Effect of Ethanol Additives on Combustion and Emissions of a Diesel Engine Fueled by Palm Oil Biodiesel at Idling Speed

Abstract

1. Introduction

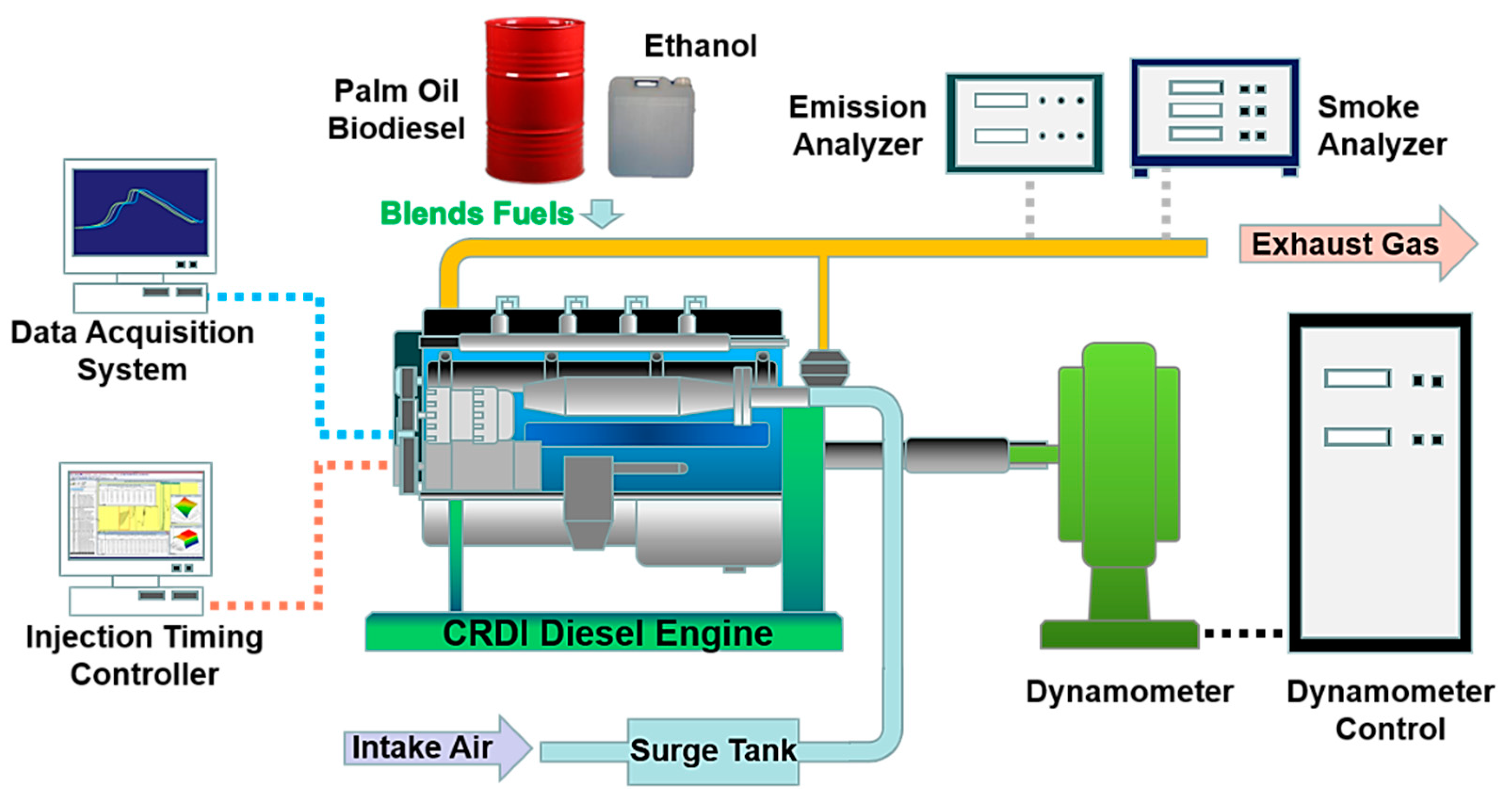

2. Experimental Setup and Procedure

2.1. Test Fuels

2.2. Test Engine and Operating Methods

3. Results and Discussion

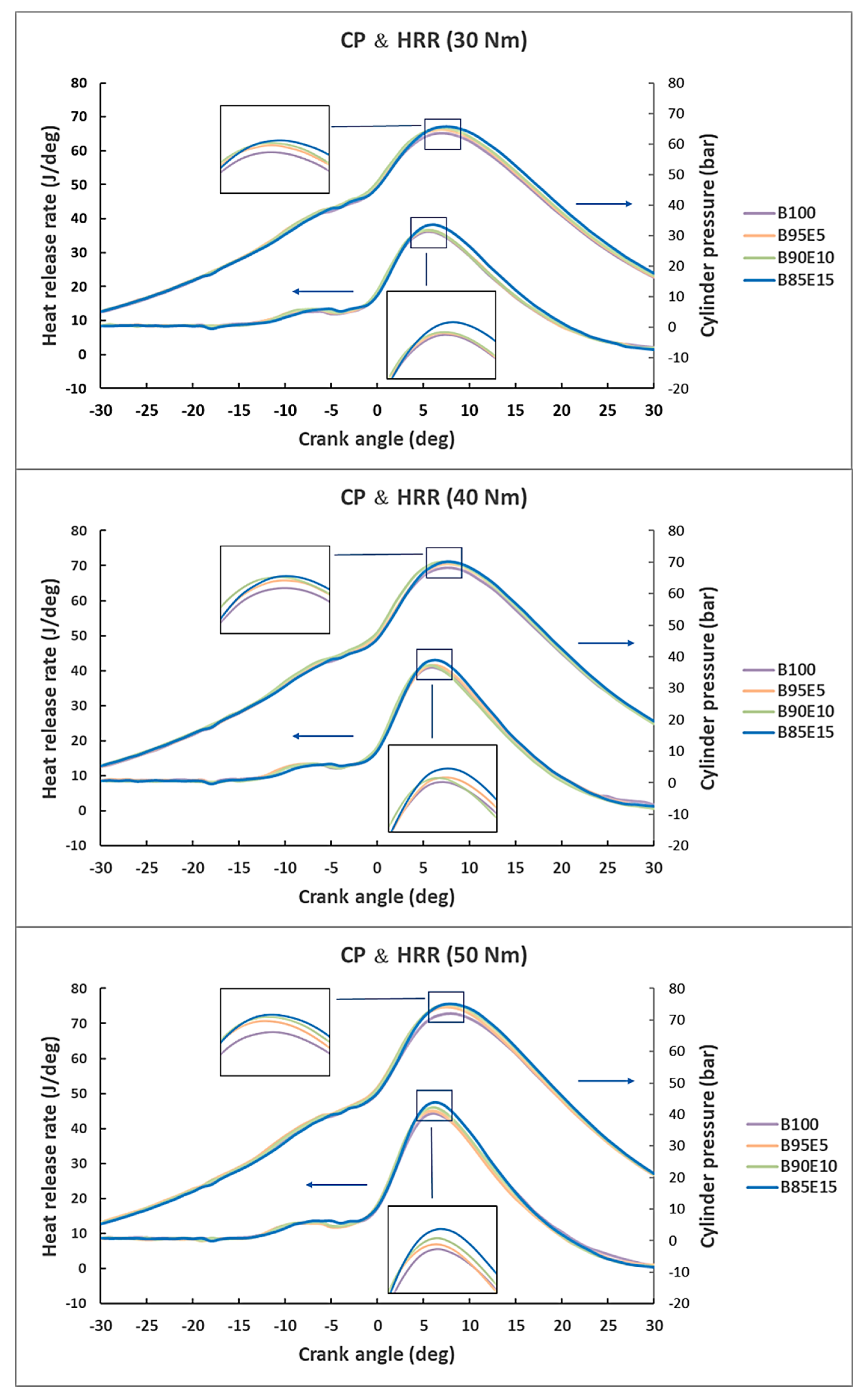

3.1. Combustion Characteristics

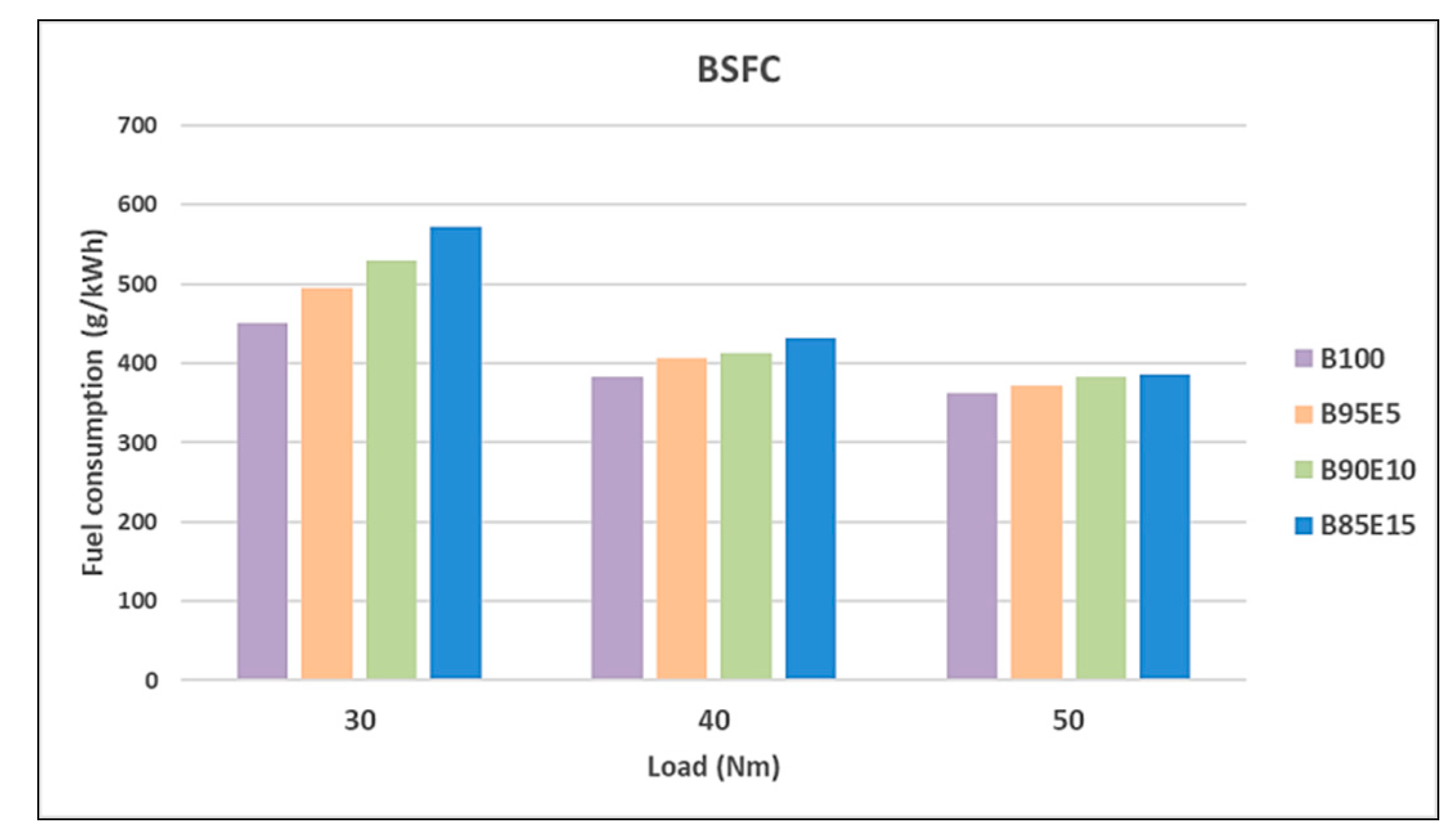

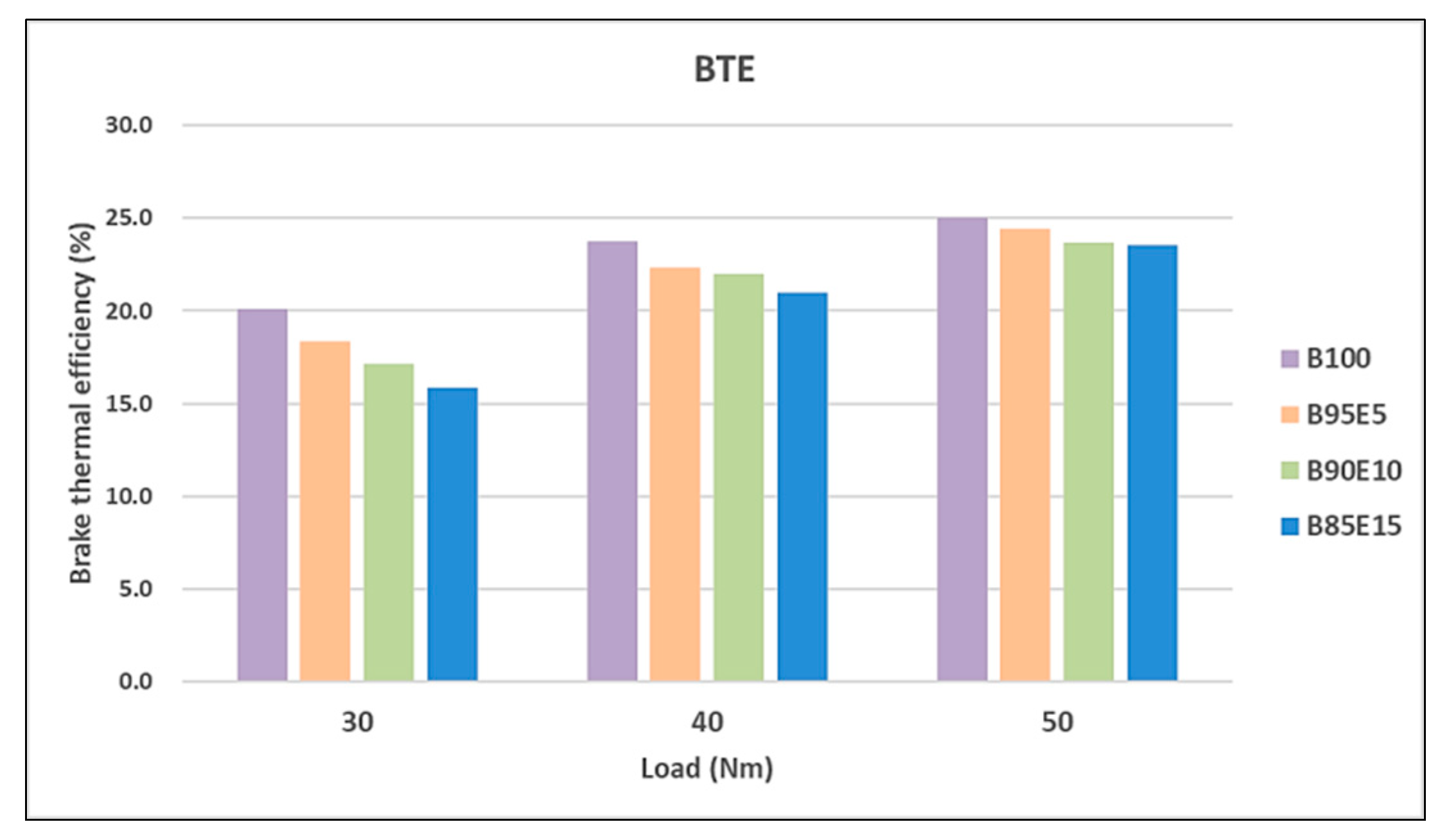

3.2. Engine Performance

3.3. Emissions Characteristics

4. Conclusions

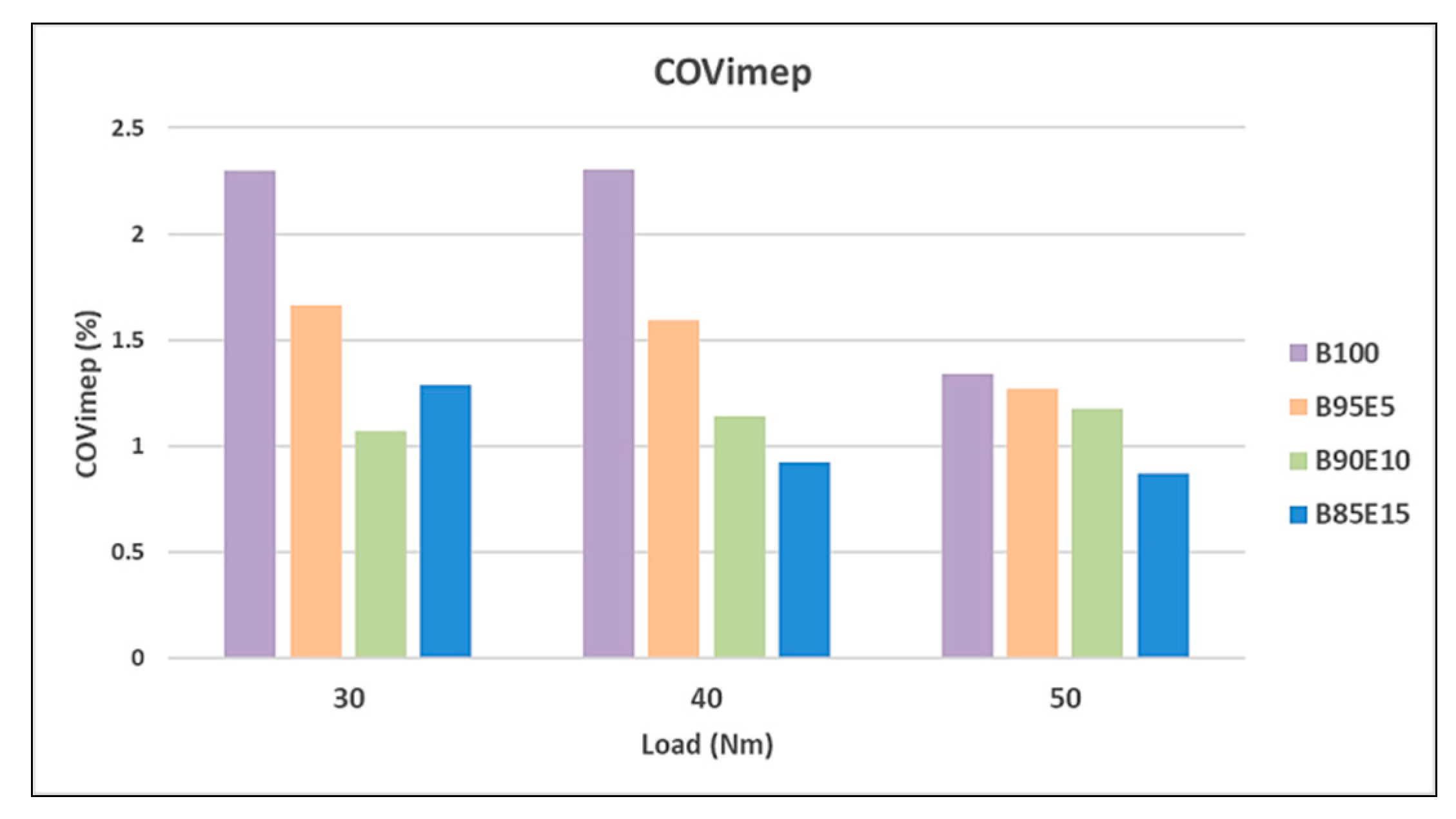

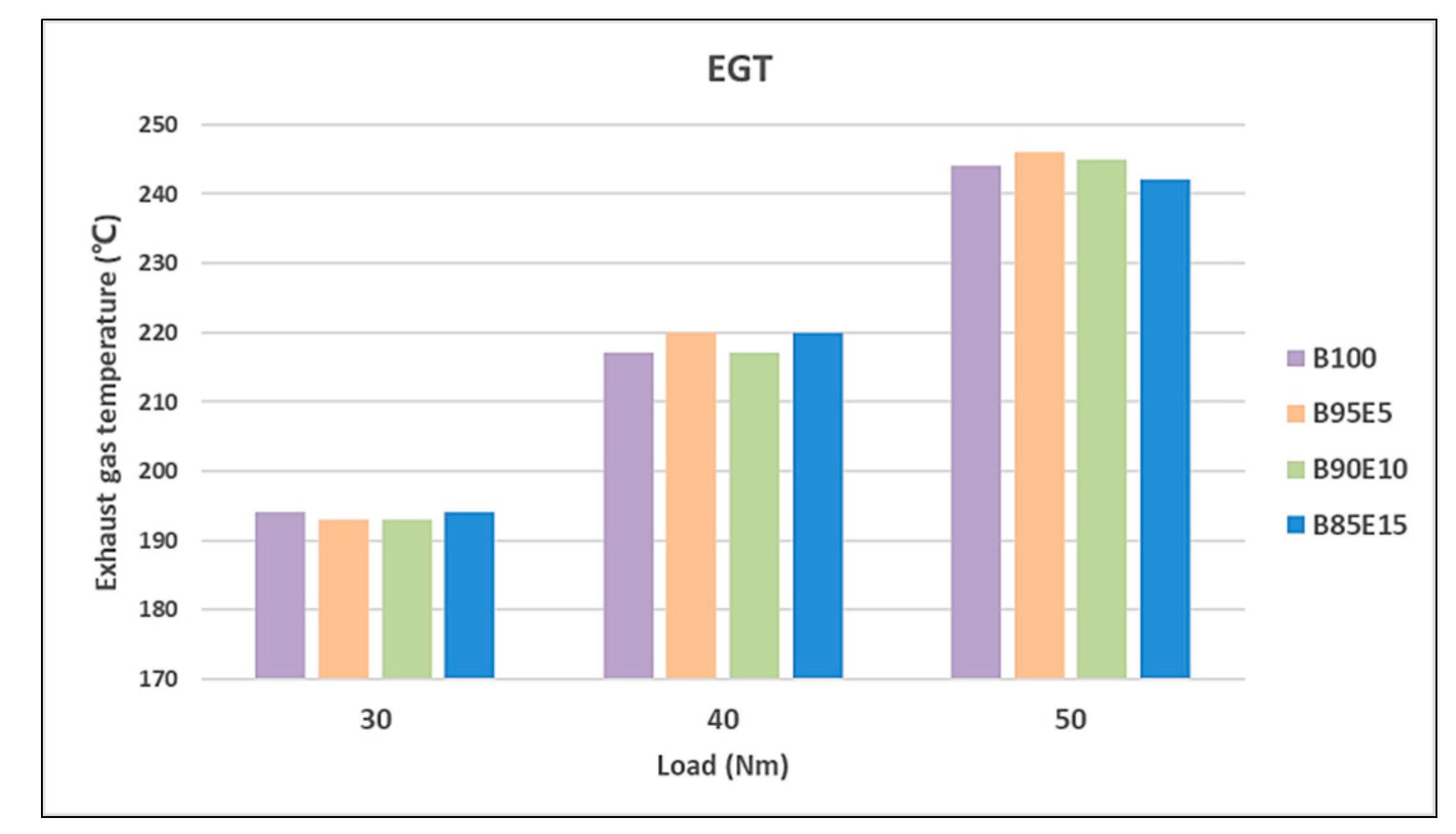

- Although the addition of ethanol significantly enhances the BSFC, increasing the load can reduce it. The trend of BTE is opposite that of the BSFC as it decreases with increasing load and with increasing ethanol concentration. Increasing the ethanol content and load reduces the COVimep. EGT also increases significantly with increasing load, but the effect of ethanol is not obvious.

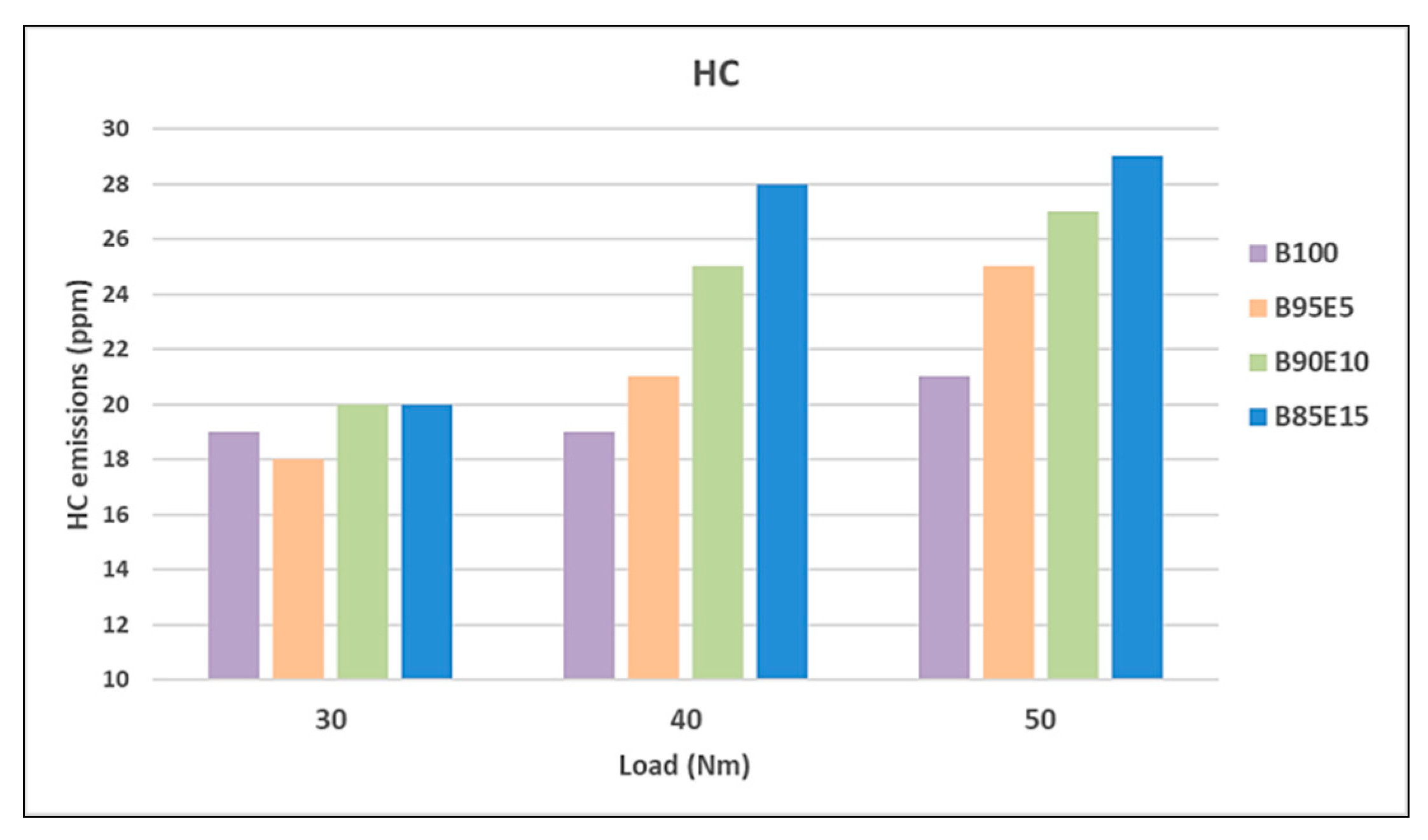

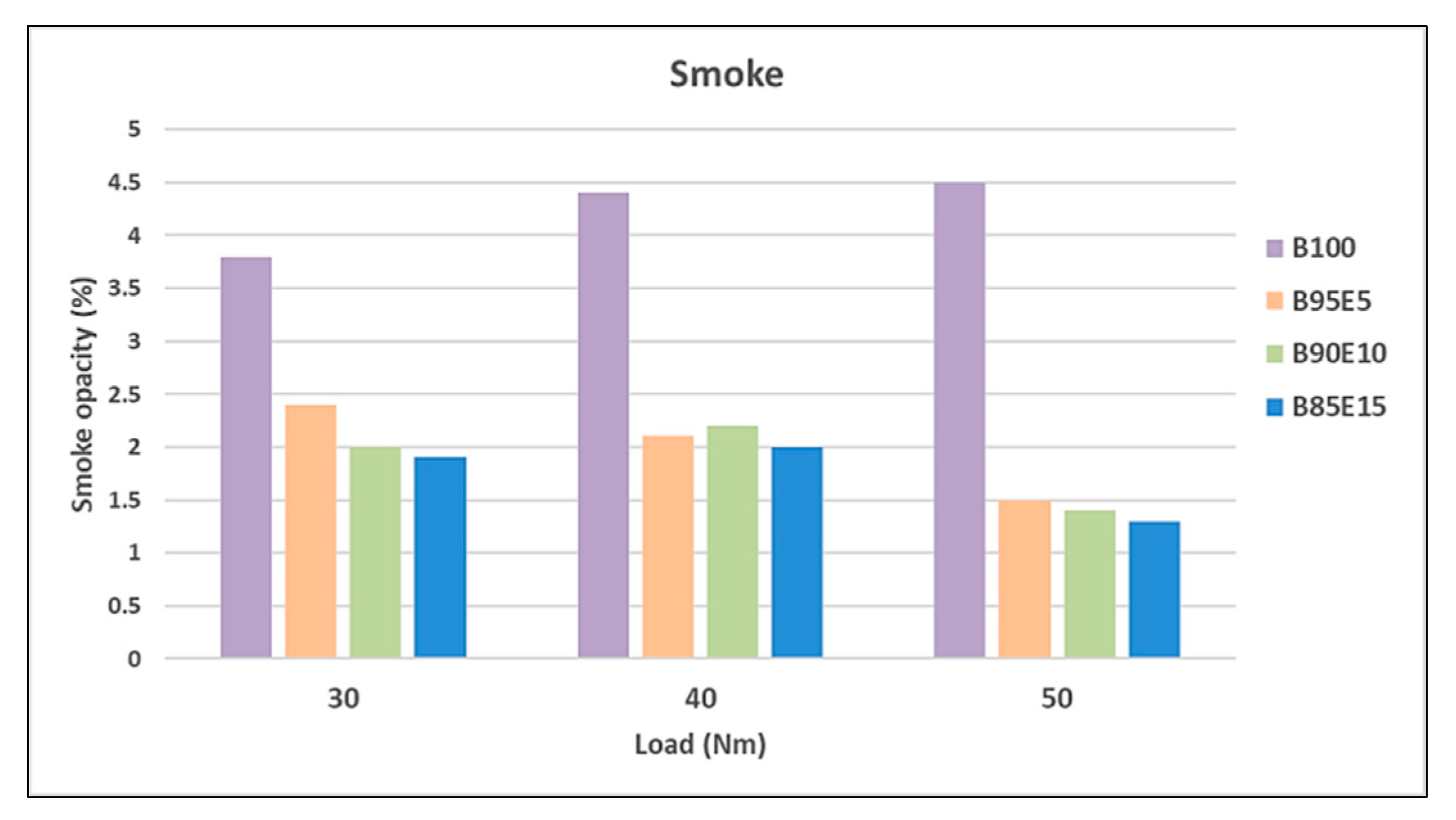

- Ethanol additives have an attenuation effect on CO and especially smoke. The maximum smoke reduction of the blends fuel with 15vol% ethanol additive reached 71%. The greater the load of ethanol, the more obvious the effect on smoke reduction. On the contrary, increases in load and ethanol content promote the generation of HC and NOx emissions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Uyumaz, A. Combustion, performance and emission characteristics of a DI diesel engine fueled with mustard oil biodiesel fuel blends at different engine loads. Fuel 2018, 212, 256–267. [Google Scholar] [CrossRef]

- Lapuerta, M.; Hernández, J.J.; Fernández-Rodríguez, D.; Cova-Bonillo, A. Autoignition of blends of n -butanol and ethanol with diesel or biodiesel fuels in a constant-volume combustion chamber. Energy 2017, 118, 613–621. [Google Scholar] [CrossRef]

- Paul, A.; Panua, R.; Debroy, D. An experimental study of combustion, performance, exergy and emission characteristics of a CI engine fueled by Diesel-ethanol-biodiesel blends. Energy 2017, 141, 839–852. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. Engine performance, combustion and emission characteristics of a compression ignition engine operating on different biodiesel-alcohol blends. Energy 2017, 125, 470–483. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, H.Y.; Yoon, S.K.; Choi, N.J. Reducing volatile organic compound emissions from diesel engines using canola oil biodiesel fuel and blends. Fuel 2018, 218, 266–274. [Google Scholar] [CrossRef]

- Mayo, M.P.; Boehman, A.L. Ignition behavior of biodiesel and diesel under reduced oxygen atmospheres. Energy Fuels 2015, 29, 6793–6803. [Google Scholar] [CrossRef]

- Pullen, J.; Saeed, K. An overview of biodiesel oxidation stability. Renew. Sustain. Energy Rev. 2012, 16, 5924–5950. [Google Scholar] [CrossRef]

- Fazal, M.A.; Haseeb, A.S.M.A.; Masjuki, H.H. Biodiesel feasibility study: An evaluation of material compatibility per-formance; emission and engine durability. Renew. Sustain. Energy Rev. 2011, 15, 1314–1324. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Demirbas, A. A comprehensive review on the environmental impacts of diesel/biodiesel additives. Energy Convers. Manag. 2018, 174, 579–614. [Google Scholar] [CrossRef]

- Kannan, G.; Karvembu, R.; Anand, R. Effect of metal based additive on performance emission and combustion charac-teristics of diesel engine fuelled with biodiesel. Appl. Energy 2011, 88, 3694–3703. [Google Scholar] [CrossRef]

- Kumar, S.; Dinesha, P.; Rosen, M.A. Effect of injection pressure on the combustion, performance and emission character-istics of a biodiesel engine with cerium oxide nanoparticle additive. Energy 2019, 185, 1163–1173. [Google Scholar] [CrossRef]

- Dagle, R.A.; Winkelman, A.D.; Ramasamy, K.K.; Dagle, V.L.; Weber, R.S. Ethanol as a renewable building block for fuels and chemicals. Ind. Eng. Chem. Res. 2020, 59, 4843–4853. [Google Scholar] [CrossRef]

- Holladay, J.E.; Male, J.L.; Rousseau, R.; Weber, R.S. Synthesizing clean transportation fuels from CO2 will at least quintuple the demand for non-carbogenic electricity in the United States. Energy Fuels 2020, 34, 15433–15442. [Google Scholar] [CrossRef]

- Xu, C.; Paone, E.; Rodríguez-Padrón, D.; Luque, R.; Mauriello, F. Reductive catalytic routes towards sustainable production of hydrogen, fuels and chemicals from biomass derived polyols. Renew. Sustain. Energy Rev. 2020, 127, 109852. [Google Scholar] [CrossRef]

- Alptekin, E. Emission, injection and combustion characteristics of biodiesel and oxygenated fuel blends in a common rail diesel engine. Energy 2017, 119, 44–52. [Google Scholar] [CrossRef]

- Zhan, C.; Feng, Z.; Ma, W.; Zhang, M.; Tang, C.; Huang, Z. Experimental investigation on effect of ethanol and di-ethyl ether addition on the spray characteristics of diesel/biodiesel blends under high injection pressure. Fuel 2018, 218, 1–11. [Google Scholar] [CrossRef]

- Zhu, L.; Cheung, C.; Zhang, W.; Huang, Z. Combustion, performance and emission characteristics of a DI diesel engine fueled with ethanol–biodiesel blends. Fuel 2011, 90, 1743–1750. [Google Scholar] [CrossRef]

- Pradelle, F.; Braga, S.L.; Martins, A.R.F.D.A.; Turkovics, F.; Pradelle, R.N.C. Experimental assessment of some key physicochemical properties of diesel-biodiesel-ethanol (DBE) blends for use in compression ignition engines. Fuel 2019, 248, 241–253. [Google Scholar] [CrossRef]

- Madiwale, S.; Karthikeyan, A.; Bhojwani, V. Properties investigation and performance analysis of a diesel engine fuelled with jatropha, soybean, palm and cottonseed biodiesel using ethanol as an additive. Mater. Today Proc. 2018, 5, 657–664. [Google Scholar] [CrossRef]

- Rahman, S.A.; Masjuki, H.; Kalam, M.; Abedin, M.; Sanjid, A.; Sajjad, H. Production of palm and Calophyllum inophyllum based biodiesel and investigation of blend performance and exhaust emission in an unmodified diesel engine at high idling conditions. Energy Convers. Manag. 2013, 76, 362–367. [Google Scholar] [CrossRef]

- Rahman, S.A.; Masjuki, H.; Kalam, M.; Abedin, M.; Sanjid, A.; Rahman, M. Assessing idling effects on a compression ignition engine fueled with Jatropha and Palm biodiesel blends. Renew. Energy 2014, 68, 644–650. [Google Scholar] [CrossRef]

- Yasin, M.H.M.; Mamat, R.; Najafi, G.; Ali, O.M.; Yusop, A.F.; Ali, M.H. Potentials of palm oil as new feedstock oil for a global alternative fuel: A review. Renew. Sustain. Energy Rev. 2017, 79, 1034–1049. [Google Scholar] [CrossRef]

- Mekhilef, S.; Siga, S.; Saidur, R. A review on palm oil biodiesel as a source of renewable fuel. Renew. Sustain. Energy Rev. 2011, 15, 1937–1949. [Google Scholar] [CrossRef]

- Ong, H.; Mahlia, T.; Masjuki, H.; Norhasyima, R. Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: A review. Renew. Sustain. Energy Rev. 2011, 15, 3501–3515. [Google Scholar] [CrossRef]

- Dey, S.; Reang, N.; Das, P.; Deb, M. A comprehensive study on prospects of economy, environment, and efficiency of palm oil biodiesel as a renewable fuel. J. Clean. Prod. 2021, 286, 124981. [Google Scholar] [CrossRef]

- Wei, L.; Cheung, C.; Ning, Z. Effects of biodiesel-ethanol and biodiesel-butanol blends on the combustion, performance and emissions of a diesel engine. Energy 2018, 155, 957–970. [Google Scholar] [CrossRef]

- Kim, H.Y.; Ge, J.C.; Choi, N.J. Effects of ethanol–diesel on the combustion and emissions from a diesel engine at a low idle speed. Appl. Sci. 2020, 10, 4153. [Google Scholar] [CrossRef]

- Jiang, Z.; Gan, Y.; Ju, Y.; Liang, J.; Zhou, Y. Experimental study on the electrospray and combustion characteristics of biodiesel-ethanol blends in a meso-scale combustor. Energy 2019, 179, 843–849. [Google Scholar] [CrossRef]

- Tse, H.; Leung, C.W.; Cheung, C.S. Investigation on the combustion characteristics and particulate emissions from a diesel engine fueled with diesel-biodiesel-ethanol blends. Energy 2015, 83, 343–350. [Google Scholar] [CrossRef]

- Khoobbakht, G.; Karimi, M.; Kheiralipour, K. Effects of biodiesel-ethanol-diesel blends on the performance indicators of a diesel engine: A study by response surface modeling. Appl. Eng. 2019, 148, 1385–1394. [Google Scholar] [CrossRef]

- Tutak, W.; Jamrozik, A.; Pyrc, M.; Sobiepański, M. A comparative study of co-combustion process of diesel-ethanol and biodiesel-ethanol blends in the direct injection diesel engine. Appl. Therm. Eng. 2017, 117, 155–163. [Google Scholar] [CrossRef]

- Padala, S.; Woo, C.; Kook, S.; Hawkes, E.R. Ethanol utilisation in a diesel engine using dual-fuelling technology. Fuel 2013, 109, 597–607. [Google Scholar] [CrossRef]

- Shamun, S.; Belgiorno, G.; Di Blasio, G.; Beatrice, C.; Tunér, M.; Tunestål, P. Performance and emissions of die-sel-biodiesel-ethanol blends in a light duty compression ignition engine. Appl. Therm. Eng. 2018, 145, 444–452. [Google Scholar] [CrossRef]

- Xiao, H.; Guo, F.; Wang, R.; Yang, X.; Li, S.; Ruan, J. Combustion performance and emission characteristics of diesel engine fueled with iso-butanol/biodiesel blends. Fuel 2020, 268, 117387. [Google Scholar] [CrossRef]

- Yilmaz, N. Comparative analysis of biodiesel–ethanol–diesel and biodiesel–methanol–diesel blends in a diesel engine. Energy 2012, 40, 210–213. [Google Scholar] [CrossRef]

- Kandasamy, S.K.; Selvaraj, A.S.; Rajagopal, T.K.R. Experimental investigations of ethanol blended biodiesel fuel on au-tomotive diesel engine performance, emission and durability characteristics. Renew. Energy 2019, 141, 411–419. [Google Scholar] [CrossRef]

- Barabás, I.; Todoruţ, A.; Băldean, D. Performance and emission characteristics of an CI engine fueled with diesel–biodiesel–bioethanol blends. Fuel 2010, 89, 3827–3832. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Wang, X.; Yao, M. Experimental study on combustion and emissions of dual fuel RCCI mode fueled with biodiesel/n-butanol, biodiesel/2,5-dimethylfuran and biodiesel/ethanol. Energy 2018, 148, 824–838. [Google Scholar] [CrossRef]

| Properties (Units) | B100 | B95E5 | B90E10 | B85E15 | Ethanol |

|---|---|---|---|---|---|

| Density (kg/m3 at 15 °C) | 877 | 873.12 | 869.24 | 865.36 | 799.4 |

| Calorific value (MJ/kg) | 39.72 | 39.19 | 38.66 | 38.12 | 28.18 |

| Oxygen content (%) | 11.26 | 12.43 | 13.6 | 14.78 | 34.7 |

| Viscosity (mm2/s at 40 °C) | 4.56 | - | - | - | 1.10 |

| Cetane index | 57.3 | - | - | - | 8 |

| Flash point (°C) | 196 | - | - | - | 12 |

| Engine Type | 4-Cylinder 4-Stroke Direct Injection |

|---|---|

| Fuel injection system | Bosch common-rail |

| Air system | Turbocharger with WGT |

| Bore (mm) × Stroke (mm) | 83 × 92 |

| Displacement (cc) | 1991 |

| Compression ratio | 17.7:1 |

| Max. power (kW/rpm) | 82/4000 |

| Injector hole diameter (mm) | 0.17 |

| Test Fuels | B100, B95E5, B90E10, B85E15 |

|---|---|

| Engine load | 30, 40, 50 Nm |

| Engine speed | 750 rpm |

| Fuel injection pressure | 350 bar |

| Pilot injection timing | 18 °CA BTDC |

| Main injection timing | 5 °CA BTDC |

| Intake air temperature | 25 ± 3 °C |

| Cooling water temperature | 85 ± 3 °C |

| Fuel | Load (Nm) | CPmax (bar) | HRRmax (J/deg) | Ignition Delay (°CA) | Combustion Duration (°CA) |

|---|---|---|---|---|---|

| B100 | 30 | 65.2 | 31.27 | 5.45 | 20.95 |

| 40 | 69.3 | 36.69 | 5.4 | 21.35 | |

| 50 | 72.9 | 39.23 | 5.3 | 22 | |

| B95E5 | 30 | 66.4 | 31.57 | 5.65 | 20.4 |

| 40 | 70.5 | 37.07 | 5.55 | 21.35 | |

| 50 | 74.6 | 41.13 | 5.43 | 21.17 | |

| B90E10 | 30 | 66.8 | 31.77 | 6.15 | 20 |

| 40 | 71 | 37.15 | 6 | 20.4 | |

| 50 | 75.3 | 42.31 | 5.8 | 21 | |

| B85E15 | 30 | 67.1 | 33.73 | 6.6 | 19.55 |

| 40 | 71.2 | 38.93 | 6.55 | 20.4 | |

| 50 | 75.6 | 43.8 | 6.05 | 20.95 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, G.; Ge, J.C.; Choi, N.J. Effect of Ethanol Additives on Combustion and Emissions of a Diesel Engine Fueled by Palm Oil Biodiesel at Idling Speed. Energies 2021, 14, 1428. https://doi.org/10.3390/en14051428

Wu G, Ge JC, Choi NJ. Effect of Ethanol Additives on Combustion and Emissions of a Diesel Engine Fueled by Palm Oil Biodiesel at Idling Speed. Energies. 2021; 14(5):1428. https://doi.org/10.3390/en14051428

Chicago/Turabian StyleWu, Guirong, Jun Cong Ge, and Nag Jung Choi. 2021. "Effect of Ethanol Additives on Combustion and Emissions of a Diesel Engine Fueled by Palm Oil Biodiesel at Idling Speed" Energies 14, no. 5: 1428. https://doi.org/10.3390/en14051428

APA StyleWu, G., Ge, J. C., & Choi, N. J. (2021). Effect of Ethanol Additives on Combustion and Emissions of a Diesel Engine Fueled by Palm Oil Biodiesel at Idling Speed. Energies, 14(5), 1428. https://doi.org/10.3390/en14051428