132–140. [Google Scholar] [CrossRef]

- El-Seesy, A.I.; Abdel-Rahman, A.K.; Bady, M.; Ookawara, S. Performance, combustion, and emission characteristics of a diesel engine fueled by biodiesel-diesel mixtures with multi-walled carbon nanotubes additives. Energy Convers. Manag. 2017, 135, 373–393. [Google Scholar] [CrossRef]

- Basha, J.S. An Experimental Analysis of a Diesel Engine Using Alumina Nanoparticles Blended DIESEL fuel; 0148-7191; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2014. [Google Scholar]

- Harari, P.; Banapurmath, N.; Yaliwal, V.; Khan, T.Y.; Soudagar, M.E.M.; Sajjan, A. Experimental studies on performance and emission characteristics of reactivity controlled compression ignition (RCCI) engine operated with gasoline and Thevetia Peruviana biodiesel. Renew. Energy 2020, 160, 865–875. [Google Scholar] [CrossRef]

- Akkoli, K.M.; Banapurmath, N.R.; Shivashimpi, M.M.; Soudagar, M.E.M.; Badruddin, I.A.; Alazwari, M.A.; Yaliwal, V.S.; Mujtaba, M.A.; Akram, N.; Goodarzi, M.; et al. Effect of injection parameters and producer gas derived from redgram stalk on the performance and emission characteristics of a diesel engine. Alex. Eng. J. 2021, 60, 3133–3142. [Google Scholar] [CrossRef]

- Ming, C.; Rizwanul Fattah, I.M.; Chan, Q.N.; Pham, P.X.; Medwell, P.R.; Kook, S.; Yeoh, G.H.; Hawkes, E.R.; Masri, A.R. Combustion scharacterisation of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel 2018, 224, 167–177. [Google Scholar] [CrossRef]

- Sayin, C.; Ilhan, M.; Canakci, M.; Gumus, M. Effect of injection timing on the exhaust emissions of a diesel engine using diesel–methanol blends. Renew. Energy 2009, 34, 1261–1269. [Google Scholar] [CrossRef]

- Soudagar, M.; Afzal, A.; Kareemullah, M. Waste coconut oil methyl ester with and without additives as an alternative fuel in diesel engine at two different injection pressures. Energy Sources Part A Recovery Util. Environ. Eff. 2020. [Google Scholar] [CrossRef]

| Property | Units | Diesel | SBME25 | SBME25SiO225 | SBME25SiO250 | SBME25SiO275 |

|---|---|---|---|---|---|---|

| Density @25 °C | kg/m3 | 830 | 876 | 842 | 844 | 845 |

| Heating Value | kJ/kg | 43,994 | 40,884 | 41,312 | 42,459 | 42,489 |

| Flash Point | °C | 70 | 86 | 81 | 79 | 78 |

| Fire Point | °C | 76 | 98 | 86 | 85 | 83 |

| Cloud Point | °C | −6 | −2 | −2 | −3 | −3 |

| Pour Point | °C | −10 | −5 | −9 | −7 | −8 |

| Kinematic Viscosity @40 °C | CSt | 2.8 | 4.72 | 5.4 | 5.3 | 5.3 |

| Parameter | Specification |

|---|---|

| Rated Power | 5 HP@ 1800 rpm |

| Bore | 87.5 mm |

| Stroke | 110 mm |

| Connecting Rod Length | 232 mm |

| Compression Ratio | 5 to 11 for SI mode and 12 to 21.5 for CI mode |

| Type | 4 Stroke, Single Cylinder |

| Fuel tank | 15 L with glass fuel metering column |

| Piezo sensor | Range 5000 psi, with low noise cable |

| Temperature sensor | RTD, PT100 and thermocouple type K |

| Rotameter | Eureka, Engine cooling 40–400 LPH; Calorimeter 25–250 LPH |

| Temperature sensor | Radix, Type RTD, PT100 and Thermocouple, Type K |

| Load sensor | Load cell, strain gauge type, range: 0–50 kg |

| Dynamometer | Type eddy current, water-cooled with loading unit |

| Crank angle sensor | Kübler Germany, Resolution 1 Deg, Speed 5500 RPM with top dead centre (TDC) pulse |

| Piezo pressure transducer | Make: Kistler |

| Parameters | Accuracy (±) | Uncertainty (%) |

|---|---|---|

| BP (kW) | - | ±0.4 |

| BTE (%) | - | ±0.4 |

| BSFC (%) | - | ±0.4 |

| CO emission (%) | ±0.01% | ±0.3 |

| NOx emission (ppm) | ±8 ppm | ±0.5 |

| HC emission (ppm) | ±8 ppm | ±0.4 |

| Smoke meter (HSU) | ±1 | ±0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gavhane, R.S.; Kate, A.M.; Soudagar, M.E.M.; Wakchaure, V.D.; Balgude, S.; Rizwanul Fattah, I.M.; Nik-Ghazali, N.-N.; Fayaz, H.; Khan, T.M.Y.; Mujtaba, M.A.; et al. Influence of Silica Nano-Additives on Performance and Emission Characteristics of Soybean Biodiesel Fuelled Diesel Engine. Energies 2021, 14, 1489. https://doi.org/10.3390/en14051489

Gavhane RS, Kate AM, Soudagar MEM, Wakchaure VD, Balgude S, Rizwanul Fattah IM, Nik-Ghazali N-N, Fayaz H, Khan TMY, Mujtaba MA, et al. Influence of Silica Nano-Additives on Performance and Emission Characteristics of Soybean Biodiesel Fuelled Diesel Engine. Energies. 2021; 14(5):1489. https://doi.org/10.3390/en14051489

Chicago/Turabian StyleGavhane, R. S., A. M. Kate, Manzoore Elahi M. Soudagar, V. D. Wakchaure, Sagar Balgude, I. M. Rizwanul Fattah, Nik-Nazri Nik-Ghazali, H. Fayaz, T. M. Yunus Khan, M. A. Mujtaba, and et al. 2021. "Influence of Silica Nano-Additives on Performance and Emission Characteristics of Soybean Biodiesel Fuelled Diesel Engine" Energies 14, no. 5: 1489. https://doi.org/10.3390/en14051489