Abstract

A driving cycle is a record intended to reflect the regular use of a given type of vehicle, presented as a speed profile recorded over a certain period of time. It is used for the assessment of engine pollutant emissions, fuel consumption analysis and environmental certification procedures. Different driving cycles are used, depending on the region of the world. In addition, drive cycles are used by car manufacturers to optimize vehicle drivelines. The basis of the work presented in the manuscript was a developed computer tool using tests on the Toyota Camry LE 2018 chassis dynamometer, the results of the optimization process of neural network structures and the properties of fuels and biofuels. As a result of the work of the computer tool, the consumption of petrol 95, ethanol, methanol, DME, CNG, LPG and CO2 emissions for the vehicle in question were analyzed in the following driving tests: Environmental Protection Agency (EPA US06 and EPA USSC03); Supplemental Federal Test Procedure (SFTP); Highway Fuel Economy Driving Schedule (HWFET); Federal Test Procedure (FTP-75–EPA); New European Driving Cycle (NEDC); Random Cycle Low (×05); Random Cycle High (×95); Mobile Air Conditioning Test Procedure (MAC TP); Common Artemis Driving Cycles (CADC–Artemis); Worldwide Harmonized Light-Duty Vehicle Test Procedure (WLTP).

1. Introduction

The dynamic development of technology, which the automotive industry has seen for many years, includes both achieving an appropriate level of vehicle performance and meeting appropriate environmental protection requirements [1,2,3,4]. Keeping exhaust gas emissions under the permissible limits is the basic criterion that determines the directions of further development of engines used to drive motor vehicles [5,6,7,8]. Increasingly restrictive legal regulations are introduced to protect the climate [9,10,11,12]. The European Union (EU) has long been setting ambitious climate goals, which will not be achievable without reducing greenhouse gas emissions in transport—which consumes a third of the energy in the EU [13,14,15]. It is the transport sector in the EU that accounts for almost 30% of total CO2 emissions, 72% of which comes from road transport [16,17]. Passenger cars are responsible for 60.7% of all CO2 emissions from road transport in Europe [18,19].

Additionally, in the United States, car exhaust gases are the main source of greenhouse gas emissions, thus causing climate change [20,21,22]. The local permissible exhaust emission standards are based on research by a federal US body—the Environmental Protection Agency (EPA) [23,24]. Greenhouse gas emissions from transport account for approximately 28 percent of total US greenhouse gas emissions [25,26].

In China, combustion tests are a mixture of the abovementioned European and American regulations [27,28]. Work is also underway on a new type of test, which will be even more complicated and will much better reflect actual conditions [29,30]. The Chinese transport sector is responsible for around 12% of domestic emissions [31,32,33,34].

Each new passenger car must meet exhaust gas toxicity standards before it is introduced to the market [35,36,37]. The test conditions depend on the vehicle class and the country of destination [38,39,40]. Such tests, carried out in laboratory conditions, enable the repeatability and comparability of the obtained results [41,42,43]. By carrying out such tests, it is possible to avoid many of the risk factors associated with the actual road testing of vehicles that will affect fuel consumption—such as driving style, terrain or weather conditions. In order to execute these tests, a chassis dynamometer is needed (on a roller dynamometric stand) with adjustable motion resistance and execution of driving cycles [44,45,46].

Until August 2017, light vehicles in the European Union (with a reference mass not exceeding 2610 kg) were tested with the standard New European Driving Cycle (NEDC) driving test that included four repeated Urban Driving Cycles (UDCs) and one Extra Urban Driving Cycle (EUDC) [47,48,49,50]. Since September 2017, there has been a new procedure in force in the EU in the area of fuel consumption, carbon dioxide and exhaust emission standards: the Worldwide Harmonized Light-Duty Vehicles Test Procedure (WLTP) EU [51,52,53]. Although the WLTP is also a test carried out under laboratory conditions, it covers situations possibly closest to everyday actual operating conditions. Four speed ranges are measured from the moment the engine is started: up to 60, up to 80, up to 100 and over 130 km/h. During each of these phases, the vehicle always slows down and accelerates [54,55]. The maximum speed is 10 km/h more than that of the NEDC test. The average speed is 47 km/h—much higher than the previous 33 km/h. A complete WLTP cycle takes about 30 min, whereas the NEDC only takes about 20 min [56,57,58]. The cycle distance has more than doubled and is now 23 km instead of the previous 11 km. Unlike the NEDC cycle, the requirements of the car’s electrical system and additional equipment are also taken into account: its weight, aerodynamics and rolling resistance [59,60]. Any additional vehicle equipment that is highly energy-consuming, such as those with air conditioning or heated seats, remains excluded from the WLTP test [61,62].

The conditions for dynamometric testing and vehicle loading are based on the strict guidelines of the WLTP test procedure including several Worldwide Harmonized Light-Duty Vehicles Test Cycles (WLTC) [63,64]. These cycles are applicable to vehicle categories with different power-to-weight ratios (unladen weight) [65,66].

In addition to the WLTP, the EU Commission also enforces the so-called Real Driving Emissions (RDE) as an additional approval requirement under Article EU6d of the directive for emissions [67,68,69,70]. Contrary to the NEDC and WLTP, the RDE tests set out acceptable limits for nitrogen oxides (NOx) and solid particle emissions in real conditions [71,72]. The RDE does not require a strictly defined driving cycle. Its parameters, including distance, acceleration, outside temperature, wind strength or traffic intensity, are freely selected within the specified statistical boundary conditions [73,74,75].

The European project Assessment and Reliability of Transport Emission Models and Inventory Systems (ARTEMIS) developed a chassis dynamometer procedure called Common Artemis Driving Cycles (CADC) that can be characterized by stronger acceleration, higher driving dynamics and a realistic proportion of high speeds (with peaks up to 130 and 150 km/h) [76,77,78]. The cycles realized as part of the procedure include three driving plans: urban (distance 4.8 km), rural road (distance 17.2 km) and two variants of the motorway plan (distances of 28.7 and 29.5 km) [79,80,81].

There is a test procedure in the EU for measuring additional fuel consumption and pollutant emissions caused by the operation of the Mobile Air Conditioning (MAC) system in a passenger car [82,83,84]. The procedure for a physical test of the whole vehicle on a chassis dynamometer includes a double test run (with MAC ON and MAC OFF) with the same three phases of the fixed condition of the test cycle [85,86].

In the United States of America, the Federal Transient Procedure (FTP-75) test is used to evaluate the environmental performance of passenger cars and delivery vans, whereas the Highway Federal Extra Test (HWFET) test is used to assess fuel consumption [87,88,89,90]. The FTP-75 simulates a city route with frequent stops, combined with both a cold and hot start transition phase [91,92,93]. The entire cycle, in which the vehicle travels 17.77 km, at an average speed of 34.12 km/h, takes about 31 min [94,95]. Cycle FTP-75 is among two variants of the Urban Dynamometer Driving Schedule (UDDS).

Furthermore, the Supplemental Federal Test Procedure (SFTP) applies [96,97]. It was developed for the purposes of a driving analysis of a vehicle with an air conditioner, dynamic changes in its driving speed as well as acceleration and deceleration of the vehicle. The high speed and rapid acceleration analysis was covered by the US06 SFTP cycle and standards [98,99,100,101]. During the cycle, the car covers a distance of 12.8 km in 596 s, reaching a maximum speed of 129.2 km/h [102,103]. An additional SC03 SFTP test procedure covers an analysis of emissions related to the use of air conditioners on vehicles certified under the FTP-75 test cycle [104,105,106]. In this test, the vehicle travels 5.8 km in 596 s, reaching a maximum speed of 88.2 km/h [107,108]. It should be emphasized that the SFTP emission levels are a combination of the emission levels of the two test cycles and the FTP cycle. This means that the SFTP emissions from each test group of vehicles must meet all SFTP and FTP emission standards [109]. In addition, there is the California Unified Cycle LA92 [110].

The diminishing resources of natural fossil fuels and the growing demand for energy pose serious social, technological and scientific challenges [111,112,113,114,115]. Alternative fuels have been developed for many years, and their use in the automotive industry will undoubtedly continue to be verified in the context of road tests [116,117,118,119,120]. Alternative fuels for internal combustion engines are defined in relation to the classic liquid petroleum fuels, such as petrol for spark ignition engines and diesel oil for compression ignition engines [121,122,123]. All other fuels for internal combustion engines are an alternative to classical liquid petroleum fuels [124,125,126].

Among the methods of fuel classification may be their state of matter [127,128,129,130]. In the case of engines, liquid and gaseous fuels seem predominant, and the only example of solid fuel in the literature is coal dust [131,132]. Further non-renewable alternative liquid fuels include fossil coal processing products and non-petroleum mineral oil processing products [133,134,135,136,137]. The properties of respective fuels depend on their chemical composition [138,139,140].

The most popular of the fuels produced from crude oil is petrol [141,142]. The refining process begins with distillation. The individual distillation fractions are processed in order to obtain base substances that can later be used in fuels and lubricants [143,144]. The physical properties of petrol have a great influence on the entire fuel supply system and combustion process [145,146,147]. Therefore, petrol must meet a number of requirements regarding its volatility, octane number and the propensity to form engine deposits. Petrol is made up of a mixture of alkanes and cycloalkanes. The calorific value of petrol, depending on the exact composition of the fuel, is 45.8 MJ/kg. The average consumption of 1 L of petrol per 100 km corresponds to approximately 2.39 kg CO2/km [148,149]. The volatility of petrol is always included in the specifications (e.g., EN 228 in Europe and ASTM D 4814 in the USA). In Europe, conventional unleaded petrol must have a density between 0.725 and 0.78 g/cm3, in the USA from 0.745 to 0.765 g/cm3 [150,151].

Non-renewable alternative gaseous fuels mainly include fuels based on petroleum gas (consisting mainly of propane and butane)—Liquefied Petroleum Gas (LPG)—fuels based on natural gas whose main component is methane—Compressed Natural Gas (CNG), Liquefied Natural Gas (LNG) as well as fossil coal processing products [152,153,154,155,156].

LPG is a by-product of natural gas production processes or crude oil distillation processes in refineries. Depending on the region of the world, its composition includes 90% propane, 2.5% butane, traces of ethane and propylene with heavy hydrocarbons. LPG as a fuel for transport is a source of cleaner energy, since it emits about 20% less carbon compounds than petrol. The reduction in pollutants in transport thanks to LPG can amount to approx. 10–15% less CO2, 20% less CO and 60% less hydrocarbons [157,158,159].

CNG is a natural gas compressed to 20–25 MPa, used in spark ignition and compression ignition engines. Under normal conditions, the energy value of 1 m3 of CNG is approximately equal to the energy value of 1 L of petrol. The mass of 1 m3 of natural gas under normal conditions is approximately 0.7 kg and depends on the gas composition. The main component of CNG is methane [160,161].

The most important renewable liquid fuels are Pure Vegetable Oils (PVO), esters of higher carboxylic acids: methyl Fatty Acid Methyl Esters (FAME), ethyl Fatty Acid Ethyl Esters (FAEE) and alcohols, mainly primary: methanol and ethanol; secondary, alcohol derivatives (mainly ethers); and liquid products of biomass processing Biomass to Liquid (BTL) [162,163,164].

Among the abovementioned renewable liquid fuels, ethanol and methanol warrant special attention.

Ethanol is obtained from plant products through the process of the fermentation of sugar. The largest disadvantage of ethanol is its low calorific value (30.4 kJ/g). In relation to a liter, this value is 1/3 lower than for petrol, i.e., 10 L of petrol corresponds to approx. 15 L of ethanol (the calorific value of petrol is 45.0 kJ/g). The octane number of this fuel can exceed 108. This enables an increase in the compression ratio or the boost pressure. Commercially, ethanol fuels are sold with the E prefix (e.g., E85 contains 85% ethanol and 15% petrol) [165,166,167].

Methanol is a technical alcohol that is obtained by the dry distillation of wood or evaporation of coal. Its properties are similar to ethanol, but it has a lower calorific value (20.1 kJ/g). The octane number of methyl alcohol exceeds even 110. A large part of its mass is occupied by oxygen, one atom of which is present in each methanol molecule. This means that its calorific value is much lower than that of petrol or ethanol. Methanol is also used to power speedway motorcycles equipped with engines with compression ratios exceeding 16 [168,169,170,171,172].

For many years, efforts have been made to develop dedicated tools for computer simulations of the analysis of the amount of pollutants emitted from motor vehicles.

An example of such a tool is the Vehicle Energy Consumption Calculation Tool (VECTO) [173,174,175]. The simulation tool launched by the European Commission is used to calculate the amount of fuel consumed and carbon dioxide emitted by brand new trucks. The tool calculates driving behavior, load capacity, vehicle configurations, axle configurations, vehicle weight, engine characteristics (engine capacity, fuel map and full load curve), aerodynamic drag and tire rolling resistance. The VECTO calculates the fuel consumption in liters per 100 km and the fuel consumption per ton-kilometer transported, as well as the CO2 emissions. The program can affect the fuel efficiency of the fleet, due to its thorough analysis of fuel consumption in various vehicle configurations [176,177,178,179].

Another tool used as a fuel consumption simulator for passenger cars and delivery vans was CO2Mpas. It enabled a simulation run that showed the results that a given vehicle with WLTP tests would achieve in the NEDC test. The tool used correlation methods [180,181,182].

The literature describes tools for the analysis of pollutant emissions from bus fleets in urban areas [183]. The proposed solution uses the results of measurements made with on-board instrumentation and the calculation method to estimate the emissions and fuel consumption as a function of vehicle parameters and the operating cycle.

The aim of this work was to build a computer tool for simulating driving tests as a function of the consumption of selected fuels and biofuels and CO2 emissivity. The developed tool is dedicated to vehicles with a spark ignition engine.

2. Materials and Methods

The list below contains a set of the most important quantities used in the calculations with the appropriate symbols and units (Table 1).

Table 1.

Abbreviations, symbols and units used in the paper.

The development of the simulation model for driving tests was based on the research of the Toyota Camry LE 2018 and published [184]. Table 2 below presents the most important technical parameters of the vehicle and the factors necessary to be used in driving tests and programs generating the required waveforms: vehicle speed, gear number, clutch engagement and pedal position. The values of the Ratio n/v coefficient for individual runs were calculated on the basis of the dependencies, including the data contained in [185]:

Table 2.

Parameters of the vehicle used in the research for driving tests [185,186].

2.1. Building a Quantitative Model

In order to construct a quantitative model that would enable the calculation of the instantaneous value of the fuel flow as a function of engine speed, engine torque, transmission gear number and vehicle speed, published data were used, which were obtained during Toyota Camry LE 2018 tests on a chassis dynamometer [184].

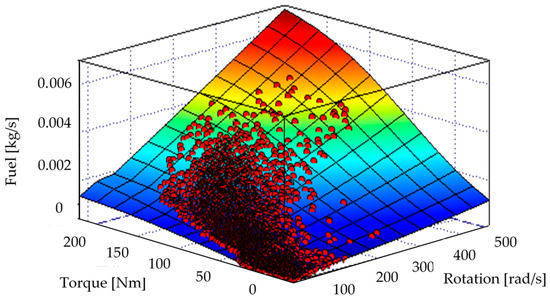

Figure 1 presents the set of points obtained during vehicle tests on a chassis dynamometer, converted to the value of hourly fuel consumption as a function of engine speed and torque generated by the engine.

Figure 1.

Measurement points of hourly fuel consumption as a function of engine rotational speed and engine torque, used to build the quantitative model [184].

The EPA published data included measurement points from actual measurements of the vehicle under consideration on a chassis dynamometer for 6 road tests (UDDS, HWFET, US06, LA92, WLTC and NEDC), for which multiple test repetitions were also provided. These data in spreadsheet form contained instantaneous values of engine speed, engine load torque, vehicle speed, transmission gear number, fuel consumption, etc. These were recorded during the EPA’s surveys every 0.1 s. A total of about 350,000 measurement points were used to build the neural model and verify its performance. To build the neural model, about 80% of the available data were used as a learning set, while about 20% of the data were used in the process of verifying the performance of the developed simulation.

In order to construct a quantitative model of instantaneous fuel consumption as a function of engine rotational speed and its generated torque, structures of the “Multilayer Feedforward Backpropagation Network” neural networks with approximating properties were used. The neural network structure itself used (in the hidden layers) a non-linear F1(x) activating function determined by the dependency, and a linear F2(x) activating function (in the output layer), in the following form:

In the learning process of the network, the Levenberg–Marquardt algorithm was used, the basis of which is the optimization process through finding the minimum value of the objective function defined as the average value of the sum of squared differences between the current values of the network outputs and the assigned values, in the following form:

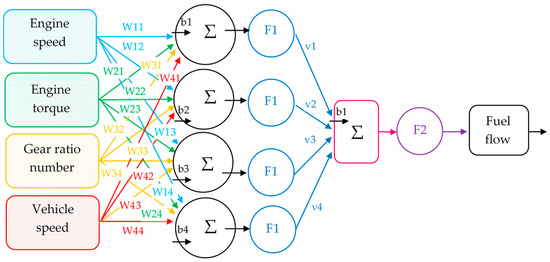

Figure 2 below shows a general scheme of the neural network structure that complies with the abovementioned relationships. The “Neural Network Module Version 3.0” library was applied within the Scilab 6.1.0 [187,188] numerical software environment in order to build the neural model.

Figure 2.

A general scheme of the structure of the neural network applied [187,188].

In order to obtain a neural model with the highest possible extent of adjustment to the research data published by EPA [184], an optimization process of the selection of the neural network structure was carried out, which included the change in the number of input parameters, engine rotational speed, engine torque, vehicle gear number, vehicle speed and the change in the number of hidden neurons. In the optimization process, a scalar objective function was used, according to the following dependence:

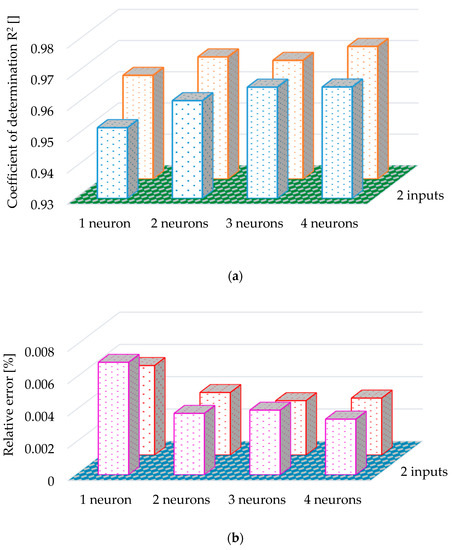

Figure 3 presents selected results of the optimization process for different network structures in question, which differ in the number of input parameters and the number of neurons in the hidden layer, which, in many iterations, obtained the greatest degree of adjustment to the research data.

Figure 3.

Summary of learning results for the best-adjusted neural networks for the characteristic of specific hourly fuel consumption. The calculated determination coefficient R2 and the relative error between the model and actual data; 1st and 2nd inputs: engine rotational speed and engine torque; 3rd input: vehicle gear number; 4th input: vehicle speed: (a) coefficient of determination R2 [-]; (b) relative error [%].

For the subsequent stages of building a vehicle simulation in road tests, a neural network structure was selected with two inputs for the input signals, engine rotational speed and engine torque, as well as three neurons in the hidden layer.

The selected neural network structure, which was characterized by achieving the smallest relative error value during the learning process for the learning data set, was verified using verification data, which represented approximately 20% of the actual vehicle test data on the chassis dynamometer for the considered tests published by the EPA. Again, the relative error between the simulation fuel consumption result and the real-world test fuel consumption, calculated from Equation (5), did not exceed 0.4%.

2.2. Theoretical Assumptions of the Driving Test Simulator

The published test results on the chassis dynamometer were obtained with the use of standard commercial 95 octane petrol fuel. The presumptions of the work conducted on the vehicle simulation in driving tests were to introduce a functionality that would enable the definition of the consumption of other fuels used to power spark ignition engines. With the use of the neural model (fNet), on the basis of the instantaneous values of the torque generated by the engine (Tengine) and the engine speed (ηengine), the instantaneous values of the fuel flow for petrol 95 are obtained from the following dependence:

Then, the simulation calculates the calorific value, in the case of using a fuel other than petrol 95 or fuel mixtures from the relationship:

It was assumed in the calculations that, for the instantaneous load value arising from the rotational engine speed and the engine-generated torque, a stream of another fuel must provide the same amount of energy over time as in the case of petrol 95. The efficiency of operation in the case of an engine powered by other fuels remains the same as for petrol 95, for each given calculation point. In this case, the instantaneous stream of fuels other than petrol 95 is calculated from the following dependence:

Table 3 presents the basic parameters of the fuels used in the simulation:

Table 3.

Basic parameters of the fuels used in the simulation [189,190,191,192,193].

The presented properties of CNG fuel refer to the mixture which is used to power vehicles in a compressed form to the value of about 20MPa, containing 96–98% of methane with a minimum amount of other polluting gases and water vapor.

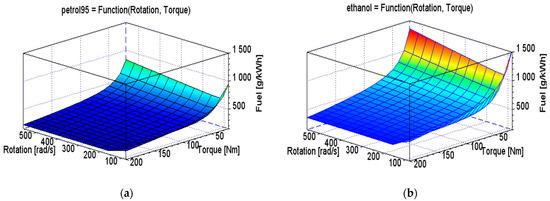

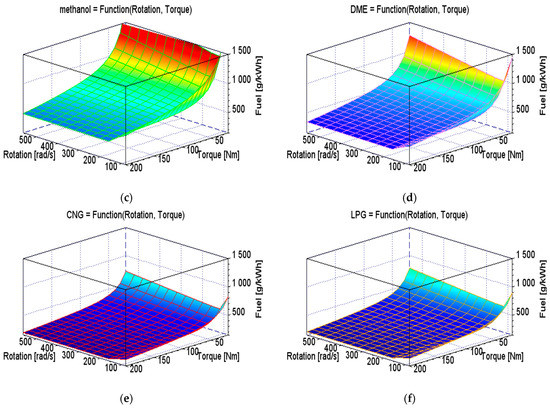

Figure 4 shows the waveforms of the instantaneous value of the specific fuel consumption as a function of the engine rotational speed and the engine-generated torque for 6 types of fuels used in the simulation (petrol 95, ethanol, methanol, DME, CNG and LPG).

Figure 4.

A model of individual fuel consumption characteristics built with the use of a neural network and used in further simulations: (a) petrol 95; (b) ethanol; (c) methanol; (d) DME; (e) CNG; (f) LPG.

In order to calculate the CO2 emissivity, the mass content of carbon in the analyzed fuel was calculated. This was performed on the basis of the available information on the chemical compositions of the individual mixture components, the mass content of the fuel in the mixture and the instantaneous fuel stream that resulted from the conditions of the engine operation conditions using the following relationship:

2.3. Driving Test Generator

The most labor intensive process was teaching neural network structures. In this study, in order to obtain an optimal neural model for determining the instantaneous value of fuel consumption as a function of the engine speed and torque, structures with 2 and 3 inputs and a variable number of neurons in the hidden layer (1–4) were used. The structure learning process for fixed inputs and number of neurons in the hidden layer were repeated at least 100 times with a fixed minimum number of learning epochs of 1000. In total, the process of learning neural network structures to select the most fitting model took about 13 h. However, the process of simulation by the selected neural model of selected driving tests took about several minutes. In the developed simulation, no correlation was made between the simulation time and the actual duration of the driving test.

Based on the collected data of operational parameters of the vehicle in question and using the “Gearshift calculation tool” [194,195] application, runs for simulation control were created for the following drive tests:

- US 06—The US06 (SFTP) [196,197];

- US highway—Highway Fuel Economy Driving Schedule (HWFET) [198,199,200];

- FTP-75—EPA Federal Test Procedure [201,202,203];

- NEDC—New European Driving Cycle (NEDC) [204,205,206];

- US SC03—The SC03 (SFTP) [207,208];

- Random Cycle Low (×05)—a test generated from a procedure in the WLTP Random Cycle Generator tool [209,210];

- Random Cycle High (×95)—a test generated from a procedure in the WLTP Random Cycle Generator tool [211,212];

- MAC TP cycle—mobile air conditioning (MAC) [213,214];

- CADC—Artemis cycle definitions, includes the following cycles: urban, rural road and motorway [215,216,217];

- CADC w/o mot—Artemis cycle definitions, includes the following cycles: Urban, Rural Road. Does not include: Motorway [215,216,217];

- CADC abridged—same as Artemis cycle definitions, includes the following cycles: urban, rural road and motorway. The duration time was shortened, similar to CADC w/o mot [215,216,217];

- WLTC 3b random—WLTP for class 3 vehicles with the engine power above 34 W/kg [218,219,220,221].

Upon entering the complete information about the vehicle, the program is ready to generate the necessary waveforms in the time domain, which in turn enable the determination of the instantaneous operating parameters of the program in question. These waveforms were then exported to text files. The instantaneous waveforms of the following quantities were used in the further stages of the simulation: simulation time [s]; engine speed [rpm]; power produced by the engine [kW]; torque generated by the engine [Nm]—a value calculated on the basis of the engine rotational speed and engine power; gear number [-]; vehicle speed [km/h].

2.4. Simulator

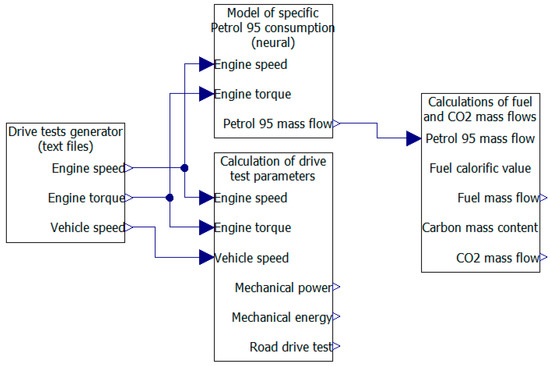

A driving test simulator was developed in OpenModelica v1.16.2, based on the analysis of the data created with the use of the “Gearshift calculation tool” programme, the results of the process of neural network structure optimization and the properties of the tested biofuels [222]. The simulator is made up of blocks that are responsible for individual functionalities, and its connection diagram is presented in Figure 5 below:

Figure 5.

A general schematic of the driving test simulator, including biofuels OpenModelica v1.16.2 software.

- Drive tests generator (text files)—responsible for loading files with data that control the selected driving test process from a text file created with the use of the “Gearshift calculation tool” application. It is also responsible for converting the read data to other formats compatible with OpenModelica v1.16.2. The following parameters are then relayed to the following calculation modules of the simulation: engine speed, engine torque, vehicle speed;

- Model of specific consumption (neural)—this block calculates the instantaneous values of petrol 95 mass flow and relays this parameter to the next block, based on the quantities which characterize the engine operating parameters: engine speed, engine torque and the prepared neural network structure;

- Calculations of fuel and CO2 mass flows—this block is responsible for calculating the streams of the tested biofuels which are necessary to power the engine in the driving test. This is achieved using the petrol 95 mass flow parameter and the fuel calorific value characteristic for the fuel in question calculated in the previous block. This block also calculates the CO2 emission stream with the use of the carbon mass content property and the instantaneous fuel stream;

- Calculation of driving test parameters—on the basis of the driving test parameters, this block calculates the distance covered by the vehicle during the test, the power generated by the engine and the mechanical energy generated during the test.

3. Results

Presented below are the processes of independent simulations of the selected Toyota Camry LE 2018 vehicle in the applied driving tests with changing fuels (petrol 95, ethanol, methanol, DME, CNG and LPG):

- the results of the simulation work for the processed EPA test data, which are learning models for the neural network;

- the results of the driving test simulator for the prepared drive tests (the “Gearshift Calculation Tool” application) in the form of vehicle speed graphs, distance travelled, engine speed, engine torque, engine power and mechanical energy used during the test;

- the simulation results for the stream and final fuel consumption;

- the simulation results for the stream and CO2 emissions for selected driving tests and selected fuels for the 2018 Toyota Camry LE vehicle;

- the results of fuel consumption and carbon dioxide emissivity per 1 km of the distance travelled by the vehicle in the tests and per 1 kWh of the mechanical energy generated in the test.

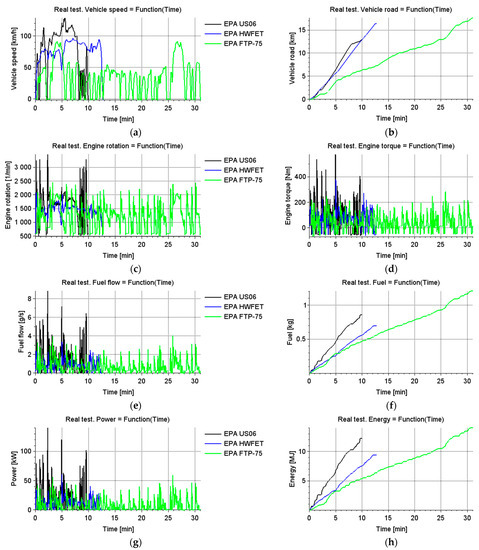

3.1. Simulation Work Results for the Processed EPA Test Data

The published data from actual vehicle tests carried out by the EPA were used in order to verify the correct operation of the driving test simulator. The input data were so transformed that they could be fed into the simulator. As a result of the simulator’s work, the instantaneous values of the key simulation parameters were obtained, which are hereby presented in the figures below (Figure 6) [184].

Figure 6.

The results of the simulation work for the processed data from EPA tests for the Toyota Camry LE 2018 vehicle: (a) waveforms of the instantaneous vehicle speed values; (b) waveforms of the instantaneous values of the distance travelled by the vehicle; (c) waveforms of the instantaneous vehicle engine speed values; (d) waveforms of the instantaneous values of torque generated by the vehicle engine; (e) waveforms of the instantaneous values of the fuel stream powering the vehicle engine; (f) waveforms of the instantaneous fuel consumption values for the vehicle; (g) waveforms of the instantaneous values of power generated by the vehicle’s engine; (h) waveforms of the instantaneous values of mechanical energy generated by the vehicle engine.

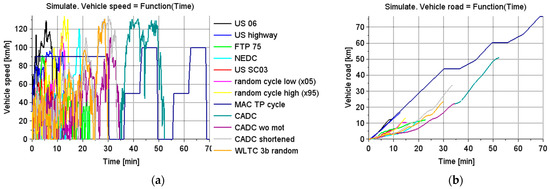

3.2. Simulation Work Results for the Driving Tests Performed

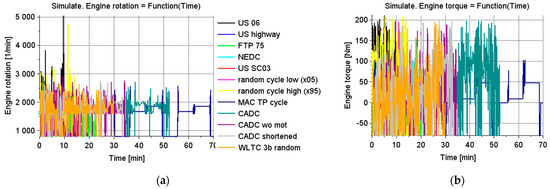

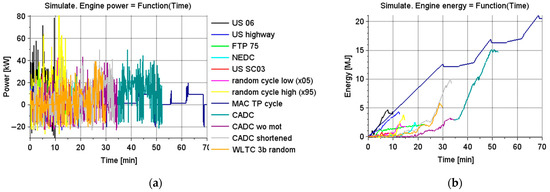

On the basis of the prepared input data, using the “Gearshift Calculation Tool” software, simulations of selected driving tests were carried out for the vehicle in question. Figure 7 below shows the waveforms of the instantaneous vehicle speed values in the test. These waveforms indicate a large variability of this parameter in the simulated tests, including mean values, the dynamics of changes and the changes in the distribution of the values over time. The simulated tests were also characterized by high variability of the execution time.

Figure 7.

Results obtained in the simulation of selected road tests for the Toyota Camry LE 2018 vehicle: (a) waveforms of the instantaneous vehicle speed values; (b) waveforms of the instantaneous values of the distance travelled by the vehicle.

Figure 8 shows the waveforms of the instantaneous values of the travelled distance in the simulated tests in question. Other input parameters for the driving test simulator were the instantaneous values of the engine speed and the engine-generated torque, whose waveforms are presented below.

Figure 8.

Results obtained in the simulation of selected road tests for the Toyota Camry LE 2018 vehicle: (a) waveforms of the instantaneous values of the vehicle engine rotational speed; (b) waveforms of the instantaneous values of the torque generated by the vehicle engine.

The instantaneous values of the power generated by the engine and the mechanical energy used during the test were calculated in the developed driving test simulator. Figure 9a,b show the waveforms of these parameters.

Figure 9.

Results obtained in the simulation of selected road tests for the Toyota Camry LE 2018 vehicle: (a) waveforms of the instantaneous values of power generated by the engine; (b) waveforms of the instantaneous values of mechanical energy generated by the vehicle engine.

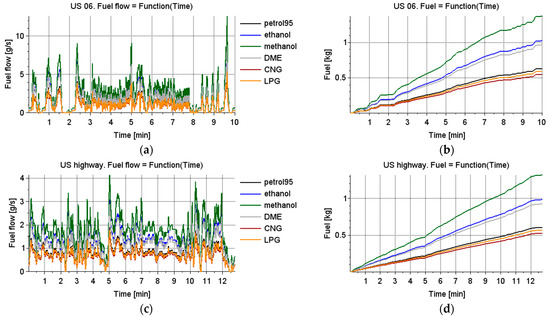

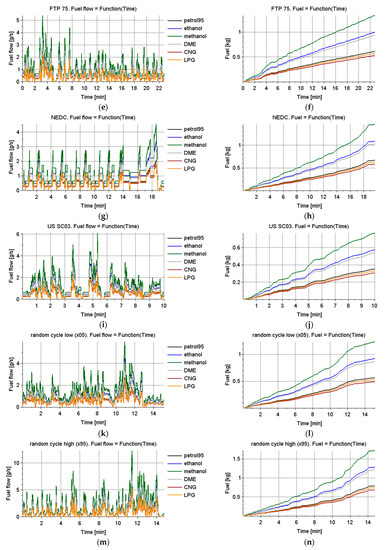

3.3. Simulation Results for the Stream and Final Fuel Consumption for the Selected Driving Tests and Fuels

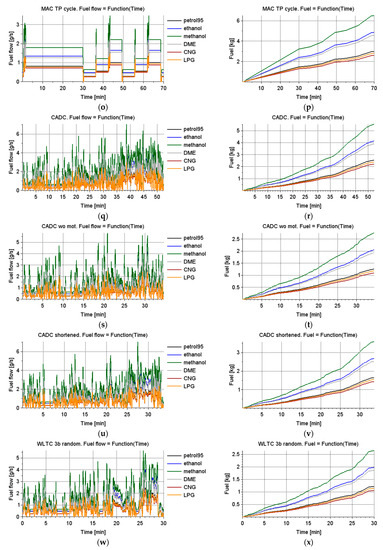

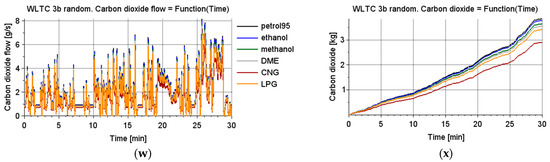

The instantaneous values of fuel streams and their mass consumption for the tests in question were calculated on the basis of the values of the petrol 95 stream calculated in the simulator, taking into account the calorific values of the other considered fuels. The figures below (Figure 10) present a summary of the obtained waveforms of the instantaneous values of fuel flows and the mass consumption of fuels in the given driving test.

Figure 10.

Results of the simulation of the stream and final fuel consumption for selected driving tests and selected fuels for the Toyota Camry LE 2018 vehicle: (a) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the US 06 road test; (b) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the US 06 road test; (c) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the US highway road test; (d) waveforms of the instantaneous values fuel consumption values for the vehicle, obtained in the US highway test simulation; (e) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the FTP-75 road test; (f) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the FTP-75 road test; (g) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the New European Driving Cycle (NEDC) road test; (h) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the NEDC road test; (i) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the US SC03 road test; (j) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the US SC03 road test; (k) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the Random Cycle Low (×05) road test; (l) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the Random Cycle Low (×05) road test; (m) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the Random Cycle High (×95) road test; (n) waveforms of the instantaneous values of the fuel consumption for the vehicle, obtained in the simulation of the Random Cycle High (×95) road test; (o) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the Mobile Air Conditioning Test Procedure (MAC TP) cycle road test; (p) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the MAC TP cycle road test; (q) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the Common Artemis Driving Cycles (CADC) road test; (r) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the CADC road test; (s) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the CADC w/o mot road test; (t) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the CADC w/o mot road test; (u) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the CADC shortened road test; (v) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the CADC shortened road test; (w) waveforms of the instantaneous values of the fuel stream powering the vehicle’s engine, obtained in the simulation of the Worldwide Harmonized Light-Duty Vehicles Test Cycles (WLTC) 3b random road test; (x) waveforms of the instantaneous values of fuel consumption for the vehicle, obtained in the simulation of the WLTC 3b random road test.

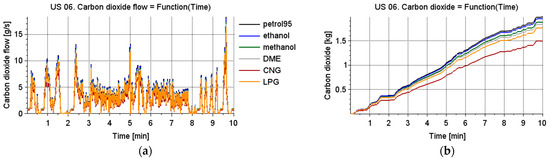

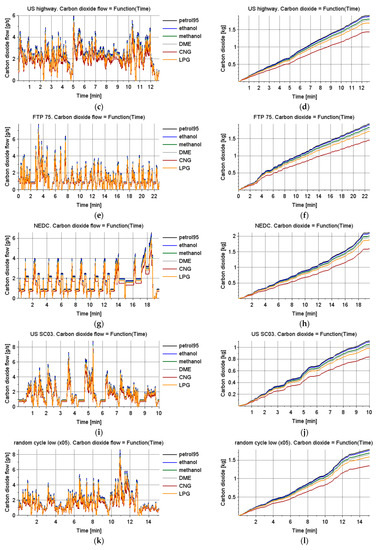

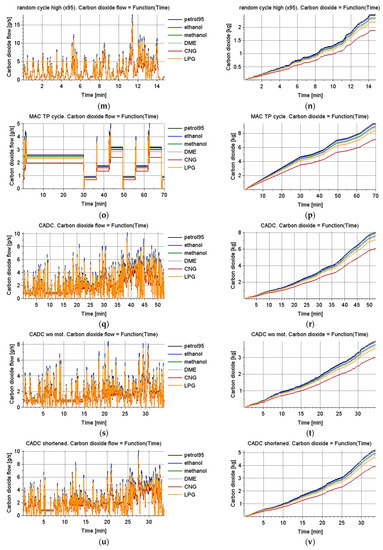

3.4. The Results of the Simulation of Carbon Dioxide Flux and Emissions for Selected Driving Tests and Fuels

As a result of the vehicle simulation processes performed for selected driving tests, including various fuels, the instantaneous values of the carbon dioxide flux and its emissivity during the test were obtained. The figures below (Figure 11) show the results of the simulator work in the form of the waveforms of carbon dioxide streams and its emissivity while taking into account the fuels considered for individual simulated tests.

Figure 11.

The results of the simulation of the carbon dioxide stream and emission for selected driving tests and fuels for the Toyota Camry LE 2018 vehicle: (a) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the US 06 road test; (b) waveforms of Table 06 road test; (c) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the US Highway road test; (d) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the US Highway road test; (e) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the FTP-75 road test; (f) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the FTP-75 road test; (g) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the NEDC road test; (h) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the US 06 road test; (i) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the US SC03 road test; (j) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the US SC03 road test; (k) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the Random Cycle Low road test (×05); (l) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the Random Cycle Low road test (×05); (m) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the Random Cycle High road test (×95); (n) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the Random Cycle High (×95) road test; (o) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the MAC TP road test; (p) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the MAC TP road test; (q) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the CADC road test; (r) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the CADC road test; (s) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the CADC w/o mot road test; (t) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the CADC w/o mot road test; (u) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the CADC shortened road test; (v) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the CADC shortened road test; (w) waveforms of the instantaneous values of the carbon dioxide emission stream produced by the vehicle engine, obtained in the simulation of the WLTC 3b random road test; (x) waveforms of the instantaneous values of the carbon dioxide emission produced by the vehicle engine, obtained in the simulation of the WLTC 3b road test.

4. Discussion

The developed tool and the methodology used to build quantitative models of fuel consumption and CO2 emissivity of the selected vehicle as a function of engine load and vehicle speed might constitute the basis for the construction of road simulators. In this case, the simulation tool can be adapted to the operational parameters of a large set of vehicles that represent a given car market. Road simulators developed on the basis of the described tool will make it possible to obtain more precise emissivity values in road traffic than the adopted environmental estimates.

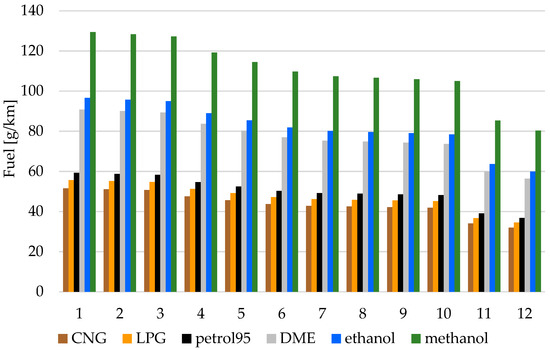

Figure 12 presents the results of the simulator work for the considered fuels and driving tests in the form of the fuel consumption parameter per one kilometer driven in the test. For CNG fuel, the minimum value was achieved at the level of 32 g/km for the US highway test, while the maximum value was obtained at the random cycle high (×95) (129.4 g/km) for methanol.

Figure 12.

A summary of the mass consumption of the tested fuels per one kilometer driven: 1—Random cycle high (×95); 2—NEDC; 3—US SC03; 4—CADC wo mot; 5—Random Cycle Low (×05); 6—WLTC 3b random; 7—FTP-75; 8—CADC; 9—US 06; 10—CADC shortened; 11—MAC TP cycle; 12—US highway.

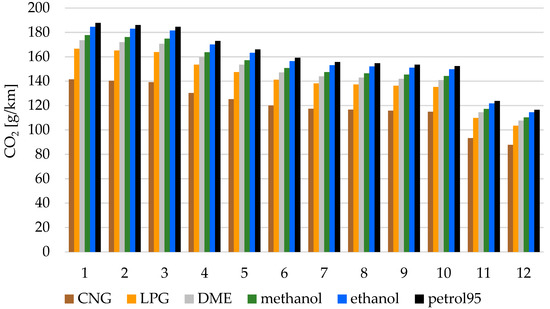

Figure 13 presents the results of the simulator work for the considered fuels and driving tests in the form of the CO2 emission parameter per one kilometer driven in the test. For petrol 95, the minimum value was reached at 116 g/km for the US highway test, while the maximum value was obtained at the random cycle high (×95) (187 g/km).

Figure 13.

A summary of the carbon dioxide emission in the tests per one kilometer driven: 1—Random cycle high (×95); 2—NEDC; 3—US SC03; 4—CADC wo mot; 5—Random Cycle Low (×05); 6—WLTC 3b random; 7—FTP-75; 8—CADC; 9—US 06; 10—CADC shortened; 11—MAC TP cycle; 12—US highway.

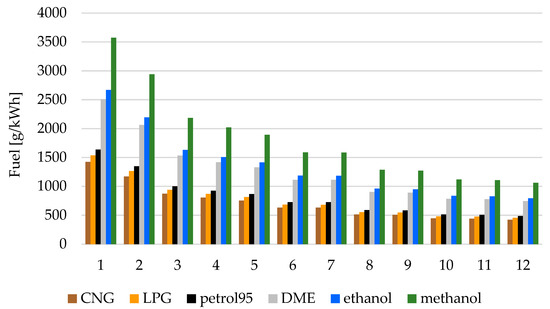

Figure 14 below shows the data obtained from the performed simulations of driving tests, including biofuels, in the form of the parameter of mass consumption of a given fuel per unit of mechanical energy produced (1 KWh). For petrol 95, the minimum value was achieved at the level of 486 g/kWh for the US 06 driving test, while the maximum value was obtained for the US SC03 test (1630 g/kWh).

Figure 14.

A summary of the fuel mass consumption in the tests per one kilowatt hour: 1—Random Cycle High (×95); 2—NEDC; 3—US SC03; 4—CADC wo mot; 5—Random Cycle Low (×05); 6—WLTC 3b random; 7—FTP-75; 8—CADC; 9—US 06; 10—CADC shortened; 11—MAC TP cycle; 12—US highway.

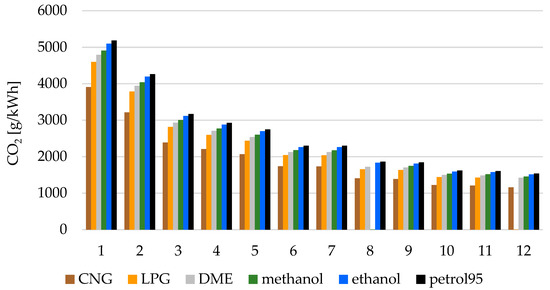

Figure 15 presents the results of the simulator work for the considered fuels and driving tests in the form of the carbon dioxide emission parameter per unit of mechanical energy produced (1 kilowatt-hour). For petrol 95, the minimum value was achieved at the level of 1538 g/kWh for the US 06 driving test, while the maximum value was obtained for the US SC03 (5182 g/kWh).

Figure 15.

A Summary of carbon dioxide emissions in the tests per one kilowatt hour: 1—Random Cycle High (×95); 2—NEDC; 3—US SC03; 4—CADC wo mot; 5—Random Cycle Low (×05); 6—WLTC 3b random; 7—FTP-75; 8—CADC; 9—US 06; 10—CADC shortened; 11—MAC TP cycle; 12—US highway.

5. Conclusions

The paper presents a computer tool for simulating driving tests as a function of the consumption of selected fuels and biofuels and CO2 emissivity, dedicated to vehicles with spark ignition engines. The basis for the work conducted was chassis dynamometer tests on the Toyota Camry LE 2018 vehicle.

- Neural network structures characterized by approximation (regression) properties were used to build a model enabling the determination of instantaneous fuel consumption values as a function of engine rotational speed and torque produced by the engine. The process of learning these network structures used data from actual driving tests performed on a selected vehicle on a chassis dynamometer published by the EPA. After selecting the neural network structure that obtained the smallest value of relative error with respect to the data from real measurements, the verification of the obtained neural model was carried out using the verification data of real tests included in the EPA publication.

- Based on the operational parameters analyzed with the use of the “Gearshift Calculation Tool” application, the results of the optimization process of the neural network structures and the properties of the biofuels in question, a driving test simulator was developed in the OpenModelica v1.16.2 program. Scilab 6.1.0 numerical software was then used to build the neural model.

- The developed simulation tool used neural networks, whose learning processes used the Levenberg–Marquardt algorithm. An optimization process was carried out for various investigated network structures differing in the number of input parameters and the number of neurons in the hidden layer. The relative error between the model and actual data did not exceed 1%.

- Twelve driving tests were analyzed in this study. These tests differed from one another in terms of the duration, speeds achieved by the vehicle and allowances for the use of any additional equipment in the vehicle (e.g., A/C).

- When analyzing the consumption parameter of a given fuel per one kilometer driven in the test, the best results were achieved for CNG fuel, for which the minimum value was reached at 32 g/km for the US highway driving test, while the maximum value was obtained in the Random Cycle High test (×95) (52.0 g/km). The highest fuel consumption per one kilometer in the test was observed in the case of methanol in the Random Cycle High (×95) (129.4 g/km).

- When considering the emissions of carbon dioxide per kilometer in the test, the highest values were recorded for petrol 95, where the minimum value was reached at 116 g/km for the US highway driving test, and the maximum value was obtained at a Random Cycle High (×95) (187 g/km). For CNG, the minimum value was reached for the US highway (87.7 g/km).

- When analyzing the parameter of mass consumption of a given fuel per unit of mechanical energy produced (1 kilowatt hour) in the case of petrol 95, the minimum value was achieved at 486 g/kWh for the US 06 driving test, while the maximum value was obtained for the US SC03 (1630 g/kWh). The highest consumption was recorded for US SC03, also for DME (2507 g/kWh), ethanol (2667 g/kWh) and methanol (3573 g/kWh).

- For the parameter of carbon dioxide emission per unit of mechanical energy produced (1 kilowatt hour), the maximum values were obtained for US SC03 CNG (3906 g/kWh), LPG (4599 g/kWh), DME (4790 g/kWh), methanol (4907 g/kWh), ethanol (5095 g/kWh) and petrol 95 (5182 g/kWh).

- The developed computer tool could be the basis for the development of a method of identifying selected aspects of operating conditions and assessing the energy efficiency of vehicles with spark ignition engines powered by fuels and biofuels.

- The research method described in the manuscript aims to obtain a simulation model to calculate instantaneous fuel consumption as a function of engine speed and engine torque produced. This method allows the simulation of vehicle operations under different load conditions and will potentially allow the calculation of fuel consumption and carbon emissions. This method can be used for many popular vehicle models in a given market. In the case of estimating carbon dioxide emissions for real facilities where vehicles move, e.g., road tunnels and large parking lots, a very large number of simulations of individual vehicles in real traffic can be used in a single simulation. The use of such simulations will allow for the more precise selection of ventilation systems for such objects, which will prevent the increase in carbon dioxide content in the air.

Funding

The APC was funded by Institute of Mechanical Engineering, Warsaw University of Life Sciences.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data are presented in this article. Data sharing is not applicable to this article.

Conflicts of Interest

The author declares no conflict of interests.

References

- Beaudet, A.; Larouche, F.; Amouzegar, K.; Bouchard, P.; Zaghib, K. Key Challenges and Opportunities for Recycling Electric Vehicle Battery Materials. Sustainability 2020, 12, 5837. [Google Scholar] [CrossRef]

- Krysko, A.V.; Awrejcewicz, J.; Pavlov, S.P.; Bodyagina, K.S.; Krysko, V.A. Topological optimization of thermoelastic composites with maximized stiffness and heat transfer. Compos. Part B Eng. 2019, 158, 319–327. [Google Scholar] [CrossRef]

- Pawełko, P.; Berczyński, S.; Grządziel, Z. Modeling roller guides with preload. Arch. Civ. Mech. Eng. 2014, 14, 691–699. [Google Scholar] [CrossRef]

- Nabagło, T.; Kowal, J.; Jurkiewicz, A. High Fidelity Model Construction and Its Verification Based on 2S1 Tracked Vehicle. In Innovative Control Systems for Tracked Vehicle Platforms. Studies in Systems, Decision and Control. Part III: Construction and Investigation of the Dynamic Characteristics of Tracked Vehicles, 1st ed.; Nawrat, M.A., Ed.; Springer: Cham, Switzerland, 2015; Volume 2, pp. 205–215. [Google Scholar]

- Maizak, D.; Wilberforce, T.; Olabi, A.G. DeNOx removal techniques for automotive applications—A review. Environ. Adv. 2020, 2, 100021. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. Exhaust emissions and engine performance analysis of a marine diesel engine fuelledwith Parinari polyandra biodiesel–diesel blends. Energy Rep. 2020, 6, 2999–3007. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Abdelkareem, M.A. Fuel cell application in the automotive industry and future perspective. Energy 2021, 214, 118955. [Google Scholar] [CrossRef]

- Kumar, M.S.; Prabhahar, M.; Sendilvelan, S.; Singh, S.; Venkatesh, R.; Bhaskar, K. Combustion, performance and emission analysis of a diesel engine fueled with methyl esters of Jatropha and fish oil with exhaust gas recirculation. Energy Procedia 2019, 160, 404–411. [Google Scholar] [CrossRef]

- Ang, J.G.; Fredriksson, P.G. Does an early start help or hurt? Statehood, institutions and modern climate change policies. Energy Econ. 2021, 94, 105075. [Google Scholar] [CrossRef]

- Fekete, H.; Kuramochi, T.; Roelfsema, M.; Den Elzen, M.; Forsell, N.; Höhne, N.; Luna, L.; Hans, F.; Sterl, S.; Olivier, J.; et al. A review of successful climate change mitigation policies in major emitting economies and the potential of global replication. Renew. Sustain. Energy Rev. 2021, 137, 110602. [Google Scholar] [CrossRef]

- Enzmann, J.; Ringel, M. Reducing Road Transport Emissions in Europe: Investigating A Demand Side Driven Approach †. Sustainability 2020, 12, 7594. [Google Scholar] [CrossRef]

- Coelho, S.; Rafael, S.; Lopes, D.; Miranda, A.I.; Ferreira, J. How changing climate may influence air pollution control strategies for 2030? Sci. Total Environ. 2021, 758, 143911. [Google Scholar] [CrossRef]

- Brodny, J.; Tutak, M. The analysis of similarities between the European Union countries in terms of the level and structure of the emissions of selected gases and air pollutants into the atmosphere. J. Clean. Prod. 2021, 279, 123641. [Google Scholar] [CrossRef] [PubMed]

- Nikas, A.; Gambhir, A.; Trutnevyte, E.; Koasidis, K.; Lund, H.; Thellufsen, J.Z.; Mayer, D.; Zachmann, G.; Miguel, L.J.; Ferreras-Alonso, N.; et al. Perspective of comprehensive and comprehensible multi-model energy and climate science in Europe. Energy 2021, 215, 119153. [Google Scholar] [CrossRef]

- Cadillo-Benalcazar, J.J.; Bukkens, S.G.F.; Ripa, M.; Giampietro, M. Why does the European Union produce biofuels? Examining consistency and plausibility in prevailing narratives with quantitative storytelling. Energy Res. Soc. Sci. 2021, 71, 101810. [Google Scholar] [CrossRef]

- CO2 Emissions from Cars: Facts and Figures (Infographics). Available online: https://www.europarl.europa.eu/news/en/headlines/society/20190313STO31218/co2-emissions-from-cars-facts-and-figures-infographics (accessed on 23 January 2021).

- McKinsey & Company. Carbon-Neutral Poland 2050. Available online: https://www.mckinsey.com/pl/our-insights/carbon-neutral-poland-2050 (accessed on 23 January 2021).

- European Parliament Approves Post-2020 CO2 Emission Targets for Cars and Vans. Available online: https://ihsmarkit.com/research-analysis/european-parliament-approves-post2020-co2-emission-targets.html (accessed on 23 January 2021).

- AECC Newsletter March 2019. Available online: https://www.aecc.eu/wp-content/uploads/2019/04/AECC-Newsletter-March-2019.pdf (accessed on 23 January 2021).

- Transport. Available online: https://www.ipcc.ch/site/assets/uploads/2018/02/ipcc_wg3_ar5_chapter8.pdf (accessed on 23 January 2021).

- Jing, R.; Yuan, C.; Rezaei, H.; Qian, J.; Zhang, Z. Assessments on emergy and greenhouse gas emissions of internal combustion engine automobiles and electric automobiles in the USA. J. Environ. Sci. 2020, 90, 297–309. [Google Scholar] [CrossRef] [PubMed]

- Akhshik, M.; Panthapulakkal, S.; Tjong, J.; Bilton, A.; Singh, C.V.; Sain, M. Cross-country analysis of life cycle assessment–based greenhouse gas emissions for automotive parts: Evaluation of coefficient of country. Renew. Sustain. Energy Rev. 2021, 138, 110546. [Google Scholar] [CrossRef]

- Daziano, R.; Waygood, E.O.D.; Patterson, Z.; Feinberg, M.; Wang, B. Reframing greenhouse gas emissions information presentation on the Environmental Protection Agency’s new-vehicle labels to increase willingness to pay. J. Clean. Prod. 2021, 279, 123669. [Google Scholar] [CrossRef]

- Neupane, B.; Rubin, J. Implications of U.S. biofuels policy for sustainable transportation energy in Maine and the Northeast. Renew. Sustain. Energy Rev. 2017, 70, 729–735. [Google Scholar] [CrossRef][Green Version]

- Fast Facts on Transportation Greenhouse Gas Emissions. Available online: https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions (accessed on 23 January 2021).

- Shahiduzzaman, M.; Layton, A. Decomposition analysis for assessing the United States 2025 emissions target: How big is the challenge? Renew. Sustain. Energy Rev. 2017, 67, 372–383. [Google Scholar] [CrossRef]

- An Overview of Automotive Vehicle and Component Regulations in China. Available online: https://incompliancemag.com/article/an-overview-of-automotive-vehicle-and-component-regulations-in-china/ (accessed on 23 January 2021).

- Yan, X.; Crookes, R.J. Energy demand and emissions from road transportation vehicles in China. Prog. Energy Combust. Sci. 2010, 36, 651–676. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, Z.X.; Zhou, H.; Zheng, H.; Yu, N.; An, X.P.; Li, J.Y.; Li, M.L. Development of China Light-Duty Vehicle Test Cycle. Int. J. Automot. Technol. 2020, 21, 1233–1246. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, H.; Xu, Y.; Qin, K.; Yu, H. Feasibility Study of Using WLTC for Fuel Consumption Certification of Chinese Light-Duty Vehicles; SAE Technical Paper 2018-01-0654; SAE International: Warrendale, PA, USA, 2018. [Google Scholar]

- Wei, L.; Li, H.; Zhang, H.; Sun, S. The Analysis of CO2 Emissions and Reduction Potential in China’s Transport Sector. Mathematical Problems in Engineering. 2016, p. 1043717. Available online: https://www.hindawi.com/journals/mpe/2016/1043717/ (accessed on 23 January 2021).

- Zheng, Y.; Li, S.; Xu, S. Transport Oil Product Consumption and GHG Emission Reduction Potential in China: An Electric Vehicle-Based Scenario Analysis. Available online: https://journals.plos.org/plosone/article?id=10.1371/journal.pone.0222448 (accessed on 23 January 2021).

- Sustainable Transport in China. Available online: https://www.sustainabletransport.org/archives/tag/carbon-emissions (accessed on 23 January 2021).

- Li, X.; Yu, B. Peaking CO2 emissions for China’s urban passenger transport sector. Energy Policy 2019, 133, 110913. [Google Scholar] [CrossRef]

- Borucka, A.; Wiśniowski, P.; Mazurkiewicz, D.; Świderski, A. Laboratory measurements of vehicle exhaust emissions in conditions reproducing real traffic. Measurement 2021, 174, 108998. [Google Scholar] [CrossRef]

- Gao, J.; Chen, H.; Li, Y.; Chen, J.; Zhang, Y.; Dave, K.; Huang, Y. Fuel consumption and exhaust emissions of diesel vehicles in worldwide harmonized light vehicles test cycles and their sensitivities to eco-driving factors. Energy Convers. Manag. 2019, 196, 605–613. [Google Scholar] [CrossRef]

- Sarkan, B.; Stopka, O.; Gnap, J.; Caban, J. Investigation of Exhaust Emissions of Vehicles with the Spark Ignition Engine within Emission Control. Procedia Eng. 2017, 187, 775–782. [Google Scholar] [CrossRef]

- Xing, J.; Shao, L.; Zhang, W.; Peng, J.; Wang, W.; Hou, C.; Shuai, S.; Hu, M.; Zhang, D. Morphology and composition of particles emitted from a port fuel injection gasoline vehicle under real-world driving test cycles. J. Environ. Sci. 2019, 76, 339–348. [Google Scholar] [CrossRef] [PubMed]

- Koossalapeerom, T.; Satiennam, T.; Satiennam, W.; Leelapatra, W.; Seedam, A.; Rakpukdee, T. Comparative study of real-world driving cycles, energy consumption, and CO2 emissions of electric and gasoline motorcycles driving in a congested urban corridor. Sustain. Cities Soc. 2019, 45, 619–627. [Google Scholar] [CrossRef]

- Wang, Y.; Hao, C.; Ge, Y.; Hao, L.; Tan, J.; Wang, X.; Zhang, P.; Wang, Y.; Tian, W.; Lin, Z.; et al. Fuel consumption and emission performance from light-duty conventional/hybrid-electric vehicles over different cycles and real driving tests. Fuel 2020, 278, 118340. [Google Scholar] [CrossRef]

- Hagino, H.; Oyama, M.; Sasaki, S. Laboratory testing of airborne brake wear particle emissions using a dynamometer system under urban city driving cycles. Atmos. Environ. 2016, 131, 269–278. [Google Scholar] [CrossRef]

- Wihersaari, H.; Pirjola, L.; Karjalainen, P.; Saukko, E.; Kuuluvainen, H.; Kulmala, K.; Keskinen, J.; Rönkkö, T. Particulate emissions of a modern diesel passenger car under laboratory and real-world transient driving conditions. Environ. Pollut. 2020, 265, 114948. [Google Scholar] [CrossRef]

- Davari, M.M.; Jerrelind, J.; Trigell, A.S. Energy efficiency analyses of a vehicle in modal and transient driving cycles including longitudinal and vertical dynamics. Transp. Res. Part D Transp. Environ. 2017, 53, 263–275. [Google Scholar] [CrossRef]

- Triantafyllopoulos, G.; Dimaratos, A.; Ntziachristos, L.; Bernard, Y.; Dornoff, J.; Samaras, Z. A study on the CO2 and NOx emissions performance of Euro 6 diesel vehicles under various chassis dynamometer and on-road conditions including latest regulatory provisions. Sci. Total Environ. 2019, 666, 337–346. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Z.; Liu, S.; Qu, L. Using a chassis dynamometer to determine the influencing factors for the emissions of Euro VI vehicles. Transp. Res. Part D Transp. Environ. 2018, 65, 564–573. [Google Scholar] [CrossRef]

- Lohse-Busch, H.; Stutenberg, K.; Duoba, M.; Liu, X.; Elgowainy, A.; Wang, M.; Wallner, T.; Richard, B.; Christenson, M. Automotive fuel cell stack and system efficiency and fuel consumption based on vehicle testing on a chassis dynamometer at minus 18 °C to positive 35 °C temperatures. Int. J. Hydrogen Energy 2020, 45, 861–872. [Google Scholar] [CrossRef]

- Zhu, G.; Liu, F.J.; Xu, Z.; Guo, Q.; Zhao, H. Experimental study on combustion and emission characteristics of turbocharged gasoline direct injection (GDI) engine under cold start new European driving cycle (NEDC). Fuel 2015, 215, 272–284. [Google Scholar] [CrossRef]

- Armas, O.; García-Contreras, R.; Ramos, A. Pollutant emissions from New European Driving Cycle with ethanol and butanol diesel blends. Fuel Process. Technol. 2014, 122, 64–71. [Google Scholar] [CrossRef]

- Degraeuwe, B.; Weiss, M. Does the New European Driving Cycle (NEDC) really fail to capture the NOX emissions of diesel cars in Europe? Environ. Pollut. 2017, 222, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Ramos, A.; Muñoz, J.; Andrés, F.; Armas, O. NOx emissions from diesel light duty vehicle tested under NEDC and real-word driving conditions. Transp. Res. Part D Transp. Environ. 2018, 63, 37–48. [Google Scholar] [CrossRef]

- Fontaras, G.; Valverde, V.; Arcidiacono, V.; Tsiakmakis, S.; Anagnostopoulos, K.; Komnos, D.; Pavlovic, J.; Ciuffo, B. The development and validation of a vehicle simulator for the introduction of Worldwide Harmonized test protocol in the European light duty vehicle CO2 certification process. Appl. Energy 2018, 226, 784–796. [Google Scholar] [CrossRef]

- Tsiakmakis, S.; Fontaras, G.; Anagnostopoulos, K.; Ciuffo, B.; Pavlovic, J.; Marotta, A. A simulation based approach for quantifying CO2 emissions of light duty vehicle fleets. A case study on WLTP introduction. Transp. Res. Procedia 2017, 25, 3898–3908. [Google Scholar] [CrossRef]

- Massaguer, E.; Massaguer, A.; Pujol, T.; Comamala, M.; Montoro, L.; Gonzalez, J.R. Fuel economy analysis under a WLTP cycle on a mid-size vehicle equipped with a thermoelectric energy recovery system. Energy 2019, 179, 306–314. [Google Scholar] [CrossRef]

- The Introduction of the WLTP into the European Type-Approval for Light-Duty Vehicles. Available online: https://ec.europa.eu/jrc/sites/jrcsh/files/wltp_20oct-morning_1.pdf (accessed on 27 January 2021).

- Tutuianu, M.; Bonnel, P.; Ciuffo, B.; Haniu, T.; Ichikawa, N.; Marotta, A.; Pavlovic, J.; Steven, H. Development of the World-wide harmonized Light duty Test Cycle (WLTC) and a possible pathway for its introduction in the European legislation. Transp. Res. Part D Transp. Environ. 2015, 40, 61–75. [Google Scholar] [CrossRef]

- Dimaratos, A.; Tsokolis, D.; Fontaras, G.; Tsiakmakis, S.; Ciuffo, B.; Samaras, Z. Comparative Evaluation of the Effect of Various Technologies on Light-duty Vehicle CO2 Emissions over NEDC and WLTP. Transp. Res. Procedia 2016, 14, 3169–3178. [Google Scholar] [CrossRef]

- Duarte, G.O.; Gonçalves, G.A.; Farias, T.L. Analysis of fuel consumption and pollutant emissions of regulated and alternative driving cycles based on real-world measurements. Transp. Res. Part D Transp. Environ. 2016, 44, 43–54. [Google Scholar] [CrossRef]

- From NEDC to WLTP: What Will Change? Available online: https://www.wltpfacts.eu/from-nedc-to-wltp-change/ (accessed on 27 January 2021).

- Abdelkareem, M.A.A.; Xu, L.; Guo, X.; Ali, M.K.A.; Elagouz, A.; Hassan, M.A.; Essa, F.A.; Zou, J. Energy harvesting sensitivity analysis and assessment of the potential power and full car dynamics for different road modes. Mech. Syst. Signal Process. 2018, 110, 307–332. [Google Scholar] [CrossRef]

- Björnsson, L.H.; Karlsson, S. The potential for brake energy regeneration under Swedish conditions. Appl. Energy 2016, 168, 75–84. [Google Scholar] [CrossRef]

- Global WLTP Roll-Out for More Realistic Results in Fuel Consumption. Available online: https://www.vda.de/en/topics/environment-and-climate/Global-WLTP-roll-out-for-more-realistic-results-in-fuel-consumption/WLTP-How-realistic-is-the-WLTP.html (accessed on 27 January 2021).

- WLTP Driving Cycle. Available online: https://www.vauxhall.co.uk/wltp.html (accessed on 27 January 2021).

- Wang, S.; Li, Y.; Fu, J.; Liu, J.; Dong, H. Numerical research on the performance, combustion and energy flow characteristics of gasoline-powered vehicle under WLTC. Fuel 2021, 285, 119135. [Google Scholar] [CrossRef]

- Karagöz, Y. Analysis of the impact of gasoline, biogas and biogas + hydrogen fuels on emissions and vehicle performance in the WLTC and NEDC. Int. J. Hydrogen Energy 2019, 44, 31621–31632. [Google Scholar] [CrossRef]

- Sileghem, L.; Bosteels, D.; May, J.; Favre, C.; Verhelst, S. Analysis of vehicle emission measurements on the new WLTC, the NEDC and the CADC. Transp. Res. Part D Transp. Environ. 2014, 32, 70–85. [Google Scholar] [CrossRef]

- Zachiotis, A.T.; Giakoumis, E.G. Non-regulatory parameters effect on consumption and emissions from a diesel-powered van over the WLTC. Transp. Res. Part D Transp. Environ. 2019, 74, 104–123. [Google Scholar] [CrossRef]

- Wang, Y.; Ge, Y.; Wang, J.; Wang, X.; Yin, H.; Hao, L.; Tan, J. Impact of altitude on the real driving emission (RDE) results calculated in accordance to moving averaging window (MAW) method. Fuel 2020, 277, 117929. [Google Scholar] [CrossRef]

- Kurtyka, K.; Pielecha, J. The evaluation of exhaust emission in RDE tests including dynamic driving conditions. Transp. Res. Procedia 2019, 40, 338–345. [Google Scholar] [CrossRef]

- García-Contreras, R.; Soriano, J.A.; Fernández-Yáñez, P.; Sánchez-Rodríguez, L.; Mata, C.; Gómez, A.; Armas, O.; Cárdenas, M.D. Impact of regulated pollutant emissions of Euro 6d-Temp light-duty diesel vehicles under real driving conditions. J. Clean. Prod. 2021, 286, 124927. [Google Scholar] [CrossRef]

- Expectations for Actual Euro 6 Vehicle Emissions. Available online: https://www.concawe.eu/publication/expectations-actual-euro-6-vehicle-emissions/ (accessed on 27 January 2021).

- Park, J.; Shin, M.; Lee, J.; Lee, J. Estimating the effectiveness of vehicle emission regulations for reducing NOx from light-duty vehicles in Korea using on-road measurements. Sci. Total Environ. 2021, 767, 144250. [Google Scholar] [CrossRef]

- Triantafyllopoulos, G.; Katsaounis, D.; Karamitros, D.; Ntziachristos, L.; Samaras, Z. Experimental assessment of the potential to decrease diesel NOx emissions beyond minimum requirements for Euro 6 Real Drive Emissions (RDE) compliance. Sci. Total Environ. 2018, 618, 1400–1407. [Google Scholar] [CrossRef]

- Du, B.; Zhang, L.; Geng, Y.; Zhang, Y.; Xu, H.; Xiang, G. Testing and evaluation of cold-start emissions in a real driving emissions test. Transp. Res. Part D Transp. Environ. 2020, 86, 102447. [Google Scholar] [CrossRef]

- Yang, Z.; Ge, Y.; Thomas, D.; Wang, X.; Su, S.; Li, H.; He, H. Real driving particle number (PN) emissions from China-6 compliant PFI and GDI hybrid electrical vehicles. Atmos. Environ. 2019, 199, 70–79. [Google Scholar] [CrossRef]

- Varella, R.A.; Faria, M.V.; Mendoza-Villafuerte, P.; Baptista, P.C.; Sousa, L.; Duarte, G.O. Assessing the influence of boundary conditions, driving behavior and data analysis methods on real driving CO2 and NOx emissions. Sci. Total Environ. 2019, 658, 879–894. [Google Scholar] [CrossRef] [PubMed]

- Lenz, M.; Hoehl, T.; Zanger, L.; Pischinger, S. Approach to determine the entropy coefficient of a battery by numerical optimization. J. Power Sources 2020, 480, 228841. [Google Scholar] [CrossRef]

- Chindamo, D.; Gadola, M. What is the Most Representative Standard Driving Cycle to Estimate Diesel Emissions of a Light Commercial Vehicle? IFAC-PapersOnLine 2018, 51, 73–78. [Google Scholar] [CrossRef]

- Napolitano, P.; Guido, C.; Beatrice, C.; Pellegrini, L. Impact of hydrocracked diesel fuel and Hydrotreated Vegetable Oil blends on the fuel consumption of automotive diesel engines. Fuel 2018, 222, 718–732. [Google Scholar] [CrossRef]

- Scaradozzi, D.; Fanesi, M. Advanced Control Strategies to Improve Nonlinear Automotive Dynamical Systems Consumption. Axioms 2019, 8, 123. [Google Scholar] [CrossRef]

- Institute of Internal Combustion Engines and Thermodynamics. Measurement of CO2- and Fuel Consumption from Cars in the NEDC and in Real-World-Driving Cycles. Available online: https://ermes-group.eu/web/system/files/filedepot/9/2009-TUG-NEDC-real-world-CO2.pdf (accessed on 28 January 2021).

- Association for Emissions Control by Catalyst (AECC). Particulate Emissions from Typical Light-Duty Vehicles Taken from the European Fleet, Equipped with a Variety of Emissions Control Technologies. Available online: https://www.nanoparticles.ch/archive/2011_May_PR.pdf (accessed on 28 January 2021).

- The Mobile Air-Conditioning Systems MACs. Available online: https://ec.europa.eu/growth/sectors/automotive/environment-protection/mobile-air-conditioning-systems_en (accessed on 28 January 2021).

- Li, C.; Brewer, E.; Pham, L.; Jung, H. Reducing Mobile Air Conditioner (MAC) Power Consumption Using Active Cabin-Air-Recirculation in A Plug-In Hybrid Electric Vehicle (PHEV). World Electr. Veh. J. 2018, 9, 51. [Google Scholar] [CrossRef]

- Shendge, S.; Tilekar, P.; Dahiya, S.; Kapoor, S. Reduction of MAC Power Requirement in a Small Car; 2010-01-0803; SAE International: Warrendale, PA, USA, 2010. [Google Scholar]

- Monforte, R.; Lovuolo, F.; Rostagno, M.; Seccardini, R. New MAC Technologies: Fuel Efficiency Effect in Real Driving of the Air Intake Flap Management; 2015-01-1609; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Sciance, F.; Nelson, B.; Yassine, M.; Patti, A.; Rao, L. Developing the AC17 Efficiency Test for Mobile Air Conditioners; 2013-01-0569; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Kim, J.; Choi, K.; Myung, C.L.; Lee, Y.; Park, S. Comparative investigation of regulated emissions and nano-particle characteristics of light duty vehicles using various fuels for the FTP-75 and the NEDC mode. Fuel 2013, 106, 335–343. [Google Scholar] [CrossRef]

- Zhang, C.; Miller, E.; Kotz, A.; Kelly, K.; Thornton, M.; Geller, M.; Brezny, R. Characterization of commercial vehicles’ start-up operations from in-use data. Transp. Res. Part D Transp. Environ. 2021, 91, 102694. [Google Scholar] [CrossRef]

- Myung, C.L.; Jang, W.; Kwon, S.; Ko, J.; Jin, D.; Park, S. Evaluation of the real-time de-NOx performance characteristics of a LNT-equipped Euro-6 diesel passenger car with various vehicle emissions certification cycles. Energy 2017, 132, 356–369. [Google Scholar] [CrossRef]

- Myung, C.L.; Choi, K.; Kim, J.; Lim, Y.; Lee, J.; Park, S. Comparative study of regulated and unregulated toxic emissions characteristics from a spark ignition direct injection light-duty vehicle fueled with gasoline and liquid phase LPG (liquefied petroleum gas). Energy 2012, 44, 189–196. [Google Scholar] [CrossRef]

- Roso, V.R.; Santos, N.D.S.A.; Valle, R.M.; Alvarez, C.E.C.; Monsalve-Serrano, J.; García, A. Evaluation of a stratified prechamber ignition concept for vehicular applications in real world and standardized driving cycles. Appl. Energy 2019, 254, 113691. [Google Scholar] [CrossRef]

- Benajes, J.; García, A.; Monsalve-Serrano, J.; Sari, R.L. Fuel consumption and engine-out emissions estimations of a light-duty engine running in dual-mode RCCI/CDC with different fuels and driving cycles. Energy 2018, 157, 19–30. [Google Scholar] [CrossRef]

- Kim, J.; Kim, K.; Oh, S. An assessment of the ultra-lean combustion direct-injection LPG (liquefied petroleum gas) engine for passenger-car applications under the FTP-75 mode. Fuel Process. Technol. 2016, 154, 219–226. [Google Scholar] [CrossRef]

- Jhang, S.R.; Lin, Y.C.; Chen, K.S.; Lin, S.L.; Batterman, S. Evaluation of fuel consumption, pollutant emissions and well-to-wheel GHGs assessment from a vehicle operation fueled with bioethanol, gasoline and hydrogen. Energy 2020, 209, 118436. [Google Scholar] [CrossRef]

- Hu, Z.; Lu, Z.; Song, B.; Quan, Y. Impact of test cycle on mass, number and particle size distribution of particulates emitted from gasoline direct injection vehicles. Sci. Total Environ. 2021, 762, 143128. [Google Scholar] [CrossRef] [PubMed]

- Supplemental Federal Test Procedures; Overview. Available online: https://www.govregs.com/regulations/expand/title40_chapterI-i36_part1066_subpartI_section1066.830 (accessed on 29 January 2021).

- Lee, J.S. Stability Analysis of Deadbeat-Direct Torque and Flux Control for Permanent Magnet Synchronous Motor Drives with Respect to Parameter Variations. Energies 2018, 11, 2027. [Google Scholar] [CrossRef]

- Rask, E.; Bocci, D.; Duoba, M.; Lohse-Busch, H. Model Year 2010 Ford Fusion Level-1 Testing Report. Available online: https://www.osti.gov/biblio/993395-model-year-ford-fusion-level-testing-report (accessed on 29 January 2021).

- Continental. Worldwide Emission Standards and Related Regulations. Passenger Cars/Light and Medium Duty Vehicles May 2019. Available online: https://www.continental-automotive.com/getattachment/8f2dedad-b510-4672-a005-3156f77d1f85/EMISSIONBOOKLET2019.pdf (accessed on 29 January 2021).

- Delphi. Worldwide Emission Standards. Passenger Cars and Light Dudy. Available online: https://www.delphi.com/sites/default/files/inline-files/delphi-worldwide-emissions-standards-passenger-cars-light-duty-2016-7.pdf (accessed on 29 January 2021).

- EPA Emission Standards for Light-Duty Vehicles and Trucks and Motorcycles. Available online: https://www.epa.gov/emission-standards-reference-guide/epa-emission-standards-light-duty-vehicles-and-trucks-and (accessed on 29 January 2021).

- Khan, T.; Frey, H.C. Comparison of real-world and certification emission rates for light duty gasoline vehicles. Sci. Total Environ. 2018, 622–623, 790–800. [Google Scholar] [CrossRef] [PubMed]

- Saw, L.H.; Poon, H.M.; Chong, W.T.; Wang, C.T.; Yew, M.C.; Yew, M.K.; Ng, T.C. Numerical modeling of hybrid supercapacitor battery energy storage system for electric vehicles. Energy Procedia 2019, 158, 2750–2755. [Google Scholar] [CrossRef]

- Changizian, S.; Ahmadi, P.; Raeesi, M.; Javani, N. Performance optimization of hybrid hydrogen fuel cell-electric vehicles in real driving cycles. Int. J. Hydrogen Energy 2020, 45, 35180–35197. [Google Scholar] [CrossRef]

- Giakoumis, E.G. Light-Duty Vehicles. In Driving and Engine Cycles, 1st ed.; Giakoumis, E.G., Ed.; Springer: Cham, Switzerland, 2017; Volume 1, pp. 65–166. [Google Scholar]

- Nam, E.K.; Colvin, A.D. An Experimental Procedure for Simulating an SC03 Emissions Test with Air Conditioner On; SAE Technical Paper 2004-01-0594; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- McDonald, J. Progress in the Development of Tier 2 Light-Duty Diesel Vehicles. Available online: http://www.4cleanair.org/Oldmembers/members/committee/mobile/Progressindev.pdf (accessed on 29 January 2021).

- Samuel, S.; Austin, L.; Morrey, D. Automotive test drive cycles for emission measurement and real-world emission levels—A review. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2002, 216, 555–564. [Google Scholar] [CrossRef]

- Exhaust Emission Test Procedures for Motor Vehicles. Available online: https://www.govinfo.gov/content/pkg/CFR-2016-title40-vol37/pdf/CFR-2016-title40-vol37-part1066-subpartI.pdf (accessed on 29 January 2021).

- Accounting for the Variation of Driver Aggression in the Simulation of Conventional and Advanced Vehicles. Available online: https://www.nrel.gov/docs/fy13osti/57503.pdf (accessed on 7 February 2021).

- Wasiak, A. Modeling Energetic Efficiency of Biofuels Production. Green Energy and Technology, 1st ed.; Springer Nature Switzerland: Cham, Switzerland, 2018; pp. 29–47. ISBN 978-3-319-98430-8. [Google Scholar] [CrossRef]

- Tucki, K.; Orynycz, O.; Swić, A.; Mitoraj-Wojtanek, M. The Development of Electromobility in Poland and EU States as a Tool for Management of CO2 Emissions. Energies 2019, 12, 2942. [Google Scholar] [CrossRef]

- Dzikuć, M.; Piwowar, A.; Szufa, S.; Adamczyk, J.; Dzikuć, M. Potential and Scenarios of Variants of Thermo-Modernization of Single-Family Houses: An Example of the Lubuskie Voivodeship. Energies 2021, 14, 191. [Google Scholar] [CrossRef]

- Saggu, M.H.; Sheikh, N.A.; Muhamad Niazi, U.; Irfan, M.; Glowacz, A.; Legutko, S. Improved Analysis on the Fin Reliability of a Plate Fin Heat Exchanger for Usage in LNG Applications. Energies 2020, 13, 3624. [Google Scholar] [CrossRef]

- Kropiwnicki, J. A unified approach to the analysis of electric energy and fuel consumption of cars in city traffic. Energy 2019, 182, 1045–1057. [Google Scholar] [CrossRef]

- Tucki, K.; Mruk, R.; Orynycz, O.; Gola, A. The Effects of Pressure and Temperature on the Process of Auto-Ignition and Combustion of Rape Oil and Its Mixtures. Sustainability 2019, 11, 3451. [Google Scholar] [CrossRef]

- Potter, A.; Graham, S. Supplier involvement in eco-innovation: The co-development of electric, hybrid and fuel cell technologies within the Japanese automotive industry. J. Clean. Prod. 2019, 210, 1216–1228. [Google Scholar] [CrossRef]

- Pichler, M.; Krenmayr, N.; Schneider, E.; Brand, U. EU industrial policy: Between modernization and transformation of the automotive industry. Environ. Innov. Soc. Transit. 2021, 38, 140–152. [Google Scholar] [CrossRef]

- Jiao, J.; Zuo, F.; Li, L.; Yuan, J.; Li, J. Estimation of China’s alternative policies of automotive fuels—A perspective of oil dependence. J. Clean. Prod. 2017, 161, 698–707. [Google Scholar] [CrossRef]

- Lapuerta, M.; Rodríguez-Fernández, J.; García-Contreras, R. Effect of a glycerol-derived advanced biofuel—FAGE (fatty acid formal glycerol ester)—on the emissions of a diesel engine tested under the New European Driving Cycle. Energy 2015, 93, 568–579. [Google Scholar] [CrossRef]